Page 1

WSC 267-E

Operating instructions en

Mode d’emploi fr

Manual de instrucciones es

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

Page 2

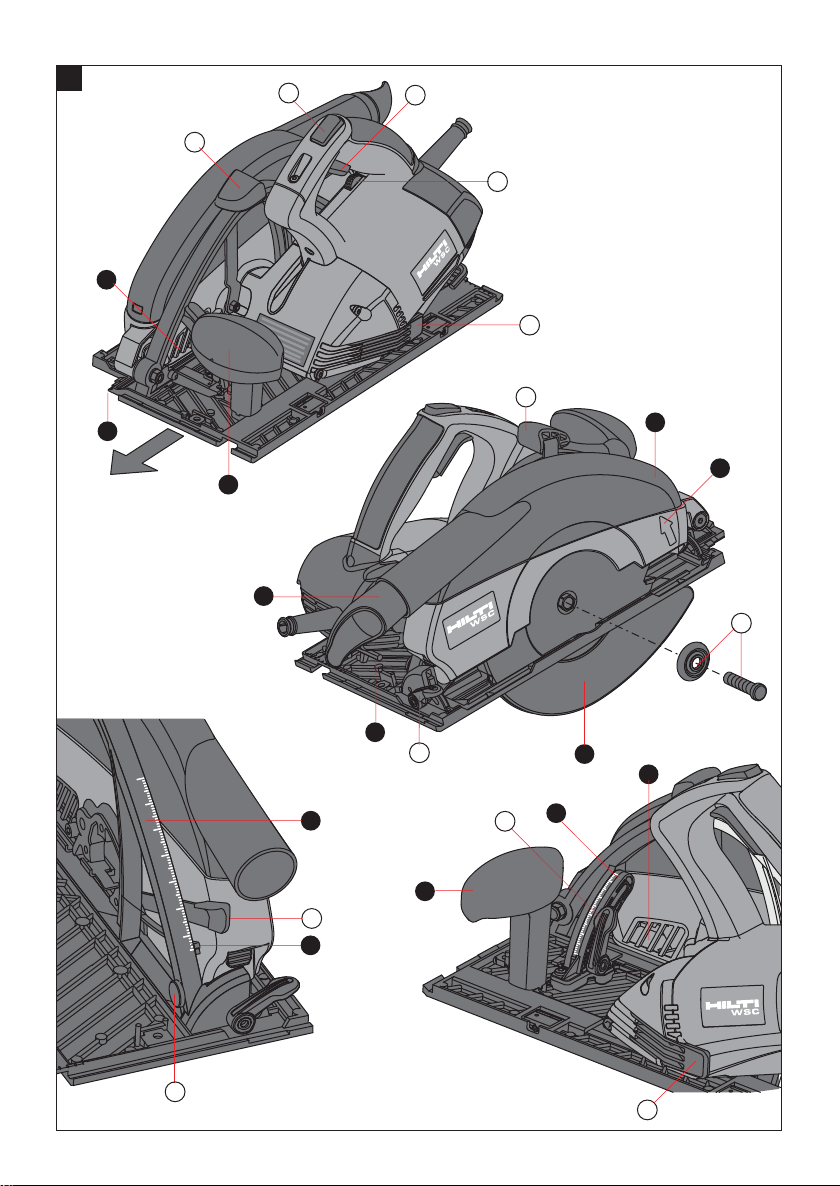

1

1

2

9

3

21

4

9

19

13

11

14

12

5

20

6

15

21

17

16

6

11

7

18

8

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

4

Page 3

Este producto està contenido en la list UL y tiene la certificación CSA

Ce produit est homologué UL et certifié CSA

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

This product is UL listed and CSA certified

Page 4

2

3

5

2

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

1

6

4

3

Page 5

4

1

2

55 in (1400 mm)

9

5

7

7.8 in (200 mm)

3

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

10

60° 45° 45°30° 30°22.5° 22.5°0°

6

4

8

2

Page 6

WSC 267-E hand-held circular saw

Operating controls and parts of the WSC267-E

It is essential that the operating

instructions are read before the

tool is operated for the first time.

Always keep these operating

instructions together with the tool.

Ensure that the operating

instructions are with the tool when

it is given to other persons.

햲 Switch interlock

햳 On / off switch

햴 Speed pre-selection thumbwheel

햵 Clamping lever

햶 Clamping screw and clamping flange

햷 Cutting angle adjustment clamp

햸 Cutting depth locking lever

햹 Cutting depth selector

햺 Manual control for pivoting guard

Parts of the WSC 267-E

쐈 Auxiliary grip

쐉 Pivoting chip ejector nozzle

씈 Chip ejector cover

씉 Blade guard

씊 Pivoting guard

씋 Cutting angle scale

씌 Cutting depth scale

씍 Pre-set cutting depth

씎 Cutting line indicator

씏 Hex. socket wrench

쏹

21

Viewing grill

Parts of the WGS 1400-2 guide rail (Accessories)

쐃 Guide rail

쐇 Screw clamps (accessories)

쐋 Stop

쐏 Channel for screw clamps

쐄 0° indicator mark

쐂 Lateral cutting angle scale (up to 60°)

쐆 Saw positioning / starting section

쐊 Non-slip strips

쐎 Guide rail cutting edge

쐅 Grip opening

Contents Page

1. General information 2

2. Technical data 2

3. General safety rules 3

4. Specific safety ruels 4

5. Additional specific safety rules and symbols 5

6. Functional description 6

7. Assembly 6

8. Operation 6

9. Care and maintenance 8

10. Accessories 9

11. Manufacturer's warranty – tools 10

12. Disposal 11

13. Troubleshooting 11

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

Parts of the WPG 265 parallel guide (Accessory)

Parallel guide

Hex. screw

Pressure spring

Clamping piece

Hex. nut

Clamping lever

1

Page 7

1. General information

1.1 Indication of danger

-WARNING-

The word WARNING is used to draw attention to a potentially dangerous situation which could lead to severe

personal injury or death.

