Page 1

Biofuge

Instructions for Use

Page 2

How to use this manual

Use this manual to get acquainted with your

centrifuge and its accessories.

The manual helps you to avoid inappropriate handling.

Make sure to keep it always close to the centrifuge.

A manual that is not kept handy cannot provide

protection against improper handling and thus

against damage to persons and objects.

The manual comprises chapters on

• Safety regulations

• Instrument description

• Rotor program and accessories

• Transportation and hook-up

• Use of the centrifuge

• Maintenance and care

• Troubleshooting

• Technical data

• Index

Overleaf you will find a graphic

representation of the control panel

with a survey of the most important

functions

Please fold out

Page 3

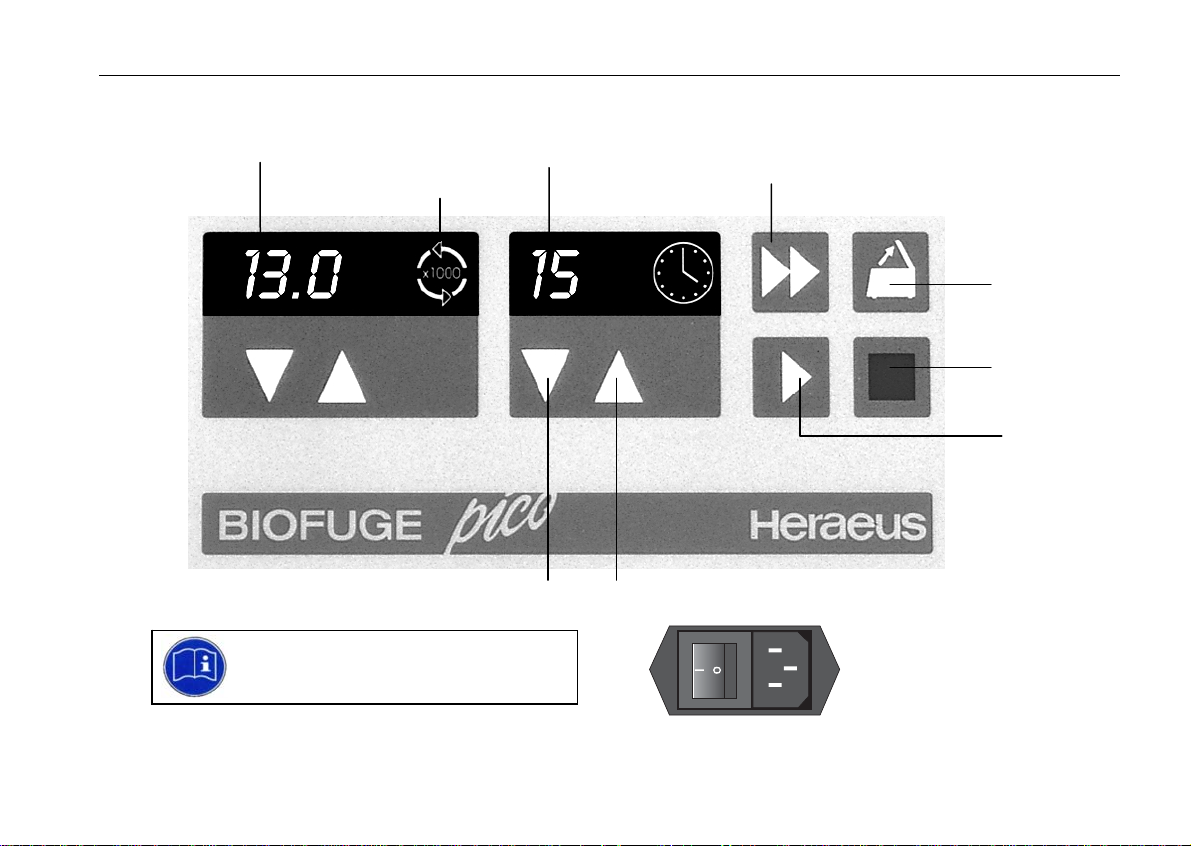

speed

rotor turns

Before switching on the centrifuge

please read this manual

time

"set" keys

quick run

open lid

stop

start

back panel:

socket for mains connection

mains switch

Page 4

The control panel of the

Biofuge pico

Display

Speed

Resting state: preselected speed

During run: current speed; rotating light: rotor turns

End: "End"

Running/resting: error codes (if present)

Time

Resting/end: preselected run time (in minutes; in

"hold" mode, "hd")

During run: remaining run time or (with quick start)

run time passed

Lid open: "OP"

Keys

Start: normal start

Stop: manual stop

Open lid: open lid

(possible only with mains switch ON)

Quick run: short-term acceleration as long as key is

pressed, with indication of run time passed

"Set" keys: stepwise increase/decrease of preset

values, accelerated change when pressed permanently

Short pressing of any of the "set" keys: switch from

current to preset value

Error codes (troubleshooting see chapter

"Troubleshooting")

E-0: motor blockage (transport protection removed?)

E-8: excess voltage

E-10: internal error

E-11: internal error

br: power turned off during run or power failure

Lid: lid turned loose or opened during run;

drive overheated

OP: with lid closed: safety circuit triggered (drive

overheated)

Warnings can span several display panels

Page 5

Contents

Contents

For your safety............................................ 3

Proper use................................................................ 3

Improper use............................................................3

Centrifuging hazardous materials............................3

Handling the centrifuge............................................4

Conformity to current standards............................... 5

Safety instructions in this manual ............................ 5

The Biofuge pico ........................................ 7

Safety systems......................................................... 7

Properties................................................................. 8

„Quick run“ operation ............................................... 8

Pieces delivered.......................................................9

Accessories .............................................. 11

Rotor program........................................................ 12

Adapters for rotor order no. 7500 3328 .................13

Before use................................................. 15

Where to install the centrifuge ............................... 15

Mains connection...................................................15

Removing the transport protection.........................15

Operation .................................................. 17

Transport and installation....................................... 17

Mains connection...................................................17

Opening the lid....................................................... 18

Emergency lid release ........................................... 18

Inserting the rotor................................................... 20

Permissible rotor temperature............................21

Lifetime of the rotor ............................................ 21

Removing the rotor................................................. 22

Loading the rotor.................................................... 22

Maximum loading ............................................... 22

Filling the centrifuge tubes ................................. 23

Aerosol-tight application......................................... 24

Checking for aerosol tightness............................... 25

Placing the tubes in the rotor................................. 26

Selecting the speed................................................ 27

Selecting the run time ............................................ 27

Preselected run time .......................................... 27

Continuous operation.........................................28

Starting the centrifuge............................................ 28

Changing the settings during the run..................... 28

Stopping the centrifuge.......................................... 29

Stopping with preset time................................... 29

Stopping with continuous operation................... 29

Short-time centrifugation........................................ 29

RCF value .............................................................. 30

Turning off the centrifuge....................................... 31

WEEE Compliance:................................................ 31

1

Page 6

Contents

Maintenance and care .............................. 33

Maintenance to be performed by the customer .....33

Cleaning..............................................................33

Disinfection......................................................... 34

Decontamination.................................................36

Autoclaving.........................................................36

Check whether autoclaving is permitted! ...........36

The Thermo Electron Service offer........................37

Warranty conditions ...............................................37

Troubleshooting .......................................39

Problems you can handle yourself.........................39

In case you must call the Service...........................44

Technical data...........................................46

Component parts and performance.......................46

The "Easycontrol" user interface............................49

Electrical connections / fuses.................................51

Index..........................................................53

Autoclaving protocol................................59

Speed / RCF diagrams..............................60

2

Page 7

For your safety

For your safety

Heraeus centrifuges are manufactured according to

current technical standards and regulations. Nonetheless, centrifuges may pose danger to individuals and

surrounding if

• they are not used as designed

• they are operated by untrained personnel

• their design is improperly changed

• the safety instructions are not followed

Therefore, personnel involved with operation and

maintenance of the centrifuge must read and follow the safety instructions.

