Page 1

UH240-A

*000000*

000000

Bedienungsanleitung de

Operating instructions en

Hilti Corporation

FL-9494 Schaan

Tel.: +423/ 2342111

Fax: +423 /2342965

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan W 0000 0403 0,5-Pos. 1 1 Printed in Liechtenstein © 2003

Right of technical and programme changes reserved S. E. & O.

000000/A

Page 2

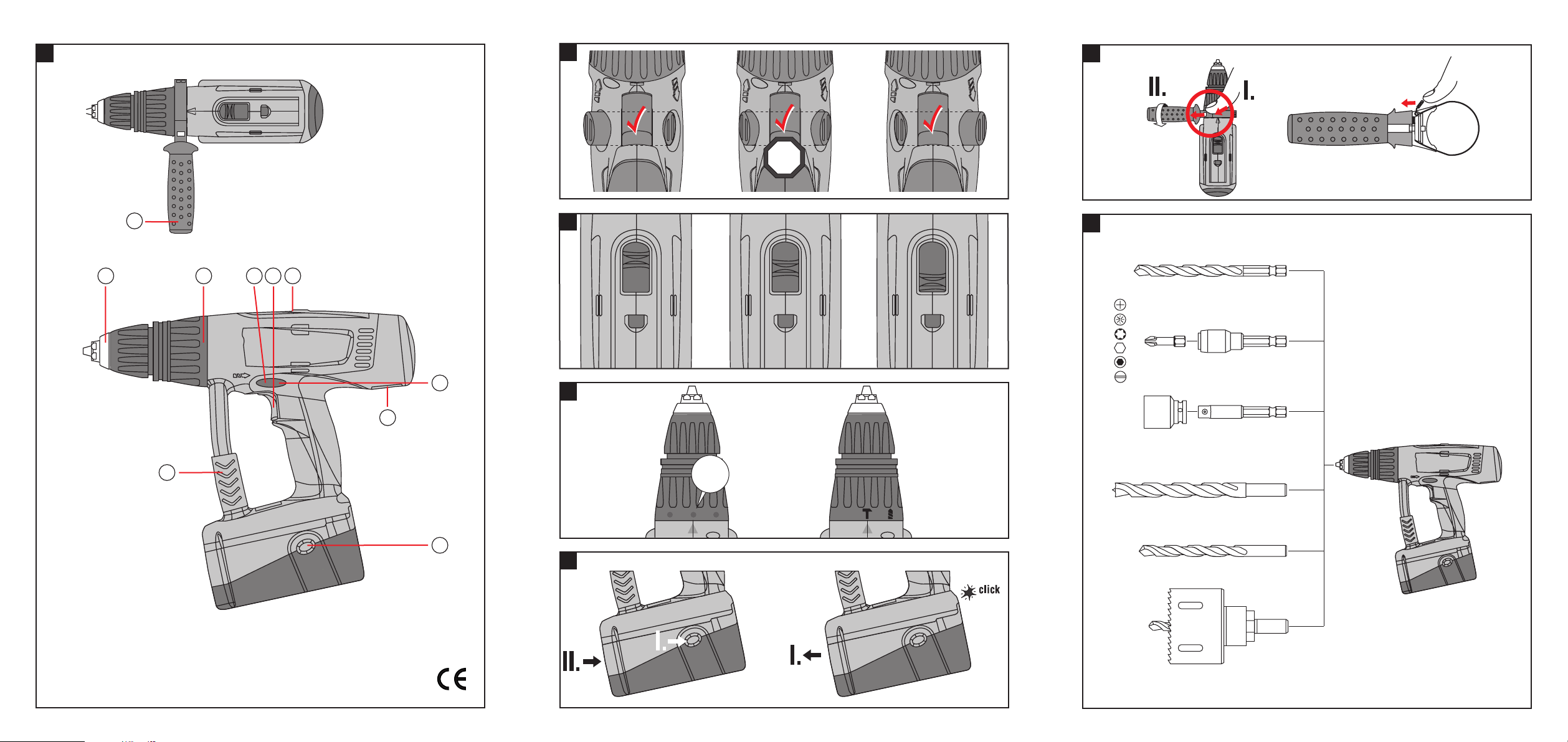

1

1

2

L

R

6

STOP

2

3 6

4 51

7

3

1

2

3

7

4

1

8

10

5791

1-15

15

9

5

Page 3

11

en

It is essential that the operating instructions

are read before the tool is operated for the

first time.

