Page 1

0

0

1

0

9

0

2x

11

10

HIT-ED 3500

Hilti Corporation

LI-9494 Schaan

Tel.:+423 / 23421 11

Fax: +423 /234 29 65

www.hilti.com

12

*273302*

Hilti = registered trademark of Hilti Corp., Schaan W 3203 0107 00-Pos. 1 1 Printed in Liechtenstein © 2007

Right of technical and programme changes reserved S. E. & O.

273302 / E

273302

Bedienungsanleitung de

Operating instructions en

Mode d’emploi fr

Istruzioni d’uso it

Gebruiksaanwijzing nl

Manual de instruções pt

Manual de instrucciones es

Brugsanvisning da

Käyttöohje fi

Bruksanvisning no

Bruksanvisning sv

Οδηγιες χρησεως

Instrukcja obsługi pl

Инструкция по зксплуатации ru

Navodila za uporabo sl

Návod k obsluze cs

Használati utasítás hu

el

zh

ja

ko

ar

Page 2

1

1

2

2

0

3

1 1

1

2

3

4 5

Hilti HIT

HY 150

123456

02/06

4

8

+“

+±

5

6

0

7

9

+≠

+“

6

2

7

1

0

1

8

0

OK

3

0

1

Page 3

11

en

It is essential that the operating instructions

are read before the tool is operated for the

first time.

Always keep these operating instructions

together with the tool.

Ensure that the operating instructions are

with the tool when it is given to other

persons.

