Henny Penny OFE Series, OFG Series, OEA Series, OGA Series, ODE Series Operation Manual

...

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

Model OFE/OFG-321

Model OFE/OFG-322

Model OFE/OFG-323

Model OFE/OFG-324

Model OEA/OGA-321

Model OEA/OGA-322

Model OEA/OGA-323

Model OEA/OGA-324

Model ODE/ODG-323

Henny Penny

Open Fryer

(Full & Split Vat)

’

Model OFE/OFG-321,322,323,324

LIMITED WARRANTY FOR HENNY PENNY EQUIPMENT

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the original

purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

in material or workmanship within two (2) years from date of original installation, will be repaired or replaced

without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. Baskets will be repaired or replaced

for ninety (90) days from date of original installation. Lamps and fuses are not covered under this Limited

Warranty. To validate this warranty, the registration card for the appliance must be mailed to Henny Penny within

ten (10) days after installation.

FILTER SYSTEM

other unapproved filters is not

REPLACEMENT PARTS:

in material or workmanship within ninety (90) days from date of original installation will be repaired or replaced

without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment covers the repair or replacement of the defective part and includes labor charges and

maximum mileage charges of 200 miles round trip for a period of one (1) year from the date of original installation.

The warranty for replacement parts covers only the repair or replacement of the defective part and does not include any

labor charges for the removal and installation of any parts, travel, or other expenses incidental to the repair or replacement of

a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover any frypot

that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new frypot at no

cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

will be replaced at no charge for the frypot only. Any freight charges and labor costs to install the new

frypot as well as the cost of any other parts replaced, such as insulation, thermal sensors, high limits,

fittings, and hardware, will be the responsibility of the owner.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was purchased. No

allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If damage occurs during

shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY FOR ANY

BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY (INCLUDING

CLAIMS FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) if the

equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED WARRANTY IS

EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY

AND FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR

AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Any part of a new appliance, except baskets, lamps, and fuses, which proves to be defective

: Failure of any parts within a fryer filter system caused by the use of the non-OEM filters or

covered under this Limited Warranty.

Any appliance replacement part, except lamps and fuses, which proves to be defective

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship issues

During this time, any frypot that fails due to manufacturing or workmanship issues

Revised 01/01/07

.

FM05-012-I

Revised 12-16-09

Model OFE/OFG-321,322,323,324

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the inside of the right side panel.

Post in a prominent location, instructions to be followed in event user smells gas. This information shall

be obtained by consulting the local gas supplier.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance must be left all around

appliance for sufficient air to the combustion chamber.

The Model OFG/OGA-32X open fryer is equipped with a continuous pilot. But the open fryer cannot be

operated without electric power. The unit will automatically return to normal operation when power is

restored.

To avoid a fire, keep appliance area free and clear from combustibles.

Improper installation, adjustment, alteration, service, or maintenance can cause property damage,

injury, or death. Read the installation, operating, and maintenance instructions thoroughly before

installing or servicing this equipment.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. FIRE OR

EXPLOSION COULD RESULT.

Model OFE/OFG-321,322,323,324

Technical Data for CE Marked Products

Nominal Heat Input: Natural (I2H) = 24.9 KW (85,000 Btu/h)

(Net) Natural (I

Natural (I

Natural (I

Liquid Propane (I

Nominal Heat Input: Natural (I

(Gross) Natural (I

Natural (I

Natural (I

Liquid Propane (I

Supply Pressure: Natural (I

Natural (I

Natural (I

Natural (I

Liquid Propane (I

Liquid Propane (I

Liquid Propane (I

Test Point Pressure: Natural (I

Natural (I

Natural (I

Natural (I

Liquid Propane (I3P) = 24.5 mbar

Injector Size: Natural (I

Natural (I

Natural (I

Natural (I

Liquid Propane (I

Restrictor Size: Natural (I

This appliance must be installed in accordance with the manufacturer’s instructions and the regulations

in force and only used in a suitably ventilated location. Read the instructions fully before installing or

using the appliance.

) = 24.9 KW (85,000 Btu/h)

2E

+) = 24.9 KW (85,000 Btu/h)

2E

) = 24.9 KW (85,000 Btu/h)

2L

) = 24.9 KW (85,000 Btu/h)

3P

) = 27.7 KW (94,500 Btu/h)

2H

) = 27.7 KW (94,500 Btu/h)

2E

+) = 27.7 KW (94,500 Btu/h)

2E

) = 27.7 KW (94,500 Btu/h)

2L

) = 27.1 KW (92,500 Btu/h)

3P

) = 20 mbar

2H

) = 20 mbar

2E

+) = 20/25 mbar

2E

) = 25 mbar

2L

) = 30 mbar

3P

) = 37 mbar

3P

) = 50 mbar

3P

) = 8.7 mbar

2H

) = 8.7 mbar

2E

+) = 8.7/10 mbar

2E

) = 10 mbar

2L

) = 3.26 mm

2H

) = 3.26 mm

2E

+) = 3.26 mm

2E

) = 3.26 mm

2L

) = 1.93 mm

3P

+) = 4.6 mm

2E

Model OFE/OFG-321,322,323,324

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION ............................................................................................................1-1

1-1. Introduction.............................................................................................................1-1

1-2. Features...................................................................................................................1-1

1-3. Proper Care .............................................................................................................1-1

1-4. Assistance ...............................................................................................................1-1

1-5. Safety ......................................................................................................................1-2

Section 2. INSTALLATION .............................................................................................................2-1

2-1. Introduction.............................................................................................................2-1

2-2. Unpacking............................................................................................................... 2-1

2-3. Selecting the Location ............................................................................................2-2

