Henny Penny OFE Series, OFG Series, OEA Series, OGA Series General Manual

Henny Penny Model OFE/OFG-321,322,323,324

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the inside of the right side panel.

Post in a prominent location, instructions to be followed in event user smells gas. This

information shall be obtained by consulting the local gas supplier.

FORYOURSAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

Keep appliance area free and clear from combustibles.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance must be left all

around appliance for sufficient air to the combustion chamber.

NOTE

The Model OFG/OGA-32X Fryer is equipped with a continuous pilot. But Fryer can not be

operated without electric power. Fryer will automatically return to normal operation when power

is restored.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

FM01-650

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Henny Penny Model OFE/OFG-321,322,323,324

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION .....................................................................................................1-1

1-1 Introduction ...................................................................................................1-1

1-2 Model Variations ...........................................................................................1-1

1-3 Features .........................................................................................................1-1

1-4 Safety.............................................................................................................1-1

1-5 Assistance......................................................................................................1-2

Section 2. INSTALLATION ...................................................................................................... 2-1

2-1 Introduction ................................................................................................... 2-1

2-2 Unpacking......................................................................................................2-1

2-3 Selecting the Location ...................................................................................2-2

2-4 Leveling the Fry Station ................................................................................2-2

2-5 Ventilation of Fry Station..............................................................................2-2

2-6 Gas Supply.....................................................................................................2-3

2-7 Gas Leak Test ................................................................................................2-5

2-8 Gas Pressure Regulator .................................................................................2-6

2-9 Electrical Requirements OFE-320 Series......................................................2-6

2-10 Testing the Fry Station ..................................................................................2-7

2-11 Joining Instructions .......................................................................................2-7

Section 3. OPERATION............................................................................................................. 3-1

3-1 Introduction ................................................................................................... 3-1

3-2 Operating Controls ........................................................................................3-1

3-3 Filling or Adding Shortening.........................................................................3-5

3-4 Basic Operations and Procedures (6 Product Controls) ................................3-5

3-5 Basic Operations and Procedures (Electro-Mechanical)............................... 3-7

3-6 Basic Operations and Procedures (12 Product Controls/Auto-lift)...............3-9

3-7 Filtering of Shortening ..................................................................................3-12

3-8 Filter Pump Problems....................................................................................3-14

3-9 Filter Pump Motor Protector .........................................................................3-14

3-10 Changing the Filter Envelope........................................................................ 3-15

3-11 Cleaning the Cookpots ..................................................................................3-16

3-12 Lighting and Shutdown of Burners ...............................................................3-19

3-13 Regular Maintenance.....................................................................................3-20

Section 4. PROGRAMMING ......................................................................................................4-1

4-1 Introduction ....................................................................................................4-1

4-2 Product Program Mode ..................................................................................4-1

4-3SpecialProgramMode...................................................................................4-4

Section 5. TROUBLESHOOTING..............................................................................................5-1

5-1 Introduction ....................................................................................................5-1

5-2 Troubleshooting .............................................................................................5-1

Section 6. MAINTENANCE........................................................................................................ 6-1

6-1 Introduction ....................................................................................................6-1

6-2 Maintenance Hints .........................................................................................6-1

Henny Penny Model OFE/OFG-321,322,323,324

TABLE OF CONTENTS

Section Page

Section 6. MAINTENANCE (Continued)

6-3 High Temperature Limit Control (Gas Units)................................................6-1

6-4 Complete Control Panel Replacement ...........................................................6-4

6-5 Power Switch.................................................................................................. 6-4

6-6 Temperature Probe Replacement ................................................................... 6-5

6-7 Flame Sensor (Gas Units) ..............................................................................6-6

6-8 Pilot/Ignitor Assembly ...................................................................................6-7

6-9 Ignition Module..............................................................................................6-8

6-10 Transformer....................................................................................................6-8

6-11 I/O Power Supply Board Assembly ...............................................................6-9

6-12 Airflow Switch ............................................................................................... 6-9

6-13 Speaker Assembly (Gas Units) ......................................................................6-10

6-14 Drain Microswitch .........................................................................................6-11

6-15 Filter Switch ...................................................................................................6-11

6-16 Gas Valve Assembly ......................................................................................6-12

6-17 Blower Motor Assembly ................................................................................6-14

6-18 Heating Elements (Electric Only) ..................................................................6-16

6-19 Heating Contactors (Electric Only)................................................................6-19

6-20 Speaker Assembly (Electric Units) ................................................................6-21

6-21 High Temperature Limit Control (Electric Units) ......................................... 6-21

Section 7. PARTS INFORMATION............................................................................................ 7-1

7-1 Introduction ....................................................................................................7-1

7-2 Genuine Parts .................................................................................................7-1

7-3 When Ordering Parts......................................................................................7-1

7-4 Prices ..............................................................................................................7-1

7-5 Delivery..........................................................................................................7-1

7-6 Warranty......................................................................................................... 7-1

120V/60Hz/1Ph (OFG-32X Gas) Wiring Diagram........................................7-13

208-240V/60Hz/1Ph (Domestic-OFE-32X Electric) Wiring Diagram..........7-14

120V/50/60Hz/1Ph (OFG-322) Wiring Diagram...........................................7-15

230V/50Hz/1 Ph (OFG-321) Wiring Diagram...............................................7-16

208-240V/50-60 Hz/3Ph (OFE-321/2/3 Electric) Wiring Diagram............... 7-17

120V/50-60Hz/1Ph (OFG-321) Wiring Diagram ..........................................7-18

380-415V/50-60Hz/3Ph (OFE-321/2/3) Wiring Diagram ............................. 7-19

120V/50-60Hz/1Ph (OGA-323) Wiring Diagram..........................................7-20

120V/50-60/1Ph (OGA-321) Wiring Diagram .............................................. 7-21

380-480V/50-60Hz/3Ph (OFE-321/2/3) Wiring Diagram ............................. 7-22

230V/50Hz/1Ph (OFG-323) Wiring Diagram................................................ 7-23

120V/50-60Hz/1Ph (ODG-323) Wiring Diagram..........................................7-24

230V/50Hz/1Ph (OFG-322) Wiring Diagram................................................ 7-25

120V/50-60Hz/1Ph (OFG-323) Wiring Diagram ..........................................7-26

208-240V/50-60Hz/3Ph (OFE-321/2/3) Wiring Diagram ............................. 7-27

208-240V/50-60Hz/3Ph (OEA-321/2/3) Wiring Diagram.............................7-28

Distributors List - Domestic and International

Henny Penny Model OFE/OFG-321,322,323,324

SECTION 1. INTRODUCTION

1-1. INTRODUCTION. The Henny Penny Open Fry Station is a basic unit of food

equipment designed to cook foods better and easier. The

microcomputer based design helps make this possible. This

unit is used only in institutional and commercial food service

operations.