Hilti HIT-ED 3500 (12V) electric dispenser

Contents Page

1. General information 11

2. Description 12

3. Accessories 12

4. Technical data 12

5. Safety rules 13

6. Before use 15

7. Operation 16

8. Care and maintenance 17

9. Troubleshooting 17

10. Disposal 18

11. Manufacturer's warranty – tools 19

12. EC declaration of conformity 19

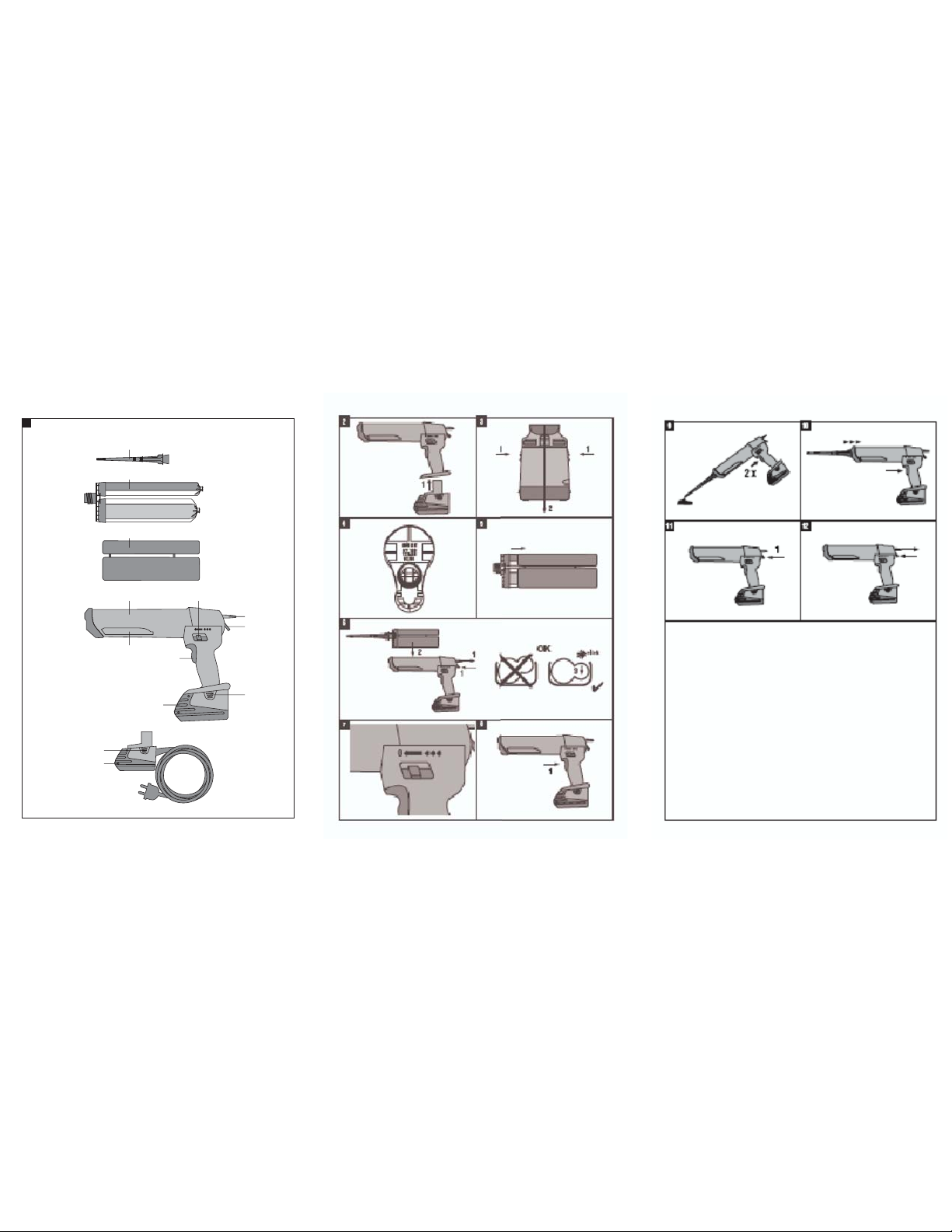

Operating controls and parts

햲 Mixing nozzle for use with Hilti HIT adhesive

mortar (see applicable operating instructions)

햳 Hilti HIT foil pack (inserted)

햴 Foil pack holder

햵 Impact-resistant, metal-reinforced plastic cradle

for the holder

햶 Switch for selecting neutral position, single-stroke

or continuous operating mode

햷 Parallel piston rods with plastic grip for retracting

the rods

햸 Release button

햹 Opening to facilitate removal of the foil pack holder

햺 Trigger for controlling injection of the adhesive

mortar

햻 Battery

햽 Mains adaptor

햾 Release buttons for detaching the battery / mains

adaptor (both sides)

These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover pages. Keep these pages open while studying the operating instructions.

In these operating instructions, the designation “the tool”

always refers to the Hilti HIT-ED 3500 (12V) electric dispenser with battery fitted.

Location of identification data on the tool

The type designation and serial number can be found on

the type identification plate on the tool. Make a note of

this data in your operating instructions and always refer

to it when making an enquiry to your Hilti representative

or service department.

Type:

Serial no.:

Warning signs

General

warning

Warning:

electricity

Warning:

caustic

substances

Obligation signs

Wear

protective

gloves.

Wear eye

protection.

Read the

operating

instructions

before use.

Symbols

1. General information

1.1 Safety notices and their meaning

-WARNING-

Draws attention to a potentially dangerous situation that

could lead to serious personal injury or fatality.

-CAUTION-

Draws attention to a potentially dangerous situation that

could lead to slight personal injury or damage to the

equipment or other property.

-NOTE-

Draws attention to instructions and other useful information.

1.2 Explanation of the pictograms and other

information

Return waste

material for

recycling.

Page 4

3. Accessories

Charger C 7/24

Charger C 7/36-ACS

Battery SFB 121

Battery SFB 126

Mains adaptor ED 3500-PS

12

en

2. Description

2.1 Use of the product as directed

The Hilti HIT-ED 3500 electric dispenser should be used

exclusively with Hilti HIT foil packs. The dispenser is

equipped with a holder in which the Hilti HIT foil packs

are inserted. Products from other manufacturers must

not be used in this dispenser.

Do not use the battery or ED 3500-PS mains adaptor as

a power source for other unspecified appliances.

Changes or modifications to the tool are not permissible.

To avoid the risk of injury, use only genuine Hilti accessories.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

The tool is designed for professional use and may be

operated, serviced and maintained only by trained, authorized personnel. This personnel must be informed of

any special hazards that may be encountered. The tool

and its ancillary equipment may present hazards when

used incorrectly by untrained personnel or when used

not as directed.

The working environment may be as follows: construction site, workshop, renovation, conversion or new construction.