2-4. Leveling the Open Fryer .........................................................................................2-2

2-5. Ventilation of Open Fryer.......................................................................................2-2

2-6. Gas Supply..............................................................................................................2-3

2-7. Gas Leak Test .........................................................................................................2-6

2-8. Gas Pressure Regulator Setting...............................................................................2-6

2-9. Electrical Requirements OFG-320 Series...............................................................2-6

2-10. Electrical Requirements OFE-320 Series ...............................................................2-7

2-11. Joining Instructions.................................................................................................2-8

Section 3. OPERATION....................................................................................................................3-1

3-1. Operating Components C1000 Controls.................................................................3-1

3-2. Operating Components 6 & 12 Button Controls ....................................................3-3

3-3. Clock Set.................................................................................................................3-7

3-4. Filling or Adding Shortening..................................................................................3-9

3-5. C1000 Operations and Procedures..........................................................................3-10

3-6. C1000 Programming Instructions...........................................................................3-11

3-7. C1000 Special Programming ..................................................................................3-12

3-8. Basic Operations and Procedures (6 Product Controls)..........................................3-13

3-9. Basic Operations and Procedures (12 Product Controls/Auto-Lift) .......................3-15

3-10. Care of Shortening ..................................................................................................3-17

3-11. Filtering of Shortening............................................................................................3-18

3-12. Filter Pump Problem Prevention.............................................................................3-22

3-13. Filter Pump Motor Protector - Manual Reset .........................................................3-22

3-14. Changing the Filter Envelope .................................................................................3-22

3-15. Cleaning the Frypot ................................................................................................3-24

3-16. Clean-Out Mode .....................................................................................................2-26

3-17. Operating Instructions for Optional Direct-Connect Shortening System...............3-27

3-18. Lighting and Shutdown of the Burners...................................................................3-28

3-19. High Temperature Limit Control............................................................................3-29

3-17. Regular Maintenance ..............................................................................................3-29

i 308

Model OFE/OFG-321,322,323,324

TABLE OF CONTENTS

Section Page

Section 4. PROGRAMMING – 6 & 12 PRODUCT CONTROLS ..................................................4-1

4-1. Introduction.............................................................................................................4-1

4-2. Product Program Mode...........................................................................................4-1

4-3. Special Program Mode............................................................................................4-4

4-4. Data Logging, Heat Control, Tech, and Stat Modes...............................................4-15

Section 5. TROUBLESHOOTING...................................................................................................5-1

5-1. Troubleshooting Guide ...........................................................................................5-1

5-2. Error Codes .............................................................................................................5-2

Section 6. INFORMATION MODE.................................................................................................6-1

GLOSSARY ....................................................................................................................G-1

Distributors List - Domestic and International

308 i

Model OFE/OFG-321,322,323,324

SECTION 1. INTRODUCTION

1-1. INTRODUCTION The Henny Penny Open Fryer is a basic unit of food

equipment designed to cook foods better and easier. The

microcomputer-based design helps make this possible. This

unit is used only in institutional and commercial food service

operations.

As of August 16, 2005, the Waste Electrical and

Electronic Equipment directive went into effect for the

European Union. Our products have been evaluated to

the WEEE directive. We have also reviewed our

products to determine if they comply with the

Restriction of Hazardous Substances directive (RoHS)

and have redesigned our products as needed in order to

comply. To continue compliance with these directives,

this unit must not be disposed as unsorted municipal

waste. For proper disposal, please contact your nearest

Henny Penny distributor.

1-2. FEATURES

• Easily cleaned

• Full frypot 65 lbs. (29.5 kg.) shortening capacity

• Split frypot 25 lbs. (11.3 kg.) shortening cap.

(elec. only)

• 2 Half size baskets per well (or full size baskets)

• Stainless steel construction

• Manual reset high limit control

• Self-diagnostic system built into controls

• Built in filter (handles all 3 wells)

• Propane or natural gas; 85,000 btu/pot (26.38 kw)

• Energy Save Mode upon activation for gas fryers

• Many combinations of split frypot/full frypot fryers

• Simplistic electronic Computron 1000 controls available,

or more diverse multifunctional controls available

1-3. PROPER CARE

As in any unit of food servicing equipment, the open fryer

does require care and maintenance. Requirements for the

maintenance and cleaning are contained in this manual and

must become a regular part of the operation of the unit at all

times.

1-4. ASSISTANCE

Should you require outside assistance, call your local

independent Henny Penny distributor in your area, call

Henny Penny Corp. at 1-800-417-8405 or 1-937-456-8405,

or go to Henny Penny online at www.hennypenny.com

1-1 108

.

Model OFE/OFG-321,322,323,324

1-5. SAFETY The Henny Penny Open Fryer has many safety features

incorporated. However, the only way to ensure safe

operation is to fully understand the proper installation,

operation, and maintenance procedures. The instructions in

this manual have been prepared to aid you in learning the

proper procedures. Where information is of particular

importance or is safety related, the words DANGER,

WARNING, CAUTION, or NOTE are used. Their usage is

described on the next page:

SAFETY ALERT SYMBOL is used with

DANGER, WARNING or CAUTION which

indicates a personal injury type hazard.

NOTICE is used to highlight especially important

information

.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

DANGER INDICATES AN IMMINENTLY

HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, WILL RESULT IN DEATH OR

SERIOUS INJURY.

703 1-2

Model OFE/OFG-321,322,323,324

SECTION 2. INSTALLATION

2-1. INTRODUCTION This section provides the installation instructions for

the Henny Penny Open Fryer.

