Page 1

Multifuge® 1 S / 1 S-R

Instruction Manual

Page 2

How to use this manual

Use this manual to get acquainted with your centrifuge and its accessories.

This manual helps you to avoid inappropriate handling. Make sure to keep it close to the centrifuge.

A manual that is not kept handy cannot provide

protection against improper handling and thus

against damage to persons and objects.

The manual comprises chapters on

• Safety regulations

• Instrument description

• Transportation and hook-up

• Rotor program and accessories

• Use of the centrifuge

• Maintenance and care

• Troubleshooting

• Technical data

• Index

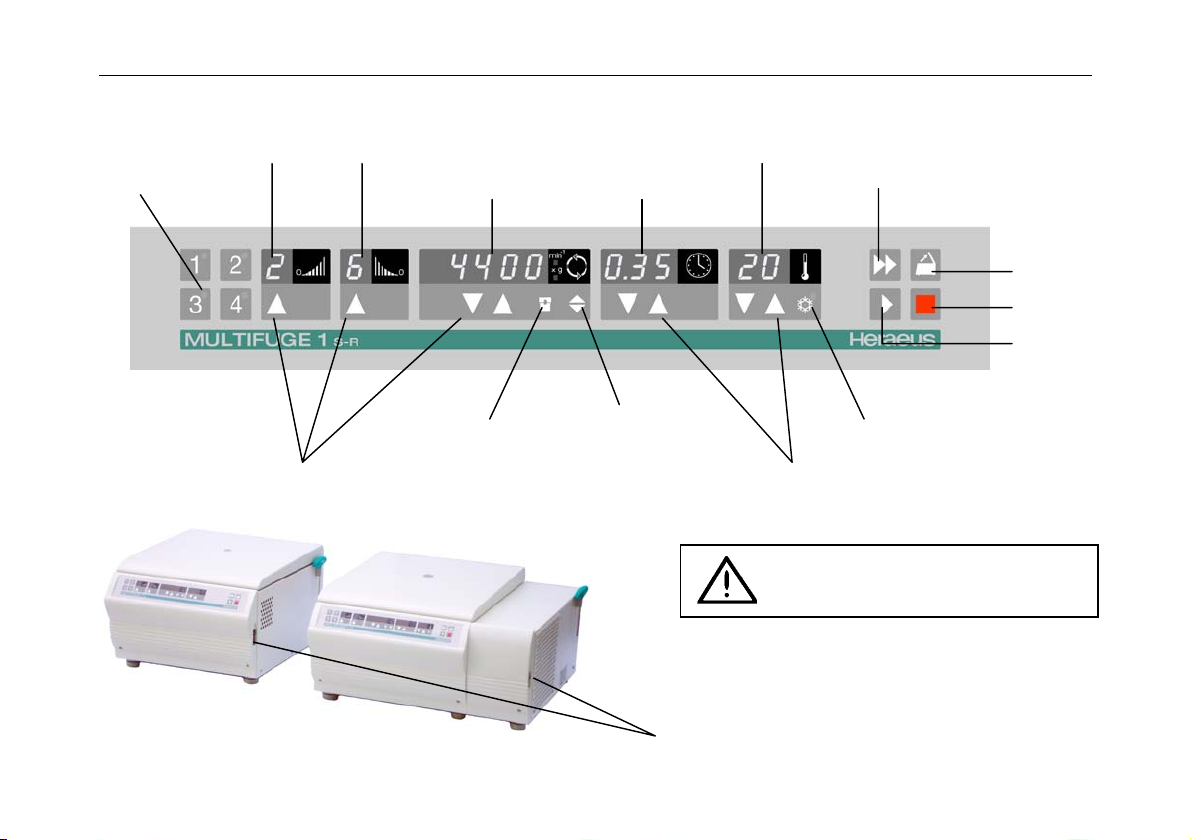

Overleaf you will find a graphic

representation of the control panel

with a survey of the most important

functions

Please fold out

Page 3

acceleration

profiles

program selection

"set" keys

deceleration

profiles

speed/RCF

Bucket selection

(only for instruments with refrigeration unit)

temperature

run time

rpm/RCF

Quick run

pre-temperature-regulation

switch key

display

"set" keys

Before switching on the centrifuge

please read this manual

The mains switch is located on the right-hand

side panel.

Pressed up = ON I

Pressed down = OFF 0

open lid

stop

start

Page 4

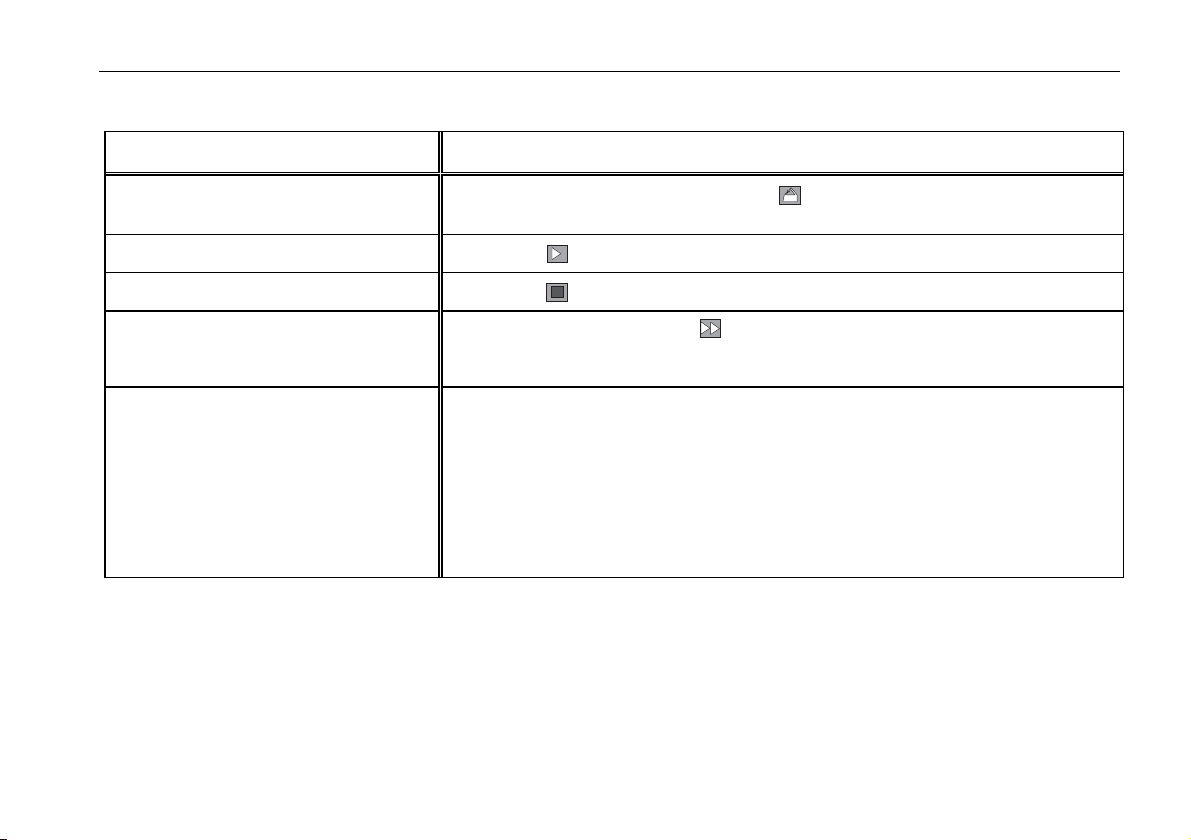

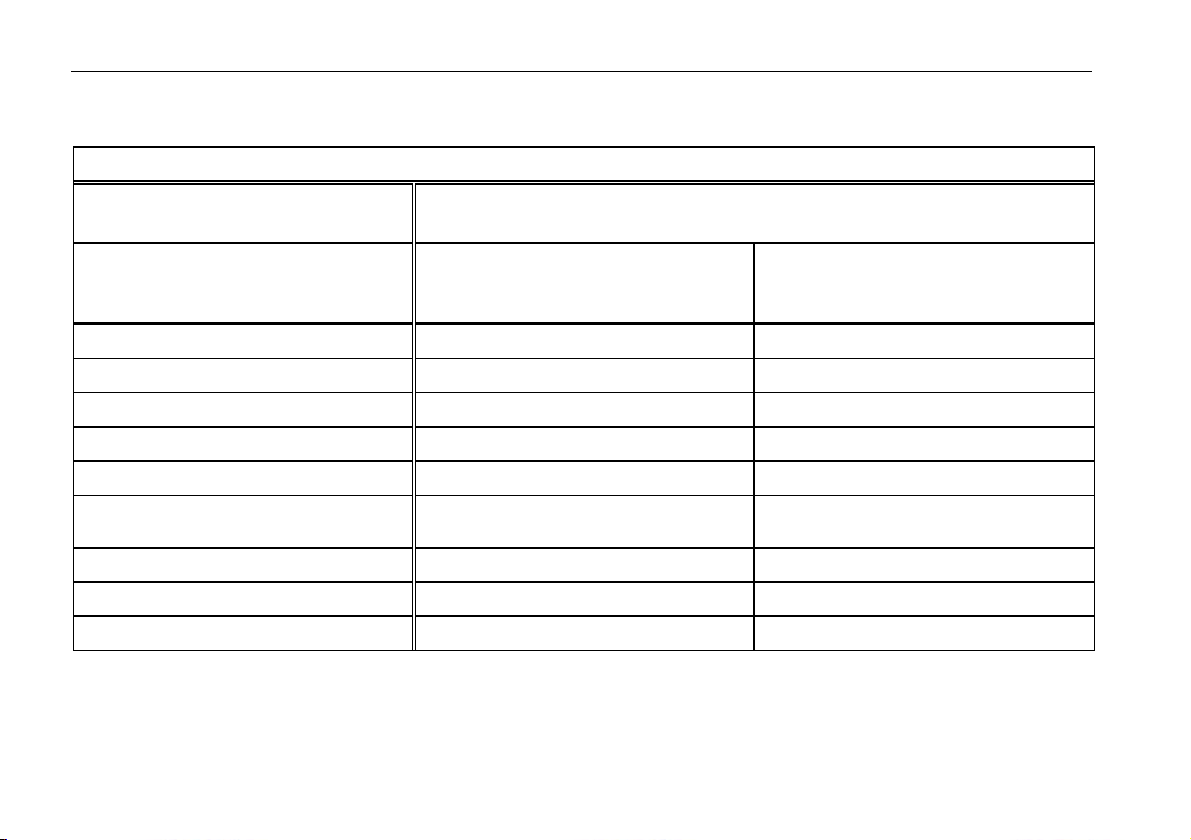

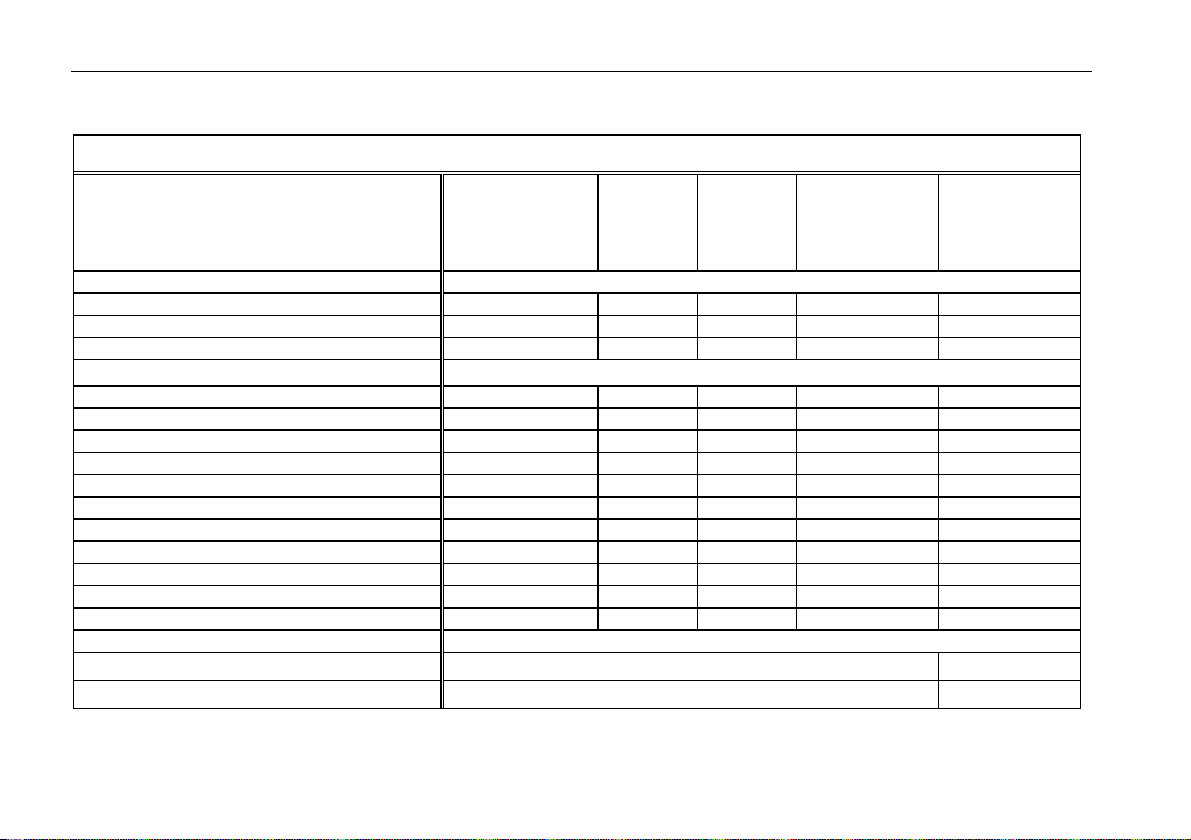

Control panel of the Multifuge® 1 S / 1 S-R

Display panels

Program selection

key 1 - 4 : store or recall programs.

acceleration profiles (1= slowest ...... 9= fastest)

permanent display: acceleration profile last set 1- 9

Deceleration profiles (1= slowest ...... 9= fastest)

permanent display: deceleration profile last set 1- 9

Speed / RCF

run: current value of speed or RCF after activation of

switch key

end: "End"

lid open: "OPEN"

"Lift Lid" (if lid is not automatically lifted off)

(before start)

lid closed: "0" with flashing point

(rotor not yet identified)

error code: will flash in display

Run time

time selection: - remaining run time to 0

continuous operation (hld):

- run time passed (in hours, minutes)

quick run: - run time passed (as long as button is held;

in minutes and seconds)

Temperature*

run: current sample temperature in °C

(in temperature equilibrium)

* only for instruments with refrigeration unit

Keys

start : normal start of the centrifuge

stop : manual stop of a run

open lid: open lid

quick run: short-term operation of the centrifuge as long as

rpm/RCF

switch: switching between rpm and RCF display

bucket set.: Setting of the bucket number

pretemp : Pre-temp-function*

"set" keys: stepwise increase/decrease of setpoint values

Short pressing of any of the "set" keys: switch from current to preset

value, signaled by flashing display.

