Hestan GRFR24, GFDSR241 Installation Manual

INDOOR / OUTDOOR

UNDERCOUNTER REFRIGERATION

Refrigerators & Freezers

Installation Manual

EN

DANGER

DANGER

NOTICE

TABLE OF CONTENTS

2 SAFETY DEFINITIONS

3 MODEL NUMBERS

4 RATING LABEL

4 REGULATORY/CODE REQUIREMENTS

4 SAFETY

6 CABINET INSTALLATION

10 DOOR INFORMATION

12 DISPOSAL

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY

BEFORE INSTALLING OR USING YOUR APPLIANCE TO REDUCE

THE RISK OF FIRE, SHOCK HAZARD, OR OTHER INJURY. KEEP

THIS MANUAL FOR FUTURE REFERENCE.

IMPORTANT! IMPORTANT! Read and understand all information in this manual before

attempting the installation. All plumbing and electrical work must be

performed by a qualified technician and conform to all applicable state and

local codes.

INSTALLER: LEAVE THIS MANUAL WITH THE OWNER OF THE APPLIANCE.

HOMEOWNER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

SAFETY DEFINITIONS

THIS INDICATES A HAZARD THAT WILL RESULT IN SERIOUS

INJURY OR DEATH IF PRECAUTIONS ARE NOT FOLLOWED.

THIS INDICATES A HAZARD THAT MAY RESULT IN SERIOUS

INJURY OR DEATH IF PRECAUTIONS ARE NOT FOLLOWED.

THIS INDICATES A HAZARD WHERE MINOR INJURY

OR PRODUCT OR PROPERTY DAMAGE MAY OCCUR IF

PRECAUTIONS ARE NOT FOLLOWED.

THIS INDICATES THAT PRODUCT OR PROPERTY DAMAGE MAY

OCCUR IF PRECAUTIONS ARE NOT FOLLOWED.

RISK OF FIRE OR EXPLOSION - FLAMMABLE REFRIGERANT USED. Consult

repair manual/owners guide before attempting to service this product. All

safety precautions must be followed. To be repaired by trained service personnel only. Use caution

when handling, moving and using the product to avoid damaging the refrigerant tubing or increasing

the risk of a leak.

2

All service work shall be performed by factory authorized service personnel and

all component parts shall be replaced with like components to minimize the risk

of possible ignition due to incorrect parts or improper service.

If service is necessary, repair work must be performed by a Hestan authorized

servicer. Work done by unqualified individuals could potentially be dangerous

and will void the warranty.

©2021 Hestan Commercial Corporation

SAFETY

NOTICE

All models covered in this manual are manufactured using refrigerant R600a (Isobutane). R600a is

a hydrocarbon. This refrigerant is flammable and is only allowed for use in appliances which fulfill

the requirements of UL/IEC 60335-1 and UL/IEC 60335-2-24 (To cover potential risk originated from

the use of flammable refrigerants). Consequently, R600a is only allowed to be used in refrigerating

appliances which are designed for this refrigerant and fulfill the above-mentioned standard.

• R600a is heavier than air. The concentration will always be highest at the floor level.

• The explosion limits are as follows:

o Lower Limit: 1.8% by volume

o Upper Limit: 8.4% by volume

o Ignition Temperature: 860ºF [460°C]

DEFINITIIONS

This product contains blown foam insulation using blowing agent R-611 (Methyl

Formate). The foam in this product does not contain HFC’s, CFC’s, or HCFC’s.