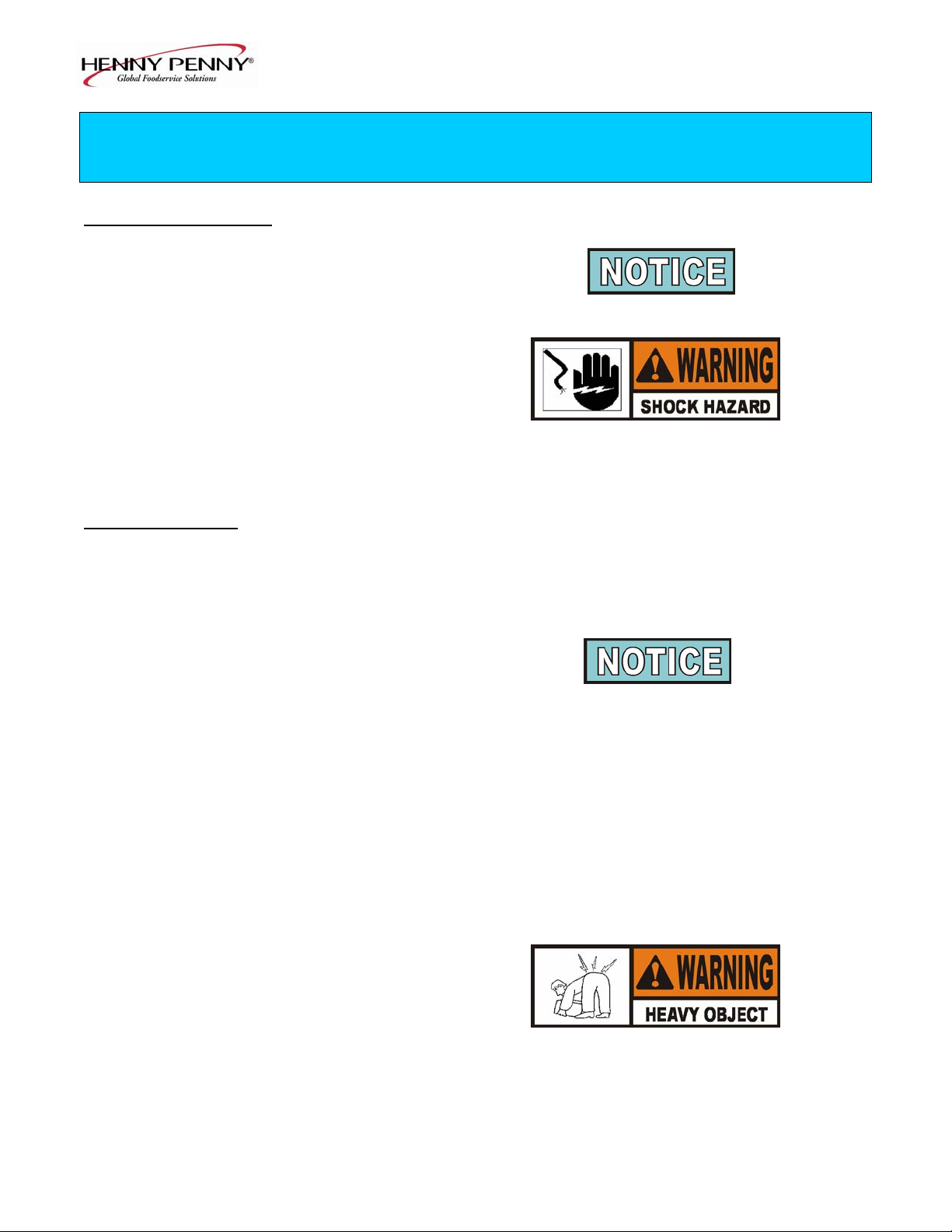

Installation of the unit should be performed only by a

qualified service technician.

Do not puncture the unit with any objects such as

drills or screws as component damage or electrical

shock could result.

2-2. UNPACKING

The Henny Penny Open Fryer has been tested, inspected, and

expertly packed to ensure arrival at its destination in the best

possible condition. The unit is banded to a wooden skid and

then packed inside a heavy cardboard carton with sufficient

padding to withstand normal shipping treatment.

Any shipping damage should be noted in the presence

of the delivery agent and signed prior to his or her

departure.

1. Carefully cut bands from cardboard carton.

2. Lift carton from the unit.

3. Cut and remove the metal bands holding the fryer to the

pallet.

4. Remove the fryer from the pallet.

Take care when moving the fryer to prevent

personal injury. The fryer can weigh between

305 lbs. (138 kg) and 616 lbs. (279 kg).

2-1 703

Model OFE/OFG-321,322,323,324

2-3. SELECTING THE The proper location of the open fryer is very important for

LOCATION

the duration, speed, and convenience. The location of the

open fryer should allow clearances for servicing and proper

operation. Choose a location which will provide easy

loading and unloading without interfering with the final

assembly of food orders. Operators have found that frying

from raw to finish, and holding the product in warmers

provides fast continuous service. Keep in mind, the best

efficiency will be obtained by a straight line operation, i.e.,

raw in one side and finished out the other side. Order

assembly can be moved away with only a slight loss of

efficiency.

To prevent severe burns from splashing hot

shortening, position and install fryer to prevent

tipping or movement. Restraining ties may be used

for stabilization.

To avoid fire, install the open fryer with minimum

clearance from all combustible and noncombustible

materials, 4 inches (10.16 cm) from the side and 4

inches (10.16 cm) from the back. If installed properly,

the open fryer is designed for operation on combustible

floors and adjacent to combustible walls.

2-4. LEVELING THE OPEN

FRYER

side to side and front to back. Using a level placed on the

For proper operation, the open fryer should be level from

flat areas around the frypot collar, on the middle well, adjust

the casters until the unit is level.

