Hickory N-5.7G User Manual

Hickory Industries, Inc.

Installation & Operation Manual

Hickory Rotisseries

Model: N/5.7 G

USA

Voltage:120V single phase, Amps: 3, Hz: 60

Cooking burners: 2 Pressurized burners Orifice Size

BTU's / Cooking Burner: 36,000 Natural #32

20,000 Propane #48

Show Burner: 20,000 Natural or Propane (3)#51 / #56

Manifold Pressure: 5.5 in W.C. Natural

11 in W.C. Propane

Minimum Installation Clearance:

3 Inches sides and back. 15 inches rear with glass door in back

Lamps should be replaced with 120V, 40W rated bulbs or equivalent

Specifications and manual subject to change without notice

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/5.7G - 9/01

Page 1 of 25

Hickory Industries, Inc.

Table of Contents

Installation Tips .................................................. 3

Overview Of The Unit ......................................... 4

Unpacking The Unit ........................................... 5

Setting Up The Rotisserie.................................. 5

Control Panel Overview ..................................... 7

Spit Preparation Using Angle Spits ................... 8

Spit Preparation Using Spits & Skewers ........... 13

Daily Operation ................................................. 18

Cleaning............................................................ 19

Thermometer Guidelines ................................... 20

Temperature Chart............................................. 21

Do's and Don'ts ................................................. 22

Parts Diagram................................................... 23

Electrical Diagram............................................. 24

Warranty ............................................................ 25

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/5.7G - 9/01

Page 2 of 25

Hickory Industries, Inc.

Installation Tips

a. When installing these units, it is important to comply with the most recently established

rules and regulations as deemed pertinent by the local and national electrical, gas, ventilation,

sanitation, and fire codes. These units are classified by Underwriters Laboratories, Inc. as

Gas-Fired Food Service Equipment in accordance with American National Standards Institute

ANSI Z83.11b-1991, Gas Food Service Equipment - Ranges and Unit Boilers.

b. These gas units may not be directly connected to a gas flue or exhaust. However, the

units may only be operated in conjunction with a canopy type exhaust hood.

c. The room where the units are being installed must be ventilated in accordance to the

valid codes and regulations.

d. The units are to be installed securely and horizontally. The units may be installed on

combustible floors.

e. The minimum clearance to the rear or side walls must be 3 inches. It is also important

to insure that the bottom of the units is kept clear so that proper ventilation or air exchange can

occur.

f. Normally, the units will be sent to the operator already set up for the particulartype of

gas available at their location. However, unless otherwise specified, the units will be set up for

natural gas use. Before installing and using the units for the first time, it is important to make

sure that the gas type and pressure indicated on the data plate matches the type of gas available in the location. Should this not be the case, it is imperative to change or convert the units

to the needed gas type.

g. The units must be fitted with the manual shut-off gas cock (valve) supplied with the

machine. This manual valve is needed to shut off the gas to the machine during maintenance

work, repairs, pressure testing and if the unit needs to be disconnected for any reason. DO

NOT REMOVE otherwise warranty will be voided.

h. A gas regulator is also supplied with the machine. This component is needed so that

the appropriate gas pressure can be set and insure an optimum operation of the unit. DO

NOT REMOVE otherwise warranty will be voided.

i. When installing this unit with a gas quick disconnect, a tethering device must be used.

j. Depending on local codes or if deemed necessary, a gas filter may also be required.

k. Do connect the unit to a 1" gas line. Connecting the unit to a lesser line can reduce the

units effectiveness or cause improper operation.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/5.7G - 9/01

Page 3 of 25

Hickory Industries, Inc.

l. After connecting the unit, make sure that the line has been bled and that a static pressure reading of at least 7" water column pressure is obtained.

m. The unit is equipped with a water connection to facilitate filling of the drip pan with

water. Connect the 1/2 inch water valve to a flexible connection to facilitate movement of the

unit for cleaning.

n. Drain - the unit is equipped with an 1 1/2" drain. If connecting to the drain, make sure

the drain it is connected to a fat trap. Adhere to all local plumbing codes.

o. When the waste valve is not connected, we recommend the use of a bucket. At the end

of the day, place the bucket at the waste valve. Open the water inlet slightly and fill the drain

until the fat and grease has floated into the drain. Shut the water and bring the bucket to the

cooler and let the fat rise and skim off the fat and place into the fat rendering tank. The remaining water can be discarded into the sink.