Error codes (troubleshooting see chapter "Troubleshooting"):

E-19: Unpermissible rotor

E-20: Rotor not identified

E-29: Motor or rotor blocked

E-31: Overtemperature in motor

E-32: Overtemperature in electronic

E-33: Excessive pressure in the refrigeration unit

E-34: Overvoltage

E-35: Overcurrent

Lift Lid : Smoothly lift the lid

rotor: set speed higher than permissible speed of

the rotor

bAL : imbalance

(possible only with the instrument switched on)

key remains pressed

Page 5

Contents

Contents

For your safety............................................ 3

Proper use................................................................ 3

Improper use ............................................................ 3

Centrifuging hazardous materials ............................ 3

Handling the centrifuge ............................................ 4

Conformity to current standards............................... 5

Safety instructions in this manual ............................ 5

The Multifuge® 1 S / 1 S-R.......................... 7

Description ............................................................... 7

Safety systems......................................................... 8

Parts supplied .......................................................... 8

Function and features .............................................. 9

Before use................................................. 13

Centrifuge transport and installation ...................... 13

Proper location ....................................................... 13

Main connection ..................................................... 14

Rotors and accessories ........................... 15

Rotors for the Multifuge® 1 S.................................. 16

Rotors for the Multifuge® 1 S-R.............................. 20

Handling the rotor................................................... 29

Aerosol-tight operation ....................................... 32

Checking of aerosol-tight bio-containment......... 36

Operation .................................................. 37

Switching on the centrifuge .................................... 37

Actuating the lid...................................................... 37

Opening the lid ................................................... 37

Closing the lid ..................................................... 37

Installing the rotor................................................... 38

Loading the rotor .................................................... 39

Maximum loading ............................................... 39

Filling the centrifuge tubes ................................. 40

Maximum permissible load difference ................ 40

Inserting the centrifuge tubes ............................. 41

Entering parameters............................................... 43

Deceleration curves ............................................... 43

Switching from speed to RCF display .................... 43

Bucket selection for swinging bucket rotors........... 43

Selecting speed...................................................... 44

Entering the RCF value.......................................... 44

More about the RCF value ................................. 45

Selecting run time .................................................. 45

Run time selection .............................................. 45

Continuous operation ......................................... 46

Extended time mode........................................... 46

Selecting the temperature ...................................... 47

Pretemp function .................................................... 47

Starting the centrifuge ............................................ 48

1

Page 6

Contents

Imbalance display................................................... 48

Changing the settings during the run ..................... 48

Stopping the centrifuge ..........................................49

Stopping with preset run time............................. 49

Stopping with continuous operation ................... 49

Temperature control during standby ...................... 49

Working with programs........................................... 50

Program display.................................................. 50

Entering/changing a program ............................. 50

Centrifuging with a program ............................... 50

”Quick Run” ............................................................51

Removing the rotor................................................. 51

Audible alarm ......................................................... 52

Turning off the centrifuge .......................................52

Maintenance and care .............................. 53

Maintenance to be performed by the customer ..... 53

Cleaning.............................................................. 53

Disinfection ......................................................... 54

Decontamination................................................. 56

Autoclaving ......................................................... 56

The KENDRO service offer .................................... 57

Warranty conditions................................................ 57

Troubleshooting .......................................59

Emergency lid release............................................ 59

Error troubleshooting.............................................. 61

Contacting Kendro Service..................................... 70

Technical Data ..........................................71

Electrical connections / fuses ................................. 73

Appendix ................................................... 75

Acceleration and deceleration profiles ................... 75

Speed/RCF diagrams............................................. 87

Index .......................................................... 93

2

Page 7

For your safety

For your safety

Heraeus centrifuges are manufactured according to

current technical standards and regulations. Nonetheless, centrifuges may pose danger to individuals and

surrounding if

• they are not used as designed

• they are operated by untrained personnel

• their design is improperly changed

• the safety instructions are not followed

Therefore, personnel involved with operation and

maintenance of the centrifuge must read and follow

the safety instructions.

In addition, the pertinent regulations for prevention of

accidents must be strictly followed.

This manual is an integral part of the centrifuge assembly and must be kept close at

hand at all times.

When damages to the power cord or at

casing are noticed the centrifuge must

to be set out of operation!

Proper use

The centrifuge is designed to separate liquidsuspended materials having different densities and

particle size, respectively (maximum sample density is

1.2 g/cm³ {ml} at maximum speed).

Improper use

During a run, a safety zone of 30 cm around the centrifuge must be maintained where neither persons nor

hazardous materials may be present.

The centrifuge may cause harm to its user or other

persons or may damage goods if safety measures are

not followed

:

Centrifuging hazardous materials

• The centrifuge is neither made inert, nor is it explo-

sion-proof. Therefore never use the centrifuge in an

explosion-prone environment.

• Do not centrifuge explosive or flammable sub-

stances. The same holds for substances prone to

react violently with each other.

3

Page 8

For your safety

• Do not centrifuge toxic or radioactive substances or

pathogenic microorganisms without suitable safety

systems.

If microbiological samples of risk group II (according

to "Laboratory Bio-safety Manual" of WHO) are being centrifuged, aerosol-tight bio-seals have to be

used.

For materials in a higher risk group, more than one

precaution is required.

• Should toxins or pathogenic substances enter the

centrifuge or its parts, you must perform appropriate

procedures for disinfection (see "Maintenance and

care – Disinfection").

• Strongly corrosive substances that may cause

damage to materials and reduce the mechanical

strength of the rotor may be centrifuged only inside

protective tubes.

Handling the centrifuge

• Use only original accessories for the centrifuge. The

only exceptions are common glass or plastic centrifuge tubes if they are approved for the rotor speed

and RCF values.

• Never use the centrifuge unless the rotor is properly

installed.

• You may use the centrifuge only with a properly

loaded rotor. You must not overload the rotor.

• Strictly follow the rules and regulations for cleaning

and disinfection

• If the rotor or the rotor lid shows signs of corrosion

wear, you must stop using it.

or

• Never open the lid manually if the rotor is still turn-

ing.

• You may use the emergency lid release only in

case of emergency, e.g. during an interruption of

power supply

(see chapter "Troubleshooting").

• Never use the centrifuge with an opened lid.

• Never use the centrifuge if the front panel has been

partially or totally removed.

• Changes in mechanical or electrical components of

the centrifuge may only be carried out by individuals

authorized by Kendro Laboratory Products.

4

Page 9

For your safety

Conformity to current standards

Heraeus centrifuges are manufactured and tested

according to the following standards and regulations:

- For all voltages

• IEC 61010

- For 120 V only

•

- For 230 V only

•

Please get acquainted with the details of the test standards from the technical data.

Safety instructions in this manual

This symbol denotes potential hazards to

persons.

This symbol denotes potential damage to

the centrifuge or parts in its immediate

surroundings.

General comments are marked with this

symbol.

In addition, you are asked to adhere to the pertinent

regulations, in Germany

• Regulations for prevention of accidents BGV A2

• Regulations for prevention of accidents VBG 5

• Regulations for prevention of accidents VBG 7z

- with cooled devices additionally

• Regulations for prevention of accidents BGV D4

5

Page 10

For your safety

Notes

6

Page 11

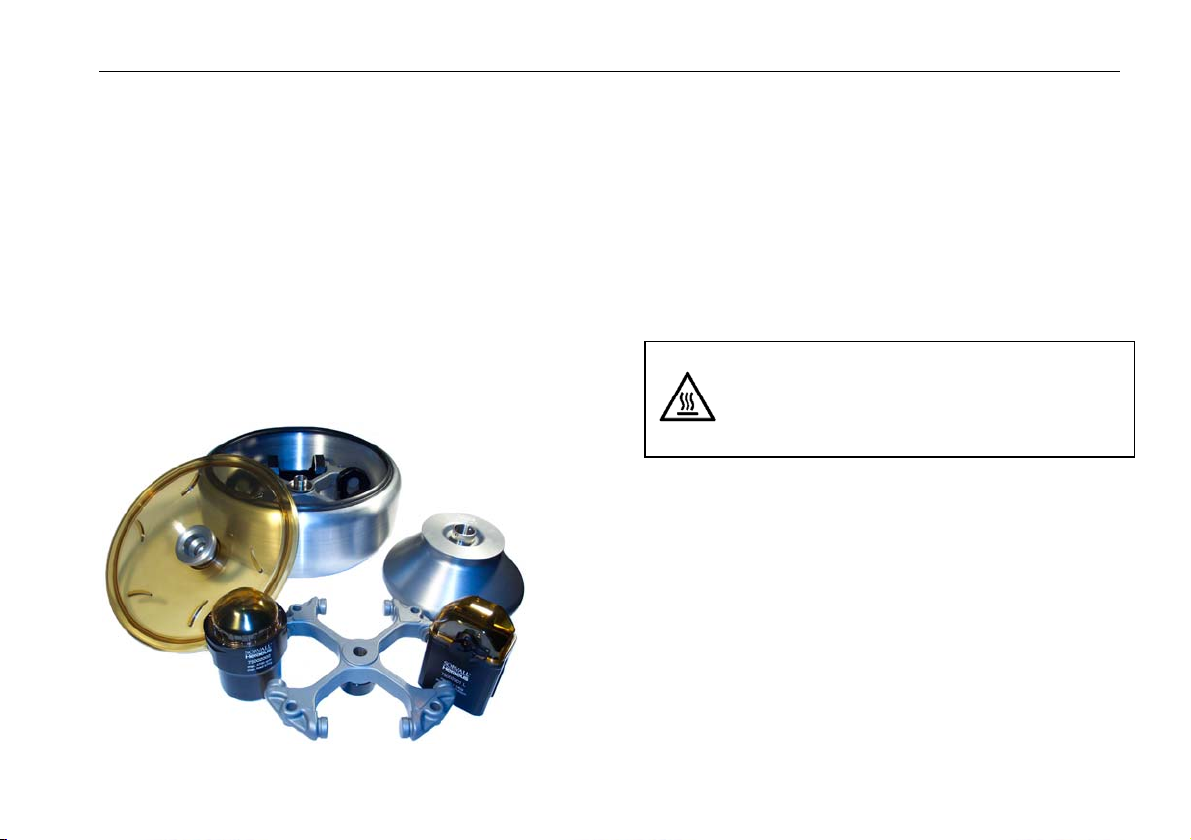

Description of the Multifuge®

The Multifuge® 1 S / 1 S-R

The figure below shows a Multifuge® 1 S-R with an

opened lid and a swinging bucket rotor installed.

Description

The Multifuge® 1 S-R is a general-purpose tabletop

centrifuge for biotechnological and pharmaceutical

research that moves high capacity centrifugation onto

the fast track. It spins more tubes at higher RCFs more

rapidly than competitive instruments and can process

nominally 1.6 liters of sample in a single run. There are

various rotors available that can achieve high RCFs

and accommodate a wide range of accessories for all

common tube types, micro titer and deep well plates.

The user-friendly "EASYset" control panel permits easy

selection of speed, RCF value, run time and run profile

(acceleration and deceleration), as well as temperature

of the Multifuge

RCF display and vice versa, with a touch of a button

and even during a run.

®

1 S-R. You can switch from speed to

7

Page 12

Description of the Multifuge®

Safety systems

The Multifuge® is equipped with a number of safety

systems:

• Housing and lid are constructed of 6 mm steel.

• Lid with window

• Lid lock with safety check

You can only open the centrifuge lid when the

power is turned on and the rotor has come to a

stop. You can only start the centrifuge if the lid is

properly locked.

• Automatic rotor identification

• Electronic imbalance detection as a function of rotor

(SMARTspin

TM

)

Do not tamper with the safety

systems!

Parts supplied

Accessories supplied with the centrifuge are:

− power cord

− a special wrench for securing the rotor

(As seen in the picture)

− condensed operating instructions

− corrosion protective oil

The printed documents consist of the delivery notes

and this Manual.