4. Technical data

Tool Hilti HIT-ED 3500 (12 V)

Selector switch: For selecting single-stroke or continuous mode

Motor cut-out: Electronic overload cut-out

Weight (incl. battery): 2.7 kg

Noise and vibration information (measured in accordance with EN 60745):

Typical A-weighted sound power level (LwA): < 70 dB (A)

Typical A-weighted sound pressure level (LpA): < 70 dB (A)

Uncertainty for the given sound level as per EN 60745 3 dB

Typical weighted vibration at the grips: < 2.5 m/s

2

Battery SFB 121 SFB 126

Rated voltage 12 V 12 V

Capacity 2 Ah 3 Ah

Energy content 24 Wh 36 Wh

Weight 0.72 kg 0.77 kg

Temperature monitoring Yes Yes

Type of cell Nickel-cadmium Nickel-metal hydride

SUB C size SUB C size

No. of cells 10 10

Page 5

13

en

5. Safety rules

5.1 General safety rules

WARNING! Read all instructions! Failure to follow all

instructions listed below may result in electric shock, fire

and/or serious injury. The term "power tool” in all of the

warnings listed below refers to your mains operated

(corded) power tool or battery operated (cordless) power tool. SAVE THESE INSTRUCTIONS.

5.1.1 Work area safety

a) Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite

the dust or fumes.

c) Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

5.1.2 Electrical safety

a) Power tool plugs must match the outlet. Never mod-

ify the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for car-

rying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk

of electric shock.

e) When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

5.1.3 Personal safety

a) Stay alert, watch what you are doing and use com-

mon sense when operating a power tool. Do not use

a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in

serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the

off-position before plugging in. Carrying power tools

with your finger on the switch or plugging in power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to

a rotating part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jew-

ellery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can

be caught in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of these devices

can reduce dust-related hazards.

5.1.4 Power tool use and care

a) Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be

repaired.

c) Disconnect the plug from the power source and / or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of untrained

users.

Mains adaptor ED 3500-PS (12 V)

Input: 90–260 V AC

Mains frequency: 50/60 Hz

Output: 12 V DC

Power: 80 W

Right of technical modifications reserved

Page 6

14

en

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc.,

in accordance with these instructions and in the manner intended for the particular type of power tool,

taking into account the working conditions and the

work to be performed. Use of the power tool for oper-

ations different from those intended could result in a

hazardous situation.

5.1.5 Battery tool use and care

a) Ensure the switch is in the off-position before insert-

ing battery pack. Inserting the battery pack into pow-

er tools that have the switch on invites accidents.

b) Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used

with another battery pack.

c) Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fire.

d) When battery pack is not in use, keep it away from

other metal objects like paper clips, coins, keys,

nails, screws, or other small metal objects that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause

burns or a fire.

e) Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from

the battery may cause irritation or burns.

5.1.6 Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

5.2 Additional safety precautions

5.2.1 Electrical safety

a) Mobile generators may generate an excessively high

voltage. Check that the mains adaptor is operated

only within the specified voltage and frequency range.

The mains adaptor may otherwise suffer damage.

b) Check the condition of the supply cord and its plug

connections and have it replaced by a qualified electrician if damage is found. Check the condition of

the extension cord and replace it if damage is found.

Do not touch the supply in the event of it suffering

damage while working. Disconnect the supply cord

plug from the socket. Damaged supply cords and

extension cords present a risk of electric shock.

c) Do not insert the mains adaptor into the battery charg-

er, especially when the mains adaptor supply cord

is plugged into the electric supply.

5.2.2 Work area

a) Ensure that the workplace is well lit.

b) Ensure that the workplace is well ventilated. Expo-

sure to dust at a poorly ventilated workplace may result

in damage to the health.

5.2.3 Safety equipment

a) The user and any other persons in the vicinity must

wear suitable eye protection and protective gloves

while the tool is in use.

Page 7

15

en

6. Before use

6.1 Battery use and care

-NOTE-

Battery performance drops at low temperatures. Never

use the battery until the cells become fully discharged.

Change to the second battery as soon as a drop in performance is noticed. Recharge the battery immediately

so that it is ready for reuse.

Batteries should be stored at room temperature. Never

store the battery where it is exposed to direct sunlight or

sources of heat, e.g. on heaters / radiators or behind a

motor vehicle windscreen. Batteries that have reached

the end of their life must be disposed of safely and correctly to avoid environmental pollution.

To achieve optimum results, it is recommended that the

dispenser, battery and foil packs are at room temperature before use. The foil packs and battery should always

be kept warm when working outdoors in low temperatures.