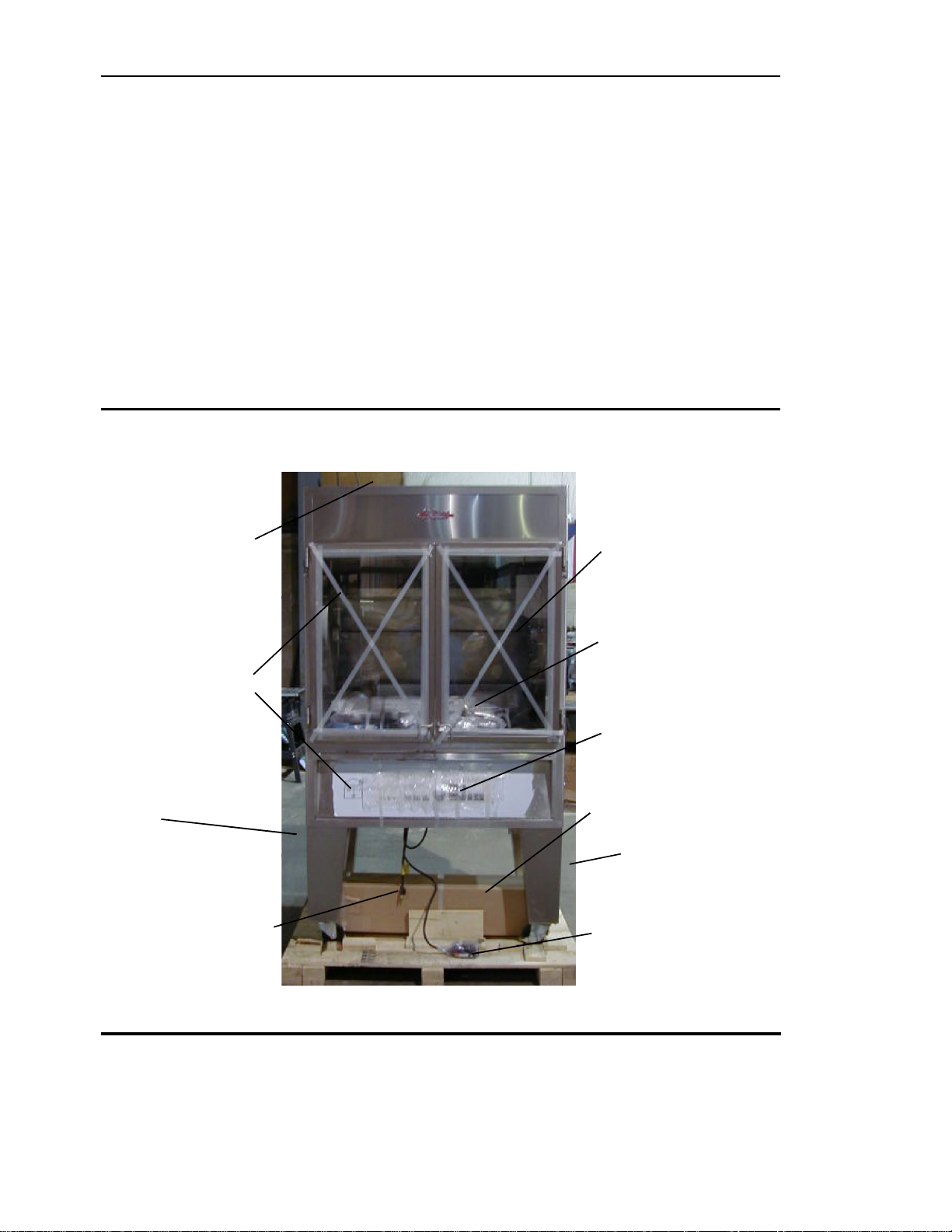

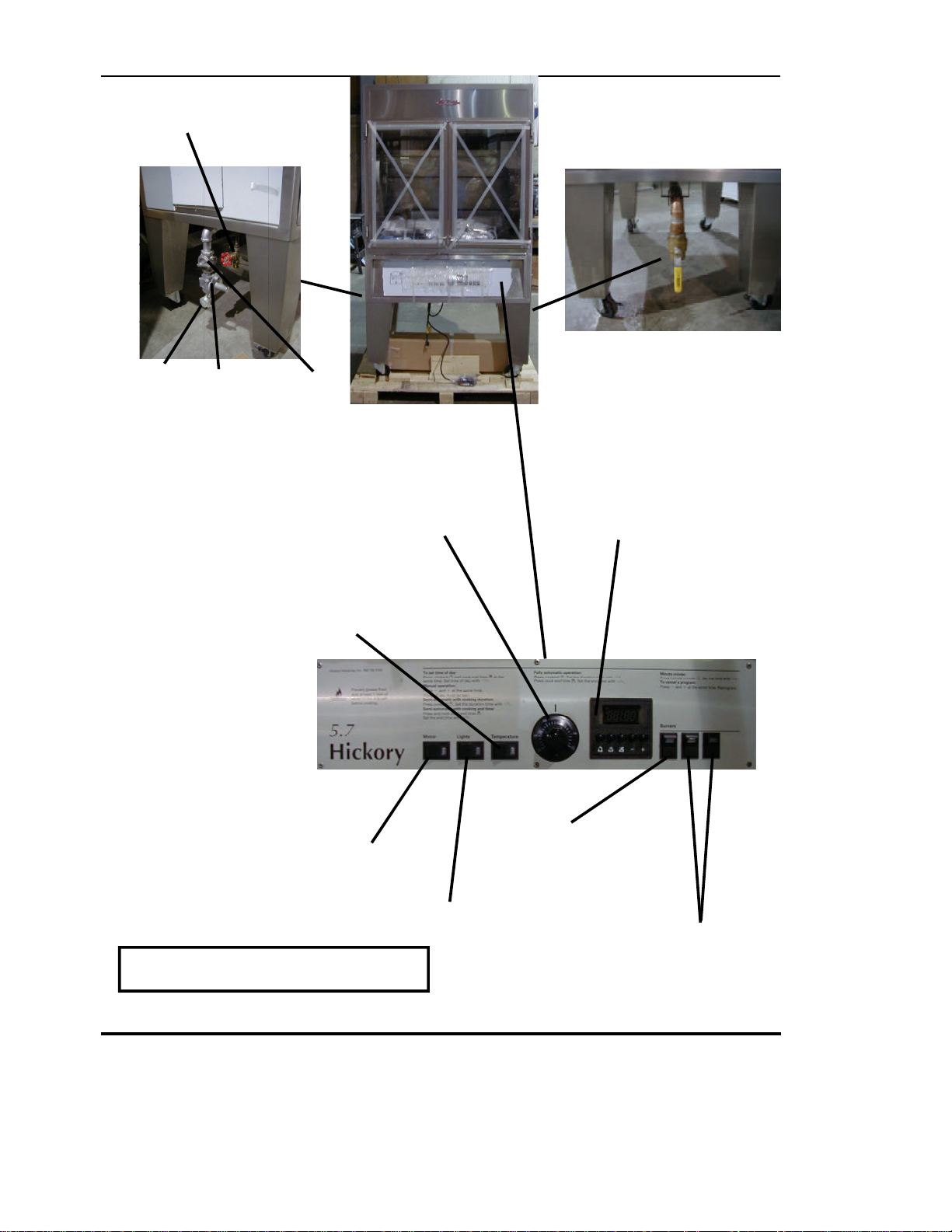

Exhaust

WARNING DO NOT store

or place any items here.

