Page 1

■■■■■■■■

1 MENU

FOREWORD

This workshop manual has been prepared to provide information regarding repair procedures on Hino Vehicles.

Applicable for FR1E, FS1E, FY1E, SH1E, SS1E and ZS1E series, equipped with E13C engine

When making any repairs on your vehicle, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owner’s Manual.

All information and specifications in this manual are based upon the latest product information available at the time of printing.

Hino Motors reserves the right to make changes at any time without prior notice.

This manual is divided into 9 sections with a thumb index for each section at the edge of the pages.

Please note that the publications below have also been prepared as relevant service manuals for the components and systems in this vehicles.

Manual Name Pub. No.

Chassis Workshop Manual S1-YFSE16A 1/3

Chassis Workshop Manual S1-YFSE16A 3/3

E13C Engine Workshop Manual S5-YE13E01A

Page 2

CHAPTER REFERENCES REGARDING THIS WORKSHOP MANUAL

Use this chart to the appropriate chapter numbers for servicing your particular vehicle.

CHAPTER

GENERAL INTRODUCTION GN02-001

CLUTCH MAIN UNIT CL02-001 CL02-002 CL02-003 CL02-004

CLUTCH CONTROL CL03-001 CL03-002 CL03-003 CL03-004

TRANSMISSION MAIN UNIT TR02-001 TR02-002 TR02-003 TR02-004

P.T.O. (POWER TAKE-OFF) TR05-001 TR05-002 TR05-003

TRANSMISSION/TRANSFER CONTROL TR06-001

PROPELLER SHAFT PP02-001 PP02-002 PP02-003

DIFFERENTIAL EQUIPMENT DF01-001

DIFFERENTIAL CARRIER DF02-001 DF02-002 DF02-003 DF02-004 DF02-005

BRAKE EQUIPMENT BR01-001

SERVICE BRAKE BR02-001

ABS (ANTI-LOCK BRAKE SYSTEM) BR03-001

MANUAL NO. S1-YFSE16A 2/3

MODELS FR1E, FS1E, FY1E, SH1E, SS1E, ZS1E

ES START (EASY & SMOOTH START) SYSTEM BR04-001

STEERING EQUIPMENT SR01-001

STEERING UNIT SR02-001

POWER STEERING SR03-001

FRONT AXLE AX02-001 AX02-002

REAR AXLE AX03-001 AX03-002

WHEEL & TIRE AX04-001

SUSPENSION SU02-001 SU02-002 SU02-003 SU02-004

CHASSIS FRAME FC02-001

COUPLER (5TH WHEEL) FC03-001

PINTLE HOOK FC04-001

CAB CA02-001

ELECTRICAL EQUIPMENT EL01-001

ELECTRIC WIRE EL02-001

BRAKE CONTROL DN03-001 DN03-002

SUSPENSION CONTROL DN04-001

OTHERS DN06-001

This manual does not contain items on half-tone dot meshing.

Page 3

INDEX: CHASSIS GROUP 1/4

GENERAL INTRODUCTION

CLUTCH EQUIPMENT

CLUTCH MAIN UNIT

WORKSHOP

MANUAL

CLUTCH CONTROL

TRANSMISSION EQUIPMENT

TRANSMISSION MAIN UNIT

TRANSFER MAIN UNIT

AUTOMATIC TRANSMISSION

P.T.O. (POWER TAKE-OFF)

TRANSMISSION / TRANSFER CONTROL

PROPELLER SHAFT EQUIPMENT

All rights reserved. This manual may not be

reproduced or copied in whole in part, without the written consent of Hino Motors, Ltd.

PROPELLER SHAFT

DIFFERENTIAL EQUIPMENT

DIFFERENTIAL CARRIER

BRAKE EQUIPMENT

SERVICE BRAKE

ABS (ANTI-LOCK BRAKE SYSTEM)

ES START (EASY & SMOOTH START) SYSTEM

This manual does not contain items on half-tone dot meshing.

Page 4

Page 5

INDEX: CHASSIS GROUP 2/4

EXHAUST BRAKE

RETARDER BRAKE

PARKING BRAKE

STEERING EQUIPMENT

STEERING UNIT

POWER STEERING

AXLE EQUIPMENT

FRONT AXLE

REAR AXLE

WHEEL & TIRE

SUSPENSION EQUIPMENT

SUSPENSION

CHASSIS EQUIPMENT

CHASSIS FRAME

COUPLER (5TH WHEEL)

PINTLE HOOK

CAB EQUIPMENT

CAB

This manual does not contain items on half-tone dot meshing.

Page 6

Page 7

INDEX: CHASSIS GROUP 3/4

ELECTRICAL EQUIPMENT

ELECTRIC WIRE

This manual does not contain items on half-tone dot meshing.

Page 8

Page 9

INDEX: CHASSIS GROUP 4/4

ENGINE CONTROL

FUEL CONTROL

BRAKE CONTROL

SUSPENSION CONTROL

CAB EQUIPMENT CONTROL

OTHERS

This manual does not contain items on half-tone dot meshing.

Page 10

Page 11

BRAKE EQUIPMENT BR01–1

BR01

BRAKE EQUIPMENT

SERVICE BRAKE ASSEMBLY.................BR01-2

DESCRIPTION ................................................ BR01-2

DIAGRAM ........................................................ BR01-3

TROUBLESHOOTING................................... BR01-41

BR01-001

Page 12

BRAKE EQUIPMENTBR01–2

SERVICE BRAKE ASSEMBLY

DESCRIPTION

EN0680201C100001

Type of service brake Drum-shoe type wheel brake activated by compressed air.

Air charging system Air charging is from piston type air compressor and air flow is directed and con-

trolled by a pressure regulator, the necessary valves, and lines as required.

Pressure sensor and air pressure warning switch are used for indicating the

pressure level in the system.

Service brake control system Two independent lines for front and rear wheels with air flow controlled by a

brake valve, and each line comprises a group of valve and brake chambers

(one/ wheel).

Stop lamp switch is used to operate the stop lamps.

Spring brake control system Single line for all spring brake chambers.

The line comprises a control valve which controls air flow, the other necessary

valve and spring brake chambers.

A stop lamp switch is used to turn on the stop lamps.

A parking brake switch is used to turn off the warning buzzer and to turn on the

parking brake warning lamp.

Wheel brake Drum brake with internally expanding, leading-trailing shoes are operated by

slack adjuster and cam shaft or expander in all wheels.

NOTICE

See "DIAGRAM" of the following page the component parts

(Valves, Switches, etc.) used in easy system.

Page 13

BRAKE EQUIPMENT BR01–3

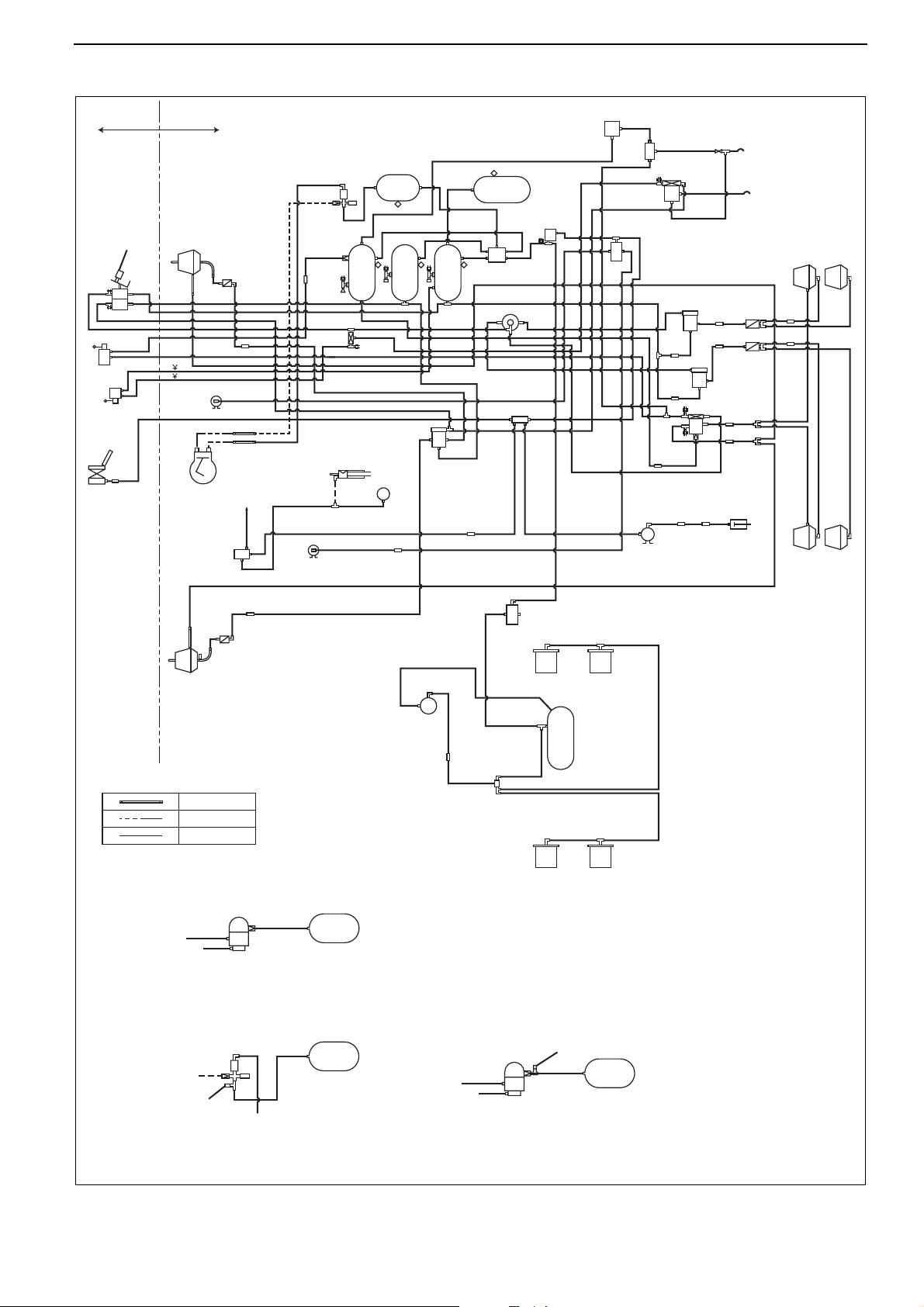

DIAGRAM

EN0680201J100001

MODELS: FS (DUMP, MIXER AND CARGO TRUCK), ZS (DUMP AND CARGO TRUCK)

