Hilti D-LP 32, DS-TS 32 Operating Instructions Manual

Operating instructions en

D-LP 32/

DS-T S 32

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

2

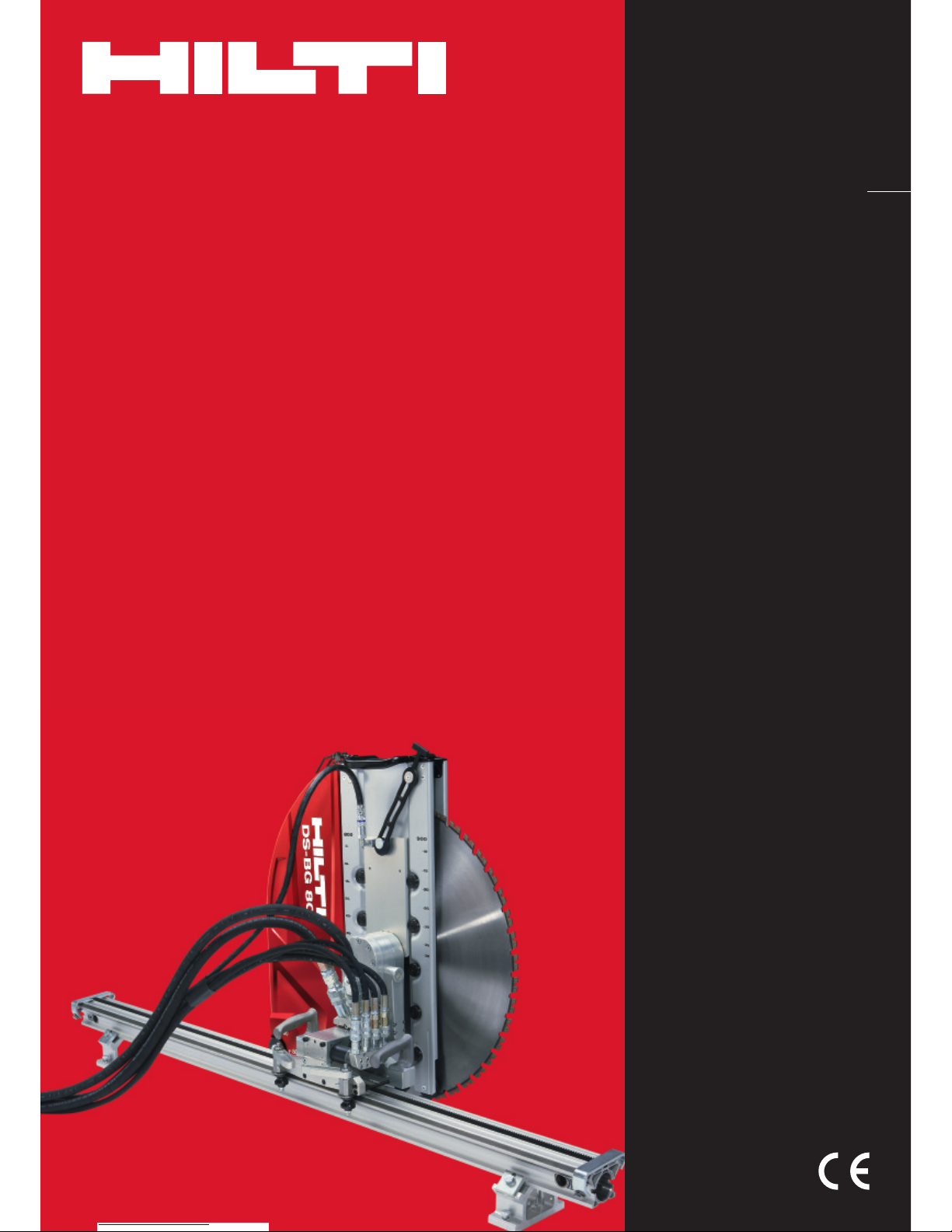

D-LP32/DS-TS32

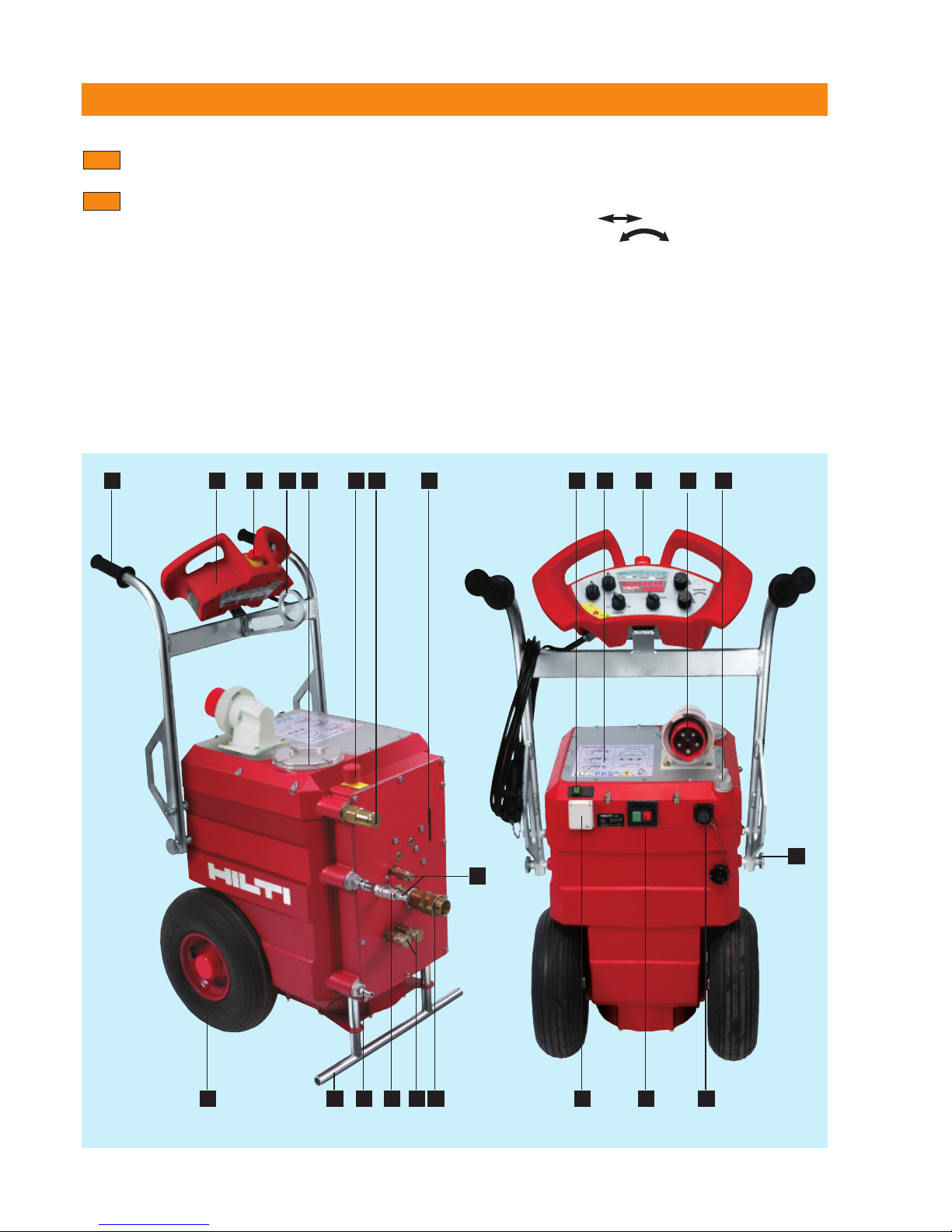

Hydraulic unit

Remote control unit

Rail

Saw blade

Blade guard

Hydraulic hoses

End stop

Rail support

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

3

Contents

1. General information 4

2. Description 5

3. System components, tools and accessories 13

4. Technical data 17

5. Safety precautions 21

6. Before use 27

7. Operation 35

8. Care and maintenance 43

9. Troubleshooting 45

10. Disposal 50

11. Manufacturer's warranty – tools 51

12. EU declaration of conformity (original) 52

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

4

1. General information

It is essential that the operating instructions are read

before the equipment is operated for the first time.

Always keep these operating instructions together

with the equipment.

Ensure that the operating instructions are with the

equipment when it is given to other persons.

Safety notices and their meaning

1.1

DANGER

Draws attention to imminent danger that will lead to

serious bodily injury or fatality.

WARNING

Draws attention to a potentially dangerous situation that

could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation that