-CAUTION-

This word is used to draw attention to a potentially dangerous situation which could lead to minor personal injury

or damage to the equipment or other property.

1.2 Pictograms

Warning signs

Symbols

The numbers refer to the illustrations. The illustrations can be found on the fold-out cover pages. Keep

these pages open while you read the operating instructions.

“The tool” referred to in these operating instructions is

always the WSC 267-E circular saw.

Location of identification data on the tool

The type designation and serial number can be found

on the type plate of the tool. Make a note of this data in

your operating instructions and always refer to it when

making an enquiry to your Hilti representative or service department.

Type:

General

warning

Warning:

electricity

Read the operat-

ing instructions

before use.

Serial no:

Obligation signs

Wear eye

protection

Wear breathing

protection

Wear ear

protection

Wear

protective

gloves

2. Technical data WSC267-E (constant-speed Electronics)

Rated power: 1500 W

Power output: 800 W

Nominal voltage: ~120 V AC

Nominal current input: 13.5 A

Spindle speed under no load: 4300 r.p.m. (setting 6)

Spindle speed under load (settings1–6): 1900–3900 r.p.m.

Cutting depth at 0°: 0–67 mm 0–25/8″

Cutting depth at 45°: 0–54 mm 0–2″

Angular adjustment: 0°–45°

Saw blade specification:

– Maximum saw blade diameter: 184 mm 7

– Minimum saw blade diameter: 165 mm 6

– Blade mounting hole diameter:

– Steel disc core thickness: 1.2–1.5 mm

– Maximum kerf width: 1.9–2.4 mm

– Minimum rated blade speed when idling (n): n ≥ 6500 r.p.m

Dust extraction connector internal dia.: 35 mm 13/8″

Machine weight: 4.5 kg 10 Pounds

Electrical protection class: Z / II (double insulated)

Right of technical changes reserved.

1

/4″

1

/2″

5

/8″

3

/64″–1/16″

1

/16″–3/32″

2

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

Page 8

3. General safety rules

1. WARNING!

Read and understand all instructions.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious personal

injury.

SAVE THESE INSTRUCTIONS

2. Work Area

2.1 Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

2.2 Do not operate power tools in explosive

atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create

sparks which may ignite the dust or fumes.

2.3 Keep bystanders, children and visitors away

while operating a power tool. Distractions can

cause you to lose control.

tention while operating power tools may result in

serious personal injury.

4.2 Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts.

4.3 Avoid accidental starting. Be sure switch is off

before plugging in. Carrying tools with your finger

on the switch or plugging in tools that have the

switch on invites accidents.

4.4 Remove adjusting keys or wrenches before

turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

4.5 Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance

enables better control of the tool in unexpected situations.

3. Electrical Safety

3.1 Double Insulated tools are equipped with a polarized plug (one blade is wider than the other.) This

plug will fit in a polarized outlet only one way. If the

plug does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to

install a polarized outlet. Do not change the plug in

any way. Double Insulation Z eliminates the need for

the three wire grounded power cord and grounded power

supply system. Applicable only to Class II tools.

3.2 Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your

body is grounded.

3.3 Do not expose power tools to rain or wet con-

ditions. Water entering a power tool will increase

the risk of electric shock.

3.4 Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric

shock.

3.5 When operating a power tool outside, use an

outdoor extension cord marked «W-A» or «W».

These cords are rated for outdoor use and reduce

the risk of electric shock.

4. Personal Safety

4.1 Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inat-

4.6 Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat

or hearing protection must be used for appropriate

conditions.

5. Tool Use and Care

5.1 Use clamps or other practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your body is

unstable and may lead to loss of control.

5.2 Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

5.3 Do not use tool if the switch does not turn it on

or off. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

5.4 Disconnect the plug from the power source be-

fore making any adjustments, changing accessories, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

5.5 Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

5.6 Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with

sharp cutting edges are less likely to bind and are

easier to control.

5.7 Check for misalignment or binding of moving

parts, breakage of parts and any other condition

that may affect the tools operation. If damaged,

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

3

Page 9

have the tool serviced before using. Many accidents are caused by poorly maintained tools.

5.8 Use only accessories that are recommended

by the manufacturer for your model. Accessories

that may be suitable for one tool may become hazardous when used on another tool.

6. Service

6.1 Tool service must be performed only by qualified repair personnel. Service or maintenance per-

formed by unqualified personnel could result in a risk

of injury.

6.2 When servicing a tool, use only identical

replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized

parts or failure to follow Maintenance Instructions

may create a risk of electric shock or injury.

4. Specific safety rules

G DANGER! Keep hands away from cutting area and

blade. Keep your second hand on auxiliary handle, or

motor housing. If both hands are holding the saw, they

cannot be cut by the blade.

G Keep your body positioned to either side of the saw

blade, but not in line with the saw blade. KICKBACK

could cause the saw to jump backwards (see ”Causes

and Operator Prevention of Kickback”).

G Do not reach underneath the work. The guard can

not protect you from the blade below the work.

