BT3554

BT3554-10

BT3554-01

BT3554-11

BATTERY TESTER

Instruction Manual

Oct. 2018 Revised edition 3

BT3554A961-03 18-10H

EN

Battery Tester Quick Guide

Let's Start by Measuring a New Battery

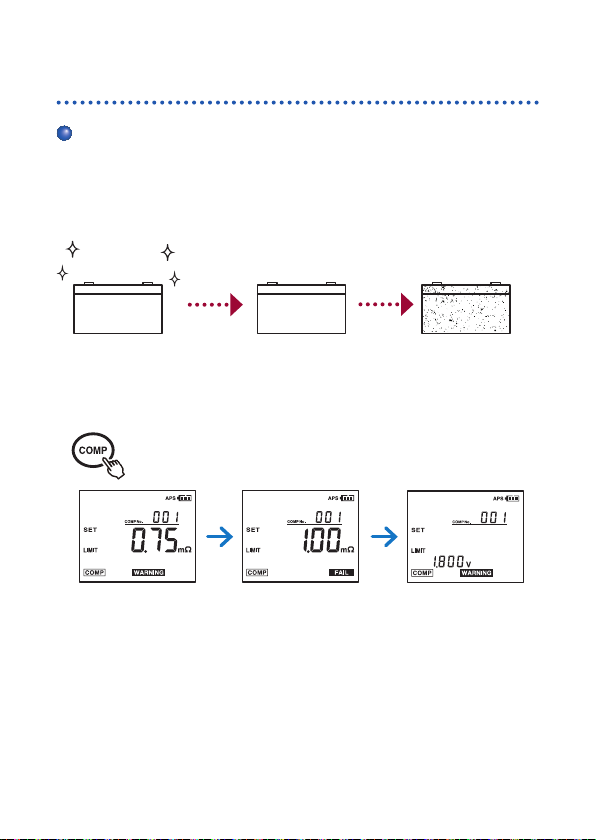

To determine if a battery is worn out, measure the data of a new

battery. As a battery wears out, its internal resistance increases to

approximately 1.5 to 2 times (reference value) that of a new one.

Use these values as guidelines when determining the battery wear

judgment values.

Example: Changes in the internal resistance and voltage

due to battery wear

Resistance has doubled...

Worn out

1

2

3

4

New battery

Internal resistance: 0.5 m

Voltage: 2.0 V

(The above values are examples.)

Resistance

wear out limit

FAIL

Default value × 2

WARNING

Default value × 1.5

PASS

Default value

BT3554A961-03

Battery requiring replacement

1.0 m

Ω

(twice the value of a

Ω

new battery)

1.8 V (90% of the value of a

new battery)

PassedPassedPassedPassed

Failed

5

6

Internal

resistance

7

Appx. Index

Discharge

capacity

Basic Usage

Connect the test leads to the instrument.

1

Turn the instrument power on.

2

Check the clock settings when using the

instrument for the rst time. (p. 36)

Changing the ranges. (p. 39)

3

Turn on the auto-hold function and auto-

4

memory function.

(

Auto-hold function: Holds measurement values automatically when they

become stable. (p. 75)

Auto-memory function: Automatically stores measurement values

immediately after they are held. (p. 76)

Connect the test leads to the battery.

5

Press the key to read out the

6

measurement values. (p. 69)

and are displayed.)

Data is stored

in internal

memory.

(Black)

Hold at least

1 sec.

(Black)(Red)

−+

(Red)

Handy Features

Comparator function

With the comparator function, the threshold values can be set to

determine if the battery is worn out. (p. 55)

1

Setting examples of the battery wear judgment values

PASS

(Passing limit)

New battery

Resistance: 0.5 m

Voltage: 2.0 V

(The above values are examples.)

Ω

WARNING

(Warning limit)

In use

0.75 mΩ (1.5 times the

value of a new battery)

1.8 V (90% of the value

of a new battery)

(Failure limit)

Battery requiring

replacement

1.0 mΩ (twice the

value of a new battery)

FAIL

2

3

4

5

6

7

Appx. Index

Downloading measurement values to a computer

By connecting the instrument to a computer with the included USB

cable, the measurement data can be downloaded to the computer.

(p. 83)

Viewing measurement values on a mobile device (only

for BT3554-01)

With the Bluetooth® Communication function, the measurement data

can be viewed on a smart phone or tablet. (p. 84)

Contents

Introduction .........................................................................1

Verifying Package Contents ..............................................2

Options ................................................................................ 4

Safety Information .............................................................. 7

Operating Precautions ..................................................... 12

1 Overview 19

1.1 Measuring Battery Wear ............................... 19

1.2 Overview ........................................................21

1.3 Features .........................................................22

1.4 Names and Functions of Parts .................... 24

1.5 Dimensions .................................................... 29

2 Measurement Preparations 31

2.1 Attaching the Neck Strap ............................. 31

2.2 Installing/Replacing Alkaline Batteries ....... 32

2.3 Connecting the Test Lead .............................33

Connecting a Pin Type Lead and the Model

9466 Remote Control Switch .................................... 34

2.4 Turning the Power ON/OFF ..........................35

2.5 Clock Function .............................................. 36

Turning the Date and Time Display ON/OFF ............ 36

Adjusting the Date and Time .....................................36

1

2

3

4

5

6

7

3 Measurement 37

3.1 Pre-operation Inspection .............................. 38

3.2 Setting the Measurement Range ................. 39

3.3 Adjusting Zero Value

(Zero Adjustment) .........................................40

Appx. Index

8

9

i

Contents

Shorting Methods for Various Test Leads ................. 41

Performing Zero Adjustment ..................................... 44

Zero Adjustment Troubleshooting ............................. 46

Canceling the Zero Adjustment Operation ................46

3.4 Retaining the Displayed Values ................... 47

Canceling the Retaining State ..................................47

When retaining with the Model 9466 Remote

Control Switch ........................................................... 48

3.5 Determining Battery-wear Judgment

Values .............................................................49

3.6 Measuring a Battery (Inspection) ................ 50

Error Measurements ................................................. 52

Warning Display ........................................................52

3.7 Measuring the Temperature .........................53

Changing the temperature display unit ..................... 54

4 Comparator Function (Evaluation by

Threshold Values) 55

4.1 Overview ........................................................55

4.2 Turning On the Comparator Function .........56

4.3 Setting Threshold Values for the

Comparator .................................................... 57

Comparison Table for the Comparator ...................... 61

4.4 Setting the Comparator Buzzer ................... 63

4.5 Canceling the Comparator Function ........... 64

5 Memory Function 65

5.1 Overview ........................................................65

Memory Structure .....................................................65

5.2 Storing Data in the Memory ......................... 66

5.3 Canceling the Memory Function .................. 68

5.4 Reading Out Stored Data .............................. 69

ii

Contents

5.5 Clearing Stored Data ..................................... 70

Clearing a Single Set of Data ...................................70

Clearing Data from Each Unit ................................... 71

Clearing All Data ....................................................... 72

6 Other Features 73

6.1 Noise Frequency Avoidance Function ........73

6.2 Auto-hold Function ....................................... 75

6.3 Auto-memory Function ................................. 76

6.4 Auto Power Save Function (APS) ................ 77

6.5 Backlight ........................................................ 78

6.6 System Reset ................................................. 79

Default Settings (Factory Defaults) ........................... 80

6.7 Battery Level Warning ..................................81

7 Communications Function 83

7.1 Communicating with a Computer ................ 83

7.2 Communicating with a Smart Phone or

Tablet (Only for BT3554-01) ..........................84

Installing the smartphone app GENNECT Cross ...... 85

Turning ON/OFF the Bluetooth® function .................. 86

Pairing the app with the battery tester (BT3554-01) . 87

Making measurements with the Bluetooth

®

function . 88

Appx.

1

2

3

4

5

6

8 Specications 89

8.1 GeneralSpecications ................................. 89

8.2 BasicSpecications ..................................... 91

8.3 AccuracySpecications ............................... 93

8.4 FunctionalSpecications ............................. 95

8.5 CommunicationSpecications .................. 102

iii

7

8

9

Contents

9 Maintenance and Service 103

9.1 Repair, Inspection, Cleaning ...................... 103

9.2 Troubleshooting ..........................................105

Before Returning for Repair .................................... 105

9.3 Error Messages ........................................... 107

9.4 Frequently Asked Questions ...................... 108

9.5 Replacing the Fuse ..................................... 109

9.6 Replacing the Test Lead’s Tip Pin ............. 110

9.7 Disposing the Instrument (Removing

the Lithium Battery) .................................... 113

Appendix Appx.1

Appx. 1 Effect of Extending the Test Lead

and Induced Voltage ......................... Appx.1

Reducing Induced Voltage ............................Appx.1

Appx. 2 Effect of Eddy Currents.................... Appx.2

Appx. 3 AC 4-terminal Measurement Method .

Appx.3

Appx. 4 Effects of Current Density ............... Appx.5

When the Measurement target is Wide or

Thick .............................................................Appx.5

Appx. 5 Synchronous Detection System...... Appx.7

Appx. 6 Calibration ......................................... Appx.8

Calibrating the Resistance Measurement

Component ...................................................Appx.8

Calibrating the Voltage Measurement Unit ...Appx.9

iv

Introduction

Introduction

Thank you for purchasing the Hioki BT3554, BT3554‑01, BT3554‑10,

BT3554‑11 Battery Tester.

To obtain maximum performance from the instrument, please read

this manual rst, and keep it handy for future reference.

In this document, the model is indicated as BT3554 or BT3554‑01 (as

printed on the instrument), shown below.