Always keep these operating instructions

together with the tool.

Ensure that the operating instructions are with

the tool when it is given to other persons.

UH240-A cordless hammer drill

1. General information

1.1 Signal words and their meaning

-CAUTION-

Used to draw attention to a potentially dangerous situation which could lead to minor personal injury or damage

to the equipment or other property.

-NOTE-

Used to draw attention to an instruction or other useful

information. Not used for dangerous situations or where

damage to the equipment or property could occur.

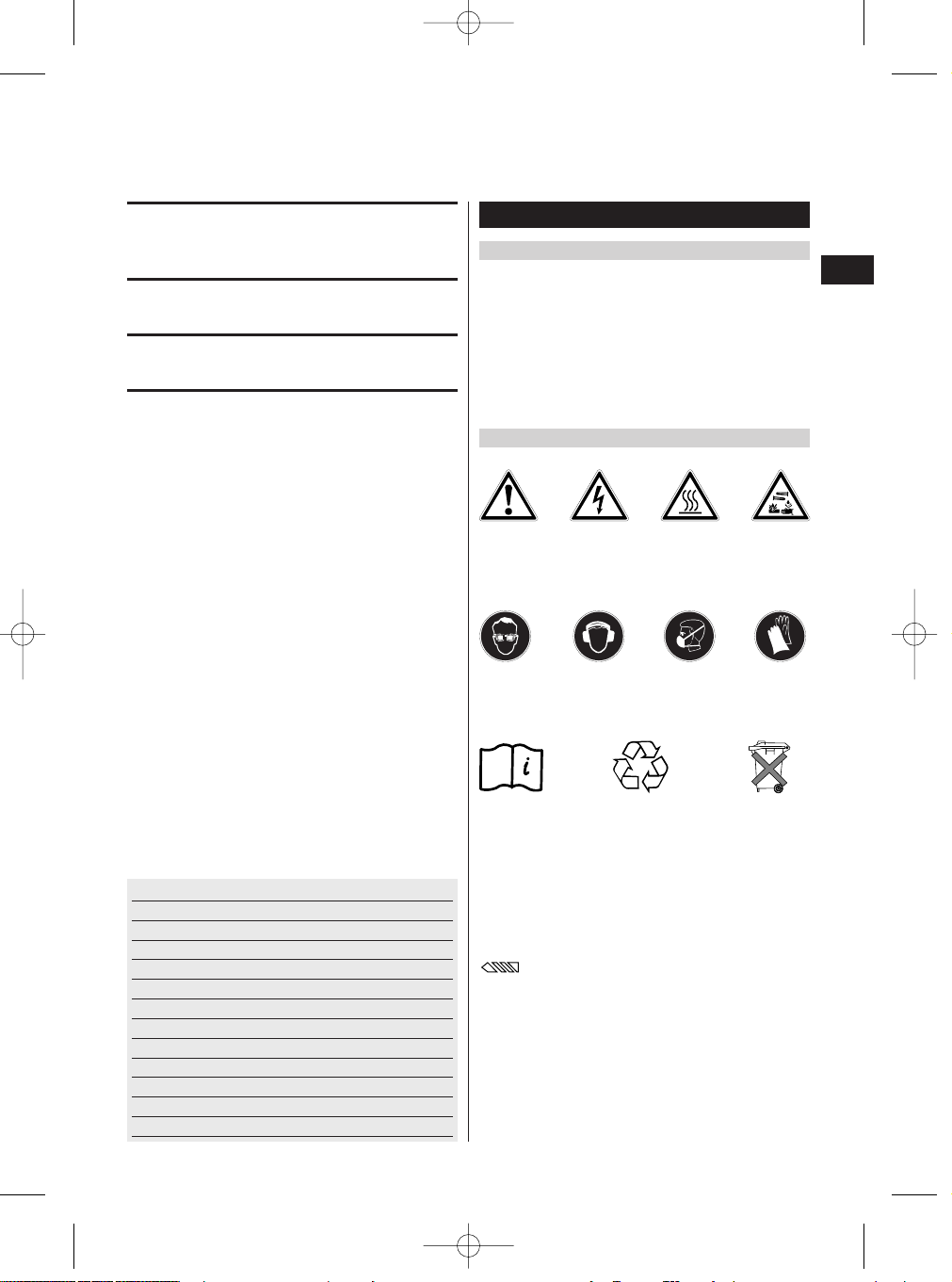

1.2 Pictograms

Contents Page

1. General information 11

2. Description 12

3. Accessories 12

4. Technical data 13

5. Safety precautions 13

6. Before use 15

7. Operation 16

8. Care and maintenance 17

9. Troubleshooting 18

10. Disposal 18

11. Warranty 19

12. Declaration of conformity 19

Operating controls and parts

Quick release clutch

Side handle

Torque clutch setting ring

Forward / reverse switch

Control switch

(with electronic speed control)