G Check lower guard for proper closing before each

use. Do not operate saw if lower guard does not move

freely and close instantly. Never clamp or tie the lower guard into the open position. If saw is accidentally

dropped, lower guard may be bent. Raise the lower guard

with the Retracting Handle and make sure it moves freely

and does not touch the blade or any other part, in all

angles and depths of cut.

G Check the operation and condition of the lower guard

spring. If the guard and the spring are not operating

properly, they must be serviced before use. Lower

guard may operate sluggishly due to damaged parts,

gummy deposits, or a buildup of debris.

G Lower guard should be retracted manually only for

special cuts such as ”Pocket Cuts” and ”Compound

Cuts”. Raise lower guard by Retracting Handle. As

soon as blade enters the material, lower guard must

be released. For all other sawing, the lower guard should

operate automatically.

G Always observe that the lower guard is covering the

blade before placing saw down on bench or floor. An

unprotected, coasting blade will cause the saw to walk

backwards, cutting whatever is in its path. Be aware of

the time it takes for the blade to stop after switch is

released.

4

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

G NEVER hold piece being cut in your hands or across

your leg. It is important to support the work properly to

minimize body exposure, blade binding or loss of control.

G Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a ”live”

wire also make exposed metal parts of the tool ”live” and

shock the operator.

G When ripping always use a rip fence or straight edge

guide. This improves the accuracy of cut and reduces

the chance for blade binding.

G Always use blades with correct size and shape (diamond vs. round) arbor holes. Blades that do not match

the mounting hardware of the saw will run eccentrically, causing loss of control.

G Never use damaged or incorrect blade washers or

bolts. The blade washers and bolt were specially designed

for your saw, for optimum performance and safety of

operation.

Causes and Operator Prevention of Kickback:

– Kickback is a sudden reaction to a pinched, bound or

misaligned saw blade, causing an uncontrolled saw

to lift up and out of workpiece toward the operator.

– When the blade is pinched or bound tightly by the kerf

closing down, the blade stalls and the motor reaction

drives the unit rapidly back toward the operator.

– If the blade becomes twisted or misaligned in the cut,

the teeth at the black edge of the blade can dig into the

top surface of the wood causing the blade to climb out

of the kerf and jump back toward operator.

– Kickback is the result of tool misuse and/or incorrect

operating procedures or conditions and can be avoided by taking proper precautions as given below:

G Maintain a firm grip with both hands on the saw and

position your body and arm to allow you to resist KICKBACK forces. KICKBACK forces can be controlled by the

operator, if proper precautions are taken.

G When blade is binding, or when interrupting a cut

for any reason, release the trigger and hold the saw

motionless in the material until the blade comes to a

complete stop. Never attempt to remove the saw from

the work or pull the saw backward while the blade is

in motion or KICKBACK may occur. Investigate and take

corrective actions to eliminate the cause of blade binding.

G When restarting a saw in the workpiece, center the

saw blade in the kerf and check that saw teeth are not

engaged into the material. If saw blade is binding, it

may walk up or KICKBACK from the workpiece as the

saw is restarted.

G Support large panels to minimize the risk of blade

pinching and KICKBACK.

under their own weight. Supports must be placed under

the panel on both sides, near the line of cut and near the

edge of the panel.

G Do not use dull or damaged blade. Unsharpened or

improperly set blades produce narrow kerf causing excessive friction, blade binding and KICKBACK.

Large panels tend to sage

Page 10

G Blade depth and bevel adjusting locking levers must

be tight and secure before making cut. If blade adjust-

ment shifts while cutting, it may cause binding and KICKBACK.

G Use extra caution when making a ”Pocket Cut” into

existing walls or other blind areas. The protruding blade

may cut objects that can cause KICKBACK.

5. Additional specific safety rules and

symbols

Basic information concerning safety

In addition to the information relevant to safety given in

each of the sections of these operating instructions, the

following points must be strictly observed at all times:

Correct use

G The tool is designed for cutting through, cutting grooves

and cutting into wood, wood-like materials, plaster- and

cement-bonded fibre materials (no asbestos) and plastics.

G The working environment may be on a construction

site or in a workshop and may consist of renovation, conversion or new building work.

G The tool may be operated only when connected to a

power supply providing a voltage and frequency in compliance with the information given on the type plate.

Incorrect use (misuse)

G Sawing metals is not permissible.

G The tool may be operated only when held and guided

by both hands.

G No changes or modifications may be made to the tool

and its protective equipment and it must not be manipulated in any way other than as described in the operating instructions.

G To avoid the risk of injury, always use only Hilti original accessories.

G Do not use the tool for cutting branches off trees or

for cutting logs.

G Avoid cutting nails. Inspect for and remove all nails

from workpiece before cutting.

Observe the information given in the operating instructions concerning operation, care and maintenance.

State of the art

The tool is designed and manufactured in accordance

with state of the art technology and thus provides a high

level of operating safety. Nevertheless, the tool and its

accessories may present hazards when used incorrectly by untrained personnel or when misused.

Take the necessary precautions to make the workplace

safe

G Take care to avoid tripping over the supply cord or

extraction hose.

G Whenthetoolisinuse,alwaysguidethesupplycord

and extraction hose away from the tool to the rear.

G Keep the area above and below the cutting line free of

obstacles.

G Place the wider portion of the tool guide plate on the

part of the workpiece which is supported, not on the part

that will drop when the cut is made. If the workpiece is

small, clamp it down before cutting.

G Never attempt to clamp the tool down and move the

workpiece into the tool.