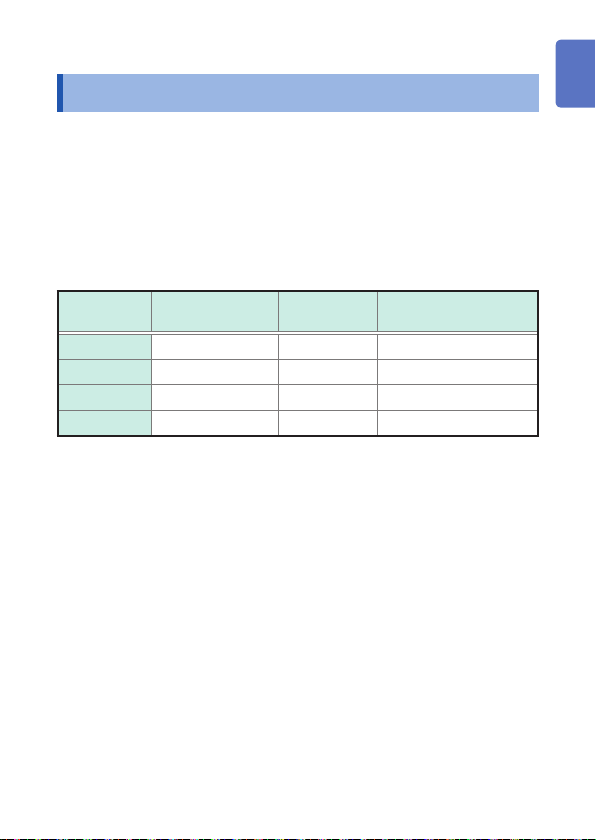

Model

BT3554 BT3554 – 9465‑10

BT3554‑01 BT3554‑01

BT3554‑10 BT3554 – L2020

BT3554‑11 BT3554‑01

Model printed on

the instrument

Bluetooth

Standard accessory:

®

9465‑10

L2020

: Yes,

Pin Type Lead

– : No

Trademarks

• Bluetooth® is a registered trademark of Bluetooth SIG, Inc.(USA).

The trademark is used by HIOKI E.E. CORPORATION under

license.

• Android and Google Play are trademarks of Google, Inc.

• IOS is a registered trademark of Cisco Systems, Inc. and/or its

afliates in the United States and certain other countries.

• iPhone, iPad, iPad miniTM, iPad Pro, and iPod touch are

trademarks of Apple Inc.

• The App Store is a service mark of Apple Inc.

1

2

3

4

5

6

7

AppendixIndex

1

Verifying Package Contents

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure

that no damage occurred during shipping. In particular, check the

accessories, panel switches, and connectors. If damage is evident,

or if it fails to operate according to the specications, contact your

authorized Hioki distributor or reseller.

Conrm that these contents are provided.

(4)

(5)

(3)

(2)

(6)

(7)

(1)

(8)

(9)

2

Verifying Package Contents

(1) Model BT3554 or BT3554‑01 Battery Tester × 1,

Protector × 1 (attached)

(2) Zero adjustment board × 1

(3) Instruction manual*

Emits Radio Waves (only for BT3554‑01) × 1,

Application software*

(4) Carrying Case × 1

(5) Spare fuse × 1

(6) LR6 (AA) alkaline batteries × 8

(7) USB cable × 1

(8) Model 9465‑10 or L2020 Pin Type Lead × 1

(9) Neck strap × 1

*1 Instruction manuals may also be available in other languages.

Please visit our website at http://www.hioki.com.

*2 The latest version can be downloaded from our website.

*3 Apply to battery cover or other location as desired.

1

× 1, Precautions Concerning Use of Equipment That

2

CD × 1, Power‑on option sticker*3 × 1

1

2

3

4

5

6

7

AppendixIndex

3

Options

Options

The following options are available for the instrument. Contact your

authorized Hioki distributor or reseller when ordering.

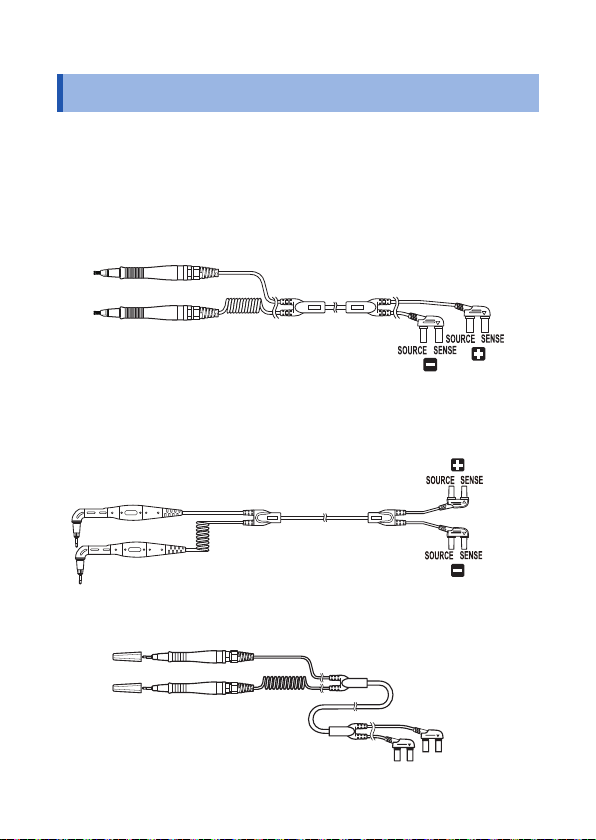

Model 9772 Pin Type Lead

The lead's pins are arranged parallel to each other. It is a strong,

wear‑resistant lead.

(Red)

(Red)

(Black)

(Black)

Model L2020 Pin Type Lead

This pin type lead has a four-terminal structure and can be used in conned

spaces where the measurement target is difcult to reach.

(Red)

(Red)

(Black)

(Black)

Model 9465-10 Pin Type Lead

This pin type lead has a four‑terminal structure.

(Red)

(Black)

(Black)

(Red)

4

Model 9772-90 Tip Pin

The replacement tip pin for the model 9772 Pin Type Lead.

9.15 mm

1.8 mm

2.5 mm

4.3 mm

φ

Options

1

2

Model 9465-90 Tip Pin

The replacement tip pin for the model 9465‑10 and L2020 Pin Type Lead.

2.7 mm φ1.27 mm

φ

Model 9466 Remote Control Switch

When this switch is attached to the test lead, the instrument can hold the

values while measuring them.

Wearable models: • Model 9465‑10 Pin Type Lead

• Model 9772 Pin Type Lead

• Model L2020 Pin Type Lead

Switch

Miniplug φ2.5 mm

(EXT.HOLD)

3

4

5

6

7

AppendixIndex

5

Options

Model Z5038 0 ADJ Board

Hook and loop fastener is necessary seperately to stick to the carrying case

and use model Z5038.

(For models 9772, L2020, and 9465‑10)

Model 9460 Clip Type Lead with Temperature Sensor

Resistance, voltage, and temperature can be measured simultaneously with

this lead.

(Red)

Temperature

sensor

(Black)

Miniplug

(TEMP SENSOR)

(Red)

(Black)

Model 9467 Large Clip Type Lead

These can clip the test lead to the measurement target with a thick bar. Four‑

terminal measurement can be conducted just by clipping the lead to the target.

(Red)

(Red)

Approx.

29 mm

φ

6

(Black)

Approx. 850 mm

Approx. 250 mm

(Black)

Safety Information

Safety Information

This instrument is designed to conform to IEC 61010 Safety

Standards, and has been thoroughly tested for safety prior to

shipment. However, using the instrument in a way not described in

this manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the

following safety notes:

DANGER

Mishandling during use could result in injury or death,

as well as damage to the instrument. Be certain that

you understand the instructions and precautions in

the manual before use.

WARNING

With regard to the electricity supply, there are risks of

electric shock, heat generation, re, and arc ash due

to short circuits. If persons unfamiliar with electricity

measuring instrument are to use the instrument,

another person familiar with such instruments must

supervise operations.

Protective gear

WARNING

This instrument is measured on a live line. To prevent

electric shock, use appropriate protective insulation

and adhere to applicable laws and regulations.

1

2

3

4

5

6

7

AppendixIndex

7

Safety Information

Notation

In this document, the risk seriousness and the hazard levels are

classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that

will result in death or serious injury to the operator.

Indicates a potentially hazardous situation that may

result in death or serious injury to the operator.

Indicates a potentially hazardous situation that may

result in minor or moderate injury to the operator or

damage to the instrument or malfunction.

Indicates information related to the operation of the

instrument or maintenance tasks with which the

operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the

instrument is mishandled, this may give rise to a

hazardous situation; the operator may receive an

electric shock, may get burnt or may even be fatally

injured.

Indicates prohibited actions.

Indicates the action which must be performed.

8

HOLD

[HOLD]

Indicates a control key.

Indicates the display on the screen.

Symbols on the instrument

Safety Information

Indicates cautions and hazards. When the symbol is printed on

the instrument, refer to a corresponding topic in the Instruction

Manual.

Indicates a fuse.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment

Directive (WEEE Directive) in EU member states.

Indicates that the product conforms to regulations set out by the

EU Directive.

Indicates that the product incorporates Bluetooth® wireless

technology.

FCC ID

FCC ID Indicates the ID number of the wireless module certied

by the U.S. Federal Communications Commission (FCC).

Indicates the identication number of a wireless module

IC

approved by Industry Canada (IC).

1

2

3

4

5

6

7

AppendixIndex

9

Safety Information

Screen Display

The instrument screen displays the alphanumeric characters as

follows.