(continued)

MODEL NUMBERS

Model No. Description

GRS_24 INDOOR / OUTDOOR REFRIGERATOR, SOLID DOOR, 24”

GRS_24-XX INDOOR / OUTDOOR REFRIGERATOR, SOLID DOOR, COLOR, 24”

GRG_24 INDOOR / OUTDOOR REFRIGERATOR, GLASS DOOR, 24”

GRG_24-XX INDOOR / OUTDOOR REFRIGERATOR, GLASS DOOR, COLOR, 24”

GRR24 INDOOR / OUTDOOR REFRIGERATOR DRAWERS, 24”

GRR24-XX INDOOR / OUTDOOR REFRIGERATOR DRAWERS, COLOR, 24”

GRFR24 INDOOR / OUTDOOR REFRIGERATOR DRAWER AND FREEZER DRAWER, 24”

GRFR24-XX INDOOR / OUTDOOR REFRIGERATOR DRAWER AND FREEZER DRAWER, COLOR, 24”

GRWS_24 INDOOR / OUTDOOR DUAL ZONE REFRIGERATOR WITH WINE, SOLID DOOR, 24”

GRWS_24-XX INDOOR / OUTDOOR DUAL ZONE REFRIGERATOR WITH WINE, SOLID DOOR, COLOR, 24”

GRWG_24 INDOOR / OUTDOOR DUAL ZONE REFRIGERATOR WITH WINE, GLASS DOOR, 24”

GRWG_24-XX INDOOR / OUTDOOR DUAL ZONE REFRIGERATOR WITH WINE, GLASS DOOR, COLOR, 24”

EN

GRSR24 shown

R600a Refrigerant

_ = Right (R) or Left (L) Hinged Model

GRR24 shownGRWGR24 shown

©2021 Hestan Commercial Corporation

3

RATING LABEL

DANGER

DANGER

The rating label contains important information about your Hestan appliance such as the model and

serial number, and refrigerant information if service is required.

EN

RATING LABEL

The rating label is attached to

the inside top of the cabinet.

REGULATORY / CODE REQUIREMENTS

Installation of this appliance must be made in accordance with local codes. In the absence of local

codes, this unit should be installed in accordance with the National Electrical Code and local codes.

This appliance must be electrically grounded in accordance with local codes or in the absence of

local codes with the National Electrical Code

C22.1

.

ANSI/NFPA 70

, or Canadian Electrical code

CSA

SAFETY

CHILD SAFETYCHILD SAFETY

Risk of child entrapment. Before you throw away your old

refrigerator or freezer:

• Take off the doors.

• Leave the shelves in place so that children may not easily climb inside.

NEVER allow children to play inside the appliance.

PRIOR TO INSTALLATIONPRIOR TO INSTALLATION

Carefully inspect cabinet for hidden damage. If damage is discovered, file your

claim immediately with the transport company. Hestan is not responsible for

damage in transit. Remove any packaging materials before operating.

RISK OF FIRE OR EXPLOSION - FLAMMABLE REFRIGERANT USED.

Use caution when handling, moving and using the product to avoid damaging

the refrigerant tubing or increasing the risk of a leak.

When moving the unit, be sure to protect finished flooring with appropriate

material to avoid damage from moving the unit. Do not lift unit by drawer,

shelving or door handles, as damage to the unit could occur if not moved as instructed.

To prevent personal injury, a minimum of two people are required to lift the

unit. Larger units may require additional personnel.

Before moving the unit, secure the door shut with tape to prevent door from swinging open while

being moved. Carefully move unit to installation site and place in front of opening.

4

©2021 Hestan Commercial Corporation

If unit has been laid on its back or sides, place unit upright and allow a

minimum of 24 hours before connecting power.

DANGER

NOTICE

DANGER

SAFETY

(continued)

PLUMBINGPLUMBING

No plumbing connections are required. Condensate from the cooling coil is automatically evaporated

through a condensate pan located in the condensing section of the unit.

ELECTRICAL SHOCK HAZARDELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing appliance. Failure to do so can result in death or

electrical shock.

ELECTRICAL GROUNDINGELECTRICAL GROUNDING

• This appliance must be grounded. Grounding reduces the risk of electric

shock in the event of a short circuit.

• DO NOT ground to a gas pipe.

• DO NOT use an extension cord with this appliance.