General hazards presented by the tool

G The tool may be used only for the purposes for which

it was designed, when in faultless condition and when

used correctly.

G Keep the grips clean, dry and free of oil and grease.

G Always hold the tool securely in both hands.

G Never place your hands in front of the circular saw

blade.

G Always switch on the tool and allow it to reach full

operating speed before bringing it into contact with the

workpiece.

G Operate the tool only together with the applicable protective equipment.

G The rotating saw blade must not be touched while sawing. The part of the saw blade projecting below the workpiece, the clamping flange and the clamping screw must

not be touched.

G When not in use, the tool must be locked away in a

dry place, out of reach of children.

G Do not allow the saw to brush against your leg or other part of your body. The pivoting guard could catch on

your clothing and expose the blade.

G Proposition 65 warning: This product contains or produces an exposure to chemicals known to the State of

California to cause cancer and birth defects (or othe reproductive harm).

G Children must be instructed not to play with the tool.

G The tool is not intended for use by children, by debil-

itated persons or those who have received no instruction or training.

G WARNING: Some dust created by grinding, sanding, cutting and drilling contains chemicals known to

cause cancer, birth defects, infertility or other reproductive harm; or serious and permanent respiratory or

other injury. Some examples of these chemicals are:

lead from lead-based paints, crystalline silica from bricks,

concrete and other masonry products and natural stone,

arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce exposure

to these chemicals, the operator and bystanders should

work in a well-ventilated area, work with approved

safety equipment, such as respiratory protection appropriate for the type of dust generated, and designed to

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

5

Page 11

filter out microscopic particles and direct dust away

from the face and body. Avoid prolonged contact with

dust. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your

mouth, eyes, or to remain on your skin may promote

absorption of harmful chemicals.

Electrical

G Concealed electric cables or gas and water pipes present a serious hazard if damaged while you are working. Accordingly, check the area in which you are working beforehand, e.g. by using a metal detector.

G External metal parts of the tool may become live, for

example, when the saw cuts inadvertently into an electric cable.

G Do not touch the supply cord if it has become damaged while working. Disconnect the supply cord plug

from the mains socket immediately.

G Dust or dampness on the surface of the tool make it

slippery and difficult to hold and may, under unfavourable

conditions, present a risk of electric shock.

Conditions to be fulfilled by the user

G The tool is designed for professional use.

Personal protective equipment

Protective devices

Do not switch on the tool when the saw blade, the blade

guard, the pivoting guard are not fitted correctly.

G The pivoting guard must be able to move freely. It must

not be fixed in an open position.

Symbols used on the tool:

V volts n

~ alternating current /min rev olution sp er minute

no load speed

0

Hz hertz ∅ diameter

A amperes Z double insulated

7. Assembly

-CAUTION-

I The cutting edges of the saw blade

are sharp.

I The cutting edges may present a risk

of injury.

I Wear protective gloves.

It is essential that the safety precautions printed in these

operating instructions are read and observed.

G Disconnect the plug from the mains socket.

G Check that the saw blade is mounted securely and that

it runs freely.

G Check all safety equipment for correct functionality.

If extension cords are used: only extension cords of a

type approved for the intended use and of adequate cross

section may be used. Failure to observe this point may

result in reduced performance of the tool and over heating of the cord. Check the extension cord for damage at

regular intervals. Damaged extension cords must be

replaced.

Recommended minimum cross sections and max. cord

lengths:

Extension Cord Table

Volts Total Length of Cord inFeet

120 V 0–25 26– 50 51–100 101–150

240 V 0–50 51–100 101–200 201–300

Ampere Rating AWG

More Than Not More Than

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 Not recommended

Extension cords for outdoor use

For outdoor work use only extension cords approved and

correspondingly marked as suitable for outdoor use.

Pay attention at all times

Always concentrate on the job. Proceed carefully and do

not use the tool if you are distracted from your work.

6. Functional description

The WSC 267-E is an electrically powered hand-held tool

designed for the sawing of wood, plastics and composite

materials by professional users.

The following items are supplied: power tool with saw

blade, operating instructions, pivoting chip ejector and

toolbox.

6

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

8. Operation

-CAUTION-

I The cutting edges of the saw blade

are sharp.

I The cutting edges may present a risk

of injury.

I Wear protective gloves.

Page 12

-CAUTION-

I The sawing operation creates up dust

and wood chips.

I The dust and wood chips may be

harmful to the eyes and lungs.

I Wear protective goggles and respi-

ratory protection.

-CAUTION-

I Operation of the tool creates noise.

I Noise may damage the hearing.

I Wear ear protection.

System

G Always direct the tool away from the body when working.

G Lay the tool down only when the pivoting guard is

closed.

G Do not work overhead with the tool.

G Do not brake the saw blade by applying lateral pres-

sure.

G Use only saw blades in good condition in order to

achieve good cutting performance and to minimise wear

and tear on the tool.

G Use of the following is not permissible:

- Blunt saw blades

- Unsuitable saw blades

- Cracked saw blades

- Cutting discs (designed for use with angle grinders

etc.)

- Saw blades made from high-alloyed, high-speed

steel (HSS steel)

G Always disconnect the supply cord plug from the mains

socket before disassembling or adjusting the tool.

G Do not switch the tool on before it has been brought

into position where the cut is to be made.

G Do not overload the tool.

Cutting along a line

A cutting line indicator (0° / 22.5° / 45°), is located on

the front section of the baseplate of the tool. This permits

precise cuts to be made at the selected cutting angle. The

viewing grill provides a better view of the cutting line,

thus making it easier to check the progress of the cut.

