Heraeus VACUUM HEATING User Manual

VACUUM HEATING AND

DRYING OVENS

VACUUM HEATING AND

DRYING OVENS

Gentle and safe

Quality Products – Lifetime Care

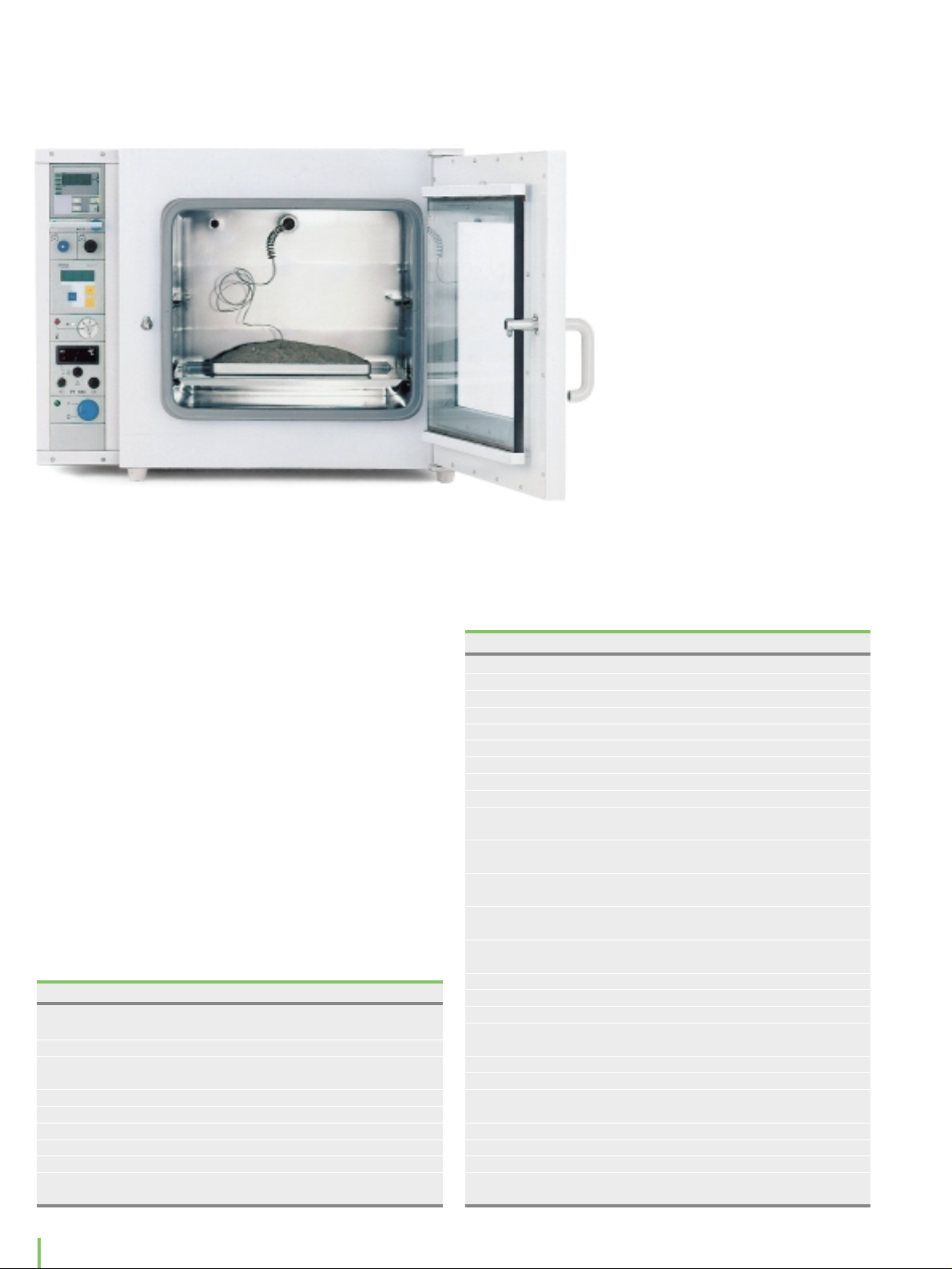

VACUTHERM®6000 –

USER FRIENDLY AS NEVER BEFORE

02

VACUTHERM®6000 –

USER FRIENDLY AS NEVER BEFORE

The intelligent, modular system: three sizes and two types of heating

Series 6000 vacutherm

®

ovens uncompromisingly meet all demands relating to heat

treatment in vacuum, whether simple routines or complicated processes up to 400 °C

are involved. Starting with high quality standard models, application specific configurations can be realised through selection from a wide range of equipment options.

User comfort

With the inert gas connection

incorporating a precision valve,

process gas is dispensed

accurately. Drying times are therefore reduced and condensation

is prevented. Furthermore, the

precision valve can safely prevent

blowing of powders when the

vacuum chamber is ventilated.

Cleaning

The vacuum chamber has electropolished surfaces and rounded

corners, and is therefore easy-toclean.

Corrosion resistance

The vacuum chamber is made of

high quality stainless steel (1.4571)

with outstanding corrosion

resistance.

Economic viability

With their high quality standard

features, extreme reliability and

state of the art safety concepts,

vacutherm®ovens offer the best

price/performance ratio.

Safety tested

Kendro has set new safety standards with Heraeus®vacutherm

®

6000 Vacuum Drying Ovens.

With the double-pane door made

of safety glass, for instance, implosion protection is guaranteed

throughout the equipment's

working life. The glass cannot become brittle or dull as with plastic.

Special versions are available for

drying applications that involve

flammable solvents.

Process safety

With heating systems that have

been tried and tested for decades,

uniform and reproducible drying

and heat treatment is ensured.

Time saving

Jacket- or shelf-heating results in

reduced heating-up times.

Process times are up to six times

faster than in conventional

Vacuum Drying Ovens.