could lead to slight personal injury or damage to the

equipment or other property.

NOTE

Draws attention to an instruction or other useful information.

Explanation of the pictograms and

other information

1.2

General warning Warning:

electricity

Warning:

avoid hand injuries

Warning signs

Obligation signs

Warning:

Risk of cutting

injury

Wear protective

gloves.

Wear safety

footwear.

Wear respiratory

protection.

Wear eye

protection.

Wear a hard hat.

Wear ear

protection.

Symbols

Return waste

material for recy-

cling Return waste

material for

recycling

Always fit the blade

guard

Always fit the rail

end stops

Read the operating

instructions before

use

A

Amps

V

Volts

kW

Kilowatts

Hz

Hertz

mm

Millimeters

/min

Revolutions

per minute

l/min

Liters per minute

rpm

Revolutions

per minute

bar

Bar

ii

Alternating current

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

5

2. Description

Description 2.1 Areas of application 6

2.2 D-LP32/DS-TS32 hydraulic saw system components 6

2.3 Parts and operating controls 8

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

6

2. Description

Areas of application

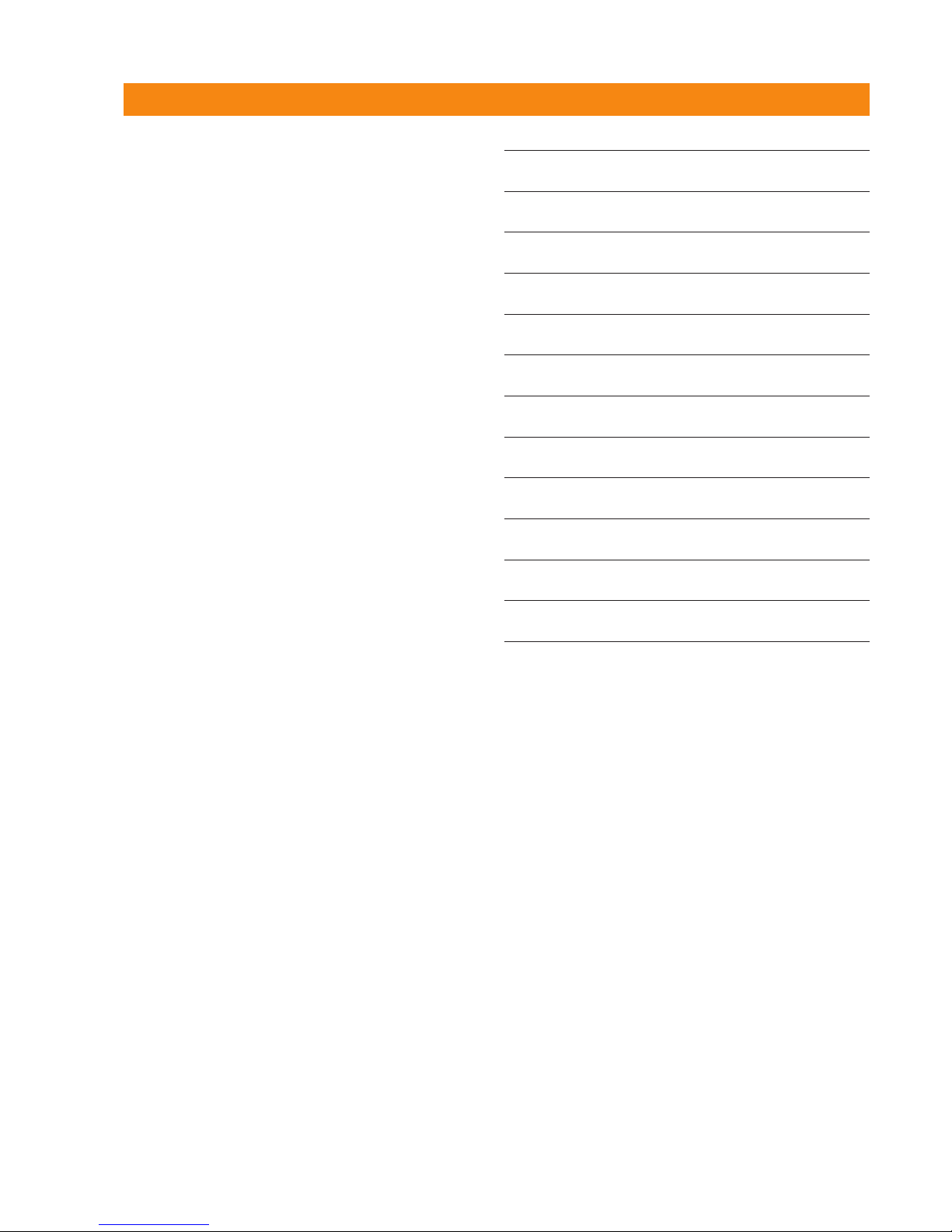

TheD-LP 32/DS-TS32 is a medium to heavy-duty, high-

performance wall saw system for use with saw blades

of up to 1600 mm dia. It is capable of cutting to a depth

of 73 cm.