If required, the cutting depth can be pre-set to any value

within the 0–65 mm (0–2

Best results will be obtained when the saw blade projects

approx. 5–10 mm (

5

/8″) depth range.

1

/4–1/2″) beyond the underside of the

workpiece.

G Check that the control switch on the tool is in the OFF

position.

G Connect the supply cord plug to the mains socket.

G Position the tool with the baseplate on the workpiece

so that the saw blade is not in contact with the workpiece.

G Switch the tool on by pressing the switch interlock

and the on/off switch.

G Guide the saw at a suitable speed through the workpiece while following the cutting line.

Mitre cuts

Adjusting the cutting angle

G Release both cutting angle clamping levers.

G Pivot the mechanism until the desired cutting angle

of 0°–45° is indicated by the cutting angle scale.

G Retighten both clamping levers.

G Make the cut while observing the cutting line indica-

tor at the front section of the baseplate.

Returning the saw to the 0° position

G Clean the baseplate to remove wood chips or other

foreign material from the pivoting section before returning the saw to its original position.

Plunge cutting

To reduce the risk of kick-back when starting a plunge

cut, a wooden batten or similar stop should be securely

fastened to the workpiece behind the rear of the tool

baseplate.

When cutting to the full depth, the length of the cut can

be checked at the plunge cut marks located on the baseplate.

G Check that the switch on the tool is in the OFF position.

G Connect the supply cord plug to the mains socket.

G Place the tool on a suitable surface.

G Release the cutting depth locking lever.

G Lift the tool by the grip. Use the pivoting guard man-

ual control to open the pivoting guard.

G Position the tool at the point where the plunge cut is

to be made.

G Switch on the tool by pressing the switch interlock

and the on / off switch and then plunge the blade into the

workpiece carefully until the cut has been made to the

desired length.

Setting the cutting depth

The cutting depth can be set to any value within the 0–

65 mm (0–2

5

/8″) range.

G Place the tool on a suitable suface.

G Release the cutting depth adjusting lever.

G Lift the tool as far as it will go and lock in position at

the maximum height.

G Adjust the cutting depth by releasing the screw, moving along the scale to the desired position and then fixing the cutting depth at this point.

G Release the cutting depth locking lever and return the

tool to the pre-set height.

Except when plunge cutting it is advisable, for safety reasons, to lock the cutting depth at this height. Nevertheless, as deviations may occur due to various factors (e.g.

worn or resharpened saw blade etc.), it is recommended that the cutting depth is checked again exactly before

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

7

Page 13

beginning sawing by measuring the projection of the saw

blade from the baseplate.

Constant speed electronics / speed pre-selection

The WSC 267-E is equipped with constant speed electronics.

The speed regulator can be used to adjust the speed of

the saw blade to any value within the 2200–4300 r.p.m.

range. The numbers on the speed regulator represent the

following approximate saw blade speeds:

1 2200 r .p.m.

2 2600 r .p.m.

3 3000 r .p.m.

4 3500 r .p.m.

5 3900 r .p.m.

6 4300 r .p.m.

The built-in constant speed electronics maintain the preselected speed at an almost constant level even when the

tool is under load. The recommended speeds and information concerning choice of the correct saw blade can

be found in the product information and corresponding

table of applications.

Smooth starting

The tool is equipped with a starting current limitation

device which ensures optimum working comfort. The

tool thus starts and runs up to speed without an unpleasant jolt.