(For GENERAL COUNTRIES, CHILE, CHINA, G.C.C. COUNTRIES, HONG KONG, IRELAND,

SOUTH AFRICA, TAIWAN)

Q1

3

26L

26L

A5

A6

A7

R

A4

4

F

26L

5

E3

D1

C3

9

19

H1

H3

H2

20

20

6

E5

E4

13

E6

21

P3

E7

P4

P9P13

Q4Q3

18

F21

F51

P5

32

32

14

15

P6

F11P3

7

17

24

2

A/D

CHASSIS

CAB

8

11

R

F

C1

E1

C2

E2

P1

P2

S1

P15

D3

32

D40

P14

H20

27

A3

B1

C0

A2

B2

1

16

23

12

P18

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

TRANSMISSION

25

L1

28

D60

32

D8

21

CHASSIS

19

X5

H12 H11

H41 H4

H22

H5

22

21

H21

P8

14

D6

H7

22

X4

21

L1

25

21

H7

X3

X2

25

23

X1

H41

H6

H5

16 12

F16P6

15

WITH MZ12 TRANSMISSION

(IF SO EQUIPPED)

12

H9

H5

21

22

H7

21

WITH HX07 TRANSMISSION

(IF SO EQUIPPED)

WITH ZF TRANSMISSION

(IF SO EQUIPPED)

21

W1 W2

25

W3 W4W31

WITH INER-AXLE DIFFERENTIAL LOCK

(IF SO EQUIPPED)

SHTS068020100001

26

Page 14

BRAKE EQUIPMENTBR01–4

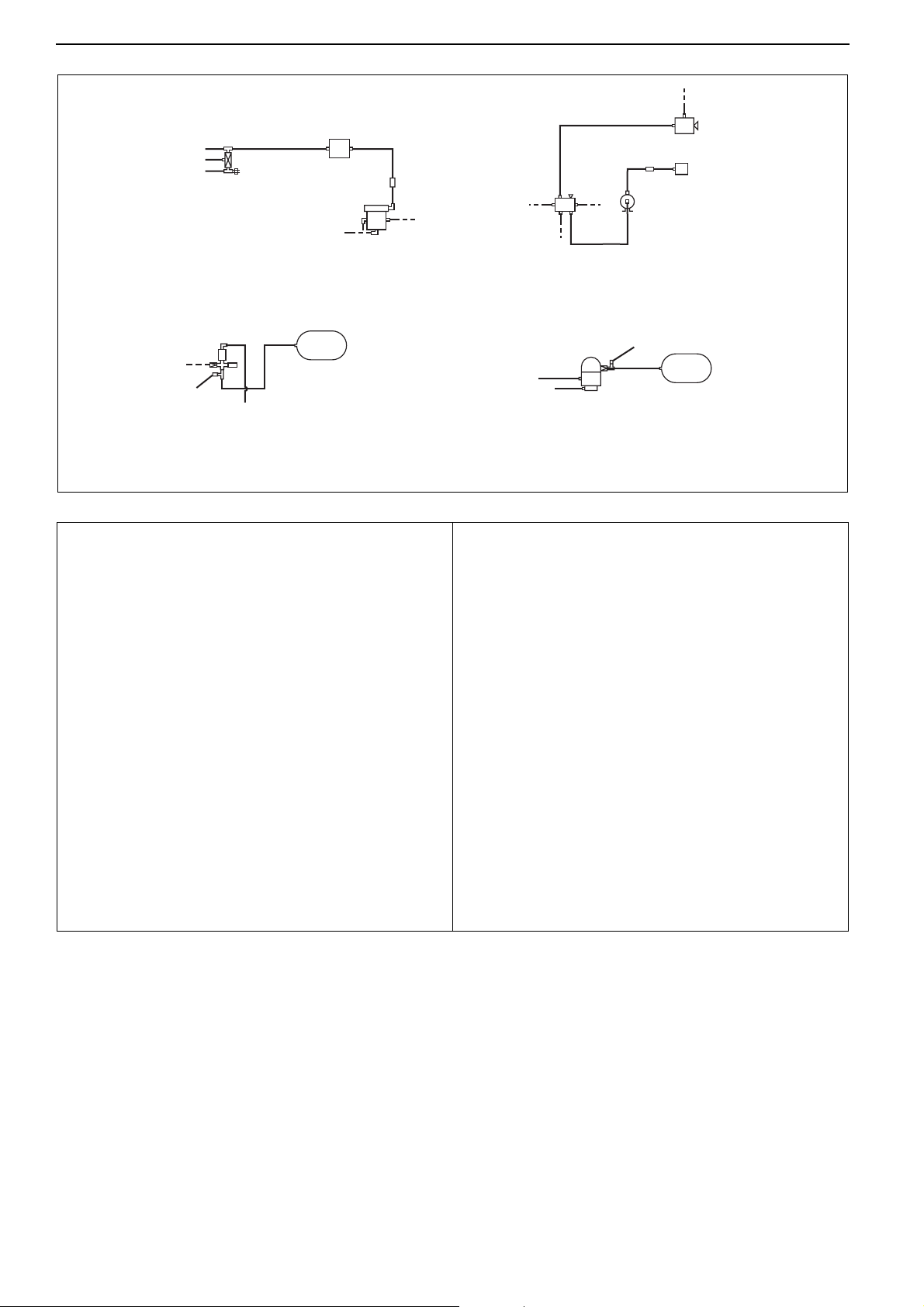

(

)

(

)

E3

B1

10

A3

A4

3

29

13

E31

E4

21

WITHOUT AIR DRYER

(IF SO EQUIPPED)

H5

J2J1J4

21

J5

30

25

21

WITH TRANSMISSION P.T.O.

(WITH HX07 AND MZ12 TRANSMISSION)

(IF SO EQUIPPED)

10

H50

E3E50E2

33

A3

31

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

H5

J2J1J4

21

30

25

21

WITH TRANSMISSION P.T.O.

(WITH ZF TRANSMISSION)

(IF SO EQUIPPED)

B1

A4

2

3

A/D

A3

B1

31

A4

3

WITH ES START

(IF SO EQUIPPED)

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

IF SO EQUIPPED

WITH TIRE INFLATOR

(WITH AIR DRYER)

IF SO EQUIPPED

SHTS068020100002

1 Air compressor 18 Relay valve-Spring brake

2 Air dryer (If so equipped) 19 Reducing valve

3 Air tank-Water separator 20 Protection valve

4 Air tank-Front brake 21 Multi joint

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Range valve

7 Brake valve 24 Air suspension seat

8 Stop lamp switch 25 Magnetic valve

9 Relay valve-Front brake 26 Inter-axle differential lock control cylinder

10 Pressure regulator 27 Cab suspension-Front

11 Spring brake chamber-Front 28 Cab suspension-Rear

12 Power shift 29 Load sensing valve (If so equipped)

13 Release valve-Rear brake 30 Transmission P.T.O. (If so equipped)

14 Spring brake chamber-Rear 31 Tire inflator (If so equipped)

15 Brake chamber 32 ABS control valve (If so equipped)

16 Splitter valve 33 ES start control valve (If so equipped)

17 Spring brake control valve

Page 15

MODEL: FS (For AUSTRALIA)

CHASSIS

CAB

B1

A3

8

7

17

35

24

11

D3

R

F

E2

P1

S1

P15

C1

E1

C2

P2

1

2

32

D20

D40

H20

27

A2

B2

1

L1

21

D60

D30

P18

32

D8

11

P0

16

H7

28

BRAKE EQUIPMENT BR01–5

3

10

22

26L

A4

A8

R

F

26L

26L26L

4

E3

C3

D1

9

23

H10H5

H41 H4

H22 H21

D6

R7

R5

19

Z8

33

Z2

34

E5

E12

E15

E13

E16 E14

P4

Q1

Q4

W2 W3 W4

Z6

Z4

Z9

13

E5

13

Z3

A9

A5

A6

26L

R

5

19

A7

5

H11

6

P22

H3H2

20

12

C7

21

W1

25

R1

P17

EMERGENCY

SERVICE

15

14

F20F1

F21

32

F3

F11

32

P6

18

P51

P5

P9

E7

F6

F16

P8

26

14

15

20

R13

31 31

R6

R1

R2

RUBBER HOSE

STEEL PIPE

NYLON TUBE

2

A/D

A3

B1

A4

WITH AIR DRYER

B1

10

A3

A4

36

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

R4

30

R2

26L

29

R3

R1

R10

R20 R17

R2

25

31 31

3

36

2

A/D

3

A3

B1

A4

3

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

SHTS068020100003

Page 16

BRAKE EQUIPMENTBR01–6

1 Air compressor 19 Reducing valve

2 Air dryer (If so equipped) 20 Protection valve

3 Air tank-Water separator 21 Multi joint

4 Air tank-Front brake 22 Clutch booster

5 Air tank-Rear brake 23 Range valve

6 Protection valve 24 Air suspension seat

7 Brake valve 25 Magnetic valve

8 Stop lamp switch 26 Inter-axle differential lock control cylinder

9 Relay valve-Front brake 27 Cab suspension-Front

10 Pressure regulator 28 Cab suspension-Rear

11 Spring brake chamber-Front 29 Air tank-Air suspension

12 Quick release valve 30 Leveling valve

13 Release valve-Rear brake 31 Air spring

14 Spring brake chamber-Rear 32 ABS control valve

15 Brake chamber 33 Cut valve

16 Air tank-Spring brake and trailer brake 34 Trailer control valve

17 Spring brake control valve 35 Trailer hand brake valve

18 Relay valve-Spring brake 36 Tire inflator (If so equipped)

Page 17

BRAKE EQUIPMENT BR01–7

MODEL: FS (CARGO TRUCK) (For HONG KONG, IRELAND, TAIWAN)

