Hilti CP 672 INSTALLATION

Installation instructions for CP 672

Firestop

System

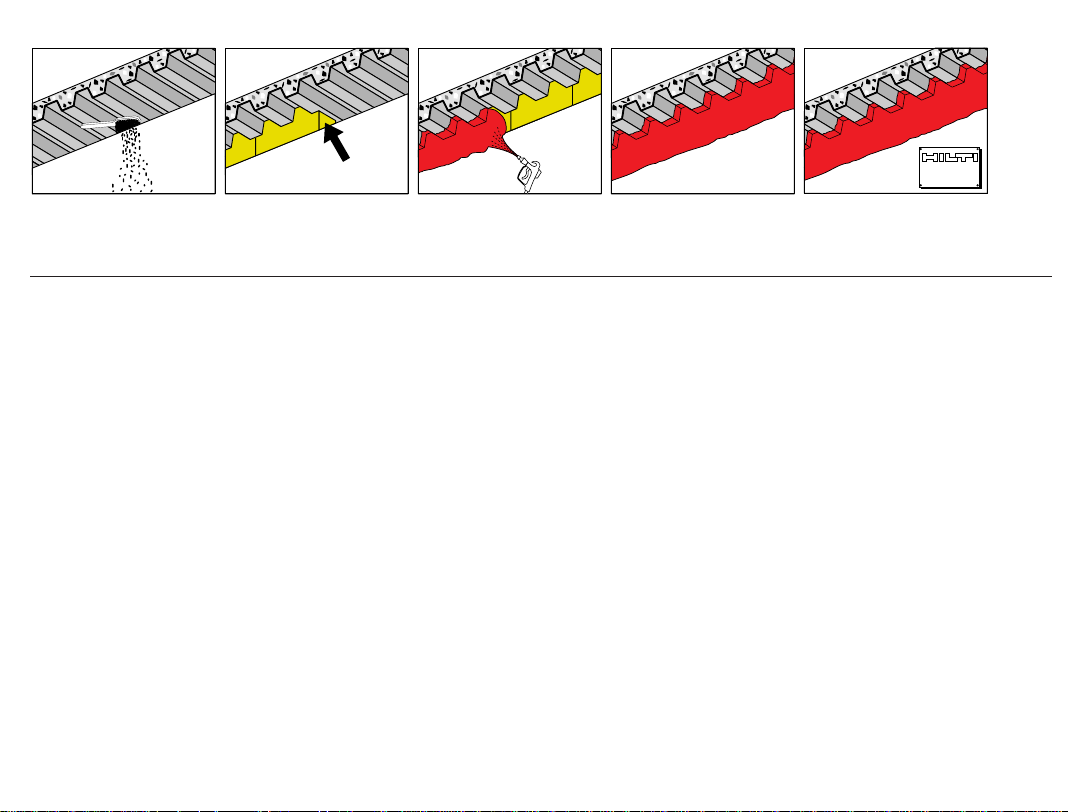

1. Clean opening

2. Pack in mineral wool 3. Spray on CP 672

Opening

1. Clean the opening. Surfaces to which CP 672 will be applied

should be cleaned of loose debris, dirt, oil, moisture, frost and wax.

Application of firestop spray

2. Mineral wool packing

– Install the prescribed back filling material type and depth to

obtain desired rating.

3. Application of firestop spray

– Apply CP 672 to the required depth in order to obtain the

desired rating. Make sure CP 672 contacts all surfaces and

overlaps 1/2" beyond all surrounding surfaces.

– Benron EZ-Tex Sprayer and Graco Texspray Compact HP

pumps have been successful in applying CP 672 Firestop Joint

Spray. Contact Hilti Technical Support for more information.

4. Curing of firestop spray

– Allow 5 to 7 days (@ 73°F) for CP 672 to fully cure

5. For maintenance reasons, joint seal could be permanently marked

with an identification plate. In such a case, mark the installation

plate and fasten it in a visible position next to the seal.

4. Allow CP 672 to cure

5. Fasten identification

plate (if required)

Notice about approvals

• When making a seal using Hilti CP 672 Firestop Joint Spray,

please refer to the UL Directory or the Hilti Firestop Manual for

restrictions as to joint size, type and thickness of wall or floor,

movement capabilities, etc.

Not to be used...

• In areas underwater

• On hot surfaces (above 200°F)

Safety precautions

• Before handling, read the Material Safety Data Sheet for detailed

use and health information

• Wear suitable gloves and eye protection.

• Keep out of the reach of children.

Storage

• Store only in the original packaging at temperatures

40°F (5°C) to 100°F (37°C).

• Observe expiration date on package.

Loading...

Loading...