1-2. MODEL VARIATIONS This manual covers the following variations of the Henny

Penny Open Fry Station:

• Model OFG/OFE-323

• Model OFG/OFE-322

• Model OFG/OFE-321

• Model OFG/OFE-324

• Model OGA/OEA-323

• Model OGA/OEA-322

• Model OGA/OEA-321

1-3. FEATURES • Easily cleaned.

• 55 lb. (24.94 kg.) shortening capacity

• 2 Half size baskets per well (or full size baskets).

• Microcomputer control.

• Stainless steel construction.

• Manual reset high limit control.

• Self-diagnostic system built into controls.

• Built in filter (handles all 3 wells).

• Propane or Natural Gas; 85,000 BTU/pot (26.38 kW)

1-4. SAFETY The Henny Penny Fry Station has many safety features

incorporated. However, the only way to ensure safe

operation is to fully understand the proper installation,

operation, and maintenance procedures. The instructions in

this manual have been prepared to aid you in learning the

proper procedures. Where information is of particular

importance or is safety related, the words DANGER,

WARNING, CAUTION, or NOTE are used. Their usage is

described below:

The word DANGER indicates an imminent hazard

which will result in highly serious injury such as second

or third degree burns.

998 1-1

Henny Penny Model OFE/OFG-321,322,323,324

1-4. SAFETY

(Continued)

The word WARNING is used to alert you to a

procedure that if not performed properly, might cause

personal injury.

ThewordCAUTIONisusedtoalertyoutoaprocedure

that, if not performed properly, may damage the fry

station.

NOTE

The word NOTE is used to highlight especially

important information.

1-5. ASSISTANCE Should you require outside assistance, just call your local

independent distributor maintained by Henny Penny

Corporation.

In addition, feel free to contact our corporate headquarters in

Eaton,Ohio.Dial1-800-417-8405 tollfree,or

937-456-8405.

1-2 998

Henny Penny Model OFE/OFG-321,322,323,324

SECTION 2. INSTALLATION

2-1. INTRODUCTION This section provides the installation instructions for the

Henny Penny Fry Station.

NOTE

Installation of the unit should be preformed only by a

qualified service technician.

Do not puncture the unit with any objects such as drills

or screws as component damage or electrical shock

could result.

2-2. UNPACKING The Henny Penny Fry Station has been tested, inspected,

and expertly packed to ensure arrival at its destination in

the best possible condition. The unit is banded to a wooden

skid and then packed inside a heavy cardboard carton with

sufficient padding to withstand normal shipping treatment.

NOTE

Any shipping damage should be noted in the presence

of the delivery agent and signed prior to his or her

departure.

1. Carefully cut bands from cardboard carton.

2. Lift carton from fryer.

This manual should be retained in a convenient location

for future reference.

Wiring diagram for this appliance is located on the inside

of the Service and Operation Manual. Post in a prominent

location, instructions to be followed in event user smells gas.

This information shall be obtained by consulting the local gas

supplier.

998 2-1

Henny Penny Model OFE/OFG-321,322,323,324

2-3. SELECTING THE The proper location of the Fry Station is very important

LOCATION for operation, speed, and convenience. The location of the

fry station should allow clearances for servicing and proper

operation. Choose a location which will provide easy loading

and unloading without interfering with the final assembly of

food orders. Operators have found that frying from raw to

finish, and holding the product in warmers provides fast

continuous service. Keep in mind the best efficiency will be

obtained by a straight line operation, i.e. raw in one side and

finished out the other side. Order assembly can be moved

away with only a slight loss of efficiency.

NOTE

The fryer should be installed in such a way as to prevent

tipping or movement causing splashing of hot liquid

shortening. This may be accomplished by the location

the fry station is in, or by restraining ties.

The gas Model OFG-320 Series Fry Station is designed

for installation on combustible floors and adjacent to

combustible walls. Fry Station must be installed with a

minimum clearance from all combustible materials, 4

inches (10.16 cm) from side and 4 inches (10.16 cm)

from the back.

2-4. LEVELING THE FRY For proper operation, the fry station should be level from

STATION side to side and front to back. Using a level place on the

flat areas around the frypot collar, on the middle well, adjust

the casters until the unit is level.

2-5. VENTILATION OF FRY The fry station should be located with provision for venting

STATION into an adequate exhaust hood or ventilation system. This

is essential to permit efficient removal of the steam exhaust

and frying odors. Special precaution must be taken in

designing an exhaust canopy to avoid interference with the

operation of the fry station. We recommend you consult a

local ventilation or heating company to help in designing an

adequate system.

NOTE

Ventilation must conform to local, state, and national

codes. Consult your local fire department or building

authorities.

2-2 998

Henny Penny Model OFE/OFG-321,322,323,324

2-5. VENTILATION OF FRY

STATION (Continued)

When installing the gas fry station do not attach an extension to the gas flue exhaust stack. This may impair proper

operation of the burner, causing malfunctions and possible

negative back draft.

2-6. GAS SUPPLY The gas fry station is factory available for either natural or

propane gas. Check the data plate inside the front door of the

cabinet to determine the proper gas supply requirements.

Do not attempt to use any gas other than that specified on

the data plate. Incorrect gas supply could result in a fire or

explosion.