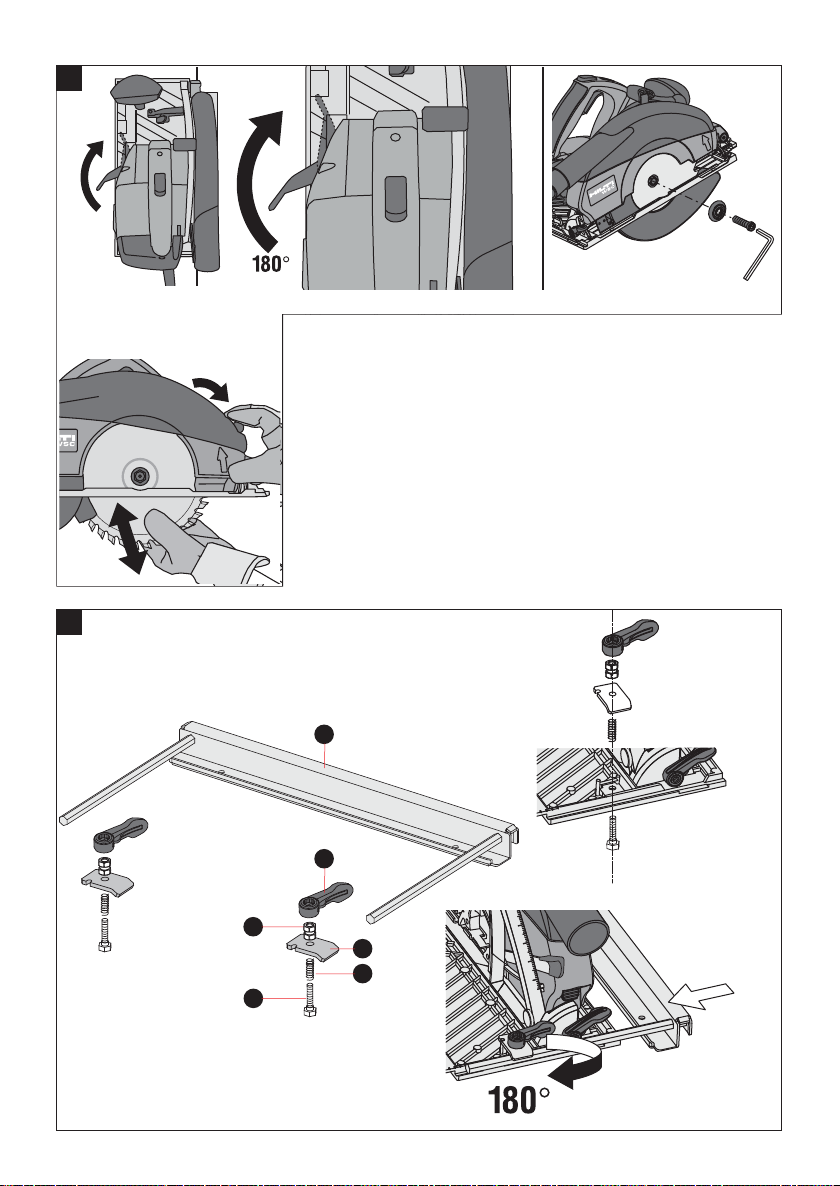

Changing saw blades without the use of tools

-CAUTION-

I The saw blade becomes hot when

used for long periods.

I There is a risk of burning if the blade

is touched.

I Wear protective gloves.

G Disconnect the supply cord plug from the mains socket.

G Place the tool on its baseplate, on a suitable surface.

G Open the clamping lever as far as it will go.

G Tip the tool onto the supporting rib provided at the

motor side, so that the saw blade faces upwards and is

easily accessible.

G Release the clamping sccccrew and clamping flange

by turning in a counter-clockwise direction.

G Use the manual control to swing the pivoting guard

back and remove the saw blade.

G Clean the saw blade contact surfaces to remove wood

chips and other foreign material.

G Check again that the data for the saw blade complies

with the information given in these operating instructions.

G The saw blade must meet the specification for the tool

with regard to spindle speed, spindle size and shape, disc

core thickness, kerf width and blade diameter.

Use of other saw blades is not permissible.

G When fitting the new saw blade, take care to ensure

that the direction of rotation arrow on the saw blade corresponds to the direction of rotation arrow on the guard.

G Check that the saw blade is seated correctly.

G Use the wrench included to tighten the clamping screw

and flange securely in a clockwise direction.

G Stand the tool on its baseplate.

G Bring the clamping lever back to its original position.

The following design aspects were incorporated in the

tool for more safety when changing saw blades:

G The clamping lever cannot be opened when the switch

interlock is depressed, i.e. when the tool is running.

G The switch interlock cannot be depressed when the

clamping lever is open, i.e. the tool cannot be started.

G Do not attempt to overcome the interlock by using

tools or applying excessive force.

9. Care and maintenance

Care

G Used saw blades should be cleaned to remove resin

deposits at regular intervals as clean blades achieve a

much higher cutting performance. Resin deposits can

be removed by placing the saw blades in a bath of petroleum (paraffin, kerosene) or commercially available resin

remover.

G Carbide-tipped circular saw blades

must no longer be used when the

remaining height or thickness of the

brazed-on tips is less than 1 mm

1

(

/16″).

G The tool was lubricated adequately when it was manufactured. After long periods of heavy use, it is recommended that the tool is inspected at a Hilti repair center.

This will increase the life expectancy of the tool and avoid

unnecessary repair costs.

G Repairs to the electrical section of the tool may be carried out only by a trained electrical specialist.

CAUTION

Keep the power tool, especially its grip surfaces, clean

and free from oil and grease. Do not use cleaning

agents which contain silicone.

The outer casing of the power tool is made from impactresistant plastic. Sections of the grip are made from a

synthetic rubber material.

Never operate the power tool when the ventilation slots

are blocked. Clean the ventilation slots carefully using

a dry brush. Do not permit foreign objects to enter the

interior of the power tool. Clean the outside of the power tool at regular intervals with a slightly damp cloth. Do

1/16″

1/16″

8

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

Page 14

not use a spray, steam pressure cleaning equipment or

running water for cleaning. This may negatively affect

the electrical safety of the power tool.

Maintenance

Regularly check all external parts of the tool for damage

and check that all controls operate faultessly. Don’t operate the tool when parts are damaged or when the controls do not function faultessly. Have your tool repaired

by a Hilti service center.

Repairs to the electrical selections of the tool may be

carried out only by trained electrical specialists.

10. Accessories

Guides

Sawing using the parallel guide

G The parallel guide (accessory) is used to make precise

cuts along the edge of the workpiece, thus making it possible to cut strips of even width. In addition, it can be

used as an extension to the saw baseplate.

Fitting the parallel guide

G When fitting the parallel guide, better access can be

achieved by releasing the cutting depth locking lever and

raising the tool as far as it will go. The locking lever should

then be re-engaged to lock the tool at its maximum height.

G Insert the hex. screws through the holes in the baseplate from the contact surface side so that the threaded

sections of the screws are visible from above

G Place the pressure springs and then the clamping

plates on the screws.

G Screw the hex. nuts onto the screws. Do not tighten

the nuts.

G Slide the rods of the parallel guide into the guide channels provided in the baseplate until they are under the

clamping plates.

G Tighten the hex. nuts by hand until they are free of play.

G Push the clamping lever onto the hex. nut while press-

ing the tab located on the inside of the lever. This should

be done so that the concave surface of the lever faces to

the right and the hex. nut is thus tightened when the

clamping lever is brought into the closed position.