The D-LP 32 hydraulic unit has a nominal power of

32 kW at 63 amps but can also be operated on 32 amp

mains supplies.

Its modular design permits rapid assembly and use for

many different applications. The DS-TS32 saw head, for

example,can be used to power the Hilti DS-WSS 30 high-

performance wire saw system.

Using the D-RC-LP32digital remotecontrol unit to adjust

the infinitely variable oil flow rate, the operator canselect

the optimum speed and most suitable rate of advance.

This feature ensures optimum efficiency for wall sawing, hydraulic coring, plunge sawing or wire sawing.

2.1

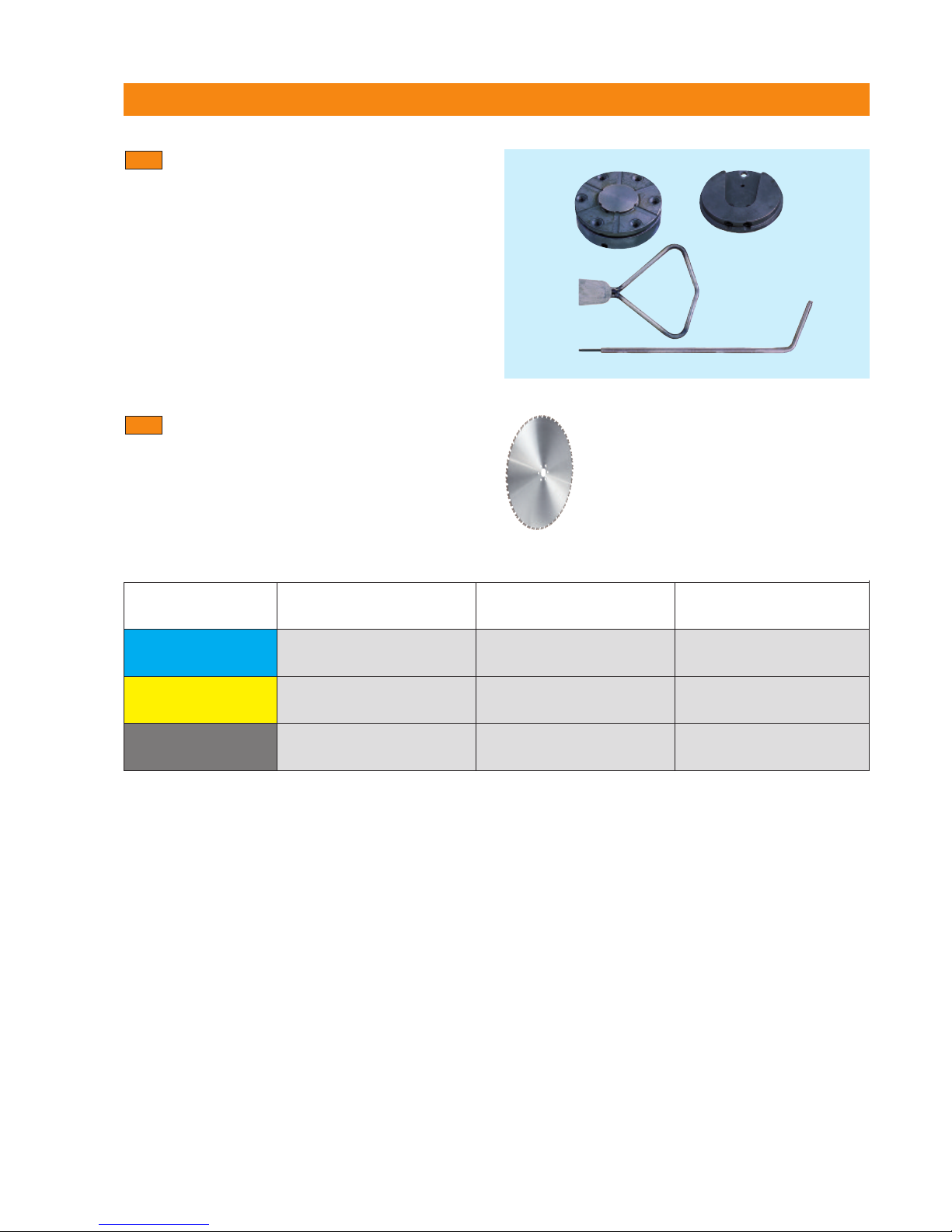

D-LP32 /DS-TS32 hydraulic saw

system components

The basic diamond saw system consists of the following components:

D-LP32 hydraulic unit

D-RC-LP32 remote control unit

DS-TS 32 saw head

D-R 200L rail

DS-C...H saw blade

DS-BG blade guard

D-PH/FH hydraulic hoses and water supply hose

DS-ES-L end stop (2 end stops supplied with each

D-R..L rail)

D-LP32/ DS-TS 32 tool set

2.2

9

1

2

7

3

5

4

6

8

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

7

2. Description

D

-LP

3

2

D

-R 50-230L

DS-TS 32

DS-RF DS-RFP

D-EP-ML

DS-TS 22

D-CO-ML

D

S-ES-L

DS-BG

800 - 1600

mm

DS-BGF

800 - 1600

mm

D-FH14/14-10

D

-LP15

D-PH58-10 (2x)

D-PH34-10 (2x)

D-FH4/14-10

3/4" - 5/8"

(2x)