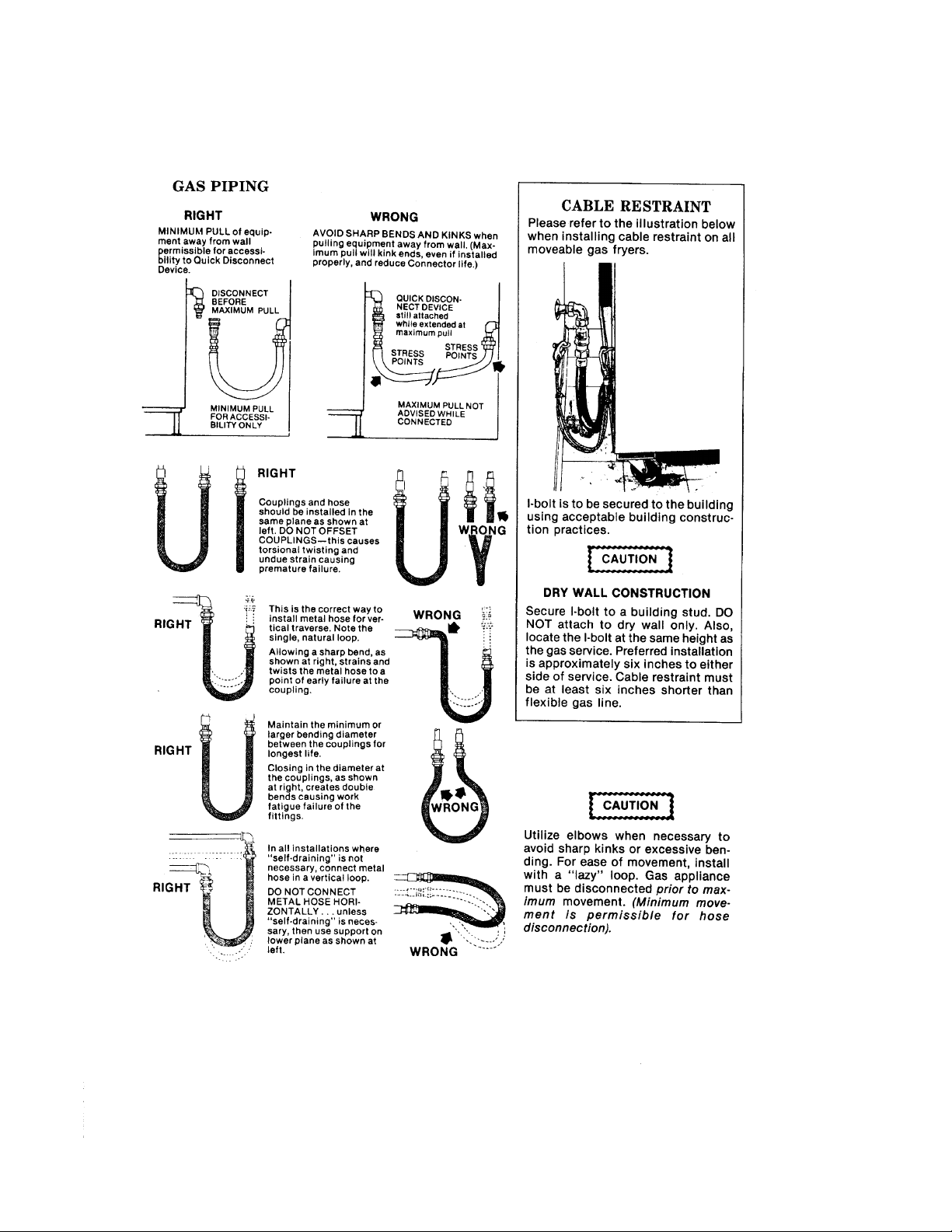

Please refer to the illustration on the following page for the

recommended hookup of the fry station to the main gas line

supply.

To avoid possible serious personal injury:

• Installation must conform with local, state, and national codes.

• Installation must conform with American National Standard

Z223.1-Latest Edition National Fuel Gas Code and the local

municipal building codes. In Canada, installation must be in

accordance with Standard CAN/CGA B 149.1 & Installation

Codes - Gas Burning Appliances and local codes.

• The fry station must be isolated from the gas supply piping

system by closing its individual manual shut off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 PSIG (3.45 KPA) (34.47

mbar).

998 2-3

Henny Penny Model OFE/OFG-321,322,323,324

2-4 998

Henny Penny Model OFE/OFG-321,322,323,324

2-6. GAS SUPPLY • A standard one inch, black steel pipe and malleable fit-

(Continued) tings should be used for gas service connections.

• Do not use cast iron fittings.

• Although one inch (2.54 cm) size pipe is recommended,

piping should be of adequate size and installed to provide a

supply of gas sufficient to meet the maximum demand

without undue loss of pressure between the meter and the

fry station. The pressure loss in the piping system should

not exceed 0.3 inch water column (.747 mbar).

• Do not adjust the vacuum pressure switch. It is factory set

for the most efficiency.

Provisions should be made for moving the fry station for

cleaning and servicing. This may be accomplished by:

1. Installing a manual gas shut off valve and a disconnect

union, or

2. Installing a heavy-duty design A.G.A. certified

connector. In order to be able to service this appliance,

which is provided with casters, a connector complying

with ANSI Z21.69 or CAN 1-6.l0m88 and a

quick-disconnect device, complying with ANSI Z21.41

or CAN 1-6.9m70, must be installed. It must also be

installed with restraining means to guard against

transmission of strain to the connector as specified in

the appliance manufacturer's instruction.

3. Refer to the cable restraint instructions, on preceding page,

on how and where to attach the restraining devices to

the wall and fryer.

2-7. GAS LEAK TEST NOTE

Upon initial installation, and after moving the unit, be

sure the gas dial cock on fry station gas valve is in the

OFF position. After the piping and fittings have been

installed, check for gas leaks. A simple checking

method is to turn on the gas and brush all connections

with a soap solution. If bubbles occur, it indicates

escaping gas. In this event, the piping connection must

be redone.

Never use a lighted match or open flame to test for gas

leaks. Escaping gas could cause an explosion resulting

in severe personal injury.

998 2-5

Henny Penny Model OFE/OFG-321,322,323,324

2-8. PRESSURE REGULATOR The gas pressure regulator on the automatic gas valve is

factory set as follows:

• Natural: 3.5 inches water column (8.7 mbar).

• Propane 10.0 inches water column (24.9 mbar).

2-9. ELECTRICAL

REQUIREMENTS

OFG-320 SERIES • 120 V, 50/60 Hz., 12 A, 1 PH

• 230 V, 50 Hz., 1 PH

The 120 V gas fry station requires a 3 wire grounded

(Earthed) service and is supplied with a grounded cord and

plug. Any 230 volt plug used on the 230 volt unit must

conform to all local, state, and national codes.

DO NOT DISCONNECT THE GROUND (EARTH)

PLUG. This fry station MUST be adequately and

safely grounded or electrical shock could result. Refer

to local electrical codes for correct grounding

(Earthing) procedures or in absence of local codes, with

the National Electrical Code, ANSO/NFPA No. 70

Latest Edition. Canadian models are supplied with a

terminal box, suitable for conduit connection. In

Canada, all electrical connections are to be made in

accordance with CSA C221, Canadian Electrical Code

Part 1, and/or local codes.

Servicing of the filter pump is done at the rear of the unit. If

service is required, disconnect the fry station from the

electrical power source. The fry station will have to be

pulled out from the wall to gain access to rear.

2-6 998

Henny Penny Model OFE/OFG-321,322,323,324

2-9. ELECTRICAL

REQUIREMENTS

OFE-320 SERIES Refer to the table below for supply wiring and fusing.

(Per Well)

Volts Phase Kw Amps

200-208 3 14.4 40

220/240 3 14.4 40

440-480 3 14.4 17

380-415 3 14.4 20

This fry station must be adequately and safely grounded.

Refer to local electrical codes for correct grounding procedures. If fry station is not adequately grounded, electrical

shock could result.

A separate disconnect switch with proper capacity fuses or

breakers must be installed at a convenient location between

the fry station and the power switch.

NOTE

CE units require a minimum wire size of 6mm to be wired

to the terminal block.

2-10 TESTING THE

FRY STATION Each Henny Penny Fry Station was completely checked and

tested prior to shipment. However, it is good practice to

check the unit again after installation.

