Page 1

A

10

11 12

13

10

11 12

13

≤ T

max

≤ T

max

dhesive Anchoring Systems

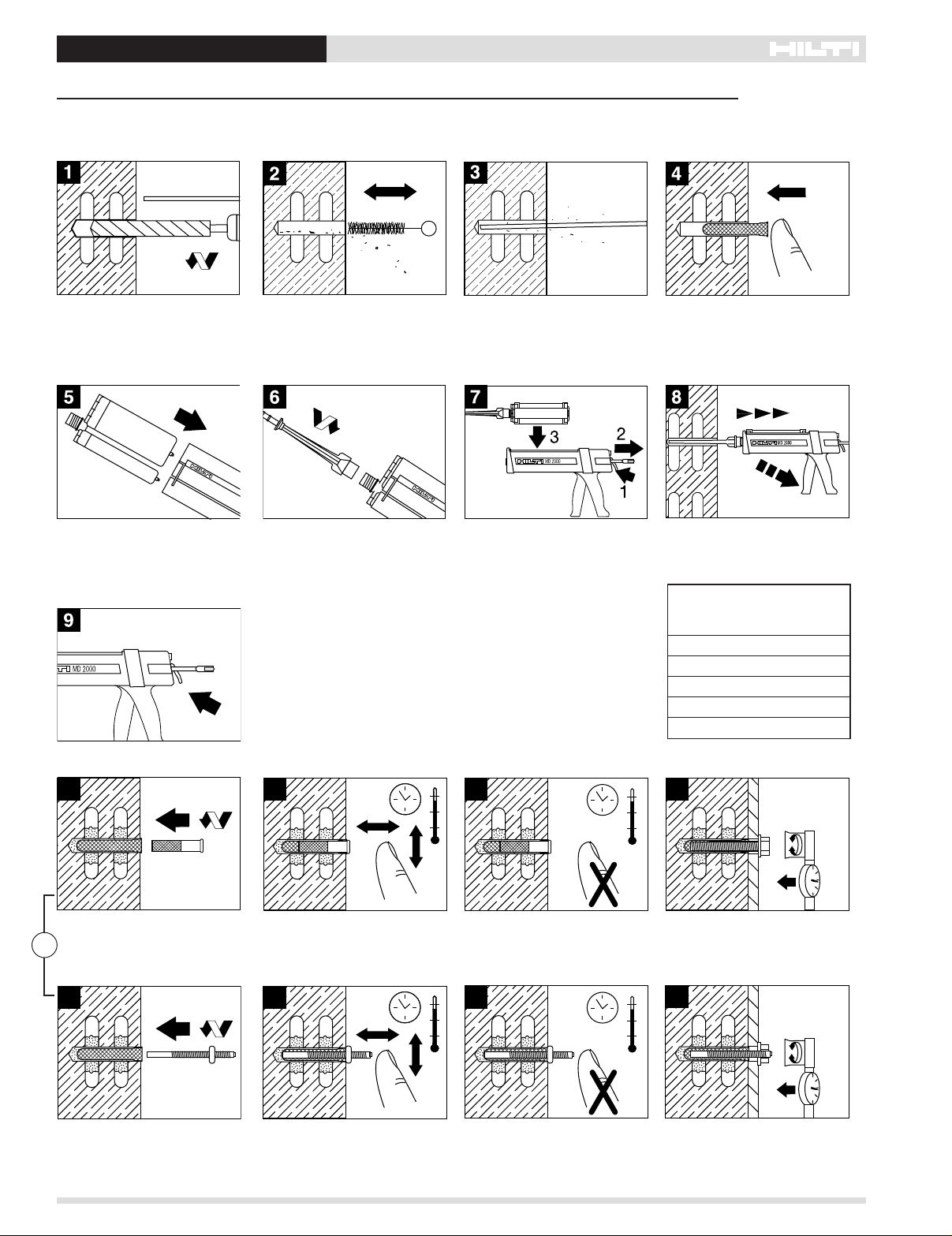

4.2.7 HIT HY 20 for Masonry Construction

4.2.7.4 Installation Instructions

IT-I Inserts and HIT-A Rods into Hollow Brick, Hollow Block or Tile

H

1. Select the proper bit. Set the depth

gauge, drill the hole, rotation only.

Hilti URM bits are recommended for

drilling into masonry.

5. Insert refill pack into holder. 6. Screw on mixing nozzle with exten-

9. Unlock dispenser

2. Proper hole cleaning is essential. Use

a nylon brush to remove loose material. Do not use brushes with metal

bristles.

sion.

3. Use compressed air to blow out the

hole from the bottom. The Hilti air

nozzle is designed for hole cleaning.

7. Put holder into dispenser and

CARD FIRST THREE TRIGGERPULLS OF ADHESIVE FROM EACH

REFILL PACK

.

DIS-

4. Insert specified HIT-S type screen

tube into hole.

8. Fill HIT-S type screen tube com-

pletely from back to front edge of

screen using the minimum number

of trigger pulls listed in table.

The minimum number

of trigger pulls to fill each

screen is as follows:

S12 1 pump

S16/2 4 pumps

S16 6 pumps

S22/2 4 pumps

S22 6 pumps

-I INSERT

HIT

or HIT

-I Insert,

Insert HIT

10.

into adhesive-filled screen,

OR

slightl

.

y

HIT-A ROD

182 Hilti, Inc. (US) 1-800-879-8000 | www

-A Rod

twisting

Fastener ma

11.

specified gel time.

y be adjusted during

.us.hilti.com

I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www

Do not disturb fastener between

12.

specified gel and cure time.

