Page 1

1

2

3

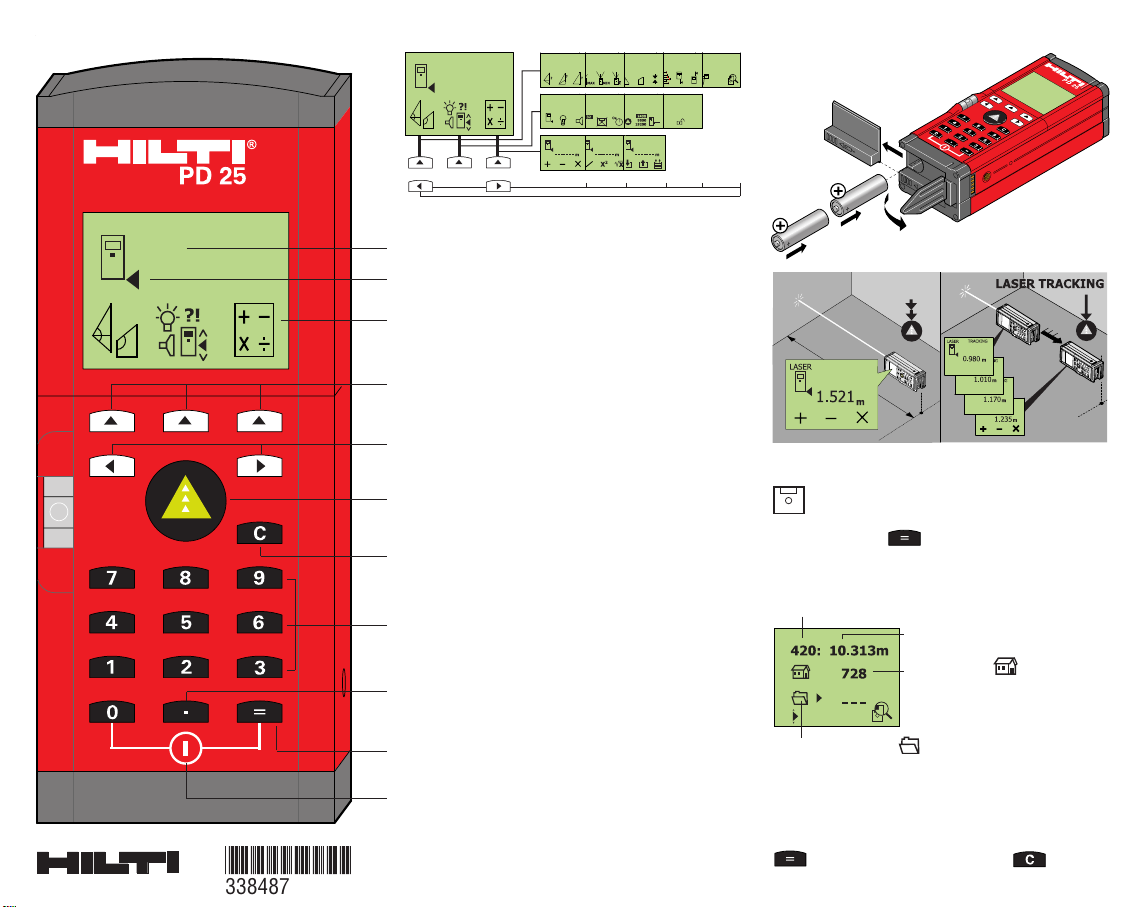

PD 25 quick-start instructions

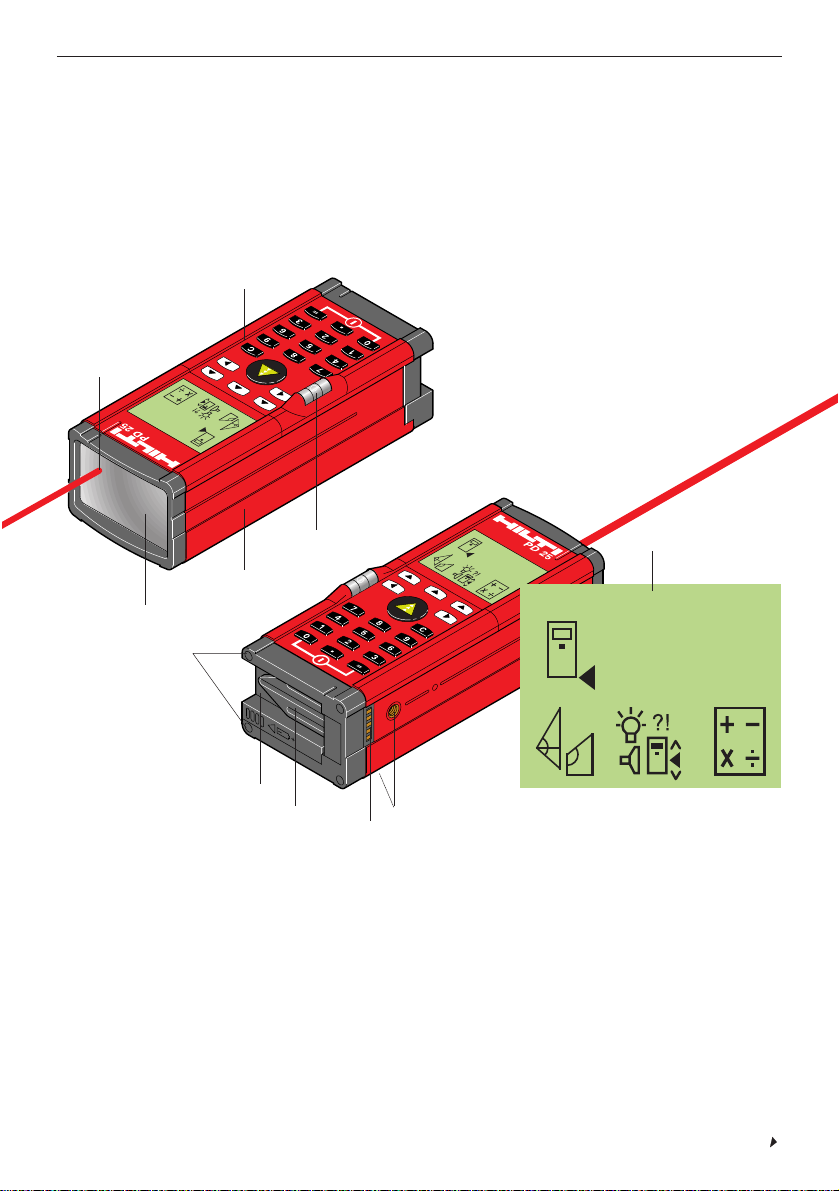

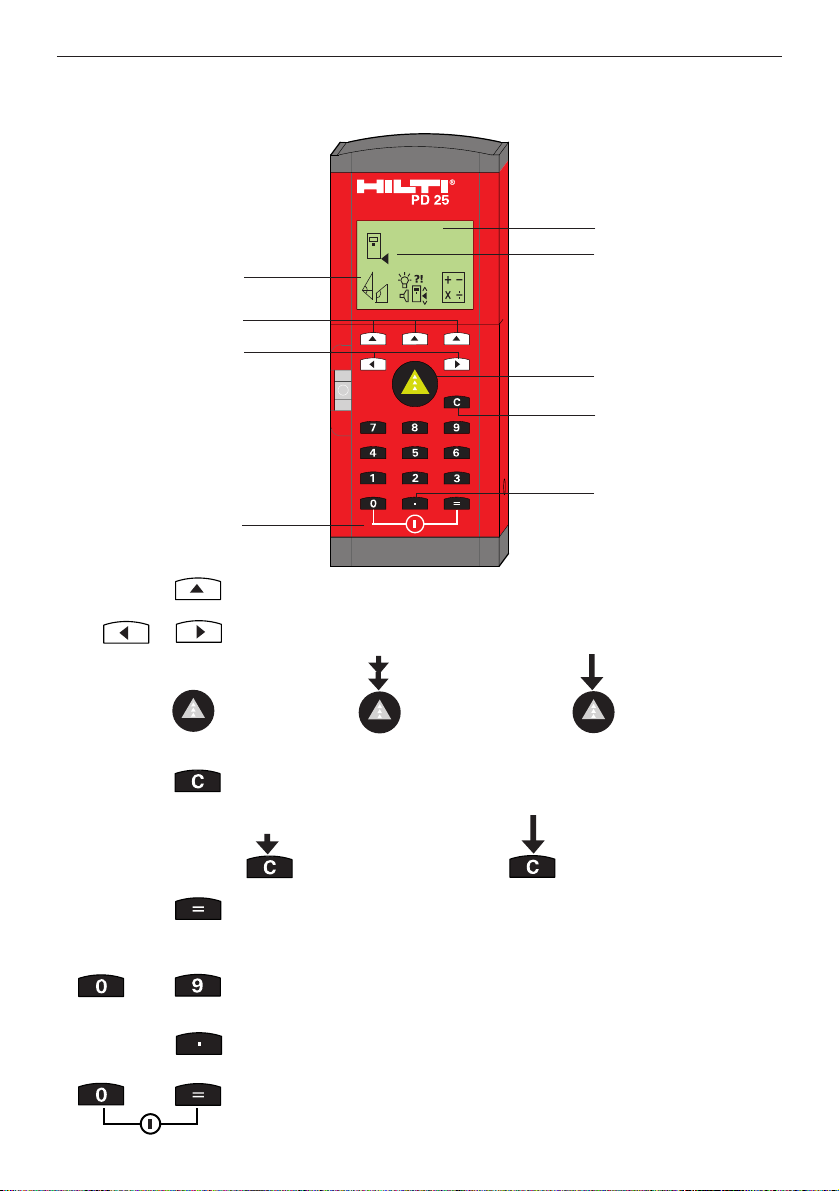

Display and control panel

Button functions

Memory functions

Display functions

Type AA

“Clear” button

for clearing the display (also

individual place values) and for cancelling a function

(press briefly to go back step by step,

press long to go back to start menu)

Button for

switching on and taking measurements

Press twice briefly: T ake measurement

Press once (long press): Begin continuous

measurement (tracking)

Main menu

Graphical display

Buttons for menu selection

Show menu / select function

Status indicator (measuring reference point)

Scroll forward / back in the selected menu

Switch the tool off

“Equals” button,

for executing a calculation,

confirming an entry or accening the memory menu

Numeric keypad (0...9) for entering identification

codes and values used in calculations

“Decimal value” button for entering decimal values

or for setting units to entered values

The measurement can be saved and

identified (tagged).

On pressing the button (after taking a

measurement or, additionally, after a calculation), the

memory menu is shown in the display:

The group and measurement codes can be entered

using the numeric keypad (0...9).

The memory operation is confirmed by pressing the

button or cancelled by pressing .

Group code

e.g. for identification of the

jobsite (max. 3-digit number)

Measurement

Memory locations 0-999 (assigned by the PD 25)

Measurement code e.g. type of measurement

(max. 3-digit number)

*338487*

338487

Page 2

active

inactive

active

inactive

Note the CODE!