2-5. VENTILATION OF OPEN

FRYER

into an adequate exhaust hood or ventilation system. This is

The open fryer should be located with provision for venting

essential to permit efficient removal of the steam exhaust and

frying odors. Special precaution must be taken in designing

an exhaust canopy to avoid interference with the operation of

the open fryer. We recommend you consult a local

ventilation or heating company to help in designing an

adequate system.

703 2-2

Model OFE/OFG-321,322,323,324

2-5. VENTILATION OF OPEN

FRYER

(Continued)

Ventilation must conform to local, state, and national

codes. Consult your local fire department or building

authorities.

When installing the gas open fryer, do not attach an

extension to the gas flue exhaust stack. This may impair

proper operation of the burner, causing malfunctions

and possible negative back draft.

2-6. GAS SUPPLY

cabinet to determine the proper gas supply requirements. The

minimum supply for natural gas is 7 inches water column

(1.7 kPa), and 10 inches water column (2.49 kPa) for propane.

The gas open fryer is factory available for either natural or propane

gas. Check the data plate inside the front door of the

Do not attempt to use any gas other than that specified

on the data plate. Incorrect gas supply could cause a fire

or explosion resulting in severe injuries and/or property

damage.

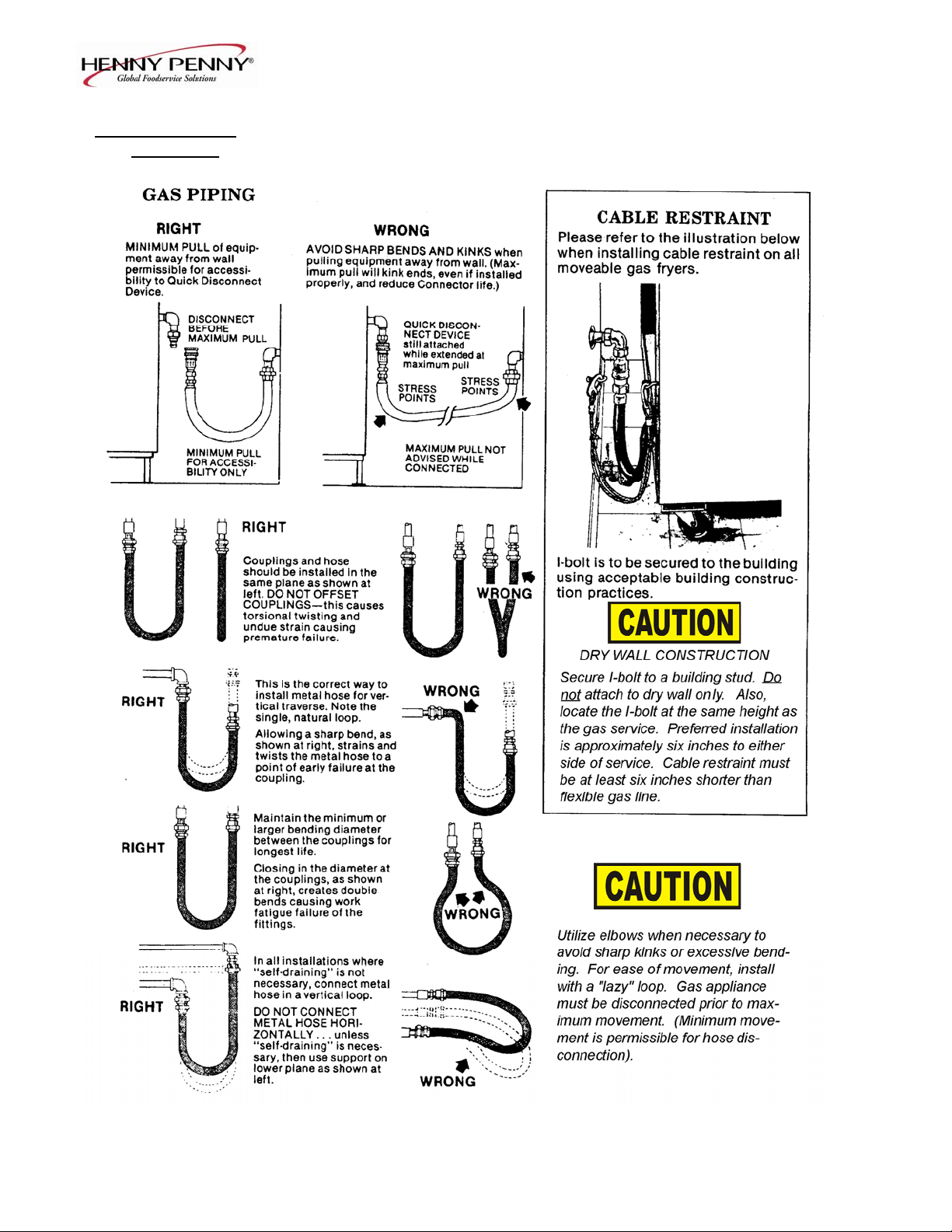

Please refer below for the recommended hookup of the fryer to

main gas line supply.

To avoid possible serious personal injury:

codes, the American National Standard Z223.1-(the latest

edition) National Fuel Gas Code, and the local

municipal building codes. In Canada, installation must be

in accordance with Standard CAN/CSA B 149.1 &

Installation Codes - Gas Burning Appliances and local codes.

• Installation must conform with local, state, and national

In Australia, in accordance with Australian Gas

Authority rules AG601-2000, section AS5601.