Make sure that the hood

is operating before turning oven on!

Remove all tape and Vinyl

Gas and water connection

Electrical Plug 120V

Unless another voltage is specified

Always plug into a grounded circuit

Front pivoting glass doors

DO NOT use abrasives,

scouring pads or razor

blades to clean the glass.

Parts included with the unit

are packed inside the rotisserie. See page 5 Item "d" under

unpacking the unit

Control panel See page 7

DO NOT powerwash outside or

inside the unit - damage will

occur!

Spits and/or accessories if not

packed in the unit.

Waste ON/OFF valve

Foot pedal - Used to stop the

motor when loading and

unloading. DO NOT leave on

the floor when powerwashing

the floor - water damage can

occur!

Overview of the unit before set up

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/5.7G - 9/01

Page 4 of 25

Hickory Industries, Inc.

Unpacking the unit:

a. After the unit is un-crated, roll the unit and all accessories into place.

b. Remove all vinyl paper on the stainless steel

c. Remove all tape from glass surfaces and metal surfaces

d. Carefully remove and inspect parts that are inside the unit. Ensure that all materials

sent with the crate are inspected:

Items that are sent with the unit are:

(extra parts vary from customer to customer)

Cooking Spits (7) Spits and skewers, Angle spits or thermowave spits.

Over Flow Tubes (2)

Removable rear cleaning panel (1)

Wire Rack (1)

Ceramic Logs (4)

Ball Knobs (2)

Log Carrier (1) Installed on the rear burner

Thumbscrew Key (1) If sent with spits and skewers

Setting Up The Rotisserie

a. Clean, rinse and sanitize the spits. If baskets and accessories are ordered, clean and

sanitize as well.