Enable data saving

Disable data saving

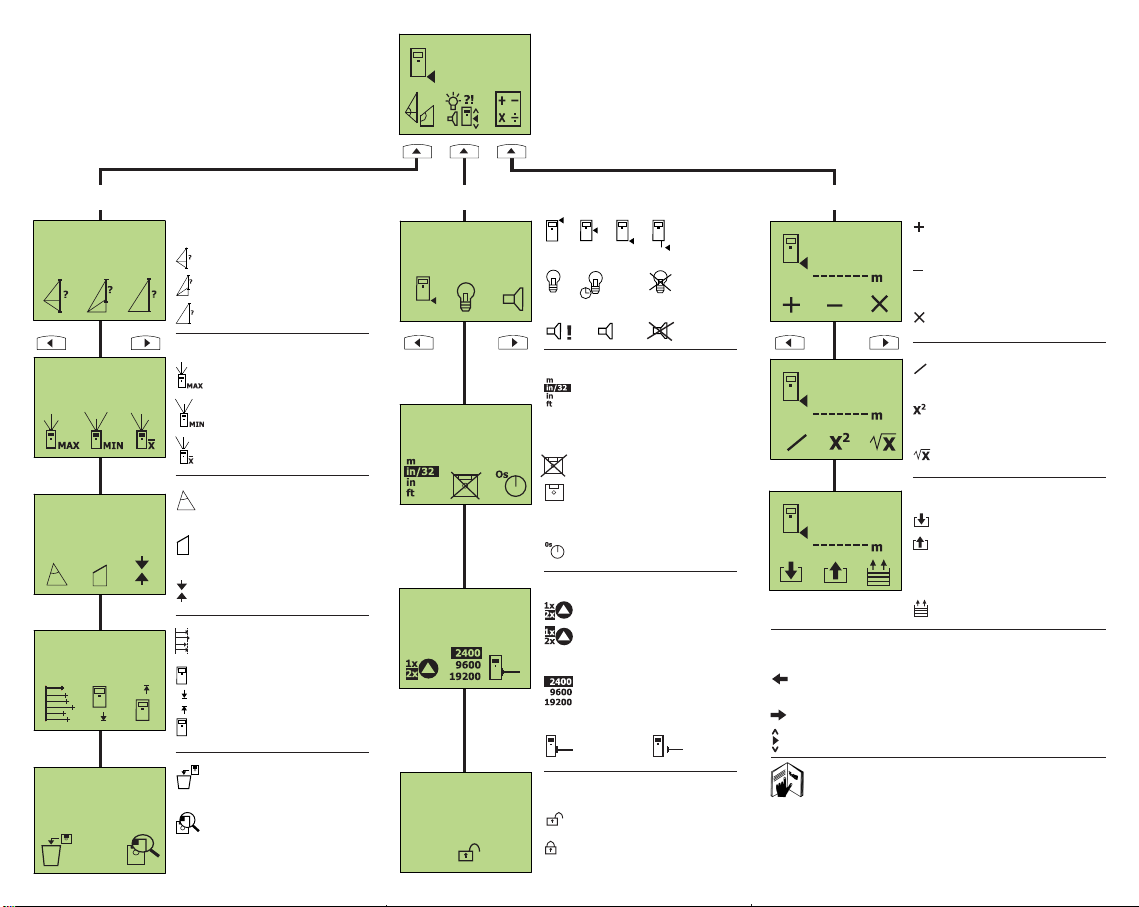

PD 25 menu overview

Special measuring functions Settings Calculation and memory functions

Determine lengths of sides, or

parts of sides, of a triangle

Triangle calculations

(height, angle, area)

Set out distances

Pitched roof calculations

(length of inclined section,

angle, area of gable end)

“MIN / MAX” function

Total length

Part length

Opposite side

Determine maximum

distance

Mean value measurement

Determine shortest

distance

Mean value from several

measurements (max. 99)

Shift measuring reference

point back

Shift measuring reference

point forward

Delete all data from

memory

Show or delete memory

contents (max. 1000

memory locations with

identification tags)

Addition

Subtraction

Multiplication

Reference point on tool

Display illumination

Beep signal during operation

Units displayed

[m] / Feet [’] Inch [’’] /

Inch [in] / Feet [ft]

Memory with identification tags

(max. 1000 values)

Self-timer

(0 / 2 / 5 / 10 / 20 sec.)

Division

Squares

Square roots

Scroll (0-8)

Manual intermediate memory

Last 10 distance

measurements

Save (0-9)

Recall (0-9)

15s

only when measuring

permanently

Laser beam on

Log function

Switch-on lock

Baud rate

for data transfer

Navigation aids

Scroll back

Scroll forward

Scroll up or down within a function

For further information, please refer to the PD

25 operating instructions.

Hilti = registered trademark of Hilti Corp., Schaan

Right of technical and programme changes reserved

W2403 0500 6 english 9 Printed in Liechtenstein © 2000 S.E.&O.

Page 3

PD25

Operating instructions

GB

*334080*

334080

Page 4

2

1

2

3

ON

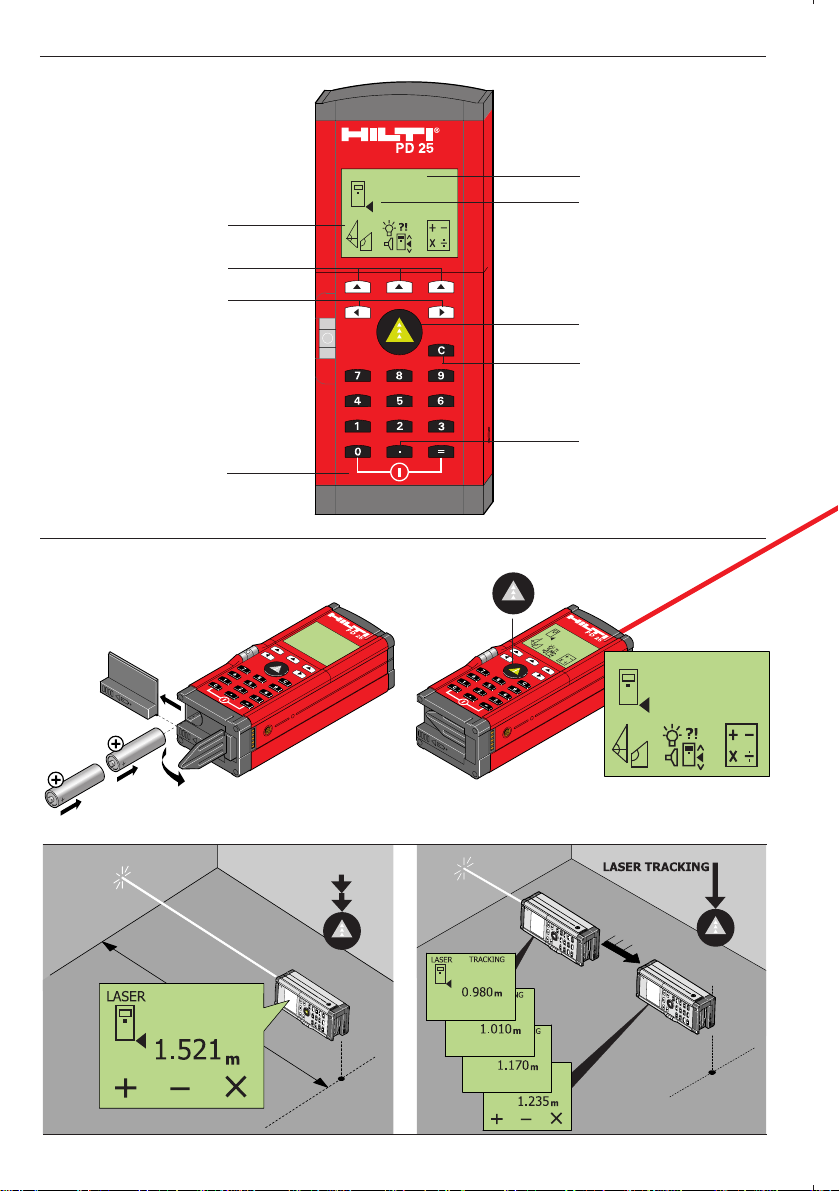

PD 25 quick-start instructions

“Clear” button

“Decimal value”

button

Switch off

Switch on and take

measurement

Main menus

Scroll through menu

Graphical display

Select menu

Reference point

indicator

(Measurement

reference)

Page 5

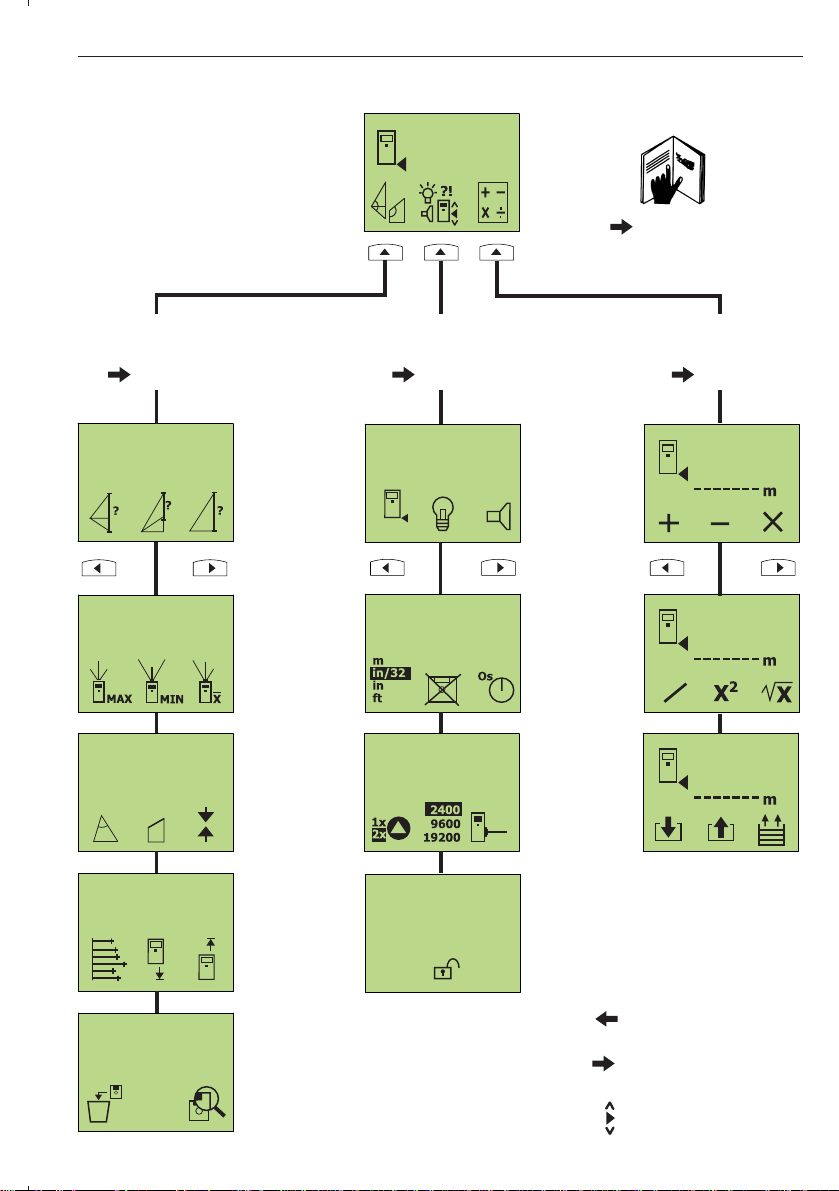

PD 25 menu overview

3

PD 25 quick-start instructions

Page 22

Special measuring

functions

Settings

Calculation and

memory functions

Page 23 Page 25 Page 31

Navigation aids

Scroll forward

Scroll back

Scroll up or down

Page 6

4

PD 25 laser range meter

PD25 operation instructions

In addition to the instructions for use, this manual also contains

important safety information (see “Safety precautions” section).

Please read these instructions carefully before using the tool and

give them to all other persons to read before they use the tool for

the first time.

We recommend that the operating instructions are kept together

with the tool.

Symbols used

Product identification

The type designation and serial number can be found on a nameplate attached to the rear of the product. Make a note of this information in the operating instructions and always refer to it when

addressing any enquiries to our agents or service department.

Type: PD 25

Serial no.: ____________________

The symbols used in these operating instructions have the following

meanings:

Warning

Operating risk or misuse which may lead to serious personal injury

or death.

