Hickory N-7.7G Operators Manual

Hickory Industries, Inc.

Installation Manual

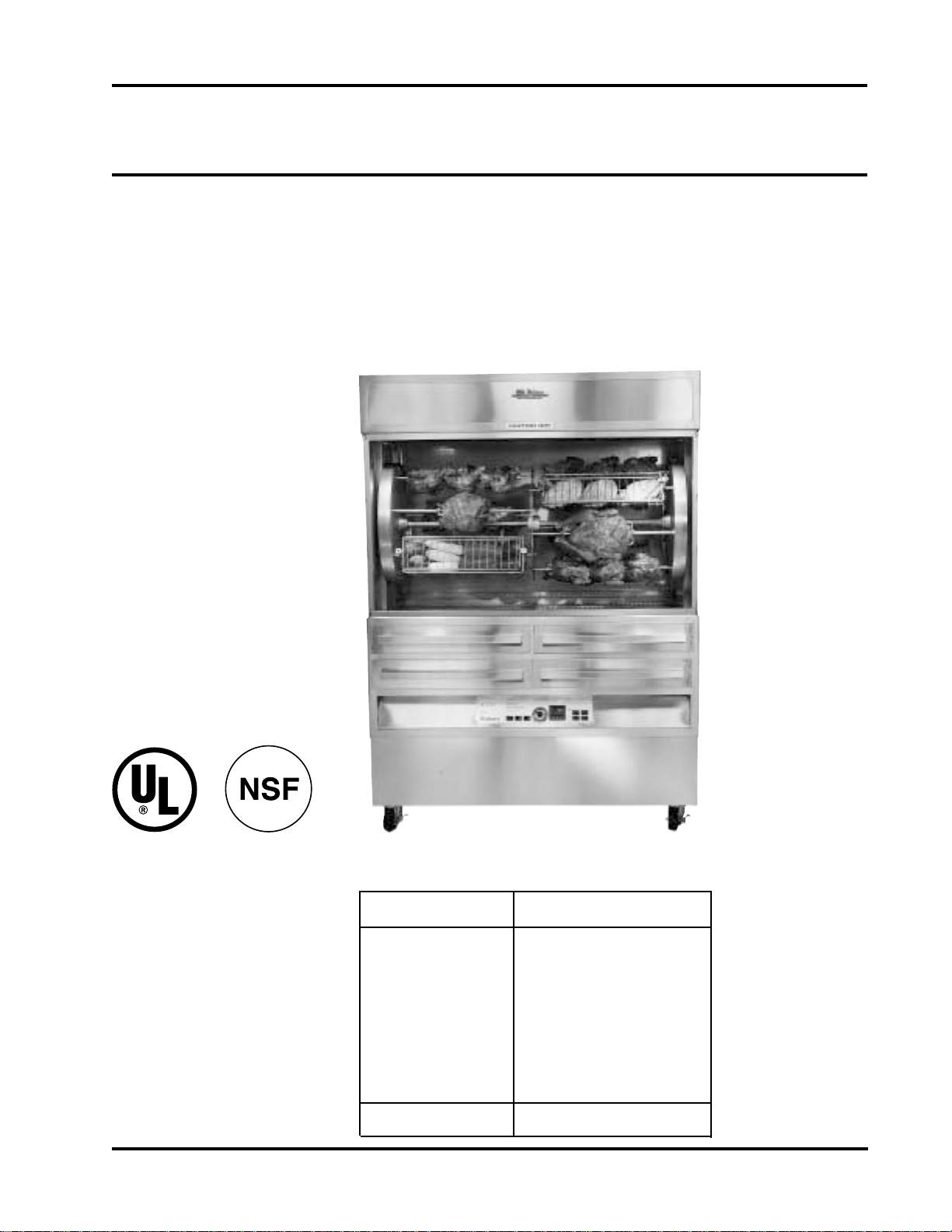

Hickory Rotisseries

Models: N/7.7 G

USA

Machine Type N/7. 7 G

T otal Power Rating

Burner / Spits

Gas Category

Fittings

Ignition

Delivery Date:

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

160,000 or 180,000 BTU

4 or 5 Burners with 14 Spits

Natural Gas, LPG

4 Infra-Red Gas Generators /

1 pipe burner

4 or 5 Electronic Ignitors

Final Inspection:

N/7.7G Installation 10/97

Page 1 of 28

Hickory Industries, Inc.