Q1

7

17

24

CHASSIS

CAB

11

D3

8

R

F

C1

E1

C2

E2

P1

P2

S1

12

D40

H20

27

B1

10

A3

A2

B2

C0

3

A5A4

26L

4

f

26L

A6

R

26L

5

D1

1

L1

11

D8

RUBBER HOSE

STEEL PIPE

NYLON TUBE

21

28

D60

12

H41

H22

H4

H21

D6

R5

R9

R16

25

20

19

H1

6

A7

H3

H2

14

15

20

P11

F11

F3

P6

9

C3

E3

E5

21

Q3

R1

P10

E4

13

F1

F4

P4P3

P9

Q4

12

E6

12

E7

P5

18

P12

F21F2

F7

F12

F5 F51

P51

14

F8

F13

F16

F6

P8

15

20

R13

R1

R2

31 31

R4

R2

29

26L

29

26L

R3

R10

R20 R17

21

R1

H7

22

X4

L1

25

X3

X2

25

23

X1

H41

H6

H5

31 32

31

31 31

23

32

R2

TRANSMISSION CHASSIS

X5

H12 H11

25

WITH ZF TRANSMISSION WITH MZ12 TRANSMISSION

H9

21

2

H5

H7

21

22

A/D

A3

B1

A4

3

WITH HX07 TRANSMISSION WITH AIR DRYER

(IF SO EQUIPPED)

19

H5

22

21

SHTS068020100004

21

H7

Page 18

BRAKE EQUIPMENTBR01–8

H5

J2J1J4

21

30

25

21

WITH TRANSMISSION P.T.O.

(WITH ZF TRANSMISSION)

(IF SO EQUIPPED)

E3

33

13

WITH LOADSENSING VALVE

(IF SO EQUIPPED)

E31

H5

J2J1J4

21

J5

30

25

21

WITH TRANSMISSION P.T.O.

(WITH HX07, MZ12 TRANSMISSION)

(IF SO EQUIPPED)

21

E4

H50

E3E50E2

16

WITH ES START

(IF SO EQUIPPED)

B1

10

A3

A4

34

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

2

3

A/D

A3

B1

A4

3

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

34

21

W1 W2

25

W3 W4W31

26

WITH INTER-AXLE DIFFERENTIAL LOCK

(MODEL: FS)

SHTS068020100005

Page 19

BRAKE EQUIPMENT BR01–9

1 Air compressor 18 Relay valve-Spring brake

2 Air dryer (If so equipped) 19 Reducing valve

3 Air tank-Water separator 20 Protection valve

4 Air tank-Front brake 21 Multi joint

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Range valve

7 Brake valve 24 Air suspension seat

8 Stop lamp switch 25 Magnetic valve

9 Relay valve-Front brake 26 Inter-axle differential lock control cylinder

10 Pressure regulator 27 Cab suspension-Front

11 Brake chamber 28 Cab suspension-Rear

12 ABS control valve (If so equipped) 29 Air tank-Air suspension

13 Relay valve-Rear 30 Transmission P.T.O.

14 Spring brake chamber-Rear, Frontward 31 Splitter valve

15 Spring brake chamber-Rear, Rearward 32 Power shift

16 ES start control valve (If so equipped) 33 Load sensing valve

17 Spring brake control valve 34 Tire inflator (If so equipped)

Page 20

MODEL: FS (For NEW ZEALAND)

(

)

(

)

Y

BRAKE EQUIPMENTBR01–10

17

12

7

24

F2

F21

F7

F12

F5 F51

P51

14

14

19

33

P6

P8

Z8

Z4

Z6

EMERGENC

15

F8

F13

15

SERVICE

F11F3

F16F6

Z3

CHASSIS

CAB

10

3

11

P15

D3

D20

C1

E1

C2

E2

P1

P2

㩯1

㩯2

H20

8

R

F

P21

S1

27

D40

32

A3

B1

C0

A2

B2

1

26L

F

4

26L

22

A9

A5A4

A6

R

5

26L

E3

23

H5 H10

11

P18

L1

D30

D8

32

28

D40

21

H41

H22

H4

H21

P17

5

P10

16

F

A8

26L

Q3

Z2

C7

P22

E4

13

F1

F4

P4P3

P9

Q4

R2

32

E6

E7

32

P5

18

26LR

19

H1

6

9

D1

C3

H3

H2

20

E5

21

R1

20

R13

R2

R1

31 31

RUBBER HOSE

STEEL PIPE

NYLON TUBE

R3

30

26L

29

R10

R20 R17

R1

R2

31 31

21

W1 W2

25

W3 W4W31

26

2

A/D

A3

B1

WITH INTER-AXLE DIFFERENTIAL LOCK WITH AIR DRYER

(IF SO EQUIPPED)

B1

10

A3

34

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

IF SO EQUIPPED

A4

2

3

A/D

A3

B1

WITH TIRE INFLATOR

(WITH AIR DRYER)

IF SO EQUIPPED

A4

3

34

A4

3

SHTS068020100006

Page 21

BRAKE EQUIPMENT BR01–11

1 Air compressor 18 Relay valve-Spring brake

2 Air dryer (If so equipped) 19 Reducing valve

3 Air tank-Water separator 20 Protection valve

4 Air tank-Front brake 21 Multi joint

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Range valve

7 Brake valve 24 Air suspension seat

8 Stop lamp switch 25 Magnetic valve

9 Relay valve-Front brake 26 Inter-axle differential lock control cylinder

10 Pressure regulator 27 Cab suspension-Front

11 Spring brake chamber-Front 28 Cab suspension-Rear

12 Trailer hand brake valve 29 Air tank-Air suspension

13 Release valve-Rear brake 30 Leveling valve

14 Spring brake chamber-Rear 31 Air spring

15 Brake chamber 32 ABS control valve

16 Air tank-Spring brake and trailer brake 33 Trailer control valve

17 Spring brake control valve 34 Tire inflator (If so equipped)

Page 22

BRAKE EQUIPMENTBR01–12

MODEL: FS (FULL TRACTOR) (For GENERAL COUNTRIES, CHILE, G.C.C. COUNTRIES)

7

17

24

CHASSIS

CAB

11

D3

8

R

F

D20

P15

P14

C1

E1

C2

E2

P1

P2

H20

27

S1

1

L1

B1

10

A3

A2

B2

C0

3

A4 A5

26L

4

F

R

26L

26L

D1

19

A6

5

A7

H1

A8

6

9

C3

21

H3

H2

26L

15

Q3

14

20

E4E3

F21

F3

F11

13

E6

F51

E7

P6

18

P5

P8

F16

P10

E5

P4P3

P9

Q4

21

16

14

F6

15

P18

11

D30

H41

28

D60

D8

H22

P17

RUBBER HOSE

STEEL PIPE

NYLON TUBE

H4

H21

D6

34

CAB

CHASSIS

>1

>2

19

Z8

33

Z3

16

26L

5

R

26L

Z2

P22

P4

C7

9

WITH TRAILER CONTROL

(IF SO EQUIPPED)

Z6

35

18

H7

22

EMERGENCY

X4

21

L1

25

Z4

Z9

SERVICE

X3

X2

25

23

X1

H41

H6

H5

29 30

WITH ZF TRANSMISSION

SHTS068020100007

Page 23

BRAKE EQUIPMENT BR01–13

H5

J2J1J4

21

31

25

21

WITH TRANSMISSION P.T.O.

(WITH ZF TRANSMISSION)

(IF SO EQUIPPED)

H5

J2J1J4

31

25

21

WITH TRANSMISSION P.T.O.