3-speed gear selector switch

Motor brake

Rating plate

Battery release buttons (2)

Bit box

These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover

pages. Keep these pages open while studying the operating instructions.

In these operating instructions, the UH 240-A cordless

hammer drill with battery fitted is referred to as “the tool”.

Warning signs

General

warning

Warning:

electricity

Warning:

caustic

substances

Obligation signs

Wear

breathing

protection

Wear

ear

protection

Wear

protective

gloves

Wear

eye

protection

Warning:

hot surface

Symbols

Read the

operating

instructions

before use

Return waste material for

recycling

Do not dispose of

batteries with

general refuse

V= volts

–––

- - -

= direct current

n

o = no load speed

/min = revolutions per minute

j = hammer drilling

= rotation only

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 11

Page 4

12

en

2. Description

The UH 240-A is a cordless hammer drill for professional

use.

The tool is suitable for use by right or left-handed

persons. The ergonomically designed rubber-padded

grip reduces fatigue and is designed to provide a secure

hold.

The items supplied include: Electric tool with side handle,

3 bits and magnetic bit holder, two B24/2.0 NiCd, B24/2.4

NiCd or B24/3.0 NiMH batteries, C 7/24, C 7/36-ACS or

TCU 7/36 charger in toolbox or cardboard box.

2.1 Correct use

The UH 240-A is hand-held cordless hammer drill for

driving and removing screws, drilling in steel, wood and

masonry and hammer drilling in masonry only.

It is intended for use on construction sites of all kinds

for general construction, interior finishing, conversion

and renovation work.

● The tool may be used only in a dry environment.

● Do not use the tool where there is a risk of fire or explo-

sion.

● Use only the insert tools and accessories intended for

use with this tool.

● The tool may be powered only by the batteries approved

for use with this tool.

● Do not use the batteries as a power source for other

equipment.

● Use only the recommended battery charger.

● Modification or manipulation of the tool other than

described in these operating instructions is not permissible.

● To avoid the risk of injury, use only original Hilti acces-

sories and additional equipment.

● Observe the information printed in the operating instruc-

tions concerning operation, care and maintenance.

● The tool and its ancillary equipment may present ha-

zards when used incorrectly by untrained personnel

or when used not as directed.

2.2 Important features of the tool

– Vibration-absorbing grip (rubber-padded)

– Smooth speed control

– Gearing and clutch with permanent lubrication

(grease)

– Automatic cut-out carbon brushes

– Forward / reverse rotation

3. Accessories

Magnetic bit holder S-BH 50M

Bits EU USA

Pozidrive S-B PZD 3T 2 Phillips S-B PH 3×2″

Torx S-B TX 30T 1 Phillips S-B PH SQ2

Torx S-B TX 40

Charger C 7/24

Charger C 7/36-ACS

Charger TCU 7/36

Battery B24/2.0 NiCd, B24/2.4 NiCd or B24/3.0 NiMH

Toolbox / cardboard box

Belt adaptor BAP 24

Dust shield

Location of identification data on the tool

The type designation, item number, year of manufacture

and technical status can be found on the rating plate on

the tool. The serial number is located on the left side of

the motor housing. Make a note of this data in your operating instructions and always refer to it when making

an enquiry to your Hilti representative or service department.

Type:

Serial no.:

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 12

Page 5

13

en

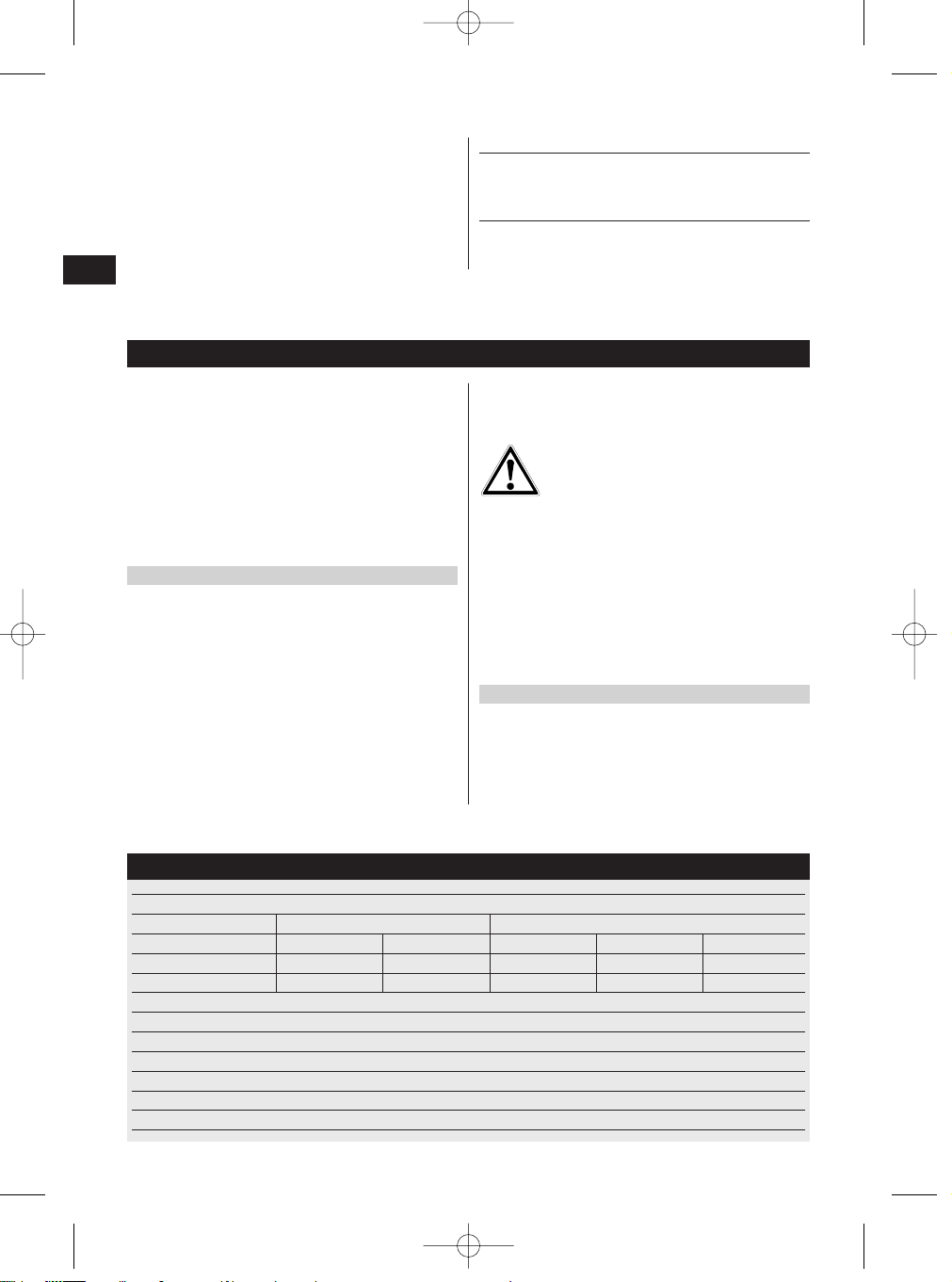

4. Technical data

Tool

Rated voltage 24 V

–––

- - -

Weight of tool including battery and chuck 3.8 kg

Dimensions (L×H×W) 320×286×92 mm

Speed 1

st

gear: 0– 350 r.p.m.

2

nd

gear:0– 1300 r.p.m.

3rdgear: 0– 1950 r.p.m.

Chuck / clamping dia. range (quick-release chuck) 1.5–13 mm

Torque Max. 45 Nm (at drilling setting)

Torque adjustment 5–17 Nm (in 15 increments)

Speed control Electronic control switch

Forward / reverse Electrical switch with interlock to prevent activation

when running

Spindle lock When control switch is in the “off” position

Motor brake By way of the control switch

Gearing section sealed to prevent entry of dust and with permanent lubrication (maintenance-free)

Noise and vibration information (measured in accordance with EN 50260):

Typical A-weighted noise power level: 104 dB (A)

Typical A-weighted noise pressure level: 93 dB (A)

Wear ear protection!