• DO NOT have a fuse in the NEUTRAL or GROUNDING circuit. A fuse in

the NEUTRAL or GROUNDING circuit could result in an electrical shock.

ELECTRICAL SUPPLYELECTRICAL SUPPLY

A 115 volt AC, 60 Hz, 15 Amp circuit breaker and electrical supply is required. A Ground Fault Circuit

Interrupter (GFCI) protected circuit must be used when installed outdoors.

EN

This appliance is NOT designed for installation in manufactured (mobile) homes or recreational park

trailers.

All units are provided with a 5 ft [1.5 m] cord with three-prong grounding plug. It is imperative that

this plug be connected to a properly grounded three-prong receptacle. If the receptacle is not the

proper grounding type, contact an electrician. The receptacle must be flush or recessed into the wall

surface behind the unit.

• Never remove the grounding prong from this plug.

• Never use a 2-prong adapter.

• If a 2-prong receptacle is encountered, or a longer power cord is required, contract a qualified

electrician to have it replaced in accordance with applicable electrical codes.

Inspect the electrical cord and plug for damage prior to energizing the unit to

avoid potential electric shock.

The unit must NOT be totally enclosed or damage may occur. Air circulation must not

be restricted. The condenser at the cabinet front must be provided with a minimum of

2” [5 cm] air space. Be sure to provide access so the front cover can be removed to clean the condenser.

Do not attempt to operate the equipment on any power source / voltage other

than that listed on the Electrical Specification Plate attached to the unit.

Do not store flammable liquids (i.e. Gasoline or Lighter Fluid) or vapors near the

appliance to avoid a fire.

ADDITIONAL GENERAL INFORMATIONADDITIONAL GENERAL INFORMATION

All electrical instructions assume the outlet is located 4 - 10” [10 - 25 cm] above the floor surface.

Floor must be level in the area of installation. Leg levelers are used for fine-tune adjustment only and

should not be used to compensate for floor differences exceeding 1/2” [13 mm].

©2021 Hestan Commercial Corporation

5

EN

DANGER

NOTICE

CABINET INSTALLATION

RISK OF FIRE OR EXPLOSION - FLAMMABLE REFRIGERANT USED.

Use caution when handling, moving and using the product to avoid damaging

the refrigerant tubing or increasing the risk of a leak.

CASTER KIT (OPTIONAL)CASTER KIT (OPTIONAL)

A Caster Kit (AGCK24) is available for Hestan undercounter refrigeration models. Refer to the

instructions supplied with the caster kit for proper installation.

Note: Installation of the kit adds 3.75” [9.5 cm] to overall height of the unit.

