Customer manual

LFM LP Reader Rev.1.2

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 2 of 119

0. Table of contents

0. Table of contents 2

1. Introduction 5

2. Version history 7

3. Used abbreviations and designations 7

4. General instructions 8

5. Safety instructions and warnings 9

5.5.1 Regulations and certifications 14

6. Functional description 15

6.2.4 Test module 16

6.3.1 Top view 17

6.4.1 Power supply and current input 20

6.4.2 Device labels 21

6.4.3 Device Label FCC ID 2AP5OLFM-LP 21

7. Installation 22

7.5.1 Positioning the antenna 25

7.5.2 Antennas dimensions 26

7.6.1 Tuning push button 27

7.6.2 Test push button 28

8. Commissioning 29

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 3 of 119

9. Operating 34

9.2.1 General 34

9.2.2 Automatic protocol detection 34

9.2.3 Triggered protocol change 34

10. ASCI-I1 Communication protocol 36

10.4.1 X – Read data 44

10.4.2 R – Automatic read 45

10.4.3 W – Write data 46

10.4.4 G Query parameter 46

10.4.5 F – Query parameter 47

10.4.6 P – Set parameter 48

10.4.7 N – Reset 49

10.4.8 e – Error message 50

10.4.9 H – Heartbeat 50

10.4.10 V – Query software version 51

10.4.11 L – Lock data area 52

10.4.12 I – Adjust RF module 53

10.4.13 J – RF module Queries the vote 54

10.4.14 A – Sensor event object removed 55

10.4.15 B – Sensor event object detected 56

10.4.16 O – Set output 57

10.4.17 Q – Querying the status of the inputs and outputs 58

10.8.1 Reader operation mode and sensor triggered reading 66

11. SECS / HSMS Communications protocol 71

11.3.1 Stream 1 (system state) 86

11.3.2 Stream 2 (system control) 87

11.3.3 Stream 3 (Material-state) 89

11.3.4 Stream 5 (Exception handling) 91

11.3.5 Stream 9 (system error) 91

11.3.6 Stream 18 (control and data transfer) 93

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 4 of 119

12. Service and Troubleshooting 115

13. Disassembly and storage 119

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

These operating instructions correspond with the "Radio and Telecommunications Terminal.

Equipment Act and Directive 2014/53/EU (RED) "

These operating instructions are intended for the operator who must pass these on to the

personnel responsible for installation, connection, use, and repairs of the machine.

The operator must ensure that the information contained in these operating instructions and in

the accompanying documents has been read and understood.

The operating instructions must be kept at a known place that is easy to reach, and they must

be consulted if there is the slightest doubt.

The manufacturer assumes no responsibility for damage to persons, animals, or objects or to

the unit itself arising from the improper use or the disregard or insufficient consideration to the

safety criteria contained in these operating instructions or based on modifications of the unit or

the use of unsuitable replacement parts.

The copyright for the operating instructions lies solely with

HERMOS AG

Track & Trace - RFID Division

Gartenstr.19

95490 Mistelgau, Germany

or its legal successor.

Reproduction or circulation of this document to third parties only by express written permission

of copyright holder. This also applies if only excerpts of the document are copied or circulated.

These same conditions apply to the disclosure of the document in digital format.

As of: Juli – 2017

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 5 of 119

1. Introduction

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

WARNING

Danger of injury due to unauthorised modifications

There are risks from unauthorised modifications on the device.

Only original spare parts from the manufacturer must be used. No modification,

attachment or conversion may be performed on the device without the permission

of HERMOS AG.

WARNING

Danger of injury and interruption of operation due to improper use

There are risks through the improper use of the device.

The device must only be used according to its intended use.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 6 of 119

Using the device

The device is exclusively used to read and write passive LF transponders.

Any other use of the machine or any use beyond its intended purpose is considered non-intended and

thus improper.

In this case, the device safety and the device protection provided may be compromised. HERMOS AG

is not liable for damages resulting from such use.

The device was developed for the use in an industrial environment as a built-in device in other systems.

It was not developed as a stand-alone or mobile device in a non-industrial environment, such as

domestic, vehicle or open air use.

Intended use also includes the following:

Following all the operating instructions

Following all the safety instructions

Improper use, which can endanger the unit, the user and third parties, include:

The use of the device contrary to its intended use

Changes to the device as well as attachments and conversions

Operating the unit when there are obvious problems

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Version

Date

Author

Amendments

1.1

26.09.2018

HERMOS AG RK

Initial version of customer

documentation

1.2

16.11.2018

HERMOS AG RK

FCC, additional Parameters

RFID

Radio Frequency Identification

LF

Low Frequency 134,2 kHz

SEMI

Semiconductor Equipment and Materials

SECS

SEMI Equipment Communications Standard

HSMS

High-Speed SECS Message Service

PoE

Power over Ethernet

DHCP

Dynamic Host Configuration Protocol

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 7 of 119

2. Version history

3. Used abbreviations and designations

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 8 of 119

4. General instructions

All previous versions of this document lose their validity with the issue of this version.

We compiled the information in this document according to the best of our ability. HERMOS AG does

not guarantee the accuracy and completeness of the information provided in this document and is also

not liable for consequential damages based on faulty or incomplete information.

Objective of the product manual

The product manual serves as support and contains all the necessary information that must be followed

for general safety, transport, installation and operation.

The product manual with all safety instructions (as well as all additional documents) must be:

Followed, read and understood by all persons working with the unit (especially

knowledge of the safety instructions)

Easily available at all times to all persons

Consulted if even the slightest doubt arises (safety)

Objectives:

Prevent accidents

Increase the service life and reliability of the unit

Reduce the costs of production downtime

Warranty and liability

The "General Terms and Conditions of Sale and Delivery" of HERMOS AG shall apply.

The warranty period is 24 months beginning with the delivery of the device, which is verified by the

invoice or other documents.

The warranty includes repairs of all damages to the unit that occur during the warranty period, and

were clearly caused by material or manufacturing defects.

Warranty and liability claims in the event of personal injury or property damage are excluded if they

arise from one or more of the following causes:

Improper use of the unit

Disregarding the information in the operating instructions

Unauthorised structural modifications of the unit

Insufficient maintenance and repairs

Disaster events due to impact with foreign objects or force majeure

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

DANGER

Risk of death, injury and property damage.

There is a risk of danger due to disregard of the product manual and the

safety information contained therein.

Read the product manual carefully before putting the unit into operation for

the first time. Fulfil all required safety conditions.

DANGER

Risk of injury due to disregarding the safety symbols.

Risks exist when disregarding warnings in the operating instructions.

Follow all warnings.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 9 of 119

5. Safety instructions and warnings

Scope and symbols

Follow the general safety instructions as well as special safety instructions included in the chapters.

The unit was built according to state-of -the-art technology and recognised safety regulations. In order

to prevent danger to life and limb of the user, third parties, or the unit, only use the unit for its intended

purpose and in perfect condition with regard to safety.

Bodily injuries and/or property damages resulting from non-compliance with the instructions provided in

the operating instructions are the responsibility of the company operating the unit or the assigned

personnel.

Faults that may compromise safety must be eliminated immediately.

Safety symbols - according to DIN 4844-2

The following special safety symbols in accordance with DIN 4844-2 are used at the corresponding

passages in the text of this product manual and require special attention depending on the combination of

the signal word and symbol.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Observe additional information

Use safety goggles

Wear ear protection

Wear safety shoes

Important note

Warning of a hazardous area

Warning of hazardous electrical

voltage

Warning of electromagnetic

radiation

Warning of flammable substances

Warning of explosive substances

Warning of electrostatically

sensitive components

Unauthorised access is prohibited

Fire, open flame and smoking

prohibited

Switching prohibited

Prohibited

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 10 of 119

5.2.1 Mandatory signs

5.2.2 Warning signs

5.2.3 Prohibition signs

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Dispose of packaging material

according to rules and regulations

Recycling

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 11 of 119

5.2.4 Other signs

Obligations

5.3.1 Operator’s obligations

A safe condition and use of the unit is a requirement for a safe operation of the unit. For that reason,

the operator has the obligation to ensure that the following points are adhered to:

The unit may only be operated by trained and authorised personnel.

Prohibit unsafe or dangerous working methods! If necessary, check the conduct

and actions of its personnel!

Have personnel who must be trained, instructed or within the scope of general

training work only on the unit under the supervision of an experienced person!

Have the personnel confirm by their signature that the operating instructions have

been understood!

Precisely establish responsibilities according to the various task areas (operation,

installation)!

Operating personnel must be required to immediately report any occurring and

identifiable safety deficiencies to their superior!

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

WARNING

Risk of injury due to insufficient personnel qualifications

There are dangers to personnel and the proper operation due to

inadequately qualified personnel.

Only trained personnel may operate the unit.

New operating personnel must be instructed by the existing operating

personnel. The operator must precisely regulate the personnel’s areas of

responsibility, competence, and monitoring precisely.

The personnel for the areas of responsibility mentioned above must have the

corresponding qualification for this work (training, instruction).

If necessary, this can be done by the manufacturer on behalf of the operator.

In case of disregard, all warranty claims are void.

CAUTION

Static electricity can damage electronic components in the unit. All persons

who install or maintain the unit must be trained in ESD protection.

ESD protective measures must be applied when opening the unit.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 12 of 119

5.3.2 Responsibilities of operating personnel

The operating personnel are obligated to contribute to the prevention of work accidents and their

consequences by their personal conduct.

5.3.3 ESD Instructions

Disconnect the power supply prior to removing or adding components!