13.

exceed maximum recommended

torque.

.ca.hilti.com

I Pr

oduct T

y torque to anchor

Appl

Do not

.

echnical Guide 2006

Page 2

HIT HY 20 for Masonry Construction 4.2.7

2

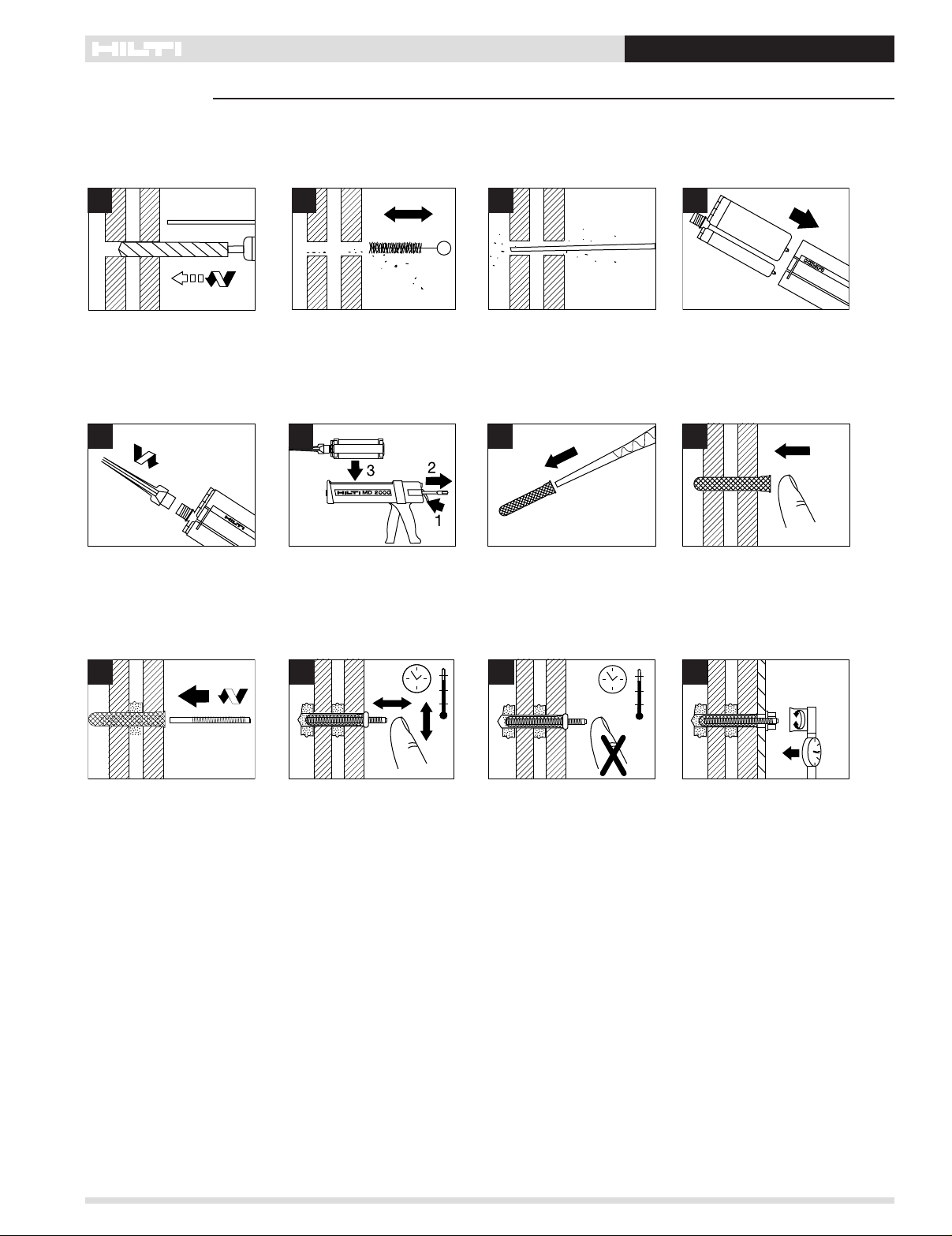

Installation of HAS-E Rods in Masonry Construction with Voids

(e.g. Multi-wythe Construction)

A

dhesive Anchoring Systems

1

1. Select the proper bit. Set the

depth gauge. Drill the hole,

rotation only (unless otherwise

specified).

5

5. Screw on mixer and remove

extension.

2

2. Proper hole cleaning is essential.

Use a nylon brush to remove loose

material. Do not use brushes with

metal bristles.

3 4

3. Use compressed air to blow out

the hole from the bottom. The Hilti

air nozzle is designed for hole

cleaning.

4. Insert refill pack into holder.

6 7 8

6. Put holder into dispenser.

DISCARD FIRST THREE TRIGGER

PULLS OF ADHESIVE FROM EACH

REFILL PACK.

7. Fill the screen tube completely,

beginning at the bottom. Use

mixer filler extension tubes when

needed to reach the screen tube

bottom.

8. Insert specified screen tube into

hole.

9

Insert HAS-E or HIT Rod into

9.

adhesive-filled screen, twisting

slightly.

10

Fastener ma

10.

specified gel time.

y be adjusted during

11

Do not disturb faster between

11.

specified gel and cure time

12

Load fastener onl

12.

time has elapsed.

≤ T

max

y after cure

Hilti, Inc. (US) 1-800-879-8000 | www

.us.hilti.com

I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www

.ca.hilti.com

I Pr

echnical Guide 2006 183

oduct T

Loading...

Loading...