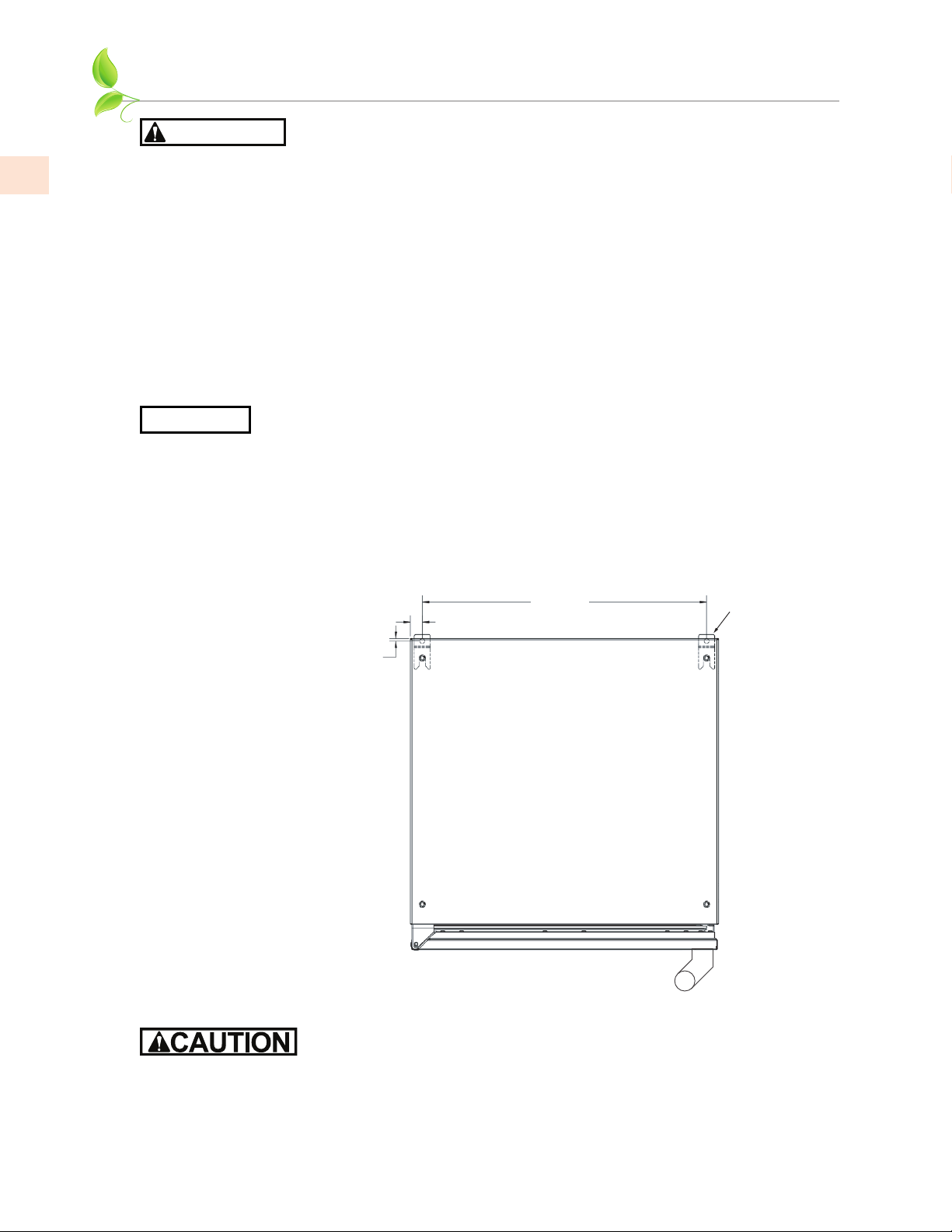

ANTI-TIP BRACKETSANTI-TIP BRACKETS

Unit may tip forward if loaded racks/shelves are all pulled out at the same time. To prevent tipping,

and to provide stable installation, the unit must be secured in place with the anti-tip brackets

supplied with the unit. The anti-tip brackets, when properly installed, should secure the rear legs/

glides to the mounting surface and prevent the unit from tipping forward.

Anti-tip brackets are only used for stationary cabinets and should not be installed on

cabinets with accessory casters.

If installing on a concrete floor, concrete fasteners are required and not included with the anti-tip kit.

Some installation sites may require modifications to provide a secure surface for attaching the

brackets.