In addition, the pertinent regulations for prevention of

accidents must be strictly followed.

This manual is an integral part of the centrifuge assembly and must be kept close at

hand at all times.

When damages to the power cord or at

casing are noticed the centrifuge must

to be set out of operation!

Proper use

The centrifuge is designed to separate liquidsuspended materials having different densities and

particle size, respectively (maximum sample density is

1.2 g/cm³ {ml} at maximum speed).

Improper use

During a run, a safety zone of 30 cm around the centrifuge must be maintained where neither persons nor

hazardous materials may be present.

The centrifuge may cause harm to its user or other persons or may damage goods if safety measures are not

followed

:

Centrifuging hazardous materials

• The centrifuge is neither made inert, nor is it explosion-proof. Therefore never use the centrifuge in an

explosion-prone environment.

• Do not centrifuge explosive or flammable substances. The same holds for substances prone to

react violently with each other.

3

Page 8

For your safety

• Do not centrifuge toxic or radioactive substances or

pathogenic microorganisms without suitable safety

systems.

If microbiological samples of risk group II (according

to "Laboratory Bio-safety Manual" of WHO) are being centrifuged, aerosol-tight bio-seals have to be

used.

For materials in a higher risk group, more than one

precaution is required.

• Should toxins or pathogenic substances enter the

centrifuge or its parts, you must perform appropriate

procedures for disinfection (see "Maintenance and

care – Disinfection").

• Strongly corrosive substances that may cause damage to materials and reduce the mechanical

strength of the rotor may be centrifuged only inside

protective tubes.

Handling the centrifuge

• Use only original accessories for the centrifuge. The

only exceptions are common glass or plastic centrifuge tubes if they are approved for the rotor speed

and RCF values.

• Never use the centrifuge unless the rotor is properly

installed.

• You may use the centrifuge only with a properly

loaded rotor. You must not overload the rotor.

• Strictly follow the rules and regulations for cleaning

and disinfection

• If the rotor or the rotor lid shows signs of corrosion

or

wear, you must stop using it.

• Never open the lid manually if the rotor is still turning.

• You may use the emergency lid release only in

case of emergency, e.g. during an interruption of

power supply

(see chapter "Troubleshooting").

• Never use the centrifuge with an opened lid.

• Never use the centrifuge if the front panel has been

partially or totally removed.

• Changes in mechanical or electrical components of

the centrifuge may only be carried out by individuals

authorized by Thermo Electron.

4

Page 9

For your safety

Conformity to current standards

Heraeus centrifuges are manufactured and tested

according to the following standards and regulations:

for all voltages:

• IEC 1010-1 / EN 61010-1

• IEC 1010-2 / EN 61010-2-020

− Pollution degree 2

− Overvoltage category II

for 120 V only:

• CAN/CSA-C22.2 No. 1010.1-92

• CAN/CSA-C22.2 No. 1010.2.020-94

Safety instructions in this manual

This symbol denotes potential hazards to

persons.

This symbol denotes potential damage to

the centrifuge or parts in its immediate surroundings.

General hints are marked with this symbol.

Before switching on the centrifuge please

read this manual

5

Page 10

For your safety

for your notes

6

Page 11

The Biofuge pico

The Biofuge pico

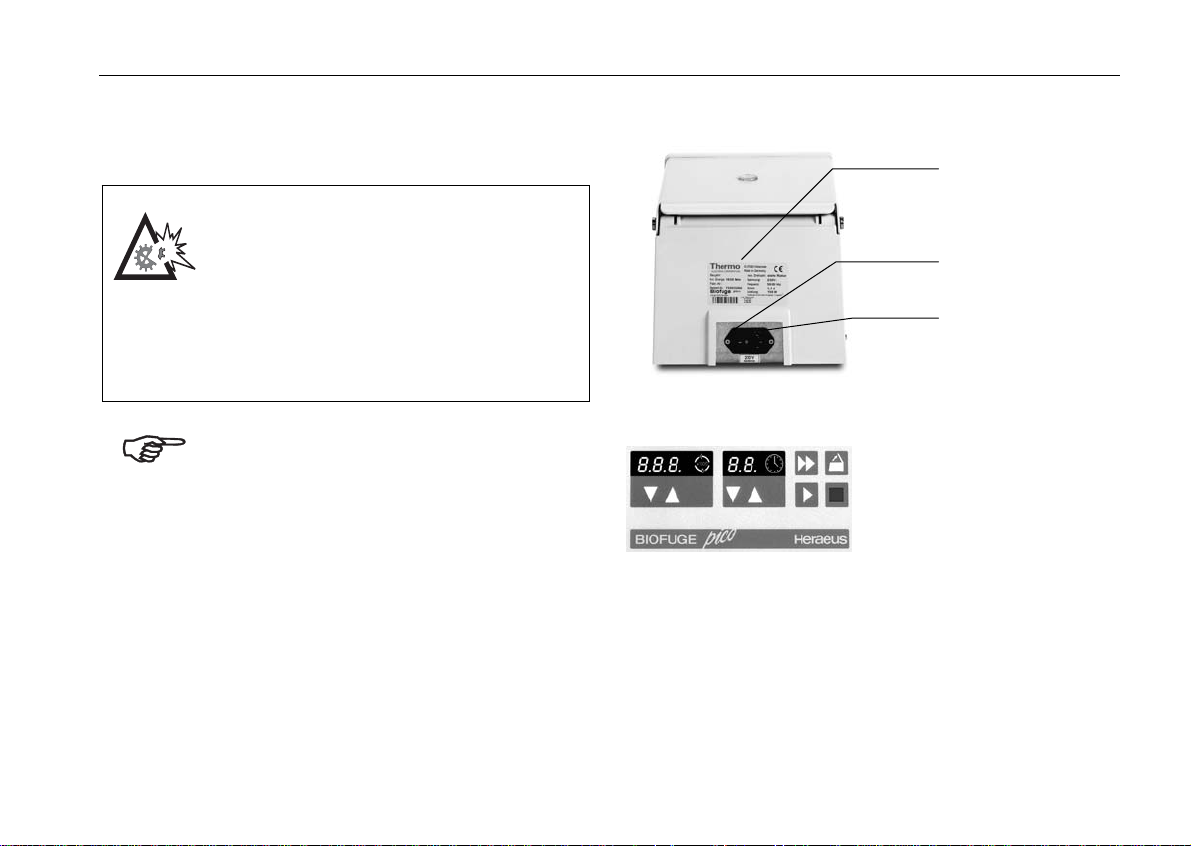

The figure below shows the Biofuge pico with the lid

opened and the rotor put in place.

Safety systems

The Biofuge pico is equipped with a number of safety

systems.

• Connection rotor – motor

• Body and rotor chamber made from impact-

resistant plastic

• Lid with hinge and control window

• Lid lock mechanism

You can open the lid only when the power is turned

on and the rotor has come to a halt. You can start

the centrifuge only if the lid is properly locked.

• Warning if lid is manually opened during a run (sa-

fety circuit actuated)

If the lid is manually opened during a run, or if the

temperature of the drive exceeds a critical value, a

corresponding message appears in the display("Lid" and "OP", respectively).

• Emergency lid release (only in case of emergency)

In order to permit you to remove samples even after

a power failure, the centrifuge is equipped with an

emergency lid release. (see chapter "Operation").

Do not tamper with the safety systems!

7

Page 12

The Biofuge pico

Properties

The Biofuge pico is a benchtop centrifuge for use in the

biochemical and medical laboratory.

The preset speed is reached in seconds. You can also

spin samples for only a few seconds using the "quick

run" key (

The extremely long-lived, maintenance-free induction

motor provides quiet and vibration-free operation even

at high speeds.

The user-friendly "Easycontrol" control panel permits

easy operation. With the centrifuge turned on and the

lid closed, the preset speed and run time are displayed

before the run. During operation, the control panel

shows the actual values; upon briefly pressing any one

of the "set" keys

and run time are displayed instead. After the run, the

"speed" panel displays "End".

If you press the

the corresponding preset value stepwise. If you press

and hold down the chosen key, the respective value

increases continuously, at first slowly and, after a few

seconds, at an accelerated pace.

You can change the preset values during operation.

) if this is required for the task in question.

or the preset values for speed

or keys repeatedly, you increase

„Quick run“ operation

As long as the "quick run" key ( ) is pressed, the rotor is accelerated with maximum power, potentially up

to the maximum speed (overriding any preset speed

value).

8

Page 13

The Biofuge pico

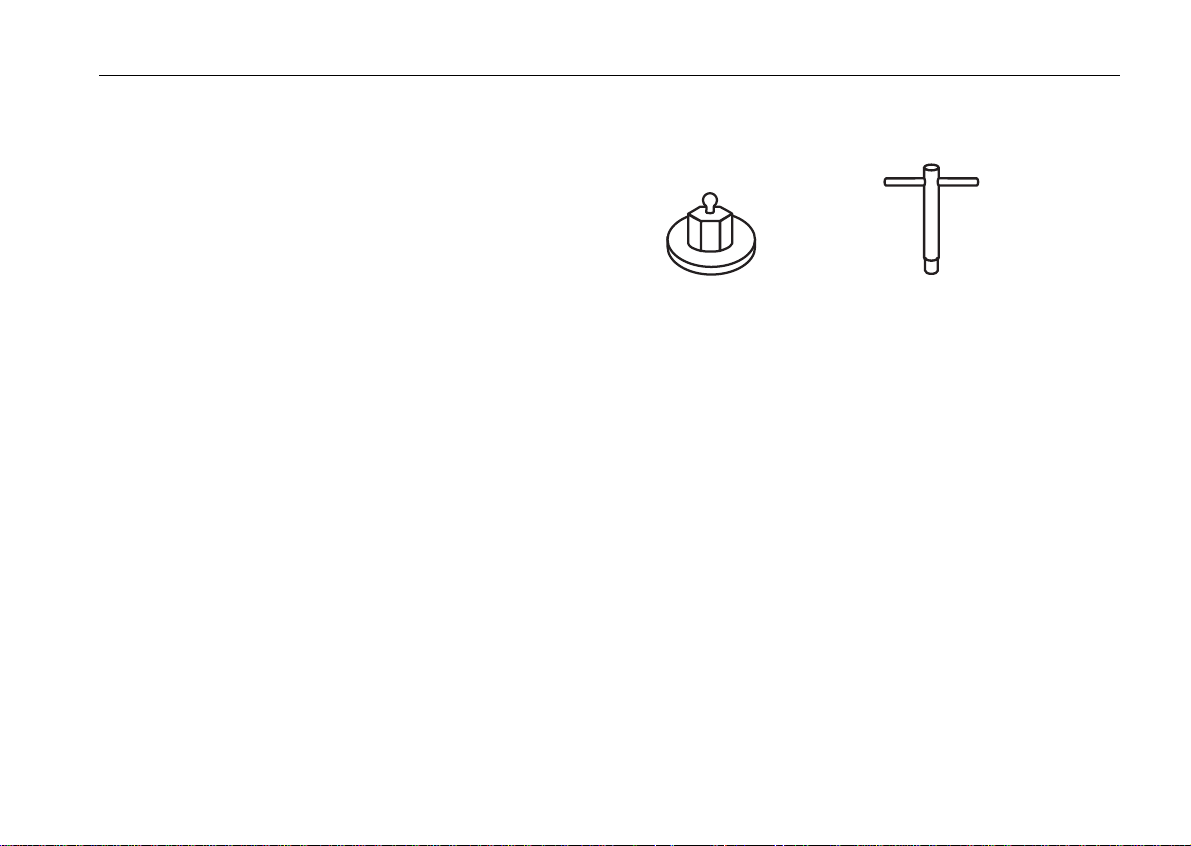

Pieces delivered

The Biofuge pico is delivered complete with:

• a special cap nut for fixing the rotor

• 10-mm tubular socket wrench for fastening the

cap nut

• fixed-angle rotor 24 x 1,5 / 2 ml 7500 3328

• cable for mains connection

• this Manual

cap nut

order no.

70056208

tubular socket

wrench

order no.

2036 0072

9

Page 14

The Biofuge pico

for your notes

10

Page 15

Accessories

Accessories

The Biofuge pico is delivered complete with a fixedangle rotor with 24 holes for placing microliter tubes

with a volume of 1.5 or 2.0 ml.

In addition you may order three sets of adapters containing 24 reduction sleeves each. With these adapters

you can centrifuge all commercially available microliter

tubes with a volume between 0.2 and 0.6 ml as well as

0.2-ml PCR reaction vessels.

A further option is a PCR-Strip rotor.

Please consult our sales documentation for a complete

collection of accessories including technical data, order

numbers and special low-cost package offers.

For more information you can visit our web site at

http://www.Thermo.com

11

Page 16

Accessories

Rotor program

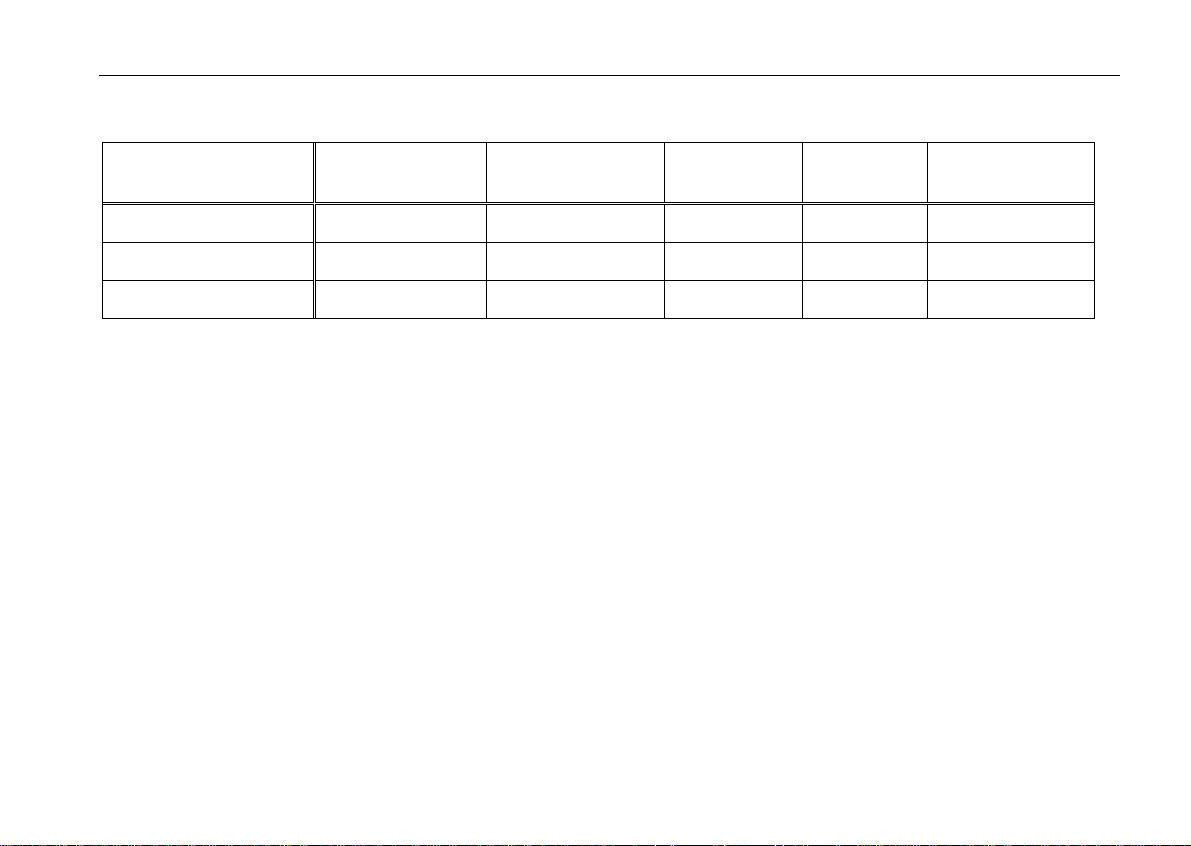

Rotor designation

Microliter rotor

PCR-rotor

24 x 2 ml PP

order no.

7500 3328 7500 3327

places / volume 24 x 1,5 / 2 ml 4 x PCR-Strip

maximum permissible load [ g ] 24 x 4 4 x 4 ( 32 x 0,5 )

maximum speed n

minimum speed n

maximum RCF value at n

[ min-1 ] 13 000 13 000

max

[ min-1 ] 2 000 2 000

min

16 060 12 846 ( 11 524* )

max

maximum radius [ cm ] 8,5 6,8 ( 6,1* )

minimum radius [ cm ]

5,9 6,1 ( 4,7* )

angle [ ° ] 40 45

acceleration / deceleration time [ s ] 15 / 12 15 / 12

aerosol-tight yes (reduced filling) yes (reduced filling)

permissible temperature range

autoclavable (number of cycles)

* The values relate to vessel places 4 and 5 in the PCR-Rotor

-4 °C to +40 °C

121°C, (10 cycles)

-4 °C to +40 °C

121°C, (10 cycles)

12

Page 17

Adapters for rotor order no. 7500 3328

Accessories

Adapter Dimensions

(∅ x H)

reduction sleeve PCR 6,2 x 20 mm 0,2 ml 24 gray 7600 3750

reduction sleeve 8 x 43,5 mm 0,5/0,6 ml 24 turquoise 7600 3758

reduction sleeve 6 x 46 mm 0,25/0,4 ml 24 red 7600 3759

Capacity Number per

Set

Color Order No.

13

Page 18

Accessories

for your notes

14

Page 19

Before use

Before use

Where to install the centrifuge

The centrifuge must be operated in a place meeting

the following criteria:

• A safety zone of 30 cm around the centrifuge must

be maintained. Hazardous materials must not be

kept within this zone during centrifugation.

• The substructure must be stable and resonancefree. A good support is provided by a plane laboratory bench or a large laboratory carriage with casters that may be locked.

• To ensure sufficient air circulation, a minimum distance from the wall of 10 cm at the back and of

15 cm on each side must be kept.

• The centrifuge must be protected from heat and direct sunshine.

• The location should be well ventilated.

Mains connection

Make sure that voltage and frequency correspond to

the specifications on the instrument label.

Turn the mains switch on the back panel off (press

"0"); only then connect the centrifuge with the mains

supply using the power cord supplied with the instrument.

Removing the transport protection

Turn the instrument on. The display panel shows for

about 12 s the routine internal software check sequence. Open the lid by pressing the "open lid" key

and remove the transport protection for the rotor.

Check that the rotor moves freely by lightly turning it,

and make sure the rotor is tightly screwed on.

The Biofuge pico is now ready for use.

15

Page 20

Before use

for your notes

16

Page 21

Operation

q

y

Operation

Transport and installation

Damage to the centrifuge by jolts

or jerky placement!

Transport the centrifuge only in the

upright position using the special

box provided with the instrument

and secure it properly. Place the

Mains connection

Make sure that your mains voltage and frequency

match the specifications on the instrument. Turn off the

mains switch on the back panel (push down the "0"

mark), then connect the instrument to the mains supply.

Turn on the mains switch at the back of the centrifuge.

centrifuge carefully.

Before using the centrifuge, make sure that

the transport protection has been removed!

type plate with voltage

uenc

and fre

mains switch

socket for mains

cable

For a couple of seconds the following reading appears

in the control panel:

This tells you that the instrument carries out an internal check of its software.

(see table on page 44).

After this check the display changes. The values now

shown in the display panel are the ones last used.

The following figure gives an example of possible readings. A detailed description of possible settings is given

below.

17

Page 22

Operation

In this example, the preset speed is 5,000 rpm

and the preset run time

is 10 min.

Opening the lid

For normal electrical unlocking, connect the centrifuge

to the mains supply, turn the mains switch on and push

the "open lid" key

.

Emergency lid release

In case of a power failure you cannot open the lid normally using the "open lid" key. To permit unloading

even in this case, the centrifuge is equipped with a

mechanical lid unlocking system. However, you may

use this system only in case of emergency.

Rotor can spin at high speed!

Touching it may cause severe injuries!

Always wait for several minutes until

the rotor has come to a complete

stop. Without power the brake does

not function, and braking takes

much longer than normal!

Should it be necessary to open the lid manually, proceed as follows using an appropriate tool:

1. Make sure the rotor stands still. (control window).

2. Unplug the mains plug.

3. Push a 7-cm end of thin wire, e.g. a bent-up paper

clip or another suitable tool, through the hole on the

18

Page 23

Operation

upper right of the front panel (see figure). Push the

lock bolt back until the lid unlocks audibly. Remove

the auxiliary tool and open the lid.

4. In case the rotor still turns, close lid immediately

and wait until it has come to a complete stop.

Never brake the rotor using your

hands or tools!

5. As soon as the rotor stands still, remove your samples and close the lid.

Emergency

lid release

19

Page 24

Operation

Inserting the rotor

Improper or improperly combined

accessories may cause severe damage to the centrifuge!

Rotors which are allowed for use in a Biofuge pico centrifuge are detailed in the chapter "Accessories", and

only these rotors are to be used in this centrifuge.

To insert the rotor you will need the cap nut and the

socket wrench delivered with the centrifuge (see the

chapter “The Biofuge pico – Pieces delivered”).

Possible damage to drive and rotor!

You may insert the rotor only if the

temperature of the drive, the rotor

and the cap nut is between 10 °C

and 30 °C.

Proceed as follows:

1. Open the lid and make sure that the rotor chamber

and the rotor are clean. Remove eventual dust, foreign material or sample residues. The thread and

the O-Ring on the motor shaft must be in perfect

condition.

2. Turn the rotor so that the notch for engaging the

drive shaft points downward.

3. Place the rotor on top of the drive shaft so that the

notch of the rotor is located precisely above the retaining pin.

4. Push the rotor gently down until the thread is completely laid bare (see figure).

20

Page 25

Operation

5. If you have placed the rotor correctly, you can

screw on the cap nut easily and secure it with the

tubular socket wrench delivered with the instrument.

6. Place the rotor cap onto the rotor.

Do not push the rotor down using

force. If you cannot screw on the

cap nut, you must carefully lift off

the rotor and insert it again.

Regularly check the proper positioning of

the rotor and retighten the cap nut as needed.

Permissible rotor temperature

The rotors are only to be used

within the temperature range from 4oC to +40oC. Pre-cooling in the

freezer is not permitted

Lifetime of the rotor

There is no limitation on the service life of the high performance rotors. However please observe the following

due to safety reasons:

Rotors and accessories made of

plastic should not be exposed to

direct sunlight and UV rays!

If the rotor shows signs of discoloration, deformation or wear, or is out

of balance it must be exchanged

straight away!

21

Page 26

Operation

Removing the rotor

To remove the rotor, you must follow the steps described above in reverse order.

With the hermetic lid, you may in case of contamination

separate the rotor from the drive without opening the

lid! In this case you can open rotor upon removal from

the centrifuge using e.g. a safety work bench before

decontaminating it.

Danger of irreparable motor damage!

Never tilt the rotor. Always grab it in

the middle and pull out perpendicularly.

1. Open the lid of the centrifuge.

2. Screw the cap nut open by turning it counterclockwise using the socket wrench delivered with the instrument. Remove the cap nut.

3. Grab the rotor in the middle and pull gently upwards

off the drive shaft. Be careful not to jam it.

Loading the rotor

Maximum loading

Overloading may cause the rotor to

explode! Exploding parts may severely damage the centrifuge!

Never exceed the maximum permissible load of 4 g per place.

The Biofuge pico can reach high rotational speeds implying enormous centrifugal force. The rotors are designed in a way warranting sufficient residual strength

even at the highest permissible speed.

However, this safety system presupposes that the

maximum permissible load of the rotor is not exceeded.

If you wish to centrifuge samples that together with the

adapters exceed the maximum permissible load, you

must either reduce the sample volume or calculate the

permissible speed n

mula:

according to the following for-

perm

22

Page 27

Operation

n

perm

n= ∗

max

maximum permissible load

actual load

Filling the centrifuge tubes

Check carefully whether your sample vessels are permissible for the

respective g value and reduce the

speed if necessary.

The smaller the unbalance of the centrifuge, the better

the separation since separated zones are no longer

perturbed by vibration. It is therefore important to balance the centrifuge tubes as well as possible.

To minimize unbalance you should fill the tubes as

evenly as possible. You can achieve this by eye. However, you must nonetheless ensure that opposite tubes

are filled to the same level.

Please note that plastic sample vessels only

have a limited service life - particularly when

used at maximum rpm or temperature - and

must be replaced as necessary!

23

Page 28

Operation

Aerosol-tight application

not with open container lids!

The following steps have to be carried out:

• Lubricate the seals before inserting them (lubricant

order no. 75003500)

• Insert the seal (C profile) in the groove at the side

of the body of the rotor.

• Insert the O-ring into the inner groove on the

screw-on top.

Attention :

Please check that your sample containers are suitable

for the centrifugal application desired.

(16060 x g ; temperature in uncooled devices approx.

10 K above room temperature)

Please observe the permissible filling volumes!

Nominal volume: Permissible volume:

2.0 ml - 1.5 ml

1.5 ml - 1.0 ml

others -

2

/3 nominal volume

The sealing elements are to be checked regularly for

damage to the shape and surface!

Exchange faulty parts immediately.

Spare sealing rings 75003268

24

Page 29

Operation

Checking for aerosol tightness

The checking of the rotor type and bucket was done

according to the dynamic microbiological test procedure with regard to EN 61010-2-020 appendix AA.

The aerosol-tight bio-containment of the rotor mainly

depends on proper handling!

Check the aerosol-tight bio-containment

of your rotor whenever necessary!

It is very important that all the seals and

seal-surfaces are carefully inspected for

wear and damages like cracks, scratches

and embrittlements!

For a quick test one can check the aerosol-tight buckets and fixed angle rotors according to the following

procedure:

• Slightly grease all seals.

• Fill the bucket or rotor with approx. 50 ml carbon

dioxide mineral water.

• Close the bucket or rotor according to the respec-

tive handling instructions.

• Shaking the bucket releases the carbon dioxide of

the water, and an excessive pressure is built up.

• Leaks are recognized by humidity release and au-

dible disinflation of gas mix.

• Finally buckets respectively rotor, lid and lid seal

have to be dried.

25

Page 30

Operation

Placing the tubes in the rotor

The rotor must be loaded symmetrically. When loading

the rotor only partially, you must ensure that opposite

bores always receive tubes of equal weight (when centrifuging a single sample, place a centrifuge tube e.g.

filled with water). The following figure gives examples

for proper loading.

properly loaded rotors

Improper loading can in the worst

case lead to damage to rotor and

centrifuge. Unbalance not only

causes a noisy run, but rapidly damages the motor suspension.

improperly loaded rotors

When you have loaded the tubes, fasten the rotor lid

by screwing the cap nut centrally on it.

Close the lid of the centrifuge by firmly pressing it

down. There must be a clicking sound, and the lid must

be locked so that it cannot be opened manually.

26

Page 31

Operation

Selecting the speed

The centrifuge can be set to a minimum of 2000 min-1

and to a maximum of 13 000 min

processor prevents higher or lower speed settings. Between these extremes, you can select the speed in

steps of 100 rpm using the following procedure:

1. Press one of the "set" keys

(for a decrease) in the "speed" section of the

control panel (see also the foldout page in the cover).

By pressing the selected key

briefly, you increase or decrease the speed in steps of

100 rpm. This option is supposed to be used for small

changes and fine tuning.

2. If you keep the key pressed, the display changes at

first slowly and after a few seconds at an accelerated pace.

3. Release the key as soon as you have reached the

desired value, and fine tune if necessary by repeatedly pressing one of the keys. The digit after the

decimal point flashes for a number of seconds, then

changes to permanent display. The speed is now

stored.

-1

. The built-in micro-

(for an increase) or

Selecting the run time

You can select a run time between 1 and 99 min or

continuous operation.

Preselected run time

To predetermine the run time, proceed as follows:

1. Press one of the "set" keys

(for a decrease) in the "time" section of the con-

trol panel (see also the foldout page in the cover).

By pressing the selected key

briefly, you increase or decrease the preset run time in

steps of 1 min. This option is

supposed to be used for small

changes and fine tuning.

2. If you keep the key pressed, the display changes at

first slowly and after a few seconds at an accelerated pace.

3. Release the key as soon as you have reached the

desired value, and fine tune if necessary by repeatedly pressing one of the keys. The minute display

flashes for a number of seconds, then changes to

permanent. The run time is now stored.

(for an increase) or

27

Page 32

Operation

Continuous operation

To operate the Biofuge pico in the continuous mode,

you must press the key

until the display changes to

„hd“ (for "hold").

With this setting, the centrifuge keeps running until

stopped manually.

Please note that the lifetime of plastic tubes

in particular is limited. Extended use may

damage them.

Starting the centrifuge

Once the rotor is in place, the mains switch turned on

and the lid closed, you can start the centrifuge.

Press the "start" key

in the control panel. The centrifuge accelerates to the preselected value. Simultaneously, the run time display starts going backward from

the preset time, giving the remaining run time in minutes. After reaching the last minute, the display

switches to seconds remaining. During the run, the rotating light in the "speed" panel signals that the centrifuge is running. During the run you cannot open the lid.

Changing the settings during the run

You can change the settings during a run. The respective altered setting flashes for a couple of seconds.

Once the display changes to the continuous mode, the

new settings become operative.

28

Page 33

Operation

Stopping the centrifuge

Stopping with preset time

Normally the run time has been preselected, and all

you have to do is wait until the centrifuge terminates

the run automatically. As soon as the speed is down to

zero, the display reads "End". By pressing the "open lid

" key

samples.

You can stop the centrifuge at any time by pressing the

"stop“ key

Stopping with continuous operation

If you have chosen continuous operation, you must

stop the centrifuge manually. Press the "stop" key

the control panel. The centrifuge starts braking at once

and stops within a few seconds. The display reads

"End", the electrical lid unlocking mechanism is available. You can now open the lid by pressing the "open

lid" key

, you can now open the lid and remove your

.

in

and remove your samples.

Short-time centrifugation

For short-term operation, the Biofuge pico is equipped

with a "quick run" function.

Short-term centrifugation is started by pressing the

"quick run" key

key is released.

In this mode the centrifuge accelerates with full power

up to the maximum speed of 13,000 rpm unless you

release the "quick run" key

nored.

The centrifuge accelerates to the

maximum speed of 13000 min

Check carefully whether you have to

maintain a specific speed for your

application.

During acceleration the time is counted forward in seconds. After 60 seconds the display changes to the minute mode.

continuously; it stops as soon as the

The preset speed is ig-

-1

.

29

Page 34

Operation

RCF value

The relative centrifugal force (RCF) is usually given in

multiples of the earth gravity g. It is a dimensionless

number that allows one to compare the efficiency of

separation or sedimentation of diverse instruments,

since it is independent of the instrument used. The only

values entered in the equation are radius and speed of

centrifugation:

2

n

⎛

⎞

RCF

.

⎜

⎝

r = radius of centrifugation in cm

n = speed in rpm

At a speed of 13000 min-1, the centrifuge achieves a maximum performance of 16060 g!

Check carefully whether your tubes

are designed for this centrifugal

force, and reduce the speed if necessary.

1000

∗1118

r=∗

⎟

⎠

The figure for the maximum RCF value is based on the

maximum radius of the tube.

Please note that this value becomes lower

depending on the tubes and adapters used.

You may take this into account when calculating the

RCF value for your application.

The figure on the last page of this manual gives a

graphic representation of the relation between speed

and RCF.

Apart from the maximum RCF value RCF

(lower li-

max

ne) this graph also shows the minimum RCF value

RCF

, calculated for the meniscus of the sample (up-

min

per line).

30

Page 35

Operation

Turning off the centrifuge

The centrifuge is turned off by switching the main

switch into the "0"position.

The main power switch should be turned off

after a complete centrifugation run. Without

motor deceleration, it takes much longer until the rotor comes to a halt.

The centrifuge lid can only be opened automatically if

the centrifuge is turned on!

WEEE Compliance:

This product is required to comply with the European

Union`s Waste Electrical & Electronic Equipment

(WEEE) Directive 2002/96/EC. It is marked with the following symbol:

Thermo Electron has contracted with one or more recycling/disposal companies in each EU Member State,

and this product should be disposed of or recycled

through them. Further information on Thermo Electron`s compliance with these Directives, the recyclers

in your country, and information on Thermo Electron

products wich may assist the detection of substances

subject to the RoHS Directive are available at

www.thermo.com/WEEERoHS.

31

Page 36

Operation

for your notes

32

Page 37

Maintenance and care

Maintenance and care

Maintenance to be performed by the

customer

For the protection of persons, environment and material you are obliged to clean the centrifuge regularly

and to disinfect it if necessary.

Unsuitable cleaning agents or disinfection procedures may damage the

centrifuge and its accessories!

If you intend to use cleaning agents

or disinfection procedures not recommended by the manufacturer,

you have to make sure by consulting the manufacturer, that the procedure foreseen does not cause any

damages to the instrument!

Cleaning

Pull mains plug before cleaning the

Clean the casing, the rotor chamber, the rotor and the

accessories regularly and in case of need. This is indicated both for reasons of hygiene and to prevent corrosion due to contamination sticking to the instrument

and its accessories.

Clean them with mild agents of pH values ranging from

6 to 8.

Immediately after cleaning, dry the aluminum parts or

put them into a warm-air dryer at a temperature not exceeding 50°C.

instrument!

During cleaning liquids and especially organic solvents should not

come into contact with the drive

shaft and the ball bearing.

Organic solvents may decompose

the lubricant of the motor bearing.

The drive shaft may block.

33

Page 38

Maintenance and care

Disinfection

If a centrifuge tube containing infectious material leaks

during a run, you have to disinfect the centrifuge immediately.

Infectious material could enter the centrifuge if spills or tube breakage occur

Danger of infection may occur upon con-

! Take appropriate protective meas-

tact

ures for personnel!

Mind the permissible filling volumes and

loading limits for the tubes

In case of contamination the operator has

to make sure, that no further persons are

jeopardized

Contaminated parts have to be decontaminated immediately

If required further protective measures

have to be initiated

!

.

!

.

.

Rotor and rotor chamber must be treated with a neutral, universal disinfectant. Best suited for this purpose

are disinfectant sprays, ensuring that all rotor and accessory surfaces are covered evenly.

Please note the safety measures

and handling hints when applying

these substances!

• You may disinfect the rotor and the accessories as

described in the following section. Be sure to follow

the pertinent safety procedures for handling infectious material.

1. Pull mains plug.

2. Unscrew the rotor chuck.

3. Grab the rotor with both hands and pull it perpen-

dicularly off the drive shaft.

34

Page 39

Maintenance and care

4. Remove the centrifuge tubes and adapters, and disinfect them or dispose of them as necessary.

5. Treat the rotor and the rotor lid according to the instructions given for the disinfectant (soaking in liquid or spraying). You must strictly observe the

specified action times!

6. Turn the rotor head down and drain off the disinfectant. Thereafter thoroughly rinse rotor and lid with

water.

7. Dispose of the disinfectant according to valid regulations.

8. Aluminum rotors have to be treated with anticorrosive protective oil subsequently.

Disinfection with bleaching lye

These agents contain highly aggressive hypochlorites and must not be

used with aluminum rotors!

The following precautionary measures are to be taken

for extensive protection of the 7500 3327 and

7500 3328 rotors:

1. Avoid high temperatures!

The bleaching solution and the rotor should not be

warmer than ca. 25 °C.

2. Do not let the bleaching solution act longer than absolutely necessary!

3. After disinfection, rinse the rotor thoroughly with distilled water and allow to dry.

35

Page 40

Maintenance and care

Decontamination

For general radioactive decontamination, use a solution of equal parts of 70% ethanol, 10% SDS and water. Follow this with ethanol rinses, then de-ionized water rinses, and dry with a soft absorbent cloth.

Dispose of all washing solutions in appropriate radioactive waste containers!

Autoclaving

Check whether autoclaving is permitted!

You may autoclave the rotor and the adapters at

121 °C.

Maximum permissible autoclaving cycle:

20 min at 121 °C.

For safety reasons, the 7500 3327 and

7500 3328 rotors must only be subjected

to a maximum of 10 autoclavings!

The rotor must be cleaned and rinsed with distilled water before being autoclaved. Remove the rotor lid, the

centrifuge tubes and the adapters. Place plastic rotors

on an even surface to avoid deformation.

Chemical additives to the steam are not

permitted.

Never exceed the maximum permissible values for autoclaving temperature and autoclaving time.

Should the rotor show signs of

wear, you must stop using it!

36

Page 41

Maintenance and care

The Thermo Electron Service offer

Thermo Electron recommends annual servicing of the

centrifuge and the accessories by authorized customer

service or trained professionals. The customer service

personnel is inspecting:

• the electrical installations

• the suitability of the location

• the lid lock mechanism and the safety circuit

• the rotor

• the rotor fastening and the drive shaft

Defective material is exchanged.

Thermo Electron offers inspection and service con-

tracts covering it. Inspection costs are charged as flatrate contracts.

Necessary repairs are carried out free of cost within

the warranty conditions, and against payment after expiration of the warranty period.

Warranty conditions

The warranty period starts with the day of delivery.

Within the warranty period the centrifuge is repaired or

replaced free of cost if there are provable faults in materials or workmanship.

Conditions for a warranty are:

• the centrifuge is used according to the instructions

of use

• mounting, extensions, settings, alterations or re-

pairs are carried out exclusively by personnel authorized by Thermo Electron

• the required maintenance and care procedures are

carried out regularly.

37

Page 42

Maintenance and care

for your notes

38

Page 43

Troubleshooting

Problems you can handle yourself

If problems other than those described in the following tables arise, you must consult your nearest

Error Behavior of the centrifuge Possible cause(s) and measures to be taken

authorized service.

Troubleshooting

Displays remain

dark

Displays fail

briefly

The motor stops.

The rotor stops without braking.

The lid cannot be opened.

The motor stops suddenly.

The rotor stops without braking.

The display reads "br", see br.

Mains failure or not connected

1. Is the mains switch turned on?

2. Check the mains connection.

3. If the mains connection is OK, call your nearest Service.

Brief interruption of mains supply

1. Check whether the plug is plugged in properly.

2. Wait for 75 seconds.

3. Restart the centrifuge

39

Page 44

Troubleshooting

Error Behavior of the centrifuge Possible cause(s) and measures to be taken

Lid cannot be

opened

Pressing the "open lid" key has

no effect

- Centrifuge is exceptionally noisy.

br Instruments stops without brak-

ing.

A) Lid not correctly engaged or lid warped.

1. Check whether the mains supply is OK and the instrument is

switched on (displays lit).

2. Press the lid down on the right-hand front end and actuate

the "open lid" key once again.

3. In case these measures have not the desired effect, you may

open the lid with the emergency lid release. (see page 18).

B) Heat monitoring relays in the lid unlocking magnets ha-

ve been actuated.

Press the key again after waiting for about 1 min.

1. Stop the centrifuge by pressing the "stop" key

, in case of

emergency pull mains plug.

2. Wait until the centrifuge stands still.

3. Check whether the rotor is properly loaded

4. Check whether a broken vessel, damage to the rotor or motor malfunction was responsible for the noise.

5. If you cannot locate and solve the problem, call Service.

There was a short mains failure, or the instrument was switched

off during the run.

Wait for about 75 seconds; the instrument is then again ready for

use.

40

Page 45

Error Behavior of the centrifuge Possible cause(s) and measures to be taken

Troubleshooting

E-0

E-8

Motor does not start

Overvoltage or over-current at

the U/F converter

E-10

Wrong check sum in the NVRAM

E-11 Error in data transfer from NV-

RAM

Motor or rotor blocked.

1. Switch the instrument off and on again with the mains switch.

2. Open the lid.

3. Check whether the transport protection has been removed.

If you cannot solve the problem, call nearest Service.

Mains voltage outside tolerance. Brake resistance defective.

Switch the instrument off and on again. If the problem persists,

call Service.

Switch the instrument off and on again. If the problem persists,

call Service.

Switch the instrument off and on again. If the problem persists,

call Service.

41

Page 46

Troubleshooting

Error Behavior of the centrifuge Possible cause(s) and measures to be taken

Message "Lid"

appears in the

display

Display "OP“

appears although lid is

closed

Motor stops.

Rotor comes to a stop without

braking.

Start impossible

A) The lid was manually opened during the run.

1. Press the lid shut. The instrument comes to a stop without

braking.

2. If you want to continue the centrifugation, you must switch

the instrument off and on again. The message "br" is displayed and the centrifuge brakes (see br).

B) The excess temperature safety circuit of the motor has

been actuated

1. Pull mains plug.

2. Control ventilation slots underneath the instrument and clean

if necessary.

3. After 20 min you can start the instrument again.

4. If the safety circuit is again actuated, call Service.

A) The lid is not properly closed

Press the lid forcefully down on the right-hand front part.

B) The excess temperature safety circuit of the motor has

been actuated

1. Pull mains plug.

2. Control ventilation slots underneath the instrument and clean

if necessary.

3. After 20 min you can start the instrument again.

4. If the safety circuit is again actuated, call Service.

42

Page 47

Troubleshooting

43

Page 48

Troubleshooting

In case you must call the Service

Should you require our Service, please tell us the order

no. and serial number of the instrument. You find the

pertinent information at the back of the instrument near

the socket for the mains plug.

Moreover it is helpful for our service technician to know

the valid software version. You can determine the software version as follows:

1. Switch the instrument off.

2. Switch the instrument on.

The display reads 888 88 for a couple of seconds.

Subsequently, the display may read e.g. the following readings for 2 seconds each:

Software number

Software version

NV-RAM number

NV-RAM-version

047 8_

_01

104 1_

_01

The values shown above are just examples. Your readings may be different. In the example shown here the

values mean the following:

• Software 0478 version 01

• NV-Ram 1041 version 01

44

Page 49

for your notes

Troubleshooting

45

Page 50

Technical data

Technical data

Component parts and performance

Part / function Description

Body Sheet steel with fitted plastic chassis

Keys and display panel Keys and display panel covered with easy care protective foil

Operation "Easycontrol" system

Rotor chamber Dimensions (diameter x height): 188 mm x 63 mm

Rotor chamber Up to 48 ml of spilled liquids are retained in the rotor chamber and cannot

enter the instrument.

Lid lock Automatic locking when the lid is pressed shut

Lid opening Electromagnetic release via the "open lid" key when connected to mains

Emergency lid release Lid release in case of power failure: emergency opening with auxiliary tool.

46

Page 51

Function / parameter Value

environmental conditions - indoor use

- max. elevation 2000 m above sea level

- max. relative humidity 80 % up to 31 °C; linearly decreasing down to

50 % relative humidity at 40 °C.

Permissible temperature of the environment +2 °C to +40 °C

Technical data

Maximum speed n

Maximum RCF value at n

Minimum speed n

13 000 min-1

max

16 060

max

2 000 min-1

min

Maximum kinetic energy 1,65 kNm

Permissible temperature of the rotor -4 °C to +40 °C

Maximum sample temperature after 30 min

room temperature + 15 K

run time

Noise 56 dB (A) at maximum speed

Dimensions (H x W x D) 206 mm x 233 mm x 335 mm

Weight without rotor 9,8 kg

47

Page 52

Technical data

48

Page 53

Technical data

The "Easycontrol" user interface

Function Performance

Start Start key ( )

Stop Stop key ( )

Short-term start and stop, respectively „Quick run“ key ( ): short-term run when pressed permanently; stop

when released

Mode of operation display Turning rotor is signalled by rotating light (LED display) in the speed pa-

nel.

End of run The speed display reads "end"

Cycle counter

Number of cycles is displayed upon pressing the two keys

below the

speed display.

Digital parameter display

• speed

• run time

Speed selection adjustable in steps of 100 min-1 in the range of 2000 min-1 to 13000 min-1

Run time selection adjustable in minutes from 1 min to 99 min; „hd“-mode: continuous opera-

tion

Time display in „quick run“ mode between 1 s and 60 s in seconds, over 1 min in minutes

49

Page 54

Technical data

Function Performance

Parameter memory

• speed

• time

Function Performance

Diagnostic messages

• lid not properly closed: display „OP“

• general malfunction

(ERROR Codes, see page 39)

Testing standards

230V instruments

Manufactured and tested in accordance with

120 / 100V instruments

Manufactured and tested in accordance with

EN 61 010-1, EN 61 010-2-020

EN 61326 (+ EN 61000-3-2/A14:2000-6)

EN 55011 B

IEC 61010-1:1990 + amendment 1:1992 + amendment 2:1995

IEC 61010-2-020:1993 + amendment 1:1996

CAN/CSA-C22.2 No. 1010-1.92

CAN/CSA-C22.2 No. 1010-1.B97 amendment 2

50

Page 55

Technical data

Electrical connections / fuses

Order no. Voltage Frequency Nominal current Power consumption Fuses inside instrument *

7500 3235 230 V 50/60 Hz 1,1 A 150 W 2 x 2 A slow-blow

(5 x 20 mm)

7500 3236 110/120 V 60 Hz 2 A 150 W 2 x 4 A slow-blow

(6.3 x 32 mm)

* The fuse may be replaced only by authorized servicing personnel!

51

Page 56

Technical data

for your notes

52

Page 57

Index

A

acceleration 8

accessories

cap nut 9

rotor 11

tubular socket wrench 9

aerosol-tightness

test 25

aluminum rotor: 35

autoclaving 36

autoclaving cycle

permissible maximum 36

Index

during run 28

cleaning 33

common glass or plastic centrifuge tubes 4

conditions of warranty 37

contamination

necessary measures 34

continuous operation 29

control panel

readings 8

corrosion 4

corrosive substances

protective tubes for corrosive substances 4

cycle counter 47

D

C

cap nut

for fixing rotor 9

centrifuge tubes

types 11

volume range 11

centrifuging cycles

display 47

changing settings

damage

symbol for potential 5

dangerous chemicals 3

decontamination 34

disinfectant 34

disinfection 4

procedure 34

disinfection with bleaching lye 35

display

during run 28

displays

53

Page 58

Index

brief failure 39

not lit 39

E

EC Guidelines 5

electrical connections 49

emergency lid release 7

emergency release

lid 7

error messages

„br“ 40

„E-0“ 41

„E-10“ 41

„E-11“ 41

„E-8“ 41

„lid 42

„OP“ with lid closed 42

F

fine tuning

run time 27

speed setting 27

first steps 15

fixed-angle rotor 11

formula

maximum permissible load 22

frequency 15

fuses 49

H

handling the centrifuge 4

hazardous substances 3

hazards

symbols used for 5

hints

symbol for 5

I

icons

for denoting dangers and potential damage 5

infectious material

precautions in case of tube breakage 34

Instructions for use

delivered with instrument 9

items delivered 9

54

Page 59

Index

K

key

"quick run" 8

"set" 8

keys

general operation 8

L

lid

blockage 40

lid lock mechanism 7

lid open during run

warning 7

lid opening 18

lid release

emergency 7

M

mains connection 15

fuses 49

mains switch 17

maintenance 33

manual lid release 18

manual stop 29

maximum permissible load

formula for 22

maximum sample density 3

mechanical lid release 18

O

opening the lid 18

operation

continuous 29

preselected run time 27

short-time 29

organic solvents

not allowed for cleaning 33

overloading

dangers implied 22

P

partial loading

of rotor 26

pathogenic microorganisms

protection against 4

permissible speed 22

power on 17

power supply 15

problems

55

Page 60

Index

handling of 39

protective tubes

for corrosive substances 4

Q

quick run function 29

quick run key 8

R

radius of centrifugation

for calculation of RCF value 30

RCF value 30

readings

of control panel during run 8

relative centrifugal force 30

rotor

cap nut for fixing 9

loading 26

partial loading 26

removal 22

rotor cap 21

rotor insertion

temperature 20

run time

continuous operation 28

fine tuning 27

range 27

setting 27

RZB-Wert 12

S

safety instructions 3

safety measures 3

safety standards 5

safety systems

built-in 7

safety zone 3

30 cm around centrifuge 15

sample density

maximum 3

service 37

service contracts 37

set keys 8

setting

run time 27

short-time operation 29

socket wrench 9

software check

internal 17

software version

determination 43

speed

fine tuning 27

56

Page 61

Index

permissible 22

speed of centrifugation

for calculation of RCF value 30

speed setting 27

stopping 29

substructure 15

symbols

for hazards and dangers 5

T

temperature of the environment

permissible 46

temperature range for rotor

permissible 46

test

aerosol-tightness 25

toxins

protection against 4

transport

precautions for 17

tube

breakage with infectious material 34

tubes

types 11

volume range 11

Turning the centrifuge off 31

U

unbalance 23

V

voltage 15

W

warning

lid open during run 7

warranty conditions 37

wear 4

57

Page 62

Index

58

Page 63

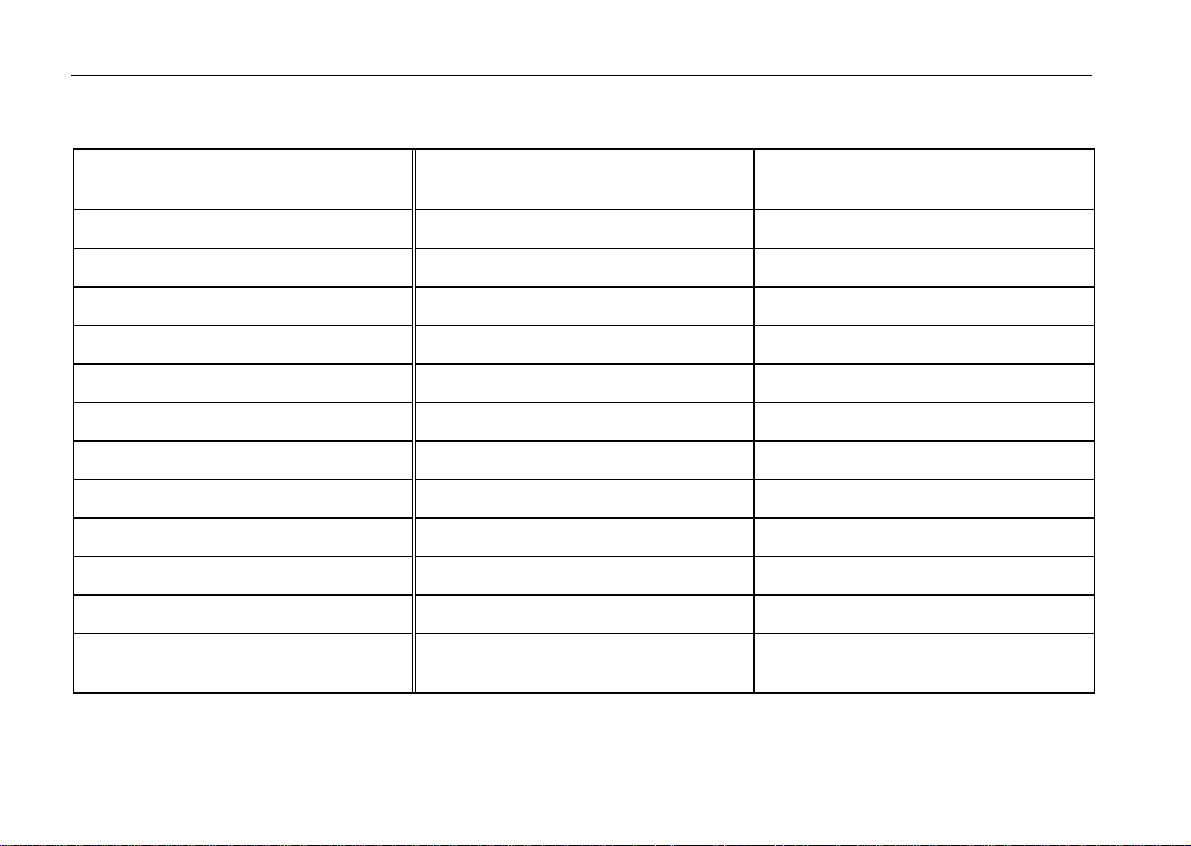

Autoclaving protocol

Autoclaving protocol

1 Date Remark Operator Signature

2

3

4

5

6

7

8

9

10

59

Page 64

Speed / RCF diagrams for PCR-Rotor 7500 3327

100000

13000

10000

speed [rpm]

1000

60

r

r

100

10 100 1000 10000 100000

RCF [x g]

12846

= 4,7 cm

min

= 6,8 cm

max

Page 65

Speed / RCF diagrams for 24 x 2ml Rotor 7500 3328

100000

13000

10000

speed [rpm]

1000

r

r

100

10 100 1000 10000 100000

RCF [x g]

16060

= 5,9 cm

min

= 8,5 cm

max

61

Page 66

62

Page 67

International contacts

Europe, Middle East and Africa

Thermo Electron Corporation · Robert-Bosch-Straße 1 · D-63505 Langenselbold

Phone +49 (0) 6184 / 90 69 40 · Fax +49 (0) 6184 / 90 74 74 · E-Mail info.labequipment.de@thermo.com

Asia Pacific

Thermo Electron Corporation · 275 Aiken Road · Asheville, NC 28804 · USA

Phone +1 852-2711 3910 · Fax +1 852-2711 3858 · E-Mail info.labequipment@thermo.com

Latin America

Thermo Electron Corporation · 275 Aiken Road · Asheville, NC 28804 · USA

Phone +1 828-658 2711 · Fax +1 828-645 9466 · E-Mail info.labequipment@thermo.com

North America

Thermo Electron Corporation · 275 Aiken Road · Asheville, NC 28804 · USA

Phone +1 800-879 7767 · Fax +1 828-658 0363 · E-Mail info.labequipment@thermo.com

Internet http://www.thermo.com

Thermo Electron Corporation

Robert-Bosch-Straße 1

D-63505 Langenselbold

Phone: +49 (0) 61 84 / 90 60 00

Fax: +49 (0) 61 84 / 90 70 00

In the interest of continuous product

development, we reserve the right to make

changes without express notice.

20057861 Pico-NEU_uk 11/05

Printed in Germany

Loading...

Loading...