D-RC-LP 32

DS-TS 30

D

S-ES-L

D-LP32/DS-TS 32

Wall saws

2x DS-WS-SPP

7

DS-WSWS

6

2x DS-WSRF

5

DS-WSRP

4

DS-WSWD

3

DS-WSTA

2

DS-WSW500

1

DS-W11

7

6

5

7

4

123

D-LP 32/DD-750 HY/DS-PS 30

Hydraulic core drilling rig

Plunge saw

D-LP32/DS-TS32/DS-WSS 30

Wire saw

D-LP32/DS-TS, PS, WSS and DD modular system

2.2.1

D-R 150-L

D-S 150

D-R 200-L

DD-BA 6/DD-BA 3-70

DD-AF-HY

D-RC-LP 32

DD-CA-L

DD-MF-ML

DD-750HY

DD-BU-202

DD-R 100-M

DD-R 40-M

D-CO-ML

DS-CA-L/M

DD-R 130-M

DS-PS30

D-LP32

DD-FH

DS-B

O

600 - 1200

D

S-BG 12-PS

PH

FH

D-R 100-L

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

8

2. Description

Parts and operating controls

D-LP32 hydraulic unit

Transport handle, hinged

Lifting point for transport by crane

400 V 63 A socket, mains supply (Euro standard

socket as per EN CEE63)

230 V socket

Socket for D-RC-LP32 remote control unit

Oil level sight glass

Oil filter cover

Emergency off switch

Guidelines for use (sticker)

2.3

2.3.1

Wheels with puncture-proof tyres

PH

3

/4˝ coupling for pressure hose

PH3/4˝ coupling for return hose

FH1/4˝ couplings for advance control hoses

FH1/4˝ couplings for saw arm

Coupling for water supply from the site

Water supply to saw head (with water flow rate reg-

ulation)

D-RC-LP32 remote control unit

On / off control switch

Cap / oil filler neck

230 V socket overload reset button

Front support

Hinged transport handle locking mechanism

28171 7 68 12

10 1521 16 14 11

13

9 820

3

19

184 5

22

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

9

2. Description

Guidelines for use (sticker on D-LP32 hydraulic unit)