Observe the basic principles of ESD protection

Take the appropriate ESD precautionary measures

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

DANGER

Danger caused by electrical current

Electrical residual energy remains in lines, equipment and devices after

shutting down the device.

Only qualified electricians may perform work on the electrical supply

system.

ATTENTION

Disconnect the unit from the power supply system if active parts of the

unit can be accessed using tools. Access is only permitted by

authorised personnel.

Regularly check the electrical equipment of the unit. Regularly check all

moving cables for damage within the scope of maintenance and repair

work.

DANGER

Dangers of fire and explosion

There is a risk of fire and explosions in the vicinity of the device.

Smoking, exposed flames and fire are strictly prohibited in the vicinity of

the unit. Do not store any flammable liquids within the hazardous area of

the device.

A fire extinguisher must be kept in the vicinity of the device.

WARNING

Warning of electromagnetic radiation

Electromagnetic radiation develops when transmitting and receiving

data.

Arrange the antenna in such a position that it is not in the vicinity or

make contact with the human body while transmitting.

The device satisfies the standard EN50364:2010 (Human Exposure).

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 13 of 119

Residual risks

Despite all precautionary measures taken, there may still be residual risks that are not

apparent.

Adhering to the safety instructions, the intended use, and the product manual as a whole can

reduce residual risks.

Supplemental instructions

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 14 of 119

Read and understand all safety and operating instructions prior to installing and

operating the device.

This documentation was written for specifically trained personnel. The installation,

operation and error handling may only be carried out by specifically trained

personnel.

Keep these instructions. Keep this documentation in a location that is accessible

to all personnel involved with the installation, use, and error handling of the

device.

Follow all warnings. Follow all warnings on and in the device and in the

documentation.

Install the unit only in accordance with the manufacturer's instructions.

Use only the accessories and cables from the manufacturer.

Troubleshooting that is not described in the chapter service and

troubleshooting may only be performed by the manufacturer.

When connecting cable connections, only pull on the plug and not on the cable.

Only use spare parts specified by the manufacturer.

The provisions of the accident-prevention regulations of the government safety organisations always

apply to all work on the unit.

Applicable, legally binding accident prevention regulations.

Applicable binding regulations at the place of use

Technical standards for safety and professional work

Existing environmental protection regulations

Other applicable regulations

5.5.1 Regulations and certifications

The electrical design and documentation satisfy the DIN / VDE, EN / IEC regulations.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 15 of 119

6. Functional description

General information

LF reading devices are radio frequency identification systems that use radio transmission to read or

write data of LF transponders (134,2 kHz), which operate as tamper-proof electronic tags. The LF

reading devices communicate with common transponders according to ISO 18000-2 and ISO 11785

that are available on the market.

The data is transmitted via the existing interface with the preset transmission parameters. If several

interfaces are available and connected to the host, the transmission is always carried out on the most

recently used interface. The data is embedded in a defined communication protocol and exchanged

between the reader and host.

Basic functions - operating modes

During normal operation, the LF reading device supports various basic functions:

Heartbeat function, software version query

Reading data

Writing data

Locking data

Setting and reading out parameters

Setting and querying inputs and outputs

The LF devices can be set in 3 other operating modes by setting the parameters: Polling operation

(optional), sensor-triggered automatic reading and test mode.

6.2.1 Normal operation

During normal operation, the LF reading device is immediately ready for operation after a reset. It does not

perform any automatic actions in this mode (standby). During normal operation, actions are triggered by

protocol commands from the host.

A scanning procedure or reading in the data area is initiated by a command of the host system using the

communication protocol.

In addition to the actions triggered by the host, a corresponding message can be automatically sent to the

host and an automatic reading operation can be started by activating or releasing a sensor.

When the reading operation is successful, the read data is immediately transmitted to the host. If several

antenna ports are occupied simultaneously, the reading operations are processed sequentially.

Writing actions (data saved to a transponder) are generally only possible via commands from the host.

6.2.2 Polling mode

LF reading devices can be set into a continuous reading state, which is referred to as polling mode.

The device then performs reading operations at regular intervals and outputs the corresponding data of

the read LF transponder.

The reading device also continues carrying out protocol messages in polling mode. This may, however,

result in delays in the poll rhythm. The polling functionality is optional customer-specific available!

6.2.3 Sensor-triggered operation

Device versions with IO port offer the function of a sensor-triggered automatic reading operation. The

reading device automatically performs a reading operation when the input is triggered. The type of action

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 16 of 119

(inventory/reading) can be defined with the parameters „Read mode“ and „Read page“.

The read data is automatically sent to the host.

The result of the reading operation (successful, not successful) can be optionally output via I/O s of the

antenna port.

6.2.4 Test module

The HERMOS LF reading devices support a test mode that facilitates setting up the antenna and checking

the reading ranges during commissioning. These test mode can be activate with a push button.

If the device is in test mode (maintenance mode) three tri-colour LEDs shows the state of the test mode.

The chapter "Status LEDs" describes the behaviour in test mode.

