Heper POLSO S LED Installation Manual

HPR Pazarlama A.S.

Uygurlar Cd. No:1, 06935

& Organize Sanayi

Bölgesi/Sincan/Ankara

Turkey

Tel: +90 312 267 54 3030

Fax : +90 312 267 54 31

info@hepergroup.com

www.heperlighting.com

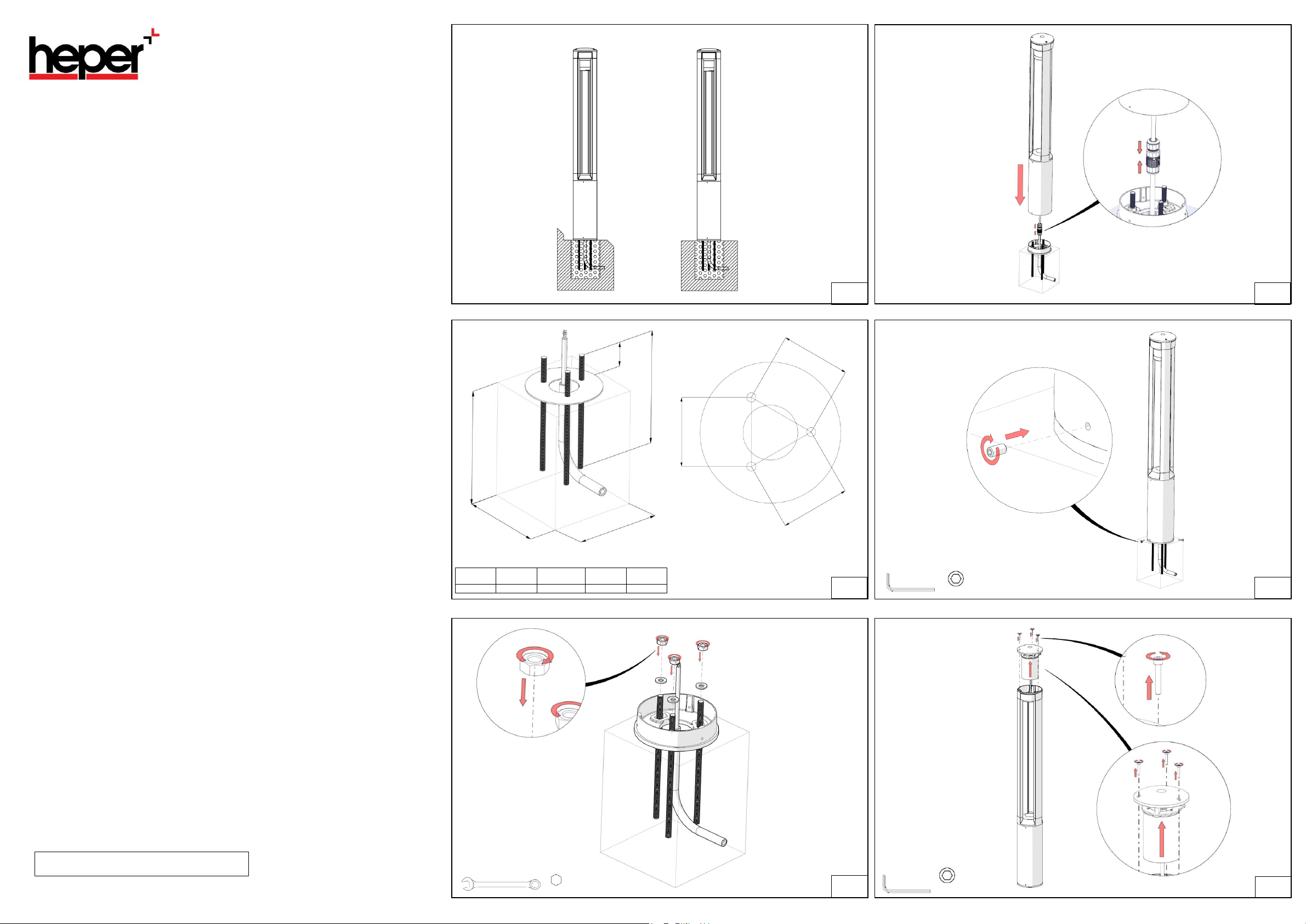

1.