Table of Contents

1.0 Installation 3

1.1 General Information 4

1. 2 Description of the Data Plate 4

1.3 Machine Dimensions in inches and mm 5

1.4 Gas Conversion and Adjustment Instructions 8

1.5.1 Gas Conversion and Adjustment Instruction for Show Burner (SB) 8

and Woodburning Module (WB)

1. 5 V erification for use with Natural Gas 8

1. 6 Gas Flow T able (Consumption) 9

1.7.1 Volumetric Method to V erify the Flame Setting, Mathematical 9

1. 7 Orifice Diameters, Electrode Gap Settings, and Air Intake Settings 1 0

1.8 Changing Gas Orifices 1 1

1.8.1 Changing the Gas Orifice - Gas Generators 1 1

1.8.2 Changing the Gas Orifice - Pipe Burner for SB and WB 1 2

1. 9 Ignition Cycle 1 3

1.9.1 Adjusting the Ignition Electrode 1 3

1.10 Checking the Connected Gas Pressure (Nominal Pressure) 15

1.11 Maintenance, Response to T echnical Problems 15

1.11.1 Reasons for problems and solutions 1 6

1.12 Spit Drive Mechanism 1 7

1.13 T esting or Checking for Safety 1 8

1.14 Description of the Electrical Connection 1 8

1.15 Electrical Diagram 1 9

1.16 Parts List for N/7.7G 2 3

1.17 List of Additional Parts for N/7.7G with Show Burner (SB) 2 5

1.18 List of Additional Parts for N/7.7G with Woodburning Module (WB) 2 5

1.19 Parts List for Woodburning Module (WB) 2 5

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/7.7G Installation 10/97

Page 2 of 28

Hickory Industries, Inc.

1.0 Installation Instructions

a. When installing these units, it is important to comply with the most recently

established rules and regulations as deemed pertinent by the local and national

electrical, gas, ventilation, sanitation, and fire codes. These units are classified

by Underwriters Laboratories, Inc. as Gas-Fired Food Service Equipment in

accordance with American National Standards Institute ANSI Z83.1 1b-1991, Gas

Food Service Equipment - Ranges and Unit Boilers.

b . These gas units must not be directly connected to a gas flue or exhaust. However, the

units may only be operated inconjuction with a canopy type exhaust hood.

c. The room where the units are being installed must be ventilated in accordance to

the valid codes and regulations.

d. The units are to be installed securely and horizontally . The units may be

installed on combustible floors. The units may be installed on adjustable legs or on

casters (wheels).

e . The minimum clearance to the rear or side walls must be 3 inches. It is also

important to insure that the bottom of the units is kept clear so that proper ventilation

or air exchange can occur .

f. Normally , the units will be sent to the operator already set up for the particular

type of gas available at their location. However , unless otherwise specified, the

units will be set up for natural gas use. Before installing and using the units for the

first time, it is important to make sure that the gas type and pressure indicated on the

data plate matches the type of gas available in the location. Should this not be the

case, it is imperative to change or convert the units to the needed gas type.

g . The units must be fitted with the manual shut-off gas cock (valve) supplied with the

machine. This manual valve is needed to shut off the gas to the machine during

maintenance work, repairs, and if the unit needs to be disconnected for any reason.

h. A gas regulator is also supplied with the machine. This component is needed so that

the appropriate gas pressure can be set and insure an optimum operation of the unit.

i. Depending on local codes or if deemed necessary, a gas filter may also be required.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/7.7G Installation 10/97

Page 3 of 28

1. 1 General Information

The Operating Instructions are to be given to the operator of the rotisserie. All unit

operators are to be familiar with the functions of the rotisserie.

The Operating Instructions should be kept in a location close to the rotisserie. It should be

easily recognizeable and easily accessible.

These rotisseries can be used with both natural and LPG gases. The rotisseries can be

converted or adjusted to any type of the locally distributed natural and LPG gases.

It is recommended that a repair and maintenance contract be signed with the

manufacturer's agent, distributor, or service agency .