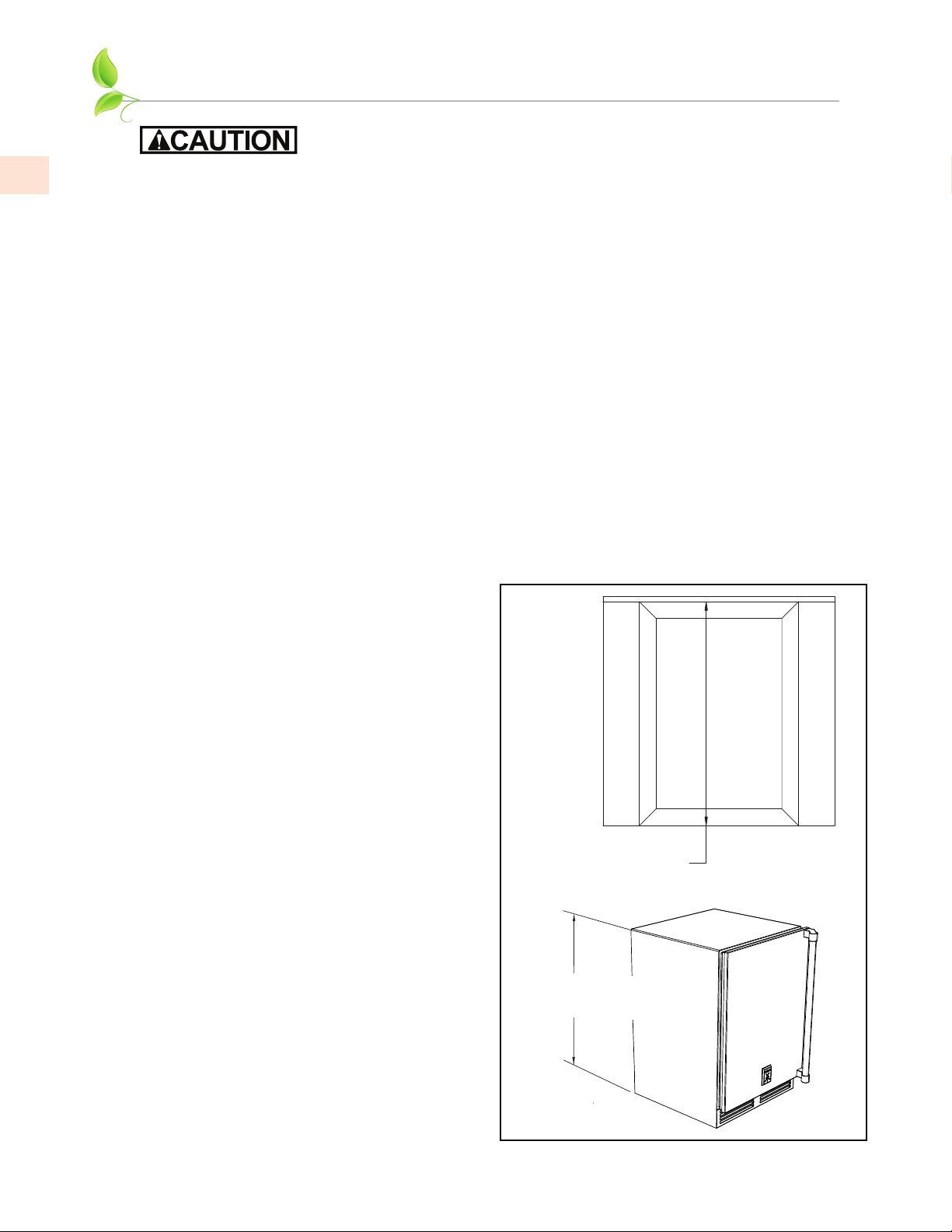

A set of anti-tip brackets is supplied with the unit. These brackets should be attached to the floor at

the rear of the unit. Each bracket must be located to engage the rear legs when the cabinet is pushed

back into position. Refer to Figure 1 (shown below) for anti-tip bracket mounting locations.

3

22-

15

⁄16”

⁄16”

BRACKETS

3

⁄16”

