Introduction

9691,9692,9693

CLAMP ON AC/DC SENSOR

Instruction Manual

November 2008 Revised edition 6 Printed in Japan

9691A981-06 08-11H

OK

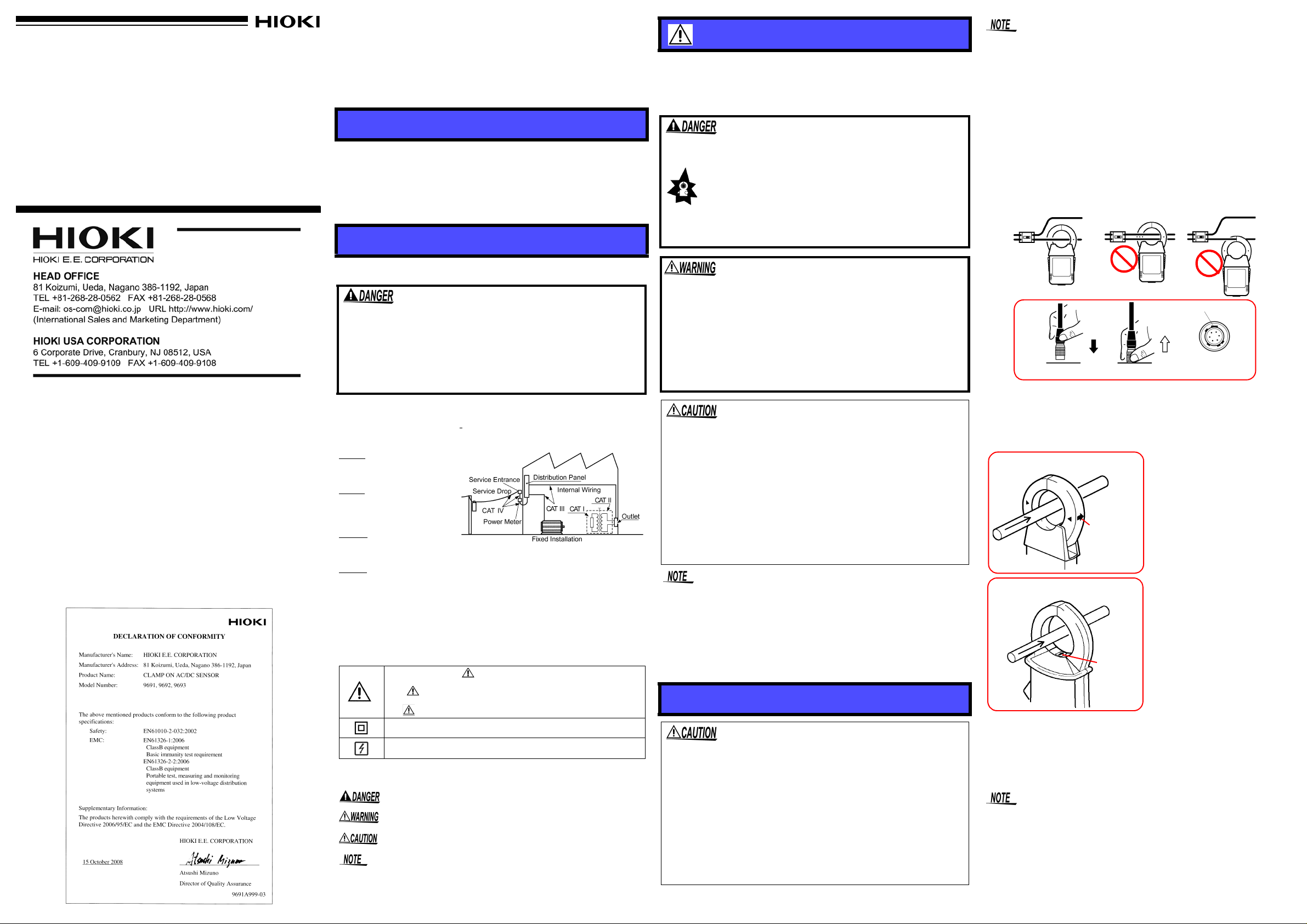

Connecting

Disconnecting

Output connector

Wide terminal

1. Confirm that power of the 3290

is OFF.

2. Connect the output connecto r of

the sensor to the sensor

connector of the 3290.