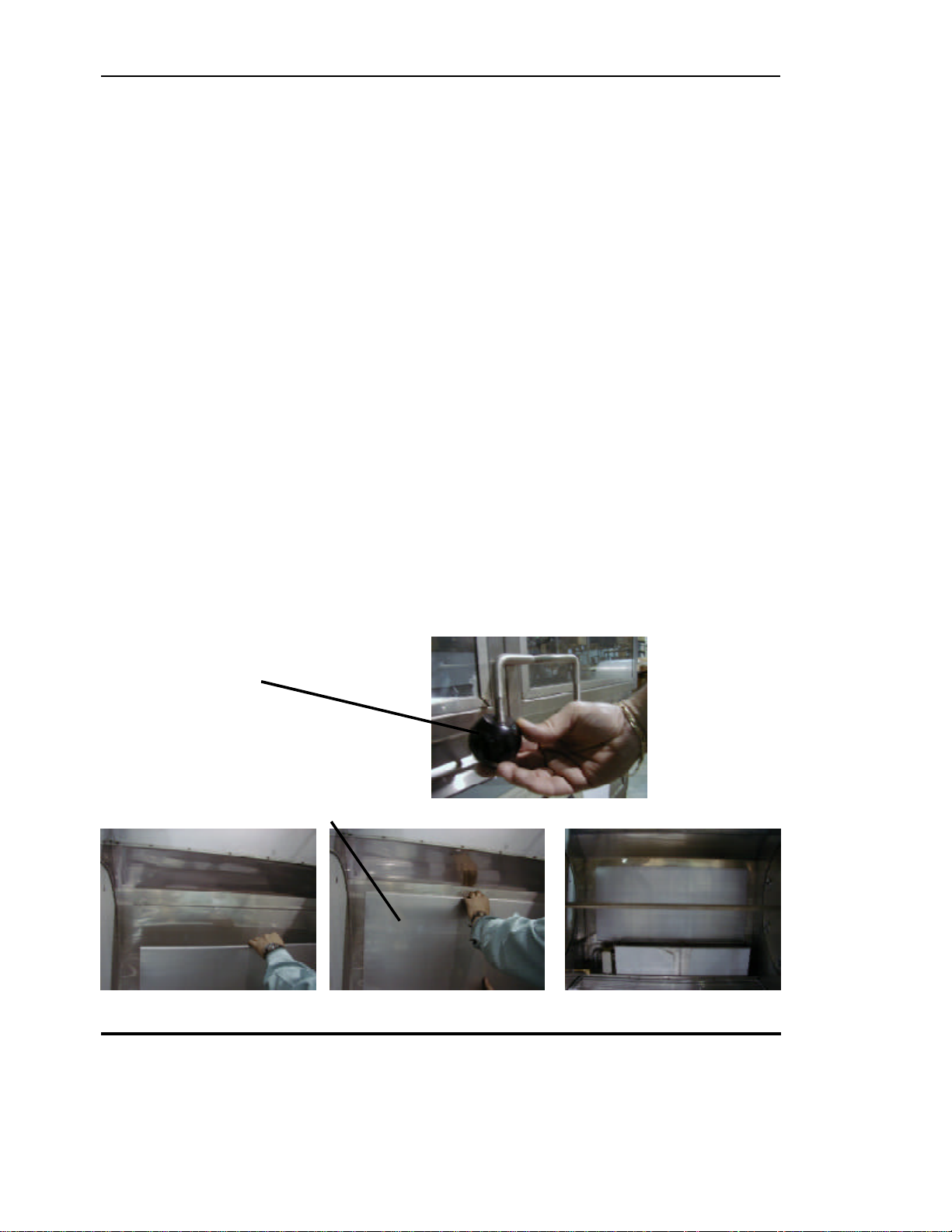

b. Place the ball knobs on the doors.

Tighten firmly.

c. Place the removable rear panel on the rear of the unit.

1. 2. 3.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/5.7G - 9/01

Page 5 of 25

Hickory Industries, Inc.