Operating risk or misuse which may lead to only minor personal

injuries, but to serious material, property or environmental damage.

Information to help the operator use the product in a technically

correct and efficient manner.

Page 7

5

Contents

Contents

Continued

1. Product information ..................................................................7

Description of functions ....................................................................7

Features of the PD 25 ......................................................................8

Display and control panel..................................................................9

Button functions ................................................................................9

Technical data ................................................................................10

Items supplied ................................................................................12

2. Safety information....................................................................13

Please read this now!......................................................................13

Purpose ..........................................................................................13

Intended uses..................................................................................13

Examples of misuse ........................................................................13

Operating limits................................................................................14

Environment ....................................................................................14

Division of responsibilities................................................................14

Operating risks ................................................................................14

Disposal ..........................................................................................18

Laser classification..........................................................................19

Information plate..............................................................................20

Electromagnetic compatibility (EMC)..............................................21

3. Operation.................................................................................. 22

Inserting the batteries......................................................................22

Menu selection and settings............................................................22

Special measuring functions............................................................23

Setting preferences..........................................................................25

Calculation and intermediate memory functions..............................31

Entering numerical values ..............................................................32

4. Working with the PD 25 .......................................................... 33

Measuring distances ......................................................................33

Measuring using the folding pointer ................................................34

Measuring using the self-timer ........................................................35

Measuring with the aid of a target object..........................................36

Taking measurements from various surfaces ..................................36

Continuous measurement (tracking) ..............................................37

Calculation......................................................................................38

Addition / subtraction (distances) ....................................................38

Multiplication (areas / volumes) ......................................................39

Page 8

6

Contents

Contents, continued

Measuring distances indirectly........................................................40

Determining the total length of the side of a triangle........................40

Measuring part of the length of the side of a triangle ......................41

Determining the length of the opposite

side of a triangle according to the Pythagoras principle ..................42

Continuous measurement “tracking MAX” ......................................44

Continuous measurement “tracking MIN”........................................45

Measuring the mean value ..............................................................46

Triangle calculations ......................................................................46

Determining the height, angle or area of a triangle..........................46

Pitched roof calculations..................................................................48

Setting out distances ......................................................................49

Calculating the mean value from several measurements................51

Shifting the measuring reference point............................................52

Memory ..........................................................................................53

Deleting memorised values ............................................................53

Searching for, identifying or deleting

measurements saved in memory ....................................................54

5. PD25 server (option) ................................................................55

PD25 server menu overview ..........................................................55

Description of PD 25 server functions..............................................55

Installing and setting up the PD 25 server software ........................57

Connecting the PD 25 to a PC ........................................................58

The PD 25 server software in use ..................................................59

PD 25 server software troubleshooting ..........................................60

Uninstalling the PD 25 server software ..........................................60

6. Care, transportation and storage............................................61

Cleaning and drying........................................................................61

Storage ..........................................................................................61

Transportation ................................................................................61

7. Symbols displayed ..................................................................62

8. Measuring equipment inspection............................................63

9. Accessories ..............................................................................64

10. FCC statement (applicable in US) ........................................66

11. EC declaration of conformity ................................................66

12. Warranty..................................................................................67

Page 9

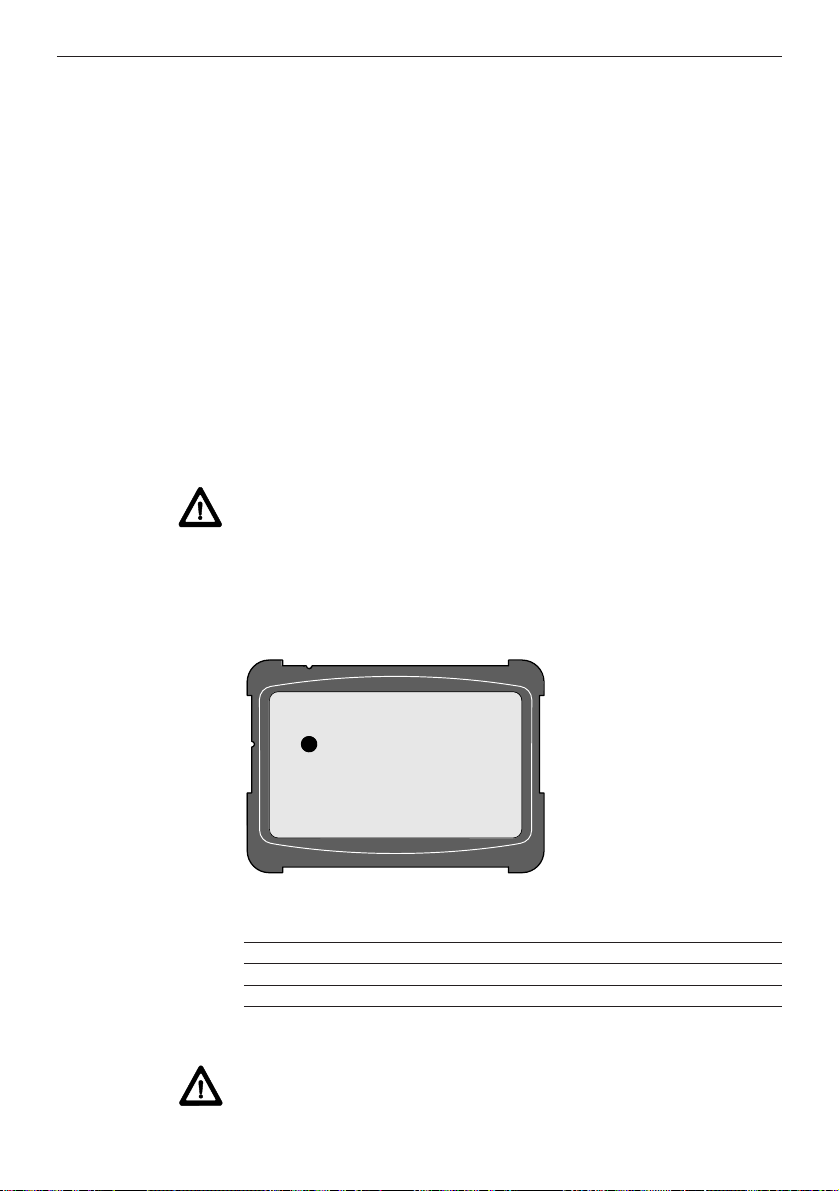

7

1. Product information

1. Product information

Description of functions

The Hilti PD 25 is a laser range meter. It uses a laser beam to measure distances within the 0.3 m - 100 m range with high precision.

1 Laser exit aperture

2 Numeric keypad

3 Receiving optics

4 Plastic casing

5 Bubble

6 Battery compartment

7 Spike (folding)

8 RS 232 interface

9 Two tripod mounting threads

10 Menu-driven graphical display

11 Four metal contact points for precise measurements

Continued

1

2

5

4

11

6

3

7

9

8

10

Page 10

8

1. Product information

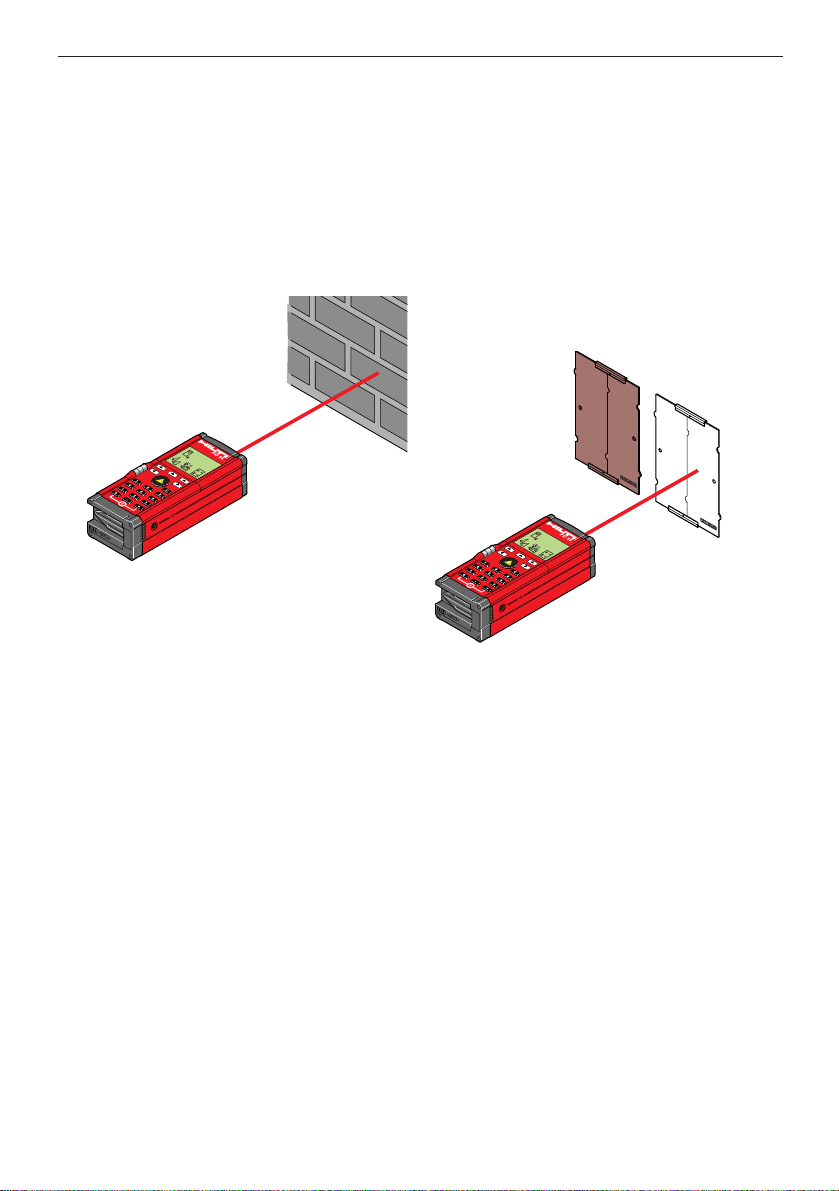

Description of functions, continued

The point from which the measurement is taken is clearly identified

by the red spot. The range of the tool depends on the reflectance

and finish of the target surface.

When reflectance of the target is good:

- Target the object directly

When reflectance of the target is unsuitable:

Use the P A411 target plate.

- White side, when reflectance is

excessive.

- Brown side, when reflectance is too low.

- Compact and functional design

- Simple, self-explanatory menu selection and menu settings

- One-man, hand-held operation for speed of use

- Large display (can be illuminated)

- The last nine measurements can be memorised.

- Addressable, intermediate memory (10 values)

- Memory capacity for 1000 values, with group codes and identification tags

- Numeric keypad

- Built-in calculation functions

- Function menus with various special measuring functions

(triangle calculations, mean values, tracking, etc.)

- RS 232 interface for transferring data to a PC, etc.

- Built-in theft deterrent

- Switches off automatically

- Built-in bubble level

- Tripod mount

(Optional: P A450 tripod adaptor with fine adjustment of the Xand Y -axes)

Features of the PD 25

Page 11

9

1. Product information

Button functions

Select menu or function

Scroll through active menu

“Clear” button for resetting the display (also individual place values) and for cancelling a function

Switch the

tool on

Short press: One step

back

Long press: Back to main

menu

Press twice (short

press): Take

measurement

Press once (long

press):

Continuous

measurement

(tracking)

Execute calculation, confirm entry or show memory menu

Numeric keypad (0...9) for entering value identification tags and

values used in calculations

“Decimal value” button for entering decimal values or calculations

using other units or without units.

Switch the tool off

Display and control panel

...