8

Page 13

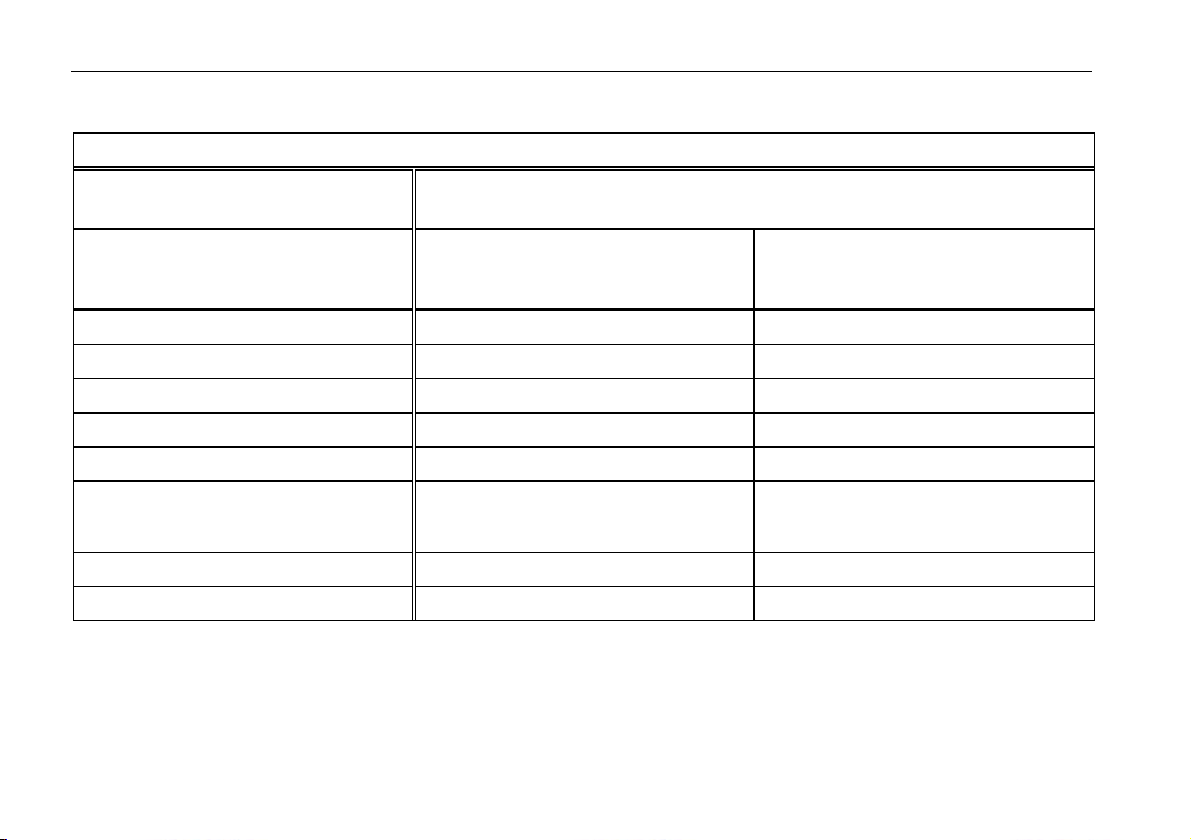

Description of the Multifuge®

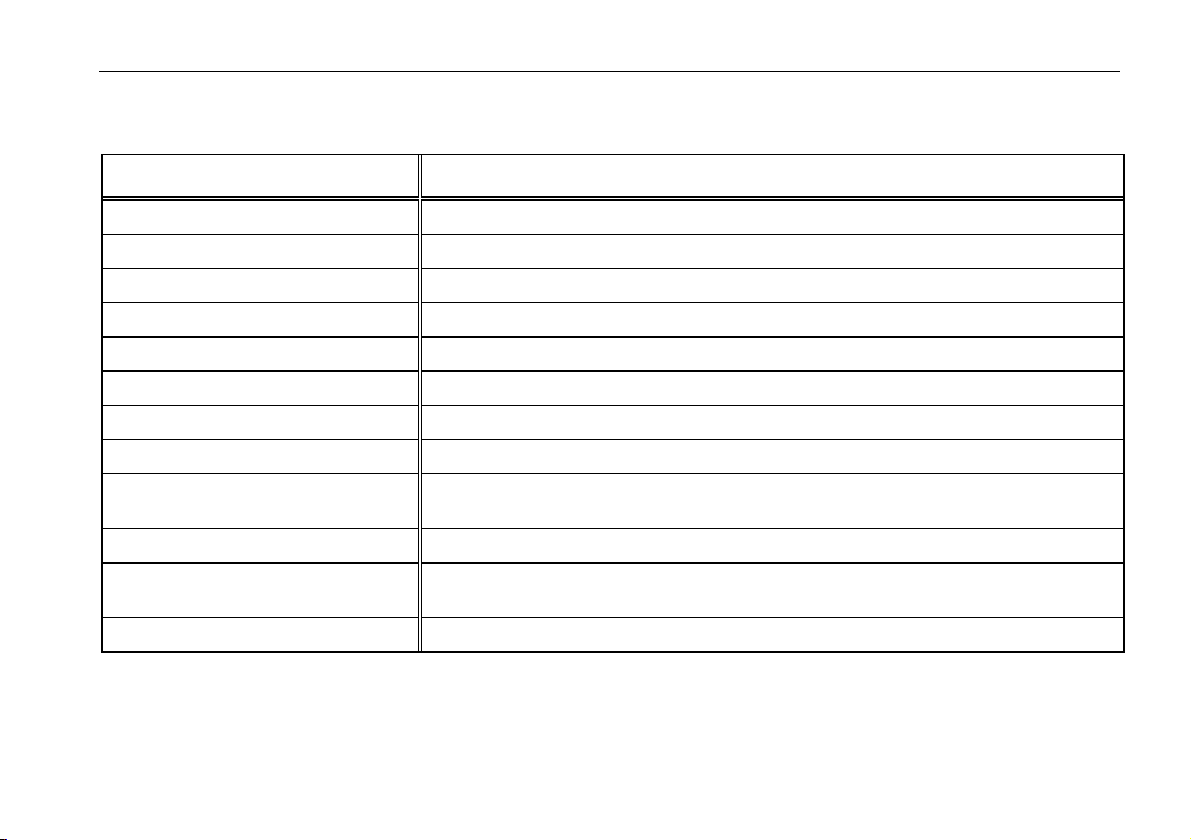

Function and features

Basic unit/ function Description / feature

Cabinet / frame Galvanized steel

Chamber Stainless steel * (Multifuge 1S: coated steel)

Drive Brushless induction drive

Key pad and display Key pad and display elements covered by an easy-care continuous surface

Control Microprocessor driven by "EASYset"

Main memory Recalls last run parameters

Program memory Data are stored until new values are entered.

Advanced features RCF-programming, quick run, pre-temp *, temperature control during standby

Acceleration and deceleration profiles

Rotor identification Automatic

SMARTspinTM

imbalance detection system

Soft touch lid lock Motor assisted lid locking

(* only with refrigeration unit)

9 acceleration and 9 deceleration profiles

Electronic, effective as a function of rotor and speed

9

Page 14

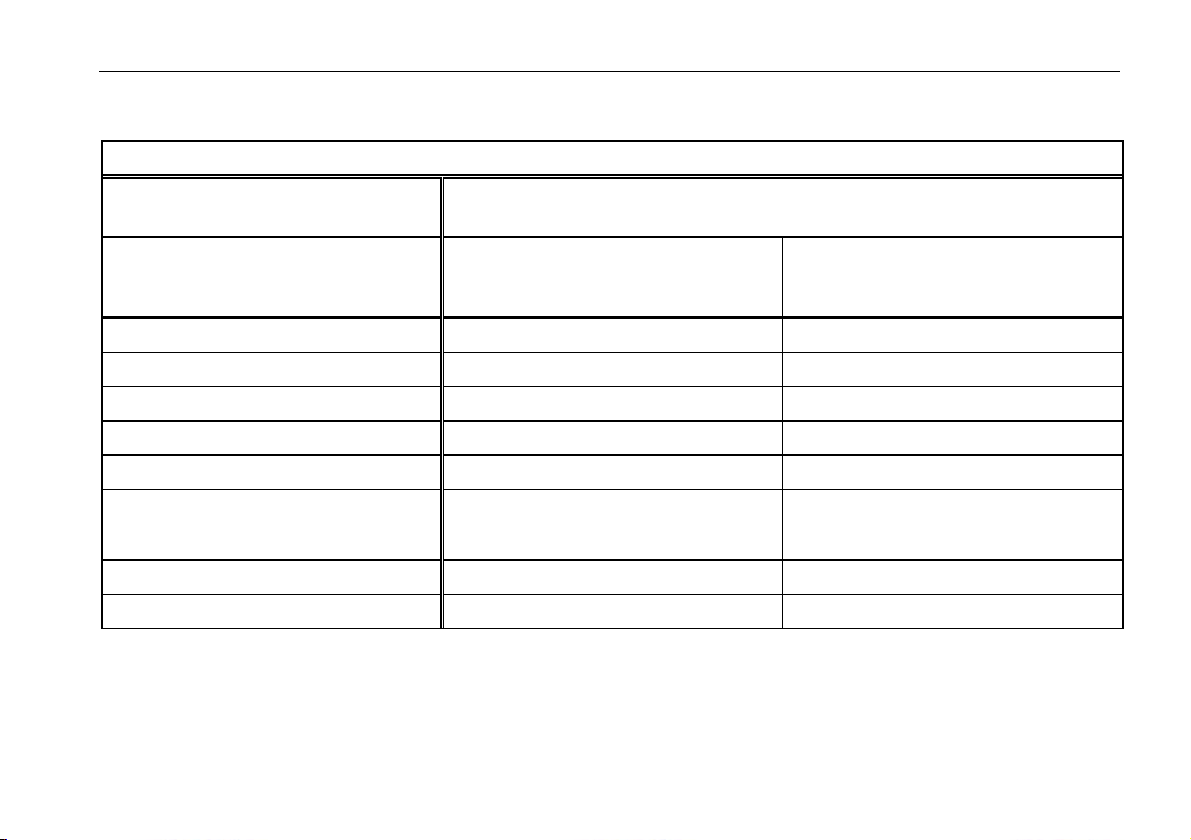

Description of the Multifuge®

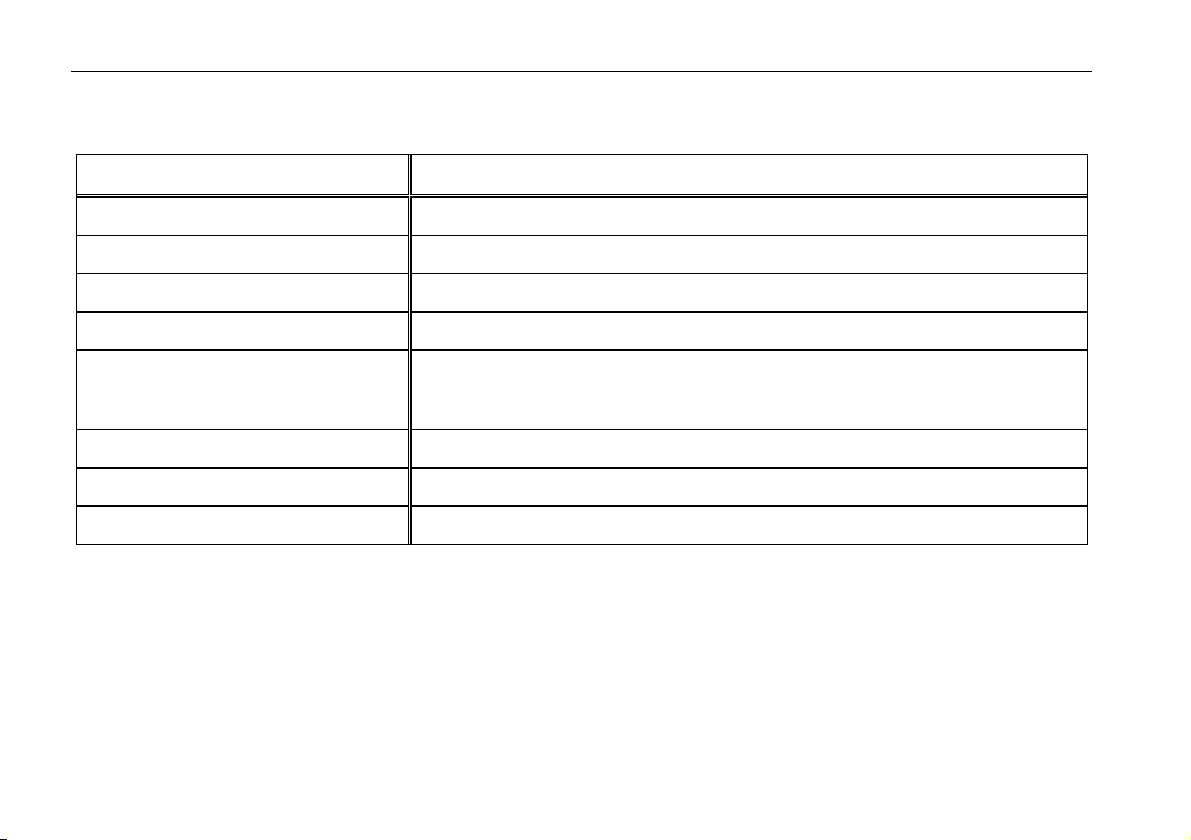

The EASYset user interface

Function Feature

Program memory keys Freely programmable

Acceleration / deceleration profile 1 = slowest, ... 9 = fastest acceleration / deceleration curve

Setting speed by rpm Adjustable from 300 rpm to 15 000 rpm, in 10 rpm increments

RCF selection Upon actuation of RCF switch , the RCF value can then be entered

Time selection

Run time display in "quick run" mode Between 1 s and 60 s in seconds´ steps, above in minutes´ steps

Setting temperature * Adjustable from -9°C to +40°C, in one degree increments

End of centrifugation The speed display will read "end"

(* only with refrigeration unit)

Adjustable in minutes from 1 min to 9 h 59 min,

or extended time mode from 1 min to 99 h,

”hld"-mode: continuous operation

10

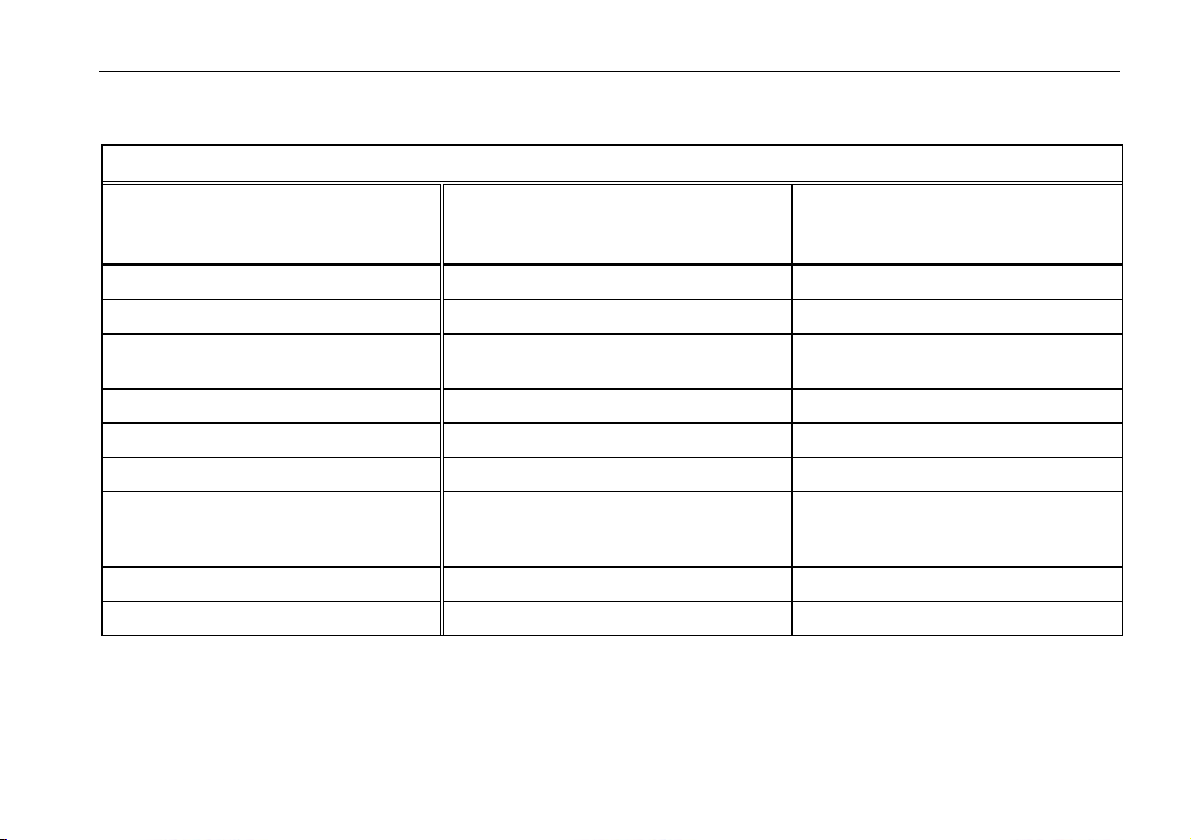

Page 15

Function Feature

Description of the Multifuge®

Lid opening

Start

Stop

"Quick Run" mode

Diagnostic messages

Automatic unlocking via ”open lid" key (

)

(unlocking in case of power failure: see chapter ”Troubleshooting")

Start key (

Stop key (

Pressing the "quick run" key (

)

)

) activates maximum acceleration up to the

maximum permissible speed of rotor; upon key release the centrifuge stops with

maximum deceleration power.

• Alternating display ”Rotor"/maximum speed or RCF

(speed selected exceeds max. speed of the rotor)

• Lid has not been lifted off the lock during opening:

display ”lift lid" (manual lifting of lid is required)

• General instrument malfunction

(error messages with ERROR codes, see "Troubleshooting")

11

Page 16

Description of the Multifuge®

Notes

12

Page 17

Before use

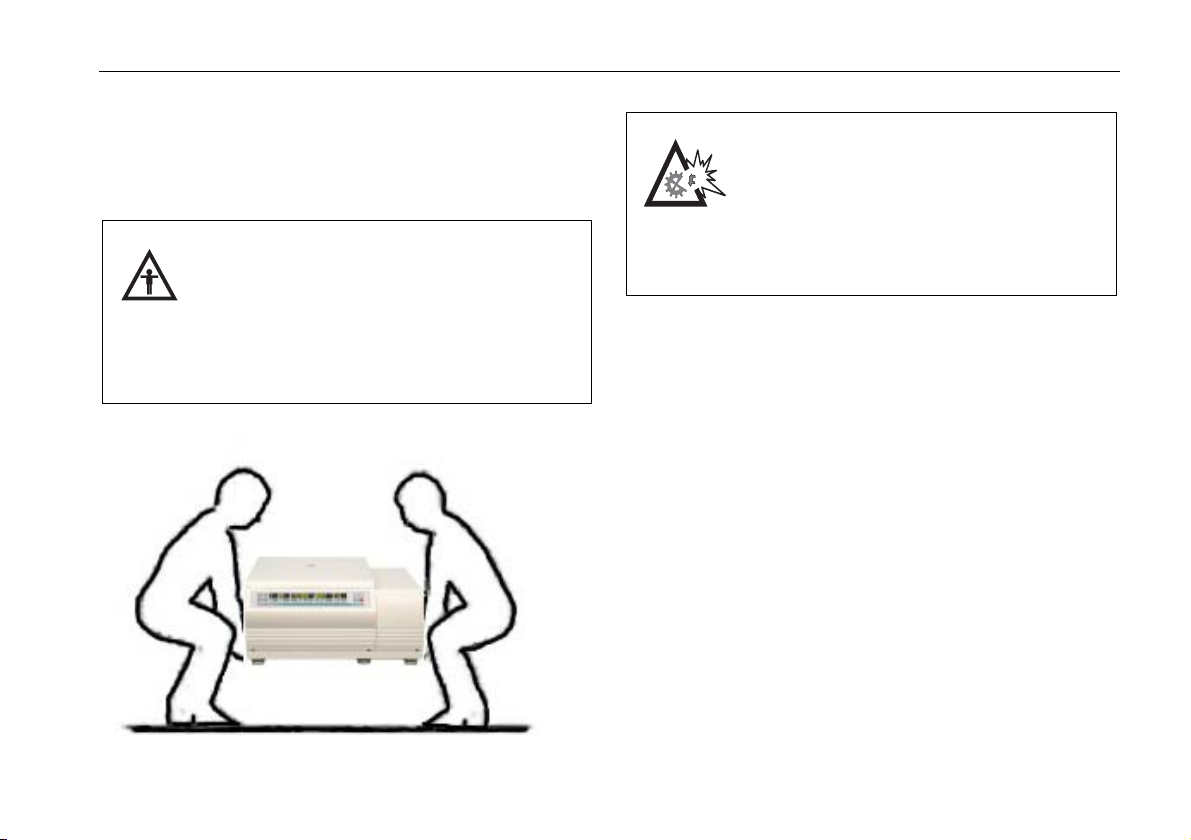

Centrifuge transport and installation

After opening the box remove the protective materials.

When transporting the centrifuge,

consider its weight (see "Technical

Data"); always grab it on both sides

ensuring that enough helpers are

around.

Do not lift on the front panel!

Before use

The centrifuge can be damaged by

jolting during the transport!

Transport the centrifuge only in the

upright position using proper containment and secure it properly.

Handle the centrifuge carefully.

Proper location

The centrifuge may only be used indoors. Its location

must meet the following criteria:

• A safety zone of at least 30 cm (12 inches) around

the centrifuge must be maintained. Hazardous materials must not be stored beside the centrifuge during its use.

• The laboratory bench or centrifuge trolley must be

stable and resonance-free. A good support is provided by a laboratory bench or a centrifuge cart with

lockable casters.

• To ensure sufficient air circulation, a minimum dis-

tance from the wall of 10 cm (4 inches) at the back

and of 15 cm (6 inches) on each side must be kept.

13

Page 18

Before use

• The centrifuge must be protected from heat and

direct sunlight.

• The location must be well ventilated at all times.

UV rays reduce the durability of

plastics.

Protect the centrifuge, rotors and

plastic accessories from direct

sunlight.

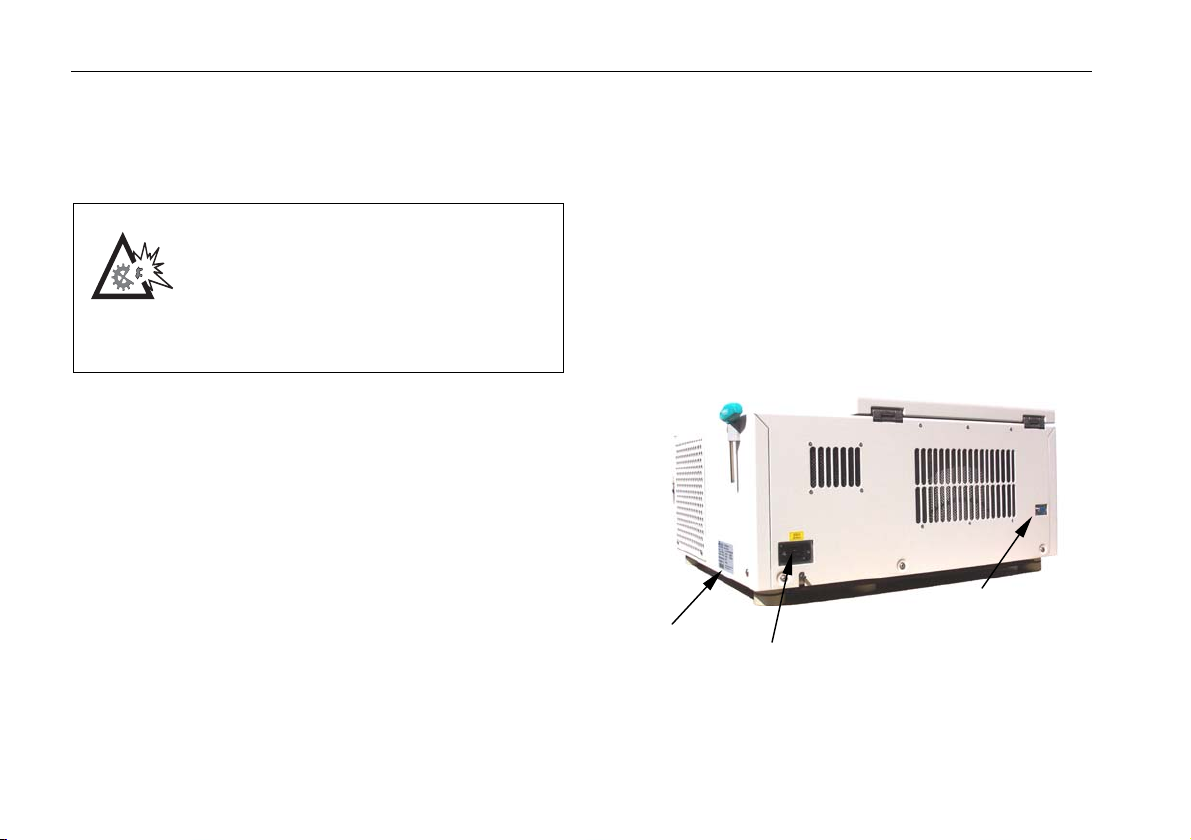

Main connection

Connect the centrifuge only to a grounded main power

supply. Make sure that the power cord is compatible

with the valid safety regulations and that your main

voltage and frequency correspond to the specifications

on the instrument label.

Make sure that the centrifuge is switched off (on the

right-hand side of front panel) before connecting

electrical wire to main power supply.

RS232 interface

specifications

Main connection

14

Page 19

Rotors and accessories

Rotors and accessories

A rotor is not included as part of a Multifuge® centrifuge.

A large variety of rotors are available as accessories.

In addition, there are adapters and reduction sleeves

for a variety of commercially available tubes and

bottles.

For a complete list of available tubes, bottles, adapters and accessories, please refer to our current sales

documentation.

For more information you can visit our web site at

http://www.Kendro.com

Multifuge

During centrifugation, heat is generated by air friction

between the rapidly spinning rotor and the air inside

the rotor chamber. The continuous air flow in the air

cooled centrifuge is restricting the temperature rise of

the samples. The equilibrium temperature rise depends on the ambient temperature, the type of rotor,

the speed, the duration and the number of runs.

®

1 S (air cooled)

Use caution when touching rotors as

they may be hot after long runs at

high speed.

15

Page 20

Rotors and accessories

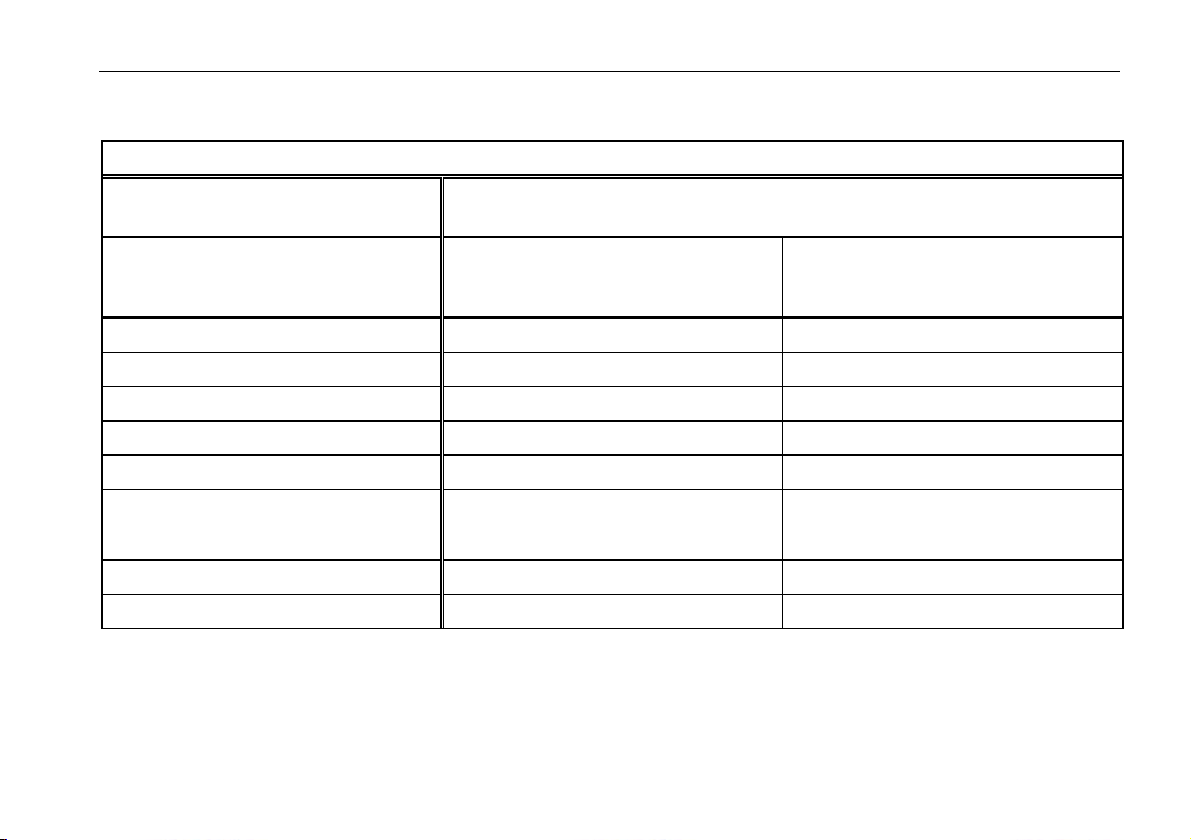

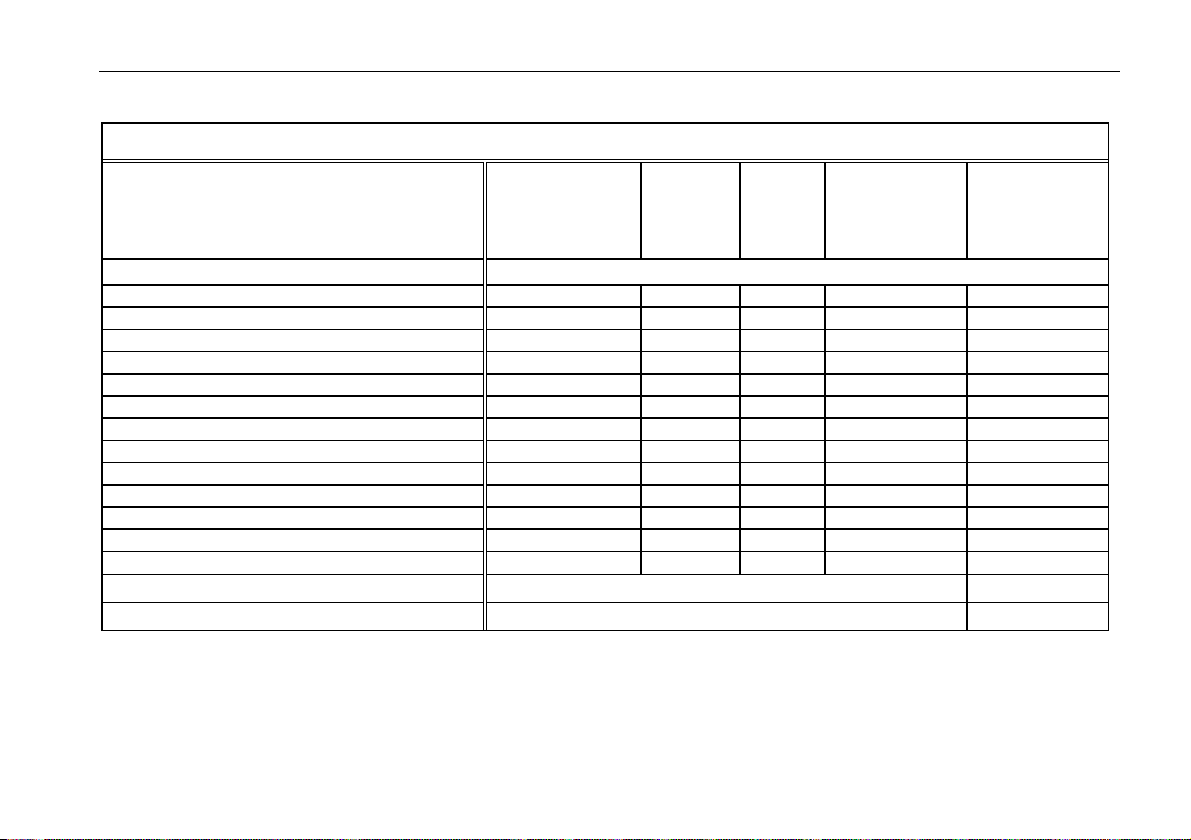

Rotors for the Multifuge® 1 S

Table 1: Rotors for Multifuge

Rotor designation Swinging Bucket Rotor TTH 400

®

1 S

Differences of 120V instruments are shown in parentheses

75002000

With bucket

Order no.

Maximum permissible load [ g ] 4 x 540 4 x 570

Maximum speed nmax [ rpm ] 4700 ( 4500 ) 4700

Maximum RCF value at nmax 4618 ( 4234 ) 4618

Radius (max.) [ cm ] 18.7 18.7

Acceleration / deceleration time [ s ] 40 / 35 ( 50 / 40 ) 40 / 35 ( 55 / 40 )

Heating of samples at nmax [ °C ]

relative to room temperature 23°C,

run time 1 hour

Aerosol-tight * Yes (with cap 75002003) Yes (with cap 75002004)

Autoclavable 121°C 121°C

* Tested and approved by CAMR, Porton-Down, UK

12.0 ( 14.0 )

Rectangular bucket

150 ml

75002001

13.0

Round bucket

400 ml

75002002

16

Page 21

Table 1: Rotors for Multifuge

Rotor designation Swinging Bucket Rotor TTH 400

®

1 S

Differences of 120V instruments are shown in parentheses

75002000

Rotors and accessories

With bucket

Order no.

Multiple carriers

14 x 15 ml

75002027

Multiple carriers

5 x 50 ml + 2 x 15 ml

75002028

Maximum permissible load [ g ] 4 x 420 4 x 430

Maximum speed nmax [ rpm ] 4700 ( 4500 ) 4700 ( 4500 )

Maximum RCF value at nmax 4642 ( 4256 ) 4593 ( 4210 )

Radius (max.) [ cm ] 18.8 18.6

Acceleration / deceleration time [ s ] 40 / 35 ( 65 / 40 ) 40 / 35 ( 65 / 40 )

Heating of samples at nmax [ °C ]

relative to room temperature 23°C,

run time 1 hour

15.0 ( 13.0 )

15.0 ( 13.0 )

Aerosol-tight — —

Autoclavable 121°C 121°C

17

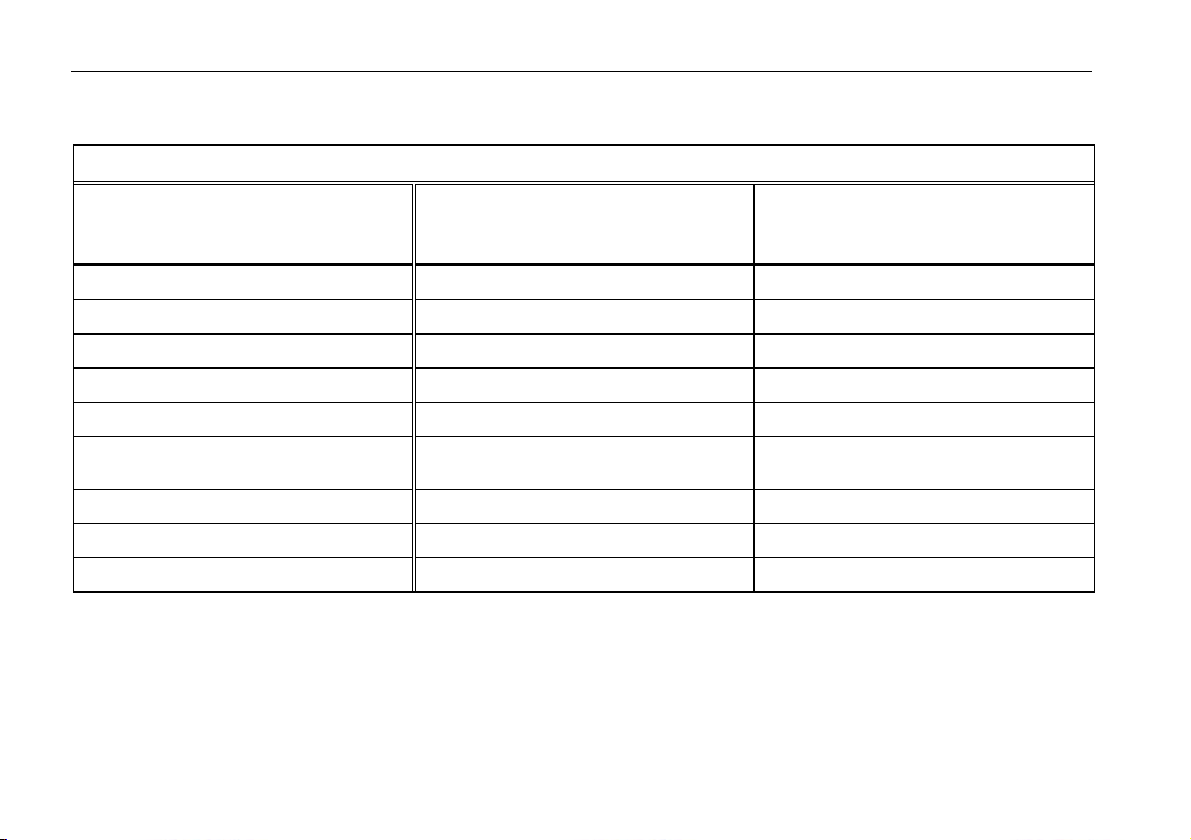

Page 22

Rotors and accessories

Table 1: Rotors for Multifuge

Rotor designation

Order no.

Maximum permissible load [ g ] 4 x 540 2 x 600

Maximum speed nmax [ rpm ] 5700 4400

Maximum RCF value at nmax 6175 3355

Radius (max.) [ cm ] 17.0 15,5

Acceleration / deceleration time [ s ] 55 / 55 ( 80 / 50 ) 35 / 35 ( 40 / 35 )

®

1 S Differences of 120V instruments are shown in parentheses

®

BIOshield

600 Rotor

4 x 150 ml

75002005

Micro plate carrier

MP 3300

75002010

Heating of samples at nmax [ °C ]

relative to room temperature 23°C,

Run time 1 hour

11.0

8.0

Aerosol-tight * Yes Yes (with cap 75002011)

Autoclavable 121°C 121°C

* Tested and approved by CAMR, Porton-Down, UK

18

Page 23

Rotors and accessories

Table 1: Rotors for Multifuge

Rotor designation

Order no.

Maximum permissible load [ g ] 6 x 140 / 12 x 30 48 x 4

Maximum speed nmax [ rpm ] 10 150 15 000

Maximum RCF value at nmax 14 513 24 652 - outer ring

Radius (max. / min.) [ cm ] 12.5 / 6.1 9.8 / 5.9

Tube angle [ ° ] 45 45

Acceleration / deceleration time [ s ] 40 / 50 ( 60 / 45 ) 35 / 30 ( 40 / 35 )

®

1 S Differences of 120V instruments are shown in parentheses

Fixed-Angle Rotor FA12.94 Highconic

6 x 94 ml / 12 x 16 ml

75002006

®

Micro Liter Rotor

48 x 2 ml

75003348

21 885 - inner ring

Heating of samples

[ °C / at rpm / run time ]

relative to room temperature 23°C

9.0 °C / 10 150 / 1 h

15.0 °C / 12 000 / 1 h

15.0 °C / 15 000 / 15 min

23.0 °C / 15 000 / 1 h

Aerosol-tight * Yes Yes

Autoclavable 121° 138°

* Tested and approved by CAMR, Porton-Down, UK

19

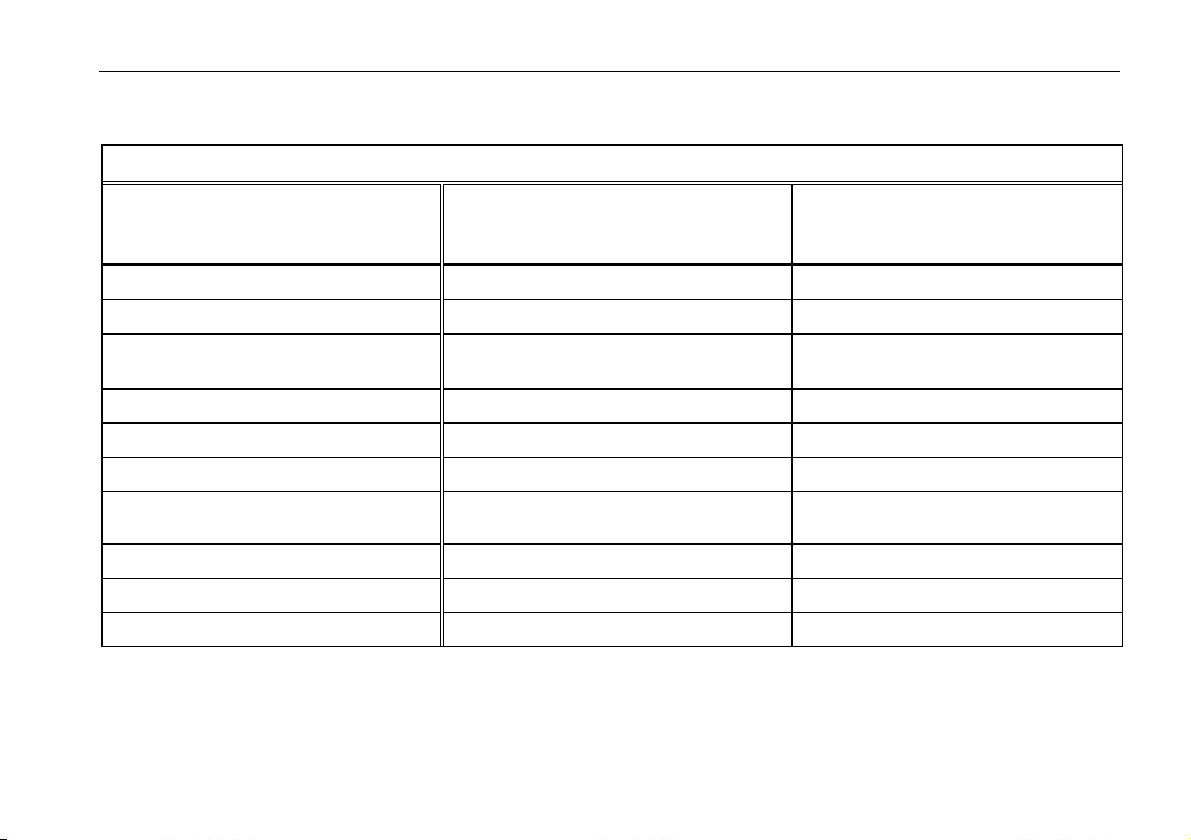

Page 24

Rotors and accessories

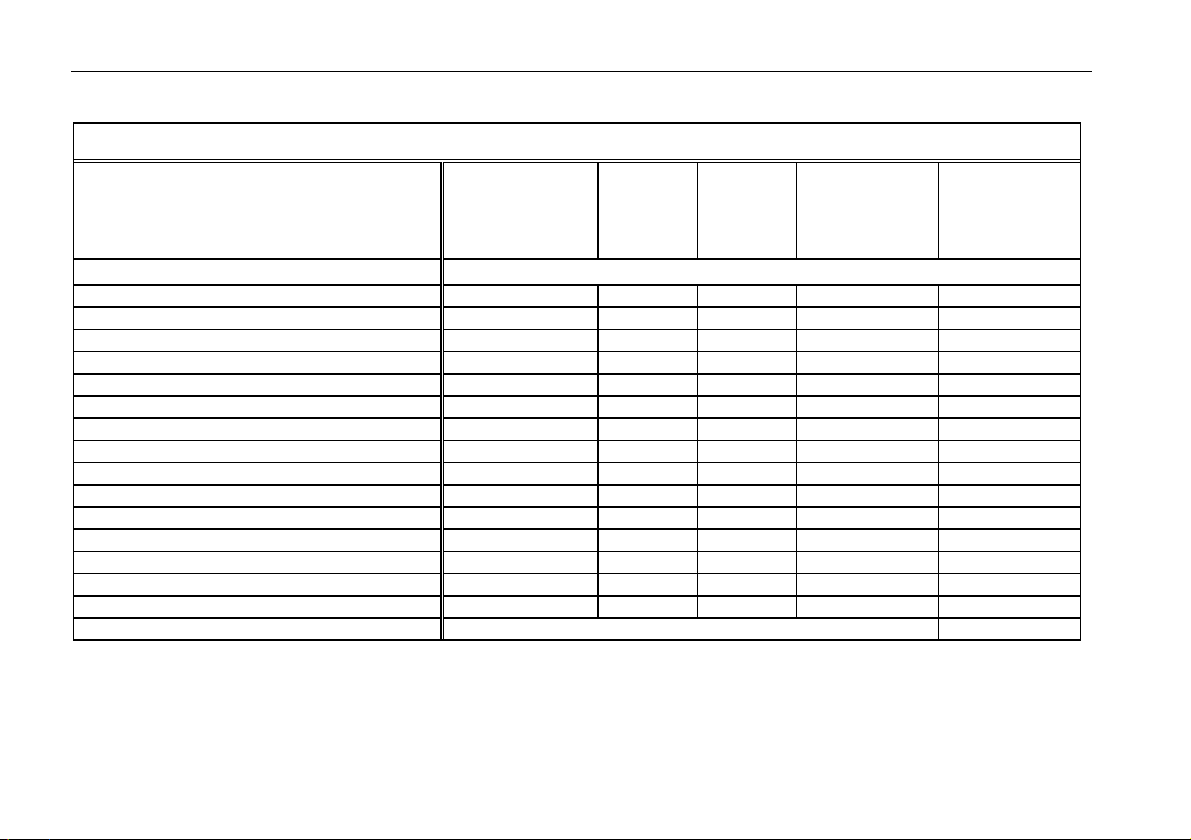

Rotors for the Multifuge® 1 S-R

Table 2: Rotors for Multifuge

Rotor designation Swinging Bucket Rotor TTH 400

®

1 S-R

Differences of 120V instruments are shown in parentheses

75002000

With bucket

Order no.

Maximum permissible load [ g ] 4 x 540 4 x 570

Maximum speed nmax [ rpm ] 4700 ( 4600 ) 4700

Maximum RCF value at nmax 4618 ( 4424 ) 4618

Radius (max.) [ cm ] 18.7 18.7

Acceleration / deceleration time [ s ] 35 / 35 ( 45 / 40 ) 35 / 35 ( 45 / 40 )

Min temperature at nmax [ °C ]

relative to room temperature 23°C

Speed at 4°C [ rpm ] 4300 ( 4100 ) 4700 ( 4450 )

Aerosol-tight * Yes (with cap 75002003) Yes (with cap 75002004)

Autoclavable 121°C 121°C

* Tested and approved by CAMR, Porton-Down, UK

10 ( 12 ) 4 ( 7 )

Rectangular bucket

150 ml

75002001

Round bucket

400 ml

75002002

20

Page 25

Table 2: Rotors for Multifuge

Rotor designation Swinging Bucket Rotor TTH 400

®

1 S-R

Differences of 120V instruments are shown in parentheses

75002000

Rotors and accessories

With bucket

Order no.

Multiple carriers

14 x 15 ml

75002027

Multiple carriers

5 x 50 ml + 2 x 15 ml

75002028

Maximum permissible load [ g ] 4 x 420 4 x 430

Maximum speed nmax [ rpm ] 4700 ( 4500 ) 4700 ( 4500 )

Maximum RCF value at nmax 4642 ( 4256 ) 4593 ( 4210 )

Radius (max.) [ cm ] 18.8 18.6

Acceleration / deceleration time [ s ] 40 / 35 ( 65 / 40 ) 40 / 35 ( 65 / 40 )

Heating of samples at nmax [ °C ]

relative to room temperature 23°C,

run time 1 hour

15.0 ( 13.0 )

15.0 ( 13.0 )

Aerosol-tight — —

Autoclavable 121°C 121°C

21

Page 26

Rotors and accessories

Table 2: Rotors for Multifuge

Rotor designation

Order no.

Maximum permissible load [ g ] 4 x 540 2 x 600

Maximum speed nmax [ rpm ] 6000 4400

Maximum RCF value at nmax 6842 3355

Radius (max.) [ cm ] 17,0 15,5

Acceleration / deceleration time [ s ] 50 / 50 ( 70 / 55 ) 35 / 40 ( 40 / 40 )

®

1 S-R Differences of 120V instruments are shown in parentheses

®

BIOshield

600 Rotor

4 x 150 ml

75002005

Micro plate carrier

MP 3300

75002010

Min temperature at nmax [ °C ]

relative to room temperature 23°C

5 ( 8 ) < 0

Speed at 4°C [ rpm ] 5900 ( 5700 ) 4400

Aerosol-tight * Yes Yes (with cap 75002011)

Autoclavable 121°C 121°C

* Tested and approved by CAMR, Porton-Down, UK

22

Page 27

Rotors and accessories

Table 2: Rotors for Multifuge

Rotor designation

Order no.

Maximum permissible load [ g ] 6 x 140 / 12 x 30 48 x 4

Maximum speed nmax [ rpm ] 10 350 15 000

Maximum RCF value at nmax 15 090 24 652 - outer ring

Radius (max./min.) [ cm ] 12.5 / 6.1 9.8 / 5.9

Tube angle [ ° ] 45 45

Acceleration / deceleration time [ s ] 45 / 45 ( 55 / 50 ) 30 / 30 ( 40 / 30 )

®

1 S-R Differences of 120V instruments are shown in parentheses

Fixed-Angle Rotor FA12.94 Highconic

6 x 94 ml / 12 x 16 ml

75002006

®

Micro Liter Rotor

48 x 2.0 ml

75003348

21 885 - inner ring

Min temperature at nmax [ °C ]

relative to room temperature 23°C

0 ( 4 ) 4 ( 6 )

Speed at 4°C [ rpm ] 10 350 15 000 ( 14 500 )

Aerosol-tight * Yes Yes

Autoclavable 121°C 138°C

* Tested and approved by CAMR, Porton-Down, UK

23

Page 28

Rotors and accessories

Adapter

Table 3: Adapter (1)

Adapter and accessories for

rectangular buckets 7500 2001

Centri-Lab® Adapter type A plus

14 x 7 ml blood sampling 13.0 x 117 16.5 56 grey 7500 2022

12 x 15 ml blood sampling 17.0 x 117 19.5 48 white 7500 2021

8 x 15 ml conical 17.0 x 120 22.0 32 brown 7500 2020

Centri-Lab® Adapter type A

40 x 1.5 / 2 ml micro liter tube 11.0 x 45 - 160 black 7500 5335

20 x 7 ml DIN 13.0 x 115 13.0 80 yellow 7500 5321

12 x 15 ml DIN 17.0 x 115 18.3 48 red 7500 5322

4 x 25 ml universal container 22.5 x 100 31.0 16 green 7500 5391

5 x 25 ml DIN 25.0 x 115 25.9 20 orange 7500 5323

2 x 50 ml DIN 34.0 x 120 35.6 8 green 7500 5324

2 x 50 ml conical 29.5 x 120 37.5 8 green-yellow 7500 5386

1 x 50 ml oil test - - 4 nature 7500 5339

1 x 100 ml DIN 44.0 x 120 48.1 4 blue 7500 5325

1 x 150 ml DIN 50.0 x 110 - 4 grey-blue 7500 5326

for cyto-system - - - - 7600 3417

Aerosol-tight caps

Spar seal

1)

d = diameter

* Max. tube length with aerosol-tight cap

Max. tube

dimensions

d1) x length/ *

[mm]

2 pieces, incl. seals and lubricants

4 pieces, incl. lubricants

Cap

diameter

[ mm ]

Tubes

per

rotor

Color

Order no.

7500 2003

7500 2008

24

Page 29

Rotors and accessories

Table 3: Adapter (2) * Max. tube length with aerosol-tight cap

Cap

diameter

[mm]

Adapter and accessories for

round buckets 7500 2002

Max. tube

dimensions

1)

d

x length / *

[mm]

Centri-Lab® Adapter type E

34 x 1.5 / 2 ml micro liter tube 10.5 x 46 14.0 136 black 7500 7578

18 x 7 ml DIN 13.0 x 123 14.0 72 yellow 7500 7571

10 x 7 ml blood sampling 13.0 x 123 18.4 40 grey 7500 7579

10 x 15 ml DIN 17.2 x 122 18.4 40 red 7500 7572

8 x 15 ml conical 17.0 x 127 23.0 32 brown 7500 7621

5 x 25 ml US-urine 16.5 x 123 27.5 20 orange-red 7500 7581

5 x 25 ml DIN 25.5 x 121 29.0 20 orange 7500 7573

3 x 50 ml universal container 25.0 x 120 32.0 12 green-yellow 7500 7580

3 x 50 ml conical 29.0 x 119 37.5 12 green-yellow 7500 7577

3 x 50 ml DIN 34.5 x 120 36.0 12 green 7500 7574

1 x 100 ml DIN 45.0 x 134 59.0 4 blue 7500 7575

1 x 250 ml bottle 62.0 x 135

400 ml bottle

Aerosol-tight caps

Spar seal

1)

d = diameter

x 135

80.0

2 pieces, incl. seals and lubricants

4 pieces, incl. lubricants

-

-

Tubes

Color

No. of order

per

rotor

4 nature 7500 7622

4

nature 7500 7583

7500 2004

7500 2009

25

Page 30

Rotors and accessories

Table 3: Adapter (3) * max. tube length with aerosol-tight cap

Cap

diameter

[ mm ]

Adapter and accessories for

BIOshield

®

600 Rotor 7500 2005

Max. tube

dimensions

1)

d

x length / *

[mm]

Centri-Lab® Adapter type A

40 x 1.5 / 2 ml micro liter tube 11.0 x 45 - 160 black 7500 5335

20 x 7 ml DIN 13.0 x 115 13.0 80 yellow 7500 5321

12 x 7 ml blood sampling 13.0 x 117 16.5 48 grey 7500 5330

11 x 15 ml blood sampling 17.0 x 117 19.5 44 white 7500 5327

6 x 15 ml conical 17.0 x 120 22.0 24 brown 7500 5387

12 x 15 ml DIN 17.0 x 115 18.3 48 red 7500 5322

4 x 25 ml universal container 22.5 x 100 31.0 16 green 7500 5391

5 x 25 ml DIN 25.0 x 115 25.9 20 orange 7500 5323

2 x 50 ml DIN 34.0 x 120 35.6 8 green 7500 5324

2 x 50 ml conical 29.5 x 120 37.5 8 green-yellow 7500 5386

1 x 50 ml oil test - - 4 nature 7500 5339

1 x 100 ml DIN 44.0 x 120 48.1 4 blue 7500 5325

1 x 150 ml DIN 50.0 x 110 - 4 black 7500 5326

for cyto-system - - - - 7600 3417

Spar seal

1)

=

1 set, incl. lubricants

Tubes

per

rotor

Color

No. of order

7500 2007

26

Page 31

Table 3: Adapter (4)

Rotors and accessories

Adapter and accessories for

Fixed-Angle Rotor FA12.94

7500 2006

Adapter for 94 ml cavity

1.5 ml micro tube 11 x 58 4 24 nature 7600 2905

3.5 ml 11 x 103 4 24 nature 7500 3091

6.5 ml 13 x 115 2 12 nature 7500 3092

12 ml 16 x 96 2 12 nature 7500 3093

16 ml * 18 x 124 1 6 nature 7600 2906

38 ml 25 x 112 1 6 nature 7500 3094

50 ml 29 x 118 1 6 blue 7500 3102

15 ml conical 16.5 x 120 1 6 nature 7500 3095

50 ml conical 30 x 117 1 6 green 7500 3103

Spare seal

Adapter for 16 ml cavity

for 10 ml Vacutainer Reducer insert (16 x 100 mm) 7500 3763

for 7 ml Vacutainer *

for 5 ml Vacutainer

1)

d = diameter

Max. tube

dimensions

1)

d

x length

[mm]

2 sets, incl. lubricants

Reducer insert (13 x 100 mm)

Reducer insert (13 x 75 mm)

Number per

adapter

Number

per

rotor

Color No. of

order

7500 3058

7600 3225

7600 3226

* For 7 ml Vacutainer, Adapter 7600 2906 and 7600 3225 required.

27

Page 32

Rotors and accessories

Tabelle 3: Adapter (5)

Accessories for

Micro plate carrier MP 3300

7500 2010

Aerosol-tight cap

Adapter for micro plate carrier

Spare seal

Table 3: Adapter (6)

2 pieces, incl. seals and lubricants

2 pieces, incl. lubricants

No. of

order

7500 2011

7500 2013

7500 2012

Max. tube

Adapter for

Micro Liter Rotor 7500 3348

Reduction sleeve PCR 6.2 x 20 0,2 24 Grey 7600 3750

Reduction sleeve 8 x 43.5 0.5 / 0,6 24 Turquoise 7600 3758

Reduction sleeve 6 x 46 0.25 / 0.4 24 Red 7600 3759

1)

d = diameter

28

dimensions

d1) x length

[ mm ]

Tube capacity

[ ml ]

Number

per set

Color No. of

order

Page 33

Handling the rotor

Rotors and accessories

Swinging Bucket Rotor TTH 400

BIOshield

®

600 Rotor

Micro plate carrier

All positions must always be loaded

with identical carrier buckets!

The various swinging buckets are split up into weight

categories. These can be identified through the letters

suffixing the order number on the bucket. Buckets of

identical weight categories should always be installed

in opposing rotor positions to avoid imbalance.

In case of repeat orders of buckets

and carriers, please indicate the

present weight category.

The swinging bucket rotors have a slide coating which

guarantees perfect operation without additional lubrication of body trunnion pins for many years.

Should an imbalanced run occur although

the weight is correct, this could be due to

wear of the slide coating.

In this case the rotor function remains intact

through normal lubrication:

at regular intervals, apply a light coating of

lubricant to the rotor body trunnion pins and

to the corresponding mating surfaces of the

buckets!

Lubricant 7000 6692 is supplied with the

centrifuge.

29

Page 34

Rotors and accessories

BIOshield

®

600 Rotor 7500 2005

Do not run the rotor without the rotor

cover installed.

Store the BIOshield

®

Rotor with the cover removed

after cleaning. This will enable the rotor to dry

thoroughly.

Always maintain the rotor in the recommended manner.

The rotor and accessories must be cleaned

and inspected regularly: do not use when

showing signs of corrosion or cracking.

30

Page 35

Rotors and accessories

Micro plate carrier MP 3300 7500 2010

Remove the appropriate plate holder from

the carrier body for loading and unloading of

micro plates in the Micro plate carrier.

Before loading, ensure that the rubber bottom is placed

in the cut-outs of the bottom of the plate holder.

The maximum loading height amounts to 55 mm!

Make sure the rotor is balanced!

The operation is permissible only

with the associated carriers!

(Label "75002010")

Some commercially available microplates are not rated for the maximum

achievable RCF of the Microplate carrier. Therefore please pay attention to

the specifications of the plate manufacturer.

31

Page 36

Rotors and accessories

Aerosol-tight operation

Aerosol-tight rotors and tubes are only

to be opened in an approved safety

work bench when centrifuging dangerous samples!

It is necessary to pay attention to the

maximum permissible filling quantities!

Correct operation when filling the sample tubes and

closing the rotor cover are prerequisites for aerosol biocontainment.

Before use, the seals in the rotors and

rotor covers as well as the aerosol-tight

caps have to be checked for abrasion

or damage and have to be slightly

greased.

Replace damaged O-rings and seals!

Use the special lubricant

7600 3500 only to grease the seals!

Spare parts are delivered with the rotor or may be ordered separately.

Replace damaged or clouded caps

and lids of rotors and tubes

immediately.

The tubes are only to be filled in such a way that the

sample does not reach the rim of the tube during centrifuging.

32

Page 37

Rotors and accessories

Closing the rectangular bucket 75002001

aerosol-tightly

After putting on the cap both levers are pressed down

until they noticeably click in.

Both of the levers must click in order to

achieve aerosol-tight bio-containment!

Closing the Micro test plates rotor MP3300

75002010

aerosol-tightly

Please flap both lock levers upward. The cap can now

be easily put on the bucket. The bucket is locked

through flapping down the levers.

Both of the levers must click in order to

achieve aerosol-tight bio-containment!

Levers not being flapped down

may cause damage to the caps

during centrifugation!

33

Page 38

Rotors and accessories

Closing the round bucket 75002002

aerosol-tightly

After greasing the seal, turn the lid until it sits lightly on

the bucket.

To achieve uniform seal, turn the lid tighter by 1 grip

area (approx. 10°). Use the setting marks on the

bucket as a guide.

Grip area

Bucket mark

Closing Fixed-Angle Rotor aerosol-tightly

The hexagon wrench should be used as a support tool

to fasten and loosen the lid of the fixed angle rotor in

order to achieve secure closing (insert the hexagon

wrench through the hole in the screw cap).

Please pay attention to the maximum

permissible filling volume during centrifugation of dangerous samples!

34

Page 39

Rotors and accessories

Rotor

Vessel type /

maximum filling volume

Micro Liter Rotor 48 x 2.0 ml

75003348

Fixed-Angle Rotor FA12.94

75002006

Micro 1,5 ml

1,0 ml

Falcon 50 ml

49 ml

Micro 2,0 ml

1,5 ml

Falcon 15 ml

14 ml

others:

- 2/3 nominal volume

• Micro – micro centrifuge tube

• Falcon – tube type Falcon

35

Page 40

Rotors and accessories

Checking of aerosol-tight bio-containment

The checking of the rotor type and bucket was done

according to the dynamic microbiological test procedure with regard to EN 61010-2-020 appendix AA.

The aerosol-tight bio-containment of the rotor mainly

depends on proper handling!

Check the aerosol-tight bio-containment

of your rotor whenever necessary!

It is very important that all the seals and

seal-surfaces are carefully inspected for

wear and damages like cracks, scratches

and embrittlements!

For a quick test one can check the aerosol-tight buckets and fixed angle rotors according to the following

procedure:

• Slightly grease all seals.

• Fill the bucket or rotor with approx. 50 ml carbon

dioxide mineral water.

• Close the bucket or rotor according to the respec-

tive handling instructions.

• Shaking the bucket releases the carbon dioxide of

the water, and an excessive pressure is built up.

• Leaks are recognized by humidity release and

audible disinflation of gas mix.

• Finally buckets respectively rotor, lid and lid seal

have to be dried.

36

Page 41

Operation

Switching on the centrifuge

Locate the main power switch on the right-hand side of

the front panel, and set it to the ON (I) position. For a

couple of seconds the following reading appears in the

control panel:

The display shows that the instrument is going through

an internal check of its software.

(See table on page 70).

After this check, the display shows the actual value

mode. The remaining run time and speed should both

read 0. The display of the acceleration/deceleration

curve depends on the last set value.

The following figure gives an example of possible readings. A detailed description of possible settings is given

below in this chapter.

Operation

Actuating the lid

Opening the lid

Press the "open lid" key

If the message "Lift lid” appears, slightly lift the lid.

(Emergency release in case of malfunction or power

failure: see chapter "Troubleshooting")

Closing the lid

The centrifuge lid is locked by slightly pressing down

the front part of the lid. Locking is motor-driven.

Do not slam the lid!

.

37

Page 42

Operation

Installing the rotor

Improper or improperly combined

accessories may cause severe damage to the centrifuge!

The rotors approved for the Multifuge® are detailed in

the chapter "Rotors and accessories". Use only rotors

listed for this instrument.

To install the rotor

ter "Parts supplied” – page 8).

Proceed as follows:

1. Open the lid and make sure that the rotor chamber

is clean. Clean any dust, foreign material or sample

residues out of the chamber before use.

2. Check if the collet chuck is loose (collet chuck

moves freely on the spindle). If not, loosen the rotor

seat using the supplied socket wrench.

3. Place the rotor on top of the collet chuck so that the

rotor is located precisely above the center.

, you will need the wrench (see chap-

4. The rotor must glide freely down the collet chuck

until it hits the lower stop.

5. If you have positioned the rotor correctly, you can

tighten the collet chuck easily using the supplied

hex wrench.

6. Place the rotor cover on applicable rotors and

tighten it securely.

Regularly check the proper positioning

of the rotor and re-tighten the collet

chuck as needed.

Please take care of the legibility of the inscription of the

installed swinging bucket rotor cross.

(Rotor identification must point to the chamber bottom)

For the swinging bucket rotor, the set bucket type must

be permitted for the operation in the respective rotor.

Please note the requirements of chapter "Bucket selection of swinging bucket rotors"

38

Page 43

Operation

Loading the rotor

Maximum loading

Overloading can result in destruction

and severe damage to the centrifuge.

The Multifuge

ing enormous centrifugal force. The rotors are designed to warrant sufficient residual strength even at

the highest permissible speed.

However, this safety system presupposes that the

maximum permissible load of the rotor is not exceeded.

®

can reach high rotational speeds exert-

Please get acquainted with the data

about the maximum permissible loads

and maximum speeds in chapter "Rotor and accessories".

If you wish to centrifuge samples that, together with the

adapters, exceed the maximum permissible load, you

must either reduce the sample volume or calculate the

permissible speed n

mula:

n

* n

n

perm

n= ∗

max

= permissible speed

perm

= maximum speed

max

according to the following for-

perm

maximum permissible load

actual load

39

Page 44

Operation

Filling the centrifuge tubes

Check carefully whether your tubes

are approved for the respective RCF

value. Follow tube manufacturer’s

recommendation.

For common borosilicate glass tubes the maximum

permissible rcf is limited to 4000 xg!

The tube manufacturers normally limit the respective

maximum allowed RCF value to the fixed angle rotor.

Please note that for the same RCF value

the stress for the tubes in a swingingbucket rotor is higher!

Because of the higher difference of the radii (r

max

- r

min

)

the pressure of liquid column to the tube bottom is

appreciably higher and strongly depended on filling.

Plastic tubes and bottles – especially for the highest

load (speed, temperature) – have a limited life time and

must be replaced as recommended by the manufacturer.

Maximum permissible load difference

The smaller the imbalance of the centrifuge,

the better the separation effect, because as

imbalance is minimized, so is the resulting

vibration, which could affect separation

quality.

Therefore it is important that the tubes are properly

balanced.

In case of exceeding the rotor specific imbalance values, the electronic imbalance shut-down is activated.

40

Page 45

Operation

Inserting the centrifuge tubes

The rotor must be loaded symmetrically. Failure to do so can cause rotor

imbalance, which may lead to noisy

operation, affect separation quality, or

result in imbalance detection shutdown, as well as introduce significant

detrimental wear to the motor and

drive system.

When only partially loading the rotor, ensure that opposite bores receive tubes of equal weight (when centrifuging a single sample, place a centrifuge tube filled

with water opposite of the sample).

After placing the tubes, install the rotor cover.

Fixed-angle rotors:

Proper loading

Improper loading

41

Page 46

Operation

Swinging bucket rotors:

Proper loading

Improper loading

These examples are to be applied to the

other rotors in an analogous manner!

42

Page 47

Operation

Entering parameters

Deceleration curves

The Multifuge® offers 9 acceleration and deceleration

profiles for optimal centrifuging of samples and gradients. Please consult the diagrams in the Appendix for

more detail of the acceleration and deceleration curves

(for rotors not mentioned here you may extrapolate the

respective values).

After switching on the centrifuge, the centrifugation

profiles last entered are selected.

By pressing the "set" key

profile settings until the desired profile is reached.

Once the display stops flashing, the value is stored in

memory and remains unchanged until changed by a

new entry.

Switching from speed to RCF display

Upon turning on the centrifuge, the speed display is

set.

Use the speed mode selection key

speed entry and display between rpm and RCF.

you can scroll through the

to switch the

Bucket selection for swinging bucket

rotors

When running a swinging bucket rotor, the automatic

rotor identification feature will recognize the rotor body.

Depending on the bucket or carrier installed on the

rotor body the corresponding type of bucket or carrier

must be selected on the bucket selection function. The

bucket selection affects the correct RCF values display

and the correct selection of the corresponding parameters of the temperature regulation.

The current part number of the buckets is displayed by

pressing the bucket selection key (corresponds to the

last four 4 digits of the order number).

To change the bucket

selection, press the

bucket selection key

again until the correct

set of buckets appears.

The value is accepted when the change back to the

speed RCF display has occurred.

43

Page 48

Operation

Selecting speed

The centrifuge speed can be set to a minimum of 300

rpm and to a maximum of 15 000 rpm (depending on

the rotor).

You can adjust the speed in 10 rpm increments. Proceed as follows:

1. By pressing the "set" keys

or

(for a decrease) in the "speed" section of the

control panel, you switch from actual to set point

values. The value last stored is displayed, with the

digit entered flashing (if there is no value stored in

memory, this is indicated by dashes -----).

2. By briefly pressing the input key you can raise or

3. If you hold down the pressed key, the display

changes slowly at first and at an accelerated pace

after a few seconds.

4. Release the key as soon as you have reached the

desired value, and adjust if necessary by repeatedly

pressing the key. The decimal place flashes for a

once (for an increase)

lower the speed by

one step (10 rpm)

at a time.

number of seconds, then changes to a permanent

display. The speed is now stored.

For faster operation, you may shift the flashing cursor in the speed/RCF and the run

time panels: just press both

and simultaneously. The cursor moves by one

digit to the left for each time the key is

pressed.

Entering the RCF value

You can adjust the RCF set point in steps of 1. The set

point is entered analogously to the speed.

As long as the rotor has not been identified, it is not

possible to display RCF values. This is signaled by

dashes ----- in the display.

Shortly after starting the centrifuge run, the rotor is

identified and the current value is displayed.

NOTE:

If you set an extremely low RCF value, this may be

automatically corrected if the resulting speed would be

lower than 300 rpm.

44

Page 49

Operation

More about the RCF value

The relative centrifugal force (RCF) is given in multiples of the earth gravity g. It is a dimensionless number

that allows comparing the efficiency of separation or

sedimentation of diverse instruments since it is independent of the instrument used. The only values entered in the equation are radius and speed of centrifugation

:

RCF ∗

r = radius of centrifugation in cm

n = speed in rpm

The maximum RCF value refers to the maximum radius of the tube bore.

You may take this into account when calculating the

RCF value for your application.

18,11

∗=

1000

Please note that this value decreases

depending on the tubes and adapters used.

2

n

r

Selecting run time

There are two time modes: standard and extended.

In the standard time mode you can select a run time

between 1 min and 9 h 59 min or continuous operation

(hLd) .

In the extended mode you can select a run time between 1 min and 99 h (from 10 h in one-hour steps), or

continuous operation (hLd).

Run time selection

To set a time, proceed as follows:

1. Press one of the "set" keys

(for a decrease) in the "run time" section of the

control panel once to switch from the actual to the

set point mode.

2. By briefly pressing the "set” key you can now

(for an increase) or

raise or lower the run

time in 1-minute increments.

45

Page 50

Operation

3 If you keep the selected key pressed, the dis-

play changes slowly at first and at an accelerated pace after a few seconds.

4 Release the key as soon as you have reached

the desired value, and adjust if necessary by

repeatedly pressing the key.

The minute display flashes for a number of

seconds, then changes to permanent display.

The run time is now stored.

You may shift the flashing cursor to set the value as

described under "Selecting speed".

Continuous operation

To switch the Multifuge

must press the key

®

to the continuous mode, you

until the display reads "hLd") .

With this

setting, the centrifuge keeps running until stopped

manually.

Extended time mode

You have the option of switching to the extended time

mode. To switch it on or off press the program selection key

and simultaneously start the centrifuge. As long as

you keep the key pressed the selective mode is active.

Pressing the upward key

, you can switch back and

forth between the signal menu "beep" and the time

menu "t-set".

After selecting the time menu "t-set”, you can switch

between the standards time mode "00.0" and the extended time mode "00”.h by pressing the upward key

.

The time input in excess of 10 hours is set in one hour

increments.

46

Page 51

Operation

Selecting the temperature

You can select the temperature in the range of -9 °C to

+40 °C.

To adjust the temperature, proceed as follows:

1. Press one of the "set" keys

(for a decrease) in the "temperature" section of

the control panel once to switch from the actual to

the set point mode.

2. By briefly pressing the input key you can now raise

or lower the run time in 1°

steps.

3. If you keep the selected key pressed, the display

changes continuously slowly at first and then at accelerated paces up or down.

4. Release the key as soon as you have reached the

desired value, and adjust if necessary by repeatedly

pressing the key.

The temperature display flashes for a number of seconds, then changes to the current value display. The

temperature set point is now stored.

(for an increase) or

Pretemp function

The Pretemp function permits easy and quick pretemperature-regulation of the empty rotor.

Upon calling this function by pressing the key

you have to do is enter the desired temperature.

After actuating the start key

, the rotor is pretempered with an optimum rotational speed set by the

pre-temperature-function.

The actually achieved temperature change in the pretemperature run time depends on the rotor used and

the ambient temperature. Occasionally multiple pretemperature runs are necessary to achieve the desired

rotor temperature.

, all

47

Page 52

Operation

Starting the centrifuge

Once the rotor is properly installed, the main switch is

turned on and the lid is closed, you can start the centrifuge.

Press the "start" key

fuge accelerates to the selected value. Simultaneously,

the time display starts counting down from the selected

set time, giving the remaining run time in minutes (during continuous operation the time display goes forward).

If a value exceeding the maximum permissible speed

or RCF of the respective rotor was entered, this is indicated after the start of the centrifuge by the alternately

flashing messages "rotor" and the maximum permissible value for the inserted rotor.

Within 15 seconds you may adopt this value by again

pressing the "start" key; the centrifugation is then continued. Otherwise the centrifuge stops, and you must

enter a permissible value.

You cannot open the lid during the run.

in the control panel. The centri-

Imbalance display

If rotor imbalance is detected, shortly after the rotor

reaches 300 rpm, the message "bAL" will appear in the

speed display.

The run is terminated,

and you may restart the

centrifuge after correcting the imbalance (check

loading).

Changing the settings during the run

You can change all settings during a run. By pressing

any one of the "set" keys in the control panel once, you

can switch from the actual to the set point mode.

The to-be-adjusted setting flashes and can then be

altered. Once the data input is finished and the display

has changed to the actual value display mode, the new

settings become operative.

48

Page 53

Operation

Stopping the centrifuge

Stopping with preset run time

Normally the run time has been selected, and all you

have to do is to wait until the centrifuge terminates the

run automatically at the end of the set time.

As soon as the speed reaches zero, the display reads

"end". You can now open the centrifuge by pressing

the "open lid" key

If the lid has not been fully lifted out of the lid lock, the

message "lift lid" appears (you must manually lift the

lid).

You can manually stop the centrifuge at any time by

pressing the "stop" key

At this point the remaining run time is displayed.

Stopping with continuous operation

If you have chosen continuous operation, you must

stop the centrifuge manually. Press the "stop" key

the control panel. The centrifuge starts deceleration

with the preset deceleration profile.

The display reads "end", and you can open the lid by

pressing the "open lid" key

ples.

and remove your samples.

.

in

and remove your sam-

Temperature control during standby

Temperature control becomes active once the rotor

has been identified. This is the case after a centrifugation run exceeding 300 rpm. At standby the display

reads "end".

If the rotor has not been identified (lid has been closed

and the "start" key

speed panel shows "0" with flashing point), the instrument regulates the temperature so that the samples

cannot freeze in any one of the usable rotors.

If you find the systematic deviation in temperature of up

to 4 K unacceptable, you have to start the centrifuge

for a short period of time until the rotor is identified.

has not yet been pressed,

49

Page 54

Operation

Working with programs

The 4 program selection keys offer the option of storing

and recalling the individual centrifugation processes.

Program display

By actuating one of the program selection keys, the

specific set point values stored are displayed.

Entering/changing a program

All program places have been factory-set at the same

values.

To change these values, proceed as follows:

− Enter the desired parameters

→ Only the selection panel affected by the changes is flashing.

− After entering all set point values, press the desired

program selection key for approx. 3 Seconds:

→ The entering is confirmed by the signal, the new program is

stored.

Repeat the process to set values to additional program

places.

Centrifuging with a program

After closing the centrifuge lid, call the desired program

memory number using the program selection key and

press the start key

.

If the rotor is started with a program the speed or RCF

set point value which exceeds the permissible value of

the inserted rotor, or the RCF/set point which is below

the rotor-specific minimum, the program selection keys

LED of the program chosen beforehand will be

switched off after the rotor identification.

50

Page 55

Operation

”Quick Run”

For short-time operation, the Multifuge® is equipped

with a "quick run" function

Short-time centrifugation is started by pressing the

"quick run" key

continuously; it stops as soon as the

key is released.

In this mode the centrifuge accelerates with full power

up to the maximum speed. The set speed or RCF is

ignored in this case.

Depending on the rotor, the centrifuge

accelerates to the maximum speed!

Check carefully whether you have to

maintain a specific speed for your

application.

During acceleration the time is counted forward in seconds. The display remains until the centrifuge lid is

opened.

.

Removing the rotor

1. Open the centrifuge lid.

2. Remove the rotor cover (on applicable rotors).

3. Unscrew the clamping sleeve counterclockwise

using the socket wrench supplied with the instrument until no resistance exists.

4. Grab the rotor with both hands and carefully pull it

perpendicularly off the drive shaft. Make sure not to

tilt it.

Grab rotor with both hands and pull

upwards perpendicularly.

When using an aerosol-tight bio-containment cover,

you may remove the respective rotor from the drive

shaft without opening the cover! You may then open

the rotor e.g. in a safety work bench and decontaminate it.

51

Page 56

Operation

Audible alarm

Accompanying all error messages, a warning signal is

given out which can be silenced upon pressing any

key.

You have the option of signaling the end of a run

acoustically. To activate or deactivate this option, press

the program key and simultaneously switch on

the centrifuge. As long as you keep this key pressed,

the selection mode is active.

The speed panel shows "beep", and the time panel

shows "on" or "off".

By actuating the upward-key

signal function can be switched on or off

When the message "rotor" flashes, pressing

the start key once is sufficient to turn off the

warning signal and to accelerate the rotor to

the maximum speed displayed by the instrument.

in the time panel the

.

Turning off the centrifuge

The centrifuge is turned off by switching the main

switch into the "0"position.

The main power switch should be turned off

after a complete centrifugation run. Without

motor deceleration, it takes much longer

until the rotor comes to a halt.

The centrifuge lid can only be opened automatically if

the centrifuge is turned on!

52

Page 57

Maintenance and care

Maintenance and care

Maintenance to be performed by the

customer

For the protection of persons, environment and material you are obliged to clean the centrifuge regularly

and to disinfect it if necessary.

Unsuitable cleaning agents or disinfection procedures may damage the

centrifuge and its accessories!

If you intend to use cleaning agents

or disinfection procedures not recommended by the manufacturer, you

have to ensure that the foreseen procedure does not cause any damages

to the instrument by consulting the

manufacturer!

Cleaning

Pull mains plug before cleaning the

instrument!

Clean the case, the rotor chamber, the rotor and the

accessories regularly, and in case of need. This is

indicated both for reasons of hygiene and to prevent

corrosion due to contamination sticking to the instrument and its accessories.

Clean them with mild agents of pH values ranging from

6 to 8.

For other cleaning agents please consult KENDRO

Services!

Immediately after cleaning, dry the aluminum parts or

put them into a warm-air dryer at a temperature not

exceeding 50°C.

53

Page 58

Maintenance and care

During cleaning, liquids and especially organic solvents should not

come into contact with the drive

shaft and the ball bearing.

Organic solvents may decompose

the lubricant of the motor bearing.

The drive shaft may seize.

Instruments with refrigeration unit:

If a strong ice sheet is present in the internal

chamber, be sure to remove all condensation after defrosting!

Please clean the venting slots regularly!

Before cleaning the venting slots,

please disconnect the centrifuge

from the mains supply.

Please pull mains plug!

Disinfection

If a centrifuge tube containing infectious material leaks

during a run, you have to disinfect the centrifuge immediately.

Infectious material could enter the

centrifuge if spills or tube breakage

occur.

Danger of infection may occur upon

contact! Take appropriate protective

measures for personnel!

Pay attention to the permissible filling

volumes and loading limits for the

tubes!

In case of contamination the operator

has to ensure that no other persons

are at risk!

Contaminated parts will have to be

decontaminated immediately.

If required, further protective measures have to be initiated.

54

Page 59

Maintenance and care

Rotor and rotor chamber must be treated with a neutral, universal disinfectant. Best suited for this purpose

are disinfectant sprays, ensuring that all rotor and accessory surfaces are covered evenly.

• Please use 70% ethanol for disinfection.

Please pay attention to the safety

measures and handling requirements

when applying these substances!

For other disinfectants please consult KENDRO

Services!

• You may disinfect the rotor and the accessories as

described in the following section. Be sure to follow

the pertinent safety procedures for handling infectious material.

1. Pull mains plug.

2. Unscrew the rotor chuck.

3. Grab the rotor with both hands and pull it perpendicularly off the drive shaft.

4. Remove the centrifuge tubes and adapters, and

disinfect them or dispose of them as necessary.

5. Treat the rotor and the rotor lid according to the

instructions given for the disinfectant (soaking in

liquid or spraying). You must strictly observe the

specified action times!

6. Turn the rotor head down and drain off the disinfectant. Afterwards thoroughly rinse rotor and lid with

water.

7. Dispose of the disinfectant according to valid regulations.

8. Aluminum rotors have to be treated with anticorrosive protective oil subsequently.

Disinfection with bleaching lye

These agents contain highly aggressive hypochlorites and must not be

used with aluminum rotors!

55

Page 60

Maintenance and care

Decontamination

For general radioactive decontamination, use a solution of equal parts of 70% ethanol, 10% SDS and water. Follow this with ethanol rinses, then de-ionized

water rinses, and dry with a soft absorbent cloth. Dispose of all washing solutions in appropriate radioactive

waste containers!

Autoclaving

Check whether autoclaving is permitted!

You may autoclave the rotor and the adapters at

121 °C.

Maximum permissible autoclaving cycle: 20 min at

121 °C.

The rotor must be cleaned and rinsed with distilled

water before being autoclaved. Remove the rotor lid,

the centrifuge tubes and the adapters. Place plastic

rotors on an even surface to avoid deformation.

Chemical additives to the steam are not

permitted.

Never exceed the maximum permissible values for autoclaving temperature and autoclaving time.

Should the rotor show signs of wear,

you must stop using it!

Corrosion protective oil 7000 9824 is delivered with the

centrifuge.

56

Page 61

Maintenance and care

The KENDRO service offer

Kendro Laboratory Products recommends annual servicing of the centrifuge and the accessories by authorized customer service or trained professionals. The

customer service personnel inspect:

• the electrical installations

• the suitability of the location

• the lid lock mechanism and the safety circuit

• the rotor

• the rotor fastening and the drive shaft

Defective material is exchanged.

KENDRO offers inspection and service contracts cov-

ering it. Inspection costs are charged as flat-rate contracts.

Necessary repairs are carried out free of charge within

the warranty conditions, and requires payment after

expiration of the warranty period.

Warranty conditions

The warranty period starts on the day of delivery.

Within the warranty period the centrifuge is repaired or

replaced free of charge if there are provable faults in

materials or workmanship.

Conditions for a warranty are:

• the centrifuge is used according to the instructions

of use

• mounting, extensions, settings, alterations or repairs are carried out exclusively by personnel authorized by KENDRO

• the required maintenance and care procedures are

carried out regularly.

57

Page 62

Maintenance and care

Notes

58

Page 63

Troubleshooting

Troubleshooting

Emergency lid release

In case of a power failure the lid cannot be opened

normally using the electrical lid unlocking mechanism.

To permit unloading in this case, the centrifuge is

equipped with an emergency override release. However, you may only use this system in case of emergency.

Rotors can spin at high speed! Touching them may cause severe injuries!

Always wait for several minutes until

the rotor has come to a complete stop.

In case of a power outage, the brake

does not function, and deceleration

takes much longer than normal!

Proceed as follows:

1. Make sure that the rotor is at a complete stop

(observe through window in the cover).

During a power outage, it is impossible

to lock the lid once the emergency lid

release has been used. Never stop the

rotor using your hands or using tools!

2. Unplug the main power cord.

3. Facing the centrifuge under the left-hand side, there

is a plastic plug that can be removed using a

screwdriver. After removal, use your fingers or a

pair of pliers to pull the attached cord and activate

the manual door override. The lid will open and you

can remove your samples.

Emergency release

59

Page 64

Troubleshooting

4. Afterwards, push the cord back into the instrument

and reinsert the plastic plug.

Once the power is restored, you can connect the instrument to the main supply and turn it on.

Following the self test of the centrifuge, the lid may be

closed and locked with the motor.

60

Page 65

Error troubleshooting

If problems other than those described in the following tables arise, you must contact

KENDRO service.

Error Symptom Possible causes and corrective measures

Troubleshooting

Displays remain dark The drive stops.

The rotor stops without

deceleration. The lid

cannot be opened.

Displays fail briefly. The drive stops suddenly.

The rotor stops without

deceleration.

Lid cannot be opened.

Pressing the "open lid" key

has no effect.

Mains voltage disconnection

1. Is the mains plug turned on?

2. Check the main connection.

3. If the main connection is ok, contact the nearest KENDRO

service station.

Main connection was briefly interrupted

1. Turn off main switch.

2. Check whether the mains power cord is connected

properly.

3. Restart the centrifuge.

Lid not correctly engaged or lid warped.

1. Check if main connection is working and the instrument is

switched on (display is lit).

2. Press the lid down in the middle of the front section once,

and press the "open lid" key.

3. If this is unsuccessful, you may open the lid using the

emergency lid release (see page 59).

61

Page 66

Troubleshooting

Error Symptom Possible causes and corrective measures

–

Message "bAl" appears

in display.

Centrifuge is exceptionally

noisy.

Rotor stops with

deceleration.

Imbalance.

1. Stop the centrifuge by pressing the "stop" key, in case of

emergency, unplug mains power cord.

2. Wait until the centrifuge comes to a complete stop.

3. Check whether the rotor is properly loaded.

4. Check whether a broken tube, damage to the rotor or

motor malfunction is responsible for the noise.

If you cannot locate and solve the problem yourself, contact a

KENDRO service station.

Imbalance switch actuated

1. Open the instrument by pressing "open lid" key

..

2. Check whether the rotor is properly loaded.

3. Check whether a broken tube or damage to the rotor was

responsible for imbalance switch actuation.

4. Check that the trunnions of the swinging bucket rotor have

been properly lubricated.

If you cannot locate and solve the problem yourself, contact

the KENDRO service station.

62

Page 67

Error Symptom Possible causes and corrective measures

Troubleshooting

Message "rotor" appears

in display.

Display "OPEN" appears

although lid is closed.

Message "Lid" appears

flashing in the display.

Message "Lift Lid"

appears in the display

Rotor decelerates with

delayed deceleration.

Will not start.

Drive stops.

Rotor stops without

deceleration to standstill.

Lid does not open

automatically.

Set speed exceeds permissible maximum speed for the

rotor. (The same holds for RCF setting)

A) For about 15 sec. the display shows alternately "rotor" and

the maximum permissible speed or RCF for the installed,

after the rotor identification. Within this period, it is

possible to accept this value by again pressing the "start"

key. The centrifugation will then be continued.

B) Following onset of deceleration you must wait until the

rotor has stopped. By opening and closing the lid you

reset the message "rotor". After entering a permissible

speed you can press start.

Lid not properly closed

Open the lid and repeat locking procedure.

Lid was opened manually during the run.

The instrument stops without deceleration. If you want to

continue the run, you must switch the instrument off and on

again.

The lid has not been unlocked after release.

1. Avoid laying objects onto the centrifuge lid.

2. Lift the lid slightly.

63

Page 68

Troubleshooting

Error Symptom Possible causes and corrective measures

E-01

|

E-13

E-14

Rotor stops without

deceleration to standstill.

Instrument cannot be

operated.

Rotor stops with

deceleration to standstill.

Instrument cannot be

operated.

E-15

|

E-16

Rotor stops with

deceleration to standstill.

Instrument cannot be

operated.

E-17 Rotor stops with

deceleration to standstill.

Instrument cannot be

Internal program error.

Switch the instrument off and on again. If the error persists,

contact KENDRO service.

Overtemperature in the centrifuge tank.

Switch the instrument off and on again. If the error persists,

contact a KENDRO service station.

Temperature measurement error.

Switch the instrument off and on again. If the problem

persists, contact a KENDRO service station.