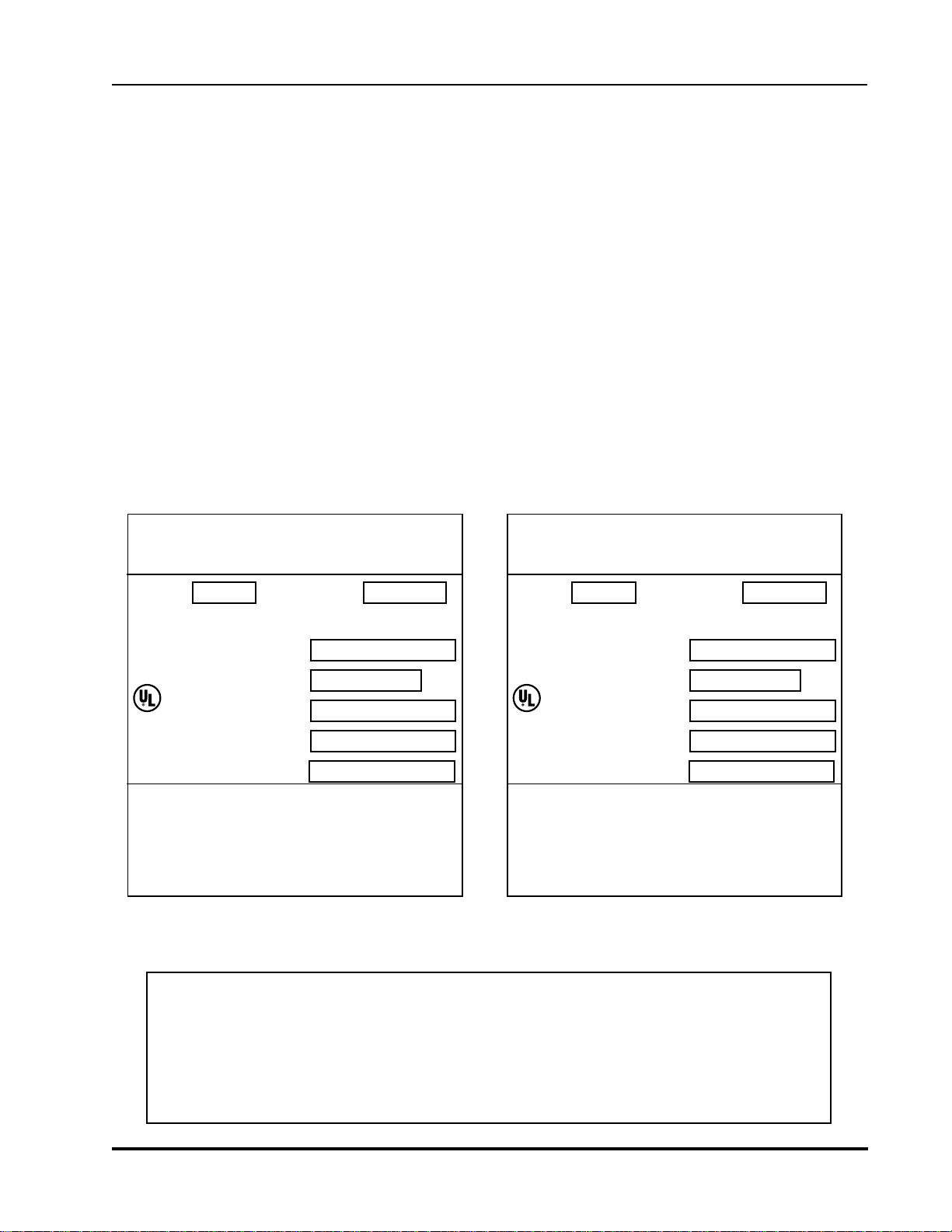

1. 2 Description of the Data Plate

Hickory Industries, Inc.

HICKORY INDUSTRIES, INC.

COMMERCIAL COOKING APPLIANCES

NORTH BERGEN, NJ 07047

MODEL N/7.7 G SERIAL NO.