(WITH MZ12 TRANSMISSION)

(IF SO EQUIPPED)

21

25

CHASSIS

19

X5

H12 H11

H5

21

H7

22

TRANSMISSION

29

23

30

21

WITH MZ12 TRANSMISSION

12

E3

J5

E31

E4

13

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

2

A/D

A3

B1

A4

WITH AIR DRYER

3

10

A3

32

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

21

W1 W2

25

W3 W4W31

WITH INTER-AXLE DIFFERENTIAL LOCK

26

B1

A4

3

2

A/D

A3

B1

32

A4

3

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

SHTS068020100008

Page 24

BRAKE EQUIPMENTBR01–14

1 Air compressor 19 Reducing valve

2 Air dryer (If so equipped) 20 Protection valve

3 Air tank-Water separator 21 Multi joint

4 Air tank-Front brake 22 Clutch booster

5 Air tank-Rear brake 23 Range valve

6 Protection valve 24 Air suspension seat

7 Brake valve 25 Magnetic valve

8 Stop lamp switch 26 Inter-axle differential lock control cylinder

9 Relay valve-Front brake 27 Cab suspension-Front

10 Pressure regulator 28 Cab suspension-Rear

11 Spring brake chamber-Front 29 Splitter valve

12 Load sensing valve (If so equipped) 30 Power shift

13 Release valve-Rear brake 31 Transmission P.T.O. (If so equipped)

14 Spring brake chamber-Rear 32 Tire inflator (If so equipped)

15 Brake chamber 33 Cut valve (If so equipped)

16 Air tank-Spring brake and trailer brake 34 Trailer hand brake valve (If so equipped)

17 Spring brake control valve 35 Trailer control valve (If so equipped)

18 Relay valve-Spring brake

Page 25

BRAKE EQUIPMENT BR01–15

MODEL: FS (FULL TRACTOR) (For SOUTH AFRICA)

19

7

17

24

26L

Z3

F

Q3

P11

13

F1

E6

F4

P5

18

A15

CHASSIS

CAB

2

A/D

A3

8

11

D3

R

F

P1

P21

C1

E1

C2

E2

P2

D40

H20

27

B1

C0

A2

B2

1

H7

22

X4

L1

X3

X2

25 25

21

28

D60

23

X1

3

A4

26L

F

26L

4

D1

C3

9

29

H6

H5

H41 H4

H22

H21

D6

26L

19

A5

A6

A7

R

5

H1

A8

6

E5

E3

H3

H2

20

21

30

P10

16

Z2

C7

P22

E4

P4P3

P9

Q4

Z8

Z4

Z6

EMERGENCY

12

14

P6

F21

F51

P51

P8

15

F8

F13

14 15

SERVICE

F11F3

F16F6

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

A3

B1

10

A4

3

WITHOUT AIR DRYER

21

W1 W2

25

W3 W4W31

26

WITH INTER-AXLE DIFFERENTIAL LOCK

SHTS068020100009

Page 26

BRAKE EQUIPMENTBR01–16

E3

31

13

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

B1

10

A3

A4

3

33

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

E31

H5

J2J1J4

E4

25

21

WITH TRANSMISSION P.T.O.

(IF SO EQUIPPED)

33

2

A/D

A3

B1

A4

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

21

32

3

SHTS068020100010

1 Air compressor 18 Relay valve-Spring brake

2 Air dryer (If so equipped) 19 Reducing valve

3 Air tank-Water separator 20 Protection valve

4 Air tank-Front brake 21 Multi joint

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Range valve

7 Brake valve 24 Air suspension seat

8 Stop lamp switch 25 Magnetic valve

9 Relay valve-Front brake 26 Inter-axle differential lock control cylinder

10 Pressure regulator 27 Cab suspension-Front

11 Brake chamber-Front 28 Cab suspension-Rear

12 Trailer control valve 29 Splitter valve

13 Release valve-Rear brake 30 Power shift

14 Spring brake chamber-Rear 31 Load sensing valve

15 Spring brake chamber-Rearward 32 Transmission P.T.O.

16 Air tank-Spring brake and trailer brake 33 Tire inflator

17 Spring brake control valve

Page 27

BRAKE EQUIPMENT BR01–17

MODEL: FY (For GENERAL COUNTRIES, NEW ZEALAND)

16

35

31

Z3

CHASSIS

CAB

34

3

22

26L

26L

4

F

11

8

7

R

F

P21

C1

E1

C2

E2

P1

P2

㩯1

㩯2

S1

27

H20

12

P15

D5

P14

A3

B1

C0

A2

B2

D3

D2

26L

A9

A5A4

A6

5

R

E3

C3

19

1

H5 H10

L1

19

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

D7

12

P18

28

H41

H22

D10D8

P17

H4

H21

D9

5

26LR

18

H1

6

H3

H2

26

9

10

P10

25

F

A8

26L

Q3

Z2

C7

P22

E4

F4

P4P3

P9

Q4

10

13

F21F1

E6

F51

E7

P51

P5

17

26

R13

R2

R1

R2

32 32

23

26L

18

26

14 15

F23

F53

P6

P8

14

Z8

Z4

Z6

EMERGENCY

21

15

SERVICE

F11F3

F16F6

19

W1 W2

20

W3 W4W31

WITH INTER-AXLE DIFFERENTIAL LOCK

33

E3

E31

E4

13

WITH LOAD SENSING VALVE

24

29

A/D

A3

B1

A4

2

WITH AIR DRYER

(IF SO EQUIPPED)

B1

34

A3

A4

30

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

3

3

R3

R1

32 32

R10

R20 R17

R2

30

A/D

A3

B1

2

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

3

A4

SHTS068020100011

Page 28

BRAKE EQUIPMENTBR01–18

1 Air compressor 19 Multi joint

2 Air dryer (If so equipped) 20 Magnetic valve

3 Air tank-Water separator 21 Trailer control valve (If so equipped)

4 Air tank-Front brake 22 Clutch booster

5 Air tank-Rear brake 23 Air tank-Air suspension (If so equipped)

6 Protection valve 24 Leveling valve (If so equipped)

7 Brake valve 25 Air tank-Spring brake and trailer brake

(If so equipped)

8 Stop lamp switch 26 Protection valve

9 Relay valve-Front brake 27 Cab suspension-Front

10 ABS control valve 28 Cab suspension-Rear

11 Brake chamber-Front 29 Inter-axle differential lock control cylinder

12 Spring brake chamber-Front 30 Tire inflator (If so equipped)

13 Relay valve-Rear brake 31 Air suspension seat (If so equipped)

14 Spring brake chamber-Rear 32 Air spring (If so equipped)

15 Brake chamber-Rear 33 Load sensing valve (If so equipped)

16 Spring brake control valve 34 Pressure regulator

17 Relay valve-Spring brake 35 Trailer hand brake valve (If so equipped)

18 Reducing valve

Page 29

BRAKE EQUIPMENT BR01–19

6

MODEL: FY (For CHINA, HONG KONG)

CHASSIS

16

31

CAB

8

7

R

F

11

C1

E1

C2

E2

P1

P2

H20

12

D3

P15

D2

27

2

A/D

A3R

B1

D5

A3

A2

B2

1

24

L1

22

H41

19

11

28

P18

12

H22 H21

D7

D10D8

3

A4

26L

4

F

C0

26L

C3

H5

H7

P17

D9

Q1

25

18

A9

H3

H2

26L

A5

5

R

A7

H1A6

6

Q3

P14

D4

9

19

H9

26

E3 E4

E5

P3

P13

5

26LR

15

14

F11F3

13

P51

F23

F53

P6

P8

F1

F6

E6

E7

F21F1

F51

P5

17

F4

P4

P9

Q4

19

14

H4

15

RUBBER HOSE

STEEL PIPE

NYLON TUBE

19

W1 W2

20

W3 W4W31

29

WITH INTER-AXLE DIFFERENTIAL LOCK

23

21

24

TRANSMISSION

CHASSIS

18

X5

H12 H11

20

WITH MZ12 TRANSMISSION

H5

22

SHTS068020100012

19

H7

Page 30

BRAKE EQUIPMENTBR01–20

)

(

)

3

B1

10

A3

A4

19

H50

A/D

E3E50E2

A3

B1

2

34

WITHOUT AIR DRYER WITH ES START WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

E3

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

33

13

E31

32

19

J5

30

H5

E4

J2J1J4

19

B1

10

A3

20

WITH TRANSMISSION P.T.O.

(IF SO EQUIPPED)

WITH TIRE INFLATOR

(WITHOUT AIR DRYER

IF SO EQUIPPED

30

3

A4

3

A4

SHTS068020100013

1 Air compressor 18 Reducing valve

2 Air dryer (If so equipped) 19 Multi joint

3 Air tank-Water separator 20 Magnetic valve

4 Air tank-Front brake 21 Range valve (If so equipped)

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Splitter valve (If so equipped)

7 Brake valve 24 Power shift

8 Stop lamp switch 25 Protection valve

9 Relay valve-Front brake 26 Protection valve

10 Pressure regulator (If so equipped) 27 Cab suspension-Front

11 Brake chamber-Front 28 Cab suspension-Rear

12 Spring brake chamber-Front 29 Inter-axle differential lock control cylinder

13 Relay valve-Rear brake 30 Tire inflator (If so equipped)

14 Spring brake chamber-Rear 31 Air suspension seat (If so equipped)

15 Brake chamber-Rear 32 Transmission P.T.O. (If so equipped)

16 Spring brake control valve 33 Load sensing valve (If so equipped)

17 Relay valve-Spring brake 34 ES start control valve (If so equipped)

Page 31

MODEL: FY (For IRELAND)

(

)

(

)

BRAKE EQUIPMENT BR01–21

16

31

26L

23

C3

P17

26L

H4

Q1

A5

5

R

A7

D4

9

10

24

6

P14

19

25

A9

18

H3

H2

H1A6

Q3

26

E3 E4

E5

P3

P13

5

26LR

15

14

F11F3

10

13

P51

F23

F53

14

P6

P8

F16F6

15

E6

E7

17

F21F1

F51

P5

F4

P4

P9

Q4

4

F

CHASSIS

CAB

8

7

R

F

C1

E1

C2

E2

P1

P2

11

H20

26L

A10

12

D3

P15

D2

27

1

2

A/D

A3R

B1

D5

A2

B2

22

H7

3

A4

4

F

C0

26L

H6

21

H5

H41

D7

D9

11

L1

19

X4

X3

X2

20 20

28

P18

12

X1

H22 H21

D10D8

RUBBER HOSE

STEEL PIPE

NYLON TUBE

19

W1 W2

20

W3 W4W31

29

WITH INTER-AXLE DIFFERENTIAL LOCK

30

A/D

A3

B1

A4

3

2

WITH TIRE INFLATOR

IF SO EQUIPPED

H5

J2

J4

19

32

20

J1

WITH TRANSMISSION P.T.O.