3. Press the POWER key of the

3290 to turn it ON.

4. Open the ends of the clamp

core. Orient the current

direction indicator on the sensor

in the current direction of the

conductor to be measured, then

clamp the conductor so that it

passes through the center of

the clamp core. (For DC

measurement, perform zero

adjustment on the 3290 before

clamping a conductor with the

clamp sensor. For AC

measurement, note that the

current direction indicator need

not be oriented in the current

direction.)

5. The 9691 has a lock

mechanism on its rear panel

side to prevent the sensor from

opening during measurement.

To prevent the sensor from

possibly being opened due to

vibration or other similar

causes, be sure to lock it before

starting measurement. (Even if

the sensor opens slightly during

measurement, the

measurement value will be less

and accuracy cannot be

guaranteed.)

Power

source

Measured

conductor

Load

9691 CLAMP ON AC/DC SENSOR

Power

source

Measured

conductor

Load

9692,9693 CLAMP ON AC/DC SENSOR

Current

direction

indicator

Current

direction

indicator

Thank you for purchasing the HIOKI “9691, 9692, 9693 CLAMP ON

AC/DC SENSOR.” To obtain maximum performance from the product,

please read this manual first, and keep it handy for future reference

Initial Inspection

When you receive the product, inspect it carefully to ensure that no

damage occurred during shipping. If damage is evident, or if it fails to

operate according to the specifications, contact your dealer or Hioki

representative.

Preliminary Checks

• Before using the product the first time, verify that it operates normally to ensure tha t th e n o d am age oc curred during storage or shipping. If you find any damage, contact your dealer or Hioki

representative.

• Before using the product, make sure that the insulation on the

cables is undamaged and that no bare conductors are improperly

exposed. Using the product in such conditions could ca us e an electric shock, so contact your dealer or Hioki representative for

repair.

Maintenance and Service

• To clean the product, wipe it gently with a soft cloth moistened with

water or mild detergent. Never use solvents such as benzene, alcohol, acetone, ether, ketones, thinners or gasoline, as they can

deform and discolor the case.

• If the product seems to be malfunctioning, contact your dealer or

Hioki representative.

Overview

The 9691, 9692, and 9693 CLAMP ON AC/DC SENSORs are

designed for use on the 3290 CLAMP ON AC/DC HiTESTER. All

three sensors are interchangeable. When any of these sensors is

connected to the 3290, the 3290 automatica lly detects this connection

and sets up the range for the sensor. The 3290 Clamp On AC/DC

HiTESTER combined with a C lamp On AC/DC Sensor is used to perform DC, AC, or AC+DC measurement on a live line.

Safety

Follow these precautions to ensure safe operation and to obtain the

full benefits of the various functions.

This product is designed to conform to IEC 61010 Safety

Standards, and has been thoroughly tested for safety prior to

shipment. However, mishandling during use could result in

injury or death, as well as damage to the product. Be certain

that you understand the instructions and precautions in the

manual before use. We disclaim any responsibility for

accidents or injuries not resulting directly from product

defects.

Measurement categories (Overvoltage categories)

This product complies with CATIII safety requirements. To ensure safe operation of measurement products, I

ious electrical environments, categorized as CAT I to CAT IV, and called

measurement categories.These are defined as follows.

CAT I

: Secondary electrical

circuits connected to an AC

electrical outlet through a

transformer or similar device.

: Primary electrical cir-

CAT II

cuits in equipment connected

to an AC electrical outlet by a

power cord (portable tools,

household appliances, etc.)

: Primary electrical cir-

CAT III

cuits of heavy equipment

(fixed installations) connected directly to the distribution panel, and feeders

from the distribution panel to outlets.

: The circuit from the service drop to the service entrance, and to t he

CAT IV

power meter and primary overcurrent protection device (distribution panel).

Higher-numbered categories correspond to electrical environments with

greater momentary energy. So a measurement device designed for CAT III

environments can endure greater momentary energy than a device designed

for CAT II.Using a measurement product in an environment designated with a

higher-numbered category than that for which the product is rated could result

in a severe accident, and must be carefully avoided.Never use a CAT I measuring product in CAT II, III, or IV environments.The measurement categories

comply with the Overvoltage Categories of the IEC60664 Standards.