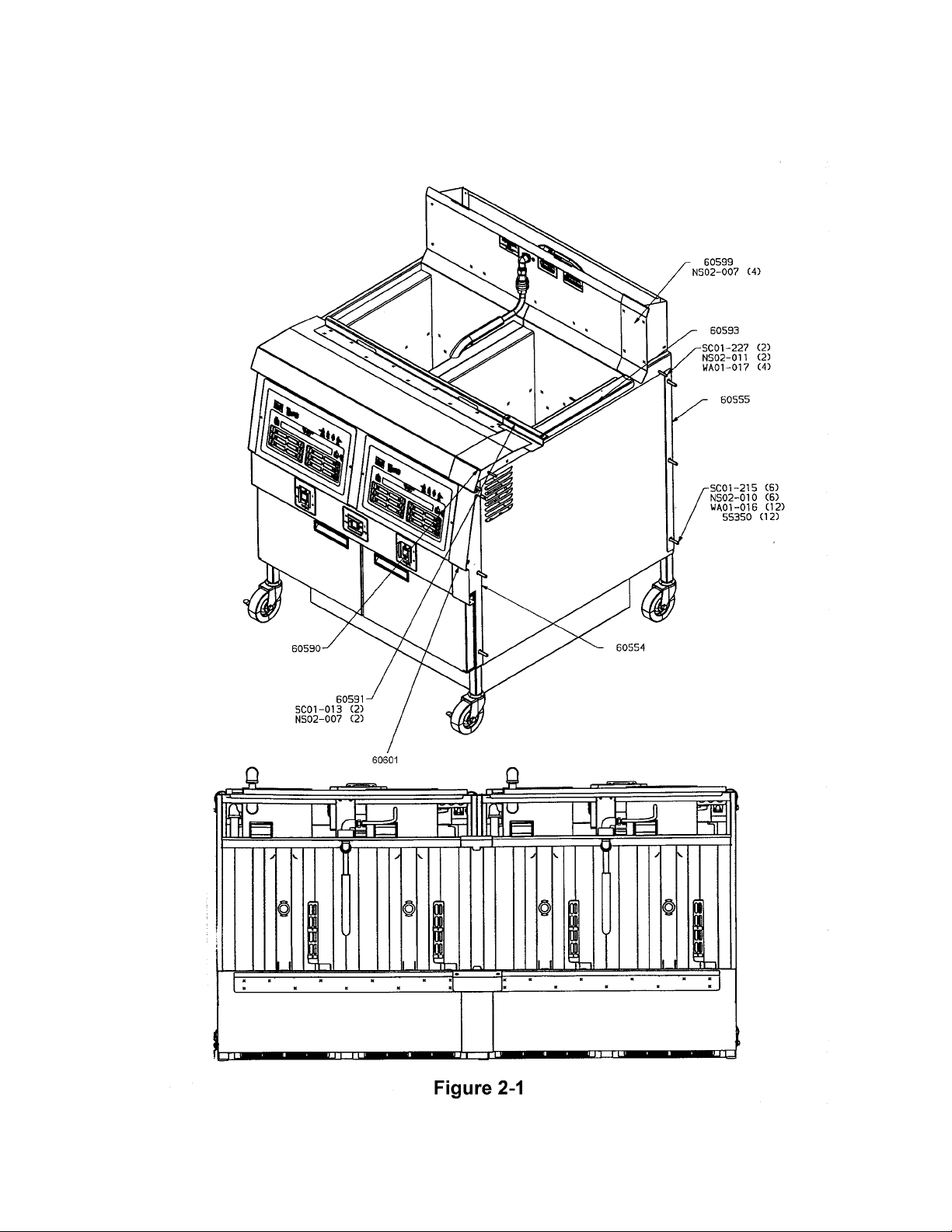

2-11 JOINING INSTRUCTIONS The following instructions are for joining two units together.

The instructions have part numbers in them. Please refer to

figure 2-1 on the following page to visually match the

numbers in the instructions to the illustration.

1. Remove all hardware from the sides of the two fryers.

2. Remove the right control panel assembly from the left

unit and the left control panel assembly from the right

unit.

499 2-7

Henny Penny Model OFE/OFG-321,322,323,324

2-11 JOINING INSTRUCTIONS

(Continued)

3. Move the two units side by side with minimal gap.

4. Remove the right front caster from the left unit and the

left rear caster from the right unit. Fasten both casters to

the rear of the unit with wire ties (EF02-041).

5. Position the two fryers by inserting bolts (SC01-227) thru

the holes in top cover and the pot sides. Use washer

(WA01-017) on both sides of the bolt when installing.

DO NOT TIGHTEN!

6. Position front spacer (60554) between the front of the two

fryers. Place bolt (SC01-215), backed by washers (55350

& WA01-016), thru three holes in the frame capturing the

spacer between the frames. Place washers ( 55350&

WA01-016) on bolt before installing nuts (NS02-010).

DO NOT TIGHTEN!

7. Repeat with rear spacer (60555).

8. Tighten all fasteners securely.

9. Place cover (60593) over gap between fryers.

10. Drill out dimples on rear shroud to 0.250 diameter holes.

11. Apply silicon around edge of unfinished side of rear

cover (60599). Install rear cover (60599) with #8 nuts

(NS02-007).

12. Apply silicon around edge of unfinished side of front

cover (60601). Install front cover (60601) using #8 self

drilling screws (SC03-005).

13. Apply silicon around edge of unfinished side of top cover

(60590) and basket rest cover ( 60591). Position top cover

(60590) on fryer top cover and install basket rest cover

( 60591) using #8 screws and nuts (Sc01-013 & Ns02-007).

14. Apply silicon to any gaps that may be left.

2-8 499

Henny Penny Model OFE/OFG-321,322,323,324

2-11 JOINING INSTRUCTIONS

( Continued)

400 2-9

Henny Penny Model OFE/OFG-321,322,323,324

SECTION 3. OPERATION

3-1. INTRODUCTION This section provides operating procedures for the Henny

Penny OFG/OFE-320 series open fryer with both 6 and 12

button timer controls. Sections 1, 2, and 3 should be read and

all instructions should be followed before operating the fryer.