2.

1 4

POLSO S LED

Installation&Maintenance

Instructions

2.

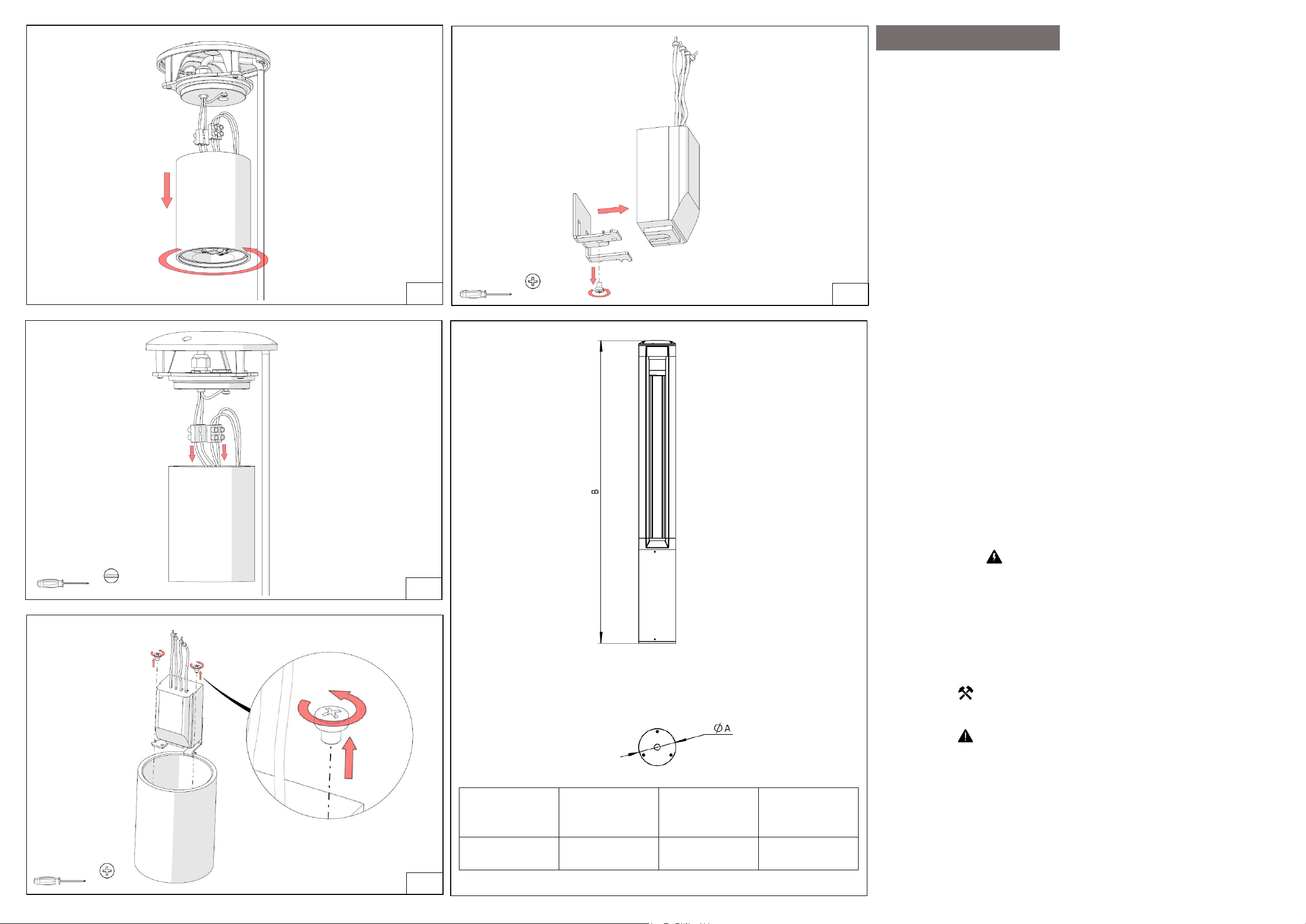

A

B

A

Inch

7 7/8

B

Inch

5 53/64

C

Inch

MIN 1 49/64

D

Inch

7 7/8

C

D

E

B

E

Inch

2 23/64

1.