MOTOR: 1 10 - 1 15 VOL TS 60 CYCLE AC CURRENT

1/2 HP SINGLE PHASE 5.7 RPM

BURNERS 4 / 1

LISTED

GAS INPUT PER BURNER

MANIFOLD PRESSURE

69D6

TYPE OF GAS

MFG. DATE

MINIMUM INSTALLATION CLEARANCE

MAXIMUM LAMP WA TTAGE: 150 WATTS

FOR INSTALLATION ON A COMBUSTIBLE FLOOR

Gas-fired Food Service Equipment Classified by

Underwriters Laboratories Inc. In accordance with American

National Standards Institute ANSI Z 83.11b-1991, Gas Food

SIDE: 6 INCHES

BACK: 6 INCHES

Service Equipment-Ranges and Unit Boilers

40,000 / 20,000

5.5"

NAT

BTU/H

HICKORY INDUSTRIES, INC.

COMMERCIAL COOKING APPLIANCES

NORTH BERGEN, NJ 07047

MODEL N/7.7 G SERIAL NO.

MOTOR: 1 10 - 1 15 VOL TS 60 CYCLE AC CURRENT

1/2 HP SINGLE PHASE 5.7 RPM

BURNERS 4 / 1

LISTED

GAS INPUT PER BURNER

MANIFOLD PRESSURE

69D6

TYPE OF GAS

MFG. DATE

MINIMUM INSTALLATION CLEARANCE

MAXIMUM LAMP WA TTAGE: 150 WATTS

FOR INSTALLATION ON A COMBUSTIBLE FLOOR

Gas-fired Food Service Equipment Classified by

Underwriters Laboratories Inc. In accordance with American

National Standards Institute ANSI Z 83.11b-1991, Gas Food

SIDE: 6 INCHES

BACK: 6 INCHES

Service Equipment-Ranges and Unit Boilers

40,000 / 20,000

11"

LPG

BTU/H

WARNING!

This unit must be installed and connected in accordance to the latest regulations

and can only be operated in conjunction with forced ventilation or exhaust hood.

This unit has been designed for professional use only

and may only be installed or repaired by licensed service agencies!

Before installing or using this equipment, read these instructions!

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/7.7G Installation 10/97

Page 4 of 28

Hickory Industries, Inc.