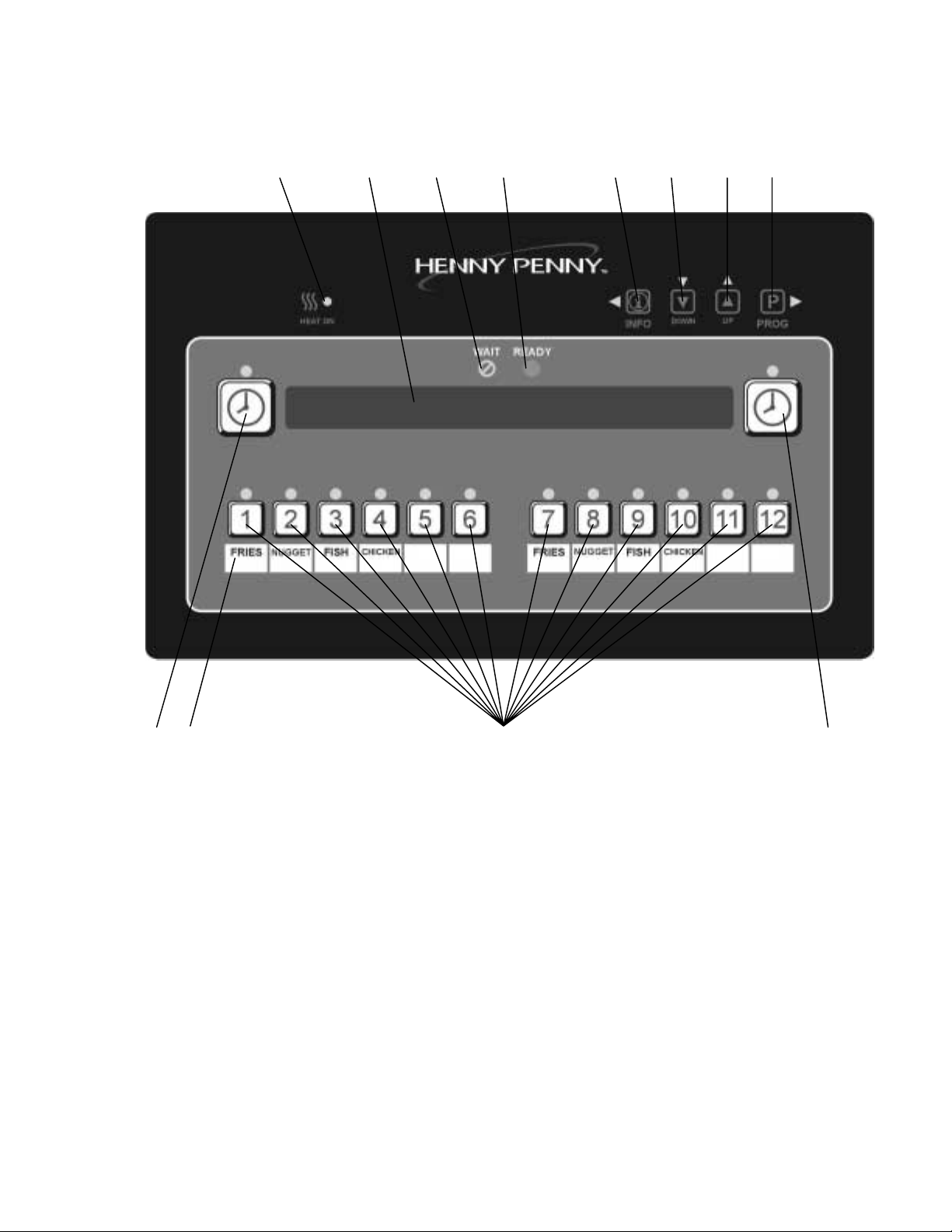

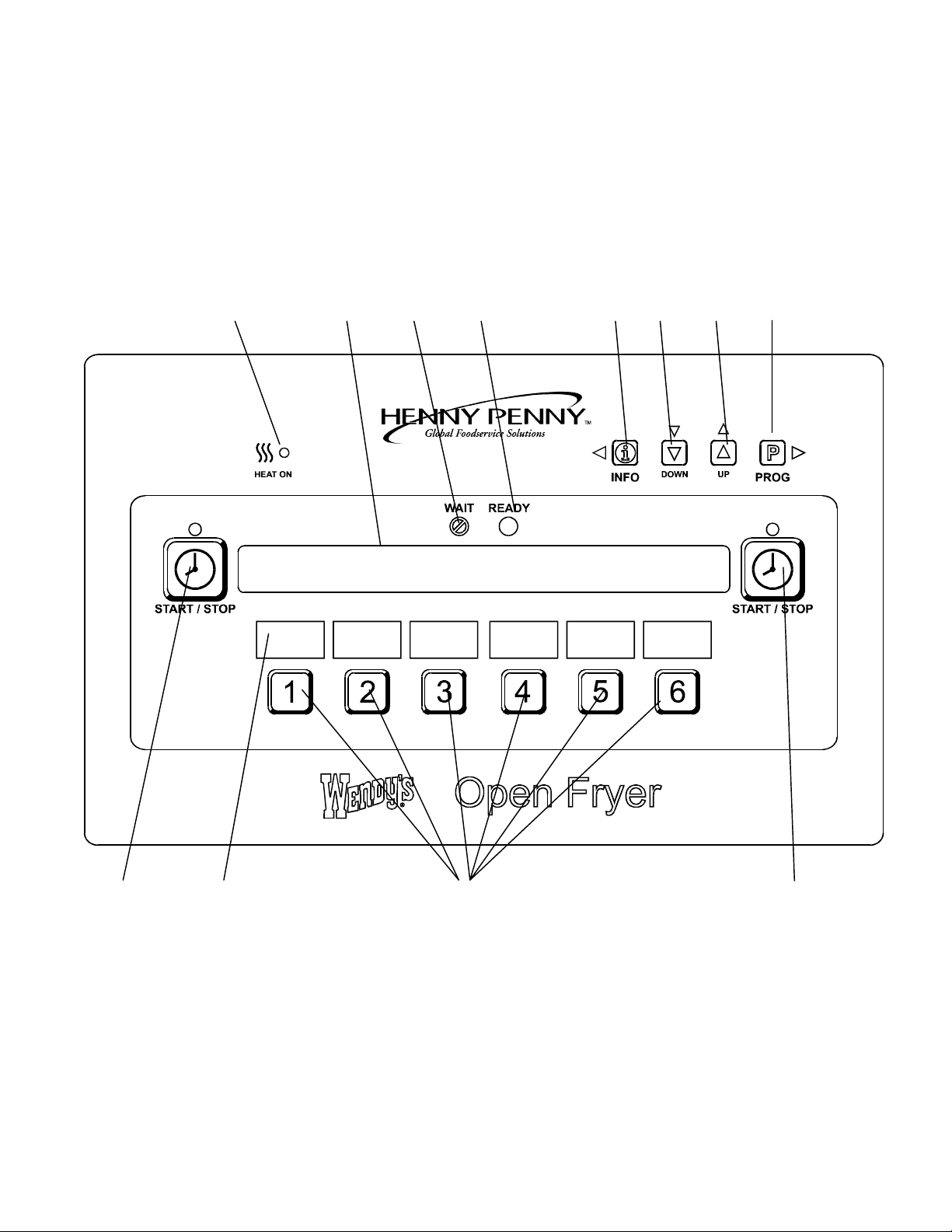

3-2. OPERATING CONTROLS Figure 3-1 shows the function of the 12 button timer control,

and Figure 3-2, shows the function of the 6 timer control.

Fig. Item Description Function

No. No.

3-1 1

The Heat-On LED will light when the control calls for heat,

3-2 and the burners should come on and heat the shortening.