3xM8 Washers

3xM8 Nuts

E

3xM4 Setscrews

E

2 5

S2

2.2 lb ft

3xM4 Head Bolt

2020-1/20.10.2020

S13

18.4 lb ft

3

2.2 lb ft

S3

6

A

(Inch)

B

(Inch)

(Lb)

4 51/60

39 3/8

7,90

LB6051.693

7 8 9

10

M3 Flat Head Screws

2xM4 Flat Head Screws

1.

2.

1.1 lb ft

English

ASSEMBLY INSTRUCTIONS

To install Bollard on the floor;

1.The floor on which the bolars will be mounted must be flat.

2.Concrete detail;

2.1.Anchor flange plate is used to align the connection holes of the product. (

2.2.The anchor stud is fixed into the concrete at a minimum of 1 49⁄64

anchor.

Note: The concrete is drilled a hole with 0 25⁄

ready before. The anchor stud is fixed with chemical anchor at minimum of 1 49⁄64" from the floor.

3.

After the anchorage flange plate is placed, flat washers are placed under them and the nuts are

tightened with torque of 18.4 lb ft. (3 Pieces, M8 Nuts)

4.

Fixing the bollard;

4.1 With the cable from the floor and the cable from the product is connected with a socket.

Note: Socket is not provided

certification suitable for the product.

4.2.The bollard body is placed on the anchor flange plate in a way that orientation does not

damage the cables.

5.Bollard setscrew bolts are fixed by tightening with torque of 2.2 lb ft. (3 Pieces, M4

To reach LED Driver;

6.The module cover bolts are removed. The module group is removed. (3 Pieces, M4 Head

Bolt)

Note: While re

7.LED driver chamber is removed by turning.

8.LED driver cables and terminal connections are disconnected.

Note: When connecting the LED driver cables to the terminals, they are tightened with torque of

1.1 lb ft.

9.The bolts that holds the LED driver plate are removed. The LED driver is removed from the

driver housing. (2 Pieces, M4 Flat Head Screws)

Note: While assemblying the LED Driver plate, the bolts are fixed with torque of

1.1 lb ft.

10. Removing the LED driver from the LED driver plate;

10.1.The bolt fixing the LED driver is removed. (1 Piece, M3 Flat Head Screws)

Note: When reassemblying the LED driver, it is fixed with torque 1.1 lb ft.

10.2.LED driver is separated from the LED driver plate.

mounting the module group, the bolts are fixed with torque of 2.2 lb ft.

with the product. Please obtain a socket with a minimum IP66

" diameter using anchor flange plate if the concrete is

64

Hole Center: 223⁄ 64" )

" from the floor with chemical

Setscrew)

LED

1.1 lb ft

WEIGHT

LUMINAIRE

CODE

WARNINGS AND REMARKS FOR INSTALLATION

AND MAINTENANCE

Safety Instructions

•

The light source contained in this luminaire shall only be replaced by the manufacturer or his

service agent or a similar qualified person. Always switch off the power prior to installation,

maintenance or repair activities.

•

The manufacturer is then discharged from liability when damage is caused by improper use or

installation.

•

If any luminaire is subsequently modified, the persons responsible for the modification shall be

considered as manufacturer.

To reduce the risk of death, personal injury or property damage from fire, electric shock, falling

•

parts, cuts, abrasions and other hazards, please read all warnings and instructions included

with the luminaire, on the luminaire’s packaging and affixed to the luminaire itself..

Installatio n

•

LEDs are high-quality electronic components! Please avoid contacting the light output opening

of the LED directly during installation or relamping.

IMPORTANT

•

To ensure secure connection, the luminaire housing must be positioned precisely

the mounting plate.

Cleaning And Maintenance

• Clean luminaire regularly with solvent-free cleaners from dirt. Please do not do not clean the

luminaire with using high-pressure liquids.

in relation to

1.1 lb ft

Loading...

Loading...