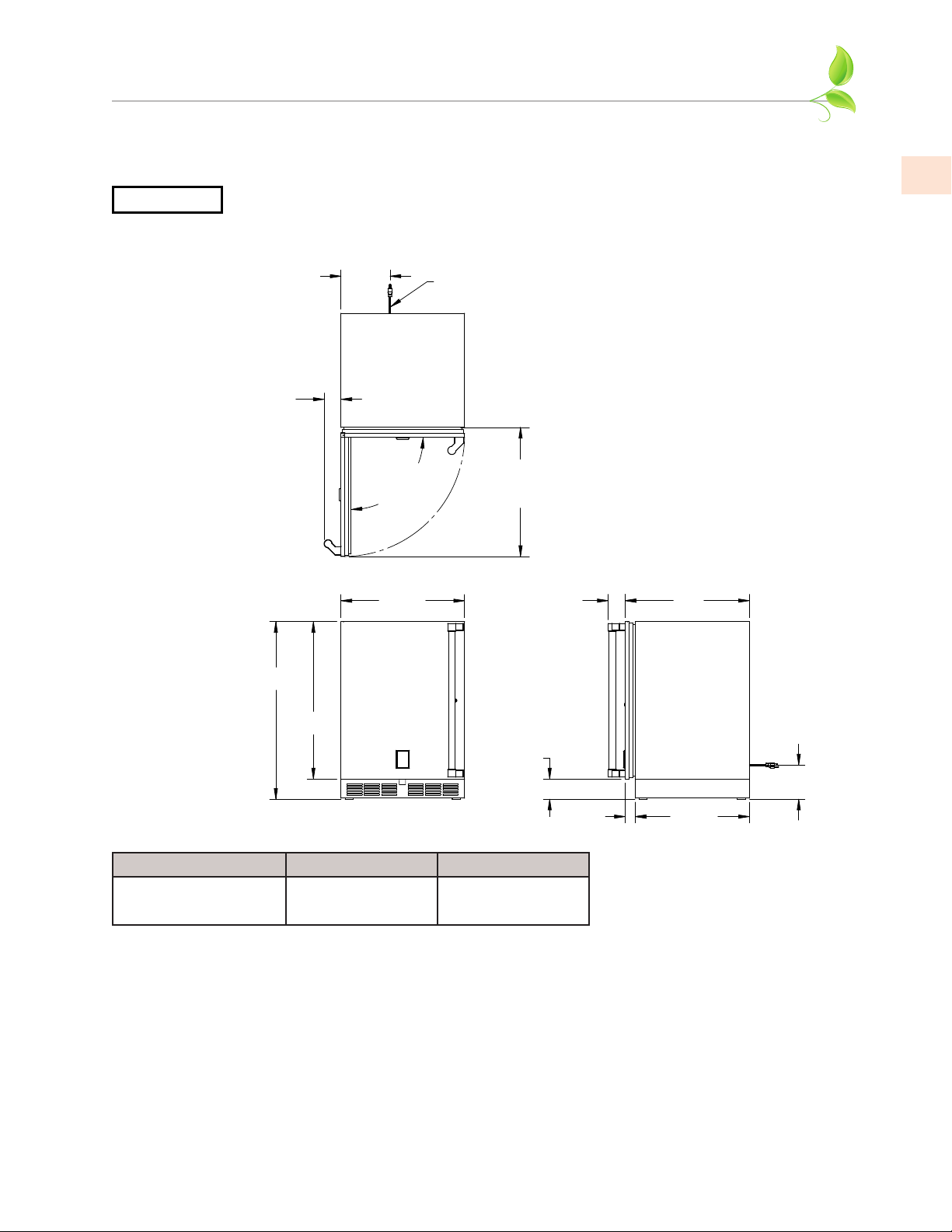

PREPARING THE SPACEPREPARING THE SPACE

If the unit is to be installed under a countertop, it is recommended that the countertop be supported

by a structure other than the unit itself to prevent damage to the unit.

Figure 1. 24” Anti-Tip Kit

Make sure the floor under the unit is level with the surrounding finished floor. Protect a finished

floor with plywood, cardboard, or some other suitable material before moving the unit into place.

Failure to do this may result in damage to the floor.

6

©2021 Hestan Commercial Corporation

CABINET INSTALLATION

NOTICE

when fully extended.

(continued)

To assure maximum performance, fresh air must be allowed to circulate through the machinery

compartment. Do not place anything in front of the unit that would obstruct air flow at these

front grilles. Do not place the unit in an unventilated small room.

Cabinet should be leveled front to back, then side to side.