“Clear” button

“Decimal value”

button

Switch off

Switch on and take

measurement

Main menus

Scroll through menu

Graphical display

Select menu

Measuring reference point indicator

Page 12

10

1. Product information

T echnical data

Measuring range

0.3 to over 100 m (1 to over 300 ft)

Typical measuring range without target plate:

Drywall panel, white 70 m (210 ft)

Concrete, dry 50 m (150 ft)

Brick, dry 50 m (150 ft)

The maximum range depends on:

- Reflectance of the target surface

- Brightness of ambient light

Use the Hilti P A411 target plate if measurement is impossible.

Accuracy

± 3 mm for individual measurement @ 23° C

(± 0.1 in for individual measurement @ 73° F)

± 5 mm @ 0° C ... +50° C (± 0.2 in @+32° F ... 122° F)

± 7 mm @ –10° C ... +50° C (± 0.3 in @14° F ... 122° F)

Smallest unit displayed 1mm (1/32 in)

Beam diameter

< 6 mm @ 10 m (< 0.2 in @ 30 ft)

< 30 mm @ 50 m (< 1.2 in @ 150 ft)

< 60 mm @ 100 m (< 2.4 in @ 300 ft)

Operating modes

• Individual measurement

• Continuous measurement

• Calculation

Operating status indicator

Liquid crystal display indicating individual operating modes and

operating status

Laser

Visible, 620-690 nm, laser class 2 (IEC825-1), class II (FDA21

CFR); output power: <1 mW

Power supply (3 V DC)

Type: AA (LR6, AM3, mignon)

Standard: 2 alkaline primary cells

Optional: rechargeable NiCd, NiMH

Battery condition

Awarning is displayed when battery voltage is low.

Continued

Page 13

11

1. Product information

T echnical data, continued

Automatic cut-out Laser: 25 sec. Tool: 5 min

Battery life at 25° C [+ 77° F]

Max. no. of measurements with a duration of 5 seconds

Alkaline: 4000 NiCd: 2000 NiMH: 3000

Operating temperature

–10° C ... +50° C (14° F ... 122°F)

Storage temperature

–30° C ... +70° C (–22° F ... 158°F)

Protection class

Dust and splash-proof, IP54 as per IEC 529 standard

Mounting points

1/4‘‘ Whitworth internal thread

1 on the side and 1 underneath (standard camera tripod thread)

Weight

380 g (without batteries)

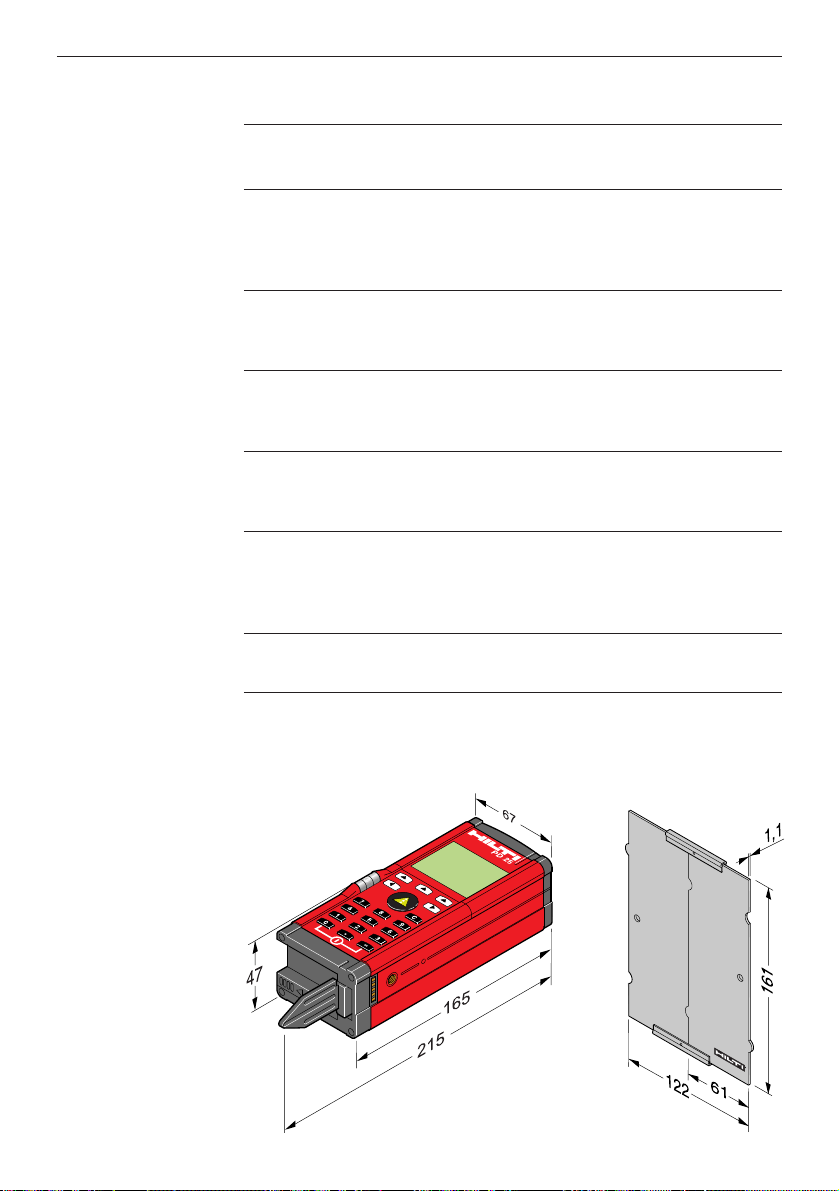

Dimensions

165 x 67 x 47 mm (6.5" x 2.6" x 1.8")

P A411 target platePD25Illustration

showing

dimensions [mm]

Page 14

12

1. Product information

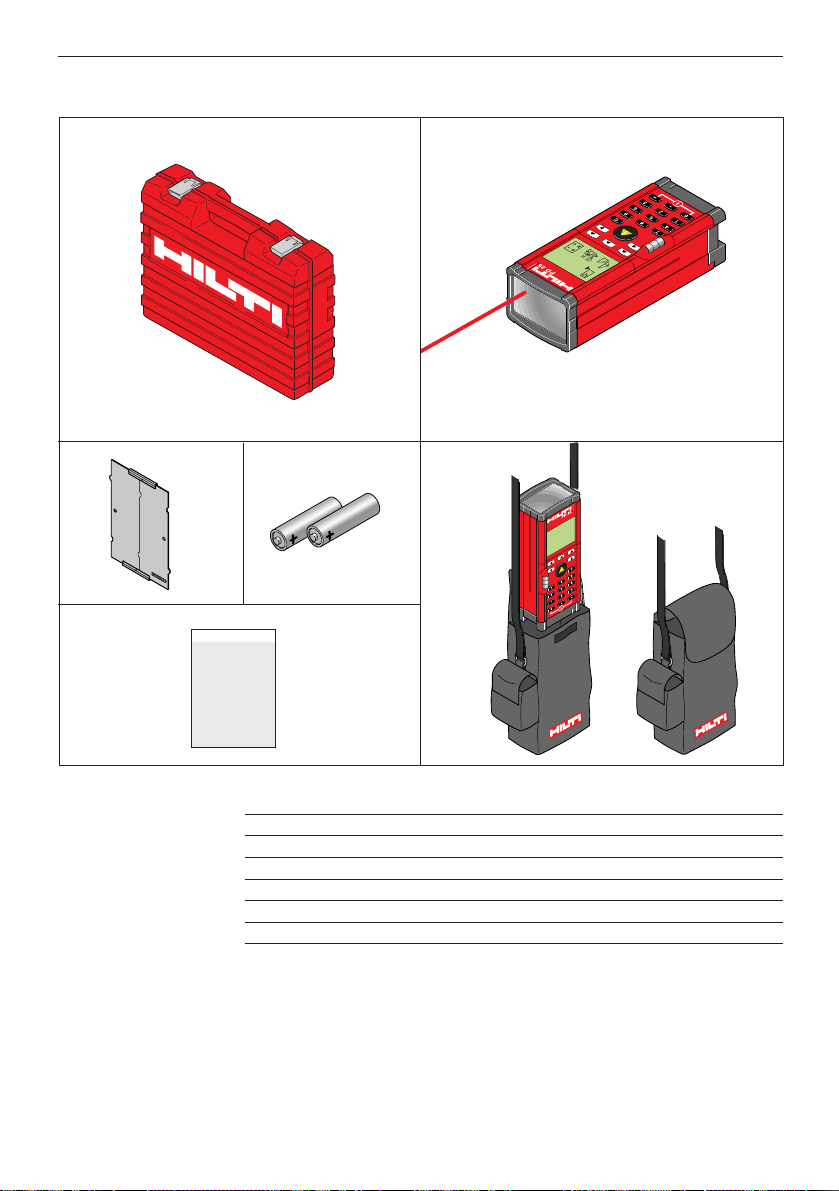

Items supplied

No. Qty. Designation

1 1 PD 25 toolbox

2 1 PD 25 laser range meter

3 1 P A411 target plate

4 2 Type AAbatteries

5 1 PD 25 carrying case

6 1 Operating instructions

PD 25

12

3

4

6

5

Page 15

13

2. Safety information

2. Safety information

Please read this now!

This information is intended to enable owners and users of the Hilti

PD 25 to identify any operating risks in good time, i.e. to eliminate

any such risks in advance where possible.

The owner of the tool must ensure that these instructions are understood and followed by all users.

Purpose

The Hilti PD 25 is intended for the following range of applications:

• Measuring distances

• Calculation of areas, volumes, hypotenuse and angles

• Addition and subtraction of lengths

• Multiplication, division, squares and square roots of measured

values

• Setting out distances

• Saving measurement data

• Special measuring functions

Intended uses

• Use of the product without prior instruction

• Use of the product outside its operating limits

• Rendering safety devices ineffective or removing notices and

warning signs

• Opening the product unless expressly permitted in certain cases

(e.g. to replace the batteries)

• Making conversions or modifications to the product, unless

expressly approved by Hilti

• Deliberately dangerous or careless behaviour on scaffolding,

when climbing ladders or when taking measurements in the vicinity of operating machinery or the exposed parts of machines or

other equipment

• Aiming directly at the sun or other powerful source of light

• Deliberately dazzling other persons

• Use of remote mode with a personal computer that is not earthed

/ grounded (e.g. battery-powered laptop that is not earthed /

grounded)

Examples of misuse

WARNING

Misuse may lead to injury , malfunction and damage to property.

The owner must inform the user of the operating risks associated

with the equipment and the corresponding safety precautions.

The PD 25 laser range meter may be operated only when the user

has received prior instruction.

Page 16

14

Operating risks

WARNING

Use of the product without instruction or with incomplete instruction

may lead to errors by the operator or misuse and thus to accidents

resulting in serious personal injury , pecuniary damage or damage to

property and the environment.

Preventative measures

All users must observe the safety information issued by the manufacturer and the owner’s instructions.

Continued

2. Safety information

Intended uses, continued

Operating limits

WARNING

The owner is responsible for the correct use of the equipment, the

use of the equipment by his employees, their instruction and the

operating safety of the equipment.

The owner has the following obligations:

• To ensure that he has understood the safety information on the

product and the information contained in the operating instructions.

• To be aware of the locally applicable industrial accident prevention regulations.

• To notify Hilti immediately of any safety-related defects or deficiencies in the equipment.

The product is suitable for use in atmospheres permanently habitable by humans. It must not be used in corrosive or explosive environments. Exposure to rain for short periods during use is permissible.

See “Technical data” section.

Environment

Responsibility of the manufacturer of the original equipment,

Hilti Corporation, FL-9494 Schaan (subsequently referred to as

“Hilti”)

Hilti is responsible for supplying a technically safe product in faultless

condition, including operating instructions and original accessories.