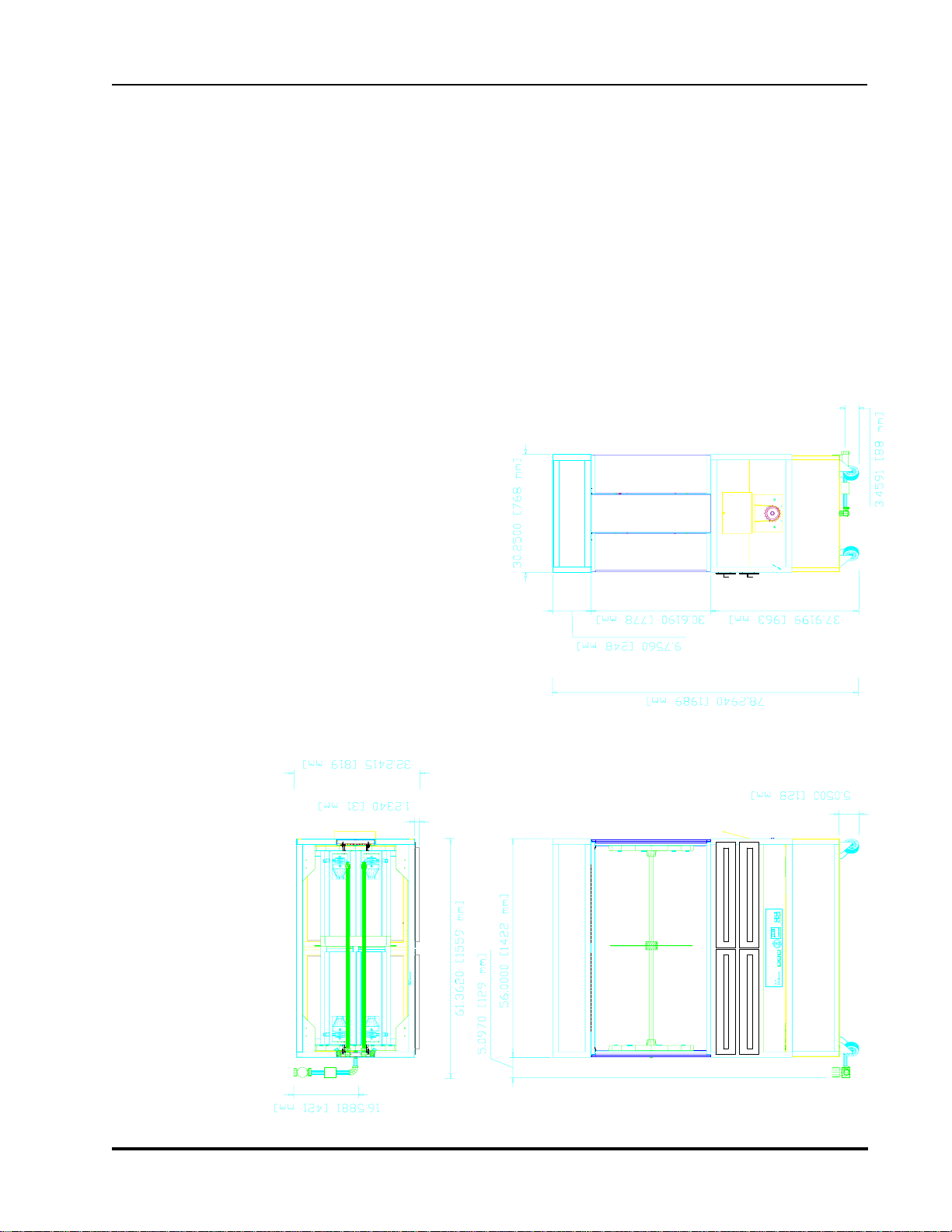

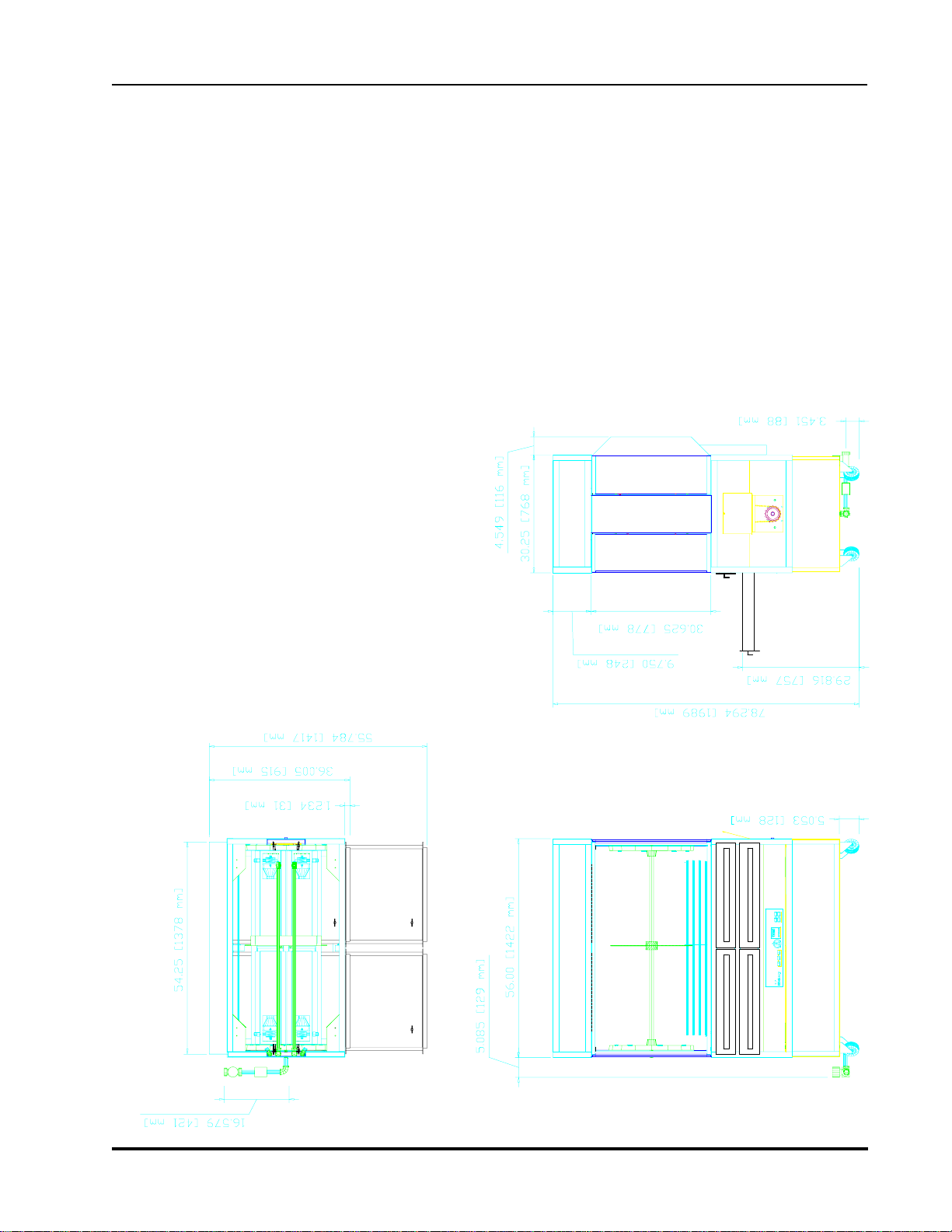

The following drawing of the Front View , Side View, and Top View indicate where the

dimensions are taken and should be used to plan the installation of the units.

N/7.7 G inches [mm]

1.3 Machine Drawings and Dimensions

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/7.7G Installation 10/97

Page 5 of 28

Hickory Industries, Inc.