6.2 Charging the battery

-CAUTION-

Use only Hilti SFB 121 or SFB 126 batteries.

6.2.1 Charging a new battery for the first time

A new battery must be charged correctly for the first

time before use. This will ensure that the cells form correctly. Incorrect initial charging may have a permanent,

negative effect on battery capacity. Please refer to the

applicable battery charger’s operating instructions for

information about initial charging.

6.2.2 Charging a previously used battery

-CAUTION-

Use only the Hilti chargers listed under "Tools and accessories”.

Ensure that the outer surfaces of the battery are clean

and dry before inserting it in the corresponding charger.

Read the operating instructions for the charger for further information about the charging procedure.

6.3 Fitting the battery

-CAUTION-

Before fitting the battery, check that the tool is switched

off and that the transport lock is engaged (selector switch

in the neutral position). Use only the Hilti batteries intended for use with this tool (SFB 121 or SFB 126).

1. Push the battery into the tool from below until it is

heard to engage with a click.

2. -CAUTION- A falling battery may present a risk of

injury to yourself or others. Check that the battery is

seated securely in the tool.

6.4 Removing the battery

1. Press both battery release buttons.

2. Pull the battery downwards out of the tool.

6.5 Fitting the mains adaptor

-WARNING-

The supply cord plug must be disconnected from the

power outlet.

-CAUTION-

Before fitting the mains adaptor, check that the tool is

switched off and the trigger lock is activated (selector

switch in the neutral position). Use only the mains adaptor specified for use with this tool (Hilti ED 3500-PS

mains adaptor).

1. Push the mains adaptor into the tool from below until

it is heard to engage with a click.

2. -CAUTION- A falling mains adaptor may present a risk

of injury to yourself or others. Check that the mains

adaptor is securely seated in the tool.

6.6 Removing the mains adaptor

1. Disconnect the supply cord plug from the power outlet.

2. Press both release buttons.

3. Pull the mains adaptor downwards out of the tool.

6.7 Transport and storage

1. The selector switch must be in the “0” position during transport and storage of the tool.

2. The battery must be removed form the tool before

transport or storage.

Page 8

16

en

7. Operation

Notes on use

Important

● Observe the safety rules.

● Observe the information in the operating instruc-

tions for the various foil packs and the safety data

sheets for chemical products.

● The cordless dispenser begins to operate when the

trigger is pressed while the selector switch is in the

single-stroke or continuous operating mode position.

It must be ensured that the trigger is not activated during transport or storage of the tool, i.e. the selector

switch must be in the left in the “0” (neutral) position

in order to prevent battery drain and to ensure that no

adhesive mortar is dispensed unintentionally.

● The use of original Hilti auxiliary items ensures opti-

mum safety. These units form a co-ordinated system.

● High dispensing performance, maximum battery capac-

ity and long life expectancy can be achieved only when

the tool is kept clean and properly maintained.

Important: The motor switches off automatically when

overloaded. In this case, relieve pressure by pressing the release button. The tool will be ready for use

again after 5 seconds.

7.1 Preparing the foil pack for use

Before use, read the safety precautions and conditions

for use given in the instructions enclosed with the foil

pack. Check the expiry date (month / year) and observe

the product designation printed on the front of the foil

pack junction piece. If it is found necessary to make a

complaint, please quote the lot number.

1. Insert the foil pack into the holder as far as it will go

and then screw on the mixing nozzle. The tempera-

ture of the foil pack before use must be no less than

the minimum temperature given in the corresponding instructions for use of the adhesive mortar.

7.2 Inserting the holder with foil pack

Check the holder for damage before use. Never use a

damaged foil pack holder.

1. Before inserting the holder in the dispenser, the piston advance rods must be pulled into the rearmost

position while pressing the release lever.

2. Grip the holder by the small cylinder. Insert the holder into the dispenser from above and then swing the

small cylinder down into position.

3. Take caution! The holder must be fully inserted into

the dispenser. Press the holder downwards with slight

force to ensure a correct fit.

7.3 Beginning dispensing

-NOTE-

The switch can be set to single-stroke or continuous dispensing mode, as desired.