Typical weighted vibration at the grips: 7 m/s

2

Battery B24/2.0 NiCd B24/2.4 NiCd B24/3.0 NiMH

Rated voltage 24 V

–––

- - -

24 V

–––

- - -

24 V

–––

- - -

Battery capacity 24 V × 2.0 Ah 24 V × 2.4 Ah 24 V × 3.0 Ah

= 48 Wh = 58 Wh = 72 Wh

Weight 1.38 kg 1.38 kg 1.45 kg

Temperature monitoring yes yes yes

Type of cell Nickel-cadmium Nickel-cadmium Nickel-metal hydride

SUB C type SUB C type SUB C type

No. of cells 20 20 20

Right of technical changes reserved!

5. Safety precautions

5.1 Basic information concerning safety

In addition to the information relevant to safety given in

each of the sections of these operating instructions, the

following points must be strictly observed at all times.

CAUTION! To reduce the risk of fire, battery leakage and

personal injury, the following basic safety precautions

must be observed when battery-powered tools are used:

Read all these instructions before operating this product

and save these instructions.

5.2 Take the necessary precautions to make the

workplace safe

● Ensure that the workplace is well lit.

● Ensure that the workplace is well ventilated.

● Keep the workplace tidy. Objects which could cause

injury should be removed from the working area. Untidiness at the workplace can lead to accidents.

● Use clamps or a vice to secure the workpiece.

The workpiece is thus held more securely than by

hand and both hands remain free to operate the

tool.

● Wear goggles and wear breathing protection during

jobs that create dust.

● Use the dust shield (accessory) to protect the chuck

when drilling overhead.

● Do not wear loose clothing, loose long hair or jewelry

as these can become caught up in moving parts. Wear

suitable headgear if you have long hair.

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 13

Page 6

14

en

● Wear non-slip shoes or boots and always ensure that

you have a secure stance.

● When working, keep other persons, particularly chil-

dren, outside the range of the tool.

● Do not permit other persons to touch the tool.

● Avoid unfavorable body positions when working. Work

from a secure stance and always stay in balance.

● Concealed electric cables or gas and water pipes pre-

sent a serious hazard if damaged while you are working.

Accordingly, check the area in which you are working

beforehand (e.g. using a metal detector). Avoid contact between your body and earthed / grounded objects,

such as pipes or radiators. External metal parts of the

tool may become live, for example, when an electric

cable is drilled into inadvertently.

5.3 General safety precautions

● Use the right electric tool for the job. Do not use the

tool for purposes for which it was not intended. Use

the tool only as directed and when it is in faultless condition.

● Avoid contact with rotating parts.

● Use only the original accessories or ancillary equip-

ment listed in the operating instructions. Use of other

insert tools or accessories may present a risk of personal injury.

● Take the influences of the surrounding area into account.

Do not expose the tool to rain or snow and do not use

it in damp or wet conditions. Do not use the tool where

there is a risk of fire or explosion.

● Keep the grips dry, clean and free from oil and grease.

● Do not overload the tool. It will work more efficiently

and more safely within its intended performance range.

● The side handle must be fitted for all types of work.

● The tool may be used hand-held only.

● Always hold the tool with both hands on the grips pro-

vided.

● Operate the tool only as directed and only when it is in

faultless condition.

● The battery should be removed from the tool when

the tool is not in use, before work breaks, before maintenance, before changing insert tools and before transport.

● Avoid unintentional starting. Do not carry the tool with

your finger on the on/off switch.

● Disconnect the tool from its battery pack when the tool

is not in use, during pauses between work, before maintenance, when changing bits and during transport.

● Take care of your insert tools. You will be able to work

more efficiently and more safely if the insert tools are

kept sharp and clean. Observe instructions on care and

maintenance and on changing insert tools.

● Check the electric tool for possible damage. Protec-

tive devices and any parts that may have suffered slight

damage should be checked for correct operation and

functionality before further use of the electric tool.

Damaged safety devices or other damaged parts should

be replaced or repaired properly by an authorized repair

workshop unless otherwise indicated in the operating instructions.

● The tool may be operated only when the bit box is

closed.

● Do not insert wires or other similar objects into the

ventilation slots.

5.3.1 Mechanical hazards

● Check that wrenches etc. have been removed from

the tool before switching it on.

● Follow the instructions concerning care and mainte-

nance.

● Check that the insert tools used are compatible with

the chuck system and that they are secured in the chuck

or gear housing correctly.

