Page 1

Page 2

Henny Penny Model OE/OG 301/302/303

Page 3

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY

FM01-360 Revised 12-29-06

Page 4

This manual should be retained in a convenient location for future reference.

Wiring diagram for this appliance is located on the inside access door below

the control panel.

Post in a prominent location, instructions to be followed in event user

smells gas. This information shall be obtained by consulting the local

gas supplier.

FORYOURSAFETY

STORE ON USE GASOLINE OR OT

VAPORS AND LIQUIDS IN THE V

ER APPLI~CE.

Keep appliance area free and clear from combustables.

Do not obstruct the flow of combustion and ventilation air. Adequate

clearance must be left all around appliance for sufficient air to the combustion chamber.

The Model OG-301/302/303 Fryers are equipped with a continuous pilot.

Fryer can not be operated without electric power. Fryer will automatically

return to normal operation when power is restored.

proper instaIlatiom, adj

Page 5

ode1

Nominal Heat Input:

(Net)

Nominal Heat Input:

(Gross)

Supply Pressure:

Test Point Pressure:

Injector Size:

This appliance must be installed in accordance with the manufacturers instructions and the regulations in

force and only used in a suitable ventilated location. Read the instructions fully before installing or

using the appliance.

Natural (I& = 2 1,l KW

Liquid Propane (I& = 21,l KW

Natural (I,,) = 23,4 KW

Liquid Propane (IJ = 23,4 KW (80,000 Btu/h)

Natural (IJ = 20 mbar

Liquid Propane (I,,) = 37 mbar

Liquid Propane (IJ = 50 mbar

Natural (I& = 8,7 mbar

I iquid Propane (I& = 25 mbar

Natural (I,,) = 0,66 mm

Liquid Propane (IJ = 1,04 mm

(72,000 B tu/h)

(72,000 Btu/h)

(80,000 Btu/h)

Consumo Calorico Nominal:

(Neto)

Consumo Calorico Nominal:

(Bruto)

Presion De Alimentacion: Gas Natural (I,,) = 20 mbar

Presion En Ez Punto De Pmeba: Gas Natural (I,,) = 8,7 mbar

Diametro Boquilla: Gas Natural (I,,) = 0,66 mm

Este equip0 debe instalarse linicamente en un recinto adecuadameute ventilado y conforme a las

indicaciones de1 fabricante y a las normas vigentes. Lea completamente las instrucciones antes de

instalar 0 usar este equipo.

Gas Natural (I,) = 21,l KW (72,000 Btu/h)

Propano Licuado (IJ = 21,l KW

Gas Natural (I,,) = 21,l KW

Propano Licuado (I& = 21,l KW

Propano Licuado (I& = 37 mbar

Propano Licuado (I& = 50 mbar

Propano Licuado (IJ = 25 mbar

Propano Licuado (I& = 1,04 mm

(72,000 Btu/h)

(80,000 Btu/h)

(80,000 Btu/h)

Page 6

Section

Page

Section 1.

Section 2.

INTRODUCTION

l-2. Model Variations

l-3.

Features

.....................................................

................................................

.......................................................

l-4. Safety .........................................................

1.5.

Assistance.

INSTALLATION.

2-l.

Introduction..

2-2. Unpacking

..........

.....................................................

... . .

......................................................

.i.

.........................................

............................................. 2-l

2-3. Selecting the Location ...........................................

2-4. Leveling the Fry Station

2-5.

2-6. Gas Supply..

2-7.

2-8.

Ventilation of Fry Station ........................................

...................................................

GasLeakTest

Gas Pilot Lighting

..................................................

...............................................

2-9. Gas Pilot Shut Down Procedure

Z-10.

Z-11.

2-12.

2-13.

Pressure Regulator

..............................................

Electrical Requirements OG-301/302/303 ............................

Electrical Requirements OE-301/302/303 ............................

Testing the Fry Station

.........................................

...................................

..........................................

l-l

l-l

l-l

l-l

l-2

2-l

2-l

2-2

2-2

2-2

2-3

2-5

2-6

2-7

2-7

2-7

2-8

2-8

:-.....i j

Section.3. OPERATION

3-l.

Introduction

3-2. Operating Controls

3-3. Filling or Adding Shortening.

3-4. Operating Controls and Procedures

3-5. Filtering of Shortening. ..........................................

3-6. Filter Pump Problems.

3-7. Filter Pump Motor Protector.

3-8.

Changing the Filter Envelope .....................................

3-9. Cleaning the Cookpots ...........................................

Section 4.

PROGRAMMING.

4-l.

4-2.

First Level Program Mode.

Second Level Program Mode. .....................................

4-3. Idle Programming ...

4-4. Third Level Program Mode

4-5. Special Program Mode

Section 5.

TROUBLE SHOOTING

5-l. Introduction

5-2. Troubleshooting.. ...............................................

.........................................................

....................................................

.............................................. 3-l

.....................................

................................ 3-11

...........................................

.:

............

.......................

.....................................................

.......................................

................................................................................... 4-3

...........................................

.................................................

.................................................... 5-l

3-l

3-l

3-11

3-13

3-14

3-15

3-15

3-17

4-l

4-l

4-2

4r3

4-4

5-l

5-l

i

Page 7

se~tio

7-7. Recommended Spare Parts for Distributors...................................................... 7-1

age

Section6. MAINTENANCE......................................................

....................................................

................................................

......................................

..........................................

............................

...............................

................................

.......................................

...............................................

..........................................

...................................................

............................................

...................................................

................................................

.................................................

..............................

...............................................

....................................................

..................................................

............................................

......................................................

Section 7.

6-l.

6-2.

6-3.

6-4.

6-5.

6-6.

6-7.

6-8.

6-9.

6-10.

6-11.

6-12.

6-13.

6-14.

6-15.

6-16.

6-17.

6-18.

Introduction

Test Instruments

Removing the Control Panel

Thermal Sensor (Probe)

High Temperature Limit Control (electric models)

High Temperature Limit Control (gas models)

Heating Elements (electric models only)

Heating Contactors (electric models)

Gas Burner Assembly (gas models).

Thermocouple (gas models)

Gas Control Valve

Fuses and Fuse Holders

Drain Switch

Power On/Off Switch

Filter Switch

Filtering System

GasConversion

Gas Safety Solenoid (gas models only)

PARTS INFORMATION

7-l.

7-2.

7-3.

7-4.

7-5.

7-6.

Introduction

Genuine Parts

When Ordering Parts

Prices .........................................................

Delivery ........................................................

Warranty

....................

.......................

6-l

6-l

6-l

6-l

6-2

6-4

6-6

6-8

6-10

6-12

6-14

6-15

6-18

6-19

6-20

6-21

6-22

6-25

6-27

7-l

7-l

7-l

7-l

7-l

7-l

7-l

Henny Penny Distributor Lists (Domestic and International)

ii

Page 8

em

The Henny Penny Open Fry Station is a basic unit of food

equipment designed to cook foods better and easier. The

microcomputer based design helps make this possible.

1-2.

NS

This manual covers the following variations of the Henny

Penny Open Fry Station:

Model OG-301/302/303 (gas model)

Model OE-301/302/303 (electric model)

0 Easily cleaned.

@ 43 lb. shortening capacity - gas model.

@ 48 lb. shortening capacity - electric model.

2 Half size baskets per well (or full size baskets).

0 Microcomputer control.

@ Stainless steel construction.

0 Manual reset high limit control.

Self-diagnostic system built into controls.

* Built in filter (handles all 3 wells).

The Henny Penny Fry Station has many safety features

incorporated. However, the only way to ensure safe

operation is to fully understand the proper installation,

operation, and maintenance procedures. The instructions

in this manual have been prepared to aid you in learning

the proper procedures. Where information is of particular

importance or is safety related, the words DANGER,

WARNING, CAUTION, or NOTE are used. Their usage is

described below:

The word DANGER indicates an imminent hazard which

will result in highly serious injury such as second or third

degree burns.

Page 9

The word WARNING is used to alert you to a procedure

that if not performed properly, might cause personal injury.

The word CAUTION is used to alert you to a procedure

that, if not performed properly, may damage the fry station.

The word NOTE is used to highlight especially important

information.

Should you require outside assistance, just call your local

independent distributor maintained by Hennv Penny

Corporation.

In addition, feel free to contact our corporate headquarters in

Eaton, Ohio. Dial l-800-4 17-84 17 toll free.

Page 10

enny

This section provides the installation instructions for the

Henny Penny Fry Station.

Installation of the unit should be performed only by a

qualified service technician.

Do not puncture the unit with any objects such as drills or

screws as component damage or electrical shock could result.

The Henny Penny Fry Station has been tested, inspected,

and expertly packed to ensure arrival at its destination in

the best possible condition. The unit is bolted to a wooden

skid and then packed inside a heavy cardboard carton with

sufficient padding to withstand normal shipping treatment.

Any shipping damage should be noted in the presence of

the delivery agent and signed prior to his or her departure.

1. Carefully cut bands from cardboard carton.

2. Lift carton from fryer.

This manual should be retained in a convenient location for

future reference.

Wiring diagram for this appliance is located on the inside

access door below the control panel. Post in a prominent

location, instructions to be followed in event user smells gas.

This information shall be obtained by consulting the local

gas supplier.

Page 11

The proper location of the Fry Station is very important

for operation, speed, and convenience. The location of the

fiy station should allow clearances for servicing and proper

operation. Choose a location which will provide easy loading

and unloading without interfering with the final assembly of

food orders. Operators have found that frying from raw to

finish, and holding the product in warmers provides fast con

tinuous service. Keep in mind the best efficiency will be

obtained by a straight line operation, i.e. raw in one side and

finished out the other side. Order assembly can be moved

away with only a slight loss of efficiency.

The fryer should be installed in such a way as to prevent

tipping or movement causing splashing of hot liquid shortening.

This may be accomplished by the location the fiy station is in, or

by restraining ties.

The gas Model OG-300 Series Fry Station is designed

for installation on combustible floors and adjacent to

combustible walls. Fry Station must be installed with a

minimum clearance from all combustible, and

noncombustible materials, 4 inches from side and 4

inches from the back.

For proper operation, the fry station should be level from

side to side and front to back. Using a level place on the

flat areas around the frypot collar, on the middle well, adjust

the casters until the unit is level.

adequate exhaust hood or vent

is essential to permit efficient removal of the steam exhaust and

frying odors. Special precaution must be taken in designing an

exhaust canopy to avoid interference with the operation of the

1 fry station. We recommend you consult a local ventilation or

heating company to help in designing an adequate system.

Ventilation must conform to local, state, and national codes.

Consult your local fire department or building authorities.

Page 12

When installing the gas fry station do not attach an extension to the gas flue exhaust stack. This may impair proper

operation of the burner, causing malfunctions and possible

negative back draft.

The gas fry station is factory available for either natural

or propane gas. Check the data plate inside the front door

of the cabinet to determine the proper gas supply

requirements.

TE

The OG-301 can be operated at altitudes of up to 4000 feet

above sea level with no changes to the unit. For operation

above 4000 feet, please contact Henny Penny Corporation

for changes to the unit.

Do not attempt to use any gas other than that specified on

the data plate. Incorrect gas supply could result in a fire

or explosion.

Please refer to the illustration on the following page for the

recommended hookup of the fry station to the main gas line

supply.

To avoid possible serious personal injury:

* Installation must conform with American National Standard

2223. l-Latest Edition National Fuel Gas Code and the local

municipal building codes. In Canada, installation must be in

accordance with Standard CAN/CGA B 1 49.1 & .2,

Installation Codes - Gas Burning Appliances and local

codes.

0 The fry station and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

l/2 PSIG (3.45 KPA).

* The fry station must be isolated from the gas supply piping

system by closing its individual manual shut off valve

during any pressure testing of the gas supply piping system

at test pressures equal to or less than l/2 PSIG (3.45 KPA).

Page 13

odel

T

INIMU~I PULL of equipment away from wall

permissible for accessibility to Quick Disconnect

Device.

Couplings and hose

should be installed in the

same plane as shown at

left. DO NOT OFFSET

COUPLINGS-this causes

torsional twisting and

undue strain causing

premature failure.

AVOID SHARP BENDS AND KINKS when

pulling equipment away from wall. (Maximum pull will kink ends, even if installed

properly, and reduce Connector life.)

~

QUICK DISCON.

NECT DEVICE

while extended

MAXIMUM PULL NOT

ADVISED WHILE

CONNECTED

Please refer to the illustration below

when installing cable restraint on all

moveable gas fryers.

at

l-bolt is to be secured to the building

using acceptable building construction practices.

This is the correct way to

install metal hose for vertical traverse. Note the

single, natural loop.

Allowing a sharp bend, as

shown at right, strains and

twists the metal hose to a

point of early failure at the

coupling.

Maintain the minimum or

larger bending diameter

between the couplings

longest life.

Closing in the diameter at

the couplings, as shown

at right, creates double

bends causing work

fatigue failure of the

fittings.

In all installations where

“self-draining” is not

necessary, connect metal

hose in a vertical loop.

~0 NOT CONNECT

METAL HOSE HORI-

ZONTALLY . . . unless

“self-draining” is neces-

sary, then us% support on

lower plane as shown at

left.

for

c

CT1

Secure l-bolt to a building stud. DO

NOT attach to dry wall only. Also,

locate the l-bolt at the same height as

the gas service. Preferred installation

is approximately six inches to either

side of service. Cable restraint must

be at least six inches shorter than

flexible gas line.

Utilize elbows when necessary to

avoid sharp kinks or excessive bending. For ease of movement, install

with a “lazy” loop. Gas appliance

must be disconnected prior to max-

imum movement. (Minimum move-

ment is permissible for hose

disconnection).

Page 14

A standard one inch, black steel pipe and malleable fittings

should be used for gas service connections.

Do not use cast iron fittings.

Although one inch size pipe is‘reconunended, piping

should be of adequate size and installed to provide a supply

of gas sufficient to meet the maximum demand without

undue loss of pressure between the meter and the fry station.

The pressure loss in the piping system should not exceed 0.3

inch water column.

“revisions should be made for moving the fry station for

leaning and servicing. This may be accomplished by:

Installing a manual gas shut off valve and a disconnect

union, or

Installing a heavy duty design A.G.A. certified

connector. In order to be able to service this appliance,

which is provided with casters, a connector complying

with ANSI 221.69 or CAN/CGA 6.16 and a

quick-disconnect device complying with ANSI 22 1.4 1

or CAN l-6.9 must be installed. It must also be

installed with restraining means to guard against

transmission of strain to the connector as specified in

the appliance manufacturer’s instruction.

Refer to the cable restraint instructions (illustration 2-6)

on how and where to attach the restraining devices to

the wall and fryer.

Prior to turning the gas supply on, be sure the gas dial

cock on fry station gas valve is in the OFF position.

After the piping and fittings have been installed, check

for gas leaks. A simple checking method is to turn on

the gas and brush all connections with a soap solution.

If bubbles occur, it indicates escaping gas. In this

event, the piping connection must be redone.

Never use a lighted.match or open flame to test for gas

leaks. Escaping gas could cause an explosion resulting

in severe personal injury.

Page 15

The following steps provide the pilot PROCEDURE lighting

procedure:

1. Open doors and open gas shut-off valve. (see illustrations)

2. The gas cock dial has a dual function:

a. Complete control of gas to the pilot and main burner.

b. When in the pilot position, it is the reset mechanism

for the automatic pilot.

3. Partially depress and turn the control gas cock dial to

the OFF position.

4. Wait a sufficient length of time to allow any gas which

may have accumulated in the burner compartment to

escape (at least 5 minutes).

5. Turn the main power switch to the OFF position.

6. Turn the gas cock dial to the PILOT position.

7. Depress and hold gas cock dial while lighting the pilot.

Allow the pilot to burn approximately 30 seconds before

releasing the gas cock dial. The pilot should remain

lighted.

If the pilot does not remain lighted, repeat steps 2 and 3,

allowing a longer period of time before releasing the gas

cock dial.

8. Turn the gas cock dial to the ON position.

9. Turn the power switch to the “ON” position.

10. Listen for the gas burner ignition. It will be an audible

sound due to the gas igniting at the gas jets within the

burner.

Do not leave the power switch on for more than 10 seconds;

damage to the frypot may result.

11. The frypots should be cleaned per the instructions in

section 3.

12. The frypots must be filled to the proper level with

shortening. Refer to section 3-4.

13. The fry station is now ready for operation.

Page 16

Depress lightly and turn manual lever on gas valve to

the OFF position.

The gas pressure regulator on the automatic gas valve is

factory set as follows:

@ Natural: 3.5 inches water column.

* Propane 10 0 inches water column.

e

120 V, 50/60 Hz., 12 A, 1 PH

0 230 V, 50/60 HZ., 6 A, 1 PH

The gas fry station requires a 3 wire grounded service.

W

I

DO NOT DISCONNECT THE GROUND PLUG. This

fry station MUST be adequately and safely grounded or

electrical shock could result. Refer to local electrical

codes for correct grounding procedures or in absence of

local codes, with the National Electrical Code,

ANSO/NFPA No. 70 Latest Edition. Canadian models

are supplied with a terminal box, suitable for conduit

connection. In Canada, all electrical connections are to

be made in accordance with CSA C22 1, Canadian

Electrical Code Part 1, and/or local codes.

Servicing of the filter pump is done at the rear of the

unit. If service is required, disconnect the fry station

from the electrical power source. The fry station will

have to be pulled out from the wall.to gain access to

rear.

ING

c

Page 17

The OE-301/302/303 is available from the factory

wired 208, or 220/240

volts, 50 or 60 hertz source.

Refer to the table below for supply wiring and fusing.

Volts Phase

208 3

208 3

220/240 3

2201240 3

400 3

400 3

KW

Amps

11.25 31

13.50 38

11.25 30132

13.50 33135

11.25 16

13.50 20

This fry station must be adequately and safely

grounded. Refer to local electrical codes for correct

grounding procedures. If fry station is not adequately

grounded, electrical shock could result.

A separate disconnect switch with proper capacity fuses

or breakers must be installed at a convenient location

between the fry station and the power source.

I

Each Hentry Penny Fry Station was completely checked

and tested prior to shipment. However, it is good

practice to check the unit a again after installation.

Page 18

odel

301/302/303

This section provides operating procedures for the Henny Penny OG/OE-301/302/303. Sections 1, 2, and 3 should be read

and all instructions should be followed before operating the

fryer.

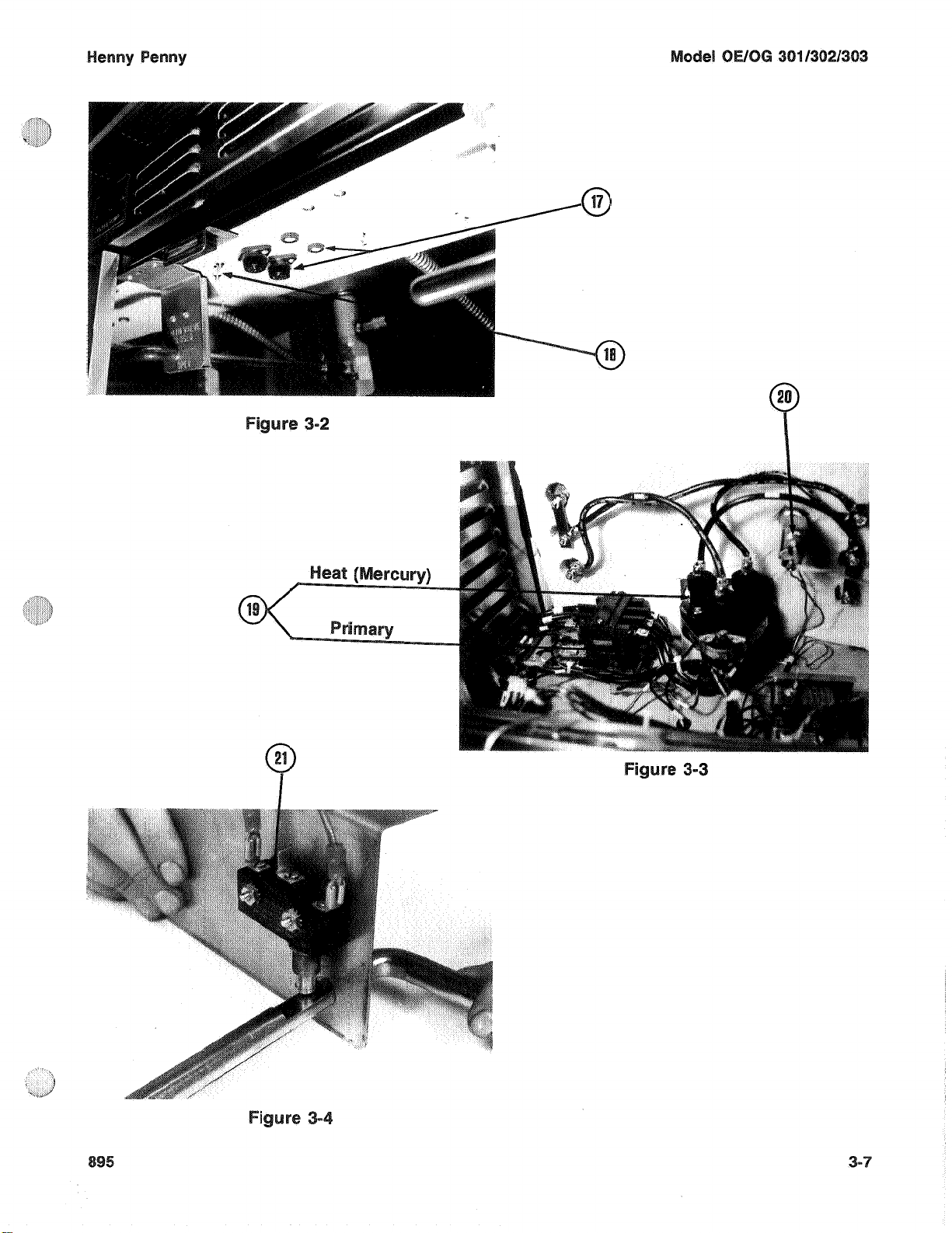

3-2. Figures 3-1 through 3-8 identify and describe the function of

all operating controls and components.

Page 3-10 describes the function of electromechanical controls,

or units without computer controls.

Fig.

No.

3-l

3-1

3-l

3-l

Item

No.

1

2

3

escription

Power Switch

Digital Display

Timer Switch

Set Switch

Function

This two position rocker type switch controls the power to the

fryer when in the on position.

The digital display is to show the shortening temperature, as

well as the timer countdown in the frying cycle. The temperature

of the shortening can be determined by depressing the

temperature switch. If the temperature is below 250°F (121°C),

the digital display will read “LO”. If the temperature exceeds

390°F (199”C), the display will read “HI”. Any temperature

between these two settings will be displayed.

The right timer can be activated or reset by gently depressing

the timer switch. The same holds true for the left timer switch.

The left display shows the left timer information and the right

display shows the information for the right timer.

The set switch is used to set the cooking cycles and to enter

the special program modes.

3-l

Exit Melt Switch

Temperature Switch

6

The exit melt swtich is used to bypass the melt cycle. By pressing and holding the exit melt switch for five seconds, the heat

will come on continuously.

By pressing the temperature switch (indicated by thermometer),

the actual shortening temperature will show on the left display

and the setpoint temperature on the right display.

Page 19

Melt LED

When the melt LED is flashing, the fryer is in the melt cycle.

When the temperature of the shortening reaches approximately

250°F (121”C), the melt LED will go off and automatically

switch to the heat cycle.

When using solid shortening, it is recommended to melt the

shortening on an outside heating source before placing shortening in the cookpots. Heating elements, and the slope of the gas

cookpot must be completely submerged in shorting. Fire could

result, or damage to the cookpot could result.

Ready LED

Head LED

Product LED

Time LED

Temperature LED

Alarm LED

The ready LED illuminates when the temperature of the

shortening is near the setpoint temperature. (It will illuminate

if the temperature is 5°F (or “C) more than the setpoint

temperature.)

The heat LED illuminates when the heat comes on.

The product LED flashes while in the program modes, and a

new product can be selected at this time.

The time LED flashes while in the program mode and a new

fry time can be programmed.

The temperature LED flashes while in the program mode and

the setpoint temperature can be programmed.

The alarm LED flashes while,the program mode. Up to four

alarms can be programmed in a cook cycle.

Page 20

tern

No.

I

escriptiori

3-l

3-2

14

15

16

17

Other LED

Idle LED

Up and Down

Switches

Fuses (electric only)

The other LED flashes while in the high level program mode

and special program modes only. Several parameters can be programmed at this time.

The idle LED illuminates when the right timer up and and down

switch is pressed for two seconds. The indicator passes through

the other product LEDs to the idle LED. The control will then

regulate the shortening temperature at a lower programmed

temperature.

Two sets of up and down switches (denoted as triangles) are

on the control. These switches are used in programming and

product selection. A product is selected by pressing and holding

either the up or down switch for two seconds. To select both

the right and left products at the same time the programmed

set point temperature must be the same.

The fuses, located on the panel behind door, are protective

devices that break the circuit when the current exceeds the rated

value. The 5 amp fuses provide an overload protection for the

control panel.

&I -;j

3-2

3-3

3-3

18

19

20

High Limit Reset

Contactors

(electric only)

Thermal Sensor

This manual reset, located on panel behind door, must be pushed

up in the event the high limit trips. This red button will manually

reset the high limit. A high limit protects each cookpot.

The contactors are the relays that route power to the heating

elements. One relay coil is in series with the high limit

temperature control, and the other relay coil is in series with

the heat control circuit, which is the mercury contactor.

The thermal sensor, located behind the control panel, determines

the shortening temperature.

Page 21

odel

Drain Interlock

(Hidden behind

bracket)

Drain Valve

The drain interlock switch is a microswitch that provides protection for the heating elements in the event an operator drains

shortening from the frypot while the power switch is on. The

drain switch is designed to automatically shut off the control

system when the drain valve is opened. A drain interlock switch

protects each cookpot.

It is recommended to turn all power off before opening

drain valve.

The drain valve is a two-way ball valve and is normally in the

closed position. Turn the handle to the open position to drain

the shortening from the frypot.

3-6 24

Filter Union

Open the drain valve slowly to eliminate splashing of hot

shortening. Severe burns could result.

The filter union connects the filter assembly to the filter pump.

It is easily disconnected to allow removal of the filter and filter

drain pan.

Page 22

odd 0

301/302/303

Fig.

NO.

3-6

Rte

No.

25

26

Filter Drain Pan

Filter Pump Switch

Function

The .removable filter drain pan houses the filter and catches the

shortening when it is drained from the frypot. It is not to be

used to remove and discard the shortening when the shortening needs replaced.

Use extreme care when handling the drain pan or any metal

which comes in contact with hot shortening. Do not move

drain pan with hot shortening in pan. Severe burns could

result. It is recommended to use gloves.

This two position rocker switch controls the power to the

filter pump motor.

3-6

3-8

3-8

27

28

29

30

Oil Return Line

Gas Shut-Off Valve

(gas only)

Gas Control Valve

(gas only)

Gas Solenoid

(gas only)

The detachable oil return line pivots to reach all three

cookpots when pumping shortening back into the cookpots.

The return line can be removed and a rinse hose connected

to unit to discard shortening from unit.

Each cookpot has its own gas shut-off valve on thegas line

going to the gas valve.

Each cookpot has its own gas control valve which controls

the flow of gas to burner assembly. It requires manual pilot

lighting.

The gas solenoid shuts the flow of gas off to the burner

in this unit that the high limit kicks out, and is present for

each cookpot.

Page 23

Y

el 0

Page 24

.

%

0

Page 25

Y

3

re

re 3-

Page 26

ode! 0

Page 27

Main Power Switch

The main power switch is a two,way switch. Move the

switch to the position marked ON to operate the fryer.

Move the switch to the position marked ON to operate the

The thermostat is an electro-mechanical device used to

below the temperature set by the thermostat.

when the shortening reaches the set temperature.

The timer is an electro-mechanical device that controls the

length of the frying cycle and activates the buzzer when the

frying cycle is complete. Turn the knob to set the black

arrow at the desired frying time.

back to the black arrow when the ON/OFF switch is moved

Move to the OFF position to stop the buzzer after the frying

cycle. This also will reset the timer to the original setting.

The timer indicating light is a red light which is illuminated

when the timer is on.

The red arrow will reset

position to start the timer.

It goes off

Page 28

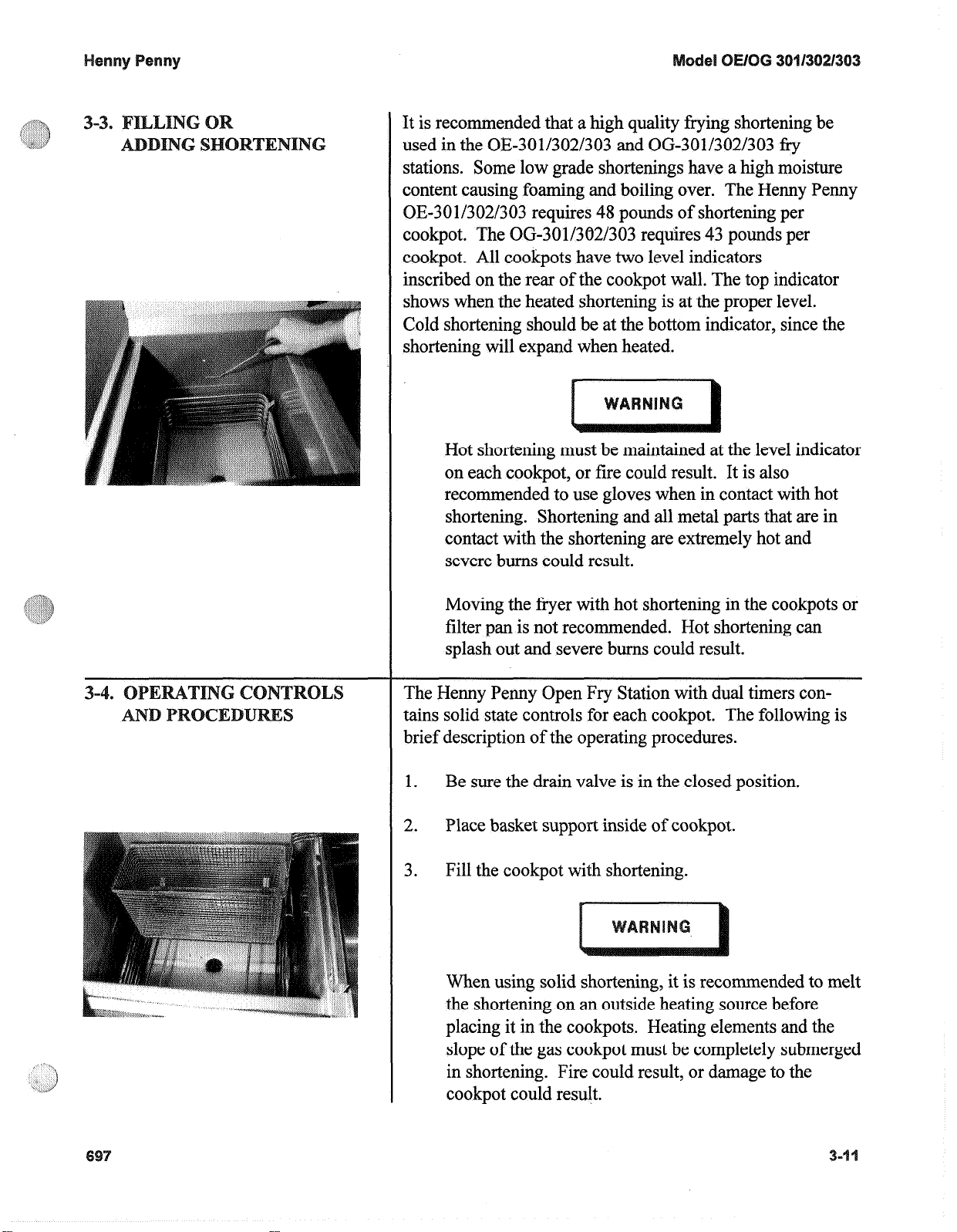

It is recommended that a high quality frying shortening be

used in the O&301/302/303 and OG-301/302/303 fry

stations. Some low grade shortenings have a high moisture

content causing foaming and boiling over. The Henny Penny

OE-301/302/303 requires 48 pounds of shortening per

cookpot. The OG-301/302/303 requires 43 pounds per

cookpot. All cookpots have two level indicators

inscribed on the rear of the cookpot wall. The top indicator

shows when the heated shortening is at the proper level.

Cold shortening should be at the bottom indicator, since the

shortening will expand when heated.

Hot shortening must be maintained at the level indicator

on each cookpot, or fire could result. It is also

recommended to use gloves when in contact with hot

shortening. Shortening and all metal parts that are in

contact with the shortening are extremely hot and

severe burns could result.

Moving the fryer with hot shortening in the cookpots or

filter pan is not recommended. Hot shortening can

splash out and severe burns could result.

The Henry Penny Open Fry Station with dual timers contains solid state controls for each cookpot. The following is

brief description of the operating procedures.

Be sure the drain valve is in the closed position.

1.

2.

Place basket support inside of cookpot.

Fill the cookpot with shortening.

3.

When using solid shortening, it is recommended to melt

the shortening on an outside heating source before

placing it in the cookpots. Heating elements and the

slope of the gas cookpot must be completely submerged

in shortening. Fire could result, or damage to the

cookpot could result.

Page 29

ove power switch to the

4.

automatically go into the melt cycle. When the

temperature reaches 250°F (121OC) the control will go

into the heat cycle. The shortening will be heated until

the temperature setting is reached.

The melt cycle may be bypassed, if desired, by pressing the

Exit Melt switch and holding it for five seconds.

Do not bypass the melt cycle unless enough shortening has

melted to completely cover all of the heating elements. If

melt cycle is bypassed before all heating elements are

covered, excessive smoking of the shortening or a fire will

result.

5. Press the up or down switch and hold for two seconds

to select a product. The times and temperatures are

preprogrammed.

“ON” position. Unit will

ri,~

:%; : :.

,\$‘,, ‘>,

The operation of the two t,imers is entirely independent.

They may be set, started, or stopped without affecting each

other.

6. Thoroughly stir shortening to stabilize the temperature

throughout the cookpots.

7. When the shortening temperature has reached setpoint,

ready LED will illuminate, indicating to the operator,

they may drop product.

8. Lower basket with product into cookpot and press timer

switch. Countdown will begin.

9. When frying cycle is complete, a pulsating beep will

sound and the display will read “DONE.” Pressing the

timer switch stops the beeping and starts the hold mode.

10. The baskets can be lifted out to drain for the duration

of the hold mode, the display will flash 0O:OO and a

pulsating beep will sound. Pressing the timer switch

resets it back to the cooking time.

Page 30

el 0

Frying breaded food requires frequent filtering. Taste the

cold shortening every day for flavor. Watch the shortening

for foaming during the frying cycle. Discard the shortening as soon as it shows sign of foaming. Clean the cookpot

as follows each time the shortening is changed or filtered.

1. Turn the main switch to the OFF position. Remove and

clean the fry basket in soap and water. Rinse thoroughly.

Best results are obtained when shortening is filtered at the

normal frying temperature.

2. Use a metal spatula to scrape any build up from the sides

of the cookpot. Do not scrape heating elements on electric models, or the slope on the gas models.

The filter pan must be in the proper position beneath the

drain valve. This will prevent the splashing of shortening

on the floor. This splashing could result in severe burns.

3. Open door(s) under unit and open the drain valve very

slowly, half a turn at first and then slowly to the full open

position. This will prevent excessive splashing of the hot

shortening as it drains into the filter drain pan.

4. As the shortening drains from the cookpot, use brushes

to scrape and clean the side of the cookpot and the

heating elements of the electric model. If the drain fills

with breading, use straight white brush to push excess

breading into the drain pan.

5. When all of the shortening has drained, scrape or brush

the sides and the bottom of the cookpot.

6. Rinse the cookpot as follows:

a. Close the drain valve.

b. Position return line over empty cookpot.

c. Move the pump switch to the pump position.

d. Fill the cookpot l/3 full, then turn off pump.

Page 31

enny

OEI

301l3~2l303

3-5.

(~o~ti~ue~)

F

If shortening is slow coming from faucet, it is possible that

the filter connecting the union on the filter tube line is not

tightened properly. If so, turn off the pump and use gloves

to tighten the union. This union will be hot. Severe burns

could result.

e. Wash down and scrub the sides of the frypot.

f. After the sides and bottom are cleaned, open the drain

valve.

7. Pump all of the shortening out of the filter pan and back

into the cookpot.

8. When the pump is pumping air only, move the pump

switch from PUMP to OFF.

9. Check the level of the shortening in the cookpot. Add

fresh shortening if necessary, until it reaches the level

indicator line on the rear wall of the cookpot.

Approximately 10 to 12 filterings can be made with one filter

paper envelope, depending on several conditions; the quantity and type of product fried and filtered, the type of

breading used, and the amount of crumb accumulation left

inside the filter drain pan. When the filter screen assembly

and filter paper become clogged and the pumping flow rate

slows down, clean the screen assembly and change the filter

envelope.

10. If frying is to be continued at this time, move the main

power switch back to the “ON” position, and allow time

for reheating of the shortening.

The following steps will help prevent filter pump problems.

1. Make certain the filter paper envelope is properly installed over the filter screens. Make sure the open end

of the envelope is properly folded over and clamped in

place with the retaining clips so that the envelope is

sealed and crumbs cannot enter.

I

2. Make sure all the shortening has been pumped from the

filter lines and the pump by allowing the filter pump

motor to run until no shortening is coming from the

nozzle.

;-,;,?;I

Page 32

The filter pump motor is equipped with a manual reset button in the event the motor’s thermal protector acuates. This

reset button is located on the rear of the motor. Wait approximately 5 minutes before attempting to reset this protector device.

To prevent burns caused by splashing shortening, the unit’s

filter pump switch must be in the OFF position before resetting the filter pump motor’s manual reset protector device.

The reset button will take some effort to reset. A

screwdriver could be used to press against the reset button

to aid in resetting the protector device.

The filter envelope should be changed after lo-12 filterings

or whenever it becomes clogged with crumbs. Proceed as

follows:

1. Move the main power switch to the OFF position.

2. Disconnect the filter union and-remove the filter drain

pan from beneath the cookpot.

This union may be hot. Use protective gloves or clothes to

prevent burns. Also use care to prevent burns caused by

splashing of hot shortening.

3. Remove drain pan cover from drain pan and lift the

screen assembly from the drain pan.

4. Wipe the shortening and crumbs from the drain pan.

Clean the drain pan with soap and water. Thoroughly

rinse with hot water.

5. Unthread the suction standpipe from the screen

assembly.

6. Remove the crumb catcher and clean thoroughly with

soap and water. Rinse thoroughly with hot water.

7. Remove the filter clips and discard the filter envelope.

Page 33

3-8. 8. Clean the top and bottom filter screen with soap and

water. Rinse thoroughly with hot water.

Be sure that the filter screens, crumb catcher, filter clips

and the suction standpipe are thoroughly dry before

assembly of filter envelope or water will dissolve the filter

paper.

9. Assemble the top filter screen to the bottom filter screen.

10. Slide the screen into a clean filter envelope.

11. Fold the corners in and then double fold the open end.

12. Clamp the envelope in place with the two filter retaining clips.

13. Replace the crumb catcher screen on top of the filter

paper. Screw on the suction standpipe assembly.

14. Place complete filter screen assembly back into filter

drain pan, replace cover, and slide pan back into place

beneath the fryer.

15. Connect the filter union by hand. Do not use a wrench

to tighten.

16. The fryer is now ready to operate.

Page 34

odel

301 l3~2l3Q3

After the initial installation of the fryer, as well as .before

every change of shortening, the cookpot should be

thoroughly cleaned as follows:

I

Melt bypass should be in operation. Refer to section 3-2

“Operating Controls” on Exit Melt Switch.

1. Turn the main power switch OFF.

I

The filter drain pan must be in position under the drain

valves to prevent splashing or spilling of hot liquids which

can cause serious burns.

2. If hot shortening is present in the cookpot, it must be

drained by slowly opening the drain valve handle one half

turn. Leave for a few minutes, then slowly open the valve

to full open position.

3. Close the drain valve. Discard the shortening in the filter

pan using the shortening shuttle. Then install the filter

drain under the fryer, leaving out the filter screen

assembly.

Moving the fry station, or drain pan, with hot shortening

in them is not recommended. Hot shortening can splash out,

and severe burns could result.

4. Fill the cookpot to the level indicator with hot water. Add

4 ounces of fryer cleaner to the water and mix

thoroughly. The fry basket can be placed inside the

cookpot for cleaning.

Always wear chemical splash goggles or face shield and protective rubber gloves when cleaning the cookpot as the cleaning solution is high in alkaline. Avoid splashing or other

contact of the solution with your eyes or skins. Severe burns

may result. Carefully read the instructions on the cleaner.

If the solution comes in contact with your eyes rinse

thoroughly with cool water and see a physician immediately.

5. Turn the main power switch to the POWER position and

set temperature to 200°F. The Exit Melt Switch must

be used.

Page 35

6. When the solution reaches 200”F, turn the main power

switch to the OFF position.

Watch cleaning solution constantly to make sure it does NOT

boil over, causing damage to controls.

7. Let the cleaning solutions stand for 15 to 20 minutes

with the power off.

8. Using the fryer brush (never use steel wool), scrub the

inside of the cookpot.

9. After cleaning, open the drain valve and drain cleaning

solution from the cookpot into the drain pan and discard.

10. Replace the empty drain pan, close the drain valve, and

refill the cookpot with plain hot water to the proper

level.

11. Add approximately 8 ounces of distilled vinegar and

bring the solution back up to 200°F (93OC).

12. Using a clean brush, scrub the interior of the cookpot.

This will neutralize the alkaline left by the cleaning

compound.

13. Drain the vinegar rinse water and discard.

14. Rinse down the cookpot using clean, hot water.

15. Thoroughly dry the drain pan and the cookpot interior.

Make sure the inside of the cookpot, the drain valve opening, and all the parts that will come in contact with new

shortening are as dry as possible.

16. Replace the clean filter screen assembly in the drain pan,

replace cover, and install drain pan under fryer.

17. Refill the cookpot with fresh shortening.

Page 36

The controls have four programming levels, a first level mode, a

second level mode, a third level mode, and a special program

mode. In each level, pressing the set switch advances through

the programmable items. Program mode can be entered at

anytime except during an alarm. The left display describes the

item being programmed. The right display shows the item setting and can be changed by pressing the right Up and Down

Switches.

The Low Level Program Mode allows the operator to program

the “global“ set point temperature (if enabled), cook and hold

time, and set up to four alarms for the selected product.

1. Press and hold Set and Temperature Switch for at least

five seconds. A tone will sound, and the left display shows

“OF” and the right display shows the set point temperature.

The temperature LED and all product indicator LED’s flash.

2. Press the right Up and Down Switches to program

desired set point temperature for all products.

3. Press the set switch and left display shows “Slct” and

the right display shows “Prod”. The product LED also

flashes.

4. Press either the left or right Up and Down Switches to select

a product to program, and the LED will be lit next, to the

desired product.

5. Press the set switch and the time LED flashes. The left

displays shows “Fry” and the right display shows the cook

time. Pressing the right Up and Down Switches adjusts the

cook time.

6. Press the set switch and the time LED continues to flash.

The left display shows “Hold,” the right display shows the

hold time and can be adjusted with the right Up and Down

Switches.

Page 37

7. Press the set switch and the alarm LED flashes. The left

display shows “AL 1”) the right display shows the alarm

time and can be adjusted with the right Up and Down

Switches.

8. Repeat step 8 for alarms 2,3, and 4.

9. Press and hold the Set Switch to exit program mode, or

continue to second level mode.

The Second Level Program Mode allows the operator to program load compensation, load anticipation, proportional control,

filter cycle for the selected product, and the idle parameters.

1. While in the first level mode, push and hold the Set and

Exit Melt Switches for five seconds. The beeper will sound

the left display will show “Slct” (Select) and the right display

will show “Prod” (Product). The Product LED also flashes.

2. Press either the right or left Up and Down Switches to

select a product to program.

3. Press Set Switch and the Other LED flashes. The left display

shows “LdCo,” and the right display shows load compensation setting, and can be adjusted with the right Up and

Down Switches.

4. Press the Set Switch and the Other LED continues to flash.

The left display shows “PC,” the right display shows the

proportional control setting, and can be adjusted with the

right Up and Down Switches.

5. Press the Set Switch and the Other LED continues to flash.

The left display shows. “LdAn,” and the right display shows

load anticipation setting, and can be adjusted with the right

Up and Down Switches.

6. Press the Set Switch and the Other LED continues to flash.

The left display shows “Filtr,” and the right display shows

filter cycles setting, and can be adjusted with the right Up

and Down Switches.

7. Press the Set Switch and the Product LED flashes. Press

~

either right or left Up and Down Switches to select another

product to program. Press and hold the Set Switch to exit the

program mode, or continue on to the third level program

mode.

Page 38

8. Also, with the Product LED flashing, pressing the right

2nd

Up and Down Switches will access the Idle Mode

parameters. The idle LED will be flashing, the left display

will continue to show “Slct” and the right display shows

“Prod.” Pressing the Set Switch allows the operator to

program the idle parameters (See Section 4-3).

4-3. I ING

The Idle Mode must be enabled for the operator to access this

mode.

1. While in the Second Program Mode, and the Product LED

is flashing, press the right Up and Down Switches to select

the idle mode items. The Idle LED will be flashing.

2. Press the Set Switch and the Time LED flashes, the left

display shows “idle,”

OFF”. Pressing the right Up and Down Switches to turn

idle on or off.

3. Press the Set Switch and the Time LED flashes. The left

display shows “Auto” and the right display shows

automatic idle time. Adjust the automatic idle time with

the right Up and Down Switches, and to disable the auto

idle feature set time to “OFF.”

4. Press the Set Switch and the Temperature LED flashes.

The left display shows “F” or “C”, and the right display

shows the idle temperature setpoint, which can be adjusted

with the right Up and Down Switches.

5. Press Set Switch and the Product LED flashes. Press and

hold the Set Switch to exit the program mode or continue

to the third level program mode.

and the right display shows “ON or

The Third Level Program Mode allows the operator to enable,

or disable “global” setpoints, program Fahrenheit or Celcius,

probe calibration, alarm duration, and hold duration.

1. While in the d level program mode, press and hold Exit

Melt and Temp switches until the buzzer sounds, and the

left display flashes “glob” and OF”, and the right display

shows “ON” or “OFF.” Pressing the right Up and Down

Switches enables, or disables the global setpoint

programming.

2. Press the Set Switch and the left displays shows “deg”

and the right display shows “OF” or ““C.” Pressing the

right Up and Down Switches allows the operator to select

Fahrenheit, or Celcius.

Page 39

el

3. Press the Set Switch and the left display flashes “Prob”

and “Calib.”

temperature, and the right Up and Down Switches are

used for calibration.

4. Press the Set Switch and the left display flashes “AL”

and “dur.” The right display shows the duration of this

alarm at the end of a cook cycle, and can be adjusted with

the right Up and Down Switches.

5. Press the Set Switch and the left display flashes “Hold”

and “dur.” The left display shows the duration of the hold

alarm at the end of the hold cycle, and can be adjusted

with the right Up & Down Switches.

6. Press and hold the Set Switch to exit the program mode.

I

The right display shows the actual pot

30113Q21303

The Special Program Mode allows the operator to initialize

the program, or to perform an input/output test.

1. Turn Power Switch off, then press and hold the right Up

and Down Switches while turning power switch back on.

The left display shows “init” and the right displays shows

“sgs.” Press and hold the right Up or Down Switch for

five seconds to initialize all settings. Special Program Mode

is automatically exited if initialize is done.

2. While in the Special Program Mode, press the Set Switch

and the left display shows “10” and the right display shows

“test,”

enables all LED’s and displays. Pressing temp. switch

turns on heat. Press and hold Set Switch exits Special Program Mode.

then they go blank. By pressing all switches,

Page 40

This section provides troubleshooting information in the form of

an easy-to-read table.

If a problem occurs during the first operation of a new fryer,

recheck the installation per Section 2 of this manual.

Before troubleshooting, always recheck the operating procedure

per Section 3 of this manual.

e

T

LES

In the event of a control system failure, the digital display will

show an “Error Message.” These messages are coded: E5, E4, E6,

ElO, E15, E41, E50, E51, and E53.

en turn

switc

display shows E4, the control board is getting too hot. Check the

louvers on each side of the unit for obstuctions. If E4 persists,

Turn switch to OFF position, then turn switch back to ON. If

display shows E6, thermal sensor must be replaced. Refer to

section 6-4.

El5

E41, E50,

E5 1, E53

button. If high limit does not reset, high limit must be replaced

per section 6-5, or 6-6.

Drain Switch Close drain, using the drain valve handle. If display still shows

Failure

E 15 check drain valve section 6- 13.

Programming Turn switch to OFF, then back to ON. If display shows any of

Failure the error codes, the control panel needs replaced.

Page 41

LE

NG

With switch in

POWER position

and switch light

not illuminated,

fryer is complete

ly inoperative.

With switch in

power position,

switch light is

on, but all other

lights are out ex

cept the pump

will operate.

Shortening will

not heat but

lights are on.

Open Circuit

No power to

board

Faulty Contactor

(elec. model)

Check to see if unit is plugged in.

Check breaker or fuse at supply box.

Check control panel fuse per Section 6-12.

@ Check POWER switch per Section 6-14. Replace if defective.

.Check voltage at wall receptacle.

Check cord and plug.

Check fuse on PC board.

Faulty Gas Valve

(gas model)

Faulty Gas

Solenoid (gas

model)

Faulty Probe

Faulty High

Limit

Faulty Drain

Switch

Check gas valve per Section 6-11.

Check gas solenoid, per Section 6-19.

Check probe per Section 6-4. “Error message” E6.

Check High Limit per Section 6-6, or 6-7. “Error message”

ElO.

Check drain switch per Section 6-13. “Error message” E15.

Page 42

Shortening will

not heat, but

lights are on.

Faulty Contactor

(elec. model)

Faulty Thermal

Sensor

Check contactor per Section 6-8.

Check thermal sensor per Section 6-4. “Error message” E6.

A. Pilot will not

light (gas model)

Faulty High

Limit

Pilot not lit

Plugged pilot

orifice, and/or

pilot supply tube

Gas supply off

Faulty gas con-

trol valve

Air in gas supply

line

Check high limit control switch per Section 6-6 or 6-7.

* Light pilot per Section 2-9.

* Unplug pilot orifice and/or pilot supply tube.

Turn ON gas supply.

Replace gas control valve.

Bleed air from supply line.

B. Pilot will not

stay lit.

C. Burner will

not light, pilot li

(gas model)

Faulty therm0

couple

Pilot magnetic

PlW

Drain valve open

High Limit con-

trol switch open

Possible faulty

gas control valve

Replace therm0 couple per Section 6-10.

Service per Section 6-11.

Close drain valve.

With power removed from fryer, check across high limit

switch terminals with ohmmeter. Replace if no reading is

indicated on meter.

With power removed from fryer, check across electrical

leads of gas control valve with ohmmeter, and gas valve in

“ON” position. Ohm reading should be 234 ohm resistance.

Replace the control valve if not within 10%.

Page 43

5-2. T

(Continued)

LES

_%

NG

Heating of

shortening too

slow

Heating of

shortening too

slow (elec. model

Low or improper

voltage (elec.

model)

Weak or burnt

out elements

(elec. model)

Points in contactor bad (elec.

model)

Wire(s) loose

Burnt or charred

wire connection

Supply line too

small - low gas

volume (gas

model)

Use a meter and check the receptacle against data plate.

Check heating elements per section (elec. model).

Check contactor per Section 6-8.

Tighten

Replace wire and clean connectors.

Increase supply line size. Refer to installation instructions.

Shortening

overheating

Incorrect jet size

(gas model)

Improper ventilation system (gas

model)

Check probe

calibration

Check contactor

for not opening

(elec. model)

Bad Controller

Replace with proper size jet for type of gas.

Refer to Section 2-5.

Calibrate probe if + 10°F or “C off. If more than + 10°F

or “C, replace probe.

Replace control board if heat indicator stays on past ready

temperature.

Page 44

odel

Foaming or boiling over of

Water in

shortening

shortening.

Improper or bad

shortening

Improper

filtering

Improper rinsing

after cleaning the

fryer

Shortening will

Drain valve

not drain from clogged with

frypot crumbs

Drain valve will

not open by turn-

ing handle

Filter motor rum

but pumps

Filter valve not

open

shortening slowly

Pump clogged

At end of frying cycle, drain shortening and clean frypot.

Add fresh shortening.

Use recommended shortening.

Refer to the procedure covering filtering the shortening.

@ Clean and rinse the frypot. Then dry thoroughly.

8 Open valve force cleaning brush through drain opening.

a Replace cotler pins in in valve capling.

Open filter valve.

Remove and clean pump per Section 6-15.

Filter switch ON

motor does not

run

.“Y Motor hums but

Lb,&> will not pump

Filter line connection loose

Solidified

shortening in

lines

Defective switch

Defective motor

Motor thermal

protector tripped

Clogged lines or

pump

Tighten all filter line connections.

Clear all filter lines of solidified shortening.

Check/replace switch per Section 6-15.

Check/replace motor per Section 6-15.

Reset thermal switch per Section 3-7.

Remove and clean pump and lines.

Replace pump seal, rotor and rollers per 6-15.

5-5

Page 45

Page 46

6-1.

This section provides procedures for checking and replacement

of the various parts used within the unit. Before replacing any

parts, refer to Section 5, Troubleshooting. It will aid you in

determining the cause of a particular malfunction.

ENTS

You may want to use two test instruments to check the electric components.

0 A continuity light

0 An ohmmeter

When the manual refers to a circuit being closed, the continuity

light will be illuminated or the ohmmeter should read (0) unless

otherwise noted.

When the manual refers to the circuit being open, the continuity light will not illuminate, or the ohmmeter will read (1).

A continuity light cannot be used to check coils or motors.

To replace parts located inside the fryer, the control panel must

be removed, or hinged down.

1. Place the power switch in the OFF position and remove

power supplied to the unit, or on electric models, to the

cookpot to be worked on.

Disconnect power supplied to the unit by unplugging the power

cord, or turning off the wall circuit breaker, or fuse. Be aware

that the other controls will HAVE power on electric models,

or electrical shock could result.

Page 47

6-3.

(~~~ti~~ed)

E

EL

Using a Phillips head screwdriver, remove the four screws

2.

securing the control panel to the unit, and let panel swing

down. The panel is hinged to hang in this position for

convenience.

3. Disconnect nine-pin connector and remove probe connection from control panel.

4. To completely remove panel from unit, pull complete control panel up and out of slots securing the panel.

The thermal sensor, or probe, determines the shortening

temperature. If a malfunction does occur, an E6 will be

displayed on the digital display. Turn unit OFF, then back on,

If E6 persists, the probe must be checked, or replaced by the

following steps:

1. Place the power switch in the OFF position, and remove

power supplied to the unit, or on electric models, to the

cookpot to be worked on.

Page 48

Disconnect power supplied to the unit by unplugging the power

cord, or turning off the wall circuit breaker, or fuse. Be aware

that the other controls will HAVE power on electric models,

or electrical shock could result.

2. Swing control panel down per section 6-3.

3. Inspect the probe connection at the board, making sure of

a good connection.

4. Replace control panel, reconnect power supply and turn

power switch to on position. If E6 persists continue on to

step 5.

5. Disconnect power to unit and remove control panel per section 6-3.

6. Drain the shortening from cookpot (electric units continue

to step 8).

7. Remove heat shield from unit.

8. Using a l/2” wrench, loosen nut on compression fitting and

pull probe from pot fitting.

9. Install new probe, making sure the probe extends out to

the outer diameter of the heating elements on electric units.

On gas units, the probe should extend to the outer edge

of probe guard, making sure it doesn’t extend out past

guard.

Care must be taken not to extend the probe beyond the points

described above, or damage to the probe could result. Also,

make sure locking ferrule is in place and do not over-tighten

nut or damage to probe could result. Snug nut up and tighten

l/4 turn past this point.

Page 49

6-5.

This high temperature control is a manual reset control which

senses the temperature of the shortening. If the shortening

temperature exceeds the safe operating limit, this control

switch will open and shut off the heat to the frypot. When the

temperature of the shortening drops to the safe operating limit,

the control must manually be reset. Each frypot has a high

temperature limit control.

Before replacing a high temperature limit control, check to

see that its circuit is closed.

The shortening temperature must be below

380°F to accurately perform this check.

1. Remove electrical power supplied to the cookpot to be

worked on.

Place POWER switch to the OFF position, and unplug

the power cord or open the wall circuit breaker. Be

aware that the other controls will have power, or elec-

trical shock could result.

2. Remove the control panel per section 6-3.

3. Remove control from bracket.

4. Remove the two electrical wires from the high temperature

limit control.

5. Check for continuity between the two terminals after

resetting the control. If the circuit is open, replace the control, then continue with this procedure. (If the circuit is

closed, the high limit is not defective. Reconnect the two

electrical wires.)

Page 50

Before following these steps, place POWER switch to

the OFF position, and unplug the power cord or open

the wall circuit breaker, or electrical shock could result.

Be aware that the other controls will HAVE power.

1. If the tube is broken or cracked, the control will open, shutting off electrical power. The control cannot be reset.

2. Drain shortening from the frypot.

3. Remove control panel, per section 6-3.

4. Loosen small inside screw nut on capillary tube.

5. Remove capillary bulb from bulb holder inside the frypot.

6. Straighten the capillary tube.

7. Remove larger outside nut that threads into pot wall.

8. Remove the two screws that secures the high limit to the

high limit bracket.

9. Loosen clamp on capillary tube.

12. Uncoil capillary line, starting at capillary tube, and insert

through frypot wall.

To avoid electrical shock or other injury, the capillary line must

run under and away from all electrical power wires and ter-

minals. The tube must never be in such a position where it could

accidentally touch the electrical power terminals.

13. Carefully bend the capillary bulb and tube toward bulb

holder on heating elements.

14. Slip capillary bulb into bulb holder located on heating

elements. Pull excess capillary line from pot and tighten

nut into frypot wall;

Page 51

6-5.

Be sure capillary bulb of high limit is located behind front edge

of elements. Capillary bulb and bulb holders should be positioned as not to interfere with basket or when cleaning the

frypot wall, or damage to capillary tube could result.

15. With excess capillary line pulled out, tighten smaller nut.

16. Clamp capillary tube down to shroud.

17. Replace front panel.

18. Refill with shortening.

The gas units, OG-301/302/303, use the same high

temperature limit control as the electric, OE-301/302/303,

but the mounting of the capillary tube and fittings are

different on the gas models compared to the electric models.

Use the same procedure as in section 6-5.

1. Place the power switch in the OFF position, and remove

power supplied to the unit.

Disconnect power supplied to the unit by unplugging the power

cord, or turning off the wall circuit breaker or fuse. Electrical

shock could result.

2. Drain shortening from frypot.

3. Remove control panel, per section 6-3.

emove screws from heat shield and remove shield.

Page 52

213

5. Remove probe as described in section 6-4.

6. Loosen small inside screw nut on capillary tube.

7. Remove capillary bulb from bulb holder on inside of frypot.

8. Remove larger outside screw nut that threads into “Y”

fitting.

9. Cut the capillary bulb on the inside of cookpot, and remove

the capillary from unit.

10. Remove capillary from clamp on shroud.

11. Remove the two screws that secures the high limit to

bracket and remove the control from the unit.

12. Insert capillary of new high limit, through “Y” fitting.

13. Put pipe sealant on threads and screw “Y” fitting back

into fitting in frypot.

14. Insert new control on bracket.

15. Carefully bend the capillary bulb towards the bulb holder

and insert into holder.

16. Pull excess capillary line from pot and tighten nut into

“Y” fitting.

Be sure capillary bulb of high limit is located close to frypot

wall. Capillary bulb and line should be positioned as not to interfere with basket, or when cleaning the frypot wall, or

damage to capillary tube could result.

17. With excess capillary line pulled out tighten smaller nut.

18. Clamp capillary tube down to shroud.

To avoid electrical shock or other injury, the capillary tube must

run under and away from all electrical power wires and terminals. The tube must never be in such a position where it could

accidentally touch the electrical power terminals.

19. Replace probe, per section 6-4.

20. Replace front panel.

21. Refill with shortening.

Page 53

Heating elements are available for 208 and 230 voltage. Check

data plate to determine the correct voltage.

If the shortening’s temperature recovery is very slow or at

a slower rate than required, this may indicate defective heating

element(s). An ohmmeter will quickly indicate if the elements

are shorted or open.

1. Remove electrical power supplied to cookpot to be worked

on.

Place power switch in the OFF position and unplug the power

cord or open the wall circuit breaker, for the cookpot to be

worked on. Be aware the other controls will have power, or

electrical shock could result.

2. Remove the control panel per section 6-3.

3. Perform an ohm check on one element at a time, with wires

disconnected from element. If the resistance is not within

tolerance, replace the element.

potage

208

208

230

230

1. Drain the shortening.

2. Remove the High Limit bulb holder from the heating element inside the frypot.

3. Remove the heating element wires from the terminals by

removing nuts (5) and washers (6 and 7). Label each so

it can be replaced in the same position on the new element.

4. Loosen the bolts on the five element spreaders.

5. Slide the element spreaders to the center of the heating

elements.

6. Remove the brass nuts (4) and washers (3), which secure

the ends of the elements through the frypot wall.

attage

3750

4500

3750

4500

esistanee 10 Ohms (cold)

11+ 1.5

9+1

12+2

11 & 1.5

Page 54

enny

7. Remove the heating elements from the frypot as a group

by lifting the far end and sliding them up and out toward

the rear of the frypot.

Always install new rubber 0 rings (2) when installing heater

elements.

8. Install new heating elements with new rubber 0 rings (2)

mounted on terminal ends, and spreaders loosely mounted

in the center of the stacked elements.

9. Replace the heating elements, terminal end first at approximately 45O angle, slipping the terminal ends through the

front wall of the frypot.

10. Replace the brass nuts (4) and washers (3) on the heating

element terminals. Tighten the brass nuts to 30 foot lbs

of torque.

11. Move the element spreaders from the center of the ele-

ment, into a position which will spread each element apart

evenly on all four sides, and tighten. Slide the fifth

spreader over to protect the probe.

12. Replace the High Limit bulb holder on the top element,

and position the bulb between the top and second element

midway from side to side, and tighten screw which holds

the bulb in place.

13. Reconnect the wires to the appropriate terminal as labeled

when they were removed.

14. Replace the front control panel.

15. Connect the power cord to the wall receptacle or close wall

circuit breaker.

Heating elements should never be energized without shortening in the frypot, or damage to elements could result.

16. Replace the shortening in the frypot.

Page 55

-8.

ode

ELS)

Each electric fryer requires two switching contactors. One is

the primary contactor and the second in line is the heat contactor. When open, the primary contactor allows no power to

flow to the heat contactor. When closed, the primary eontactor completes the timer circuit and the high limit (heat) circuit. It also supplies power to the heat contactor which is controlled by the thermostat.

1. Remove electrical power supplied to the cookpot to be worked on.

PRIMARY CONTACTOR

30 31 32

Place POWER switch to the OFF position, and unplug

the power cord or open the wall circuit breaker, or electrical shock could result. Be aware that the other con-

trols will have power.

2. Remove the control panel and insert it in the slot above the

door. Refer to section 6-3.

3. Perform a check on the contactor as follows:

Test Points

from 23 to 29

from 24 to 28

from 25 to 27

from 30 to 34

from 31 to 35

from 32 to 36

from 22 to 26

from 33 to 37

Results

open circuit