3-1 2 Digital Display The digital display is to show the shortening temperature,

3-2 the timer countdown in the frying cycle, and the selections in

the Program mode. The temperature of the shortening can be

shown by depressing the INFO button. If the

temperature exceeds 425°F (218°C), the display will read

"E-5", “FRYER TOO HOT”.

3-1 3 Wait LED Once the fryer is out of the Melt mode, the Wait LED will

3-2 light, signaling the operator that the shortening temperature is

NOT at the proper temperature for dropping product into the

cookpot.

3-1 4 Ready LED The Ready LED will light when the shortening temperature is

3-2 within 5° of the setpoint temperature, signaling the operator

that the shortening temperature is now at the proper

temperature for dropping product into the cookpot.

3-1 5 The INFO button can display the current shortening

3-2 temperature, the setpoint temperature, as well as cooking

performance. It will also show the amount of time left in

a hold mode. Also, in the program mode, it will step back

to the previous parameter.

3-1 6 & 7 The Up and Down buttons are used to adjust the value

3-2 of the currently displayed setting in the Program mode.

3-1 500

Henny Penny Model OFE/OFG-321,322,323,324

3-2. OPERATING CONTROLS

(Continued)

Fig. Item Description Function

No. No.

3-1 8 The PROG button is used access the program modes.

3-2 Also, once in the program mode, it is used to advance

to the next parameter.

3-1 9 Start/Stop Button The Start/Stop buttons are used to start and stop cooking

3-2 cycles. They will also de-activate the quality timer at the

end of a hold mode.

3-1 10 Menu Card The name of the food product associated with each Product

3-2 Window Selection button below. The menu card strip is located

Behind the decal.

3-1 11 Product Select The Product Select buttons are used to select which food

3-2 Buttons products are to be cooked. (On Auto-lift fryers, the 6 and 12

product buttons are basket lift buttons.)

500 3-2

Henny Penny Model OFE/OFG-321,322,323,324

1 2 3 4 5678

910 11 9

Figure. 3.1

3-3 400

Henny Penny Model OFE/OFG-321,322,323,324

1 234 5678

910 11 9

Figure. 3.2

400 3-4

Henny Penny Model OFE/OFG-321,322,323,324

3-3. FILLING OR It is recommended that a high quality frying shortening be

ADDING SHORTENING used in the OFG/OFE-320 fry stations. Some low grade

shortenings have a high moisture content causing foaming

and boiling over. The Henny Penny OFG-320 requires 55

pounds (24.94 kg) of shortening per cookpot. All cookpots

have two level indicators inscribed on the rear of the cookpot

wall. The top indicator shows when the heated shortening is

at the proper level. Cold shortening should be at the bottom

indicator, since the shortening will expand when heated.

Hot shortening must be maintained at the level indicator

on each cookpot, or fire could result. It is also

recommended to use gloves when in contact with hot

shortening. Shortening and all metal parts that are in

contact with the shortening are extremely hot and

severe burns could result.

Moving the fryer with hot shortening in the cookpots or

filter pan is not recommended. Hot shortening can

splash out and severe burns could result.

3-4. BASIC OPERATIONS The Henny Penny Open Fry Station has electronic controls

AND PROCEDURES for each cookpot. The following is brief description of the

(6 Product Controls) operating procedures for controls with 6 Product Buttons.

1. Be sure the drain valve is in the closed position.

2. Place basket support inside of cookpot.

3. Fill the cookpot with shortening.

When using solid shortening, it is recommended to melt

the shortening on an outside heating source before

placing it in the cookpots. The heating tubes of the gas

cookpot or the elements of the electric pot must be

completely submerged in shortening. Fire could result,

or damage to the cookpot could result.

3-5 500

Henny Penny Model OFE/OFG-321,322,323,324

3-4. BASIC OPERATIONS 4. Move power switch to the "ON" position. Unit will

AND PROCEDURES automatically go into the melt cycle. When the

(6 Product Controls) temperature reaches 230°F (110°C) the control will go

(Continued) into the heat cycle. The shortening will be heated until

the temperature setting is reached.

NOTE

The OFG-320 series fryer has several safety devices which

shuts down the gas supply when they are activated. The

above procedures should be followed to restart the cooker

and if the shut down is repeated, a qualified technician

should be notified.

NOTE

The melt cycle may be bypassed, if desired, by pressing

a Product button and holding it for five seconds.

Do not bypass the melt cycle unless enough shortening

has melted to completely cover all of the heating

tubes. If melt cycle is bypassed before all heating

tubes are covered, excessive smoking of the

shortening, or a fire will result.

5. Once out of the Melt cycle, the Wait LED will flash

until the setpoint temperature has been reached. Then

the Ready LED will light, and the selected product

will display on the left and right side of the display.

NOTE

The timing operation of the two sides of the control

is entirely independent. They may be set, started, or

stopped without affecting each other.

6. Thoroughly stir shortening to stabilize the temperature

throughout the cookpots.

7. Once the shortening temperature has stabilized at the

setpoint temperature, the operator can then lower the

basket with product into the cookpot.

Do not overload, or place product with extreme moisture

content into the basket. 12.5 lbs. (5.7 kgs.) is the maximum

amount of product per cookpot, (15 lbs. (6.75 kgs.)

maximum for Auto-lift fryers). Failure to follow these

directions can result in shortening overflowing the cookpot.

Serious burns or damage to the cookpot could result.

500 3-6

Henny Penny Model OFE/OFG-321,322,323,324

3-4. BASIC OPERATIONS 8. If the right basket was dropped into the shortening, then

AND PROCEDURES the right START/STOP button should be pressed. If the

(6 Product Controls) left basket was dropped, then the left START/STOP

(Continued) button should be pressed.

9. Once the START/STOP button has been pressed, the

timer on the appropriate side (right or left) will start

counting down.

10. At the end of the cook cycle a tone will sound the

Display will flash ‘DONE’. Press the START/STOP

button and lift the basket from the shortening.

11. The display will show which product it is ready to time

down. If a HOLD time was programmed, the controller

will automatically start the hold timer. The display will

alternately show the product selected and the quality

time remaining in minutes. If a different product is

selected during the hold cycle, the display will only

show the product selected. To view the hold time remaining,

push the INFO button.

11. At the end of the Hold mode, a tone will sound and the

display will flash “QUALITY” and the product it was

timing. Press and release the START/STOP button.

The display will show the product it is ready to start

timing for frying.

3-5. BASIC OPERATIONS

AND PROCEDURES

(Electro-Mechanical) The Henny Penny Open Fryer models OFE/OFG are avail-

able with electro-mechanical controls. The electromechanical controls consist of one timer and one thermostat per well.

1. Be sure the drain valve is in the closed position.

2. Place basket support inside of cookpot.

3. Fill the cookpot with shortening.

3-7 500

Henny Penny Model OFE/OFG-321,322,323,324

3-5. BASIC OPERATIONS

AND PROCEDURES

(Electro-Mechanical)

(Continued) When using solid shortening, it is recommended to melt

the shortening on an outside heating source before

placing it in the cookpots. The heating tubes of the gas

cookpot or the elements of the electric pot must be

completely submerged in shortening. Fire could result,

or damage to the cookpot could result.