● Check that moving parts function faultlessly and that

they are not sticking or damaged. All parts must be

correctly fitted and fulfil all requirements in order to

ensure that the tool operates faultlessly.

● Use only original Hilti insert tools.

5.3.2 Electrical hazards

● Protect yourself against electric shock. Avoid body

contact with earthed / grounded objects, e.g. pipes,

radiators, cookers and fridges.

● Check the condition of the tool. Do not operate the tool

if it is found to be damaged, if it is not complete or if

its controls cannot be operated faultlessly.

● Damaged switches must be replaced at a Hilti service

center. Do not use the tool if it cannot be switched off

and on properly.

● The tool may be repaired by trained electrical specialists

only (Hilti service) using original Hilti spare parts. Failure to observe this point may present considerable risk

to the user.

● Never operate the tool when it is dirty or wet.

● Avoid short circuiting the battery terminals. A short

circuit may cause a fire.

● Ensure that the battery contacts cannot be short circuited

by other metal objects such as screws or nails etc.

● Ensure that the outer surface of the battery is clean

and dry before inserting the battery in the appropriate charger for charging.

● Use only the batteries listed in these operating instructions.

● Check that the battery is securely attached to the tool.

A falling battery could injure you or other persons.

● Batteries that have reached the end of their life must

be disposed of safely.

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 14

Page 7

15

en

6. Before use

● Ensure that batteries are charged using the correct

charger recommended by the manufacturer. Incorrect

use may result in a risk of electric shock, overheating

or leaking of corrosive liquid from the battery.

5.3.3 Thermal hazards

● The insert tool may become hot during use. You should

therefore wear protective gloves when changing insert

tools.

5.3.4 Liquids

● A caustic liquid may leak from defective batteries. Avoid

contact with this liquid. In the event of contact with the

skin, wash the area affected with soap and plenty of

water. Should the liquid come into contact with the

eyes, flush the eyes with water immediately and subsequently consult a doctor.

5.4 Requirements to be met by users

● The tool is intended for professional use.

● The tool may be operated, serviced and repaired only

by authorized, trained personnel. This personnel must

be informed of any special hazards that may be encountered.

● Always concentrate on the job you are doing. Proceed

carefully and do not use the tool if your full attention

is not on the job.

5.5 Personal protective equipment

● The operator and other persons in the immediate vicin-

ity must always wear eye protection, ear protection

and breathing protection while the tool is in use.

1. It is essential that the safety precautions printed in

these operating instructions are read and observed.

2. It is essential that a new battery is charged correctly

before initial use so that the battery cells can form

correctly. Incorrect initial charging can lead to a permanent reduction of battery capacity.

– With the C 7/24 or TCU 7/36 charger: Charge for 24

hours in normal charging mode or for 12 hours in

conditioning mode.

– With the C 7/36-ACS charger: The charger detects

automatically whether initial charging or normal

charging is necessary.

-NOTE-

● The tool may be used only with B24/2.0 NiCd, B24/2.4

NiCd or B24/3.0 NiMH batteries.

● Battery performance drops at low temperatures.

● Batteries should be stored at room temperature.

● Never store batteries where they are exposed to the

heat of the sun, on a radiator, behind a motor vehicle

windscreen or at a window.

● Never use the battery until the cells become fully dis-

charged. Change to the second battery as soon as a

drop in performance is noticed and recharge the battery immediately so that it is ready for re-use.

● Use bits with a standard

1

/4″ hex. shank.

6.1 Fitting the side handle

1. Open the side handle clamping band by turning the

handle.

2. Slide the side handle clamping band over the chuck

and onto the tool.

3. Pivot the side handle into the desired position.

4. Secure the side handle by turning the handle.

Wear

breathing

protection

Wear

ear

protection

Wear

protective

gloves

Wear

eye

protection

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 15

Page 8

16

en

7. Operation

-CAUTION-

● The screwdriving procedure may

cause the material to splinter.

● Splintering material may cause injury

to the body, respiratory passages and

the eyes.

● Wear eye and breathing protection.

-CAUTION-

● Noise is emitted by the tool and the

screwdriving or drilling procedure.

● Excessive noise may damage the

hearing.

● Wear ear protection.

7.1 Setting forwards or reverse rotation

The direction of rotation can be selected by operating the

forward / reverse push switch . An interlock prevents

operation of the switch while the motor is running. When

in the middle position, the on / off switch is locked.