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

1 2 3 4 5 6 7 8 9 0

A different display is used in the case below:

Displays when setting the Bluetooth

:

communication.

: Displays when clearing the stored data.

Displays when setting the comparator buzzer

:

to FAIL.

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg.

(reading) and dgt. (digit) values, with the following meanings:

(maximum display value or range)

f.s.

The maximum displayable value. This is usually the name of the

currently selected range.

(reading or displayed value)

rdg.

The value currently being measured and indicated on the

measuring instrument.

(resolution)

The smallest displayable unit on a digital measuring instrument,

dgt.

i.e., the input value that causes the digital display to show a "1" as

the least-signicant digit.

®

10

Safety Information

Measurement Categories

To ensure safe operation of measuring instruments, IEC 61010

establishes safety standards for various electrical environments,

categorized as CAT II to CAT IV, and called measurement categories.

DANGER

• Using a measuring instrument in an environment

designated with a higher category than the rating

of the instrument could result in a severe accident,

and must be carefully avoided.

• Using a measuring instrument without categories

in an environment categorized as CAT II to CAT

IV could result in a severe accident, and must be

carefully avoided.

CAT II: When directly measuring the electrical outlet receptacles of the

primary electrical circuits in equipment connected to an AC electrical

outlet by a power cord (portable tools, household appliances, etc.).

CAT III: When measuring the primary electrical circuits of heavy equipment

(xed installations) connected directly to the distribution panel, and

feeders from the distribution panel to outlets.

CAT IV: When measuring the circuit from the service drop to the service

entrance, and to the power meter and primary overcurrent protection

device (distribution panel).

Distribution panel

Service entrance

Service drop

CAT IV

Power meter

Fixed installation

The instrument’s labeling does not indicate its suitability for use in any

particular measurement category.

Internal wiring

CAT III

CAT II

T

Outlet

1

2

3

4

5

6

7

AppendixIndex

11

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the

full benets of the various functions.

Ensure that your use of the product falls within the specications not

only of the instrument itself, but also of any accessories, options,

batteries, and other equipment being used.

Installing the instrument

CAUTION

Installing the instrument in inappropriate locations may

cause a malfunction of instrument or may give rise to an

accident. Avoid the following locations.

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or electrostatic

charge

• Near induction heating systems (such as high‑frequency

induction heating systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

Do not place the instrument on an unstable table or an

inclined place. Dropping or knocking down the instrument

can cause injury or damage to the instrument.

12

Preliminary checks

Operating Precautions

DANGER

If the test lead or the instrument is damaged, there is

a risk of electric shock. Before using the instrument

perform the following inspection:

• Before using the instrument check that the coating

of the test leads are neither ripped nor torn and that

no metal parts are exposed. Using the instrument

under such conditions could result in electric

shock. Replace the test leads with those specied

by our company.

• Verify that the instrument operates normally to

ensure that no damage occurred during storage

or shipping. If you nd any damage, contact your

authorized Hioki distributor or reseller.

Precautions for Transportation

During shipment of the instrument, handle it carefully so that it is not

damaged due to a vibration or shock.

Handling the instrument

DANGER

To avoid electric shock, do not remove the

instrument's case. The internal components of the

instrument carry high voltages and may become very

hot during operation.

1

2

3

4

5

6

7

AppendixIndex

13

Operating Precautions

CAUTION

To avoid damage to the instrument, protect it from physical

shock when transporting and handling. Be especially

careful to avoid physical shock from dropping.

Precautions for measurement

DANGER

To avoid electric shock, be careful to avoid shorting

live lines with the test leads.

WARNING

• Do not use the instrument and test lead with circuits

that exceed its ratings or specications. Doing so

may cause damage, resulting in an electric shock.

• Do not measure any voltage that would exceed the

instrument’s maximum input voltage (terminal-toterminal) or maximum rated terminal-to-ground

voltage of 60 V.

Maximum input voltage

(terminal-to-terminal) 60 V DC

Maximum rated terminalto-ground voltage 60 V DC

14

• Do not measure AC voltage.

Operating Precautions

WARNING

• Be sure to connect the test lead correctly.

• Wear gloves of rubber or similar material during

measurement.

• Ensure sufcient ventilation when measuring

batteries in the measurement room to prevent

explosions. Sparks may occur when the test leads

are connected to batteries, which can ignite any

accumulated inammable gases such as hydrogen.

1

2

CAUTION

• After measuring a high-voltage battery, rst short the

test leads together to discharges the DC elimination

capacitor connected across the leads before continuing

to measure a low‑voltage battery. Otherwise an excess

voltage may be applied to the low‑voltage battery

causing damage to the battery.

• To avoid damage to the instrument, do not apply voltage

to the EXT.HOLD and TEMP.SENSOR terminal.

IMPORTANT

Do not place the test leads in contact with the measurement

terminals of a battery that is leaking uid. Doing so may cause

a degradation in instrument functionality due to exposure to

electrolyte from the leaking battery.

3

4

5

6

7

AppendixIndex

15

Operating Precautions

Handling the test leads

CAUTION

Do not apply force when the pin type lead tip is in contact

with the battery at a tilted angle.

OK NO

Avoid subjecting the temperature probe tip to physical

shock, and avoid sharp bends in the leads. These may

damage the probe or break a wire.

IMPORTANT

When using the instrument, use only the test leads with those

specied by our company. Using other test leads may result

in incorrect measurements due to loose connections or other

reasons.

Zero adjustment board

WARNING

To prevent short-circuit accidents, do not place the

zero adjustment board on top of the battery.

16

Batteries and fuses

Operating Precautions

WARNING

• To avoid electric shock when replacing the batteries

and fuse, rst disconnect the test leads from the

object to be measured, and then remove the case.

• To prevent instrument damage or electric shock,

use only the screw for securing the battery cover

in place that are originally installed. If you have lost

a screw or nd that a screw is damaged, please

contact your Hioki distributor for a replacement.

• Replace the fuse only with one of the specied type,

characteristics, rated current, and rated voltage. Do

not use fuses other than those specied (especially,

do not use a fuse with higher-rated current) or do

not short circuit and use the fuse holder. Doing so

may damage the instrument and result in bodily

injury.

Fuse type: 216.630, Littelfuse Inc., fast-acting, rating

250 V / F 630 mAH, circuit breaker rating 1500 A

• Battery may explode if mistreated. Do not short-

circuit, recharge, disassemble or dispose of in re.

1

2

3

4

5

6

7

AppendixIndex

17

Operating Precautions

CAUTION

Poor performance or damage from battery leakage could

result. Observe the cautions listed below:

• Do not mix old and new batteries, or different types of

batteries.

• Be careful to observe the battery polarity during

installation.

• Do not use batteries after their recommended expiry

date.

• Do not allow weak batteries to remain in the instrument.

• Replace batteries only with the specied type.

• Remove the batteries from the instrument if it is to be

stored for a long time.

Handle and dispose of batteries in accordance with local regulations.

CD disc precautions

• Exercise care to keep the recorded side of discs free of dirt

and scratches. When writing text on a disc's label, use a pen or

marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct

sunlight, high temperature, or high humidity.

• Hioki is not liable for any issues your computer system

experiences in the course of using this disc.

18

1

Overview

1.1 Measuring Battery Wear

IMPORTANT

To determine if a battery is worn out, rst measure the internal

resistance of a new or good battery.

When the battery is worn out, the internal resistance rises to

approximately 1.5 to 2 times its default value (reference values).

The graph below shows the relation between storage capacity and

default value of internal resistance in a lead-acid battery. "CS",

"HS", and "MSE" denote JIS (Japanese Industrial Standard) leadacid battery types.

The internal resistance of an MSE (sealed stationary lead-acid

battery) can be read at approximately 1 m

approximately 0.13 m

]

[m

Ω

10

1

0.1

Internal resistance value

(1000 Ah).

Ω

CS

HS

MSE

CS Clad type stationary lead-acid

HS High discharge rate stationary

MSE Sealed stationary lead-acid

(100 Ah) and

Ω

battery

lead-acid battery

battery

1

2

3

4

5

6

7

Appx. Index

0.01

10 100 1000 10000

Lead-acid battery capacity

[Ah]

19

Measuring Battery Wear

• The warning limit (WARNING) for an MSE (sealed stationary

lead-acid battery) is when the internal resistance reaches

approximately 1.5 times its default value. The failure limit (FAIL)

varies for each manufacturer.

• Default value of internal resistance may vary among batteries

with the same capacity, depending on the model or manufacturer.

Use the graph on the previous page as reference.

• Internal resistance warning limit (WARNING) and failure limit

(FAIL) varies for each manufacturer.

Source: Battery technician certication textbook, Battery Association

of Japan (BAJ)

Comparator function (p. 55)

With the comparator function, the battery measurement values

can be compared with the present threshold values to determine

which ranges those values fall within: PASS, WARNING, or FAIL.

In open (liquid) stationary lead-acid batteries such as CS, HS, and

alkaline lead-acid batteries, variations in internal resistance are

small compared with sealed stationary lead-acid batteries, and

sometimes it is difcult to determine worn out state of the batteries.

20

Overview

1.2 Overview

This instrument measures internal resistance, voltage, and terminal

temperature* of lead-acid, nickel-cadmium, nickel-hydrogen, and

other types of batteries, enabling you to determine if the battery is

worn out.

1

2

3

* Temperature measurement requires the optional model 9460 Clip

Type Lead with Temperature Sensor.

The measurement data can be copied to a computer by connecting

the instrument to a computer after measurement with the USB cable

provided. Also, users can view the data on their smart phones or

tablets with the Bluetooth® Communication function.