2-3 703

Model OFE/OFG-321,322,323,324

2-6. GAS SUPPLY • The fryer and its manual shutoff valve must be disconnected

(Continued)

testing of that system at test pressures in excess of

(3.45 kPa) (34.5 mbar).

from the gas supply piping system during any pressure

½ PSIG

• The fryer must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than ½ PSIG

(3.45 kPa) (34.5 mbar).

• A standard one inch (2.54 cm), black steel pipe and

malleable fittings should be used for gas service connections

for 3 well open fryers, 3/4 inch (1.91 cm) for 2 wells, and 1/2

inch (1.27 cm) for single wells.

• Do not use cast iron fittings.

• Although one inch (2.54 cm) size pipe is recommended for

3 wells, 3/4 inch (1.91 cm) for 2 wells, and 1/2 inch (1.27 cm)

for single wells, piping should be of adequate size and

installed to provide a supply of gas sufficient to meet the

maximum demand without undue loss of pressure between

the meter and the open fryer. The pressure loss in the piping

system should not exceed 0.3 in. water column (0.747 mbar).

Provisions should be made for moving the open fryer for

cleaning and servicing. This may be accomplished by:

1. Installing a manual gas shut off valve and a disconnect

union, or

2. Installing a heavy-duty design A.G.A. certified

connector. In order to be able to service this appliance,

which is provided with casters, a connector complying

with ANSI Z21.69 or CAN 1-6.l0m88 and a

quick-disconnect device, complying with ANSI Z21.41

or CAN 1-6.9m70, must be installed. It must also be

installed with restraining means to guard against

transmission of strain to the connector as specified in

the appliance manufacturer's instruction.

3. See the illustration on the following page for the proper

connection of flexible gas line and cable restraint.

The cable restraint limits the distance the open fryer can be

pulled from the wall. For cleaning and servicing the unit,

the cable must be unsnapped from the open fryer and the

flexible gas line disconnected. This will allow better

access to all sides of the open fryer. The gas line and cable

restraint must

servicing is complete.

703 2-4

be reconnected once the cleaning or

Model OFE/OFG-321,322,323,324

2-6. GAS SUPPLY

(Continued)

2-5 2005

Model OFE/OFG-321,322,323,324

2-7. GAS LEAK TEST

Prior to turning the gas supply on, be sure the gas valve knob

on the gas control valve is in the OFF position.

Upon initial installation, and after moving the unit, the piping and

fittings should be checked for gas leaks. A simple checking

method is to turn on the gas and brush all connections with a soap

solution. If bubbles occur, it indicates escaping gas.

the piping connection must be redone.

To avoid fire or explosion, never use a lighted

In this event,

match or open flame to test for gas leaks.

Ignited gas could result in severe personal

injury and/or property damage.

2-8. GAS PRESSURE REGULATOR The gas pressure regulator on the gas control valve is

SETTING factory set as follows:

• Natural: 3.5 inches water column (0.87 mbar).

• Propane 10.0 inches water column (2.49 mbar).

The gas pressure regulator has been set by Henny

Penny and is not to be adjusted by the user.

2-9. ELECTRICAL REQUIREMENTS

OFG-320 SERIES

• 230 V, 50 Hz., 1 PH, 6 A

The 120 V gas open fryer requires a 3 wire grounded (earthed)

service and is supplied with a grounded cord and plug. Any 230

volt plug used on the 230 volt unit must conform to all local,

state, and national codes.

To avoid electrical shock, this appliance must be

equipped with an external circuit breaker which will

disconnect all ungrounded (unearthed) conductors.

The main power switch on this appliance does not

disconnect all line conductors.

703 2-6

• 120 V, 50/60 Hz., 1 PH, 12 A

Model OFE/OFG-321,322,323,324

2-9. ELECTRICAL REQUIREMENTS

OFG-320 SERIES (Continued)

To avoid electrical shock, do not disconnect the ground

(earth) plug.

This fryer must be adequately and

safely grounded (earthed). Refer to local electrical

codes for correct grounding (earthing) procedures or in

absence of local codes, with The National Electrical

Code, ANSI/NFPA No. 70-(the current edition). In

Canada, all electrical connections are to be made in

accordance with CSA C22.1, Canadian Electrical Code

Part 1, and/or local codes.

2-10. ELECTRICAL REQUIREMENTS

OFE-320 SERIES

(Per Well)

Volts Phase Kw Amps

Refer to the table below for supply wiring and fusing.

200-208 3 14.4 40

220/240 3 14.4 40

440-480 3 14.4 17

380-415 3 14.4 20

equipped with an external circuit breaker which will

disconnect all ungrounded (unearthed) conductors.

The main power switch on this appliance does not

disconnect all line conductors.

To avoid electrical shock, this fryer must

adequately and safely grounded (earthed). Refer to

local electrical codes for correct grounding (earthing)

procedures or in absence of local codes, with The

National Electrical Code, ANSI/NFPA No. 70-(the

current edition). In Canada, all electrical connections are

to be made in accordance with CSA C22.1, Canadian

Electrical Code Part 1, and/or local codes.