see also chapter „push button switches“

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

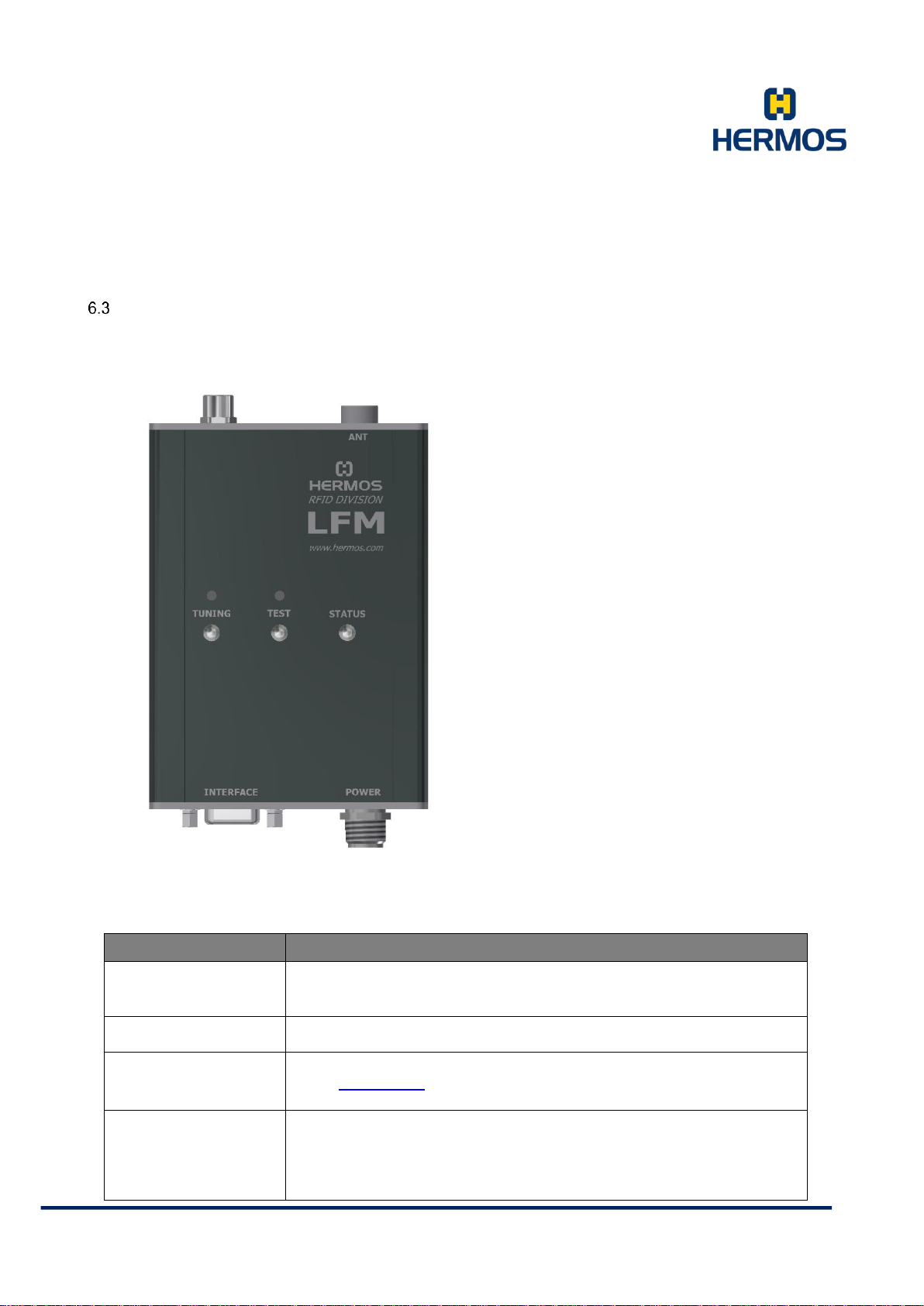

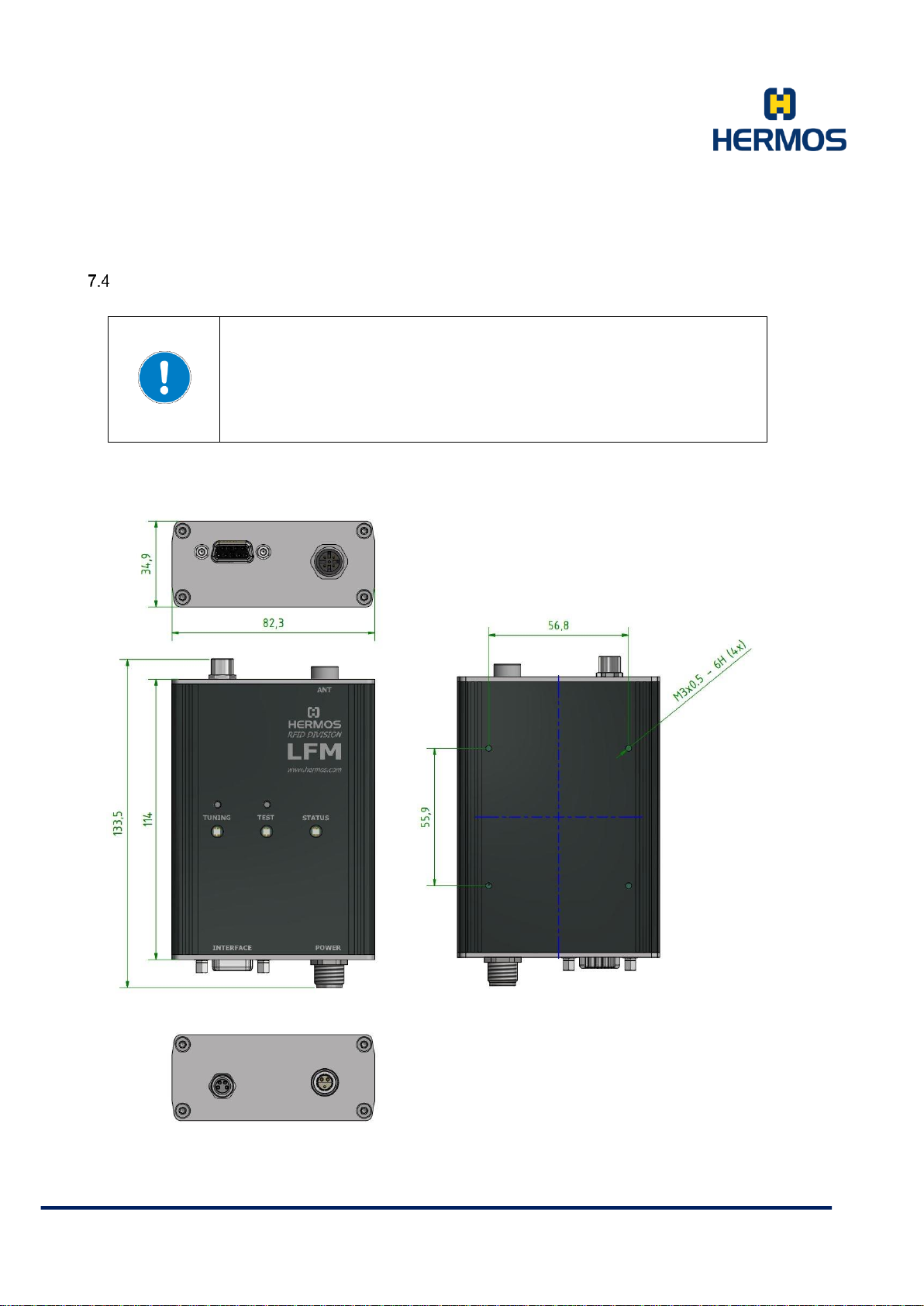

Component

Describtion

Power supply

M12-A plug for 24V DC power supply.

Antenna connection

Lemo antenna connector

Status-LEDs

--->see page 28

Push buttons

Tuning push button switch starts an automatic antenna tuning.

Test push button activates the read test mode. On a long press the

write test mode is activated.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 17 of 119

Illustration

6.3.1 Top view

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Ethernet interface

Depending on the device model, the reading device features a

10/100 BaseT Ethernet interface.

RS232 interface

Depending on the device model, the reading device features a

RS232 interface (9-pin Sub D female).

GPIO

Optional is a GPIO port available, M8 connector

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 18 of 119

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

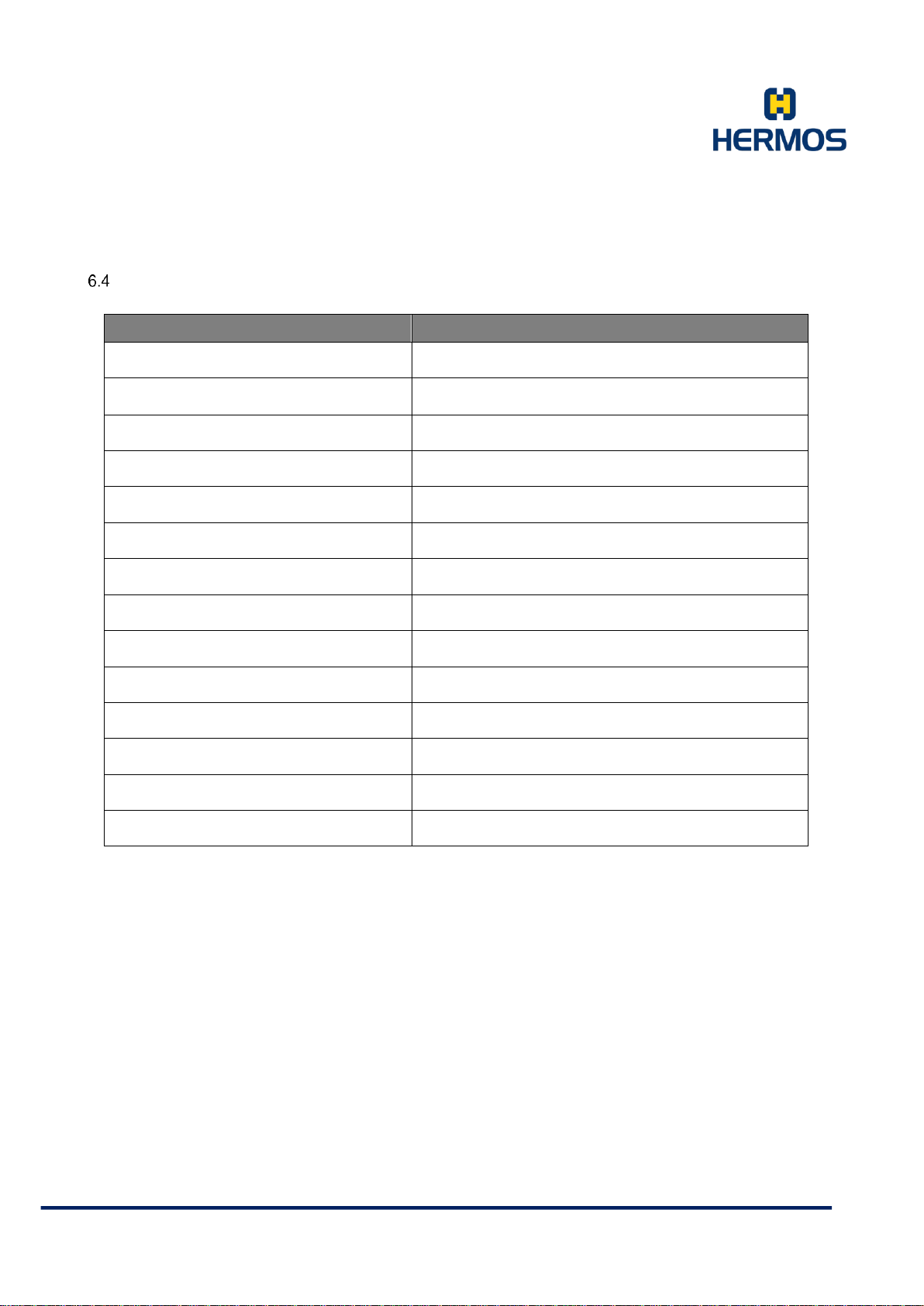

Technical data

Voltage (protected against reverse

polarity)

24VDC (18 – 30 V DC)

Current consumption @24V

(passive, reading, pulse 50ms)