IF SO EQUIPPED

SHTS068020100014

Page 32

BRAKE EQUIPMENTBR01–22

1 Air compressor 17 Relay valve-Spring brake

2 Air dryer 18 Reducing valve

3 Air tank-Water separator 19 Multi joint

4 Air tank-Front brake 20 Magnetic valve

5 Air tank-Rear brake 21 Range valve

6 Protection valve 22 Clutch booster

7 Brake valve 23 Splitter valve

8 Stop lamp switch 24 Power shift

9 Relay valve-Front brake 25 Protection valve

10 ABS control valve 26 Protection valve

11 Brake chamber-Front 27 Cab suspension-Front

12 Spring brake chamber-Front 28 Cab suspension-Rear

13 Relay valve-Rear brake 29 Inter-axle differential lock control cylinder

14 Spring brake chamber-Rear 30 Tire inflator (If so equipped)

15 Brake chamber-Rear 31 Air suspension seat (If so equipped)

16 Spring bake control valve 32 Transmission P.T.O. (If so equipped)

Page 33

BRAKE EQUIPMENT BR01–23

MODEL: SH (For CHILE, G.C.C. COUNTRIES)

Z8

32

17

10

A3

B1

Z3

14

Z2

D2

3

26L

4

F

26L26L

H41 H4

H22 H21

R5

R7

23

R6

15

22

CAB

7

CHASSIS

EMERGENCY

SERVICE

Z4

Z10

Z6

28

8

D3

R

F

E2

P1

S1

11

D40

C1

E1

C2

P2

1

2

H20

19

A2

B2

1

L1

21

20

D60 D6

11

D8

RUBBER HOSE

STEEL PIPE

NYLON TUBE

R

26L

29

A5A4

6

C3

C21

17

H1

E5

A8

A6

A7

5

21

H3

H2

18

E3

12

E6

C4

D1

C5

E71 E7

P4P3

16

Q1

E4

F1

F4

9

P5 P51

Q4

F21

F51

13

P6

F3

P8

F5

13

R1

18

31

R4

R2

26L

30

R3

R10

21

L1

R17

31

25

X4

X3

X2

23 23

H7

24

X1

H41

26

H6

H5

27

26

24

27

TRANSMISSION

23

CHASSIS

17

X5

H12 H11

21

WITH ZF TRANSMISSION WITH MZ12 TRANSMISSION

H5

H7

25

SHTS068020100015

21

Page 34

BRAKE EQUIPMENTBR01–24

(

)

H5

21

J2J1J4

35

21

23

WITH TRANSMISSION P.T.O.

(WITH ZF TRANSMISSION)

(IF SO EQUIPPED)

E3

34

R52

E32

E4

12

R10

R3

29

R17

H5

J2J1J4

21

J5

35

21

23

WITH TRANSMISSION P.T.O.

(WITH MZ12 TRANSMISSION)

(IF SO EQUIPPED)

E3

34

12

E31

E4

WITH LOAD SENSING VALVE

(WITH AIR SUSPENSION)

(IF SO EQUIPPED)

2

A/D

A3

B1

A4

3

WITH AIR DRYER

(IF SO EQUIPPED)

33

2

A/D

A3

B1

A4

3

WITH TIRE INFLATOR

(WITH AIR DRYER)

IF SO EQUIPPED

WITH LOAD SENSING VALVE

(WITH LEAF SUSPENSION)

(IF SO EQUIPPED)

B1

10

A3

A4

33

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

3

SHTS068020100016

Page 35

BRAKE EQUIPMENT BR01–25

1 Air compressor 19 Cab suspension-Front

2 Air dryer 20 Cab suspension-Rear (If so equipped)

3 Air tank-Water separator 21 Multi joint

4 Air tank-Front brake 22 Air suspension seat (If so equipped)

5 Air tank-Rear brake 23 Magnetic valve

6 Protection valve 24 Range valve

7 Brake valve 25 Clutch booster

8 Stop lamp switch 26 Splitter valve

9 Relay valve-Front brake 27 Power shift

10 Pressure regulator 28 Trailer control valve

11 Brake chamber-Front 29 Leveling valve

12 Relay valve-Rear brake 30 Air tank-Air suspension

13 Spring brake chamber-Rear 31 Air spring

14 Air tank-Spring brake and trailer brake 32 Cut valve

15 Spring brake control valve 33 Tire inflator (If so equipped)

16 Relay valve-Spring brake 34 Load sensing valve (If so equipped)

17 Reducing valve 35 Transmission P.T.O. (If so equipped)

18 Protection valve

Page 36

MODEL: SH (For CHINA)

BRAKE EQUIPMENTBR01–26

15

22

21

5

26LR

17

H2

H1

E5

E3

18

H3

13

P14

P6 F3

12

F1 F21

P9

F51F4

P5 P51

P8

F6

E6

E7

E4

Q1

P4

P9

16

Q4

Q1

13

H21

P17

CHASSIS

CAB

SERVICE

Z5

Z4

Z7

8

EMERGENCY

11

7

R

F

P1

P21

29

C1

E1

C2

E2

P2

\1

\2

19

P15

Z6

D3

D20

D40

H20

1

17

S1

L1

21

Z3

Z8

28

A2

B2

H5

D60 D6

25

H41

14

20

2

A/D

A3

B1

3

A4

26L

4

F

26L26L

Z2

C7

D2

27

H9

C3

21

H7

H22

26L

A9

A5

A8

A6

A7

R

6

5

9

H4

P18

D8

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

D30

E3

10

E31

E4

21

H5

J2J1J4

23

12

WITH LOAD SENSING VALVE WITH TRANSMISSION P.T.O.

(IF SO EQUIPPED)

26

2

A/D

A3

B1

A4

3

WITH TIRE INFLATOR

(IF SO EQUIPPED)

SHTS068020100017

21

J5

24

Page 37

BRAKE EQUIPMENT BR01–27

1 Air compressor 16 Relay valve-Spring brake

2 Air dryer 17 Reducing valve

3 Air tank-Water separator 18 Protection valve

4 Air tank-Front brake 19 Cab suspension-Front

5 Air tank-Rear brake 20 Cab suspension-Rear (If so equipped)

6 Protection valve 21 Multi joint

7 Brake valve 22 Air suspension seat (If so equipped)

8 Stop lamp switch 23 Magnetic valve

9 Relay valve-Front brake 24 Transmission P.T.O. (If so equipped)

10 Load sensing valve 25 Clutch booster

11 Brake chamber-Front 26 Tire inflator (If so equipped)

12 Relay valve-Rear brake 27 Power shift

13 Spring brake chamber-Rear 28 Trailer control valve

14 Air tank-Spring brake and trailer brake 29 Trailer hand brake valve

15 Spring brake control valve

Page 38

BRAKE EQUIPMENTBR01–28

MODEL: SH (For HONG KONG, TAIWAN)

17

Z3

Z8

10

A3

B1

A4

14

4

Z2

A2

B2

15

22

CHASSIS

CAB

SERVICE

Z5

Z4

Z7

H20

Z6

D3

28

D40

32

8

7

R

F

P1

P21

EMERGENCY

11

C1

E1

C2

P2

1

2

19

S1

1

3

26L

A5

A8

A6

A7

R

6

5

C3

C21

17

H1

E5

E3

21

H21

H2

18

H3

13

r52

34

E31

E4

12

E6

C4

D1

9

C5

E7E71

16

P4P2

Q1

P5 P51

Q4

32

F20F1

F21F4 F5

32

F2

P6

P8

26L

F

26L26L

26

24

27

L1

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

TRANSMISSION

23

21

32

D8

D60

CHASSIS

X5

H12 H11

H41

H5

21

H4

H22

13

20

D6

18

R1

29

R3

R2

26L

30

R10

31

R6 R7

R17

R5R4

23

31

21

H7

25

2

A/D

A3

B1

A4

3

WITH MZ12 TRANSMISSION

WITH AIR DRYER

(IF SO EQUIPPED)

SHTS068020100018

Page 39

BRAKE EQUIPMENT BR01–29

E3

34

E31

E4

12

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

B1

A4

A3

3

33

WITH TIRE INFLATOR

(WITH AIR SUSPENSION )

(IF SO EQUIPPED)

21

J5

35

21

H5

J2J1J4

23

WITH TRANSMISSION P.T.O.

(IF SO EQUIPPED)

33

2

A/D

A3

B1

A4

3

WITH TIRE INFLATOR

(WITH LEAF SUSPENSION)

(IF SO EQUIPPED)

SHTS068020100019

1 Air compressor 19 Cab suspension-Front

2 Air dryer 20 Cab suspension-Rear (If so equipped)

3 Air tank-Water separator 21 Multi joint

4 Air tank-Front brake 22 Air suspension seat (If so equipped)

5 Air tank-Rear brake 23 Magnetic valve

6 Protection valve 24 Range valve

7 Brake valve 25 Clutch booster

8 Stop lamp switch 26 Splitter valve

9 Relay valve-Front brake 27 Power shift

10 Pressure regulator 28 Trailer control valve

11 Brake chamber-Front 29 Leveling valve

12 Relay valve-Rear brake 30 Air tank-Air suspension

13 Spring brake chamber-Rear 31 Air spring

14 Air tank-Spring brake and trailer brake 32 ABS control valve (If so equipped)

15 Spring brake control valve 33 Tire inflator (If so equipped)

16 Relay valve-Spring brake 34 Load sensing valve (If so equipped)

17 Reducing valve 35 Transmission P.T.O. (If so equipped)

18 Protection valve

Page 40

BRAKE EQUIPMENTBR01–30

MODEL: SH (For IRELAND, SOUTH AFRICA)

17

Z8

A2

B2

X4

X3

X2

23 23

D60

Z3

2

A/D

A3

B1

3

A4

26L

4

F

26L26L

26

H6

25

14

Z2

H7

24

H5

X1

H41

D6

H4

15

22

CHASSIS

CAB

SERVICE

8

7

R

F

P1

P21

EMERGENCY

11

C1

E1

C2

P2

19

S1

H20

Z5

Z4

Z7

Z6

28

D3

D40

32

1

L1

21

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

32

D8

27

20

26L

A5

A8

A6

A7

R

5

E3

D2

H22

17

H1

6

E5

21

H21

R1

P3

18

H2

29

R10

Q1

18

H3

13

E31

E6

16

E4

C4

D1

9

C5

E7E71

P4P2

P5 P51

Q4

12

Q1

32

F20F1

F21F4 F5

32

F2

P6

P8

13

31

R5R4

R2

26L

30

R6 R7

23

31

R17

SHTS068020100020

Page 41

BRAKE EQUIPMENT BR01–31

21

B1

A4

10

A3

WITHOUT AIR DRYER

(IF SO EQUIPPED)

H5

J2J1J4

21

35

23

12

R52

E32

E4

E3

34

3

R10

R3

29

R17

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

3

B1

33

A/D

A3

B1

3

A4

10

A3

33

A4

WITH TRANSMISSION P.T.O.