Measurement data

Specifying

threshold values

Measurement data

21

4

5

6

7

Appx. Index

Features

1.3 Features

Enables measurement without shutting down UPS

systems

This instrument uses high-precision AC resistance measurement

technology, and noise reduction technology. Time required for

measurement is reduced since the instrument is capable of

measuring live wires without requiring the UPS system to be shut

down.

Reliable measurement values

This instrument is capable of obtaining reliable measurement values

without being affected by lead or connector resistance because it

uses the AC 4-terminal method to measure internal resistance.

Simultaneous display of resistance, voltage, and

temperature

Without changing functions, this instrument can display

battery internal resistance, voltage, and terminal temperature

simultaneously. Temperature measurement requires the optional

model 9460 Clip Type Lead with Temperature Sensor.

Comparator function

The comparator function enables you to set threshold values for

internal resistance and voltage. This can determine battery wear

more easily.

Large memory capacity

This instrument can store up to 6000 sets of data combining

presently measured values (resistance, voltage, temperature, and

comparator measurement results). It can be used to measure up to

12 units of 500-cell cubicles.

22

Features

Auto-memory function

Turning this function on stores the measurement values in the

instrument's internal memory automatically, the instant when each

set of data is held. This can lead to increased operational efciency.

PC interface

Measurement data can be loaded into a computer.

Bluetooth® Communication function

Users can view measurement values on their smart phones and

tablets.

Model L2020 Pin Type Lead (optional)

The model L2020 pin type lead is L-shaped and handy to measure

in conned location.

Model 9772 Pin Type Lead (optional)

Using the model 9772 Pin Type Lead with a pin tip designed to t

in holes of φ5 mm enables measurement without removing terminal

covers. Measurement is possible in virtually any location because

the pin can be inserted diagonally in hard-to-reach places.

Model 9466 Remote Control Switch (optional) for

storing measurement values

The model 9466 Remote Control Switch makes it possible to hold

and store measurement values by pressing a key. This is useful

when both hands of the operator are busy.

1

2

3

4

5

6

7

Appx. Index

23

Names and Functions of Parts

1.4 Names and Functions of Parts

Front

Display (p. 27)

Measurement

terminals

Control keys

(BT3554-01)

Measurement terminals

(1)

(p. 14, p. 33)

(1) SOURCE

terminals

(2) SENSE

terminals

24

(2)

The SOURCE side of the banana plug on the test

lead is connected to this terminal.

The SENSE side of the banana plug on the test

lead is connected to this terminal.

Control keys

Names and Functions of Parts

Pressing

−

Turns the comparator

buzzer ON/OFF.

Turns the comparator ON/

OFF.

Turns the auto-hold and

auto-memory features ON/

OFF.

Displays the clock. Adjusts the clock. −

Selects a conguration

setting.

Changes the value.

Uses the right or left key

to select a digit.

Turns on the memory

storage.

Stores measurement value

when it is retained.

Conrms the settings. −

Holds or cancels the

measurement values.

Reads or cancels stored

measurement values.

Deletes the settings.

Pressing and

holding (at

least 1 second)

Turns the power

ON/OFF.

− −

Sets comparator

threshold values.

−

− −

Turns off the

memory storage.

−

− −

Deletes the last

stored data.

Pressing and

holding the key

while turning on

the power

Displays the setup

screen for the

disconnection

detection function.

Turns the

Bluetooth

Communication

function ON/OFF

(for BT3554-01).

Displays the Serial

No.

Displays the APS

setup screen.

Displays the system

reset screen.

1

−

−

2

3

4

5

®

6

7

Appx. Index

25

Names and Functions of Parts

Pressing

−

Turns the backlight ON/

OFF.

Changes the resistance

range.

Changes the voltage

range.

Pressing and

holding (at

least 1 second)

Starts or cancels

zero adjustment.

(press and hold

for at least 2

seconds.)

− −

−

−

Pressing and

holding the key

while turning on

the power

−

Displays the setup

screen for the

noise frequency

avoidance function.

Displays all LCD

screen elements.

26

Display

Names and Functions of Parts

Data No.

Resistance

measurement

value and units

Voltage

measurement

value and

units

Zero adjustment ON

Clock display and setting

Comparator buzzer ON

Now communicating

Bluetooth® function ON

(only for BT3554-01)

Auto Power Save ON

Battery level

Auto-hold ON

Auto-memory ON

Noise frequency

avoidance function ON

Input overow

Retain measurement

value

Indicators other than those shown above may also light up when all the

indicators on the display are shown, but only the above indicators are used by

the instrument.

Temperature

measurement

value and units

Saved memory number

Read memory number

Comparator number

Selected memory

number is in use

Setting each function

For setting comparator

threshold values

For noise frequency

avoidance function

Comparator ON

PASS result

WARNING result

FAIL result

1

2

3

4

5

6

7

Appx. Index

27

Names and Functions of Parts

Top view

(1) (2) (3)

(1) EXT.HOLD terminal Connects the model 9466 Remote

(2) USB terminal Connects the USB cable.

(3) TEMP.SENSOR terminal Connects the miniplug of the model 9460

Control Switch (optional).

Clip Type Lead with Temperature Sensor

(optional).

Rear view

Fuse cover

Tightening screw

Serial No.*

Bluetooth

(only for BT3554-01)

®

label

Battery cover

* The serial number consists of 9 digits. The rst two (from the left)

indicate the year of manufacture, and the next two indicate the

month of manufacture. Required for production control. Do not

peel off the label.

(p. 17)

(p. 17)

28

1.5 Dimensions

Dimensions

1

60.6±3 mm

132±3 mm

2

199±3 mm

3

4

5

6

7

Appx. Index

29

Dimensions

30

Measurement Preparations

2

2.1 Attaching the Neck Strap

Operators can hang the instrument around their neck by attaching

the neck strap. Attach the neck strap as described below.

Switch off the instrument and

1

remove the test leads.

Pass the neck strap through

2

the 2 attachments and fasten it

in place with the buckles (2 on

each side of the instrument).

Adjust the length of the neck

3

strap.

The instrument can be placed in

the carrying case even with the

neck strap attached.

1

2

3

4

5

6

7

Appx. Index

31

Installing/Replacing Alkaline Batteries

2.2 Installing/Replacing Alkaline Batteries

When using the instrument for the rst time, insert 8 LR6 (AA)

alkaline batteries. Before attempting measurement, check to make

sure that the battery level is sufcient. If the battery level is low,

replace the batteries with new ones.

• The indicator ashes when alkaline battery voltage

becomes low. Replace the batteries as soon as possible.

• In this document, the "alkaline battery" means the LR6 (AA)

battery to run the instrument, and the "battery" refers to the

measurement target.

Switch off the instrument and

1

remove the test leads.

1

Open the alkaline battery cover

2

on the rear of the instrument.

Insert 8 alkaline batteries, taking

3

care of the proper polarities.

Replace the alkaline battery

4

cover.

32

3

4

2

Connecting the Test Lead

2.3 Connecting the Test Lead

WARNING

To avoid electric shocks, be sure to connect the test

leads properly.

Connect the test leads to the instrument. Be sure to connect all 4

terminals: SOURCE (+,−) and SENSE (+,−).

(Black)

(Red)

Align the

marks of the

same color.

When using the optional model 9460 Clip Type Lead with

Temperature Sensor, connect the miniplug to the TEMP.SENSOR

terminal. For more information, see “Measuring the Temperature” (p.

53).

1

2

3

4

5

6

7

Appx. Index

33

Connecting the Test Lead

Connecting a Pin Type Lead and the Model 9466 Remote Control Switch

The Pin Type Lead (Models 9465-10, 9772, and L2020) and the

optional model 9466 Remote Control Switch can be combined

together as shown below.

Connect the remote control switch to the probe of the lead, and join

the 2 cables using the supplied spiral tube.

(1) (2) (3) (4)

(L2020)

(4)(5)

(1) Model 9446 Remote Control Switch

(2) Probe

(3) Spiral tube (small)

Bundle up the center of the lead between the probe and junction

with a spiral tube.

(4) Junction

(5) Spiral tube (large)

Arbitrarily bundle up the lead between junctions.

34

(9465-10)

Turning the Power ON/OFF

2.4 Turning the Power ON/OFF

Press and hold the key (for at least 1 second) to turn the

power on or off. Check the clock settings when using the instrument

for the rst time.

1

Power: ON Power: OFF

The indicator ashes when alkaline battery voltage

becomes low. Replace the batteries as soon as possible.

2

3

4

5

6

7

Appx. Index

35

Clock Function

2.5 Clock Function

The date and time can be displayed by pressing the DATE key.

Check the clock settings when using the instrument for the rst

time. The time is displayed using a 24-hour clock. The instrument's

calendar recognizes leap years automatically.

Turning the Date and Time Display ON/OFF

Press the DATE key to switch date-and-time display on or off.

Date and time display: ON Date and time display: OFF

Year

Month

Time

Day

(00:00 on January 1, 2016)

Adjusting the Date and Time

1

2

3

36

(Press the key for at least

1 second.)

Enters the date and time

setup mode.

Select the values.

Conrm the specied

values.

Date and time will not be set if

you exit the clock setup screen

without pressing the ENTER key.

Measurement

3

To ensure safe operation, be sure to read "Operating Precautions" (p.

12) before starting the measurements.

• Internal battery resistance varies considerably depending

on charge or discharge status. To increase measurement

accuracy, make measurements under similar conditions (for

example, a fully charged battery).

• Lead-acid batteries (measuring objects) have high levels of

terminal resistance. For this reason, resistance values may

differ between the case and the tip of the terminal. Be sure to

connect the test lead to the terminals at a xed location.

For more information, see "Effects of Current Density" (p. Appx.5).