To avoid electrical shock, this appliance must be

be

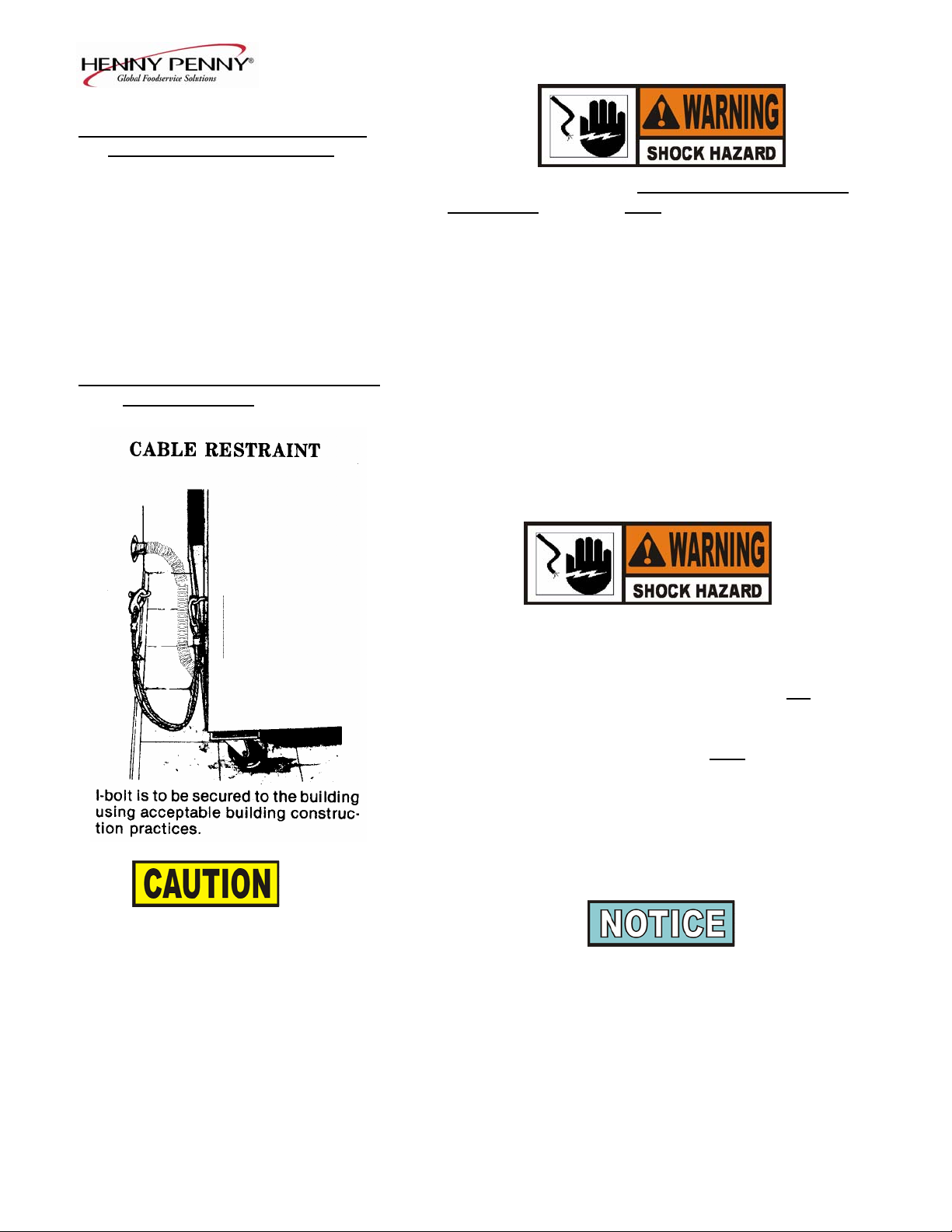

DRYWALL CONSTRUCTION

Secure I-bolt to a building stud. Do

not attach to drywall only. Preferred

installation is approximately six

inches to either side of service.

Cable restraint must be at least six

inches shorter than flexible conduit.

CE units require a minimum wire size of 6 mm to be wired

to the terminal block.

Permanently connected electric fryers with casters must be

installed with flexible conduit and a cable restraint, when

installed in the United States. See illustration at left. Holes

are available in the rear fryer frame for securing the cable

restraint to the fryer. The cable restraint does not prevent the

fryer from tipping.