– Forwards rotation: Push the forward / reverse switch

to the right (as seen from the direction in which the

tool is used).

– Reverse rotation: Push the forward / reverse switch

to the left (as seen from the direction in which the tool

is used).

7.2 Setting the speed (3-speed gear selector switch)

-CAUTION-

Operate the gear selector switch only when rotation has

stopped.

1. Set the switch to position 1 for a speed range of 0–400

r.p.m., position 2 for a speed range of 0–1200 r.p.m.

or position 3 for a speed range of 0–2000 r.p.m.

7.3 Screwdriving

1. Set the desired direction of rotation by way of the forward / reverse switch.

7.3.1 Torque setting

1. Set the torque by turning the torque clutch setting

ring to the desired torque setting(1–15).

7.4 Hammer drilling

1. Turn the torque clutch setting ring to the hammer

drilling symbol.

-CAUTION-

Take care to avoid pinching the fingers between the chuck

and setting ring.

7.5 Drilling

1. Turn the torque clutch setting ring to the drilling symbol.

-CAUTION-

A high torque is experienced if the insert tool sticks while

drilling with large-diameter drill bits and hole saws.

Accordingly, use the side handle and hold the tool with

both hands (one hand on the grip and one hand on the

side handle).

7.6 Switching on and off

Should a sticking drill bit cause the motor to stall for

longer than 2–3 seconds, the tool must be switched off

in order to avoid damage to it.

1. Use the forward / reverse switch to select the direction of rotation.

2. The speed of the tool can be controlled smoothly

between zero and maximum by pressing the on / off

switch slowly.

7.7 Removing the battery (2-finger operation)

1. Press in both release buttons.

2. Pull the battery downwards out of the tool.

7.8 Fitting the battery

Use only Hilti B24/2.0 NiCd, B24/2.4 NiCd or B24/3.0

NiMH batteries.

1. Push the battery into the tool from below until it is

heard to engage.

7.9 Charging the battery

The battery cannot be charged through the belt adaptor.

Use only the Hilti C 7/24, C 7/36-ACS or TCU 7/36 chargers.

Incorrect use may lead to electric shocks, overheating

of the battery or leakage of a caustic liquid from the battery.

Read the operating instructions for the charger before

beginning charging.

7.10 Changing the insert tool

-CAUTION-

● The insert tool may become hot dur-

ing use.

● There is a risk of burning the hands.

● Wear protective gloves when chang-

ing insert tools.

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 16

Page 9

17

en

8. Care and maintenance

8.1 Care of insert tools

Remove any dirt adhering to the surface of the insert

tools and protect them from corrosion by rubbing them

with an oily cloth from time to time.

8.2 Care of the tool

Before cleaning, remove the battery from the tool in order

to prevent inadvertent starting.

The outer casing of the tool is manufactured from impactresistant plastic. The grip comprises a synthetic rubber

section.

The ventilation slots must be unobstructed and kept clean

at all times. Use a dry brush to clean the ventilation slots

carefully. Do not permit foreign objects to enter the interior of the tool. Use a slightly damp cloth to clean the outside of the tool at regular intervals. Do not use a spray,

steam-cleaning system or running water for cleaning.

This may negatively affect the electrical safety of the tool.

Always keep the grip sections of the tool free from oil

and grease. Do not use cleaning agents or polishes, etc.

containing silicone.

8.3 Maintenance

Check all external parts of the tool for damage at regular

intervals and check that all controls operate faultlessly.

Do not operate the tool when parts are damaged or when

the controls do not operate faultlessly. If necessary, have

the tool repaired at a Hilti service center.

Electrical parts of the tool may be repaired only by trained

electrical specialists.

8.4 Care of the battery

Keep the electrical contacts free from dust, oil and grease.

If necessary, use a clean cloth to clean the contact surfaces.

Do not continue to operate the tool until the battery is

completely discharged as this may damage the battery

cells. Recharge the battery as soon as a drop in performance is noticed.

At monthly intervals or, at the latest, when battery capacity drops significantly, the battery should be conditioned

as follows:

– With the C 7/24 or TCU 7/36 charger: Charge for 24

hours in normal charging mode or for 12 hours in conditioning mode.

– With the C 7/36-ACS charger: The charger detects

automatically whether initial charging or normal charging is necessary.

If, after conditioning, battery capacity is still unsatisfactory, we recommend returning the battery to Hilti for diagnosis.