High tech equipment

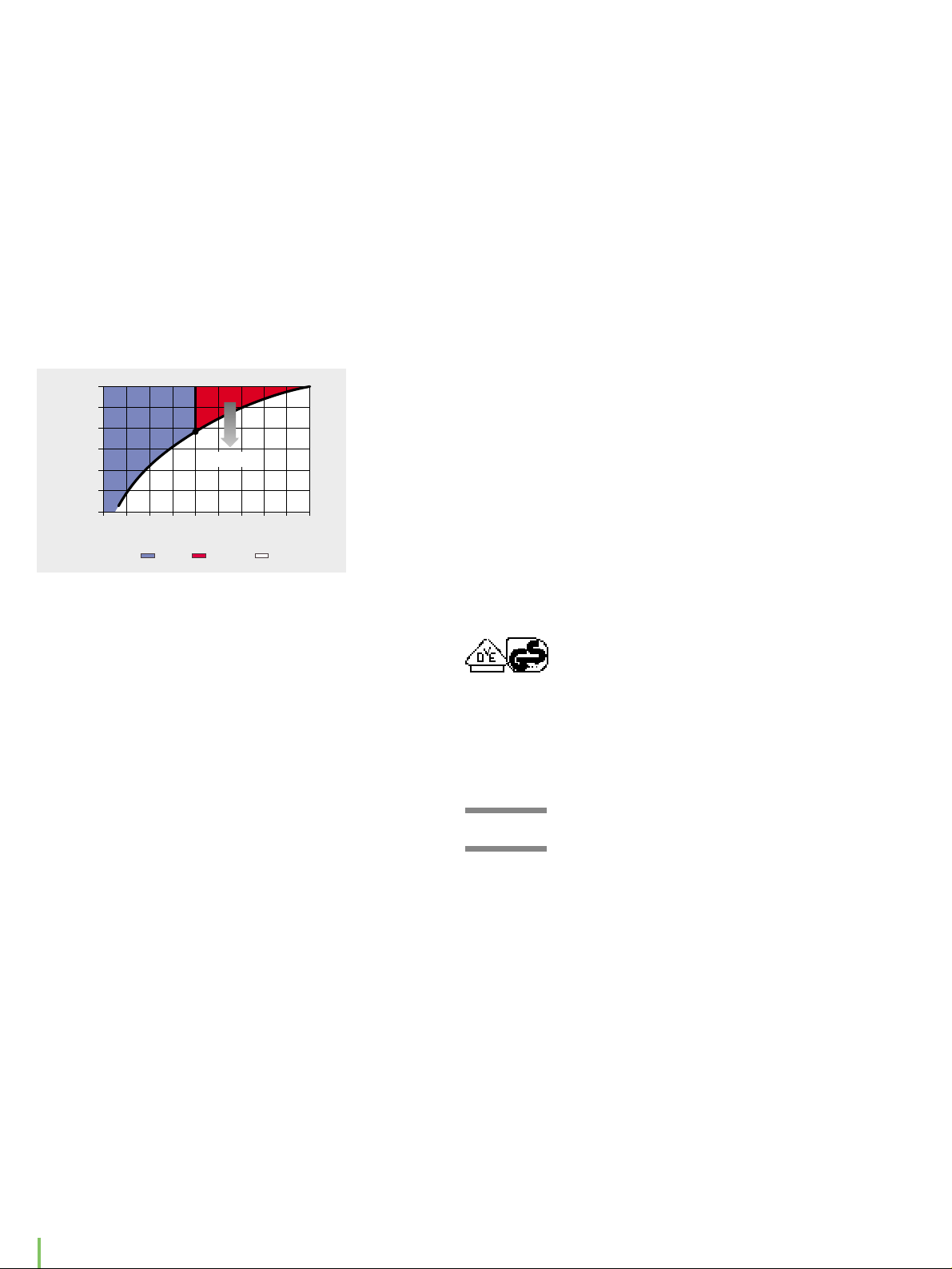

Water: Lower pressure means lower boiling point

DIN EN ISO 9000

Vacuum applications offer

many benefits:

■ Gentle drying of heat sensitive

materials

■ Significantly reduced drying

times

■ Residue free drying of intricately

designed parts

■ Elimination of oxidation

associated with heat treatment

■ Safe drying of flammable

solvents

■ Targeted recovery of degassed

products

3

10

2

10

1

10

0

Pressure [mbar]

10

-1

10

-2

10

-3

10

-60 -40 -20 0

vaporization

20 40 60 80

Temperature in °C

gaseousliquidsolid

100

Features

■ Modular design

■ Two types of heating

■ Temperatures to 200, 300

and 400 °C

■ Total volumes of 53 and 128 l

Standard features

■ User friendly Kelvitron

®

t microprocessor controller for jacket

heated ovens and Digicon

®

multi-channel Controller for shelf

heated ovens

■ Upper limit cut-out for oven and

product protection

■ Certified safety (GS-mark)

■ Vacuum chamber made of

stainless steel (1.4571),

electropolished, 100 % rounded

corners, easy-to-clean and

corrosion resistant

■ Stainless steel vacuum fittings,

tubing and ball valve

■ Analogue pressure display

■ Rapid ventilation valve for quick

ventilation of the chamber

■ Additional precision valve for

gentle ventilation

■ Inert gas connection for con-

trolled atmosphere. A safety valve

prevents overpressure inside the

vacuum chamber

■ DN 25 access port in the rear

wall

Two types of heating

The vacutherm®6000 series is

available with two different types

of heating:

■ model M, jacket heating:

Heat transfer from the vacuum

chamber via the shelves to the

load

■ model P, shelf heating:

The shelves incorporate heating

coils. Heat is transferred directly

to the load.