Examples of misuse

Page 17

15

2. Safety information

Intended uses, continued

Operating limits, continued

WARNING

Care must be taken to avoid incorrect measurements.

Preventative measures

Keep the receiving lens clean. It should be cleaned at regular intervals.

See: “Cleaning and drying”.

WARNING

Take care to avoid incorrect measurements caused by using a

defective product or a product which has been dropped or subjected

to any other inadmissible stresses or changes.

Preventative measures

Take measurements periodically to check the accuracy of the product, particularly after it has been exposed to excessive stresses

and before and after important measuring tasks.

WARNING

Failure to adequately cordon off the area in which you are measuring may lead to dangerous situations in road traffic, on building

sites or in industrial plants, etc.

Preventative measures

Always ensure that the area in which you are carrying out measuring work is properly cordoned off. Observe the statutory accident

prevention regulations and road traffic regulations of the applicable

country.

WARNING

Taking measurements from surfaces with low reflectance surrounded by areas with high reflectance may lead to measurement errors.

Preventative measures

Take measurements from the brown side of the Hilti P A411 target

plate when the PD 25 is used at the limit of its range.

Continued

Page 18

16

2. Safety information

Operating limits, continued

Note

Opening the product without authorisation will not only invalidate the

warranty , it may also cause malfunctions and measuring errors.

Preventative measures

Do not open the product. Only the battery compartment cover

should be opened (slid to the side) when replacing the batteries.

Note

If the equipment is not used for lengthy periods, there is a risk of it

being damaged by leaking batteries.

Preventative measures

Remove the batteries if you do not intend to use the equipment for

some time.

Warning

At regular intervals or before measuring, check that the folding pointer functions correctly .

The symbol illustrated is shown in the display .

Warning

Using the P A421 telescopic sight to view the directly reflected beam

from the PD 25 is hazardous to the eyes when the tool is aimed at

surfaces with mirror-like reflectance or which cause unexpected

reflections (e.g. mirror, metal surfaces, window panes, prisms).

Preventative measures

Do not aim the telescopic sight at surfaces with mirror-like reflectance or which cause unexpected reflections.

Warning

The laser beam can be set to “laser beam permanently on”, thus

possibly dazzling other persons when the tool is switched on unintentionally or handled without due care.

Preventative measures

When the tool is used in this operating mode, ensure that other persons cannot be dazzled.

Page 19

17

2. Safety information

Operating limits, continued

Note

The tool has an accuracy of ± 3 mm at room temperature. In order

to achieve this accuracy , also with calculations, measurements

should be taken carefully .

Note

Different measuring reference points can be selected. To achieve

accurate results, ensure that the correct measuring reference point

on the tool has been selected.

Warning

When taking measurements from a tripod in directly opposite directions (pivoting the tool through 180°), failure to select the correct

measuring reference point may be a cause of error.

Preventative measures

Set the measuring reference point to the tripod axis.

Check the symbol shown in the display:

Page 20

18

2. Safety information

Disposal

WARNING

Improper disposal of the equipment may lead to the following:

• Burning of plastic components generates toxic fumes which may

present a health hazard.

• If damaged or exposed to very high temperatures, batteries may

explode, causing poisoning, burns, acid burns or environmental

pollution.

• Careless disposal enables unauthorised persons to make improper use of the equipment, which may lead to serious injury to

themselves or a third party and to pollution of the environment.

Preventative measures

Most of the materials from which Hilti tools are manufactured can be

recycled.

The materials must be correctly separated before they can be recycled.

In many countries, Hilti has already made arrangements for taking

back old tools for recycling.

Ask your Hilti customer service department or Hilti representative

for further information. Please help to protect our environment.

Part, assembly Main material Recycling

Casing, keypad Plastic Plastics recycling

toolbox, target plate,

carrying case

Measuring module, V arious Electronics scrap

electronics or scrap metal

Screws, small parts Steel Scrap metal

Batteries V arious Disposal centre

Page 21

19

2. Safety information

Laser classification

The Hilti PD 25 generates a visible laser beam which is emitted from

the front side of the tool.

The product conforms to laser class 2 as per:

• IEC825-1: 1993 “Safety of laser equipment”

• EN60825-1: 1994 “Safety of laser equipment”

The product conforms to laser class II as per:

• FDA21CFR Ch.I §1040 :

1988 (US Department of Health and Human Service, Code of

Federal Regulations)

Laser class 2 / II products

Do not look into the laser beam and never aim it at other persons.

Protection of the eyes is normally ensured by defensive reactions

including the eyelid closure reflex.

WARNING

Looking directly into the beam with optical aids (e.g. binoculars or

telescopes) can be dangerous.

Preventative measures

Never look into the beam using optical aids.

Applicable standard: IEC825-1:1993 FDA 21CFR

EN60825-1:1994 Ch.I §1040:1988

Beam divergence: 0.16 x 0.6 mrad 0.16 x 0.6 mrad

Pulse duration: 1x10-9s 1x10-9s

Max. power output: 0.95 mW ±5% 0.95 mW ±5%

Warning

The product should be repaired at a Hilti-approved service centre

only.

Laser exit aperture

Page 22

20

2. Safety information

Information plate

All product identification data and warnings concerning the use of

the product can be found on the rear of the Hilti PD 25.

Page 23

21

2. Safety information

Electromagnetic compatibility (EMC)

Electromagnetic compatibility refers to the ability of the Hilti PD 25

to function correctly in an environment where it is exposed to electromagnetic radiation and electrostatic discharge, without causing

electromagnetic interference to other devices.

WARNING

There may be a possibility of interference with other equipment due

to electromagnetic radiation.

Although the Hilti PD 25 complies with the strict requirements of the

relevant directives and standards, Hilti cannot entirely rule out the

possibility of interference with other equipment.

WARNING

Measurements may exceed tolerances in the event of interference

caused by electromagnetic radiation.

Although the Hilti PD 25 complies with the strict requirements of the

relevant directives and standards, Hilti cannot entirely rule out the

possibility of the Hilti PD 25 being subject to interference caused by

very intense electromagnetic radiation, e.g. in the immediate vicinity

of radio transmitters, radio communications equipment, diesel generators, etc.

Check the readings for plausibility when measuring under these

conditions.

Page 24

22

Menu selection and settings

Navigation aids

3. Operation

3. Operation

Inserting the batteries

Symbol

displayed

Low battery voltage - insert new batteries

2x type AA(LR6 / AM3 / Mignon)

Always replace the complete set of batteries.

- Do not mix old and new batteries.

- Do not mix batteries of different makes or types.

- Use only undamaged batteries of an approved type.

When rechargeable batteries are used, each pair of batteries must

be:

- of the same make and the same type.

- of the same age and charged to the same level.

When one of the navigation symbols is dis-

played, the button positioned below it can

be used to navigate through the correspon-

ding menu.

1

2

3

Buttons for selecting

menu items

Scroll through

selected menu

Indication of reference point selected

Main menu

Take measurement

Reset display /

cancel function

Scroll back

Scroll forward

Scroll up or down

Page 25

23

Special measuring functions

Measuring distances indirectly

Triangle calculations

«MIN / MAX» function

Determining

mean

values

Measuring the complete length of a side of a triangle

e.g. measuring a height indirectly

Measuring part of the length of a side of a triangle

e.g. measuring the height of a floor level of a building

Using Pythagoras to determine the length of the opposite side of a

triangle

e.g. measuring the height of a building

To determine the maximum distance

e.g. diagonals

To determine the shortest distance

e.g. normal distance (i.e. at right angles to the distance to be determined) or, respectively, determining right angles

When measurement is started, eight measurements are taken one

after the other and the mean value then indicated.

Determining the height, angle and area of a triangle

Pitched roof calculations

Determining the length of the sloping section, its angle and the area

of the gable end

Continued

3. Operation

Page 26

24

Special measuring functions, continued

Setting out distances

For setting out distances

Mean value from several measurements

Calculates the mean value from measurements taken consecutively

(max. 99 measurements)

Shifting the measuring reference point

Erasing memory

Indicating the memory capacity in use or deleting from memory

To the front

The set value or measured value serves as the new reference

(i.e. zero point shift). All measurements are then taken from the reference point set as long as the tool is used as indicated in this menu.

To the rear

Deletes all data from memory

Memory location

0-999

(assigned by the

PD 25)

Measurement

Group code, e.g. for identification of the jobsite (max. three-digit number)

Measurement code, e.g. type of measurement (max. three-digit number)

3. Operation

Used to display memory contents or to delete values held in

memory (memory capacity for 1000 values). Measurement values

can be identified by customer’s defined identification tags in the

form of max. three-digit group and / or measurement codes.

The numeric keypad (0 ... 9) is used to enter the group codes and

measurement identification codes.

Page 27

25

Setting preferences

Measuring reference point on the tool

Units shown in display

Front edge of tool

Tripod axis

Rear edge (i.e. standard)

End of pointer

This is indicated when the pointer is

folded out (e.g. for taking measurements from the corner of a room).

Display illumination

On permanently

Off

The display illumination switches itself off automatically 15 seconds

after:

- the last press of a button, or

- a measurement is taken.

[m] metric system

Feet [‘] inches [“] and fractions in increments of 1/32

Inches [in] with decimal place

Feet [ft] with decimal place

Beep signal when operated

Abeep signal is

emitted when:

- a measurement is

taken,

- an error occurs

Off

Abeep signal is

emitted when:

- a button is pressed,

- a measurement is

taken,

- an error occurs

Continued

3. Operation

Page 28

26

Setting preferences, continued

Memorised values (max. 1000 values)

- The value can be saved and identified.

- On pressing the button (after taking a measurement or

after a calculation) the memory menu is shown in the display.

- Do not save in memory.

Memory settings

- The numeric keypad (0 ... 9) can be used to enter the group

code and measurement code. Press the button to confirm

that the value is to be memorised or press the button to

cancel the operation.

- The group code is adopted automatically from the previous

identification operation.

This can be kept as it is or redefined using the navigation button .

- When using the “triangle” and “pitched roof” special measuring

functions, three memory locations with the same group and

measurement identification codes are assigned automatically for

the results.

- Memory locations (0 ... 999) are assigned automatically by

the PD 25 as consecutive numbers.

- When all memory locations are occupied, the functions in

the menu must be used to delete all data from memory.

The selected setting ( / ) applies to every measurement

taken.

3. Operation

Memory location 0-999

(assigned by the PD 25)

Measurement

Group code

e.g. for identification of the jobsite

(max. 3-digit number)

Measuring identification code

e.g. type of measurement (max. 3-digit number)

Continued

Page 29

27

Setting preferences, continued

The measured value can be saved and identified.

The numeric keypad can be used to enter:

- the jobsite identification (i.e. Strukturcode) and

- the measurement identification (i.e. measurement code).

Enter a 1 - 3 digit number.

Confirm the entry

Alternatively:

Take next measurement

Cancel memory procedure

Or, select the search function to recall (or delete) previously saved

values

Return to the memory display

After a measurement has been taken, the value is displayed:

Press the button to activate the memory function.

The display shows the following:

3. Operation

...

Example 1: Saving a value from an individual measurement (memory setting: )

Continued

Memory settings, continued

The assignment of identification tags (codes) to memorised values

makes the task easier and prevents:

- loss of data due poor indexing or a lack of a means of indexing.

- errors due to use of incorrect values.

Note

Page 30

28

Memory settings, continued

3. Operation

Example 2:Add measurements and save the result

(Memory setting )

Press the “measure” button.

The laser beam switches on. Aim the range

meter at the target.

Press the “measure” button again.

The first distance is measured and the result

displayed (laser beam switches off).

Press the “+” button for addition.

Press the “measure” button. The laser beam

switches on. Aim the range meter at the target.

Press the “measure” button again.

The second distance is measured and the

result displayed (the laser beam switches

off).