50mA, 200mA, max.580mA

Fuse type Nano2

375 mA

Operating temperature

-0 bis 50 °C

Storage temperature

-20 °C bis 70 °C

Permissible humidity at 50°C

25 – 80 %

Transmission frequency

134,2 kHz

Serial Interface

RS232

Ethernet interface

10/100 BaseT

Protocol

ASCII, SECS / HSMS

Housing material l

Aluminium, black and white anodised

Protection

IP20

Reader dimensions

115 x 82 x 35 mm

Weight

250 g

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 19 of 119

Technical data

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

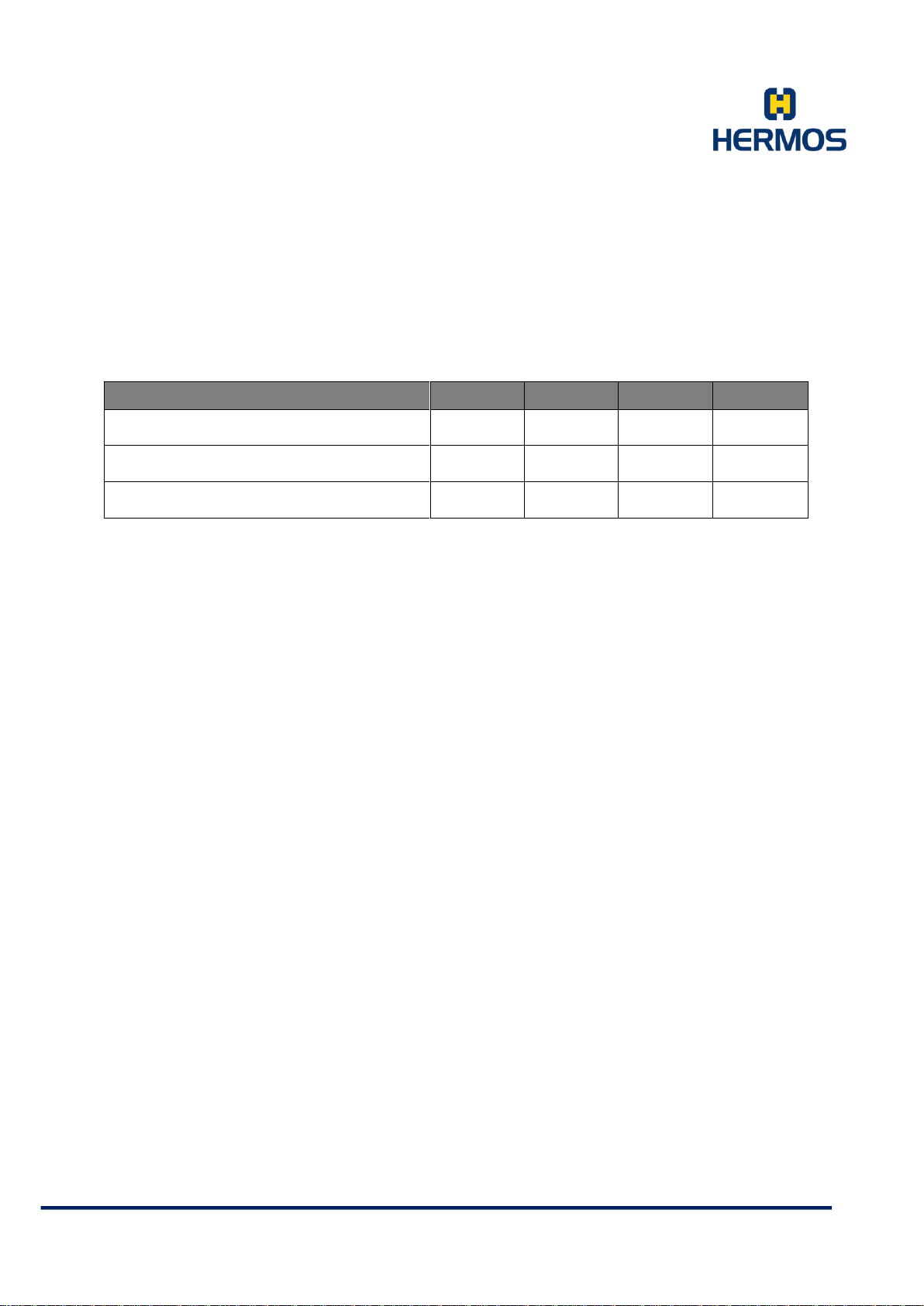

Description

Min.

Typ.

Max.

Unit

Voltage (reverse polarity protected)

18

24

30

V (DC)

Current consumption (Read/Write

Pulse 50ms)

200

350

580

mA

Current (passive)

50 mA

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 20 of 119

The device label with the CE label, article and serial number are located on the side of the reading unit.

6.4.1 Power supply and current input

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 21 of 119

6.4.2 Device labels

The device label is located on the reading unit housing.

It contains a CE mark, article/serial number and the MAC address.

1. Designation

2. Article number (variants)

3. Serial number (example)

4. MAC address (only for ethernet type)

5. Manufacturer

6.4.3 Device Label FCC ID 2AP5OLFM-LP

FCC

- The Federal Communications Commission (FCC) warns the users that changes or modifications to the unit

not expressly approved by the party responsible for compliance could void the user's authority to operate the

equipment.

RF exposure statement (mobile and fixed devices)

This device complies with the RF exposure requirements for mobile and fixed devices. However, the

device shall be used in such a manner that the potential for human contact during normal operation is

minimized.

- FCC §15.105 (a):

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

The unit is exclusively designed for indoor use in an industrial

environment.

The unit may only be installed indoors with a temperature and humidity

level with in the range of the specified technical module parameters.

Never use the unit near or in water.

Never pour liquids of any type over the unit. However, if the unit should

still come in contact with liquid, disconnect it and have it checked by a

technician.

Do not install the device near heat sources such as radiators, heat

registers, stoves or other devices (including amplifiers) that generate

heat.

Do not install the unit in a flammable environment.

Never expose the device to extreme temperature fluctuations, since

condensation otherwise develops inside the unit and causes damages.

Do not install the device in the vicinity of voltage lines or other power

lines with which they could collide (for example, drilling), which could

result in serious injuries or even death.

The device (especially the antenna) should not be installed in the

immediate vicinity of electrical equipment such as medical devices,

monitors, telephones, TV sets and magnetic disks, and metal objects.

This could result in reduced read and write ranges.

Never use the unit in explosive areas (such as paint warehouses).

Do not use the device in areas where it is exposed to vibrations or

shocks.

The installation location must be adequately illuminated during the

installation.

Never install the unit during a lightning storm.

Make sure that the installation meets the requirements of the FCC

(country specific) for human exposure to radio frequencies.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 22 of 119

7. Installation

Follow the basic safety instructions in the chapter Safety instructions.

Safety instructions

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

The unit must only be installed by specially trained personnel. If you

have any doubts about the qualifications, please contact the

manufacturer.

If the unit is operated by untrained personnel, the reading device

and or connected devices may be damaged.

The packaging material consists of cardboard and foil.

Dispose of these materials separately under the respective regulations of

your country.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 23 of 119

Qualified installation personnel

Unpacking

The LF reading device and the accessories can be packed customer-dependent in clean

room conditions. In order to maintain this condition, the devices must be unpacked in clean

room conditions.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

The mounting surface must be stable, non-flammable, dry and clean.

If necessary, clean it before you install the device.

Only use components, cable and mounting materials provided by

HERMOS.

Only mount the components at the designated locations and make sure

that the operating and ambient conditions specified in the technical data

are always maintained.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 24 of 119

Mounting the device

Dimensions:

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

When installing the antenna, observe the required reading and writing

ranges. The reading device can only be used properly,

if the transponder is located within the reading and writing range of the

antenna. Tune antenna after a new antenna installation!

Tune antenna after a new antenna installation!

The tuning function can be started with the tuning button.

Transponder is outside the

antenna range

Transponder is within the

antenna range

Transponder is outside the

antenna range

Transponder is within the

antenna range

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 25 of 119

Installing the antenna

7.5.1 Positioning the antenna

The removal and alignment of the transponder to the antenna is critical to ensure reliable reading and writing.

The following diagram displays the optimum alignment and position of the transponder to the antenna.

After positioning, the antenna must be tuned to the ambient conditions. The tuning function can be started

with the tuning button.

Transponder parallel to the antenna axis:

Transponder vertical to the antenna axis:

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 26 of 119

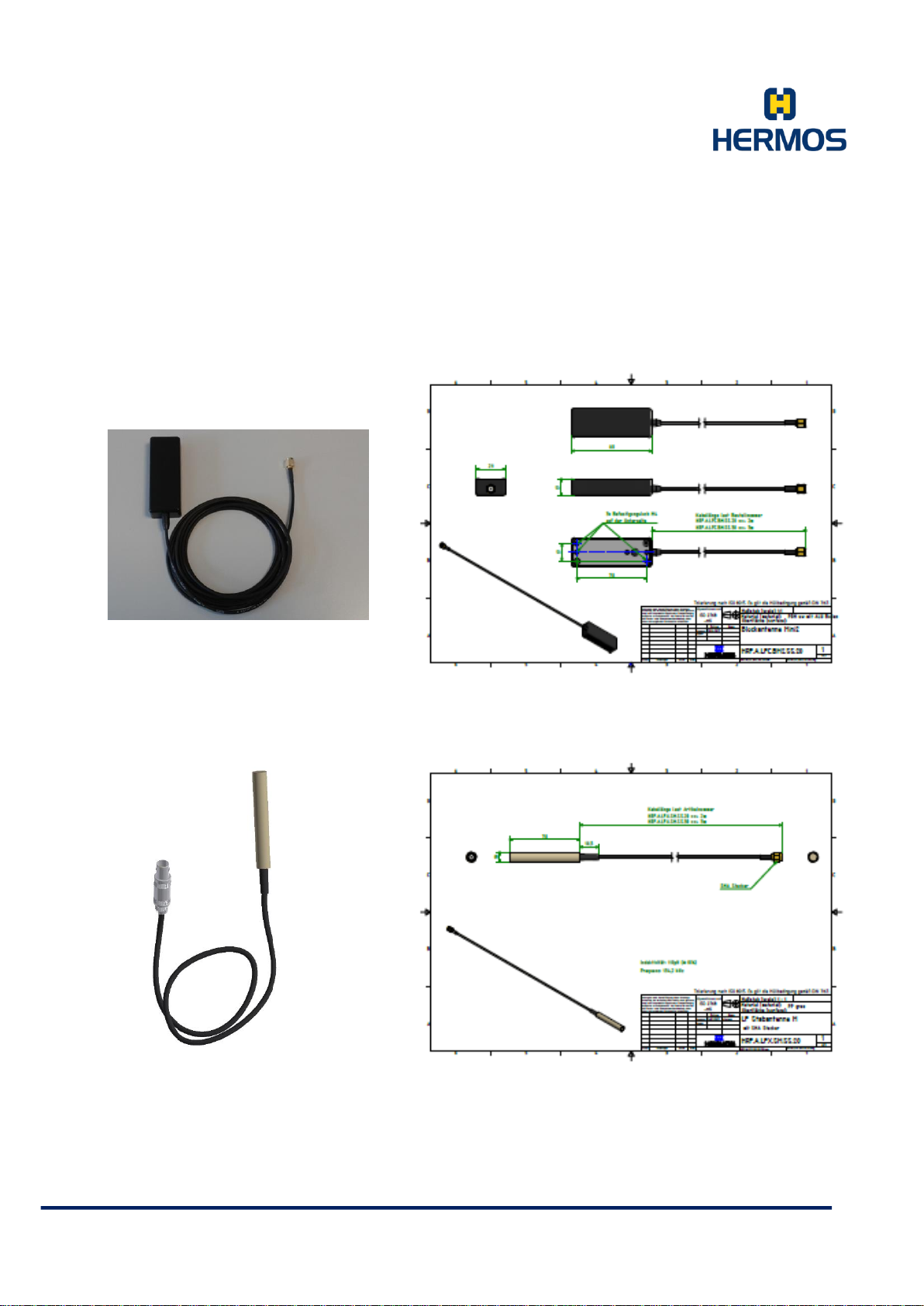

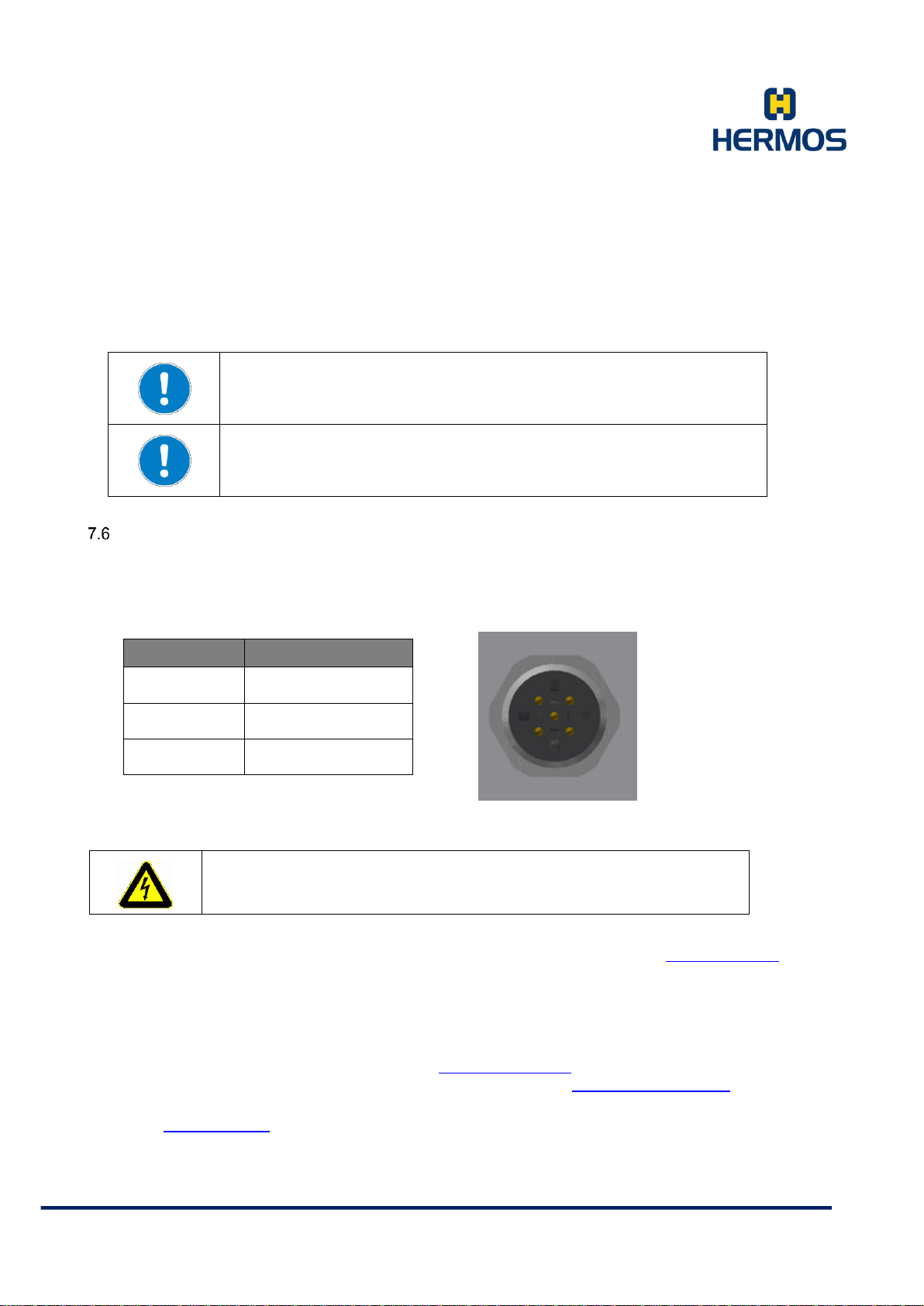

7.5.2 Antennas dimensions

Block antenna Mini2

Rod antenna M, (HRF.A.LFX.SM.LS.20)

The type of connector is only symbolic and may vary!

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Use the antennas and antenna cable from the manufacturer to ensure

optimum reading and writing ranges.

Tune antenna after a new antenna installation!

The tuning function can be started with the tuning button.

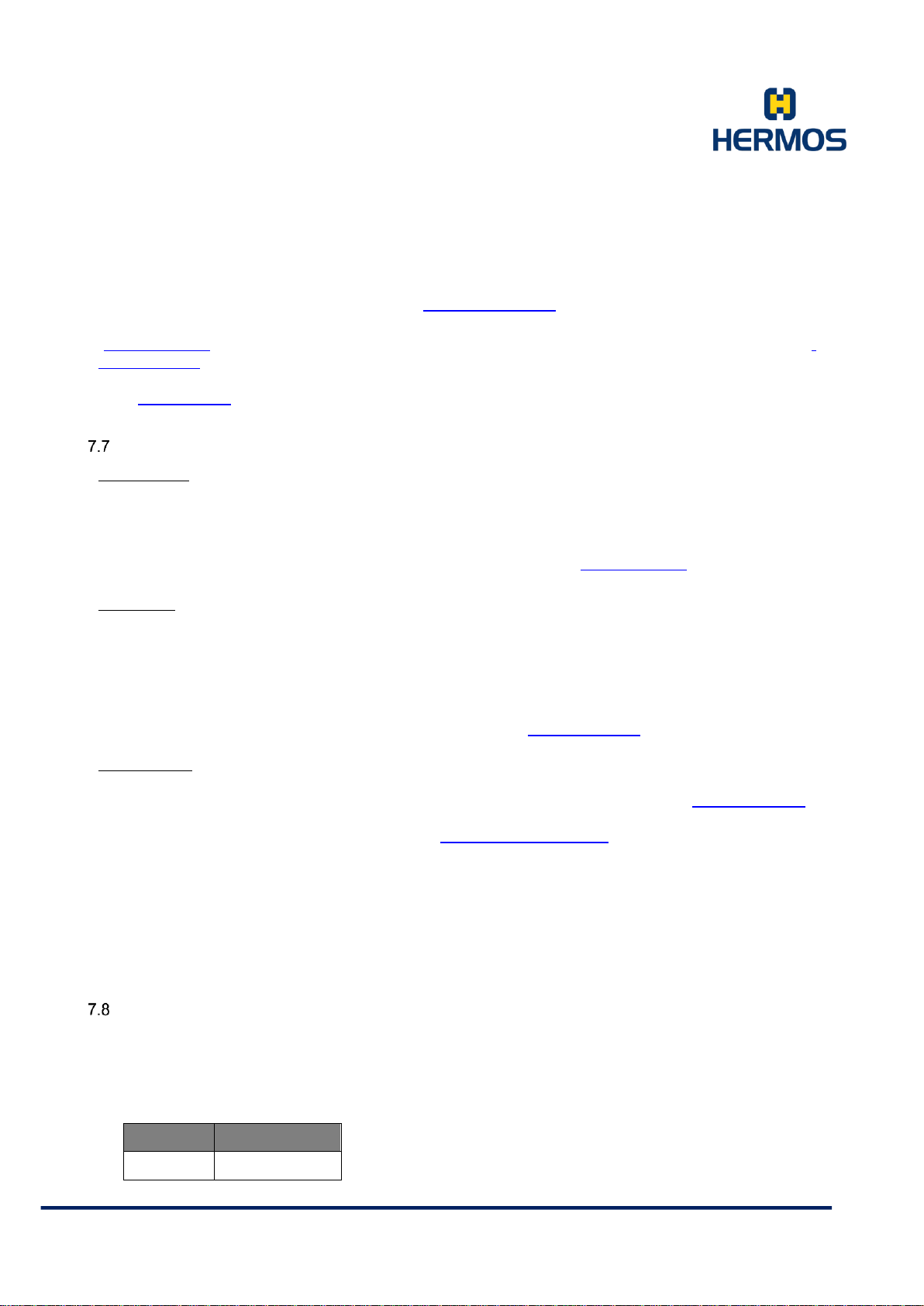

PIN

Signal

1

+24V DC

2

0 V

3,4,5

NC

There are risks if the device is supplied with the incorrect voltage.

Only use cables, plugs and adapters from the manufacturer.

Observe power ratings provided in the technical data.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 27 of 119

7.5.3 Connecting the antenna

Connect the antenna at the antenna connection at the rear of the reading unit.

Power Supply M12-A connector

The device can be connected to the system's internal power supply or an external power supply.

If the device is connected to the power supply, the Status LED lights green (->parameter 35).

7.6.1 Tuning push button

If the pushbutton is held down for a defined time (->parameter 54+55), the status of the pushbutton is

changed and an automatic antenna tuning is initiated when enabled (->parameter 33 and 36).

If the Reader is in test mode, the test mode for the automatic antenna tuning is briefly interrupted when

enabled (->parameter 33).

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

PIN

Signal

1

NC

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 28 of 119

7.6.2 Test push button

If the button is held pressed for a defined time (->parameter 56+57), the status of the button is changed.