1. Pull the trigger. The foil pack is opened automatically by a piercing point built into the junction piece. The

2 components can be seen to mix as they pass through

the nozzle. The initial quantity of mortar dispensed

(amount specified in the applicable instructions

for use of the mortar) is not suitable for use and must

be discarded. Likewise, after changing a mixing noz-

zle, the initial flow should be discarded.

7.4 Injecting the mortar

Note: In the single-stroke mode, keep the trigger pulled

until the dispenser switches itself off. This will ensure a

full stroke.

1. The hole must be filled with adhesive mortar with-

out forming air pockets. To achieve this, insert the

nozzle as far as the base of the hole (use the exten-

sion for deep holes) and slowly withdraw the nozzle,

step by step, after each pull of the trigger. Details of

the number of trigger pulls required for each anchor

size are printed in the instructions enclosed with the

foil pack. Important: failure to observe these in-

structions could negatively affect the loadbearing

capacity of the fastening!

7.5 Removing the foil pack

1.Press the release button after the hole has been

filled with adhesive. This releases pressure on the foil

pack and no further adhesive flows from the mixing

nozzle. The piston advance rods must be pulled into

the rearmost position while pressing the release button before the holder can be removed from the dispenser. To remove the holder from the dispenser, first

press the small cylinder upwards through the opening and then remove the holder completely.

Partly used foil packs should be stored in the holder with

the mixing nozzle screwed on.

The adhesive mortar in the mixing nozzle will become

hard during a long pause.

The mixing nozzle must be changed before work can

continue and, as with a new foil pack, the initial quantity of adhesive mortar must be discarded (see 7.3).

Note: Partly-used cartridges must be used up within 4

weeks.

7.6 Disposing of the foil pack

Empty foil packs should be disposed of in accordance

with the applicable regulations.

The holder can be reused.

The integrated pressure pistons return to their outset

position when a new foil pack is inserted.

Page 9

17

en

8. Care and maintenance

-CAUTION-

Before beginning cleaning, remove the battery / mains

adaptor from the tool in order to avoid accidental starting.

8.1 Care of insert tools

Clean off dirt and dust deposits adhering to the insert

tools and protect them from corrosion by wiping the

insert tools from time to time with an oil-soaked rag.

8.2 Care of the tool

The outer casing of the tool is made from impact resistant plastic. Sections of the grip are made from a synthetic rubber material.

Never operate the tool when the ventilation slots are

blocked. Clean the ventilation slots carefully using a dry

brush. Do not permit foreign objects to enter the interior of the tool. Clean the outside of the tool at regular intervals with a slightly damp cloth. Do not use a spray, steam

pressure cleaning equipment or running water for cleaning. This may negatively affect the electrical safety of the

tool. Always keep the grip surfaces of the tool free from

oil and grease. Do not use cleaning agents which contain silicone. The piston advance rods should be oiled

at regular intervals. Deposits of adhesive mortar on the

holder (inside and outside) and in the working section

of the dispenser should be removed immediately. Free

movement of the pistons in the holder must be ensured!

8.3 Maintenance

-WARNING-

Repairs to the electrical section of the tool may be carried out only by trained electrical specialists.

Check all external parts of the tool for damage at regular

intervals and check that all controls operate faultlessly.

Do not operate the tool if parts are damaged or when the

controls do not function faultlessly. If necessary, your

tool should be repaired at a Hilti repair center.

8.4 Care of the battery / mains adaptor

Keep the electrical contacts free from dust, oil and grease.

If necessary, use a clean cloth to clean the contact surfaces. Do not continue to operate the tool until the battery is completely discharged as this may damage the

battery cells. Recharge the battery as soon as a drop in

performance is noticed. At monthly intervals or, at the

latest, when battery capacity drops significantly, the battery should be given a refreshing charge, as follows:

Charge with the C 7/24, charger for 24 hours in normal

mode or for 12 hours in refresh mode. The C 7/36-ACS

charger determines automatically when an initial charge

or refreshing charge is necessary. If battery capacity is

still unsatisfactory after the refreshing charge, we recommend that the battery is returned to Hilti for diagnosis.

8.5 Checking the tool after care and maintenance

After carrying out care and maintenance work on the tool,

check that all protective and safety devices are fitted and

that they function faultlessly.