• Use the optional model 9460 Clip Type Lead with Temperature

Sensor to measure the battery temperature. Or, use a noncontact thermometer, such as a radiation thermometer, for

safety.

• Measurement may not be possible for insulated terminals, due

to insufcient ow of current for measurement. In such a case,

clean the terminal (remove the insulation) before measurement.

1

2

3

4

5

6

37

7

Appx. Index

Pre-operation Inspection

3.1 Pre-operation Inspection

Before using the instrument, verify that it operates normally to

ensure that no damage occurred during storage or shipping. If

you nd any damage, contact your authorized Hioki distributor or

reseller.

Inspection item Method of checking

Is the fuse burned

out?

Is the test lead

disconnected?

Touch the test lead to the zero adjustment board.

If the resistance display still shows [−−−−], the

fuse might be burned out or the test lead may be

disconnected. If so, replace it with a new one.

Is the battery level

sufcient?

Inspecting

batteries

38

At the upper right-hand area of the screen,

indicates the present alkaline battery status. If

is displayed, the alkaline batteries need to

be replaced soon. Be sure to have spare alkaline

batteries available.

Measurement may not be possible for insulated

terminals, due to insufcient ow of current for

measurement. In such a case, clean the terminal

(remove the insulation) before measurement.

Setting the Measurement Range

3.2 Setting the Measurement Range

Set resistance and voltage measurement ranges as described

below.

Resistance range 3 m

Voltage range 6 V/ 60 V

Temperature range

/30 mΩ/300 mΩ/3

Ω

(Single range)

Because temperature measurement uses a signal

range, range setting is not required.

Ω

1

2

Press the Ω key or V key to display the present settings. Press the

key repeatedly to cycle through the ranges.

Resistance range

3.000 m

Voltage range

6.000 V

When there is no activity for approximately 1 second, the settings on

the display get conrmed and returns to the measurement screen.

3.000

Ω

Ω

30.00 m

300.0 m

60.00 V

Ω

Ω

39

3

4

5

6

7

Appx. Index

Adjusting Zero Value (Zero Adjustment)

3.3 Adjusting Zero Value (Zero Adjustment)

The zero adjustment function displays subsequent measurement

results using the measured value (correction value) obtained when

it was performed as zero.

The dened accuracy does not require zero adjustment to be

performed when using accessory or optional test leads, but the

process should be performed in the following instances:

• When you wish to increase measurement accuracy*

• When using test leads that are not an accessory or option, or

when using test leads whose length has been extended

* For the 3 m

on whether zero adjustment has been performed.

For more information, see "8 Specications" (p. 89).

• Performing zero adjustment adjusts the zero points of all

ranges.

• Even after the instrument is turned off, the correction values

are retained and the zero adjustment function is not canceled.

• After replacing the test lead, be sure to perform zero adjustment

prior to measurement.

• Be sure to use the included or optional zero adjustment board

when performing zero adjustment.

• Be sure to keep the test lead shorted during zero adjustment.

• Keep the tip of the test lead away from the metal components.

range, the accuracy specications differ depending

Ω

40

Adjusting Zero Value (Zero Adjustment)

Shorting Methods for Various Test Leads

For Pin Type Leads

Use the included or optional zero adjustment board. The zero

adjustment can be achieved using the AC 4-terminal method.

Select 2 holes on the zero

1

adjustment board which are

at the same distance as the

terminals on the battery to be

measured.

Push the test leads in a direction perpendicular to the

2

holes so that it is symmetrical to the central plus sign (+)

on the zero adjustment board.

Model 9465-10 or L2020 Pin Type Lead

1

2

3

4

Center the plus sign (+).

Model 9772 Pin Type Lead

Insert the marked (engraved)

side into the hole.

5

6

7

Appx. Index

41

Adjusting Zero Value (Zero Adjustment)

• Keep the zero adjustment board at least 10 centimeters away

from the instrument.

• Be sure to use the included or optional zero adjustment board

when performing zero adjustment.

• Be sure to connect each of the SOURCE and SENSE terminals

by inserting the tip of the pin into the holes on the zero

adjustment board. (See the gure below.)

SOURCE

SENSE

• Do not place the zero adjustment board on top of the battery

or any metal. Electromagnetic induction effect could result in

unstable measurement values. In such a case, keep the zero

adjustment board away from any metal.

• Performing zero adjustment by connecting the tips of pin-

type leads or using a metal sheet other than the included zero

adjustment board will result in inaccurate adjustment of the

zero point.

• When the distance between the terminals on the battery

(measurement target) is more than the distance between the

holes on the zero adjustment board, use the holes at both

corners to perform zero adjustment.

• Consider the zero adjustment board to be a consumable.

Replacing it with a new one after using it around 700 times is

recommended.

42

Adjusting Zero Value (Zero Adjustment)

For Clip Type Leads

Perform zero adjustment by engaging red and black clips together.

Model 9460 Clip Type Lead with Temperature Sensor

SOURCE

SENSE

Model 9467 Large Clip Type Lead

SOURCE

SENSE

1

2

3

4

5

6

7

Appx. Index

43

Adjusting Zero Value (Zero Adjustment)

Performing Zero Adjustment

Check to ensure that the test

1

leads are connected properly.

Disconnect any leads connected

to the measurement target.

Press the 0ADJ key for at least

2

2 seconds.

This enables the standby state for

acquiring the correction values.

While [0AdJ] is ashing, short

3

the test leads using the zero

adjustment board.

For more information, see

"Shorting Methods for Various

Test Leads" (p. 41).

If the test leads are not shorted

while the display is blinking, it will

result in an error.

(Black) (Red)

1

2

Press for at

least 2 sec.

Flashes for approx.

10 secs.

For pin type leads

44

Adjusting Zero Value (Zero Adjustment)

The instrument automatically begins obtaining correction values.

When the zero adjustment operation is complete, [0ADJ] is lit

up and the instrument returns to the measurement mode:

1

2

3 mΩ range 30 mΩ range

Zero adjustment

complete

• Keep the test leads shorted until the zero adjustment operation

is complete.

• The zero adjustment starts even if a key is pressed after the

test lead has been shorted.

300 mΩ range

3

range and voltage

Ω

range

3

4

5

6

7

Appx. Index

45

Adjusting Zero Value (Zero Adjustment)

Zero Adjustment Troubleshooting

Check items Solution

Is the fuse burned out? If so, replace it with a new fuse. (p. 109)

Do the correction

values obtained exceed

300 counts in either

resistance or voltage

range?

Did you short the test

leads properly while the

instrument is in standby

for correction values?

Ensure that the test lead is properly connected

to the instrument.

The test lead may be disconnected. If so,

replace it with a new one.

Try cleaning the zero adjustment board.

While the instrument is in standby for correction

values (for approximately 10 seconds), short

the test leads using the zero adjustment board

to perform zero adjustment.

Canceling the Zero Adjustment Operation

Pressing the 0ADJ key for at least 2 seconds while the zero

adjustment function is active, cancels the zero adjustment operation.

Zero adjustment: ON Zero adjustment: OFF

Press for

at least 2

seconds.

46

Retaining the Displayed Values

3.4 Retaining the Displayed Values

• When the warning display or voltage is displayed as [−−−−],

the values cannot be retained.

• Changing any of the settings cancels retaining.

• Turning off the power cancels retaining.

Measurement values displayed on the screen can be retained.

Pressing the HOLD key will light up [HOLD], and retain the

measurement values.

Retaining function: OFF Retaining function: ON

Canceling the Retaining State

Pressing the HOLD key again cancels the retaining state.

The auto-hold function can be used to automatically recognize

the stability of measurement values and retain them. For more

information, see "6.2 Auto-hold Function" (p. 75).

1

2

3

4

5

6

7

Appx. Index

47

Retaining the Displayed Values

NO

NONO

When retaining with the Model 9466 Remote Control Switch

The optional model 9466 Remote

Control Switch is available for the

operation in the same way as when

using the HOLD key.

Disconnect the test leads from

1

the battery (measurement

target).

Insert the miniplug of the model

2

9466 Remote Control Switch

into the EXT.HOLD terminal.

Connect the connectors of the

3

test leads to the instrument.

Press the PRESS button on the

4

model 9466 Remote Control

Switch.

The measurement value is

retained.

Model 9466 Remote

Control Switch

Top of the instrument

(Black) (Red)

Canceling the retaining state

Press the PRESS button on the model 9466 Remote Control

Switch, or the HOLD key on the instrument.

48

Determining Battery-wear Judgment Values

3.5 Determining Battery-wear Judgment Values

To determine if a battery is worn out, rst measure the internal

resistance of a new or good battery, and decide the limits for judging

battery wear.

As a battery wears out, its internal resistance increases to

approximately 1.5 to 2 times (reference value) that of a new or

good battery, and voltage values decreases to 90% of the default

value. Use these values as guidelines when determining the battery

wear judgment values.

Example of the battery wear judgment values

Default value

(PASS)

Warning limit

(WARNING)

Failure limit

(FAIL)

1

2

3

4

5

Resistance:

Voltage:

The above values are examples.

The above values vary depending on the manufacturer and

battery model. For more information, see "1.1 Measuring Battery

Wear" (p. 19).

0.5 m

Ω

2.0 V 1.8 V

0.75 m

Ω

1.0 m

Ω

6

7

Appx. Index

49

Measuring a Battery (Inspection)

3.6 Measuring a Battery (Inspection)

Prepare the measurement. (p. 31)

1

Set the resistance and voltage ranges. (p. 39)

2

Perform zero adjustment. (p. 40)

3

Connect the test leads to the battery.

4

Ensure that all pins are

connected to the battery.