Press the “=” button.

Press the “=” button to access the memory

function.

The value displayed can be saved and

identified. The numeric keypad can be used

to enter:

- the jobsite identification code (i.e.

group code) e.g. 729, and

- the measurement identification code

(i.e. measurement code) e.g. 745.

Enter a 1 - 3 digit number.

Confirm the entry .

...

Page 31

29

The group code, i.e. the jobsite identification code, can be selected

as desired.

The measurement code, i.e. the measurement identification code,

can be selected as desired.

The examples given (1 - 4) are simply a suggestion. The user

should create a system to suit individual requirements.

Room

Floor

Jobsite

at floor level

1st diagonal

diagonal

e.g.:

Memory settings, continued

Example 3:

Example 4:

3. Operation

Group code

Measurement

code

Room

Jobsite

Floor level

or

Window sill

Height

e.g.:

or

Page 32

30

Memory settings, continued

3. Operation

Laser beam on only when a measurement is taken

First press of button = Aim at target

Second press of button = Take measurement

Laser beam on permanently

Single press of button = Take measurement

Self-timer

Laser beam

Baud rate

Log mode

Switch-on lock

After pressing the “measure” button, the measurement is taken

automatically after the set delay (e.g. for taking measurements from

inaccessible places).

The following delay times can be set:

When the beep signal is activated:

- Several consecutive beeps are emitted approx. 5 sec. before the

measurement is taken.

(=Off)

Possible baud rates, for example, for data transfer to a PC:

When log mode is active, all measurements are transferred directly

to the RS232 interface.

When measurements are transferred to a PC, the measurements

are also saved in memory , provided data saving is active.

active

not active active

not active

Can be activated to prevent unauthorised use of the tool, as a theft

deterrent or to ensure that data is stored safely .

It is essential that the 4-digit code entered is noted down and

kept in a safe place separate from the tool.

If you forget the numerical code:

- The tool can be unlocked at your Hilti service centre.

If the tool is stolen:

- Please contact your Hilti service centre.

Page 33

31

3. Operation

Calculation and intermediate memory functions

Addition

Subtraction

Multiplication

Division

Square

Square root

Scroll through the last 9 measured values (0-8).

Calculations can be made using:

- values measured directly

- values recalled from intermediate memory

- values entered (using the numeric keypad)

Calculation functions

Measured or calculated values can be saved by entering a memory

location number (0-9).

Measured or calculated values can be recalled by entering the

applicable memory location number (0-9).

Note

When a value is saved in an already occupied memory location, the

existing value will be overwritten.

Manual intermediate memory function (max. 10 values)

Automatic intermediate memory function (max. 9 values)

Save

Recall

Scroll

Page 34

32

Entering numerical values

3. Operation

Calculation and intermediate memory functions, continued

By pressing the “decimal value” button several times, the unit displayed can be changed, for example, from m to m

2

, m3, in, in2, in3, ft,

ft2, ft3or “no unit”.

When the entry made is unrealistic, the PD 25 reacts by causing the display to blink.

Example 1: Measured value [m] + value entered [m], e.g. 1.155 m + 5.2575 m

Example 2:Area [m

2

] + area entered [m2], e.g. 3.078 2 m2+ 91 m

2

Example 3: Measured value [in 1/32] x value entered [in 1/32], e.g. (7´ 4” 29/31) x (8” 5/32)

The value entered is set to the unit “m”.

1x

1x

1x

3x

The entries can be made in the same way when the unit is set

to ft or in.

...

...

...

...

Page 35

33

4. Working with the PD 25

Measuring distances

4. Working with the PD 25

Enter the 4-digit code and confirm by pressing the

button.

The following is shown in the display:

After switching on the tool, the measuring

reference point is always set to the rear

edge of the tool (symbol).

Switch the tool on.

If the theft deterrent is active, the following is shown in the display:

Press the “measure” button. The laser beam is switched on.

Position the tool with its rear edge against the desired starting point

for the measurement and aimed towards the target.

Press the “measure” button again.

The measured value is shown in the display .

ON

Page 36

34

Measuring using the folding pointer

Fold out the pointer when measurements are to be taken across the

diagonal of a room or from the corner of a room where access is

difficult.

Measuring from the corner of a room

Measuring from an outside corner

The measuring

reference point is

altered automatically .

Check the measu-

ring reference point.

The tool takes the extended measuring reference into account and

automatically corrects the distance measured by this value.

The measuring procedure is as previously described.

4. Working with the PD 25

Page 37

35

4. Working with the PD 25

Measuring using the self-timer

The use of an extension rod can be of great assistance for measuring with the PD 25 from points where access is difficult or even

impossible to reach without some form of aid.

One of the two threaded bushings (1/4” tripod thread) on the PD 25

can be used for attaching an extension rod.

When an extension rod is used, the delay between pressing the

“measure” button and the moment at which the measurement is

taken can be set with the assistance of the self-timer (delay) function.

Set the delay time

The measurement is taken after:

0/2/5/10/20 seconds

Press the arrow button repeatedly until the

desired delay has been set.

Page 38

36

T aking measurements from various surfaces

Plants and trees

As a rule, it is not possible to take measurements from plants and

trees, even over very short distances. Matt green surfaces decrease

the range of the PD 25.

Rough surfaces

On rough surfaces, (e.g. rough plaster), the measurement obtained

is a weighted average, whereby the centre of the laser beam receives a higher weighting than the surrounding area.

Measuring with the aid of a target object

Aboard, bricks or other suitable objects can be used as the target

when taking a measurement from an outside edge (e.g. outside

walls of houses, perimeter fences etc).

4. Working with the PD 25

Page 39

37

4. Working with the PD 25

Continuous measurement (tracking)

Switch the tool on.

Press the “measure” button once (long press) (=tracking).

The words “LASER TRACKING” appear in the display:

Move the tool to another position and read

the current distance from the display .

To cancel tracking mode, press the

button.

Page 40

38

4. Working with the PD 25

Calculation

Addition / subtraction (distances)

Individual distances can be added or subtracted easily .

The following example shows how 2 individually measured

distances can be added together.

When a tripod is used:

Set the measuring reference to the tripod axis.

Distances of over 100 m can be measured

in this way .

Pivot the tool through 180° between measurements 1 and 2.

Press the “measure” button. The laser switches on. Point the range meter at the target.

Press the “measure” button again.

The first distance is measured and indicated

(laser switches off).

Press the “+” button for addition.

Press the “measure” button. The laser switches on. Point the range meter at the target.

Press the “measure” button again.

The second distance is measured and indicated (laser switches off).

Press the “equals” button.

The total distance can then be read from the

display.

1)

2)

1)

2)

Page 41

39

4. Working with the PD 25

Calculation, continued

Multiplication (areas / volumes)

Measure the width of the room.

Measure the length of the room.

Press “x” for multiplication.

Press the “equals” button.

The floor area can then be read

from the display .

Example 1: Calculating the floor area of a room

Example 2: Calculating the volume of a room

After calculating the floor area of the room:

Press “x” for multiplication.

Measure the height of the room.

Press the

“equals” button.

The volume can

then be read from

the display .

Consecutive calculations can also be made without pressing the

“equals” button.

e.g. distance x distance x distance = m

3

or

(distance x distance) + (distance x distance) = m

2

The subtraction, square and square root functions can be used

in the same way .

Manually entered values or values from intermediate memory

can also be used for all calculation functions.

When the calculation is unrealistic (e.g. m

2

x m3) the display begins

to blink.

x

Consecutive

calculations

Page 42

40

2 < 1!

2 < 3!

4. Working with the PD 25

Measuring distances indirectly

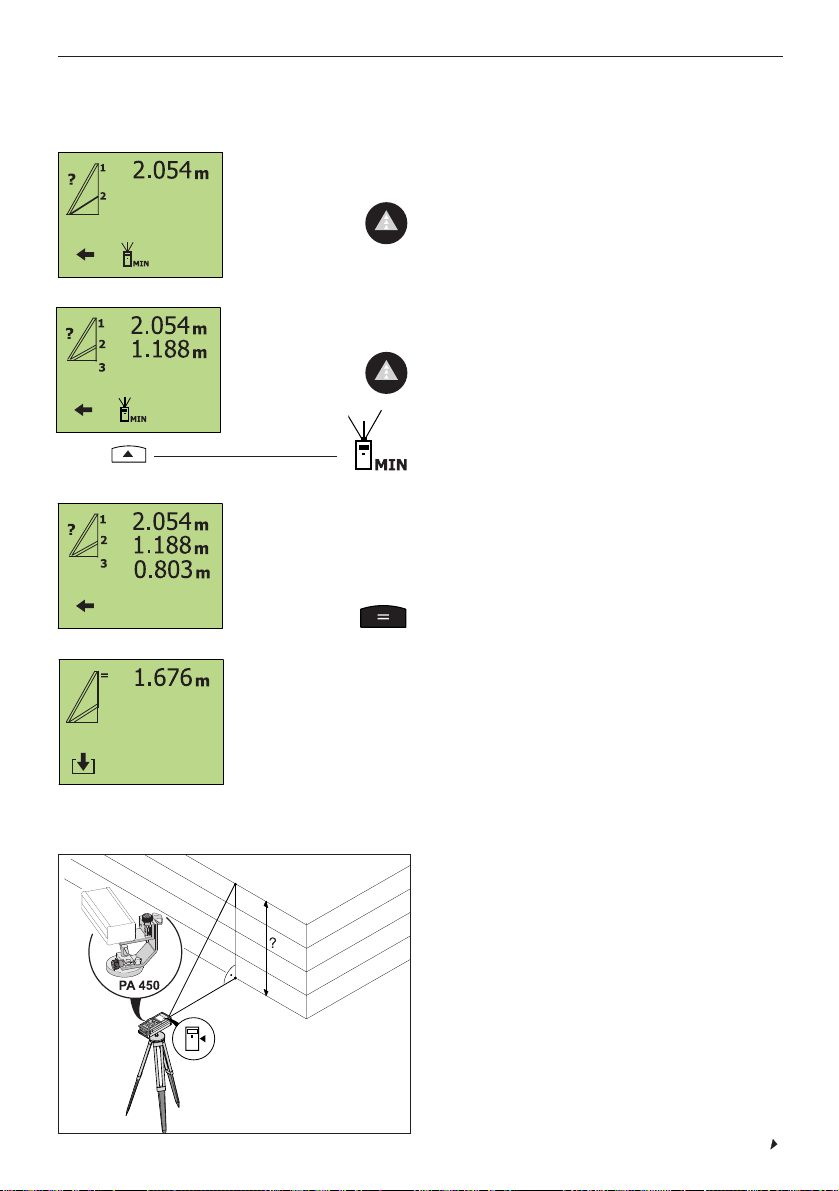

Determining the total length of the side of a triangle

Select the applicable symbol from the menu.

The display requests you to

measure the 1st distance:

The display requests you to measure the 2nd distance

(at right angles to the distance to be determined):

Take the measurement (1st distance)

Take the measurement (2nd distance)

or, alternatively:

Take the measurement in tracking mode

MIN, in order to determine the right angle

(90°) exactly .

The sequence of the measuring operations described must be

adhered to. When the measurements are unrealistic, this is

indicated by the PD 25 which causes the display to blink.

In a right-angled triangle, the distance to

be determined is calculated by the PD 25

according to the Pythagoras principle.

Application

- Determining the height of a building or

other distance which cannot be measured directly .

Continued

A

A

1

Three measurements are taken in sequence

from the fixed point A (preferably using a

tripod with the reference point set accordingly), whereby the second distance measured must be a “normal” distance (i.e. at right

angles to the distance to be determined).

The total distance is calculated by the PD 25.