2

.3.2

®

Guideline • Richtlinie • Guide

D-LP 32 /DS-TS 32

356749

D-LP 32 /DS-TS 32 /WSS 30

45-50 Ampere

100 l/min

D-LP 32 /DD 750-HY

32-45 Ampere

40–60 l/min

32-63 Ampere

80–100 l/min

D-RC-LP 32

Start

Ampere

II

I

3

263

45

1

0

0

1600

1

2

0

0

1

0

0

0

9

0

0

8

0

0

m

m

D-RC-LP 32

Start

Ampere

II

I

32 63

45

1

0

0

1600

1200

1000

9

0

0

8

0

0

m

m

220

k

g

D-RC-LP 32

Start

Ampere

II

I

32 63

4

5

1

0

0

1

6

0

0

1

2

0

0

1

0

0

0

9

0

0

8

0

0

m

m

6

0

4

0

8

0

6

0

4

0

80

6

0

4

0

80

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

10

2. Description

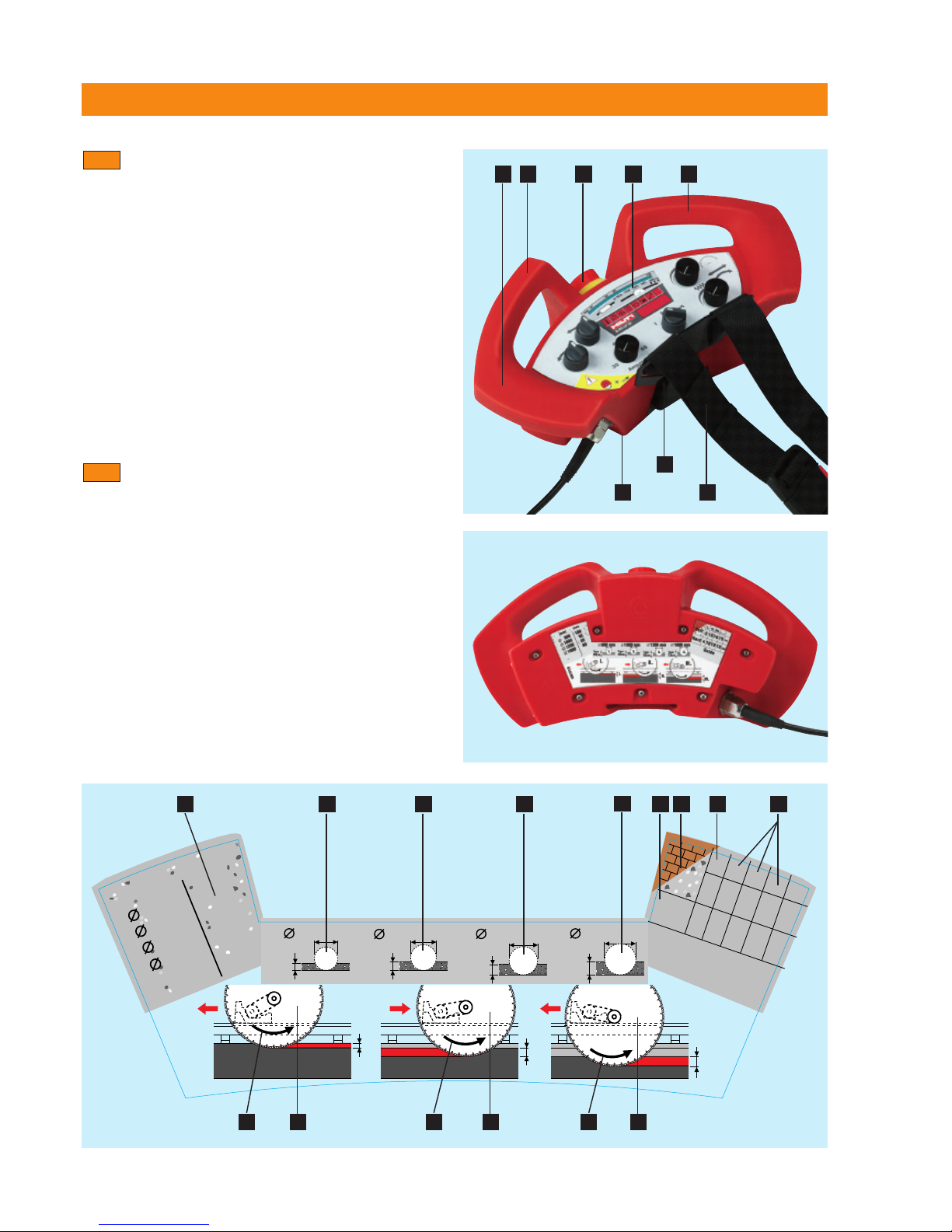

D-RC-LP32 remote control

Remote control unit casing

Grips / control panel protection bars

Display and operating controls

Attachment point for belt fastener

Shoulder belt with fastener

Rear side of remote control unit: Sawing guidelines

Emergency OFF switch

2

.3.3

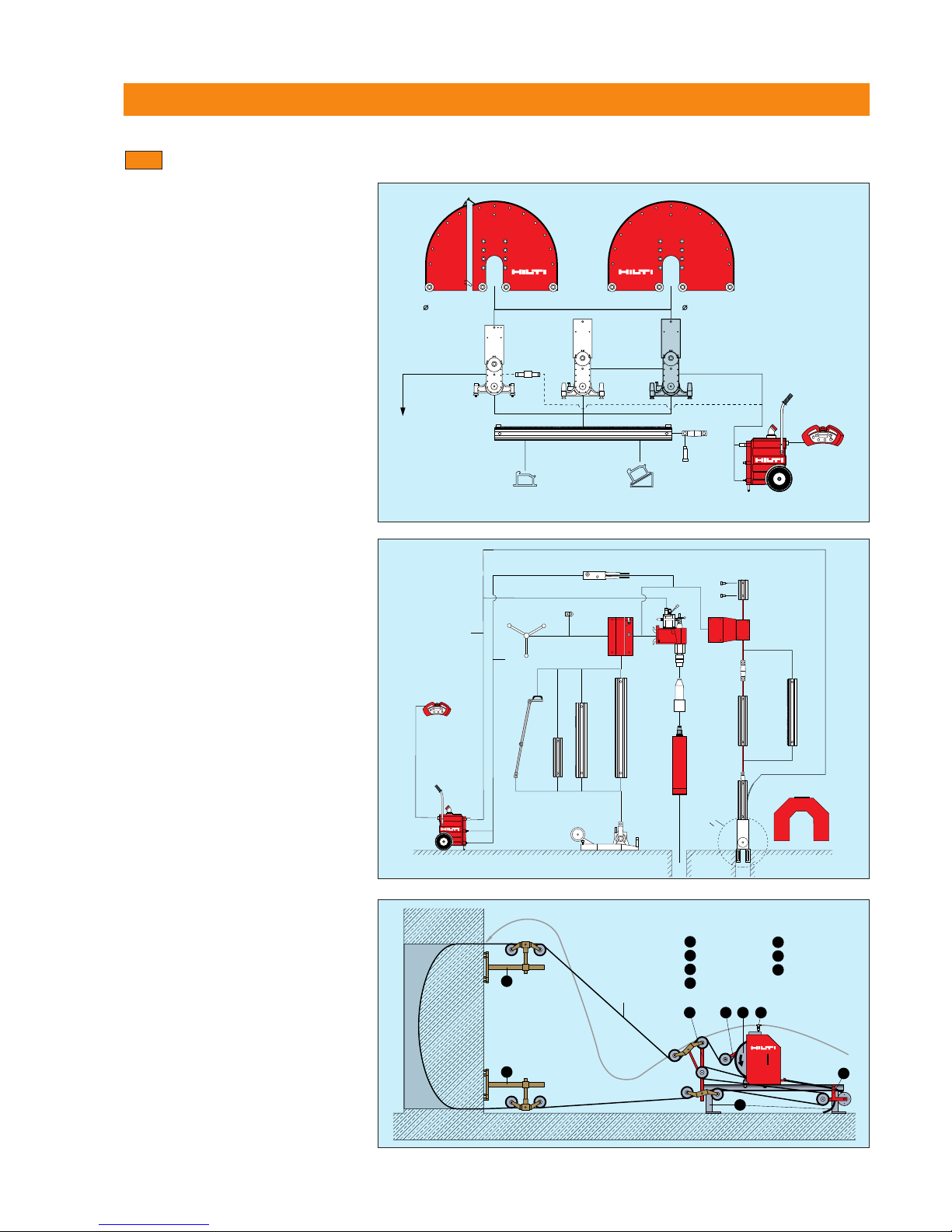

Sawing guidelines

See sticker on the rear of the D-RC-LP32 remote con-

trol unit.

Cutting depth for soft concrete / masonry

Cutting depth for hard concrete

Optimum blade diameter sequence

Plunge depth for initial guide cut

Plunge depth for subsequent cuts

Cut no. I - saw arm trailing

Cut no. II - saw arm leading

Cut no. III - saw arm trailing

Direction of blade rotation (counterclockwise, as

seen from side where blade is fitted)

Recommended oil flow rate in l/min. (speed) for

corresponding blade dia. (mm)

2.3.4

1 2 7

4

56

3 2

l.

ll.

lll.

lll.

ll.

l.

15

15

15

l.

ll.

lll.

....

cm

Hard

Guide

cm

T

max

33cm

800 mm

1.

T

max

43cm

1000 mm

2.

T

max

53cm

1200 mm

3.

T

max

73cm

1600 mm

356751/8

4.

800

100

1000

95

1200

85

1600

80

(mm)