If the state changes from "Off" to "On", the test mode Read is started when the Test push button is enabled

(->parameter 36). If the push-button is then held without interruption for a further defined period of time (-

>parameter 56), it switches to the Write test mode. If the state of the button changes from "On" to "Off", the

test mode Read or Write is terminated. The current state of the test mode is indicated by a unique status

LED (->Status LED).

Status LEDs

Status LEDs:

The status LED is a tri-colour/RGB LED. The white or blue status LED indicates the status of the test

mode. If the reader is in maintenance mode or the reading test mode is running, the white status LED

flashes at about 1 Hz in reading testmode and 2 Hz in maintenance mode. If the reader is in maintenance

mode and the writing test mode is running, the blue status LED flashes at about 1 Hz. If the reader is in

normal operation mode, the green status LED is permanently shining (->parameter 35).

Test LEDs:

The test LED is a tri-colour/RGB LED. The red and green Test LEDs are used for the reading and writing

feedback in test or polling mode.

If the read or write process is successful, the green test LED remains permanently lit. If the read or write

process fails, the red test LED shines.

In normal operation mode the red and green test LEDs are used for the last reading and writing feedback.

In this mode the red or green test LED will light for 5 seconds (->parameter 84) after the last reading.

Tuning LEDs:

The tuning LED is a tri-colour/RGB LED. The red and green tuning LEDs are used for the tuning feedback.

After a successful antenna tuning, the green tuning LED is switched on for 5 seconds (->parameter 84). If no

valid antenna tuning is found during antenna tuning or if an invalid tuning is detected during a read operation,

the red tuning LED flashes quickly for 5 seconds (->parameter 84 and 85). During automatic antenna tuning,

the blue tuning LED flashes.

After a powerup reset, the Tri-Colour LEDs undergo a short self-test and then display the set communication

protocol for one second:

SECS: The red status LED goes on briefly

ASCII: The red test LED goes on briefly

RS232 connection

The serial interface is implemented as a Sub-D plug connector (9-pin, female). A serial connection line

(1:1 circuit) can be used.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

2

TxD

3

RxD

4

NC

5

GND

6

NC

7

NC

8

NC

9

NC

PIN

Signal

1

+24V

2

LED out

3

GND

4

Input

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 29 of 119

GPIO connection (optional)

A M8 socket (4pos.) is used as connection socket for the GPIO

8. Commissioning

Operating conditions

The following requirements must be fulfilled for smooth device operation.

1. The operating temperature must be within the scope of the values specified in the technical data.

2. The device must be connected to the power supply).

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Value

Baud rate

19200

Data bits

8

Stop bits

1

Parity

ASCII: Even

SECS/HSMS: None

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 30 of 119

3. An antenna must be properly connected to the reading device. If the antenna has not yet been

tuned (->Status LEDs), then the automatic tuning must be carried out.

4. A transponder must be within the reading and writing ranges of the connected antenna.

5. After startup the reader works in operation mode.

The serial interface parameters

The following settings of the serial interfaces are set on delivery. The baud rate can be changed in the in

the SECS protocol (->Parameter 0x01). If you want to change the baud rate in the ASCII protocol, then

please contact the manufacturer HERMOS.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

1

2

3

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 31 of 119

Parameter of the ethernet interface

The unit is connected to the customer network via a 10/100BaseT Ethernet interface.

The DHCP (Dynamic Host Configuration Protocol) is activated on delivery.

If there is not a DHCP server available in your network, a random IP address is set from the ZeroConf

range (169.254.0.0/16) and operations must still be performed to obtain an IP address. If an IP address

could be obtained or with a static IP address, the device can be connected via TCP / IP port 3241 in the

delivery state.

The HERMOS "Device Discoverer" is available for configuring the network setting. HERMOS components

can be found in the LAN network and settings can be easily changed using the "Device Discoverer".

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

CAUTION

Changing network settings generally cause the reading device to reboot.

This closes an existing HSMS host connection.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 32 of 119

1. Select your network interface if you have several options on your PC.

2. Your network is automatically scanned for all HERMOS reading devices using the "Search

Devices" button.

3. Select the desired reading device in the list to open the network settings.

Here, you can edit the network settings and apply them to the reading device by pressing the

respective button. Use "HERMOS" if you are asked to enter a password!

After parameters are changed, the reading device reboots and can be read in using "Search Devices".

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

CAUTION

During the download process, do not disconnect the power supply or

interrupt the network connection.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 33 of 119

Firmware update

Firmware updates can also be performed using the "Device Discoverer" HERMOS.

Start the tool with administrator rights and scan the network for all HERMOS devices.

To do this, mark the desired reading device and select "TCP/IP Firmware Download" or "RS232

Firmware Download" button depending on your interface. Use "HERMOS" if you are asked to enter a

password!

1. Open the download connection by pressing the connect button.

2. Select the new firmware file using the load image button.

3. Start the download process.

Wait until the "Download Finished" message appears.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

The device should only be operated by specially trained personnel. If

you have any doubts about the required qualifications, please contact

the manufacturer.

The operation of the device without special expertise can result in

damages to the device or on connected devices.

If the reader receives undefined or random characters, this may result in

an accidental protocol change.

Automatic log detection can be deactivated in parameter 98. On default

the automatic protocol detection is disabled.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 34 of 119

9. Operating

Operating personnel

Protocol change

9.2.1 General

To communicate with a connected host system, the reader supports ASCII or SECS / HSMS protocols. The

protocol selection takes place by means of automatic protocol recognition.

The currently set protocol is displayed on the status LED (->Status LEDs) during the boot process.

9.2.2 Automatic protocol detection

The reader automatically adjusts to the protocol used by checking and evaluating the first message

after a reset. The interface is changed accordingly when the protocol is changed and reinitialized. This

process can take several seconds. Already sent messages are lost.

The newly recognized protocol is used for further communication. A renewed change is only possible

after another reset. Automatic log detection can be enbaled or disabled with parameter 98.

9.2.3 Triggered protocol change

During a powerup reset a protocol change can be performed. To do this, press and hold the test and tuning

button during the powerup reset until only red LED lights up at the end. If the red test LED is lit then the

protocol has been changed from SECS to ASCII. If the red status LED is lit then the protocol has been

changed from ASCII to SECS.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 35 of 119

Customer modes

The reader LFM LP can be delivered with a few customer modes. The settings of the customermode is

part of the factory settings and can only be changed by Hermos. If customer needs another customer

setting, please ask Hermos for the necessary steps. The customercode can be read by parameter 64.

Customermode 0:

The antenna will be addressed by the ReaderID „0“ or TargetID „1“.

For the SECS protocol, the standard MID range of 2 pages / 16 characters is defined.

The RS232 port can be used for serial host communication.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Packet header

Message data

Packet end

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 36 of 119

10. ASCI-I1 Communication protocol

The ASCI-I1 communication protocol defines a simple communication interface that is suitable for

exchanging messages between a HERMOS reader and a host. A host is a computer or computer network

that exchanges the information with the systems to carry out the production.

Serial communication:

On serial communication the ASCI-I1 message is transmitted with 4 bytes checksum. The data is

transmitted or received as a serial bit stream with 11 bits per character in a supported data rate. A standard

character has a start bit, 8 data bits, a parity bit and a stop bit. An even parity bit is used for transmitting the

individual bytes.

Default setting: 19200 / 8E1

Ethernet communication:

On default the reading device functions as a server. This means that it waits for a connection request from

a HOST PC (client).

TCP/IP: IP-Adresse xxx.xxx.xxx.xxx Port 3241

After a connection is established, the ASCI-I1 messages defined in the message record are transmitted

from the reading device to the respective HOST and vice versa. On default settings ASCI-I1 messages are

transmitted without any checksum. The connection remains intact until it is specifically terminated by the

host or the reading device.

All reading devices available in the network (LAN) can be operated from any HOST PC. A reading device,

however, can no longer be connected to more than one HOST simultaneously.

The network settings can be changed using a configuration tool provided by HERMOS. Each change to the

network settings causes the unit to reboot and thus disconnects existing communication connections.

Structure of the communication protocol

The communication is carried out via ASCII packets.

After each command to the reading device, a specific reply is transmitted. We recommend waiting for this

reply before transmitting a new command.

Packet content

Each message packet consists of a packet header (header = 3 characters), the message data (2 or more

characters) and the packet end.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Packet header

Start character

Length 1 (high byte)

Length 2 (low byte)

Packet header

Start 1

Start 2

Length 1

Length 2

Length 3

Length 4

Message data

Command

Address

Antenna port

Data

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 37 of 119

Packet header

The packet header contains a start character and the message length. The message length consists of 2

hexadecimal bytes and defines the number of characters in a message.

Start Start character (ASCII character "S")

Length 1 High byte of the message length (ASCII character "0"-"F")

Length 2 Low byte of the message length (ASCII character "0"-"F")

Advanced ASCII-format:

The advanced ASCII format is defined for ASCII messages whose message length exceeds 255

characters. The packet header contains two start characters and the message length. The message length

consists of 4 hexadecimal bytes and defines the number of characters in a message.

Start 1 First start character (ASCII character "S")

Start 2 Second start character (ASCII character "X" = advanced ASCII protocol)

Length 1 High byte of the message length (ASCII character "0"-"F")

Length 2 Byte packet length (ASCII character "0"-"F")

Length 3 Byte packet length (ASCII character "0"-"F")

Length 4 Low byte of the message length (ASCII character "0"-"F")

Message data

The message contains a command character, a target or source address, the number of the antenna port

(head) and the actual message data.

The number of the antenna port is not required for all messages.

Command The command is defined by an ASCII character.