(IF SO EQUIPPED)

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

SHTS068020100021

1 Air compressor 19 Cab suspension-Front

2 Air dryer 20 Cab suspension-Rear (If so equipped)

3 Air tank-Water separator 21 Multi joint

4 Air tank-Front brake 22 Air suspension seat (If so equipped)

5 Air tank-Rear brake 23 Magnetic valve

6 Protection valve 24 Range valve

7 Brake valve 25 Clutch booster

8 Stop lamp switch 26 Splitter valve

9 Relay valve-Front brake 27 Power shift

10 Pressure regulator 28 Trailer control valve

11 Brake chamber-Front 29 Leveling valve

12 Relay valve-Rear brake 30 Air tank-Air suspension

13 Spring brake chamber-Rear 31 Air spring

14 Air tank-Spring brake and trailer brake 32 ABS control valve (If so equipped)

15 Spring brake control valve 33 Tire inflator (If so equipped)

16 Relay valve-Spring brake 34 Load sensing valve (If so equipped)

17 Reducing valve 35 Transmission P.T.O. (If so equipped)

18 Protection valve

Page 42

BRAKE EQUIPMENTBR01–32

MODEL: SS (For GENERAL COUNTRIES, CHILE, G.C.C. COUNTRIES)

16

31

7

38

CHASSIS

CAB

EMERGENCY

Z6

25

SERVICE

Z4

11

Z10

C7

D3

P15

C1

E1

C2

P2

1

2

D20

D40

H20

8

R

F

P1

27

1

L1

S1

P18

19

D30

D8

11

18

Z8

39

Z3

P3

P2

2

A/D

A3

B1

37

Z2

A2

B2

28

H41

D80 D6

3

A4

26L

4

F

26L26L

C7

D2

C3

H22

26L

A9

A5

A8

A6

A7

R

5

9

5

26LR

18

H2

H1

6

E5

E3

H4

19

H21

H21

H3

26

P14

13

F1 F21

E6

E7

34

P5 P51

17

Q4

35

R6

R2

R3

E4

P4

P9

Q1

P17

R1

R7

R5

20

R4

RUBBER HOSE

STEEL PIPE

NYLON TUBE

14

P6

F51F4

P6

P8

14

R13

R1

36 36

33

26L

R20 R17

R1

15

F11

F3

F16

F6

15

R2

R10

R2

36 36

22

19

W1 W2

20

W3 W4W31

29

L1

X4

X2

20 20

H7

21

X3

X1

H41

23

H6

H5

19

WITH INTER-AXLE DIFFERENTIAL LOCK WITH ZF TRANSMISSION

TRANSMISSION CHASSIS

22

H7

H5 H10

19

21

23

21

24

20

20

X5

H12 H11

H5

19

WITH FULLER TRANSMISSION

WITH MZ12 TRANSMISSION

24

19

H7

22

SHTS068020100022

Page 43

BRAKE EQUIPMENT BR01–33

(

)

E3

12

13

WITH LOAD SENSING VALVE

(WITH LEAF SUSPENSION)

(IF SO EQUIPPED)

3

B1

10

A3

A4

WITHOUT AIR DRYER

E31

E4

H5

J2J1J4

20

19

WITH TRANSMISSION P.T.O.

(ZF TRANSMISSION)

(IF SO EQUIPPED)

E3

12

13

WITH LOAD SENSING VALVE

(WITH AIR SUSPENSION)

(IF SO EQUIPPED)

19

32

19

WITH TRANSMISSION P.T.O.

(MZ12 TRANSMISSION)

(IF SO EQUIPPED)

R10

R3

34

R17

R52

E32

E4

H5

J2J1J4

20

19

J5

32

B1

10

A3

A4

30

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

IF SO EQUIPPED

3

A3

B1

30

2

A/D

3

A4

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

SHTS068020100023

Page 44

BRAKE EQUIPMENTBR01–34

1 Air compressor 21 Range valve

2 Air dryer 22 Clutch booster

3 Air tank-Water separator 23 Splitter valve

4 Air tank-Front brake 24 Power shift

5 Air tank-Rear brake 25 Trailer control valve

6 Protection valve 26 Protection valve

7 Brake valve 27 Cab suspension-Front

8 Stop lamp switch 28 Cab suspension-Rear

9 Relay valve-Front brake 29 Inter-axle differential lock control cylinder

10 Pressure regulator 30 Tire inflator (If so equipped)

11 Brake chamber-Front 31 Air suspension seat (If so equipped)

12 Load sensing valve 32 Transmission P.T.O. (If so equipped)

13 Relay valve-Rear brake 33 Air tank-Air suspension (If so equipped)

14 Spring brake chamber-Rear 34 Leveling valve (If so equipped)

15 Brake chamber-Rear 35 Protection valve (If so equipped)

16 Spring brake control valve 36 Air spring (If so equipped)

17 Relay valve-Spring brake 37 Air tank-Trailer brake

18 Reducing valve 38 Trailer hand brake valve

19 Multi joint 39 Cut valve

20 Magnetic valve

Page 45

MODEL: SS (For AUSTRALIA)

(

)

(

)

CHASSIS

CAB

Z8

16

7

31

34

EMERGENCY

8

SERVICE

11

R

F

E2

P1

P15

C1

E1

C2

P2

1

2

27

S1

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

P18

H20

D20

1

Z6

Z4

25

Z10

D3

D40

A2

B2

L1

19

D30

D8

28

D6D60

BRAKE EQUIPMENT BR01–35

B1

10

A3

Z3

P0

33

Z2

3

26L

A4

A9

A5

A8

4

R

F

26L

26L26L

E3

P3

C3

C7

9

D2

22

H7

H22

21

H10H5

R7

R5

5

26LR

A6

A7

5

H1

6

12

19

H4H41

18

H21

W1

R1

20

26

H3H2

15

14

P14

E5

Q1

W2

E15

E16

13

E12

E13

P4

Q4

W3 W4

E14

E6

13

F1 F20

F4

17

P5

E7

F2

F5

F2

P51

P9

F3

F11

P6

F6

F16

P8

29

P17

14

15

26

R6

23

20

2

A/D

A3

B1

R2

26L

R4

R3

24

R13

R1

32

R20 R17

R1

32

R2

32

R2

32

R10

3

A4

WITH AIR DRYER

B1

10

A3

A4

30

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

IF SO EQUIPPED

3

(IF SO EQUIPPED)

30

2

A/D

A3

B1

3

A4

WITH TIRE INFLATOR

(WITH AIR DRYER)

IF SO EQUIPPED

SHTS068020100024

Page 46

BRAKE EQUIPMENTBR01–36

1 Air compressor 18 Reducing valve

2 Air dryer 19 Multi joint

3 Air tank-Water separator 20 Magnetic valve

4 Air tank-Front brake 21 Range valve

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Air tank-Air suspension

7 Brake valve 24 Leveling valve

8 Stop lamp switch 25 Trailer control valve

9 Relay valve-Front brake 26 Protection valve

10 Pressure regulator 27 Cab suspension-Front

11 Brake chamber-Front 28 Cab suspension-Rear

12 Quick release valve 29 Inter-axle differential lock control cylinder

13 Relay valve-Rear brake 30 Tire inflator (If so equipped)

14 Spring brake chamber-Rear 31 Air suspension seat (If so equipped)

15 Brake chamber-Rear 32 Air spring

16 Spring brake control valve 33 Air tank-Trailer brake

17 Relay valve-Spring brake 34 Trailer hand brake valve

Page 47

MODEL: SS (For CHINA)

BRAKE EQUIPMENT BR01–37

16

34

31

F51F4

RUBBER HOSE

STEEL PIPE

NYLON TUBE

15

14

F3

P6

P6

P8

F6

14

15

F11

F16

CHASSIS

CAB

SERVICE

8

11

7

R

F

P1

P21

C1

E1

C2

P2

>1

>2

EMERGENCY

D3

P15

H20

Z5

Z4

Z7

Z6

D20

D40

27

1

18

P18

L1

D30

D8

S1

Z3

Z8

25

A2

B2

19

D80 D6

H41

2

A/D

A3

B1

3

A4

26L

4

F

33

Z2

26L26L

C7

D2

C3

H22

26L

A9

A5

A8

A6

A7

R

5

9

28

5

26LR

18

H1

6

E5

E3

H4

19

H21

H21

H3

H2

26

P14

13

F1 F21

E6

E7

P5 P51

E4

P4

P9

17

Q4

Q1

P17

11

19

22

H7

H6

21

X4

L1

X3

X2

2020

X1

H5

H41

23

24

E3

WITH ZF TRANSMISSION WITH LOAD SENSING VALVE

19

W1 W2

20

W3 W4W31

WITH INTER-AXLE DIFFERENTIAL LOCK

29

WITH TRANSMISSION P.T.O.