Safety Symbol

In the manual, the symbol indicates particularly important

information that the user should read before using the product.

The symbol printed on the product indicates that the user

should refer to a corresponding topic in the manual (marked with

the symbol) before using the relevant function.

Indicates a double-insulated device.

Indicates that the instrument may be connected to or disconnected

from a live circuit.

The following symbols in this manual indicate the relative importance

of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of

injury to the user or damage to the product

Advisory items related to performance or correct operation

of the product.

rdg.:reading value (The value currently being measured and indicated

on the measuring product)

EC 61010 establishes safety standards for var-

Usage Notes

This manual contains information and warnings essential for safe

operation of the product and for maintaining it in safe operating condition. Before using the product, be sure to carefully read the following

safety notes.

• To avoid short circuits and potentially life-threatening

hazards, never attach the product to a circuit that

operates at more than the 600 V AC.

• This product should only be connected to the secondary side of a breaker, so the breaker can prevent

an accident if a short circuit occurs. Connections

should never be made to the primary side of a

breaker, because unrestricted current flow could

cause a serious accident if a short circuit occurs.

• To avoid electric shock, do not allow the product to get wet,

and do not use it when your hands are wet.

• To avoid electric shock when measuring live lines, wear

appropriate protective gear, such as insulated rubber gloves,

boots and a safety helmet.

• To avoid damage to the product, do not exceed the maximum

input current rating, which depends on the frequency of the

current being measured. Be careful about the evolution of

heat, when the input frequency is high.

• Do not store or us e the p roduct where it co uld be expos ed to d irect

sunlight, high temperature or humidity, or condensation. Under

such conditions, the product may be damaged and insulation may

deteriorate so that it no longer meets specifications.

• The ends of th e clam p sens or are very deli cat e. Be caref ul no t to

drop the sensor or otherwise subject it to impact. Clamps with deformed or damaged contact surfaces may result in i naccurate m easurement.

• Keep the clamp jaws and c ore slit s free from forei gn obje cts, whic h

could interfere with clamping action.

• Avoid stepping on or pinching the cable, which could damage the

cable insulation.

• To avoid damaging the cables, do not bend or pull the cables.

Accurate measurement may be impossible in the presence of strong

magnetic fields, such as near transformers and high-current conductors, or in the presence of strong electromagnetic fields such as near

radio transmitters.

Measurement Procedures

• Do not connect or disconnect the output connector of the clamp-on sensor

while power is supplied to the 3290 or the sensor is clamping a conductor

to be measured.

• When disconnecting the output connector of the clamp-on sensor from the

3290 sensor connector, be sure to hold it by the metal part and pull it

upward. If it is pulled by the cable, the lock will not be released and a broken wire in the cable may result.

• The maximum continuous-input limit is obtained from the temperature

increase due to self-heating during measurement. To prevent damage to

the clamp-on sensor, do not input a current exceeding this limit.

• The maximum continuous-input limit varies depending on the clamp-on

sensor and the frequency of the current to be measured. Please see the

dilating-characteristics graph by frequency in “Specifications.”

• The reading may show a measurement greater than the actual

value due to magnetic-field interference. The amount of interf eren ce

varies depending on the sensor. For details, see “External magnetic-field interference” in Specifications.

• The hall element is used for the detector of the clamp-on sensor.

The hall element tends to drift with ag e or d ue to th e ambie nt temperature. Keep this fact in mind w hen p erformi ng mea surem ent con tinuously.

• When a conductor to be measured is placed in the center of the

clamp core, measurement is performed the most accurately, with no

effect of the conductor position.

• Refer to the relevant instruction manual for how to operate and set

the 3290.

• Attach the clamp around only one conductor. Single-phase (2-wire)

or three-phase (3-wire) cables clamped together will not produce

any reading.

When connecting the clamp-on sensor to the 3290, hold it by the area above the metal

part of the output connector when inserting it. If it is held by the metal part, it won’t be

possible to insert the output connector into the sensor connector. Make sure the wide

terminal of the connector is at the top when the connector is inserted.

When disconnecting the clamp-on sensor from the 3290, hold the metal part of the

connector when pulling it out. If it is held by the area above the metal part, it won’t be

possible to disconnect the connector.