(See protocol commands)

Address Target/source address (ASCII characters "0", "1", …) *

Data The definition of the message data depends on the protocol command.

* Depending on customer parameters, the readers are addressed via the address "0 ... E"

( Parameter E).

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

The checksum is not necessary when using the TCP/IP interface.

(No transmission) The end character is only transmitted.

Packet end

End character

Checksum 1

Checksum 2

Checksum 3

Checksum 4

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 38 of 119

Packet end

The end of the packet contains an end character and a checksum consisting of 4 characters.

End character ASCII end character <CR> (hex 0x0D).

Checksum 1 High byte XOR logic of all data (packet header, data and end character).

(ASCII character "0"…"F")

Checksum 2 Low byte XOR logic of all data (packet header, data and end character).

(ASCII character "0"…"F")

Checksum 3 High byte addition of all data (packet header, data and end character).

(ASCII character "0"…"F")

Checksum 4 Low byte addition of all data (packet header, data and end character).

(ASCII character "0"…"F")

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Tuning value

2 Byte

CMD

1 Byte

Data

16 Bytes

Output Index

1 Byte

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 39 of 119

Data element

The data elements that are used by default ASCII messages, which are described in the message details

section, are defined in this section.

The tuning value is a set value for the optimal antenna tuning. For optimum read and write ranges, the

value is automatically determined by the reader. The value is measured in 16 steps (0-F). He can also

be targeted.

Example: "10" … automatic tuning

"00" … manual tuning 0x00

"0F" … manual tuning 0x0F

Command of the message, see table in Chapter “Commands“ .

The data is represented in HEX format by 2 ASCII characters. The data always includes every 8 bytes

of the corresponding page of the transporter

Example:

Transponder data in ASCII-Format "12345678" (8 bytes)

Transponder data in HEX-Format 0x31 0x32 0x33 0x34 0x35 0x36 0x37 0x38

Data in message "3132333435363738" (16 ASCII-characters)

The Output Index defines the index of the output that is addressed. The index is displayed as an ASCII

character (1 byte) in HEX format.

Example: "1" LED1: externe LED of the port

"2" LED2: red LED TEST

"3" LED3: blue LED TEST

"4" LED4: green LED TEST

"5" LED5: red LED TUNING

"6" LED6: blue LED TUNING

"7" LED7: green LED TUNING

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Output State

1 Byte

Parameter No.

1 Byte

Parameter-Value

2 Bytes

Reader-ID

1 Byte

Response-Code

4 Bytes

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 40 of 119

"8" LED8: red LED STATUS

"9" LED9: blue LED STATUS

"A" LEDA: green LED STATUS

The data element shows or sets the current status of one output.

The Data Element Output State includes the status of each output on the reader.

The status is displayed as an ASCII character (1 byte) in HEX format.

0 Switch off the output permanently

1 Switch on the output permanently

2 output flashes with approx. 1 Hz

3 output remains unchanged

4 output flashes with approx. 2 Hz

The number of the parameter is displayed as an ASCII character (1 byte) in HEX format.

Example: Parameter 1 "1"

Parameter 2 "2"

Parameter 15 “F“

With single-digit parameter numbers from „0“ to „F“, the actual parameter value can be decimal or

hexadecimal depending on the command and customer mode.

Example for decimal Interpretation: Value 45 „45“

Example for hexadecimal interpretation: Value 45 „2D“ (hexadecimal)

The reader ID is defined by parameter (->Parameter E).

The reader ID is displayed as an ASCII character (1 byte) in HEX format.

This feature is not required for the individual device. This code is always "0000".

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Page

2 Bytes

Serial number

4 Bytes

Software version

16 Bytes

Timeout

2 Bytes

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 41 of 119

The page of the transponder for a read / write operation is defined by 2 ASCII characters (2 bytes) in

decimal format

Example: Page 1 "01"

Page 10 "10"

Page 17 "17"

Contains 4 byte of the serial number, which are displayed as 4 ASCII characters in HEX format.

The serial number is also on the adhesive label of the device.

Example: "1707HAG04660" complete serial number

Decimal „04660“ (the last 5 characters of the complete serial number)

Hexadecimal serial number „1234“

The data item contains the software version currently used in the reader.

The version string is displayed with up to 16 characters.

Example: "4C464D3449312E31" hex-String („LFM4I1.1“)

The data element Timeout defines the period of time that elapses until the LEDs are switched off.

The timeout is displayed as 2 ASCII characters (2 byte) in HEX format.

When the timeout expires, the LED turns off.

Example: „00“ ... permanently on

„01“ to „FF“ ... 1 s to 255 s Timeout

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Command

Description

X

Read Data

R

Automatic Read

Command

Description

W

Write Data

Command

Description

G

Query Parameter

F

Query Parameter

P

Set Parameter

N

Reset

e

Error message

H

Heartbeat

V

Software-Version

L

Lock side of a transponder

I

Coordinate RF-modules

J

Querying the coordination of the RF-module

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 42 of 119

Protocol Commands

Read:

Write:

Device-Settings:

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Command

Description

O

Set Output

Q

Query Output/Input State

A

Sensor event: Sensor removed

B

Sensor event: Sensor detected

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 43 of 119

In- and Output:

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

Page

X

1 Byte

2 Bytes

Device Host

CMD

Reader-ID

Page

Data

x

1 Byte

2 Bytes

16 Bytes

Value

Description

„01“ … „17“

Read page

„98“

Read multiple pages to the end character or a blank

character 1)

„99“

Read out all transponder data

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 44 of 119

10.4.1 X – Read data

The command X starts reading of the data area from a transponder.

If there is no transponder in the read range of the antenna, the reader sends an error message (error 4

- no transponder).

The data element "page" can have the following values.

1) „E“ or „F“ in ID, Bit 0…3 of the read ID

If there is no transponder in the reading range of the antenna, the reader repeats the reading function

several times before an error message is sent. The number of repetitions is defined in parameter 4 ('r /

w maxrepeat'). If reading is still not possible, the reader sends the error message 'no tag (4)' to the host

after the repetitions have been carried out.

No confirmation is expected from the host.

For a multi-page read request (98 or 99), the protocol is retried. At the end of reading, the reader sends

an additional packet.

If the sensor check is activated (parameter 1: readmode), the assignment of the external input is

checked before the initiation of a read process by the host. The reading process is only started if the

sensor is occupied, otherwise the error message 'no tag (4)' is sent.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Device Host

CMD

Reader-ID

Page

Data

R

1 Byte

2 Bytes

16 Bytes

Host Device

CMD

Reader-ID

r

1 Byte

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 45 of 119

10.4.2 R – Automatic read

By assigning the external input, an automatic read operation can be triggered.

The command "R" sends the read data to the host. The host then has to confirm the message.

Depending on the setting of the reader (parameter 1: readmode), the reader reads the following pages:

Read Mode:

0 Reading the page defined in parameter 2

1 sequential reading of a transponder to the end character

('E' - end character or 'F' empty) in ID bit 0 ... 3

2 Reading the entire transponder (all pages)

When reading several pages (par. 1: readmode "tag" or "everything") the command is repeated for each

read page. The last package contains the command 'R' and the reader ID.

The host expects a confirmation of the read data. If there is no confirmation from the host, the

command is repeated. (Par.5: 'RS232 delay time', par.6: 'RS232 maxrepeat').

If a reading is not possible, the reader automatically repeats the reading with the set parameters.

(Par.3: 'r / w delay time', par.4 'r / w maxrepeat').

If no reading is possible, the reader sends the error message 'no tag (4)' to the host.

The delay time for the presence sensor can be set (parameter 0: 'sensor delay').

An automatic reading is only possible if all messages to be confirmed have been confirmed by the

previous reading or the waiting time (par.6: 'RS232 repeattime') has elapsed after the last transmission.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

Page

Data

W

1 Byte

2 Bytes

16 Bytes

Device Host

CMD

Reader-ID

w

1 Byte

Host Device

CMD

Reader-ID

G

1 Byte

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 46 of 119

10.4.3 W – Write data

The command W starts writing a defined data area of a transponder.

If there is no transponder in the write range of the antenna, the reader sends an error message (error 4

- no transponder).

If the describing of the tag fails, the reader repeats the writing operation several times before sending

an error message. The number of repetitions is defined in parameter 4 ('r / w maxrepeat'). If writing is

still not possible, the reader sends the error message 'no tag (4)' to the host after the repetitions have

been carried out.

If the sensor check is activated (parameter 1: readmode), the assignment of the external input is

checked before the start of the write process by the host. The write process is started only when the

sensor is busy, otherwise the error message 'no tag (4)' is sent.

10.4.4 G Query parameter

With the command "G" the values of all public parameters of the device can be queried.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Device Host

CMD

Reader-ID

Parameter No.

Parameter Value

g

1 Byte

1 Bytes

2 Bytes

Host Device

CMD

Reader-ID

Parameter No.

F

1 Byte

1 Byte or 2 Bytes

Device Host

CMD

Reader-ID

Parameter No.

Parameter Value

f

1 Byte

1 Byte or 2 Bytes

2 Bytes

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 47 of 119

The reader sends an individual protocol packet for each available public parameter. After the last

parameter, the reader sends a last packet including the command 'g' and the reader ID.

The values returned for the data item parameter value in the response are decimal values (00-99). The

values for the data item Parameter No. are hexadecimal values (0-F).

10.4.5 F – Query parameter

The command "F" can be used to query the value of a public parameter of the device.

The reader sends an individual protocol packet for the requested public parameter. The parameter number

is a one or two byte hexadecimal value (0-F or 00-FF).