4. Turn the POWER switch to the On position.

5. Determine the time and temperature settings according

to the type of product to be fried.

6. Set the thermostat to the desired temperature.

7. Set the TIMER dial, but do not turn on yet.

NOTE

Before placing the product into the basket, make certain

the shortening temperature is at the correct frying

temperature for the type of product. Also check that

the TEMPERATURE light is off.

8. Place the product into the basket. Lower the basket into

the shortening. Lift the basket slightly out of the

shortening and shake it, causing the pieces to separate.

Doing this will prevent white spots on the finished

product.

Do not overload, or place product with extreme

moisture content into the basket. 12.5 lbs. (5.7 kgs.) is

the maximum amount of product per cookpot, (15 lbs.

(6.75 kgs.) maximum for Auto-lift fryers). Failure to

follow these directions can result in shortening

overflowing the cookpot. Serious burns or damage to

the cookpot could result.

9. Turn the TIMER ON/OFF switch to ON.

10. At the end of the frying cycle (the TIMER reaches

zero), the TIMER buzzer will sound, and the Timer

light will go off.

500 3-8

Henny Penny Model OFE/OFG-321,322,323,324

3-5. BASIC OPERATIONS

AND PROCEDURES

(Electro-Mechanical)

(Continued) 11. Turn the TIMER switch to OFF. The TIMER will

automatically reset to the previously selected time

setting.

12. Lift the basket and hang it on the front of the frypot to

drain. Allow the product to drain for approximately 15

seconds before dumping the product onto a tray.

13. Place the product into a warming cabinet immediately.

14. Before frying the next load, allow time for the shortening to reheat. (Wait until the TEMPERATURE light

goes off.)

3-6. BASIC OPERATIONS

AND PROCEDURES

(12 Product Controls/Auto-lift) The Henny Penny Open Fryer models OFE/OFG are avail-

able with 12 product button controls. Also, models

OEA/OGA, are available with 12 button controls, equipped

with Auto-Lift features. The Auto-lift controls, allows the

baskets to be automatically lowered into the shortening, at the

beginning of the cook cycle, and raised from the shortening

at the end of the cycle.

1. Be sure the drain valve is in the closed position.

2. Fill the cookpot with shortening.

When using solid shortening, it is recommended to melt

the shortening on an outside heating source before

placing it in the cookpots. The heating tubes of the gas

cookpot or the elements of the electric pot must be

completely submerged in shortening. Fire could result,

or damage to the cookpot could result.

3-9 500

Henny Penny Model OFE/OFG-321,322,323,324

3-6. BASIC OPERATIONS

AND PROCEDURES

(12 Product Controls/Auto-lift)

( Continued) 3. Move power switch to the "ON" position. Unit will

automatically go into the melt cycle. When the

temperature reaches 250°F (121°C) the control will go

into the heat cycle. The shortening will be heated until

the temperature setting is reached.

NOTE

The OFG-320 series fryer has several safety devices

which shuts down the gas supply when they are

activated. The above procedures should be followed to

restart the cooker and if the shut down is repeated, a

qualified technician should be notified.

NOTE

The melt cycle may be bypassed, if desired, by pressing

Do not bypass the melt cycle unless enough shortening

has melted to completely cover all of the heating

tubes. If melt cycle is bypassed before all heating

tubes are covered, excessive smoking of the

shortening, or a fire will result.

4. Once out of the Melt cycle, the Wait LED will flash

until the setpoint temperature has been reached. Then

the Ready LED will illuminate.

NOTE

The timing operation of the two sides of the control

can be programmed entirely independent from each

other for 2 half baskets, or as one timer for a single full

sized basket which will set on both lifts. The default

setting from the factory is for two half sized baskets.

To change to a single full size basket setting, push and

hold the #1 product button while turning on the

“POWER” switch. To change back to the two basket

mode, push and hold the #2 product button while

turning on the “POWER” switch.

5. Thoroughly stir shortening to stabilize the temperature

throughout the cookpots.

500 3-10

Henny Penny Model OFE/OFG-321,322,323,324

3-6. BASIC OPERATIONS 6. Once the shortening temperature has stabilized at the

AND PROCEDURES setpoint temperature, the operator may now place the

(12 Product Controls/Auto-lift) baskets into the shortening, (or for Auto-lift fryers, lift

( Continued) basket ontothe hangers,). Place product into the basket.

Do not overload, or place product with extreme

moisture content into the basket. 12.5 lbs. (5.7 kgs.) is

the maximum amount of product per cookpot, (15 lbs.

(6.75 kgs.) maximum for Auto-lift fryers). Failure to

follow these directions can result in shortening

overflowing the cookpot. Serious burns or damage to

the cookpot could result.

7. If the right basket is to be lowered into the shortening,

then one of the right product buttons should be pressed.

If the left basket is to be lowered, then one of the left

product buttons should be pressed.

8. The timer on the appropriate side will start counting

down. (On Auto-lift fryers, the basket will

automatically lower into the shortening.)

9. At the end of the cook cycle, a tone will sound and the

display will show “DONE”. Lift the basket from the

shortening. (On Auto-lift fryers, the basket will

automatically raise out of the shortening.) To stop the

“DONE” beeper, either press the “TIMER” button, or

the product button.

NOTE

A different product can be selected during the first

minute of cooking.

10. The display will show which product it is ready to time

down. If a HOLD time was programmed, the controller

will automatically start the hold timer. The display will

alternately show the product selected and the hold

time remaining in minutes. If a different product is

selected during the hold cycle, the display will only

show the product selected.

3-11 500

Henny Penny Model OFE/OFG-321,322,323,324

3-6. BASIC OPERATIONS

AND PROCEDURES

(12 Product Controls/Auto-lift) 11. At the end of the Hold mode, a tone will sound and the

( Continued) display will flash “QUALITY” and the product it was

timing. Press and release the TIMER button.

NOTE

In the Cook mode, when "FILTER SUGGESTED,

shows in the display, the operator has the option to

filter at this time, or to continue cooking. But, if the

operator continues cooking, a Filter Lockout will occur

within the next cook cycle, or two.

When "FILTER LOCKOUT", then "YOU *MUST*

FILTER NOW........” shows in the display, the PROG

button is the only button that will function, until the unit is

filtered.

3-7. FILTERING Frying breaded food requires frequent filtering. Taste the

OF SHORTENING cold shortening every day for flavor. Watch the shortening

for foaming during the frying cycle. Discard the shortening

as soon as it shows sign of foaming. Clean the cookpot as

follows each time the shortening is changed or filtered.

1. Turn the main switch to the OFF position. Remove

and clean the fry basket in soap and water. Rinse

thoroughly.

NOTE

Best results are obtained when shortening is filtered at

the normal frying temperature.

2. Use a metal spatula to scrape any build up from the

sides of the cookpot. Do not scrape heating tubes

on the gas models, or heating elements on electric

models.

Position the filter pan properly, under the drain valve,

to prevent splashing of hot shortening. Severe burns

could result.

700 3-12

Henny Penny Model OFE/OFG-321,322,323,324

3-7. FILTERINGOF 3. Open door(s) under unit, and slowly turn drain

SHORTENING valve handle a half turn. Leave for a few minutes, then

(Continued) slowly, fully open drain valve. This prevents much

splashing of the hot shortening as it drains.

4. As the shortening drains from the cookpot, use brushes

to scrape and clean the sides of the cookpot and the

heat tubes or heating elements. If the drain fills with

breading, use straight white brush to push excess

breading into the drain pan.

5. When all of the shortening has drained, scrape or brush

the sides and the bottom of the cookpot.

6. Rinse the cookpot as follows:

Standard fryers

a. Close the drain valve.

b. Position return line over empty cookpot.

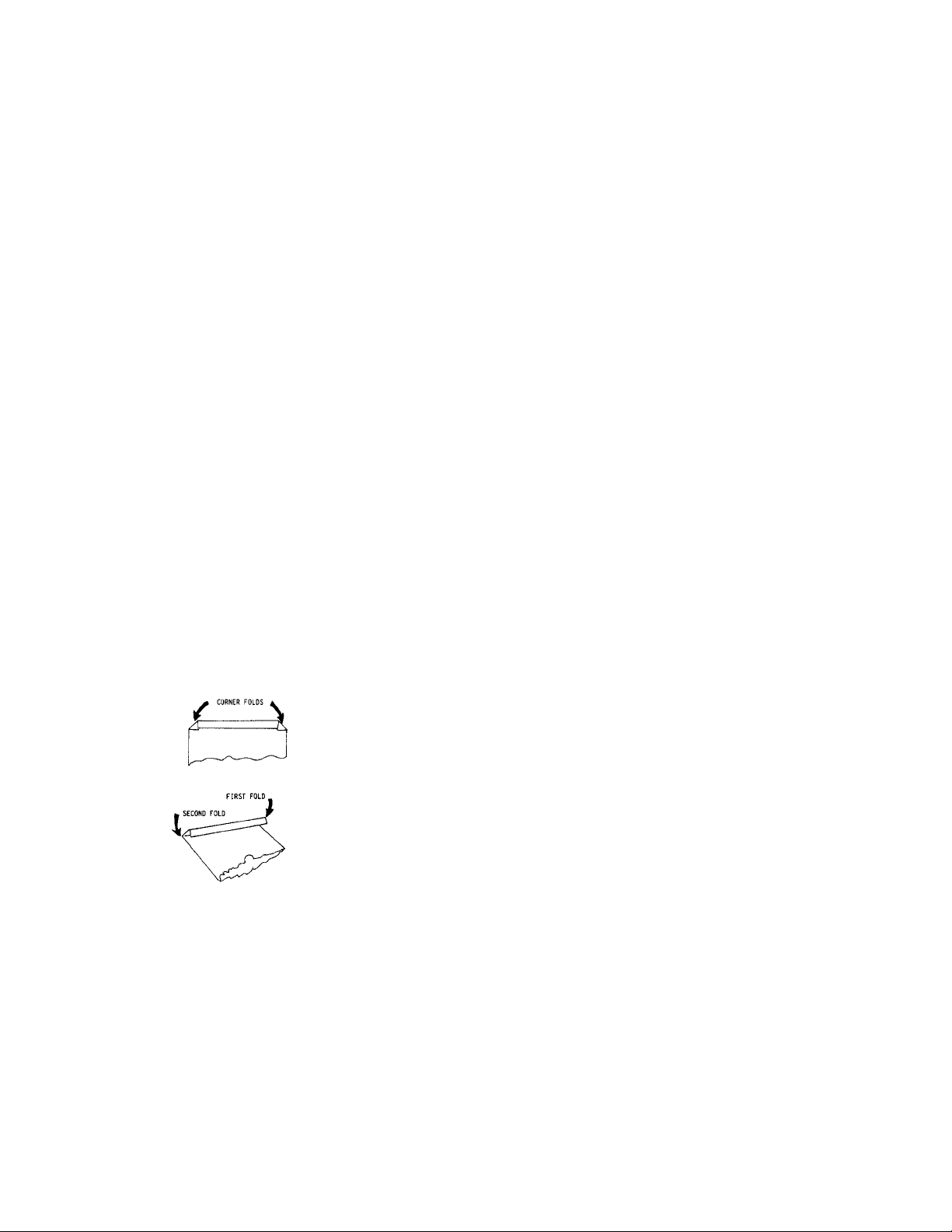

Figure 3-3 c. Move the pump switch to the pump position.

Filter Handle d. Fill the cookpot 1/3 full, then turn off pump.

Autolift fryers

a. Close the drain valve.

b. Turn filter handle to the on position. Figure 3-3.

c. Fill the cookpot 1/3 full.

d. Turn filter handle to the off position.

Use care when reaching across a cookpot of hot

shortening. Severe burns could result.

e. Wash down and scrub the sides of the frypot with

the brushes.

f. After the sides and bottom are cleaned, open the

drain valve.

If shortening flow is slow from faucet, use gloves

to tighten the filter union. This union will be hot, and

severe burns could result.

3-13 700

Henny Penny Model OFE/OFG-321,322,323,324

3-7. FILTERING OF 7. Pump all of the shortening out of the filter pan and

SHORTENING back into the cookpot.

(Continued)

8. When the pump is pumping air only, move the pump

switch from PUMP to OFF, or on autolift fryers, turn

filter handle to OFF.

9. Check the level of the shortening in the cookpot. Add

fresh shortening if necessary, until it reaches the top

level indicator line on the rear wall of the cookpot.

NOTE

About 10 to 12 filterings can be made with one filter

paper envelope, depending on:

• the quantity and type of product fried and filtered

• thetypeofbreadingused

• the amount of crumbs left inside the filter drain pan

When the filter screen assembly and filter paper become

clogged, and the pumping flow slows, clean

the screen assembly and change the filter envelope.

10. To continue cooking, move the main power switch

to the "ON" position, and shortening reheats.

3-8. FILTER PUMP PROBLEMS To help prevent filter pump problems:

1. Properly install paper envelope over the filter screens.

Fold the open end of the envelope, and clamp

With retaining clips so that crumbs cannot enter.

2. Pump shortening, until no shortening is coming from

nozzle.

3-9. FILTER PUMP MOTOR The filter pump motor is equipped with a manual reset but-

PROTECTOR ton in the event the motor's thermal protector actuates. This

reset button is located on the rear of the motor. Wait

approximately 5 minutes before attempting to reset this

protector device.

700 3-14

Loading...

Loading...