Make sure that the sens or lock lever of the 9 691 is sli d into the Lock o r

Unlock position. Leaving the level set midway between these two

positions may disable the lock function.

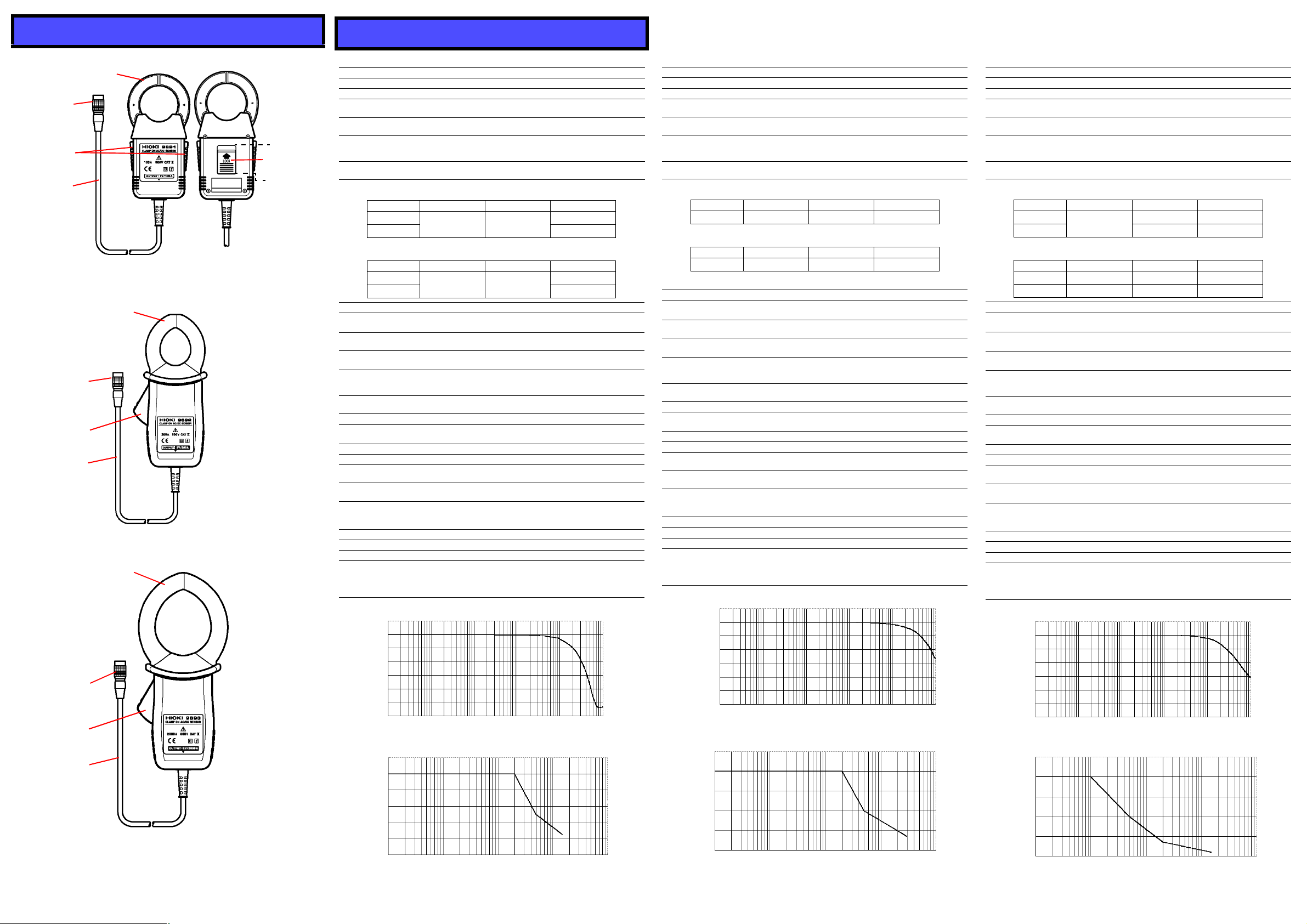

Parts Names

Output

connector

Lever

Cable

Clamp sensor

9691 CLAMP ON AC/DC SENSOR

Front side

Back side

Sensor lock

lever

LOCK

position

UNLOCK

position

Output

connector

Lever

Cable

Clamp sensor

9692 CLAMP ON AC/DC SENSOR

Output

connector

Lever

Cable

Clamp sensor

9693 CLAMP ON AC/DC SENSOR

9693 Frequency characteristics

Frequency (Hz)