Applications

- Determining a distance which cannot be

measured directly

- Measuring heights of buildings

2

3

Page 43

41

4. Working with the PD 25

Measuring distances indirectly , continued

Determining the total length of the side of a triangle, continued

The three measured values are shown in the display .

The result is shown in the display (i.e. the total distance calculated).

Calculate the total distance.

Continued

The display requests you to measure

the 3rd distance:

Take the measurement.

Measuring part of the length of the side of a triangle

Select the applicable symbol from the menu.

The display requests you to

measure the 1st distance:

Take the measurement.

A

A

Three measurements are taken in

sequence from the fixed point A (preferably

using a tripod equipped with the P A450 tripod adaptor), whereby the third distance

measured must be a “normal” distance

(i.e. at right angles to the distance to be

determined).

The distance is calculated by the PD 25.

Applications

- Determining the height of part of a facade

- Determining a distance which cannot be

measured directly

1

2

3

3 < 1!

3 < 2!

Page 44

42

Determining the length of the opposite side of a triangle according to the

Pythagoras principle

Two measurements are taken in succession

from the fixed point A (preferably using a tripod with the P A450 tripod adaptor), whereby the second distance measured must be

a “normal” distance (i.e. at right angles to

the distance to be determined).

The PD 25 calculates the distance to be

determined.

Applications

- Determining the heights of buildings

- Determining a distance which cannot be

measured directly

A

1

2

2 < 1!

4. Working with the PD 25

Measuring distances indirectly , continued

The display requests you to

measure the 2nd distance:

Take the measurement.

The display requests you to measure the 3rd distance (shortest

distance / at right angles to the distance to be determined):

Take the measurement.

or, alternatively:

Take the measurement in tracking mode

MIN in order to determine the right angle

(90°) exactly .

The three measured values are shown in the display .

The result is shown in the display (i.e. the length of part of the side

of the triangle).

Calculate the distance.

Measuring part of the length of the side of a triangle, continued

Continued

Page 45

43

Measuring distances indirectly , continued

4. Working with the PD 25

Measuring the length of the opposite side of a triangle according to the

Pythagorus principle, continued

The two measured values are shown in the display .

Calculate the distance.

Select the applicable symbol from the display . The display requests

you to measure the 1st distance:

The display requests you to measure the 2nd distance (at right

angles to the distance to be determined):

Take the measurement.

Take the measurement

or, alternatively:

Take the measurement in tracking mode

MIN in order to determine the right angle

(90°) exactly .

The result is shown in the display .

A

Notes concerning the button functions

Measured or calculated values can be saved by entering an intermediate memory location (0-9).

Measured or calculated values can be recalled by entering the

applicable intermediate memory location number (0-9).

Save

Recall

Scroll forward or back

Page 46

44

4. Working with the PD 25

The measurement is shown in the display .

Select the applicable symbol from the menu. The display then

requests you to take the

measurement:

Initiate tracking mode.

Move the tool slowly until the maximum measured value is shown in

the display .

Continuous measurement “tracking MAX”

With the “tracking MAX” function, the greatest or max. measured distance is always

shown in the display (e.g. for measuring a

diagonal).

The measured value indicated changes only

when the distance is increased.

Application

- Measuring the greatest distance between

two objects without having to target the

spot exactly .

Continued

Page 47

45

4. Working with the PD 25

The measurement is shown in the display .

Continuous measurement “tracking MIN”

Select the applicable symbol from the menu. The display then

requests you to take the measurement:

Initiate tracking mode.

With the “tracking MIN” function, the shortest or min. measured distance is always

shown in the display (e.g. for determining

the shortest distance).

The measured value indicated changes only

when the distance is decreased.

Applications

- Determining the shortest distance between two objects without having to target

the spot exactly .

- Determining a “normal” distance (at right

angles).

Move the tool slowly until the minimum measured value is shown in

the display .

Page 48

46

Select the corresponding symbol from the menu.

The display requests you to

measure the 1st distance:

Take the measurement.

4. Working with the PD 25

Measuring the mean value

After pressing the button only once,

8 measurements are taken consecutively.

Applications

- Measuring on uneven surfaces (plaster

etc.)

- Increasing accuracy

- Measuring equipment inspection

Select the corresponding symbol from the menu. The display then

requests you to take a measurement:

Initiate “mean value” measurement mode.

After the 8 measurements, the mean distance is displayed.

When the beep function is activated, the beep signal sounds each

time a measurement is taken.

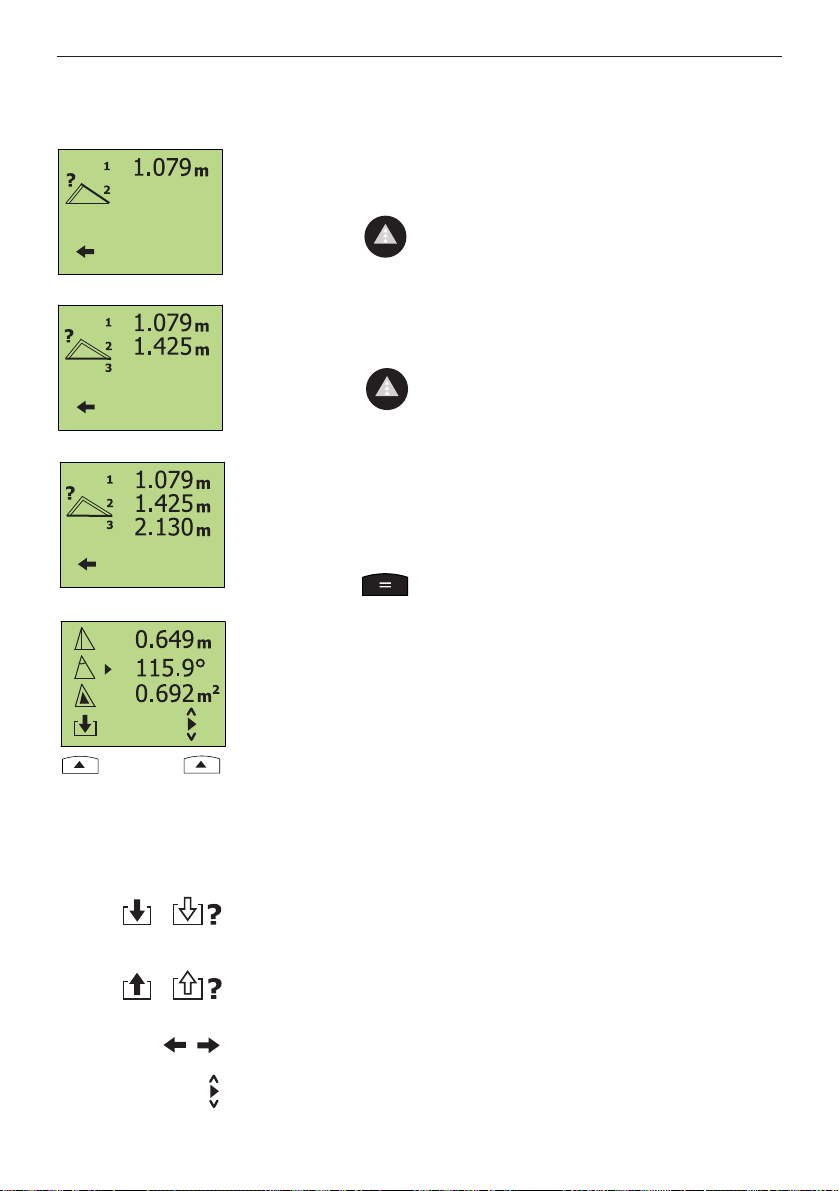

Triangle calculations

Determining the height, angle or area of a triangle

By measuring the lengths of the sides of a

triangle, the PD 25 can calculate:

- The angle between the first two measured sides

- The height and area of the triangle

Continued

Page 49

47

4. Working with the PD 25

Triangle calculations,continued

Determining the height, angle or area of a triangle, continued

The display requests you to

measure the 3rd distance:

Take the measurement.

The measured values for distances 1, 2 and 3 are shown

in the display .

Execute the calculation.

The display shows the:

- height

- angle

- area

of the triangle.

Select the desired value to be saved in intermediate memory .

The display requests you to

measure the 2nd distance:

Take the measurement.

Notes concerning the button functions

Save

Recall

Scroll forward or back

Scroll up or down

Measured or calculated values can be saved by entering an intermediate memory location (0-9).

Measured or calculated values can be recalled by entering the

applicable intermediate memory location number (0-9).

Page 50

48

Execute the calculation.

The display then shows:

- the length of the sloping section

- the angle of inclination

- the area of the gable end

of the pitched roof.

Triangle calculations,continued

Select the corresponding symbol from the menu.

The display requests you to

measure the 1st distance:

Pitched roof calculations

Take the measurement

Take the measurement

The display requests you to

measure the 2nd distance:

4. Working with the PD 25

The display requests you to

measure the 3rd distance:

Take the measurement

The measured values for distances 1, 2 and 3 are shown in the

display.

By measuring the height if the eaves, the

length of the base and the height of the

ridge, the tool is capable of calculating:

- The length of the sloping section

- The angle of inclination

- The area of the gable end

Applications

- Pitched roof calculations (gable end)

Select the desired value to be saved in intermediate memory .

Page 51

49

Setting out distances

4. Working with the PD 25

Adistance is divided into several individual distances.

The PD 25 can be used to measure the individual distances consecutively , i.e. set out the distances.

When the beep signal is activated, the frequency of the beeps

increases as the tool is moved closer to the point at which the

distance is to be marked.

Applications

- Setting out distances for drywall profiles

Select the corresponding symbol from the menu.

Enter the distance to be set out:

Use the numeric keypad to enter the following:

- Distance 1 (i.e. constant value for first

measurement)

- Distance 2 (i.e. individual, repetitive

distance)

...

Example 1: Fixed constant for 1st measurement

Move the tool slowly and set out (mark) the distances consecutively.

Move the PD 25 along the previously positioned profile until “0”

appears in the display .

Repeat the procedure until all distances to be set out have been

determined and marked.

Distances 1 and 2 can be measured, entered using the numeric

keypad or recalled from intermediate memory .

Page 52

50

Symbols shown in the display

Setting out distances, continued

4. Working with the PD 25

Increase distance

V alue displayed «-»

Distance to be set out has been reached.

Display indicates «0»

Decrease distance

V alue displayed «+»

Enter the distance to be set out

Use the numeric keypad:

- to set distance value 1 to “0”.

- distance value 2 to the desired value.

...

Example 2: Individual measurement repeated as many times as desired

Set out the distances as described previously .

Notes concerning the button functions

Save

Recall

Scroll forward or back

Scroll up or down

Measured or calculated values can be saved by entering an intermediate memory location (0-9).

Measured or calculated values can be recalled by entering the

applicable intermediate memory location number (0-9).

Page 53

51

Calculating the mean value from several measurements

4. Working with the PD 25

Select the corresponding symbol from the menu.

The display requests you to take the measurements.

Take the measurements consecutively

(max. 99).

The number of measurements taken and the corresponding mean

value are displayed continuously .

Saving the mean value or resetting the display

This function calculates the mean value from the measurements

taken (max. 99 consecutive measurements are possible).

Applications

- Continuous calculation of the mean value from several measurements.

The value displayed can be saved at a defi-

ned memory location (0....9) for use in furt-

her calculations or reset to “0” by pressing

the button.

...

Page 54

52

4. Working with the PD 25

Select the corresponding symbol from the menu.

2x

Shifting the measuring reference point to the rear

If desired, recall a predefined value from a

memory location (0...9), or

Use the numeric keypad to enter a value,

e.g. 1.500 m

Accept the value shown in the display .

Take the measurements.

The display shows the following

...

/

Shifting the measuring reference point

The measuring reference point used by the PD 25 can be shifted

forward or back by a manually entered or measured value. The set

value is then added or subtracted automatically to or from the rear

measuring reference point (standard) each time a measurement is

taken.