8.5 Checking the tool after care and maintenance

After carrying out care and maintenance work on the tool,

check that all protective and safety devices are fitted and

that they function faultlessly.

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 17

Page 10

18

en

10. Disposal

Most of the materials from which Hilti power tools are manufactured can be recycled. The materials must be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for taking

back your old electric tools for recycling. Please ask your Hilti customer service department or Hilti sales representative for further information. Should you wish to return the electric tool yourself to a disposal facility for recycling, proceed as follows: Dismantle the tool as far as possible without the need for special tools. Use absorbent

paper to wipe greasy parts clean and collect any grease that runs out. This paper should also be disposed of correctly. On no account should grease be allowed to enter the waste water system or find its way into the ground.

Separate the individual parts as follows:

Part / assembly Main material Recycling

Toolbox Plastic Plastics recycling

Outer casing Plastic / synthetic rubber Plastics recycling

Electronic switch Various Electronics scrap

Motor Steel, copper Scrap metal

Gearing parts Steel Scrap metal

Battery Nickel-cadmium *

Nickel-metal hydride

Screws, small parts Steel Scrap metal

* Return waste material for recycling.

** Dispose of the battery in accordance with national regulations or return used

* ** batteries to Hilti for recycling.

Fault Possible cause Remedy

Tool doesn‘t run Battery is discharged or not correctly Refit the battery. It must be heard to engage

fitted with an audible “click”. Charge the battery if

necessary.

Electrical fault Remove the battery and contact your

nearest Hilti service center.

Tool runs too fast / too Adjust the 3-speed gear selector Set the 3-speed gear selector switch to the

slow switch. desired position.

No hammer action Tool set to the wrong mode Set the tool to hammer drilling mode.

Clutch releases while drilling Tool set to screwdriving mode Set the tool to drilling mode.

On / off switch cannot be Forward / reverse switch is set to Move the forward / reverse switch to the

pressed middle position left/right.

Speed suddenly drops The battery is almost exhausted. Stop working with the exhausted battery

and charge it fully.

Battery becomes dis- Battery condition is not optimal. Charge the battery using conditioning mode

charged faster than usual (see battery charger operating instructions).

Battery does not engage Dirt on battery locking mechanism Clean battery locking mechanism and refit

with an audible “click” the battery. Contact your nearest Hilti ser-

vice center if the problem persists.

Tool or battery overheats Electrical fault. Switch off the tool immediately. Remove

the battery and contact your nearest Hilti

service center.

Overload due to exceeding Select the right tool for the application.

application limit

Drill bit or screwdriving bit Chuck not tightened correctly Tighten the chuck securely by applying

slips in the chuck reasonable force.

9. Troubleshooting

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 18

Page 11

19

en

11. Warranty

Hilti warrants that the tool supplied is free of defects in

material and workmanship. This warranty is valid as long

as the tool is operated and handled correctly, cleaned

and serviced properly and in accordance with the Hilti

Operating Instructions, all warranty claims are made

within 12 months from the date of the sale (invoice date),

and the technical system is maintained. This means that

only original Hilti consumables, components and spare

parts may be used in the tool.

This warranty provides the free-of-charge repair or

replacement of defective parts only. Parts requiring repair

or replacement as a result of normal wear and tear are

not covered by this warranty.

Additional claims are excluded, unless stringent

national rules prohibit such exclusion. In particular,

Hilti is not obligated for direct, indirect, incidental or

consequential damages, losses or expenses in connection with, or by reason of, the use of, or inability

to use the tool for any purpose. Implied warranties of

merchantability or fitness for a particular purpose are

specifically excluded.

For repair or replacement, send tool and/or related parts

immediately upon discovery of the defect to the address

of the local Hilti marketing organization provided.

This constitutes Hilti’s entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

12. EC declaration of conformity

We declare, on our sole responsibility, that this product

complies with the following standards or standardisation

documents: 98/37/EG, 89/336/EWG, 91/157/EWG,

93/86/EWG, EN 50260-1, EN 50260-2-1, EN 50260-2-2,

EN 55014-1, EN 55014-2, EN 61000-6-3.

Designation: Cordless hammer drill

Type: UH240-A

Year of design: 2003

Hilti Corporation

Jan Doongaij Dr. Joachim Schneider

Head of Marketing BU Rotary & UCD Head of BA LDS

June 2003 June 2003

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 19

Page 12

02 BA UH240-A en 02.12.2003 11:54 Uhr Seite 20

Loading...

Loading...