2-7 705

Model OFE/OFG-321,322,323,324

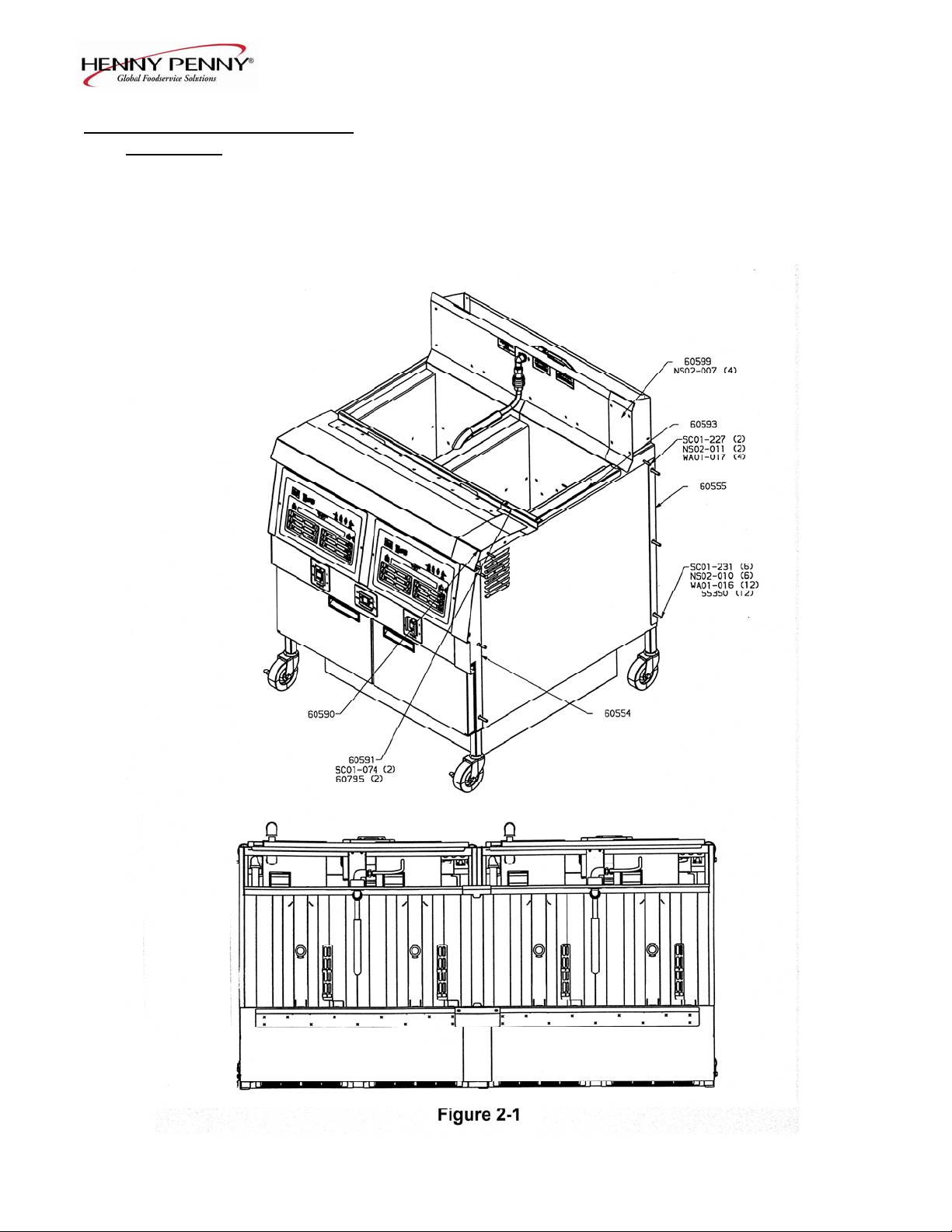

2-11. JOINING INSTRUCTIONS The following instructions are for joining two units together.

The instructions have part numbers in them. Please refer to

figure 2-1 on the following page to visually match the

numbers in the instructions below to the illustration.

1. Remove all hardware from the sides of the two open

fryers.

2. Remove the right control panel assembly from the left

unit and the left control panel assembly from the right

unit.

3. Move the two units side by side with minimal gap.

4. Remove the right front caster from the left unit and the

left rear caster from the right unit. Fasten both casters to

the rear of the unit with wire ties (EF02-041).

5. Position the two open fryers by inserting bolts

(SC01-227) thru the holes in top cover and the pot sides.

Use washer (WA01-017) on both sides of the bolt when

installing. DO NOT TIGHTEN!

6. Position front spacer (60554) between the front of the

two open fryers. Place bolt (SC01-231), backed by

washers (55350 & WA01-016), thru three holes in the

frame capturing the spacer between the frames. Place

washers

(55350 & WA01-016) on bolt before installing nuts

(NS02-010). DO NOT TIGHTEN!

7. Repeat with rear spacer (60555).

8. Tighten all fasteners securely.

9. Place cover (60593) over gap between open fryers.

10. Drill out dimples on rear shroud to 0.250 diameter holes.

11. Apply silicon around edge of unfinished side of rear

cover (60599). Install rear cover (60599) with #8 nuts

(NS02-007).

103 2-8

Model OFE/OFG-321,322,323,324

2-11. JOINING INSTRUCTIONS 12. Apply silicon around edge of unfinished side of top cover

(Continued)

(60590) and basket rest cover (60591). Position top cover

(60590) on open fryer top cover and install basket rest

cover (60591) using #10 screws and nuts (SC01-074 &

60795).

13. Apply silicon to any gaps that may be left.

2-9 1005

Model OFE/OFG-321,322,323,324

SECTION 3. OPERATION

3-1. OPERATING COMPONENTS Reference Figure 3-1.

C1000 CONTROLS

Fig. Item Description Function

No. No.

3-1 1 Digital Display Shows the shortening temperature, the timer countdown in

the Cook Cycle, and the selections in the Program Mode; the

temperature of the shortening can be shown by pressing

once, or twice to view set-point temperature;

if shortening temperature exceeds 425°F (218°C), the display

reads “E-5, FRYER TOO HOT”

3-1 2 This LED lights when the shortening temperature is within 5°

of the setpoint temperature, signaling the operator that the

shortening temperature is now at the proper temperature for

dropping product into the frypot

3-1 3 The timer buttons are used to start and stop Cook Cycles

3-1 4 The idle buttons are used to start an Idle Mode which reduces

the temperature of the shortening during non-use periods;

press and hold to exit the Idle Mode

3-1 5 The program button is used to access the Program Modes;