All measurements are then taken from this measuring reference point as long as the tool is used in this menu.

Applications

- Measuring from a relative reference point.

- Zeroing the tool in any position.

Continued

Page 55

53

Memory

Deleting memorised values

4. Working with the PD 25

Select the corresponding symbol from the menu.

Press button

to confirm.

All data is deleted

from memory .

Return to the special functions menu.

Shifting the measuring reference point, continued

Select the corresponding symbol from the menu.

Shifting the measuring reference point, continued

If desired, recall a predefined value from a

memory location (0...9), or

Use the numeric keypad to enter a value,

e.g. 1.500 m

Accept the value shown in the display .

Take the measurements.

ALL measurements saved in memory (max. 1000 memory

locations) are deleted.

...

Continued

/

/

The display shows the following:

2x

Page 56

54

Searching for, identifying or deleting measurements saved in memory

This function is used to recall or delete individual measurements

saved in memory (max. 1000 memory locations).

Measurements are identified by a max. 3-digit group and / or measurement code assigned by the user:

After selecting

the last memory location to which a value has been assigned is displayed.

Select

to scroll through memory and select, e.g.

Then press the

button to delete the measurement indicated from memory .

The value indicated is then deleted.

When deleted, a memory location is not available for further use

until all data has been deleted from memory .

Memory, continued

4. Working with the PD 25

Memory location

0-999

Measurement

Measurements can only be saved in memory (after each measurement is taken) when the memory function has been activated.

Please also refer to the section “3. Operation / setting preferences /

memory settings”.

Group code, e.g. for identification of the job

site (max. 3-digit number)

Measurement code

e.g. type of measurement (max. 3-digit

number)

Page 57

Connect (or disconnect) to/from the PD 25 for data communication.

Microsoft Excel®is started automatically when a connection has

been established successfully . Anew spreadsheet “table x” is opened in Excel®.

55

5. PD 25 server (option)

PD 25 server menu overview

5. PD 25 server (option)

The PD 25 server software permits the following:

- Transferring measurement data saved in memory to a PC

- Further processing of data in Microsoft Excel

®

When the PD 25 server software is installed, individual measurement or continuous measurement (tracking) can be carried out

directly from the PC.

- WIN95 / WIN98 / WIN NT 4.0 / WIN 2000 operating system

- RS232 interface (COM 1, 2, 3 or 4)

- Microsoft Excel

®

(version 5.0 or higher) for further processing of

data

PC requirements

Indication of

connection status

Connect

Download

Delete

Individual

remote

measurement

Downloads the measurement data from the PD 25 to the PC.

The measurement data is inserted in individual cells in the Microsoft

Excel

®

spreadsheet. Aconnection to the PD 25 is established when

this button is clicked.

Deletes all data from memory in the PD 25.

Takes an individual measurement.

The measurement is written directly into the Microsoft Excel

®

spreadsheet.

Dialog window

Log

Menus and

functions

Description of PD 25 server functions

Easy installation

using the installation

assistant

Remote

tracking

Initiates continuous measurement (tracking).

Measured values are written continuously into the Microsoft Excel

®

spreadsheet.

Continued

Page 58

56

5. PD 25 server (option)

Status indicators

Stop

Delete log

Stops the transmission of data from the PD 25 or the “tracking”

function.

Deletes all data from the log in the dialog window.

Measurement unit to

be used (m / in)

Connection with the PD 25 is active

Connection with the PD 25 is inactive

Unfavourable signal characteristics

Batteries almost exhausted

Record PD 25 data

transfer in the log in

the dialog window

(yes / no)

Preferences

Interface used

Data transfer rate

Info

Exit

Opens the preferences dialog window (settings).

The following settings can be made as long as no connection to the

PD 25 has been established:

- Baud rate

- Interface used (COM 1...4)

Opens the info dialog window showing the

PD 25 server software version number

Exit from PD 25 server software

Description of PD 25 server functions, continued

Page 59

57

5. PD 25 server (option)

Installing and setting up the PD 25 server software

1 Insert the 3 1/2” diskette in the floppy

drive and double-click with the mouse on

the symbol for the floppy drive.

2 Double-click the file “Setup.exe” to start

the installation.

3 Follow the instructions displayed on the

screen by the installation assistant.

End the installation

after entering your name and

name of company ,

target folder and programme

group.

Standard installation

Always click on “continue” in the installation assistant to install the PD 25 server

software with the standard settings or

when you are unsure of the installation

procedure.

4 When the installation has been succes-

sfully completed:

Start the server software from the programme group “Hilti PD 25”.

Amenu appears on the screen.

5 Click the symbol.

The preferences window (PD 25 server

settings) appears on the screen.

6 Check or alter the settings and confirm

the information by clicking “OK”.

Important:Activate the correct interface

(COM 1...4) to which the PD 25 is

connected for data transfer to your PC.

7 See “Connecting the PD 25 to a PC”.

Quick-start instructions (MS Word)

1

2

Installation assistent

PD 25 server dialog window

Einstellungen durchführen

Hilti PD 25 server setup is preparing the

Installshield®Assistant which will guide you

through the setup procedure. Please wait.

Page 60

58

5. PD 25 server (option)

Connecting the PD 25 to a PC

RS232

EIN

COM1 ... 4

1. Use the Hilti interface cable to connect

the PD 25 to the PC.

Tighten the screw on the PD 25

connector.

2. Switch on the PD 25.

3. Switch on the PC and the start the PD 25

server software.

4. The data transfer rate must be set to the

same baud rate in the settings menu on

the PD 25 and in the preferences window

of the PD 25 server software.

5. The other settings (COM 1...4 / metres,

inches / display data) in the PD 25 server

preferences window should be checked

and adapted if necessary .

7

C

9

8

4

5

6

1

0

2

3

.

=

l

max.

= 10m

Continued

4

1

2

3

ON

Page 61

59

5. PD 25 server (option)

The PD 25 server software in use, continued

Other functions

The PD 25 server software in use

- The PD 25 is connected to the PC

- The PD 25 and the PC are switched on

- The PD 25 server software is installed on the PC

The correct settings have been made in the “preferences” menu.

2. Click the symbol.

The connection from the PC to the PD 25 is activated.

3. Click the symbol. Measurement data is transferred from

the PD 25 and written directly in individual, consecutive lines in

Microsoft Excel.

®

4. The measurement data is then available for further processing by

the user in Microsoft Excel®.

1. Start the PD 25 server software.

The PD 25 server dialog window and Microsoft Excel®are

opened automatically .

Before beginning,

check that

Procedure

PD 25 Server MS Excel

®

Date, time (end of transfer)

Memory location number

Group code

Measurement

code

Measurement

Unit in decimal form (m / in)

Remoter

individual

measurement

Takes an individual measurement.

The measurement is written directly into Microsoft Excel

®

.

Remote

tracking

Begins continuous measurement (tracking).

Measurements are written continuously into Microsoft Excel

®

.

Stop

Stops the transmission of data from the PD 25 or the “continuous

measurement” function.

Page 62

60

Uninstalling the PD 25 server software

PD 25 server software troubleshooting

Select Preferences / Control Panel / Software / Install / Uninstall. Mark PD 25 server software and click on Add / Remove.

The PD 25 server software will then be removed from your PC.

5. PD 25 server (option)

The PD 25 server software in use, continued

Unfavourable conditions affecting the signal

Batteries almost exhausted

No connection to the PD 25

- Observe the minimum measuring distance (>300 mm).

- Clean the lens.

- Take the measurement from

a different surface (use the

P A411 target plate).

- Shield the target spot from

bright sunlight.

- Insert new batteries.

- Set the baud rate for the PD

25 (tool) and PD 25 server

software (PD 25 server preferences) to the same value

(must be identical).

- Check the plug connections.

Display Fault Remedy

Page 63

61

6. Care, transportation and storage

6. Care, transportation and storage

Cleaning and drying

• Blow dust off the lenses.

• Do not touch the glass with your fingers.

• Use only clean, soft cloths for cleaning. If necessary , moisten

slightly with pure alcohol or water.

Do not use any other liquids as these may damage the plastic components.

Observe the temperature limits when storing your equipment. This

is particularly important in summer if the equipment is kept inside a

motor vehicle (storage temperatures: -30°C to +70°C / -22°F to

+158°F)

Storage

Remove the tool from its case if it has become wet. The tool, its

carrying case, foam insert and accessories should be cleaned and

dried.

Put the equipment back into its case only when it is completely dry .

Check the accuracy of the equipment before it is used after a long

period of storage or transportation.

Transportation

Y our equipment should be shipped in the Hilti toolbox.

Always remove the batteries before shipping.

Page 64

62

7. Symbols displayed

T emperature too high

(> +50°C), in tracking mode and

in setting-out mode

(> +45°C)

T emperature too low

(< -10°C)

Unfavourable reception

conditions

General hardware fault

Batteries almost exhausted

Ambient light at target too

bright

Allow the tool to cool.

Warm the tool.

Observe the min. measuring

distance (> 300mm).

- Clean the lens.

- Take the measurement from

a different surface (target

plate).

- Shade the target point from

background light.

Switch the tool off and on

again. If the fault persists,

please contact a service

centre.

Insert new batteries.

Shade the target point from

bright light.

7. Symbols displayed

Symbol Information / fault Remedy

Page 65

63

8. Measuring equipment inspection

8. Measuring equipment inspection

Measuring equipment inspection of the PD 25 for users certified

according to ISO 900...

Y ou may carry out the measuring equipment inspection required by

ISO 900... on the PD 25 linear measuring device yourself (see DIN

18723-6; Procedures for checking the accuracy of geodetic instru-

ments in the field: Part-6, opto-electronic range meters for short

distances).

To do this, select a measuring distance which remains constant over

a period of time and which is easily accessible. It should have a

known length of approx. 1 to 5 m (e.g. a window opening or the

width of a room) and 10 measurements should be made.

Determine the deviation of the readings from the nominal measuring

distance and calculate the standard deviation on this basis.

Make a note of this value and the date or time for the next inspection.

Repeat these verification measurements at regular intervals as well

as before and after important measuring tasks.

Apply a measuring equipment inspection sticker to the PD 25 and

document the entire inspection procedure.

Y our PD 25 conforms to the specified accuracy if the standard

deviation remains less than or equal to 3mm.

APD 25 which has been tested / inspected over the test distance

will operate with the accuracy specified in the operating instructions

over the entire specified length and temperature range. Please refer

to the technical data contained in the operating instructions and to

the explanation of the accuracy values.

Recommendation

Test the tool, or have it tested, once a year. Contact your Hilti representative for further information. The tool can also be tested at one

of our repair / service centres where confirmation of inspection can

be given and, when necessary , a certificate issued for your documentation.

Page 66

64

9. Accessories

9. Accessories

P A411 target plate

With two different target surfaces

- White, for use when reflection is excessive

- Brown, when reflection is too low

P A970 sighting glasses

The sighting glasses improve visibility of the laser target spot (by

the factor 4-5).

P A440 data set for the PD 25

- RS232 serial interface cable for connecting the PD 25 to a PC

(for data transfer)

- 31/2” diskette containing the PD 25 server software

P A450 tripod adaptor

With fine adjustment of the X- and Y-axis for working accurately

from a tripod.

(The measuring reference point must be set to .)

Continued

Page 67

65

P A421 telescopic sight

Used to position the target spot exactly on objects from which measurements are taken.

9. Accessories

9. Accessories, continued

Do not aim the P A421 telescopic sight at objects with highly

reflective surfaces.

Page 68

66

10. FCC statement (applicable in US)

10. FCC statement (applicable in US)

WARNING

This equipment has been tested and found to comply with the limits

for a Class II digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment