Page 1

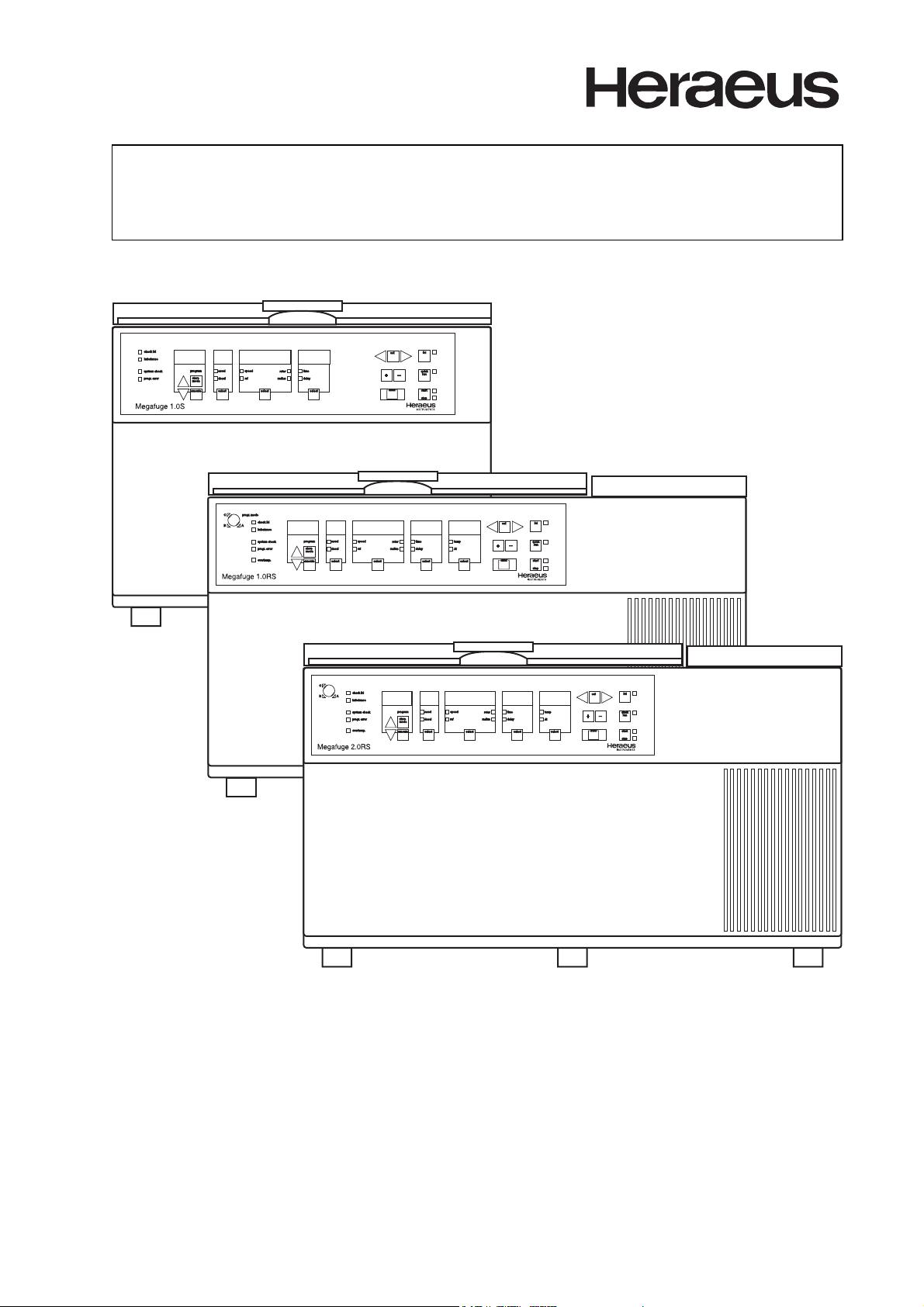

MEGAFUGE 1.0S

MEGAFUGE 1.0RS Operating instructions

MEGAFUGE 2.0RS User interface "Sepacontrol"

Page 2

User interface "Sepacontrol"

User interface "Sepacontrol"

The user interface "Sepacontrol" from Heraeus is designed for programming and using the operating functions. The present description substitutes the corresponding section of your operating instructions.

The figure below shows the user interface of the Megafuge 1.0RS, which is described in detail below. On

the last page of the Appendix you will find the same figure enlarged to full-page size.

Key-operated switch

left and right digit selection, respectively

setpoint

display,

temperature,

overtemperature

setpoint setting setpoint setting

setpoint

change

set

+

–

enter

copying

into working

memory

open lid

lid

quick

run

start

stop

INSTRUMENTS

start/stop key

lid release

Quick Run

release

Quick Run

"ready for

start"

display

stop

release

system

check

programming

error

over-

temperature

key-operated switch

progr.mode

C

BA

Megafuge 1.0RS

program number selection

diagnostic

LEDs

lid open

check lid

imbalance

system check

progr.error

overtemp.

storage in memory

program display

unbalance

display

display

acceleration/

braking

curves

store

mode

accel

decel

select

call

program

storage

mode

program

execute select select select

RCF,

rotor type,

radius,

special

messages

speed

rcf delay ∆t

rotor

radius

"select" keys

run time,

start

delay

time temp

run time

start delay

time temp

operating temperature

overtemperature

acceleration

deceleration

accel

decel

speed

RCF

rotor type

radius

speed

rcf delay ∆t

rotor

radius

assignment LEDs

You can use the key-operated switch to set the operating mode of "Sepacontrol".

Position A: Unlimited programming. You can call or change all programs.

Position B: The program memory is protected against modifications. However, the current centrifugation

program in the main memory can still be modified.

Position C: Program and main memory are protected against modifications. The preset centrifugation

program can be run an unlimited number of times by actuating the control keys.

The setpoints can be displayed any time by pressing "set" or the select key ("select").

You can pull out the key in any position. The respective setting is then valid until the next modification.

If you are in a hurry:

Setting the centrifugation conditions without storing the parameters.

Prerequisites: The centrifuge is properly installed, the rotor correctly loaded and balanced, the keyoperated switch in position A or B.

2

Page 3

User interface "Sepacontrol"

General procedure for all "select" fields:

• Press the "set" key. The display selected for the previous run flashes.

• Press the "select" key under the desired function field until the red LED next to the parameter to be

changed (e.g. "temp") is lit. Choose the digit to be altered by briefly pressing one of the direction keys

to the left and right of the "set" key (

+

count by pressing the

- or – key until the desired number is displayed.

set

) (repeatedly if necessary), and increase or decrease the

• By briefly pressing the key you increase or decrease the chosen digit by one step at a time. If you

press and hold the chosen key, the display changes continuously upward and downward, respectively. Release the key as soon as you have reached the desired value, and fine-tune if necessary by

repeatedly pressing the key.

• Acknowledge each entry by pressing "enter".

To enter parameters:

1. Press first the "set" and then the "select" key under the four-function field ("speed", "rcf", "rotor", "radius") until the red LED next to "rotor" is lit, and enter the order number of the rotor (only possible when

centrifuge is at rest).

Entering the rotor order number is mandatory. The built-in electronics uses this information to rec-

ognize the maximum permissible speed and sees to it that it is not exceeded.

2. Optional: Choose one of the accelerating and braking curves ("accel" and "decel", respectively, possible choices no. 1–9 for both, plus 0 for brakeless deceleration with "decel", see Appendix).

NOTE: If with the braking curve preset to 0, the set speed is lowered during the run, the newly set speed is

triggered with braking curve 1; the preset curve 1 remains unchanged.

3. Optional: Enter the centrifugation radius. You can set the radius in steps of 10 mm and 1 mm, respectively, from the nominal radius (maximum value) to the smallest radius compatible with the design.

When preselecting an RCF value (see below), the set RCF value corresponds to the radius entered here.

4. Set the speed, or alternatively the relative centrifugal force (RCF, in multiples of the earth gravity g). To

do this, choose the respective parameter ("speed" or "rcf") in the four-function field ("speed", "rcf", "rotor", "radius"), and enter the desired value.

5. Set the run time. Select "time", and enter the desired run time. The time measured is the one between

the start and the end of the braking process.

h.min: Entry and display in hours and minutes, between 0.00 and 9.59

h: Entry and display in hours, between 10 and 99

hld Continuous operation (hld = "hold")

6. Optional: Enter the desired start delay (1 min to 99 hours, display: "delay").

7. Only refrigerated centrifuges (MEGAFUGE series RS): Set the temperature to a value between 0 °C

and 40 °C.

8. Optional (only refrigerated centrifuges – MEGAFUGE series RS): Set the overtemperature control to

the desired value (minimum 5 K, upper limit set by the built-in microprocessor). The centrifuge switches

automatically off when the overtemperature is exceeded (setpoint + ∆t).

NOTE: Altered parameters are accepted by the main memory only if acknowledged with "enter" (or "start").

Otherwise, following a timeout of about 2 min (or about 20 s with the centrifuge running), the instrument

switches the display to the actual values without accepting the modifications.

Operation without program

1. Close the centrifuge lid if still open. The yellow LED next to the "lid" key is lit, the "ready for start" display next to the start/stop key (green LED) is activated, and the centrifuge is ready for use.

2. Press the start/stop key. The centrifuge starts according to the factory-set default value with the acceleration curve no. 9 (acceleration curves see Appendix). The "lid" LED goes out, the lid cannot be

opened any more. The very moment the centrifuge starts, the stop function is released (red LED next to

the start/stop key is lit).

3. Wait until the instrument stops automatically after completing the set run time ( braking curve, see Appendix). However, you may stop the centrifugation any time by pressing the start/stop key. At this point

the green LED is lit anew, e. g. you can continue a manually interrupted run at any time.

3

Page 4

User interface "Sepacontrol"

Turning off the continuous tone after centrifugation: any key for current run, "enter" key in actual value

mode for all subsequent runs (in this case brief display "Alert off"; renewed "enter" or mains supply

ON/OFF results in "Alert on").

Display

Actual values

If none of the display panels flashes, actual values are displayed; this is true both during a centrifuge run

and at rest. The display values changes as soon as the instrument registers new actual values (e. g.

speed during a run, temperature at rest, etc.). Following a centrifuge run, the time display reads the remaining run time (which is different from 0 only in case of premature STOP) or the run time passed (if "hld"

has been preselected). This gives the operator an opportunity to check whether the run has been prematurely interrupted e. g. by a short-term power failure. The actual time display is overwritten with the new

actual values only following a renewed start or power OFF/ON.

By pressing the respective "select" key you can switch between the parameters (acceleration or deceleration, speed, RCF etc.). The LED for the currently displayed parameter is lit (see figure under "assignment

LEDs"). Further explanations see in the following section under "setpoint values".

Setpoint values

In order to display the current setpoint values, always press first the "set" key (display panels flash) and

then the key listed below as required.

Program display displays the number of the currently active program after pressing "store

mode" key (01–32)

acceleration/

braking curves

speed, RCF, rotor type,

radius

displays the number of the acceleration curve (1–9), upon pressing the

"select" key the number of the braking curve (0–9) (see Appendix)

displays the set speed, and upon pressing the "select" key successively

the relative centrifugal force (in multiples of the earth gravity g), the rotor

type (identical to the rotor or bucket order no.) and the radius setting

run time, start delay displays the set run time and upon pressing the "select" key the start

delay (if set)

temperature, overtemperature displays the temperature setpoint, and upon pressing the "select" key the

overtemperature control (if set; lowest value 5 K)

4

Page 5

User interface "Sepacontrol"

Program settings

Entering settings for multiple runs (permanent storage in the program memory)

Prerequisites: key-operated switch in position A; centrifuge at rest.

You have the choice between the two methods described below to permanently store programs in the

program memory:

A Opening the program memory before

1. Press one of the keys

(for increasing the value) or (for decreasing the value) in the "program" field

setting the run parameters

to set the desired number (01 to 32).

2. Open the current memory location by pressing the "store mode" key. The opening is signalled by a

flashing display of one of the parameter fields and of the selected program number in the program display.

NOTE: The selected memory location can only be opened if one of the parameter display panels is flash-

ing (press one of the keys

, or "set" if necessary). Upon opening a memory location you cannot

switch to another location.

3. Set the setpoints for the parameters as detailed on page 3.

4. After having completed all settings, press "execute" key. The program number display and the parameter display stop flashing, thus showing that the recent settings have been copied from the main memory

into the program memory and are available for future runs under the chosen program number.

B Opening the program memory after

setting the run parameters

1. Select the intended program memory location exactly as described under A 1.

2. Set the desired setpoints as detailed on page 3. As soon as you change the first parameter with the "+"

or "-" key, the program number display reads "--".

3. Open the program memory selected according to B 1. by pressing "store mode" (cf. A 2.).

4. Store the program by actuating the "execute" key (cf. A 4.).

NOTE: If a memory location opened with "store mode" is not closed by "execute", it is closed automatically following a timeout of 2 min. Both program memory and main memory keep their respective former

values, i. e. any settings altered in the display are discarded.

Operation with program

You can run preset programs either as stored, or you may change individual settings for the current run.

The stored program settings are not modified by changing individual settings (this is possible only via the

programming routine, see above).

Prerequisites: The centrifuge is properly installed, the rotor correctly loaded and balanced, the keyoperated switch in position A or B.

Program run as stored

1. Program selection: Press one of the direction keys

or until the desired program number is dis-

played.

2. Press the start/stop key within 2 min. The contents of the selected program memory location is loaded

into the main memory, and the program is executed immediately. You may stop the centrifugation any

time by pressing the start/stop key once again.

Program run with modifications

1. Program selection: Press one of the direction keys

or until the desired program number is dis-

played.

2. Press the "execute" or "enter" key, the program settings are loaded into the main memory.

3. Make the desired changes as detailed on page 3. The program display reads "--" as a reminder that

the current settings do no longer correspond to those of the originally selected program. However, the

original, stored program is unchanged and still available.

4. Press the start/stop key. The program run is started at once. You may stop the centrifugation any time

by pressing the start/stop key once again.

5

Page 6

User interface "Sepacontrol"

"Quick-Run" operation

Independent of set values you can, with the lid closed, start a centrifuge run using the "Quick-Run" key.

ATTENTION – WARNING!

As long as the "Quick-Run" key is pressed, the rotor is accelerated with maximum force to its

maximum permissible speed, i. e. the set speed is ignored.

The run is continued until the key is released, upon release the rotor is braked with maximum force. By

pressing the key once again, you can switch back to acceleration.

6

Page 7

Appendix

Diagnostic LEDs

LED "lid"

check lid

Appendix

Centrifuge lid not closed.

LED "imbalance"

Rotor not evenly loaded.

rotor imbalance

LED "system check"

Electronics malfunction.

system check

LED "program error"

Operating error.

program error

LED "overtemp."

The set temperature limit is exceeded.

overtemperature

Malfunctions – measures for self-help

Malfunction Cause Remedy

Symptom Behavior

Set position

flashes upon

pressing the

"set key

Setting with "+/-"

keys impossible,

lid cannot be

opened, start and

Position of key-operated switch

prevents programming.

stop OK.

Displays remain dark

Drive stops suddenly, rotor stops

Power failure. Check power supply, if OK call

without braking, lid

cannot be opened.

Turn key-operated switch from

position C to A or B, if no response, call Service.

Service.

Displays fail

briefly

Unusually loud

running noise,

possibly with

display "imbalance"

"OPEN" message displayed

"check lid" LED

is lit and interval tone sounds

Drive stops suddenly, rotor stops

without braking.

Drive fails, brakes

or keeps running

noisily.

Centrifuge cannot

be started; lid apparently closed.

Drive is turned off

and coasts brakeless to standstill.

Short-term power failure. Start anew.

1. Sudden imbalance due to

broken vessel and mass

shift.

2. Rotor or drive damage.

3. Malfunction in the control.

If the centrifuge does not stop by

itself, press "quick run" key Look

for apparent cause at standstill

and relieve if possible. Otherwise call Service.

4. Damaged fans or compressor.

1. Lid lock not properly engaged.

2. Lid lock defective.

1. Lid lock was opened manually during the run, action

not permitted!

2. Lid lock safety circuit has

tripped.

Press lid forcefully down, do not

bang!

If LED does not go out, call Service.

1. Press lid shut immediately,

switch mains supply OFF/ON,

press "start" to resume centrifugation, otherwise "stop".

2. Safety circuit malfunction, call

Service.

7

Page 8

Appendix

Malfunction Cause Remedy

Symptom Behavior

"imbalance"LED is lit, interval tone

"overtemp"LED LED is lit,

interval tone

Centrifuge brakes

maximally with

braking profile 9.

After starting:

Drive switched off,

refrigerating unit

running.

1. Rotor unevenly loaded.

2. Bucket does not swing out

properly or not at all.

3. Sudden vessel breakage

with center of gravity shift by

leaking liquid.

4. Defective drive mechanism

(damaged motor shaft).

5. Mechanical or other changes

on rotor or buckets.

6. Centrifuge tilted.

∆t-alarm is activated because

the rotor chamber has not been

precooled to temperature setpoint.

1. Distribute buckets, inserts

and fillings evenly.

2. Clean and grease

(#70006692) rotor pin and

opposite surface on the

bucket.

3. Remove splinters, broken

parts and sample residues,

clean buckets and fill anew,

restart with reduced speed if

necessary.

4. Do not start drive any

more! Call Service.

5. Discontinue use of rotor

and/or buckets! Inform Service.

6. Align centrifuge (drive), call

Service if necessary.

Open lid, turn off ∆t ("--"), close

lid and start; wait until cooled to

desired setpoint temperature

range, then activate ∆t.

During operation:

Centrifuge stops

without braking,

refrigerating unit

running.

"E-17" display,

"system

Upon pressing "lid"

key at standstill

check"-LED is

lit, interval tone

"system

check"-LED is

lit, interval tone

"E-xx" display

flashes in the

speed panel,

other possible

xx numbers 00-

During operation:

Drive coasts

brakeless to

standstill.

At standstill:

Drive switched off

after start.

24

Overtemperature alarm, displayed temperature exceeds

permissible threshold value:

temperature of the environment

(35 °C max.) or distance to wall

(15 cm).

1. ∆t dependent: cooling capacity of refrigerating unit insufficient

2. No ∆t programmed: defective

refrigerating unit

1. Lid lock mechanism jammed,

does not open

2. Lid lock defective

Tripping of a thermal or electrical protection function, e. g. E-

08.

Malfunctions in data transmission or measuring.

Wait until centrifuge has cooled,

possibly remove and cool samples after standstill, precool centrifuge and run again if necessary, do not operate near heat

generators.

Repeat run with reduced speed,

if deviations are considerable

call Service.

Call Service.

Mains supply OFF, check lid lock

mechanism and correct if necessary.

Call Service.

Switch off centrifuge and resume

operation after a minimum of 15

min, if error occurs repeatedly

call Service.

Mains supply OFF/ON, if error

persistent call Service.

8

Page 9

Appendix

Technical data of "Sepacontrol"

Feature Possible settings

Program memory for 32 complete sets of parameters

Program backup unauthorized intervention in stored programs lockable via a three-step

key-operated switch

Data storage almost unlimited with NV-RAMs

Diagnostic messages

via LEDs for

• lid not closed during operation

• unbalanced loading

• general malfunction of the instrument

• data transmission error

• overtemperature

Digital parameter display for program number, acceleration and braking profiles, speed, RCF,

rotor, radius, time, start delay, temperature and overtemperature

Acceleration curves 1–9 profiles selectable

Braking curves 1–9 profiles and 0 = coasting to standstill

Speed selection continuously between 100 min

1000, 100 and 10 min

-1

-1

and maximum speed in steps of

RCF selection continuously between 1 x g and maximum RCF value in steps of

1000, 100, 10 and 1 x g

Rotor selection integral numbers, organized according to order numbers in ascending

order

Radius selection dependent on rotor in 0.1-cm steps

Time selection in 3 modes:

hld continuous operation

h.min 1 min – 9 h 59 min

h 10 h – 99 h

Start delay in 3 modes:

-- immediate start (no delay)

h.min 1 min – 9 h 59 min

h 10 h – 99 h

Time display with "Quick Run":

min. sec mode 1 s – 9 min 59 s

t mode 10 h – 99 h

Temperature selection 0 °C – 40 °C in steps of 10 K and 1 K

Overtemperature control ∆t:

-- no overtemperature control

5 K ≤ ∆t ≤ (40 °C –T

5 K ≤ ∆t ≤ 10 K

) if 0 °C ≤ T

setpoint

if 31 °C ≤ T

setpoint

setpoint

≤ 30 °C

≤ 40 °C

adjustable in 1 K steps

9

Page 10

Appendix

Acceleration and braking curves

Acceleration curves

speed [rpm]

4000

3000

2000

1000

23456789

1

0 60 120 180 240 300

Braking curves

4000

3000

2000

speed [rpm]

1000

8

9

7

6

time [s]

5

4

3

2

1

10

0

0 60 120 180 240 300 360 420

time [s]

Page 11

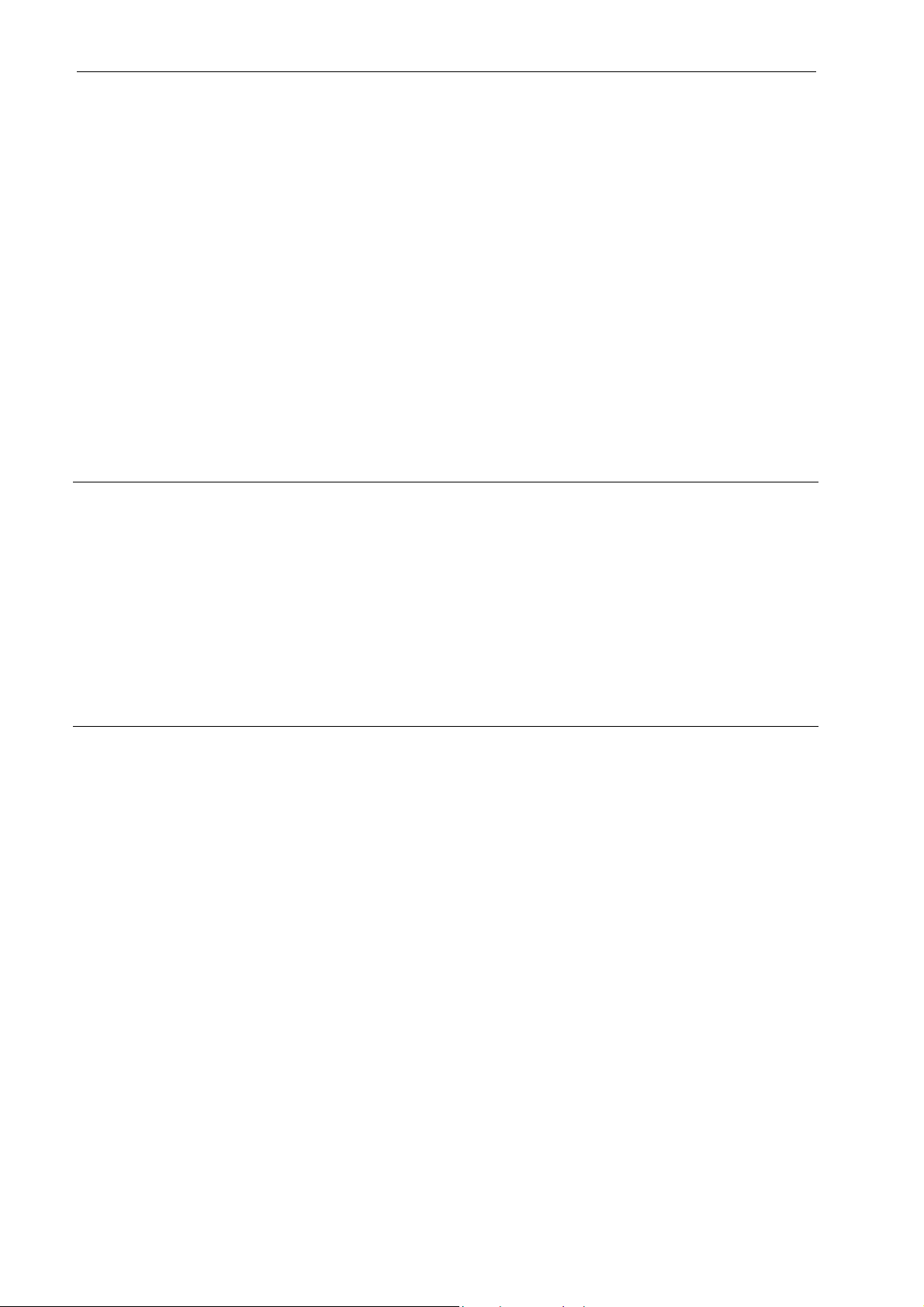

Appendix

Quick Run

release

Quick Run

"ready for

stop

start"

release

display

lid release

lid

open lid

run

start

quick

stop

INSTRUMEN T S

start/stop key

operating temperature

setpoint setting

overtemperature

–

set

setpoint

display,

setpoint

change

left and right digit selection, respectively

temperature,

over-

temperature

run time,

start

delay

temp

time

enter

+

select

∆t

select

delay

copying

into working

memory

∆t

temp

setpoint setting

run time

start delay

delay

time

diagnostic

display

RCF,

display

program display

LEDs

rotor type,

acceleration/

lid open

radius

RCF

rotor

speed

accel

radius

assignment LEDs

rcf

decel

rotor

radius

select

radius,

special

messages

rcf

speed

accel

decel

braking

curves

select

"select" keys

rotor type

call

program

storage

mode

speed

store

mode

program

execute

unbalance

storage in memory

check lid

imbalance

system check

progr.error

overtemp.

progr.mode

A

acceleration

B

C

Megafuge 1.0RS

deceleration

program number selection

key-operated switch

error

check

system

programming

over-

temperature

11

Page 12

Appendix

Contents

User interface "Sepacontrol" .........................................................................................2

Key-operated switch.....................................................................................................................................2

If you are in a hurry: Setting the centrifugation conditions without storing the parameters.........................2

Entering parameters.................................................................................................................................3

Operation without program ..........................................................................................................................3

Display..........................................................................................................................................................4

Actual values ............................................................................................................................................4

Setpoint values.........................................................................................................................................4

Program settings ..........................................................................................................................................5

Entering settings for multiple runs (permanent storage in the program memory) ...................................5

A Opening the program memory before

B Opening the program memory after setting the run parameters ..........................................................5

Operation with program ...............................................................................................................................5

Program run as stored..............................................................................................................................5

Program run with modifications................................................................................................................5

"Quick-Run" operation..................................................................................................................................6

Appendix ..........................................................................................................................7

Diagnostic LEDs...........................................................................................................................................7

Malfunctions – measures for self-help .........................................................................................................7

Technical data of "Sepacontrol"...................................................................................................................9

Acceleration and braking curves............................................................................................................... 10

Acceleration curves ............................................................................................................................... 10

Braking curves....................................................................................................................................... 10

setting the run parameters .......................................................5

12

Page 13

Kendro Laboratory Products GmbH

Postbox 15 63

D-63405 Hanau / Germany

Telephone:

(+49) 61 81/ 35-300

Telefax:

(+49) 61 81/ 3 57 49, Sales

(+49) 55 22/ 31 62 76, Service

Telephone:

(+49) 55 22/ 31 62 22, Service

In the interest of continuous product

development, we reserve the right to

make changes without express notice.

20056899 Mega S_GB 10/98

Printed in Germany

Loading...

Loading...