f

Specifications

9691 CLAMP ON AC/DC SENSOR

Rated current AC/DC 100 A

Output voltage AC/DC 1 V/100 A

Output resistance 100 Ω or less

Maximum permissi-

ble input

Maximum peak cur-

rent value

Accuracy guarantee

for temperature and

humidity

Guaranteed accuracy period

(1) Continuous input

Range DC to 66Hz 66 to 500Hz

0 to 80A

80 to 100A

(2) Peak input

Range DC to 66Hz 66 to 500Hz

0 to 110A

110 to 150A

Frequency band DC to 10 kHz (-3dB)

Effect of conductor

position

Effect of external

electromagnetic field

Temperature

characteristics

Operating

temperature and

humidity range

Storage

temperature range

Location for use Indoor, altitude up to 2000 m (6566 feet)

Maximum permitted

circuit voltage

Dielectric strength 5.55 kV AC for 1 minute (sensor - case, sensor - circuit)

Power supply ± 5 V ±0.25 V (supply from the outside)

Maximum rated

power

Measurable

conductor diameter

Dimensions Approx. 53W x 129H x 18D mm

Mass Approx. 230 g (8.1 oz.) (including batteries)

Cable length Approx. 2 m (6.5 feet)

Accessory Instruction manual 1

Applicable

standards

5

0

-5

-10

-15

GAIN (dB)

-20

-25

-30

120

100

80

60

Input current (A)

40

20

0

10

100 Arms continuous (Derating according to frequency)

150 A

23°C±5°C(73°F±9°F), 80%RH or less, no condensation

1 year

(Opening and closing of the sensor: 10,000 times)

±1.0%rdg.±0.5mV ±1.0%rdg.±0.5mV

±1.0%rdg.±2mV ±1.0%rdg.±2mV

±2.0%rdg.±0.5mV

±2.5%rdg.±0.5mV

±2.0%rdg.±2mV

±2.5%rdg.±2mV

Within ±1.0% (at 80 A (55 Hz))

0.5 A equivalent or less (in an external electromagnetic

field of 400 A/m)

0 to 40°C range: 0.1 x accuracy specifications/°C

32 to 104°F range: 0.18 x accuracy specifications/°F

0 to 40°C, 32 to 104°F, 80% RH or less; no condensation

-10 to 50°C, 14 to 122°F, 80% RH or less; no condensation

600 V

50 mVA

φ35 mm (1.38") or less

Approx. 2.09"W x 5.08"H x 0.71"D

(excluding protruding parts)

SafetyEN61010

Measurement categories III (Anticipated Transient Overvoltage: 6000 V), Pollution Degree 2

EMC EN61326

9691 Frequency characteristics

100101

Frequency (Hz)

9691 Derating according to frequency

Frequency (Hz)

1k

1k100

10k

10k

100k

100k

9692 CLAMP ON AC/DC SENSOR 9693 CLAMP ON AC/DC SENSOR

Rated current AC/DC 200 A

Output voltage AC/DC 2 V/200 A

Output resistance 100 Ω or less

Maximum permissi-

ble input

Maximum peak cur-

rent value

Accuracy guarantee

for temperature and

humidity

Guaranteed accuracy period

(1) Continuous input

Range DC to 66Hz 66 to 1kHz

0 to 200A

(2) Peak input

Range DC to 66Hz 66 to 1kHz

0 to 300A

200 Arms continuous (Derating according to frequency)

300 A

23°C±5°C(73°F±9°F), 80%RH or less, no condensation

1 year

(Opening and closing of the sensor: 10,000 times)

±1.0%rdg.±0.5mV ±1.0%rdg.±0.5mV ±2.0%rdg.±0.5mV

±1.0%rdg.±2mV ±1.0%rdg.±2mV ±2.0%rdg.±2mV

Frequency band DC to 20 kHz (-3dB)

Effect of conductor

position

Effect of external

electromagnetic field

Temperature

characteristics

Operating

temperature and

humidity range

Storage

temperature range

Within ±0.5%

0.7 A equivalent or less (in an external electromagnetic

field of 400 A/m)