l/m

i

n

Soft

5

4

10

10

10

310 3 5413

3

2

69 7 89 9

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

D-RC-LP 32

Start

Ampere

II

I

32 63

45

1

0

0

1

6

0

0

1

2

0

0

1

0

0

0

900

8

0

0

mm

8

0

6

0

4

0

11

2. Description

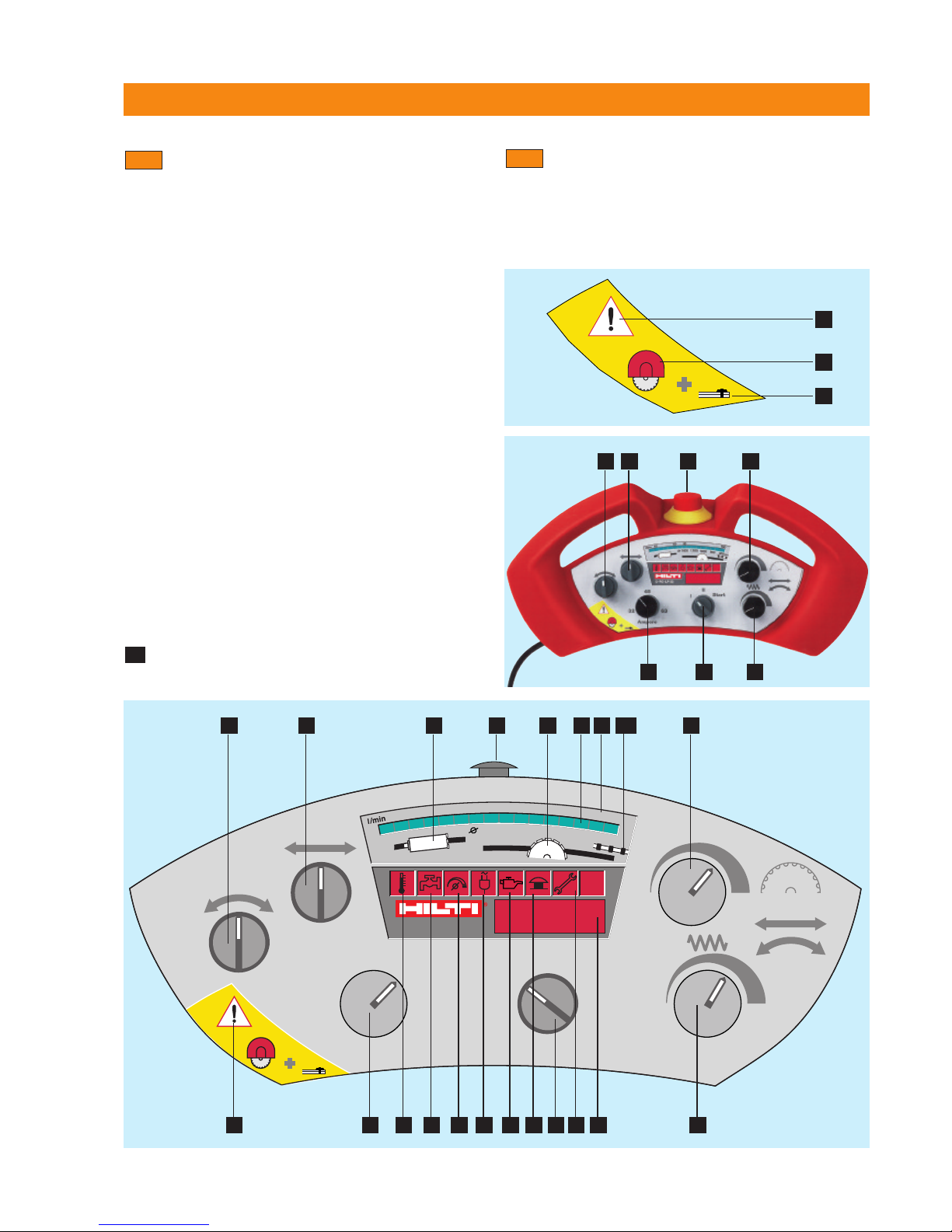

Display, symbols and warning lamps on the

D-RC-LP 32

Hydraulic unit starting switch (OFF/ON/Start)

Oil flow rate (blade drive speed) 30–100 l/min.

(green spot lights up)

Direction of blade plunge movement (right / left)

Direction of advance (left / right or up / down)

Speed control for and

Power control (amps), depending on mains supply

Emergency OFF switch

Oil flow rate indicator

Position of green spot corresponding to saw blade

diameter

Temperature indicator, lights briefly before cut-out

on overheating

Water cooling: lights when unit is inadequately cooled

Zero position: lights when one of the control knobs

is not in the "zero" or "neutral" position

Mains supply / warning lamp

Oil level: lights when oil level is too low

Emergency OFF: lights when button is pressed in

Service indicator: lights when service is due

Operating hours indicator / working pressure (bar)

Operating range for sawing

Operating range for wire sawing

Operating range for core drilling

2

.3.5

18A

Warnings

Warnings

General warning

Always fit the blade guard

Always fit the rail end stops

2.3.6

3 4 19 7 18 9 8 2

21

22

23

20 6 10 11 12 13 14 15 1 16 17 5

3 4 7

6 1 5

2

18A

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

12

2. Description

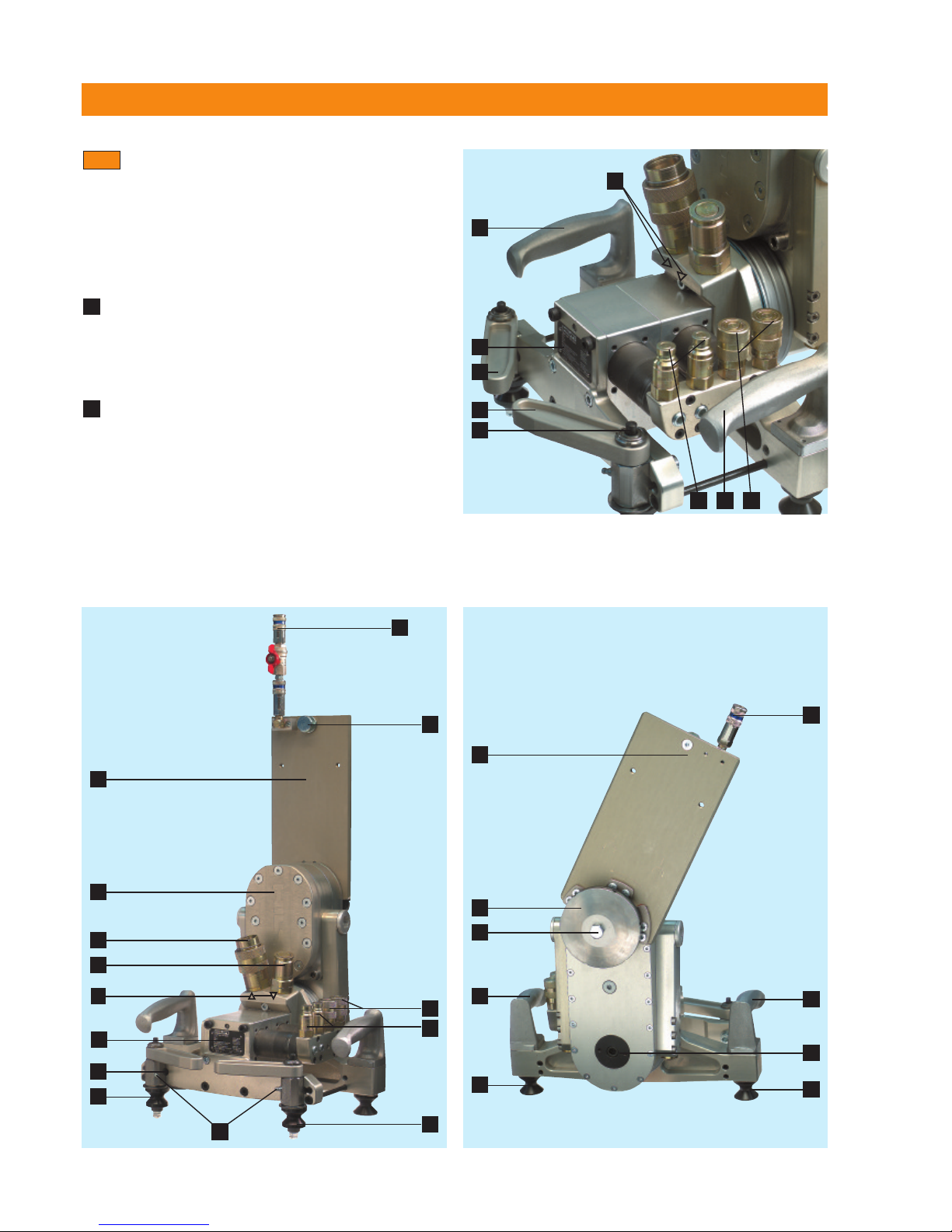

DS-TS32 saw head

Saw arm with built-in motor

Blade guard holder (moves with the saw arm)