(Red)

+

Read the measurement values.

5

50

(Black)

−

Internal resistance of the battery

Voltage

Measuring a Battery (Inspection)

Use the measurement values to judge whether the battery

6

is worn out.

Example:

Voltage

1

Default

value

(2.0 V)

Current

value

(1.8 V)

As shown above, this battery needs to be replaced.

To retain

measurement values

To store

measurement values

To load the stored

data to a computer

To set threshold

values and judge

whether the battery

is worn out

PASS

WARNING

Default value

(0.5 mΩ)

Refer to "3.4 Retaining the Displayed

Values" (p. 47).

Measurement values can be stored

by pressing the MEMO key while the

values are being retained.

Refer to "5.2 Storing Data in the

Memory" (p. 66).

Refer to "Communications Function" (p.

83).

Based on the wear judgment values,

threshold values can be set for judging

whether the battery is worn out.

Refer to "Comparator Function

(Evaluation by Threshold Values)" (p.

55).

Present value

(1.0 m

FAIL

FAIL

Resistance

)

Ω

2

3

4

5

6

7

Appx. Index

51

Measuring a Battery (Inspection)

Error Measurements

If [−−−−] is displayed and [OVER] ashes on the screen (at the

same time, the maximum display values ashes), this does not

indicate an error.

[

] • If [

−−−−

[OVER] display

and maximum

display value

ashes

• The test lead is not connected correctly to the

• The resistance of the measurement target signicantly

• This indicates that it is measuring an exceeded

] is shown in the resistance display, the test

−−−−

lead is open.

Or, a failure such as abnormal current ow due to a

disconnected test lead prevents measurements.

measurement target.

exceeds the measurement range.

measurement range of either resistance, voltage, or

temperature.

Note the maximum open-circuit terminal voltage of the instrument

(approximately 5 V maximum) when measuring the resistance

of a relay or a connector. There is a possibility that such

measurement may damage the oxidized coating on the connector

of the measurement target, leading to incorrect measurements.

Warning Display

In the event of an overvoltage input error, the [OVER] display and

maximum display value ash, the red backlight lights up, and the

buzzer sounds.

52

Measuring the Temperature

NO

NONO

3.7 Measuring the Temperature

Use the optional model 9460

Clip Type Lead with Temperature

Sensor to measure the battery

temperature.

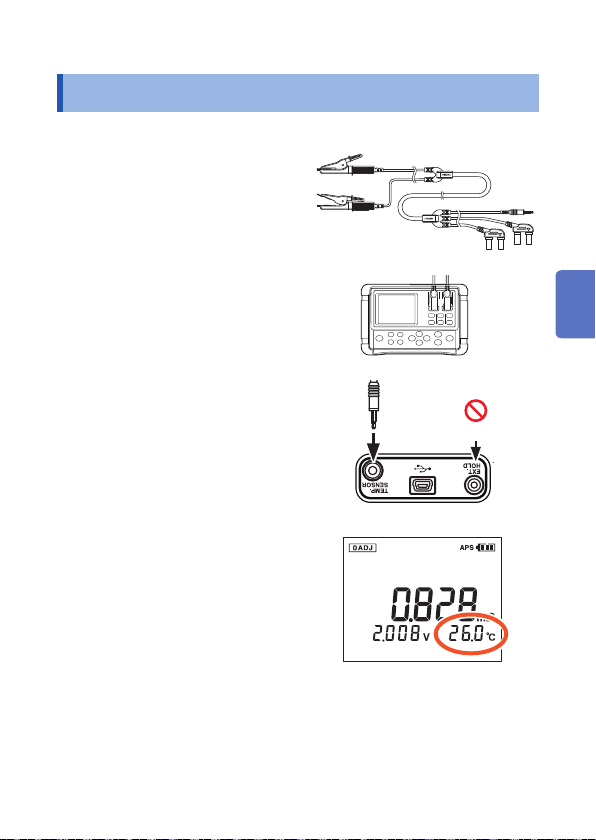

Connect the connector of

1

the model 9460 Clip Type

Lead with Temperature

Sensor to the instrument.

Connect the miniplug of the

2

model 9460 Clip Type Lead

with Temperature Sensor to

the TEMP.SENSOR terminal.

The instrument detects the

temperature sensor and

automatically displays the

temperature.

1

2

(Black) (Red)

3

4

5

Top of the instrument

6

7

Appx. Index

53

Measuring the Temperature

Changing the temperature display unit

The units of temperature (°C or °F) can be changed.

1

2

3

4

The setting of the temperature unit is retained even after the

power is turned off.

Turn off the instrument.

Display the setting of the

temperature unit.

Press the key for at least 3

seconds.

Conrm the setting.

The instrument is restarted.

The settings will not change if

the power is turned off before the

settings are applied.

54

Comparator Function

4

(Evaluation by Threshold Values)

4.1 Overview

The battery measurement values can be compared with the present

threshold values using the comparator function to determine the

ranges in which the values fall within: PASS, WARNING, or FAIL.

Up to 200 comparator conditions can be set. Refer to “Measuring

Battery Wear” (p. 19) for more information on how to determine

the threshold values.

A buzzer sounds when a measurement falls within the range of

WARNING or FAIL under the default settings. For more information,

see “4.4 Setting the Comparator Buzzer” (p. 63).

A resistance warning limit, resistance failure limit, and voltage

warning limit are available as the threshold values.

Voltage

PASS

Default value

Voltage

warning limit

WARNING

Default

value

Resistance

warning

limit

FAIL

FAIL

Resistance

failure limit

Resistance

1

2

3

4

5

6

7

Appx. Index

55

Turning On the Comparator Function

4.2 Turning On the Comparator Function

1

2

3

Press the key.

The comparator number ashes.

Press the COMP key again to return

to normal measurements.

Select the comparator

number.

(A number from 1 to 200 can be

selected.)

Conrm the settings.

The comparator function is now

turned on.

When the comparator function is turned on, the instrument

changes to the range specied by the comparator settings.

56

Setting Threshold Values for the Comparator

4.3 Setting Threshold Values for the Comparator

Threshold values can be set for the comparator (resistance warning

limit, resistance failure limit, and voltage warning limit).

1

Example: Threshold values for a battery with the default

values* 0.4

Resistance warning limit: 0.6 Ω (1.5 times of the default value)

Resistance failure limit: 0.8 Ω (2 times of the default value)

Voltage warning limit: 1.8 V

* The default value refers to the value of resistance and voltage for

a new battery or a battery in good condition.

Selecting a comparator number

1

2

3

and 2 V.

Ω

Press the key for at least 1

second.

The comparator number ashes.

Press the COMP key again to return

to normal measurements.

Select the comparator

number.

(A number from 1 to 200 can be

selected.)

Conrm the settings.

The range setup screen is displayed.

2

3

4

5

6

7

Appx. Index

57

Setting Threshold Values for the Comparator

Setting the range

Select the resistance range.

1

2

3

Setting the threshold values

1

(To shift the decimal point)

Select the voltage range.

(To shift the decimal point)

Conrm the settings.

The resistance warning limit and

[WARNING] ashes.

Set the resistance warning

limit.

2

3

58

Conrm the settings.

The resistance failure limit and

[FAIL] ashes.

Set the resistance failure

limit.

4

5

Conrm the settings.

The voltage warning limit and

[WARNING] ashes.

Set the voltage warning limit.

Setting Threshold Values for the Comparator

1

6

• Voltage is determined using absolute values. Comparison is

• If you set the resistance failure limit to a value that is less than

Conrm the settings.

Returns to the measurement screen,

with the comparator function turned

on.

The settings are now saved.

possible even if the positive and negative electrodes of the

test lead are connected to negative and positive terminals,

respectively. (Data is stored with the sign.)

the resistance warning limit as previously set, the warning limit

will be set to the same value as the new failure limit.

2

3

4

5

6

7

Appx. Index

59

Setting Threshold Values for the Comparator

When a measurement value is determined as "PASS"

Voltage

PASS

Default value

Voltage

warning limit

Measurement

value

WARNING

FAIL

FAIL

Default

value

Resistance

warning

limit

Resistance

failure limit

When a measurement value is determined as

"WARNING"

Voltage

Default value

Voltage

warning limit

PASS

WARNING

Default

value

Measurement

value

Resistance

warning

limit

FAIL

FAIL

Resistance

failure

limit

60

Resistance

Resistance

Setting Threshold Values for the Comparator

When a measurement value is determined as "FAIL"

Voltage

Default value

Voltage

warning limit

PASS

WARNING

Default

value

Resistance

warning

limit

FAIL

Measurement

value

FAIL

Resistance

failure

limit

Resistance

Comparison Table for the Comparator

The result is determined by the display and buzzer as shown in the

following table:

Resistance

warning limit

Resistance

(low)

Voltage (high) PASS WARNING FAIL

Voltage warning limit

Voltage (low) WARNING WARNING FAIL

The boundary conditions are as follows:

Resistance

PASS

Voltage

WARNING

Resistance

≤

warning limit

<

warning limit

Voltage

Resistance

<

WARNING

Voltage

≤

PASS

Resistance

failure limit

Resistance

(medium)

Resistance

≤

failure limit

Resistance

(high)

Resistance

<

FAIL

1

2

3

4

5

6

7

Appx. Index

61

Setting Threshold Values for the Comparator

Examples of how to read the comparator output table

Example 1:

If the measured resistance is less than or equal to the resistance

warning limit, and the measured voltage is more than or equal to the

voltage warning limit, [PASS] is displayed.

Example 2:

If the measured resistance is more than the resistance warning

limit and is less than or equal to the resistance failure limit, and

the measured voltage is more than the voltage warning limit,

[WARNING] is displayed and the buzzer sounds.