The benefits of shelf

heating

The direct energy transportation

ensures rapid heating-up and

process times. Drying process

times can be reduced as much

as 6 fold compared to standard

drying methods.

Type Total volume Order no.

VT 6060 M 53 litres, jacket heating 51014539

VT 6130 M 128 litres, jacket heating 51014541

VT 6060 P 53 litres, shelf heating 51014542

VT 6130 P 128 litres, shelf heating 51014543

vacutherm®6000 Order numbers

GENTLE, FAST AND EXTREMELY VERSATILE

GENTLE, FAST AND EXTREMELY VERSATILE

A well thought-out concept – Heraeus®vacutherm®VT 6060 and VT 6130

MODEL P, SHELF HEATING

■ Rated temperature of 300/400 °C

■ Rapid heating-up times

■ Direct heat transfer ensures short

process times

■ Separate temperature control and

overtemperature protection for

each shelf

MODEL M, JACKET HEATING

■ Rated temperature of 200 °C

■ The large direct contact heating

elements are reinforced at the

front and therefore compensate

natural loss

03

EVERYTHING THAT'S NEEDED

04

EVERYTHING THAT'S NEEDED

Options and accessories for the unique vacutherm®6000

Accessories for vacutherm

®

Order no.

Support stand, 780 mm height

for VT 6060 M/P 50029890

for VT 6130 M/P 50029597

Additional shelf (incl. 2 shelf supports)

for VT 6060 M 50043975

for VT 6130 M 50043976

Tray for VT 6060 M/P made of stainless steel 50048621

for VT 6060 M/P made of aluminium 50048620

for VT 6130 M/P made of stainless steel 50048619

for VT 6130 M/P made of aluminium 50048618

Stainless steel vacuum connection kit for tubing with a

diameter of 10 mm 50046860

Option for rated

temperature of 400 °C

As an option the ovens vacutherm

®

6060 P and 6130 P can operate

at temperatures up to 400 °C.

These vacuum ovens come

standard with a door without an

inspection window.

VITON door gasket

Compared to standard door

gaskets VITON provides increased

resistance to highly caustic substances.

VT 6130 with direct measurement of sample temperature

Vacuum chamber with

100 % rounded corners

This model has rounded corners

at the sides as well as at the rear

of the vacuum chamber, making

the inner casing even easier to

clean.

Accessories

For powders or granules,

trays are available as accessories.

Accessories

Options for vacutherm®6000 M/P Order no.

RS 232 computer interface for Kelvitron®controller 51900284

Digital pressure display 51900069

Pressure controller with solenoid valve 51900193

VITON door gasket for VT 6060 M 51900071

VITON door gasket for VT 6130 M 51900072

Daily program timer, mechanical 51900205

24 hour timer (20 h at 60 Hz) 51900073

Weekly program timer, mechanical 51900008

Weekly program timer, digital 51900161

Digital sample temperature display with flexible Pt 100

temperature sensor and socket for external data recorder 51900074

Thermicon

®

P temperature program controller

(for M-models only) 51900209

Eurotherm 2404/P4 temperature controller with

RS 232 interface (for M-models only) 51900297

Eurotherm 2404/P4 temperature controller with

RS 422/485 interface (for M-models only) 51900298

Digicon

®

S temperature controller with analog interface 0-20 mA/0-10 V

(200 ºC): VT 6060 M and VT 6130 M 51900194

(300 ºC): VT 6060 P and VT 6130 P 51900195

(400 ºC): VT 6060 P 51900196

VT 6130 P 51900197

Rated temperature of 400 °C, (door without inspection window)

for VT 6060 P 51900079

for VT 6130 P 51900080

Central monitoring connection 51900081

Vacuum chamber with rounded corners at the rear;

for VT 6060 M 51900075

for VT 6060 P 51900077

for VT 6130 M 51900076

for VT 6130 P 51900078

Temperature recorder with flexible Pt 100 temperature sensor

(not in combination with the 400 °C model) 51900291

Options

Loading...

Loading...