1. Make sure the space opening is correctly sized for the unit. See typical appliance dimensions

below, and the chart below for finished rough opening requirements:

11”

POWER CORD

5 FT. LONG

TYPICAL APPLIANCE

DIMENSIONS

EN

1

3-

⁄

” MIN. CLEARANCE FROM A

4

CORNER TO ACHIEVE 90° SWING

5

*34-

- Leg levelers can add

*

3/4” to these dimensions

CUTOUT DIMENSIONS:

3

⁄

” H - 24” W - 24” D

34-

8

90° SWING

REQUIRED FOR

PULL-OUT SHELF

CLEARANCE

7

23-

/8”

⁄

”

16

3

30-

⁄

”

8

15

⁄

”

24-

*3-

16

3-

15

⁄

”

16

MIN. CLEARANCE

FOR DOOR SWING

5

⁄

”

16

15

1-

⁄

”

16

24”

22-

5

*6-

⁄

”

8

1

⁄

”

16

HEIGHT WIDTH DEPTH

34-3/8” [87.3 cm] min.

35-1/2” [90.2 cm] max.

24” [61 cm] 24” [61 cm]

2. Check that the following are level and square:

• Front and interior opening

• Installation opening and floor surface

• Countertop bottom front edge

NOTE: For a door to open properly, the door must open a minimum of 90°. Use a minimum 3”

[7.6 cm] filler in corner installations to assure a full 90° opening. Allow 25” [64 cm] clearance in

front of unit for full door swing and shelf/drawer pull out.

NOTE: The floor under the unit must be at the same level as the surrounding finished floor.

©2021 Hestan Commercial Corporation

7

EN

Figure 2. Leveling the Unit

CABINET INSTALLATION

To prevent possible damage to the countertop, do not place heavy objects on

countertop directly over unit.

(continued)

INSTALLING THE UNIT INTO THE SPACEINSTALLING THE UNIT INTO THE SPACE

1. Plug the unit into the 15 amp grounded electrical outlet located within the installation opening.

With power applied to the unit, check that the lighting and cooling functions operate properly.

Turn off the power to the wall outlet at the circuit breaker.

2. With all surfaces in the installation opening square and level, refer to Figure 2 below and perform

the following steps to level the unit:

• At the front of the opening, measure from the floor to the bottom of the front edge of the

countertop.

• Measure from the floor surface to the top of the unit at the rear corners.

• Adjust the unit legs so these two measurements are equal. Using an adjustable wrench or

pliers, turn legs clockwise to lower the unit or counterclockwise to raise it.

NOTE: Legs should not extend more than 3/4” [19 mm] from the bottom of the unit.

3. Slide the unit into position in the opening. Make sure the rear leveling legs slide under the anttip brackets. Push the unit into the opening until the bottom front edge of the unit is flush with

the surrounding cabinetry, or until the rear legs are tight against the anti-tip brackets.

4. Shim the front of the unit so the front face is flush with the surrounding cabinetry. Adjust the

front legs to support the countertop at the shimmed height. Using an adjustable wrench or

pliers, turn the legs clockwise to lower the unit or counterclockwise to raise it. Countertop

should be resting on top of the unit.

NOTE: Countertop should be resting evenly

on entire top of the unit. Shim if necessary to

prevent damage to the countertop.

5. Check interior door openings to make sure

the unit is level and square. Install shelving

and/or drawers. For drawer units, place

the slide brackets squarely into the bracket

grooves. When installed properly, a “click”

should be heard from the slide bracket

retaining tabs and the brackets should slide

smoothly. The retaining tabs will stop

the shelf/drawer when pulled out to full

extension.

6. Turn on the power to the wall outlet at the

circuit breaker.

NOTE: Improper shelf/drawer installation may

not actuate slide mechanism.

Measure front of opening

from floor surface to bottom

edge of countertop.

Measure at both rear corners

of unit from floor surface to

bottom of countertop.

8

©2021 Hestan Commercial Corporation

Loading...

Loading...