When the resistance warning limit and resistance failure limit are set to the

same value, the boundary conditions are as shown below:

Resistance

PASS

≤

Resistance

warning limit

=

Resistance

failure limit

Resistance

<

FAIL

62

Setting the Comparator Buzzer

4.4 Setting the Comparator Buzzer

The buzzer can be enabled in accordance with comparison results

when the comparator function is used. The buzzer can be set to

sound in the following states. By default, the buzzer is congured to

sound when the comparison result is WARNING or FAIL.

In addition to the buzzer, when the comparison result is WARNING

or FAIL, the backlight is turned on red.

1

2

OFF

PASS (ON) The buzzer sounds when comparison results are PASS.

FAIL (ON)

When you press the key, the present comparator buzzer

setting is displayed. Press the key repeatedly to cycle through the

settings.

When there is no activity for approximately 1 second, the settings

on the display will be conrmed and returns to the measurement

screen.

The key tone settings cannot be changed.

The buzzer will not sound regardless of comparison results.

The red backlight turns on, along with the buzzer sounds

when comparison results are WARNING or FAIL.

OFF PASS

FAIL

3

4

5

6

7

Appx. Index

63

Canceling the Comparator Function

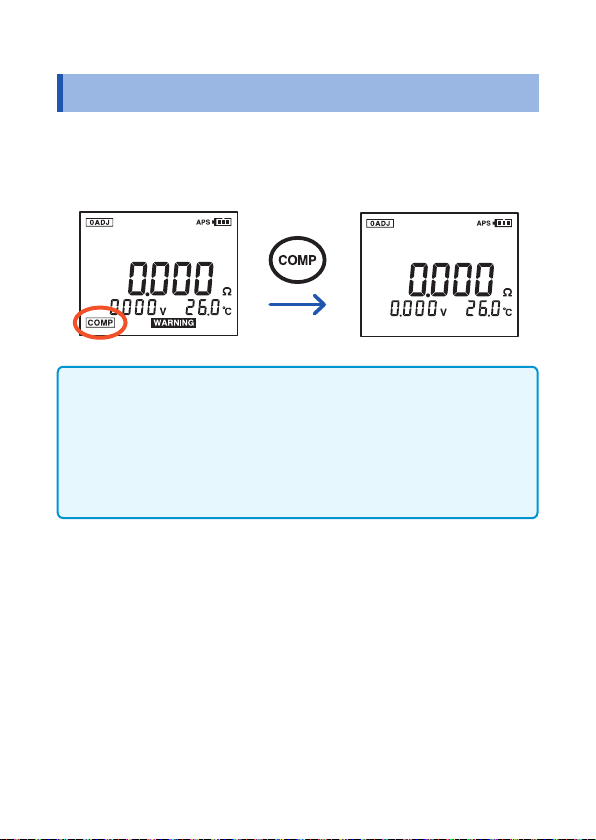

4.5 Canceling the Comparator Function

Pressing the COMP key when the comparator is turned on cancels

the comparator function.

Comparator: ON Comparator: OFF

• The range keys cannot be used while the comparator function

is turned on.

• If there are no measurement values, [−−−−] is displayed and a

comparator judgment cannot be performed.

• Even when the power is turned off, the comparator settings

are saved and the comparator will be restored to on when the

power is again turned on.

64

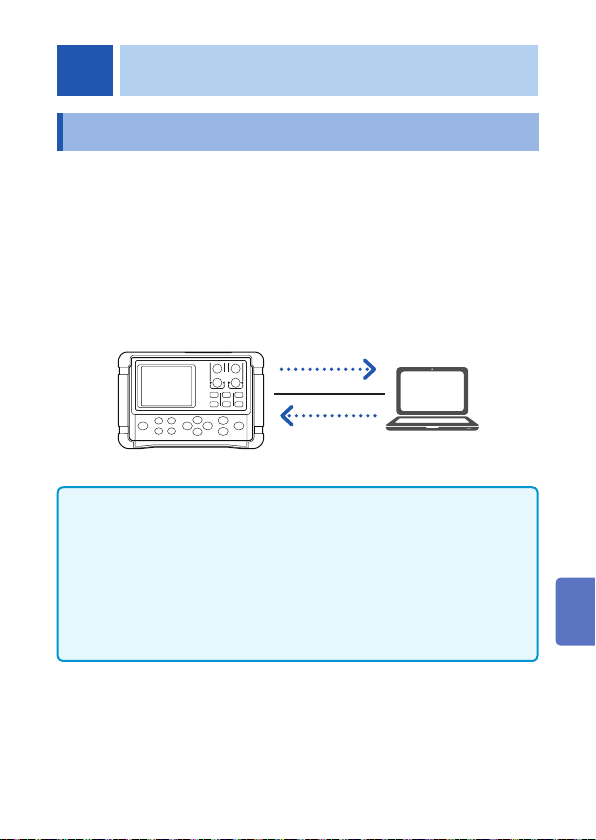

Memory Function

5

5.1 Overview

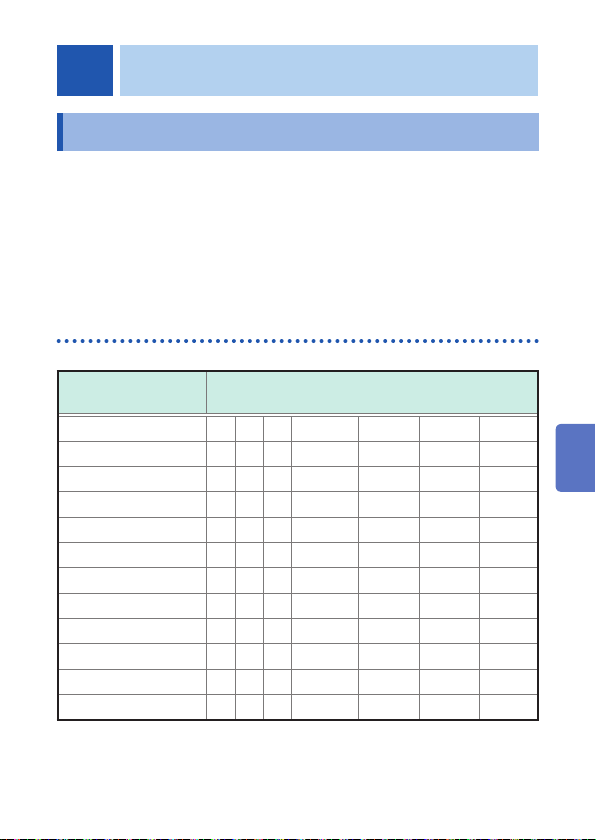

This instrument can store up to 6000 sets of data combining

presently measured values*. After measurement, saved data can be

displayed or transferred to a computer.

The structure of the internal memory is as follows:

* Date and time, resistance, voltage, temperature, comparator

threshold values, and results of judgment

Memory Structure

Unit name

(12 units)

A 1 2 3 ... 498 499 500

B 1 2 3 ... 498 499 500

C 1 2 3 ... 498 499 500

D 1 2 3 ... 498 499 500

E 1 2 3 ... 498 499 500

F 1 2 3 ... 498 499 500

G 1 2 3 ... 498 499 500

H 1 2 3 ... 498 499 500

J 1 2 3 ... 498 499 500

L 1 2 3 ... 498 499 500

N 1 2 3 ... 498 499 500

P 1 2 3 ... 498 499 500

Memory number (500 cells)

1

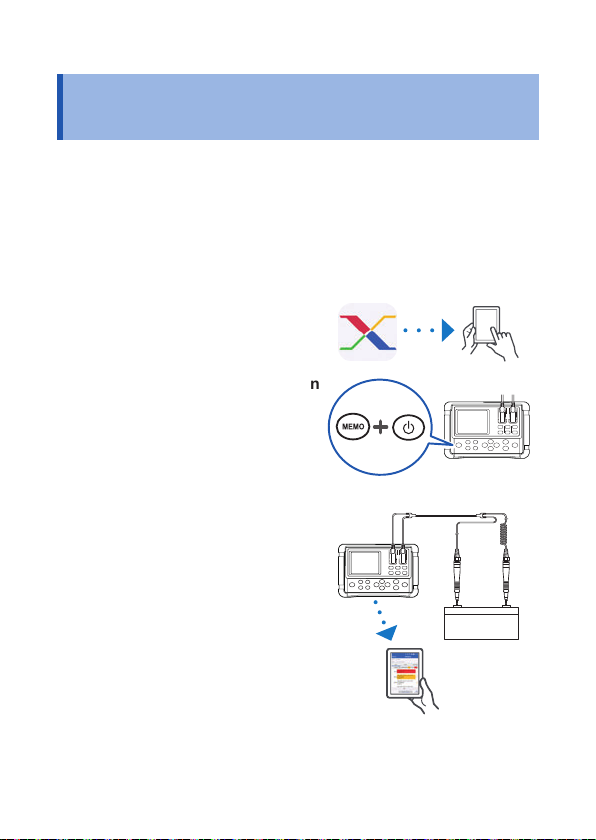

2

3

4

5

6

7

Appx. Index

65

Storing Data in the Memory

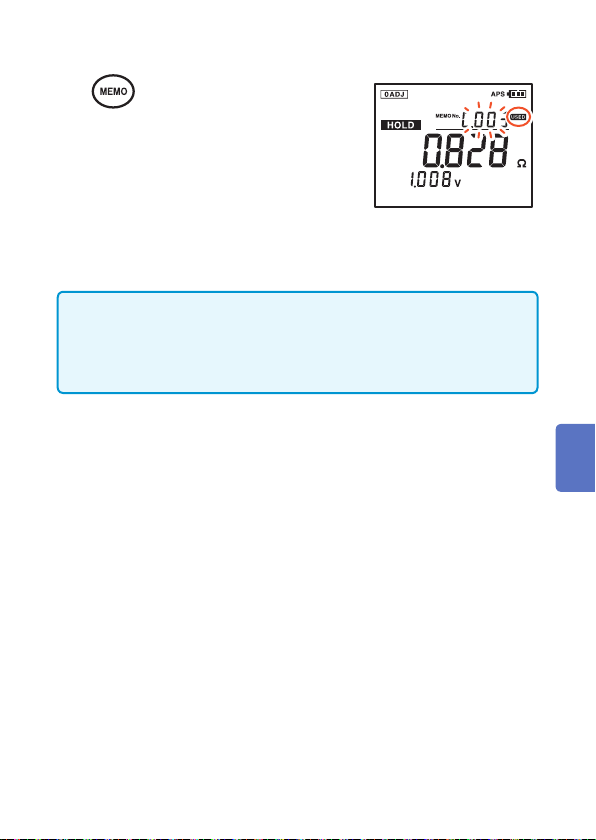

5.2 Storing Data in the Memory

Pressing the MEMO key stores the present measurement values.