The values returned in the response for the data elements parameter number and parameter value are

each hexadecimal values (0-F or 00-FF).

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

Parameter No.

Parameter Value

P

1 Byte

1 Byte

2 Bytes

Device Host

CMD

Reader-ID

p

1 Byte

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 48 of 119

10.4.6 P – Set parameter

The command "P" can be used to change the value of individual parameters.

After a parameter has been successfully changed, the reader sends a

confirmation message.

Depending on the customer mode selected, the data elements parameter number and parameter value

must be interpreted differently:

In the standard ASC-I1 protocol mode the data element "Parameter value" with decimal values (00-99)

has to be used. The values for the data item "Parameter No." are hexadecimal values

For two-digit hexadecimal parameter numbers, the value parameter must always be sent in two digits

hexadecimal.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

N

1 Byte

Device Host

CMD

Reader-ID

n

1 Byte

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 49 of 119

10.4.7 N – Reset

The command N performs a reset of the hardware/software of the reader.

After performing the reset operation, the device sends a confirmation message.

After a hardware reset, a confirmation ("n0") is sent to the host.

If TCP / IP is used as the interface, it will not be received because an existing TCP / IP connection is

interrupted by the reset.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Device Host

CMD

Reader-ID

Error ID

e

1 Byte

1 Byte

Host Device

CMD

Reader-ID

H

1 Byte - also Reader ID F allowed

Device Host

CMD

Reader-ID

Serial numberr

Response-Code

h

1 Byte

4 Bytes

4 Bytes

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 50 of 119

10.4.8 e – Error message

This message is only available in standard ASC-I1 mode!

If an error occurs the device will send an error message with the respective error code.

This message must be acknowledged by the host

Further information about error codes and the corresponding measures can be found in the chapter

Error Codes.

10.4.9 H – Heartbeat

The command "H" sends a heartbeat request to the reader.

The reader responds with its serial number and a response code.

The heartbeat function can be performed for all 4 antenna ports (1-4).

If another reader is operated as a customer variant on the RS232 port, a heartbeat can be sent to the

external reader via reader ID "5".

The response code is part of the protocol but is not used for this device.

The response code is always '0000'.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

V

1 Byte

Device Host

CMD

Reader-ID

Software version

v

1 Byte

16 Bytes

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 51 of 119

10.4.10 V – Query software version

The command V is used to query the software version of the device.

The 8 characters of the software version are represented by 16 ASCII characters. Each character is

described in hex format and transmitted by 2 ASCII characters.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

Page

L

1 Byte

2 Bytes

Device Host

CMD

Reader-ID

L

1 Byte

Locking a page cannot be reversed.

This page is permanently write protected.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 52 of 119

10.4.11 L – Lock data area

A single page of a multipage transponder can be disabled. The page can still be read, but not rewritten.

The process cannot be reversed.

If the lock of the transponder page fails, the reader repeats the procedure several times before an error

message is sent. The number of repetitions is defined in parameter 4 ('r / w maxrepeat'). If writing is

still not possible, the reader sends the error message 'no tag (4)' to the host after the repetitions have

been carried out.

If the page was already locked, a positive confirmation will be sent (same as the first block).

If the sensor check is activated (parameter 1 readmode), the assignment of the external input is

checked before the blocking process is started by the host. The locking process is only started when

the sensor is occupied, otherwise the error message 'no tag (4)' is sent.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

Vote value

I

1 Byte

2 Bytes

Device Host

CMD

Reader-ID

i

1 Byte

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 53 of 119

10.4.12 I – Adjust RF module

It is necessary to adjust the RF module in order to adapt an antenna to the ambient conditions

optimally. The tuning achieves an optimal read / write range for the present installation environment.

Tuning is performed one at a time for the antenna port and the determined tuning value is stored for the

antenna.

For optimal results, the vote should be automatic, but the voting value can also be set manually.

To start the auto-tuning process, select the value 10 .

Example: I110 … automatic tuning of antenna 1

If the reader can not determine the appropriate calibration, the error "5 - Invalid" is sent instead of the

confirmation.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

J

1 Byte

Device Host

CMD

Reader-ID

Vote value

j

1 Byte

2 Bytes

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 54 of 119

10.4.13 J – RF module Queries the vote

The command "J" can be used to query the tuning values of the individual antennas.

Each antenna port has its own tuning value.

The tuning value is a set value for the optimal antenna tuning.

For optimum read and write ranges, the value is automatically determined by the reader (I-message).

The value is measured in 16 steps (00-0F).

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

A

1 Byte

Device Host

CMD

Reader-ID

a

1 Byte

In parameter 1 "Read Mode" the sensor can be deactivated.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 55 of 119

10.4.14 A – Sensor event object removed

The message of sensor events can be activated in the parameter "Watch-Port" (par. 07).

If this is activated, the reader reports every drop of the external sensor.

The sensor message must be confirmed by the host.

The sensor event is detected after an adjustable delay time (par. 0 Sensor Delay).

During the delay time, the sensor signal must be stable.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

B

1 Byte

Device Host

CMD

Reader-ID

b

1 Byte

The assignment of the external sensor results in an automatic reading

and is not sent as a sensor event in standard ASC-I1 mode. However it

is possible to activate the sensor B event (->parameter 49).

In parameter 1 „Read Mode“ the sensor can be deactivated.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 56 of 119

10.4.15 B – Sensor event object detected

The message of sensor events can be activated in the parameter "Watch-Port" (par. 07).

If this is activated, the reader reports any recognition of the external sensor.

The sensor message must be confirmed by the host.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

Head-ID

Output

Index

Output

State

Timeout *

O

1 Byte

1 Byte

1 Byte

1 Byte

2 Bytes

Device Host

CMD

Reader-ID

Head-ID

o

1 Byte

1 Byte

The number of available outputs depends on the reader version used.

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 57 of 119

10.4.16 O – Set output

The command O can be used to set the state of the outputs.

The status of all outputs is changed in a message. In the current version, the value of the data element

Head-ID always has the value "1" for the outputs.

* The specification of a time duration (timeout) is optional.

Example: permanently switch on external LED of port:

>> O111100 or O1111

<< 011

Turn blue test LED on for 10 seconds:

>> O11310A

<< 011

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Host Device

CMD

Reader-ID

Head-ID

Q

1 Byte

1 Byte

Device Host

CMD

Reader-ID

Head-ID

Output

Index

Output

State

LED1

…

Output

State

LEDA

q

1 Byte

1 Byte

1 Byte

1 Byte

…

1 Byte

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 58 of 119

10.4.17 Q – Querying the status of the inputs and outputs

The Q command can be used to query the current status of all outputs. The status of the outputs is

queried in a message. In the current version, the value of the data element Head-ID always has the

value "1" for the outputs.

Example: Status LEDs

>> Q01

<< q012000000001 external LED (2 = flash), green status LED (1 = on)

The status of the input sensor can be queried via head ID „0“.

In this case, the answer contains the sensor state (0 -1) instead of the 10 output states.

Example: Status of input sensor

>> Q00

<< q000

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

The parameters 0, 1, 2 and 7 are only valid if the reader is equipped

with a corresponding I / O module and provides one input per antenna

port.

Nr.

(dez)

Nr.

(hex)

Parameter name

Description

0

0x00

Sensor delay

Delay time for the presence sensor.

01 .. 99 (0,1 seconds)

Default: 10 … (1 second)

1

0x01

Read mode

Read mode for reading automatically started by external

input.

00 - read only one page

01 - read until the end character or empty character2)

02 - read all pages

10 - read only one page with previous sensor Check1)

11 - read until the end character / empty character with

previous sensor check 1) 2)

12 - read all pages with previous sensor Check1)

99 - Disable sensor

1) If the Sensor Check (first byte = 1) is activated, the

assignment of the potential-free input is checked before

initiating a read / write process.

When used, the read / write process is started,

otherwise the error message "NOTAG" is sent.

2) 'E' or 'F' in ID bits 0...3 of the read ID

Default: 00 … (read only one page)

2

0x02

Read page

Page for readmode "00".

00 - First page of each transponder

01 .. 17 - Side of a multipage transponder

Default: 00 … (read first page)

3

0x03

r/w repeat time

Time between two read / write attempts.

01 .. 99 (0,1 s)

Default: 05 … (0,5 seconds)

4

0x04

r/w max repeat

Max. number of read / write attempts.

01 .. 99

Default: 05

5

0x05

RS232 repeat time

If no confirmation message was received from the host,

the device waits for this time before sending another

message.

The number of repetitions is defined in parameter 6

('RS232 max repeat').

01 .. 99 (0,1 s)

Default: 50 … (5 seconds)

Customer manual

Version 1.2

LFM LP Reader 15.01.2019

Page 59 of 119

Parameter

The data element "page" can have the following values.

HERMOS AG

Gartenstrasse 19 Tel. +49 (9279) 991-0

D-95490 Miste lgau Fax. +49 (9279) 991-100

Protocol description ASCII, SECS/HSMS

Further internal parameters (from parameter 16 onwards) are available.

Please ask the manufacturer HERMOS if you need anything.

6

0x06

RS232 max repeat

If an acknowledgement is not sent by the host, the device

repeats the message according to the set value. Only then is

an error message sent

00 - endless

01 .. 99 – Number of attempts

Default: 3

7

0x07

Watch port

Activates / deactivates the sensor event messages A or B to

the host, that the input sensor has been opened or closed.

Bit0 of the Watchport parameter (event message A):

0 - deactivate message A

1 - activate message A when sensor opened/released

Bit11) of the Watchport parameter (event message B):

0 - deactivate message B

1 - activate message B when sensor closed/occupied

Default: 01

F

0x0F

Reader address