Fault Possible cause Remedy

The tool doesn’t run. The battery / mains adaptor is The battery / mains adaptor must engage

discharged or fitted incorrectly. with an audible click or, respectively, needs

to be charged.

Electrical fault. Remove the battery / mains adaptor from

the tool and contact Hilti.

The battery reaches the Battery condition is not optimal. Charge the battery in refresh chargemode

end of its capacity more (please refer to the operating instructions

quickly than usual. for the charger).

The battery / mains The retaining lugs on the battery / Clean the retaining lugs and check that the

adaptor doesn’t engage mains adaptor are dirty. battery / mains adaptor engages securely.

with an audible click. Contact Hilti Service if the problem persists.

The tool or the battery / Electrical fault. Switch the tool off immediately, remove the

mains adaptor become battery / mains adaptor and contact Hilti

very warm. Service.

The tool has been overloaded Use the right tool for the job (don’t use a

(application limits exceeded). low-powered tool for heavy work).

Single stroke doesn’t work. No foil pack inserted. Insert foil pack.

9. Troubleshooting

Page 10

18

en

10. Disposal

-CAUTION-

Improper disposal of the equipment may have serious consequences: The burning of plastic components generates toxic fumes which may present a health hazard. Batteries may explode if damaged or exposed to very

high temperatures, causing poisoning, burns, acid burns or environmental pollution. Careless disposal may

permit unauthorized and improper use of the equipment. This may result in serious personal injury, injury to

third parties and pollution of the environment.

-CAUTION-

Dispose of defective batteries without delay. Keep them out of reach of children. Do not attempt to open or

dismantle batteries and do not dispose of them by incineration.

-CAUTION-

Dispose of the battery in accordance with national regulations or return used batteries to Hilti for recycling.

Most of the materials from which Hilti tools or machines are manufactured can be recycled. The materials must

be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements

for taking back your old tools for recycling. Please ask your Hilti customer service department or Hilti

representative for further information.

For EC countries only

Disposal of electric tools together with household waste is not permissible!

In observance of European Directive 2002/96/EC on waste electrical and electronic equipment and its

implementation in accordance with national law, electric tools that have reached the end of their life must

be collected separately and returned to an environmentally compatible recycling facility.

Batteries

Hilti batteries contains nickel and cadmium or nickel metal hydrid.

Dispose of batteries in accordance with national regulations.

Y

C

C

L

E

RBRC

NiCd

.

8

2

2

E

7

3

8

8

.

R

1

.

8

0

0

Y

C

C

L

E

RBRC

NiMh

.

8

2

2

E

7

3

8

8

.

R

1

.

8

0

0

Page 11

19

en

12. EC declaration of conformity

We declare, on our sole responsibility, that this product

complies with the following directives and standards:

98/37/EC, 89/336/EEC, 91/157/EEC, 93/86/EEC,

EN 60745-1, EN 61000-3-2, EN 61000-3-3, EN 550141, EN 55014-2.

Designation: Electric dispenser

Type: Hilti HIT-ED 3500 (12 V)

Year of design: 2006

Hilti Corporation

Clément Bourayne Rainer Huettenberger

Segment Manager Head Business Unit

Chemical Anchors Anchors

04 / 2006 04 / 2006

11. Manufacturer's warranty – tools

Hilti warrants that the tool supplied is free of defects

in material and workmanship. This warranty is valid so

long as the tool is operated and handled correctly,

cleaned and serviced properly and in accordance with

the Hilti Operating Instructions, and the technical system is maintained. This means that only original Hilti

consumables, components and spare parts may be

used in the tool.

This warranty provides the free-of-charge repair or

replacement of defective parts only over the entire lifespan of the tool. Parts requiring repair or replacement

as a result of normal wear and tear are not covered by

this warranty.

Additional claims are excluded, unless stringent

national rules prohibit such exclusion. In particular,

Hilti is not obligated for direct, indirect, incidental

or consequential damages, losses or expenses in

connection with, or by reason of, the use of, or inability to use the tool for any purpose. Implied warranties

of merchantability or fitness for a particular purpose

are specifically excluded.

For repair or replacement, send tool or related parts

immediately upon discovery of the defect to the address

of the local Hilti marketing organization provided.

This constitutes Hilti's entire obligation with regard to

warranty and supersedes all prior or contemporaneous comments and oral or written agreements concerning warranties.

Loading...

Loading...