Handy function: Auto-memory function (p. 76)

1

2

3

4

Turn on the memory function.

Select the memory number.

After a certain period of time of no

activity, the settings on the display

are conrmed and the instrument

returns to the measurement screen.

When the memory function is on,

you can select the memory number

at any time.

Conrm the settings.

Retain the measurement

values.

When [−−−−] is displayed, the

values cannot be retained.

66

5

Store the measurement

values.

The measurement values are stored

in the cell with the selected memory

number.

After the data is stored, the next

available memory number is

displayed.

The retaining is now canceled.

Storing Data in the Memory

1

2

• Pressing and holding the CLEAR key for 2 or more seconds can clear

the last stored data. However, this operation is possible only immediately

after the data is stored.

• If [USED] is displayed with a memory number, that number will be

overwritten.

3

4

5

6

7

Appx. Index

67

Canceling the Memory Function

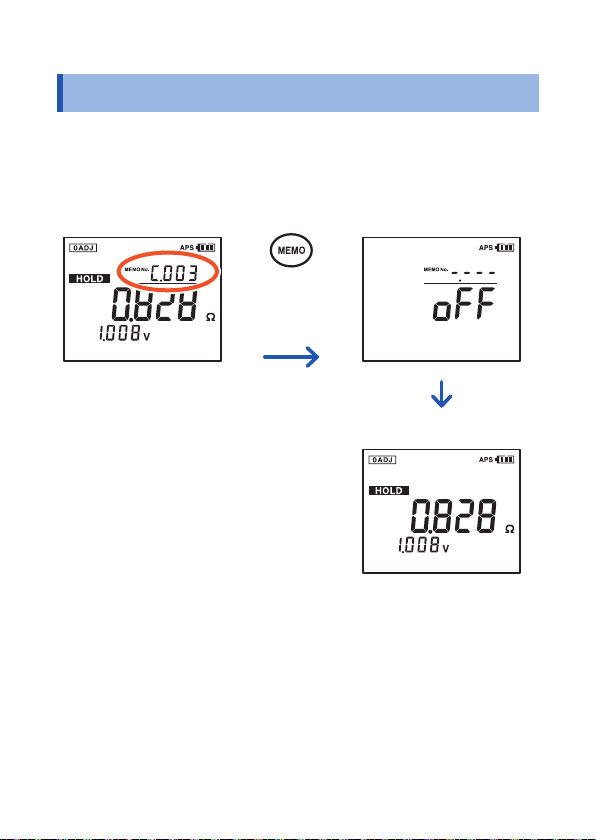

5.3 Canceling the Memory Function

To cancel the memory function when it is on, press and hold the

MEMO key for at least 1 second. [oFF] is displayed, and the

instrument returns to the normal mode.

Memory function: ON Memory function: OFF

(Press and

hold for

at least 1

second.)

Normal mode

68

Reading Out Stored Data

5.4 Reading Out Stored Data

The stored measurement values are displayed after they are read out.

1

2

3

• Press the DATE key to check the date and time when the data

• The comparator result for the data being read out is also

• You cannot select the number of the memory location in which

• If no data has been stored, [−−−−] is displayed in the memory

Display the memory readout

screen.

Select the memory number to

be read out.

The measurement values for the

selected memory number are displayed.

To return to the measurement

screen, press the READ key.

was stored.

displayed.

no data is stored.

number display area and the instrument returns to the

measurement screen.

1

2

3

4

5

6

• For data measured using the optional model 9460 Clip Type Lead

with Temperature Sensor, the temperature is also displayed.

69

7

Appx. Index

Clearing Stored Data

5.5 Clearing Stored Data

Clearing a Single Set of Data

1

2

3

4

Display the memory readout

screen.

Select the number of the

memory cell in which you

want to clear data.

The measurement values for the

selected memory number are

displayed.

Press the key once.

If there is no activity for

approximately 3 seconds, returns to

the readout screen.

Conrm the settings.

The data in the cell with the selected

memory number is now cleared.

70

Clearing Data from Each Unit

Clearing Stored Data

1

2

3

4

Display the memory readout

screen.

Select the unit in which you

want to clear data.

Press the key twice.

1

2

3

If there is no activity for

approximately 3 seconds, returns to

the readout screen.

Conrm the settings.

All data stored in the selected unit

(500 cells) are cleared.

4

5

6

7

Appx. Index

71

Clearing Stored Data

Clearing All Data

1

2

3

Display the memory readout

screen.

Press the key 3 times.

If there is no activity for

approximately 3 seconds, returns to

the readout screen.

Conrm the settings.

All data (12 units/6000 sets) is now

cleared.

72

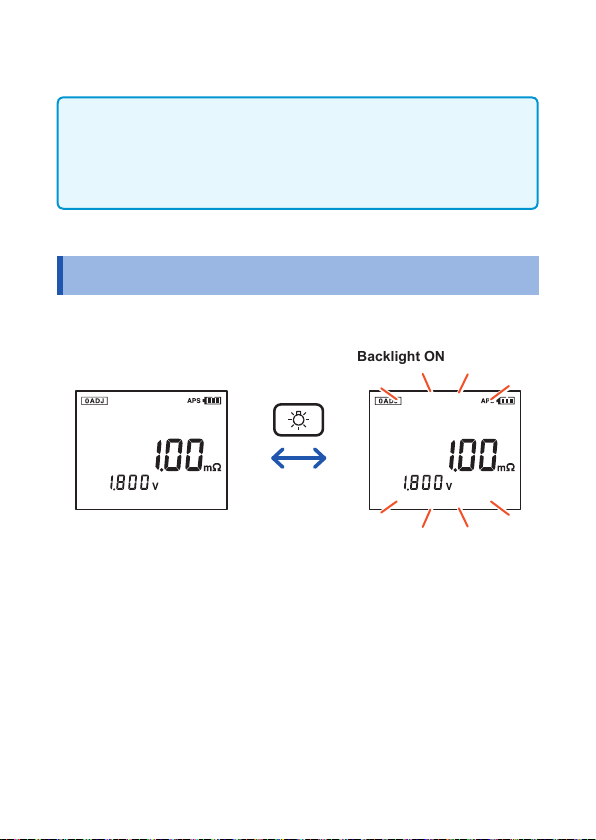

Other Features

6

6.1 Noise Frequency Avoidance Function

When the noise frequency avoidance function is used, internal

resistance with reduced noise is measured automatically.

Turning the Noise Frequency Avoidance Function ON/OFF

1

2

3

4

Turn off the instrument.

Display the setup screen

for the noise frequency

avoidance function.

Select either [oFF] or [on].

Conrm the settings.

The instrument is restarted.

The settings will not change if

the power is turned off before the

settings are applied.

(when off is selected)

(when on is selected)

1

2

3

4

5

6

7

Appx. Index

: Noise frequency

avoidance function

73

Noise Frequency Avoidance Function

Canceling the Noise Frequency Avoidance Function

The function will be canceled when the power is switched off and

turned on again.

• When the noise frequency avoidance function is turned on, the

time required for measurement may take longer. [FrEq] will

ash.

• It may not be possible to avoid all noise depending on the type

of noise.

74

Auto-hold Function

6.2 Auto-hold Function

This function automatically recognizes the stability of measurement

values and retains them.

Press the A HOLD/MEMO key several times to display [A.HOLD].

1

Auto-hold

OFF

To cancel the retaining, press the HOLD key or the PRESS button

on the model 9466 Remote Control Switch.

• When resistance is displayed as [−−−−], data is not retained

automatically.

• Data will not be retained automatically when [OVER] and the

maximum display value of the resistance are ashing.

• The instrument retains and stores measurement values

automatically when the auto-memory function is used together

with this function.

• Use the auto-hold function together with the comparator

function to determine if [OVER] (and the maximum display

value) is ashing due to a range setting error. Setting the

comparator buzzer to [FAIL] is also recommended. For more

information, see “4.4 Setting the Comparator Buzzer” (p. 63).

Canceling the Auto-hold function

Press the A HOLD/MEMO key several times to hide [A.HOLD].

Auto-memory

Auto-hold and

Auto-memory

2

3

4

5

6

7

Appx. Index

75

Auto-memory Function

6.3 Auto-memory Function

This function automatically stores measurement values in memory

immediately after they are retained.

Press the A HOLD/MEMO key several times to display [A.MEMO].

At this point, the memory function is also turned on.

Auto-hold

OFF

Use the cursor keys to select the memory number of the location