G The parallel guide can now be fixed in position by turning the clamping levers. If a secure hold cannot be obtained

by turning the clamping levers, the clamping levers should

be removed from the nuts, repositioned, and then re-tightened. The clamping levers can be removed by pressing

the tab positioned on the inside of the lever. Replace the

clamping levers as previously described (at the outset position or in the middle, depending on the clamping movement necessary) and then tighten the levers securely.

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

G The parallel guide can be removed at any time by releasing the clamping levers (the clamping levers and other

clamping parts may remain attached to the tool).

Using the parallel guide

G Release both clamping levers.

G Slide the guide to the desired position (dimension)

G Tighten the clamping levers securely.

The cutting dimension between the circular saw blade

and the parallel guide can be pre-set by making use of

the two notches in the guide rods and the corresponding scale. The parallel guide can be fitted on either side

of the baseplate. When reversed (edge of the guide facing upwards), the parallel guide serves as an extension

to the baseplate.

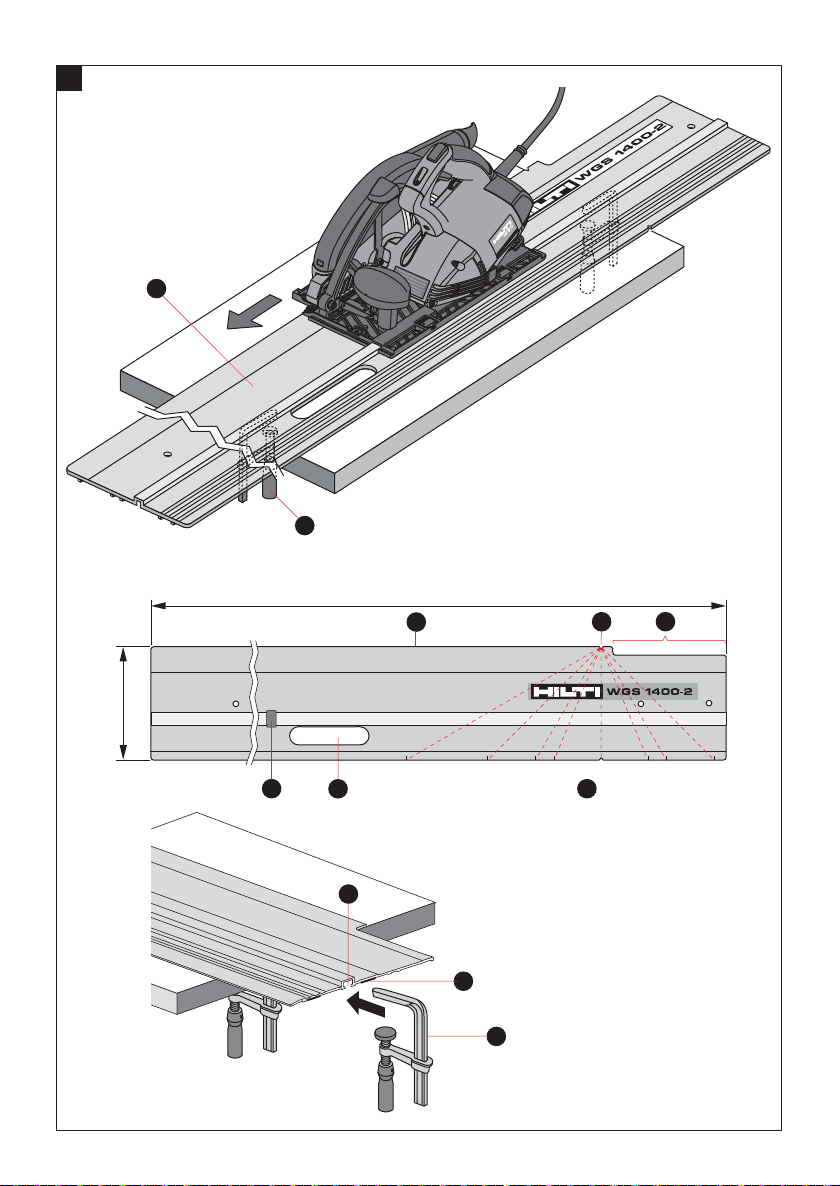

Sawing using the guide rail

The guide rail is designed for making precise mitre cuts

at up to 45° and cuts across the surface of the workpiece at angles of up to 60°. The guide rail must be in

faultless condition in order to ensure good results. The

non-slip strips located on the underside prevent the rail

slipping out of position and also protect the surface of

the workpiece. It is, however, recommended that screw

clamps are used to secure the guide rail. All parts are

manufactured from materials which ensure smooth operation. The cut is made approx. 1 mm from the edge of

the rail at all angle settings. Use of the guide rail reduces

the set cutting depth by approx. 5 mm. The tool must

be placed on the guide rail so that the rail profile and the

channel in the baseplate of the tool correspond and thus

provide a smooth guide. Two adjustable play compensators are provided on the baseplate of the circular saw.

These can be used to adjust play between the circular

saw and the guide rail, thus ensuring optimum guidance.

Cutting / trimming

G Use two screw clamps fitted from below to attach the

rail so that the section of the rail for positioning the tool

projects beyond the workpiece.

G Position the tool on the corresponding section of the

guide rail and ensure that the saw blade is not in contact

with the workpiece.

G Switch the tool on and slide it evenly towards the workpiece. The pivoting guard opens when it contacts the

edge of the rail and closes again when the saw is pushed

off the far end of the guide rail.