0 to 40°C range: 0.1 x accuracy specifications/°C

32 to 104°F range: 0.18 x accuracy specifications/°F

0 to 40°C, 32 to 104°F, 80% RH or less; no condensation

-10 to 50°C, 14 to 122°F, 80% RH or less; no condensa-

tion

Location for use Indoor, altitude up to 2000 m (6566 feet)

Maximum permitted

600 V

circuit voltage

Dielectric strength 5.55 kV AC for 1 minute (sensor - case, sensor - circuit)

Power supply ± 5 V ±0.25 V (supply from the outside)

Maximum rated

power

Measurable

conductor diameter

50 mVA

φ33 mm (1.30") or less

Dimensions Approx. 62W x 167H x 35D mm

Approx. 2.44"W x 6.57"H x 1.38"D

(excluding protruding parts)

Mass Approx. 410 g (14.5 oz.) (including batteries)

Cable length Approx. 2 m (6.5 feet)

Accessory Instruction manual 1

Applicable

standards

GAIN (dB)

Input current (A)

250

200

150

100

5

0

-5

-10

-15

-20

-25

-30

50

0

10

SafetyEN61010

Measurement categories III (Anticipated Transient Over-

voltage: 6000 V), Pollution Degree 2

EMC EN61326

9692 Frequency characteristics

100101

Frequency (Hz)

9692 Derating according to frequency

Frequency (Hz)

1k

1k100

10k

10k

100k

100k

Rated current AC/DC 2000 A

Output voltage AC/DC 2 V/2000 A

Output resistance 100 Ω or less

Maximum permissi-

ble input

Maximum peak cur-

rent value

Accuracy guarantee

for temperature and

humidity

Guaranteed accuracy period

(1) Continuous input

Range DC 45 to 66Hz to 45Hz, 66 to 1kHz

0 to 1800A

1800 to 2000A

(2) Peak input

Range DC 45 to 66Hz to 45Hz, 66 to 1kHz

0 to 2300A

2300 to 2840A

2000 Arms (Derating according to frequency)

2840 A

23°C±5°C(73°F±9°F), 80%RH or less, no condensation

1 year

(Opening and closing of the sensor: 10,000 times)

±1.5%rdg.±0.5mV

±1.5%rdg.±2mV ±1.0%rdg.±2mV ±2.0%rdg.±2mV

±6.0%rdg.±2mV ±6.0%rdg.±2mV

Frequency band DC to 15 kHz (-3dB)

Effect of conductor

Within ±0.7%

position

Effect of external

electromagnetic field

Temperat ure

characteristics

Operating

temperature and

humidity range

Storage

temperature range

2.0 A equivalent or less (in an external electromagnetic

field of 400 A/m)

0 to 40°C range: 0.1 x accuracy specifications/°C

32 to 104°F range: 0.18 x accuracy specifications/°F

0 to 40°C, 32 to 104°F, 80% RH or less; no condensation

-10 to 50°C, 14 to 122°F, 80% RH or less; no condensa-

tion

Location for use Indoor, altitude up to 2000 m (6566 feet)

Maximum permitted

600 V

circuit voltage

Dielectric strength 5.55 kV AC for 1 minute (sensor - case, sensor - circuit)

Power supply ± 5 V ±0.25 V (supply from the outside)

Maximum rated

power

Measurable

conductor diameter

50 mVA

φ55 mm (2.17") or less

Dimensions Approx. 62W x 196H x 35D mm

Approx. 2.44"W x 7.72"H x 1.38"D

(excluding protruding parts)

Mass Approx. 500 g (17.6 oz.) (including batteries)

Cable length Approx. 2 m (6.5 feet)

Accessory Instruction manual 1

Applicable

standards

SafetyEN61010

Measurement categories III (Anticipated Transient Over-

voltage: 6000 V), Pollution Degree 2

EMC EN61326

5

0

-5

-10

-15

GAIN (dB)

-20

-25

-30

9693 Derating according to frequency

2500

2000

1500

1000

Input current (A)

500

0

10

100101

Frequency (Hz)

±1.0%rdg.±0.5mV ±2.0%rdg.±0.5mV

10k

-

-

100k

100k

±2.0%rdg.±0.5mV

1k

1k100

10k

Loading...

Loading...