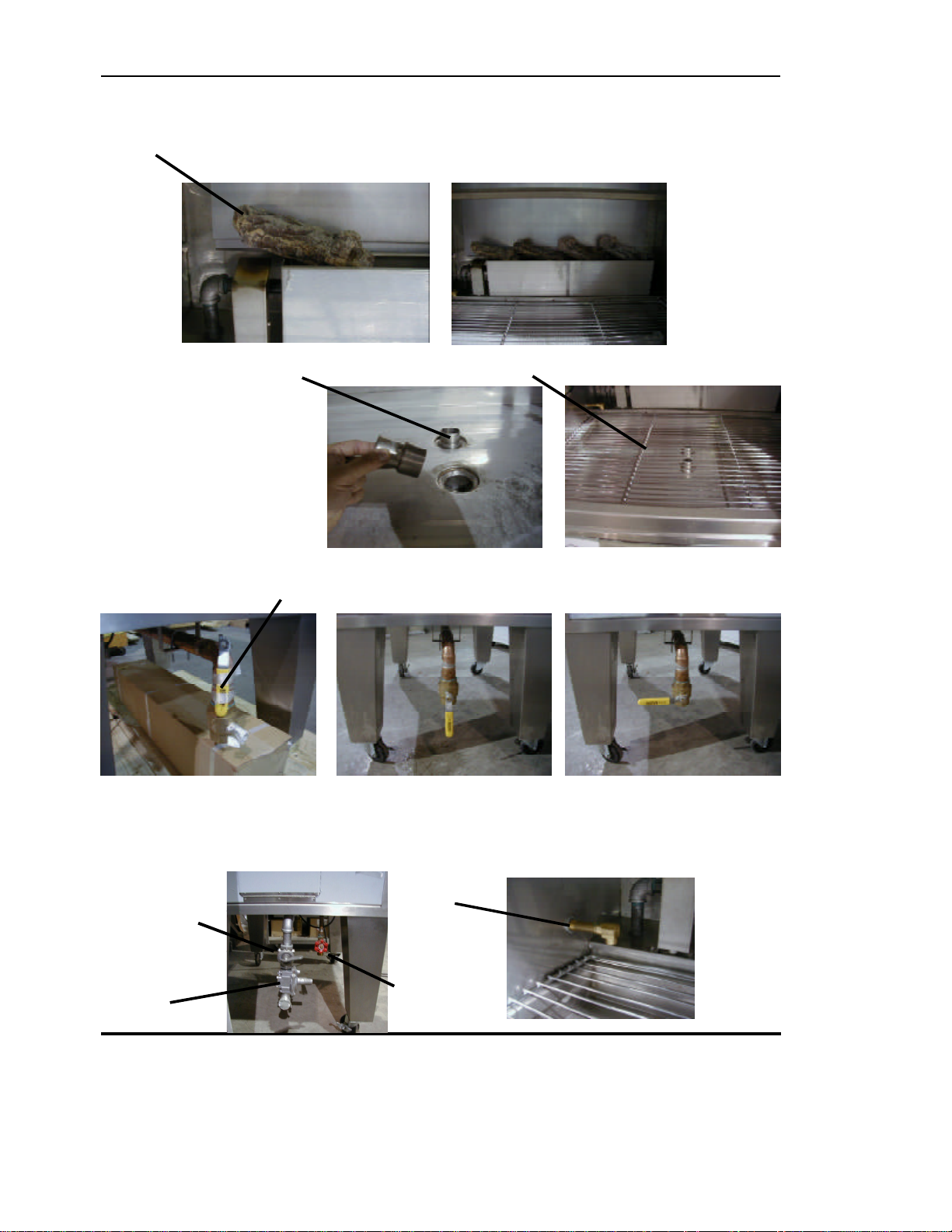

d. Place the ceramic logs on the rear ceramic log holder. Note the placement of the left

ceramic log - it must be located over the ignitor box to prevent fat from clogging the burner

holes.

e. Insert the drain overflow tubes and reinsert the wire rack.

f. Remove the drain handle and install the handle onto the valve and tighten.

Valve in open position Valve in closed position

g. The rotisserie is now ready to be plumbed by a licensed gas fitter.

Water outlet to

Gas shut off

and pressure

tap

Pressure

Regulator

drip pan

Water connection

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/5.7G - 9/01

Page 6 of 25

Water connection and drip pan water

inlet valve.

Gas inlet, pressure regulator & main

shutoff valve

Thermostat:

Cycles heat ON and OFF during cooking.

Product that has marinades, citrus, rubs etc.. may burn which can be

remedied by turning the thermostat at a lower temperature.

Temperature Switch:

Turns heat ON / OFF Indicator is illuminated when the

thermostat calls for heat.

Hickory Industries, Inc.

Drain valve "open position"

Timer:

Displays the time of day.

Allows the unit to cook and can

be used to shut the heat OFF

at the end of a cook.

Motor Switch:

Turns motor ON / OFF

Light Switch:

Turns lights ON / OFF

Control Panel Overview

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Rear Show Burner Switch:

Turns rear burner ON / OFF

MOTOR SWITCH MUST BE ON

Top Burner Switches:

Turns cooking burners ON / OFF

We recommend one burner ON with 1

to 3 spits of product and both burners

ON with 4 or more spits of product.

N/5.7G - 9/01

Page 7 of 25

Hickory Industries, Inc.