19

(IF SO EQUIPPED)

12

13

H5

J2J1J4

20

E31

E4

19

32

SHTS068020100025

Page 48

BRAKE EQUIPMENTBR01–38

A/D

30

3

A4

3

B1

A4

A3

2

A3

B1

30

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

3

B1

10

A3

A4

WITHOUT AIR DRYER

SHTS068020100026

1 Air compressor 18 Reducing valve

2 Air dryer 19 Multi joint

3 Air tank-Water separator 20 Magnetic valve

4 Air tank-Front brake 21 Range valve

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Splitter valve

7 Brake valve 24 Power shift

8 Stop lamp switch 25 Trailer control valve

9 Relay valve-Front brake 26 Protection valve

10 Pressure regulator 27 Cab suspension-Front

11 Brake chamber-Front 28 Cab suspension-Rear

12 Load sensing valve 29 Inter-axle differential lock control cylinder

13 Relay valve-Rear brake 30 Tire inflator (If so equipped)

14 Spring brake chamber-Rear 31 Air suspension seat (If so equipped)

15 Brake chamber-Rear 32 Transmission P.T.O. (If so equipped)

16 Spring brake control valve 33 Air tank-Trailer brake

17 Relay valve-Spring brake 34 Trailer hand brake valve

Page 49

BRAKE EQUIPMENT BR01–39

MODEL: SS (For HONG KONG, SOUTH AFRICA)

Z3

31

38

7

16

A9

18

CHASSIS

CAB

8

SERVICE

EMERGENCY

Z8

Z5

Z4

Z7

Z6

10

A3

A4

B1

3

26L

4

A5

A6

A7

5

RF

26LR

5

18

H1

A8

H3

H2

26

6

37

26L

F

Q1

15

14

25

D3

11

R

F

C1

E1

C2

E2

P1

P2

P21

S1

H20

27

S1

1

L1

19

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

D8

D40

X4

X3

X2

20 20

28

D60

C7

Z2

A2

21

D2

C3

H7

H6

H5

H41

H22

B2

22

X1

9

23

H4

H21

26L26L

E5

E4

E3

F4

D6

24

19

P10

P4

P9

Q4

P3

13

E6

E7

17

P11

F1

P5

P12

P6 F3 F11

F21

F51

P51

P8

14

F8

F13

F6 F16

15

35

R13

R7

R5

20

R1

36 36

R6

R2

26L

R2

33

23

21

R4

R3

R10

34

R20 R17

24

TRANSMISSION

20

CHASSIS

20

X5

H12 H11

R1

36 36

H5

19

H7

22

R2

19

W1 W2

20

W3 W4W31

19

WITH MZ12 TRANSMISSION WITH INTER-AXLE DIFFERENTIAL LOCK

SHTS068020100027

29

Page 50

BRAKE EQUIPMENTBR01–40

19

32

19

H5

J2J1J4

20

WITH TRANSMISSION P.T.O.

(WITH ZF TRANSMISSION)

(IF SO EQUIPPED)

E3

12

E31

E4

13

WITH LOAD SENSING VALVE

(WITH LEAF SUSPENSION)

(IF SO EQUIPPED)

19

J5

32

19

H5

J2J1J4

20

WITH TRANSMISSION P.T.O.

(WITH MZ12 TRANSMISSION)

(IF SO EQUIPPED)

13

R10

R52

E32

E4

R3

R17

E3

12

34

WITH LOAD SENSING VALVE

(WITH AIR SUSPENSION)

(IF SO EQUIPPED)

B1

A4

SHTS068020100028

2

A/D

A3

B1

A4

WITH AIR DRYER

(IF SO EQUIPPED)

30

3

2

A/D

A3

B1

3

A4

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

A3

30

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

10

1 Air compressor 20 Magnetic valve

2 Air dryer 21 Range valve

3 Air tank-Water separator 22 Clutch booster

4 Air tank-Front brake 23 Splitter valve

5 Air tank-Rear brake 24 Power shift

6 Protection valve 25 Trailer control valve

7 Brake valve 26 Protection valve

8 Stop lamp switch 27 Cab suspension-Front

9 Relay valve-Front brake 28 Cab suspension-Rear

10 Pressure regulator 29 Inter-axle differential lock control cylinder

11 Brake chamber-Front 30 Tire inflator (If so equipped)

12 Load sensing valve 31 Air suspension seat (If so equipped)

13 Relay valve-Rear brake 32 Transmission P.T.O. (If so equipped)

14 Spring brake chamber-Rear 33 Air tank-Air suspension (If so equipped)

15 Brake chamber-Rear 34 Leveling valve (If so equipped)

16 Spring brake control valve 35 Protection valve (If so equipped)

17 Relay valve-Spring brake 36 Air spring (If so equipped)

18 Reducing valve 37 Air tank-Trailer brake

19 Multi joint 38 Trailer hand brake valve

3

Page 51

BRAKE EQUIPMENT BR01–41

TROUBLESHOOTING

Symptom Possible cause Remedy/Prevention

Not enough braking

(Wheel brake and drum)

Not enough braking

(Control system)

Unequal or unstable braking Lining is wet with grease or fluid Replace lining.

Brake drags or does not release

(Wheel brake and drum)

Brake drags or does not release

(Control system)

Brake squeal Improper lining material or glazed lin-

Lining is wet with grease or fluid Replace the lining.

Improper contact of drum and lining Correct.

Improper lining material or glazed lining

Deformation or hardening of drum Correct or replace.

Excessively worn lining Replace.

Leakage of compressed air from brake

system

Lack of compressed air pressure due

to excessive use.

Improper operation of air compressor Repair or replace.

Improper operation of brake valve Repair or replace.

Improper operation of relay valve and

quick release valve

Clogging of brake system Replace pipe, hose, etc.

Defective lining material (Improper

combination)

Non-uniform lining contact Correct.

Improper adjustment of brake shoe Adjust.

Non-uniform shoe clearance Adjust the clearance.

Distorted drums Correct or replace.

Excessive abrasion of drums Correct or replace.

Loose hub bearing Adjust or replace bearing.

Improper or unequal pneumatic pressure of tire

Clogging of brake system Replace pipe, hose, etc.

Improper adjustment of shoe clearance

Defective shoe return spring Replace.

Lack of pedal play Adjust.

Improper return of brake pedal Repair or replace.

Improper operation of brake valve Repair or replace.

Improper operation of relay valve and

quick release valve

Clogging of brake system Replace pipe, hose, etc.

ing

Loose lining rivets Replace or tighten the rivet further.

Lining rivet in contact with drum Replace lining and rivet.

Deformation or wear of drum Repair or replace.

Intrusion of foreign matter between

drum and lining

Loose hub bearing Adjust or replace bearing.

Correct.

Tighten further or replace gasket.

Use properly.

Repair or replace.

Replace lining.

Adjust to proper pneumatic pressure.

Adjust the clearance.

Repair or replace.

Replace lining.