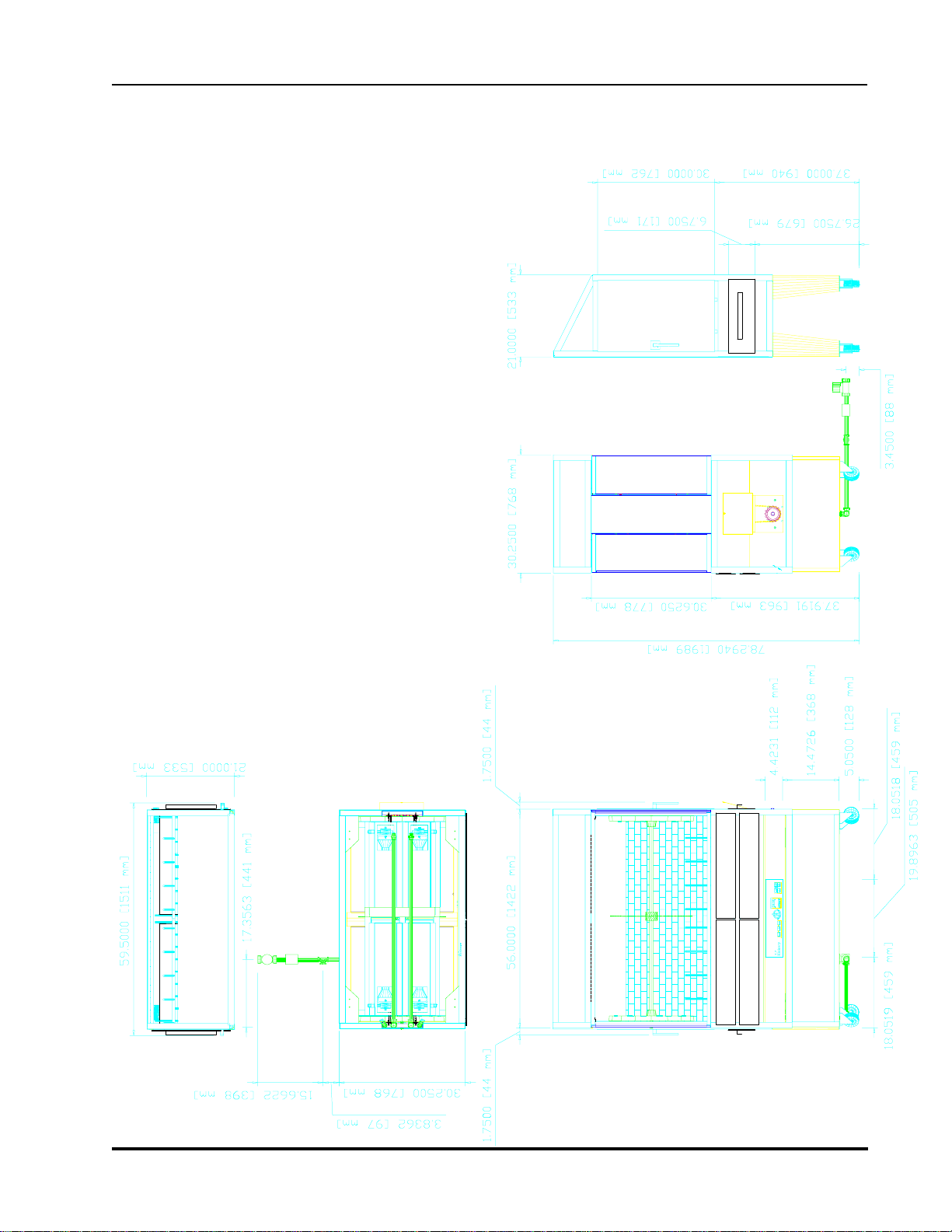

7.7 G with Show Burner inches [mm]

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/7.7G Installation 10/97

Page 6 of 28

Hickory Industries, Inc.

N/7.7 G with separate hearth burner inches [mm]

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/7.7G Installation 10/97

Page 7 of 28

Hickory Industries, Inc.

1.4 Gas Conversion and Adjustment Instructions

Before converting or adjusting the machine to another type of gas, it is imperative that the

manual gas cock be turned to the "off" position. The electrical power to the machines should

also be turned off. When converting the gas generators for use from one type of gas use to

another, the gas orifice (or injector) must be changed according to the table on page 9. In

addition, the spring in the pressure regulator supplied with the unit must be changed so that it

can operate at other gas pressures. Springs for the regulator can be ordered from Hickory

Industries.

1.4.1 Gas Conversion and Adjustment Instructions for Show Burner (SB) and

Woodburning Module (WB)

Before converting or adjusting the machine, it is imperative that the manual gas cock be

turned to the "off" position. The electrical power to the machines should also be turned off.

When converting from one type of gas to another, the gas orifice (or injector) and the

primary air adjustment must be changed according to the table on page 9. In addition, the

spring in the pressure regulator must be changed as previously explained.

1. 5 V erification for use with Natural Gas

The flame setting for each gas generator and for the pipe burner can be confirmed by using

the volumetric method in conjunction with the main gas meter . Each burner has an

independent solenoid gas valve. Each valve is controlled by its own, independent Gaslite

spark ignition module. The amount of gas flowing through the valves can not be adjusted

manually; there is only an "on" or "off" position.

T o carry out this verification procedure, it is necessary to obtain the heating value (BTU/ft

3

)

of the local gas from the local gas company . A variation in the heating value of the local

gas from that on the table (1.6) will result in a variation of the power output of the unit!

If the measured gas volume does not correspond to the values in the following table (1.6), the

items which should be checked are:

A. The incoming (connected) gas pressure while all burners and all other appliances

in the location are operational.

B. If the gas pressure is correct, it must be verified that the proper size gas orifices are in

place (see page 9).

Solenoid Valve

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/7.7G Installation 10/97

Page 8 of 28

Hickory Industries, Inc.