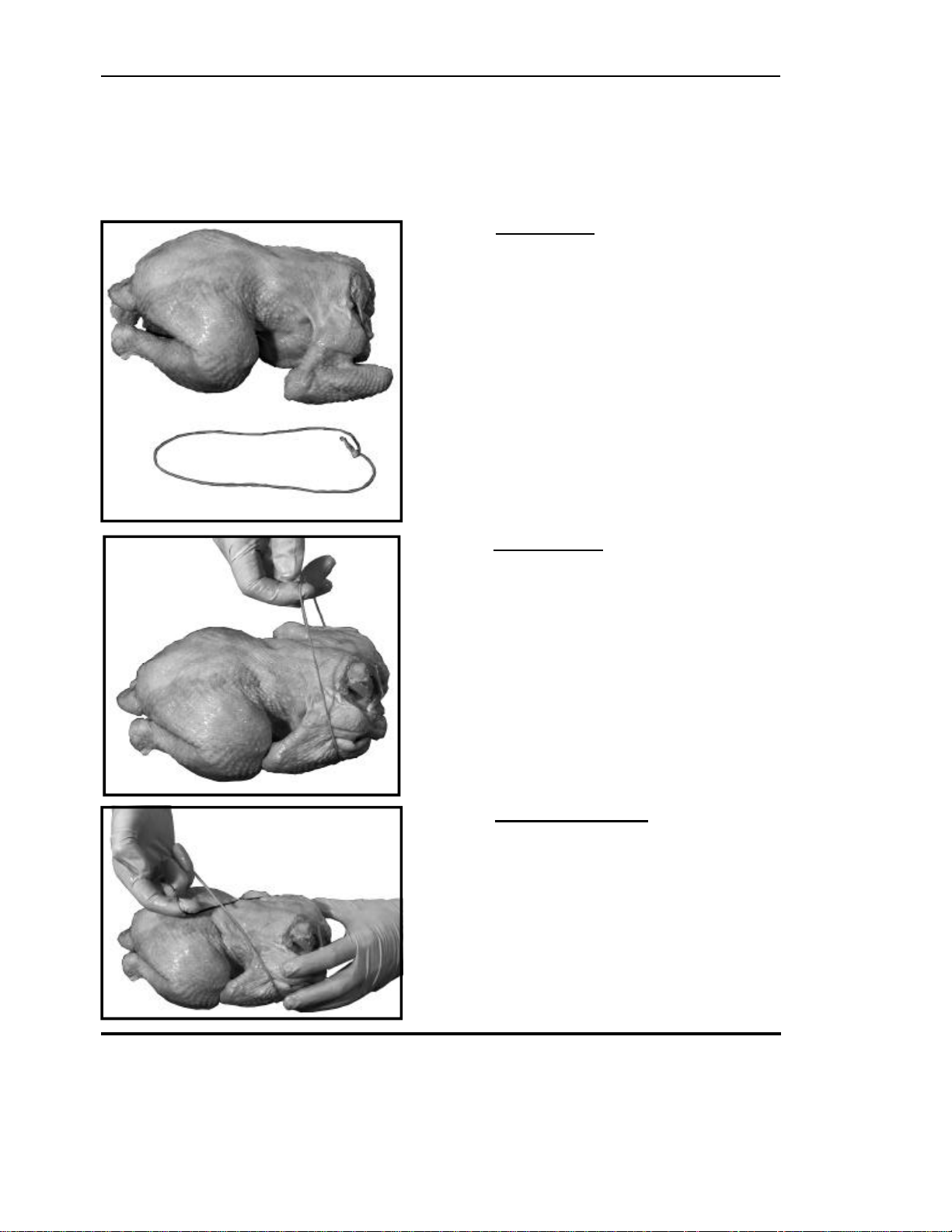

Spitting Chickens

The most important part in getting started with a rotisserie is knowing how to properly spit the product.

This is quite easy, but it must be learned! As an operator, you will become an expert in spitting chickens

within half an hour! There are two types of commonly used spits: the angle spit and the regular spit. The

following pages describe and show how spitting is done with both these types of spits.

A. Using Angle Spits

Figure 1. Chickens Ties

When using a “V” or angle spit, it is very important to tie

or truss the product being cooked. This prevents the

product from moving around the spit and also prevents

damage by preventing the legs and wings from flopping.

In this section, we will show how to properly truss a

chicken. It is important to use a tie to fit the size of the

product. In this case, we are tieing a 2 3/4 lb. chicken

with a 6” tie.

Figure 2. Trussing Wings

With the back of the chicken facing up, take the tie and

wrap it around the breast, making sure to tuck the wings

against the breast. Pull on the tie as pictured. You will

also need to hold the chicken with your other hand.

Figure 3. Trussing Across Back

While pulling on the tie, cross the strings so that you

make an “X” across the back of the chicken. With the

“loop” in your hand, you will now need to tie the legs of

the chicken.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

N/5.7G - 9/01

Page 8 of 25

Loading...

Loading...