Cuts at an angle across the surface of the workpiece

G Position the guide rail with the zero mark at the edge

of the workpiece and pivot the rail until the desired angle

shown on the angle scale is opposite zero.

G Use two screw clamps to secure the guide rail in this

position and then make the cut as described above. The

cutting angle indicated is the angle of deviation from a

straight, right-angled cut.

Plunge cutting

G Use two screw clamps to fasten the guide rail to the

workpiece.

9

Page 15

G Lock the tool at the maximum cutting height position

and use the manual control to open the pivoting guard.

G Place the tool on the guide rail, taking care to ensure

that the baseplate lies flat on the rail.

G Use the stop piece to increase safety when making the

plunge cut. It should be fixed in position at the rear edge

of the baseplate so that the rear plunge cut mark on the

circular saw coincides with the point at which the cut is

to begin.

G Set the cutting depth to maximum depth unless a predefined cutting depth is required.

G Switch the tool on and plunge the blade evenly into

the workpiece.

External dust and chip extraction

Extraction of dust and chips reduces the amount of dust

in the working environment and helps to keep the workplace clean. Connect the external extraction system when

you are using the saw for a long period or when working with materials which produce harmful dust when cut.

The hand-held circular saw is equipped with a hose connector suitable for use with conventional extraction hoses

with a diameter of ≥ 27 mm (1

3

/8″). The direction of chip

ejection can be selected simply by turning the pivoting

chip ejector until it engages in the desired position.

Cleaning the chip ejection channel

G Ensure that the tool is disconnected from the mains

socket.

G Press the plastic tab on the rear lower side of the guard

and remove the guard.

G Clean the chip ejection channel in the guard and then

replace the guard, ensuring that the plastic tab is engaged.

Ensure that only a safety vacuum cleaner of the “M” class

(wood) is used and that its equipment is of the anti-static type. We recommend use of the Hilti WVC 40-M safety vacuum cleaner.

11. Manufacturer's warranty – tools

Hilti warrants that the tool supplied is free of defects

in material and workmanship. This warranty is valid so

long as the tool is operated and handled correctly,

cleaned and serviced properly and in accordance with

the Hilti Operating Instructions, and the technical system is maintained. This means that only original Hilti

consumables, components and spare parts may be

used in the tool.

This warranty provides the free-of-charge repair or

replacement of defective parts only over the entire lifespan of the tool. Parts requiring repair or replacement

as a result of normal wear and tear are not covered by

this warranty.

Additional claims are excluded, unless stringent

national rules prohibit such exclusion. In particular,

Hilti is not obligated for direct, indirect, incidental

or consequential damages, losses or expenses in

connection with, or by reason of, the use of, or inability to use the tool for any purpose. Implied warranties

of merchantability or fitness for a particular purpose

are specifically excluded.

For repair or replacement, send tool or related parts

immediately upon discovery of the defect to the address

of the local Hilti marketing organization provided.

This constitutes Hilti's entire obligation with regard to

warranty and supersedes all prior or contemporaneous comments and oral or written agreements concerning warranties.

10

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

Page 16

12. Disposal

Most of the materials from which Hilti power tools are manufactured can be recycled. The materials must be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for taking

back your old electric tools for recycling. Please ask your Hilti customer service department or Hilti sales representative for further information.

Should you wish to return the electric tool yourself to a disposal facility for recycling, proceed as follows: Dismantle

the tool as far as possible without the need for special tools. Use absorbent paper to wipe lubricated parts clean

and to collect the grease that runs out (total quantity approx. 50 ml). This paper should also be disposed of correctly. On no account should grease be allowed to enter the waste water system or to find its way into the

ground.

The individual parts should be separated as follows:

Part / assembly Main material Recycling

Toolbox Plastic Plastic

Outer casing Plastic / elastomer Plastic

Gear housing, baseplate,

hoop Magnesium Scrap metal

Grip Plastic Plastic

Electronics module and switch Various Electronics scrap

Fan Plastic Plastic

Motor (rotor and stator) Steel and copper Electronic scrap

Supply cord Copper, elastomer sheath Electronic scrap

Gearing parts Steel Scrap metal

Screws, small parts Steel Scrap metal

Guide rail Aluminium Scrap metal

13. Troubleshooting

Symptom Possible cause Possible solution

The tool doesn’t start Fault in the electric power supply Plug in another electric tool and

check whether it starts.

Defective supply cord or plug Have it checked by an electric

specialist and replace if necessary.

Switch defective Have it checked by an electric

specialist and replace if necessary.

Tool doesn’t provide full Cross-section of the Use an extension cord of adequate

power extension cord is inadequate cross-sectional.

See section «Preparation for use»

Speed preselection thumbwheel Set the speed preselection thumbweel

is not set to position 6 to position 6

Blade clamping nut cannot Lever not moved the full distance With the blade clamping lever opened

be released when the blade was changed as far as it will go, use a suitable

previously, or contrary to wrench to release the clamping nut.

instructions, a tool was used to The clamping nut should be tightened

tighten the clamping nut. by hand only.

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

11

Page 17

Hilti Corporation

LI-9494 Schaan

Tel.:+423 / 234 21 11

Fax: +423/2342965

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan W 2530 0608 00-Pos. 3 1 Printed in Liechtenstein © 2008

Right of technical and programme changes reserved S. E. & O.

Printed: 07.07.2013 | Doc-Nr: PUB / 5071326 / 000 / 00

304422 / D

*304422*

304422

Loading...

Loading...