Carriagewithwear-resistantcam-action steelrollers

Cam-action roller locking lever

Hydraulic coupling (PH

3

/4˝) – pressure hose

Direction of oil flow

Hydraulic coupling (PH

3

/4˝) – return hose

Hydraulic couplings (FH

1

/4˝) – advance

Hydraulic couplings (FH

1

/4˝) – saw arm pivot

Water supply

Water control valve: may be fitted at blade guard or

at hydraulic unit

Sawblademountingflange with specialM12×25 / 10.9

grade steel screw

Grips

Cam-action rollers

Clamping screw for positioning blade guard holder

and blade guards

Cam-action roller lockbutton

2.3.7

5

A

9A

11 87

17

9A

9

11

13

12

8

7

12

11

15

4

4

14

2

1

6

5

5A

15

3

12

16

2

10

18

11

12

Rating plate

Grease nipple for cam-action roller bearing

Holder for blade guard rubber

Special M12×25 / 10.9 screw

5

A

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

13

3. System components, tools and accessories

System components, 3.1 Hydraulic hoses and hydraulic hose set 14

tools and accessories 3.2 D-R..L rails, DS-ES-L end stops, DS-RF rail supports

and DS-RFP angular cutting plate 14

3.3 DS-BG / BGF blade guard 14

3.4 DS-FCA-110 flush-cutting flange 15

3.5 Diamond saw blades 15

3.6 Accessories, D-LP32/DS-TS32 tool set 16

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

14

3. System components, tools and accessories

Hydraulic hoses and hydraulic hose set

3.1

DS-PH34-10 DS-FH4/14-10

hydraulic hose set hydraulic hose set (with water supply hose)

D-R50L rail

D-R100L rail

D-R150L rail

D-R200L rail

D-R230L rail

DS-ES-L end stop

D-R..L rails, DS-ES-L end stop, DS-RF rail support and

DS-RFP angular cutting plate

3.2

Accessories for securing and operating the saw

DS-BG / BGF blade guard

3.3

DS-ES-L DS-RFPDS-RF

Item no. Designation Use

238000 DS-BG65 blade guard Bladeguard for blades up to650 mm dia.

238002 DS-BG80 center section Blade guard for 600 to 900mm dia. saw blades *

238003 DS-BG80 side section Bladeguard for 600 to 900 mmdia. saw blades

238004 DS-BG120 center section Bladeguard for 1000 to 1200 mm dia. saw blades *

238005 DS-BG120 side section Bladeguard for 1000 to 1200 mm dia. saw blades

333883 DS-BG16 blade guard Bladeguard for 1200 to 1600 mm dia. saw blades

Item no. Designation Use

238006 DS-BGF80 center section Bladeguard for 600 to 900 mmdia. saw blades for flush cutting *

238007 DS-BGF80 side section Bladeguard for 600 to 900 mmdia. saw blades for flush cutting

238008 DS-BGF120 center section Bladeguard for 1000 to 1200 mm dia. saw blades for flush cutting *

238009 DS-BGF120 side section Blade guard for 1000 to 1200 mm dia. saw blades for flush cutting

256237 DS-BGF16 blade guard Blade guard for 1200 to 1600 mm dia. saw bladesfor flush cutting

* Only to be used with the corresponding side sections!