Clean the surface of lining or replace

EN0680201F300001

Page 52

Page 53

SERVICE BRAKE BR02–1

BR02

SERVICE BRAKE

BR02-001

AIR DRYER ...............................................BR02-3

DATA AND SPECIFICATIONS........................ BR02-3

DESCRIPTION ................................................ BR02-3

COMPONENT LOCATOR ............................... BR02-4

OVERHAUL ..................................................... BR02-5

INSPECTION AND REPAIR ............................ BR02-7

CHECK VALVE..........................................BR02-8

DATA AND SPECIFICATIONS........................ BR02-8

DESCRIPTION ................................................ BR02-8

COMPONENT LOCATOR ............................... BR02-9

INSPECTION AND REPAIR ............................ BR02-9

DOUBLE CHECK VALVE .......................BR02-10

DATA AND SPECIFICATION ........................ BR02-10

DESCRIPTION .............................................. BR02-10

COMPONENT LOCATOR ............................. BR02-11

OVERHAUL ................................................... BR02-12

INSPECTION AND REPAIR .......................... BR02-12

SAFETY VALVE ......................................BR02-13

DATA AND SPECIFICATIONS...................... BR02-13

DESCRIPTION .............................................. BR02-13

INSPECTION AND REPAIR .......................... BR02-13

BRAKE VALVE........................................BR02-14

DATA AND SPECIFICATION ........................ BR02-14

DESCRIPTION .............................................. BR02-14

COMPONENT LOCATOR ............................. BR02-15

OVERHAUL ................................................... BR02-17

INSPECTION AND REPAIR .......................... BR02-23

PROTECTION VALVE (WITH 4-WAY

PROTECTION VALVE) ............................BR02-31

DATA AND SPECIFICATIONS...................... BR02-31

DESCRIPTION .............................................. BR02-31

COMPONENT LOCATOR ............................. BR02-32

OVERHAUL ................................................... BR02-33

ADJUSTMENT............................................... BR02-33

INSPECTION AND REPAIR .......................... BR02-35

QUICK RELEASE VALVE .......................BR02-36

DATA AND SPECIFICATION ........................ BR02-36

DESCRIPTION .............................................. BR02-36

COMPONENT LOCATOR ............................. BR02-37

OVERHAUL ................................................... BR02-38

INSPECTION AND REPAIR .......................... BR02-38

LOAD SENSING VALVE .........................BR02-39

DATA AND SPECIFICATION ........................ BR02-39

DESCRIPTION .............................................. BR02-40

COMPONENT LOCATOR ............................. BR02-42

OVERHAUL ................................................... BR02-44

ADJUSTMENT............................................... BR02-47

INSPECTION AND REPAIR .......................... BR02-48

SPRING BRAKE CONTROL VALVE

(TYPE-A) .................................................BR02-50

DATA AND SPECIFICATIONS...................... BR02-50

DESCRIPTION .............................................. BR02-50

COMPONENT LOCATOR ............................. BR02-51

OVERHAUL ................................................... BR02-52

INSPECTION AND REPAIR .......................... BR02-54

PROTECTION VALVE (TYPE-A) ............BR02-25

DATA AND SPECIFICATIONS...................... BR02-25

DESCRIPTION .............................................. BR02-25

COMPONENT LOCATOR ............................. BR02-26

OVERHAUL ................................................... BR02-27

INSPECTION AND REPAIR .......................... BR02-27

PROTECTION VALVE (TYPE-B) ............BR02-28

DATA AND SPECIFICATIONS...................... BR02-28

DESCRIPTION .............................................. BR02-28

COMPONENT LOCATOR ............................. BR02-29

OVERHAUL ................................................... BR02-30

INSPECTION AND REPAIR .......................... BR02-30

SPRING BRAKE CONTROL VALVE

(TYPE-B) .................................................BR02-55

DATA AND SPECIFICATIONS...................... BR02-55

DESCRIPTION .............................................. BR02-55

COMPONENT LOCATOR ............................. BR02-56

OVERHAUL ................................................... BR02-57

INSPECTION AND REPAIR .......................... BR02-59

RELAY VALVE (TYPE-A) ........................BR02-60

DATA AND SPECIFICATIONS...................... BR02-60

DESCRIPTION .............................................. BR02-60

COMPONENT LOCATOR ............................. BR02-61

OVERHAUL ................................................... BR02-62

INSPECTION AND REPAIR .......................... BR02-63

Page 54

SERVICE BRAKEBR02–2

RELAY VALVE (TYPE-B)........................BR02-64

DATA AND SPECIFICATIONS ......................BR02-64

DESCRIPTION...............................................BR02-64

COMPONENT LOCATOR..............................BR02-65

OVERHAUL....................................................BR02-66

INSPECTION AND REPAIR ..........................BR02-66

CUT VALVE............................................. BR02-67

DATA AND SPECIFICATION.........................BR02-67

DESCRIPTION...............................................BR02-67

COMPONENT LOCATOR..............................BR02-68

OVERHAUL....................................................BR02-68

INSPECTION AND REPAIR ..........................BR02-69

REDUCING VALVE (TYPE-A) ................ BR02-70

DATA AND SPECIFICATIONS ......................BR02-70

DESCRIPTION...............................................BR02-70

COMPONENT LOCATOR..............................BR02-71

OVERHAUL....................................................BR02-72

INSPECTION AND REPAIR ..........................BR02-72

REDUCING VALVE (TYPE-B) ................ BR02-73

DATA AND SPECIFICATIONS ......................BR02-73

DESCRIPTION...............................................BR02-73

COMPONENT LOCATOR..............................BR02-74

OVERHAUL....................................................BR02-75

INSPECTION AND REPAIR ..........................BR02-75

BRAKE CHAMBER ................................BR02-76

DATA AND SPECIFICATION.........................BR02-76

DESCRIPTION...............................................BR02-76

COMPONENT LOCATOR..............................BR02-77

OVERHAUL....................................................BR02-78

INSPECTION AND REPAIR ..........................BR02-79

BRAKE CHAMBER

(MAKER: WABCO).................................BR02-80

DATA AND SPECIFICATION.........................BR02-80

DESCRIPTION...............................................BR02-80

COMPONENT LOCATOR..............................BR02-81

SPECIAL TOOL .............................................BR02-81

OVERHAUL....................................................BR02-82

INSPECTION AND REPAIR ..........................BR02-86

SPRING BRAKE CHAMBER ................. BR02-87

DATA AND SPECIFICATION.........................BR02-87

DESCRIPTION...............................................BR02-88

SPECIAL TOOL .............................................BR02-89

COMPONENT LOCATOR..............................BR02-89

OVERHAUL....................................................BR02-90

INSPECTION AND REPAIR ..........................BR02-94

SPRING BRAKE CHAMBER

(MAKER: NABCO) .................................BR02-95

DATA AND SPECIFICATION.........................BR02-95

DESCRIPTION ...............................................BR02-95

COMPONENT LOCATOR..............................BR02-96

BR 0 2

OVERHAUL....................................................BR02-97

INSPECTION AND REPAIR ..........................BR02-98

SPRING BRAKE CHAMBER

(MAKER: WABCO).................................BR02-99

DATA AND SPECIFICATION.........................BR02-99

DESCRIPTION ...............................................BR02-99

COMPONENT LOCATOR............................BR02-100

SPECIAL TOOL ...........................................BR02-100

OVERHAUL..................................................BR02-101

INSPECTION AND REPAIR ........................BR02-107

TRAILER HAND BRAKE

CONTROL VALVE................................. BR02-108

DATA AND SPECIFICATION.......................BR02-108

DESCRIPTION .............................................BR02-108

COMPONENT LOCATOR............................BR02-109

OVERHAUL..................................................BR02-110

INSPECTION AND REPAIR ........................BR02-112

WHEEL BRAKE

(TYPE: S-CAM BRAKE) .......................BR02-114

DATA AND SPECIFICATIONS ....................BR02-114

DESCRIPTION .............................................BR02-115

SPECIAL TOOL ...........................................BR02-121

COMPONENT LOCATOR............................BR02-122

OVERHAUL..................................................BR02-132

ADJUSTMENT .............................................BR02-141

INSPECTION AND REPAIR ........................BR02-143

WHEEL BRAKE

(TYPE: WEDGE BRAKE) .....................BR02-145

DATA AND SPECIFICATIONS ....................BR02-145

DESCRIPTION .............................................BR02-145

SPECIAL TOOL ...........................................BR02-147

COMPONENT LOCATOR............................BR02-148

OVERHAUL..................................................BR02-150

ADJUSTMENT .............................................BR02-156

INSPECTION AND REPAIR ........................BR02-158

EXPANDER ...........................................BR02-159

DESCRIPTION .............................................BR02-159

SPECIAL TOOL ...........................................BR02-160

COMPONENT LOCATOR............................BR02-161

OVERHAUL..................................................BR02-162

INSPECTION AND REPAIR ........................BR02-165

PRESSURE REGULATOR ...................BR02-167

DATA AND SPECIFICATIONS ....................BR02-167

DESCRIPTION .............................................BR02-167

COMPONENT LOCATOR............................BR02-168

OVERHAUL..................................................BR02-169

INSPECTION AND REPAIR ........................BR02-170

Page 55

SERVICE BRAKE BR02–3

AIR DRYER

DATA AND SPECIFICATIONS

Type Purge tank, desiccant, auto-purge valve.

Air and Water discharging time (Reclamation cycle) Approx. 50 sec.

DESCRIPTION

EN0680202I200001

EN0680202C100001

1 Chamber (Purge tank) 14 Plug

2 Case cover 15 Pressure regulator

3 Check valve 16 Adjusting screw

4 Spring 17 Piston

5 Body 18 Piston spring

6 Desiccant case 19 Heater (If so equipped)

7 Filter A Inlet (From air compressor)

8 Desiccant B Orifice

9 Oil separator filter C Outlet (Dried air to air tank)

10 Valve body D Purged air

11 Valve spring E Dehumidification

12 Piston F Reclamation

13 Purge valve

SHTS068020200001

Page 56

SERVICE BRAKEBR02–4

COMPONENT LOCATOR

EN0680202D100001

1 O-ring 18 Desiccant

2 Cover 19 Desiccant case

3 Piston 20 Oil separator filter

4 Valve spring 21 Body

5 Valve body 22 Valve stopper

6 Purge valve 23 Governor valve

7 Silencer case 24 Piston assembly

8 Silencer plate 25 Exhaust stem spring

9 Silencer 26 Exhaust stem

10 Retainer ring 27 Pressure regulator assembly

11 Exhaust cover 28 Valve seat

12 Chamber 29 Plate

13 Check valve 30 Heater

14 Case cover 31 Thermostat

15 Set spring 32 Plug

16 Filter plate 33 Elbow connector

17 Filter 34 Tube

SHTS068020200002

Tightening torque Unit: N⋅m {kgf⋅cm, lbf⋅ft}

A 3.9-6.9 {40-70, 2.9-5.0} D 6.9-7.8 {71-79, 5.1-5.7}

B 3.9-6.9 {40-70, 2.9-5.0} E 17.7-27.5 {181-280, 14-20}

C 4.9-5.9 {50-60, 3.7-4.3}

Page 57

SERVICE BRAKE BR02–5

OVERHAUL

EN0680202H200001

IMPORTANT POINTS - ASSEMBLY

1. LUBRICATION

C

A

A

A

A

B

(1) When assembling the air dryer, use new O-ring, gasket and seal.

(2) Apply grease (lithium base) to each sliding surface of the compo-

nent parts and O-ring groove.

• A: O-ring

• B: Sliding surface

2. ASSEMBLY

NOTICE

Before tighten the bolt with specified tightening torque, tap all

over the outer surface of the desiccant case with a plastic hammer.

• C: Bolt

SHTS068020200003

Page 58

SHTS068020200004

SERVICE BRAKEBR02–6

IMPORTANT POINTS - MOUNTING

1. INSPECTION

(1) Operate the engine and raise the air pressure until the air dis-

charge from the purge valve, then stop the engine.

(The pressure reaches the valve opening pressure of the air pressure regulator).

a. Check to see that there is no air leakage from the purge valve.

2. ADJUSTMENT

(1) Loosen the adjusting screw until the rod spring tension is

released, and start and idle the engine to charge the air for the air

tank.

(2) Tighten the adjusting screw gradually till the air pressure gauge

indicate valve opening pressure shown below and the air starts to

discharge from purge valve.

Governor valve opening pressure:

960-1,000 kPa {9.8-10.2 kgf/cm