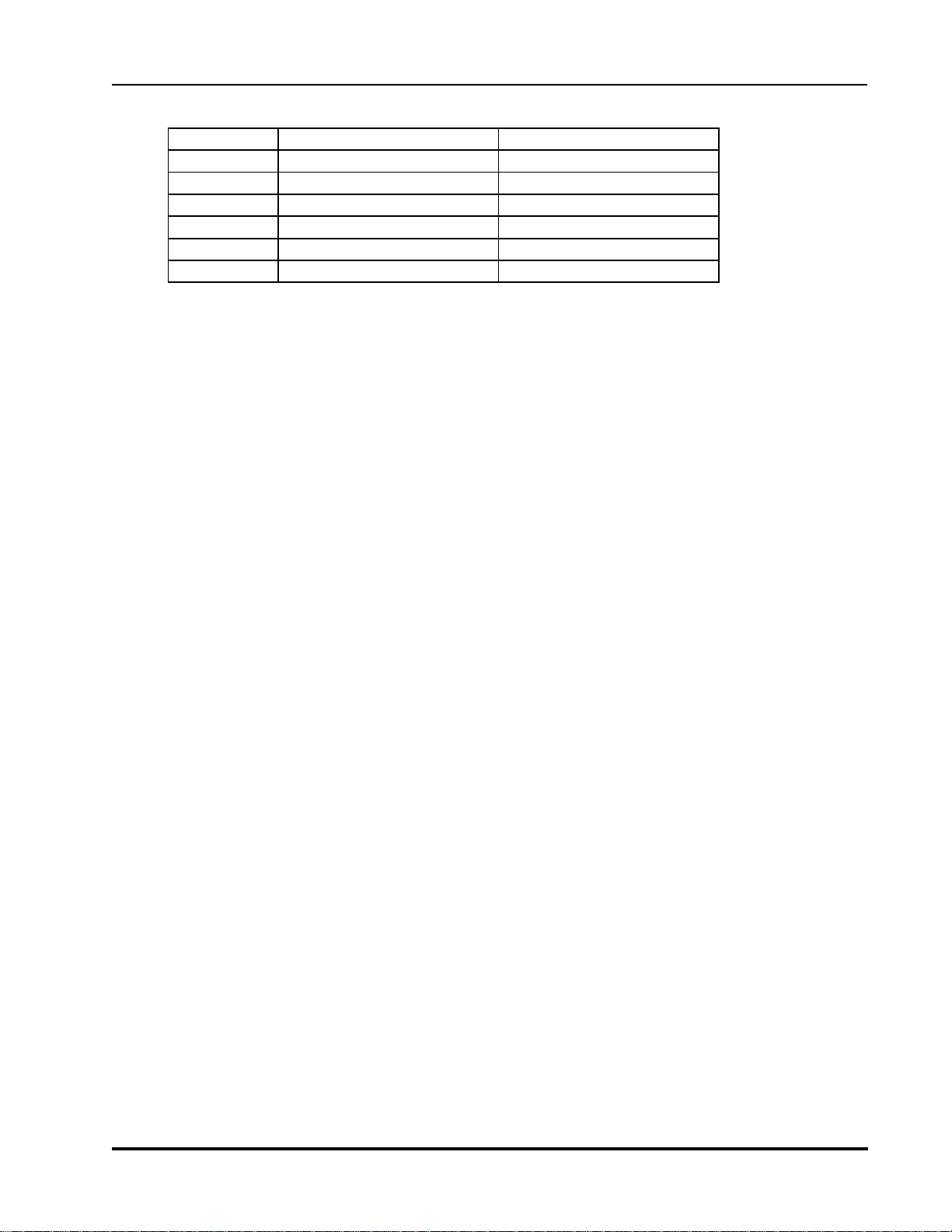

1.6 Gas Flow T able (Consumption)

Gas Flow

Gas

Natural

Propane

Butane

1.6.1 Volumetric Method to V erify the Flame Setting, Mathematical

WARNING! No other gas equipment can be in operation during this procedure.

Heating Value in

per Burner (40,000 BTU)

BTU/ft³

High Flame Setting

1040 38.50

2500

2500

in ft3/hr

16.00

16.00

Calculation of flow rate E in ft

3

/hour

Q = E

H

i

Q = Flow rate in ft3/time

E = High Flame Power setting in BTU/hr

Hi= Heating value in BTU/ft

3

Thus, for natural gas:

Q = 40,000 BTU/hr = 38.50 ft3/hr = 0.64 ft3/min.

1040 BTU/ft

3

Q = 0.64 ft3/min.

Calculation of the natural gas needed in 1 hour by a 7.7G (4 burners) at full power:

Q = 38.50 * 4 = 154 ft3/hr = 2.56 ft3/min.

The time and the flow measurements should be taken at the gas (flow) meter with a

chronometer (stop watch).

T o run the test, open the manual gas cock valve, start up the unit according to the start-up

instructions.

Allow the unit to pre-heat (burn) for 10 to 15 minutes. Verify that the flow rate is calibrated

to the appropriate flow rate indicated in the table.

NOTE: This mathematical calculation was done assuming a #38 orifice size and a connected

gas pressure of 5.5" with an infra-red generator . The actual flow rate will vary

depending on the Heating V alue of the local gas and on the set gas pressure!

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/7.7G Installation 10/97

Page 9 of 28

Loading...

Loading...