also, once in the Program Mode, it is used to advance to the

next parameter

3-1 6 & 7 Used to adjust the value of the currently displayed setting

in the Program Mode and to change set-point temperature for

the left frypot, or basket

3-1 8 & 9 Used to adjust the value of the currently displayed setting

in the Program Mode and to change set-point temperature for

the right frypot, or basket

Proceed onto Section 3-4, Filling or Adding Shortening

108 3-1

Model OFE/OFG-321,322,323,324

6

7 5 8 9

Figure 3-1

3-2 108

Model OFE/OFG-321,322,323,324

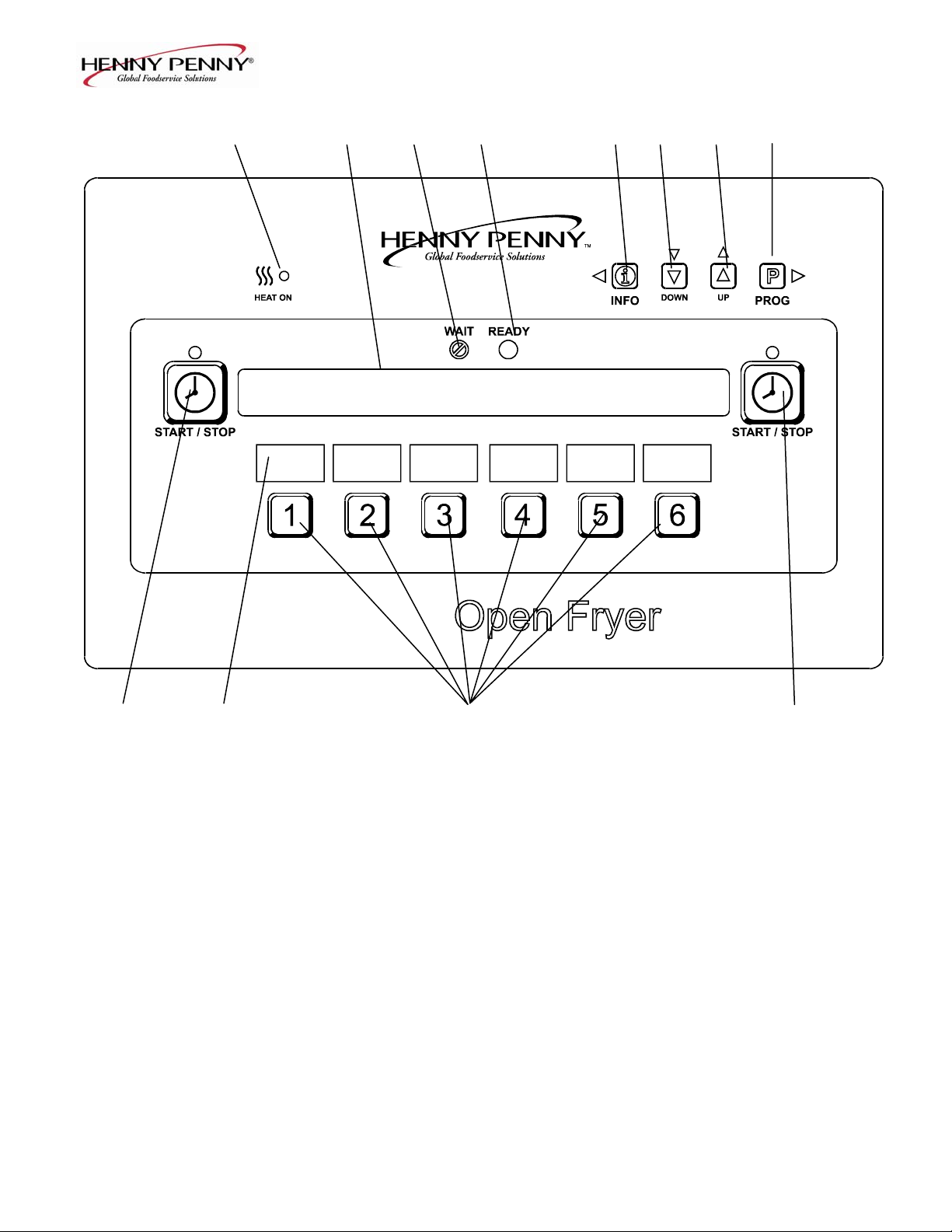

3-2. OPERATING COMPONENTS Figure 3-2 shows the function of the 12 button timer control,

6 & 12 BUTTON CONTROLS and Figure 3-3 shows the function of the 6 button timer control.

Fig. Item Description Function

No. No.

3-1 1 This LED lights when the control calls for heat,

3-2 and the burners come on and heat the shortening

3-1 2 Digital Displays Shows the shortening temperature, the timer countdown in

3-2 the Cook Cycle, and the selections in the Program Mode; the

temperature of the shortening can be shown by depressing

the INFO button; if the temperature exceeds 425°F (218°C),

the display reads “E-5, FRYER TOO HOT”

3-1 3 WAIT LED Once the open fryer is out of the Melt Cycle, this LED lights,

3-2 signaling the operator that the shortening temperature is not

proper temperature for dropping product into the frypot

3-1 4 READY LED This LED lights when the shortening temperature

3-2 is within 5° of the setpoint temperature, signaling the

operator that the shortening temperature is now at the proper

temperature for dropping product into the frypot

3-1 5 Press to display the following fryer information and status:

3-2 a. The temperature of the shortening

b. The temperature setpoint

c. Filter status

d. The number of times filtered today

e. The average no. of filters per day

f. No. of times Cook Cycle was stopped early today

g. No. of times Cook Cycle was stopped early in past week

e. Date and time

3-1 6 & 7 Used to adjust the value of the currently displayed setting

3-2 in the Program Mode

3-1 8 Used to access the Program Modes; also, once in the

3-2 Program Mode, it is used to advance to the next parameter

3-1 9 START/STOP Used to start and stop Cook Cycles; also de-activates

3-2 Button the quality timer at the end of a Hold Mode

3-1 10 Menu Card Displays the food product associated with each product

3-2 Window selection button below; the menu card strip is located

behind the decal

3-1 11 Product Select Used to select which food products are to be cooked

3-2 Buttons (on auto-lift open fryers, the 6 and 12 product buttons are basket

lift buttons)

1005 3-3

at the

Model OFE/OFG-321,322,323,324

1 2 3 4 5 6 7 8

9 10 11 9

Figure 3-2

3-4 103

Model OFE/OFG-321,322,323,324

1 2 3 4 5 6 7 8

9 10 11 9

Figure 3-3

103 3-5

Loading...

Loading...