DS-BG DS-BGF

D-R..L

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

15

3. System components, tools and accessories

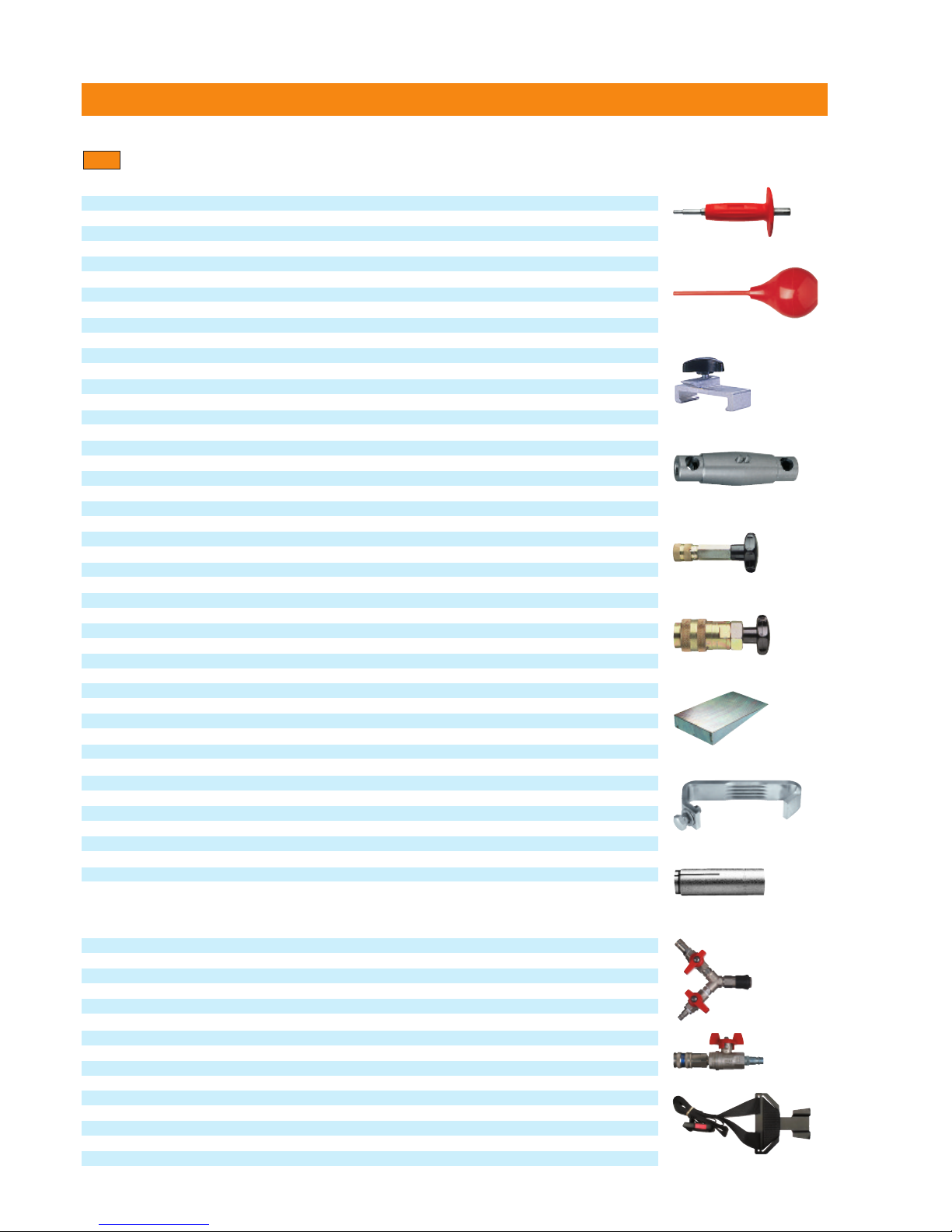

Recommendations for use: Which specification for which material?

Diamond saw blades

We recommend Hilti CS-H, CM-H or CH-H saw blades

for use with the D-LP32/DS-TS32. The saw blades can

be selected from the following table, taking material,

steel content and dimensions into account.

3.5

Important

■ Sawing at a lower speed (reduced saw blade r.p.m.) is usually advantageous when difficult conditions such as

high steel content or hard aggregates etc. are encountered.

■ Safety precaution: Keep to the recommended settings in order to ensure that blade peripheral speed remains

within the safe range for the saw blade used.

DS-FCA-110 flush-cutting flange

3.4

Specification Cutting characteristics Type of concrete Reinforcement

CS-H / UP Fast-cutting Soft aggregates Normal to high

CM-H / UP Well-balanced, good speed and life Hard aggregates Normal

CH-H / SP Fast-cutting and long life Soft to very hard aggregates Normal to high

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

3. System components, tools and accessories

D-LP32 / DS-TS32 tool set

3.6

16

O

rdering designation Qty. Use

D-LP32/DS-TS32 tool set 1 LP 32/TS32 hydr. saw system

comprising:

Hilti plastictoolbox with insert 1 Operator

Accessories,listofcontents and theiruse 1 Operator

F

olding rule, 2 m 1 Operator

STOFcleaningcloth 1 Operator

Flatbrush 1 Operator

Hilti spray 1 Operator

Hilti grease dispenser 1 Operator

Ear protectors 1 Operator

S

afety goggles 1 Operator

HSD-G M12 settingtool 1

Setting anchors

BB blow out pump 1

Anchor holes

Spirit level 1 Assemblingrails

Open-end/ ring wrench,19 mm 1 Assemblingrails

Open-end/ ring wrench,18 mm 1 Assemblingrails

Screwdriver 1 Assembly

Hammer 1

1

/2kg 1 Setting anchors

Socket, 19 mm AF 1 Assemblingrails

Extension,

1

/2˝ square drive 1 Assembling rails

Ratchet,1/2˝ square drive 1 Assemblingrails

D lever with

1

/2˝ square drive 1 Assemblingrails

D-CP-ML rail clamp 1

Mountingrails

Hex.screw,M12×40/8.8 8 Fastening rail support

Hex.screw,M12×70/8.8 8 Fastening rail support

Washer 8 Fastening rail support

Clampingpiece 1 Sparepartrailsupport

Washer,12×18×1 3 Spare part rail support

Spring, 1×12×25 3 Spare part rail support

M12nut with collar 8 Angular cutting plate

D-EP-ML1/2˝ eccentric pin 3 Rail extension

D-CO-ML taper 1

Railextension

Rubber 2 Blade guard holder

Gripnut 1 Fastening blade guard

Hex.key, 4 mm 2 Eccentric rollers / covers

Hex.key, 10 mm 1 Fastening blade guard holder

DS hex. key with T-grip 1 Eccentric rollers

D-PRT pressure releasevalve FH

1

/4˝ 1

Pressurerelease FH1/4˝

D-PRT pressure releasevalve PH3/4˝ 1

Pressurerelease PH3/4˝

D-steel wedge130×70×20 6

Securingconcreteblock

Copper ring 5 Core bit extension

Special M10 countersunk-head srew (6 screws) 1 Spare part,DS-FCA flange

Set of 3 seals 1 Spare part, DS-FCA flange

Special hex. screw, M12×25/10.9 2 Spare part,mountingsaw blade

Hosecoupling, 15–24 mm 2 Attaching water hose

Additional accessoriesfor the D-LP32/DS-TS32 (not includedin the toolset)

Ordering designation Qty. Use

DS-ES-L end stop 2

SecuringcarriageL

HKD-D M12×50 flushanchor 50

16 mm dia. hole

Water valve Y-piece 1

Water supply

Water valve 1

Water supply

Water connector for saw head 1 Spare part for saw head

Hydraulic coupling, FH

1

/4˝ (female) 1 Spare part for FH1/4˝

Hydraulic coupling, FH1/4˝ (male) 1 Sparepartfor FH1/4˝

Hydraulic coupling, PH

3

/4˝ (female) 1 Sparepartfor PH3/4˝

Hydraulic coupling, PH3/4˝ (male) 1 Spare part for PH3/4˝

HVLP46 hydraulic oil (25 litres) 1 Hydraulic unit

Sharpening plate,319 × 319× 18 mm 1 Sawblades, core bids

D-RC-Ext10 extension cable, 10 m 1 For remote controlunit

CEE 63 A plug socket (female) 1 Power extensioncable

ShoulderbeltwithfastenerRC-LP 32/TS5-E 1

Spare part for remote control unit

Shoulderbelt 1

Spare part for 373243/5

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

17

4. Technical data

Technical data 4.1 Power supply 18

4.2 Dimensions and weights 18

4.3 IP enclosure protection code 18

4.4 Climatic conditions for operation and storage 18

4.5 Technical data 19

4.6 Noise information 19

4.7 Rating plates 20

Printed: 08.07.2013 | Doc-Nr: PUB / 5069667 / 000 / 01

Loading...

Loading...