PROJECT QUANTITY ITEM NO

Open fryer with dump station

Two fry wells, one dump well

General Information

The Henny Penny ODE/ODG-323

open fryer is designed to combine the

flexibility of multi-well frying with the

convenience and efficiency of an

integral product dump station.

Cooked product is drained over fry

wells and then dumped directly into

the central well. Extra motion in work

flow is reduced, and the need for a

separate dumping station is

eliminated. The dump station also

cuts down on messy drips and helps

conserve frying oil. Excess oil from

product drains directly from the dump

well back into the fryer filter pan.

The ODE/ODG-323 offers highvolume two-well frying on a three-well

platform, with programmable

operation, oil management functions

and fast, easy filtration.

Two-well open fryer with

central dump station, model ODE-323.

Standard Features

• Stainless steel construction for

easy-cleaning and long life.

• Two heavy-duty stainless steel

rectangular fry pots with 7-year

warranty.

• Central dump well

Serves both fry wells

Drains directly into filter pan

Integral stainless steel

construction

Coved corners for easy cleaning

• Fry pot protection system (gas.)

• Easy basket set and release.

• Specially designed cold zone

prevents scorching.

• Four heavy-duty casters, two

locking.

Henny Penny’s unique heat-

exchange design produces extremely

™

• COMPUTRON

8000 control

(additional charge.)

12 programmable cook cycles

Melt mode

Idle mode

Load compensation

Proportional control

Optional filter prompt and

customizable filter tracking

Clean-out mode.

16-character digital display with

multiple language settings.

• COMPUTRON

™

1000 simple digital

control

▪ Programmable

▪ LED Time/Temp display

▪ Simple UP/DOWN arrows

• Built-in filtration (additional charge.)

Single well/sequential filter pan

Three-well filter pan

MODEL ODE-323 electric

ODG-323 gas

fast temperature recovery—typically in

seconds—while requiring less than 2

kW per gallon of oil or shortening.

That level of efficiency has earned the

Henny Penny 320 series open fryer

the ENERGY STAR

®

mark.

Fast recovery also increases frying

program profits with increased

throughput, lower energy costs, and

longer frying oil life that comes from

reduced temperature fluctuations.

A built-in filtration system filters hot

frying oil in under 4 minutes, with no

separate pumps or pans required. Hot

filtered oil returns directly to each well.

Henny Penny’s heavy-duty stainless

steel rectangular fry pots promote fast

even cooking and come with a 7-year

warranty—the best in the business.

Available with COMPUTRON

control or COMPUTRON

™

1000

™

8000

simple digital control.

Accessories shipped with unit

• Fry baskets—please select one

2 full baskets

1 full and 2 half baskets

4 half baskets

• 2 basket supports

Accessories and options available

separately

Direct Connect shortening disposal

(filtration equipped units, only)

Shortening shuttle

Filter rinse hose

Fry well covers

APPROVED APPROVED AS NOTED RESUBMIT

AUTHORIZED SIGNATURE DATE

© 2006 Henny Penny Corporation, Eaton, O H 45320 USA Revised 09/10/08

Henny Penny Corporation

PO Box 60 Eaton OH 45320 USA

+1 937 456.8400 800 417.8417

+1 937 456.8434 Fax 800 417.8434 Fax

www.hennypenny.com

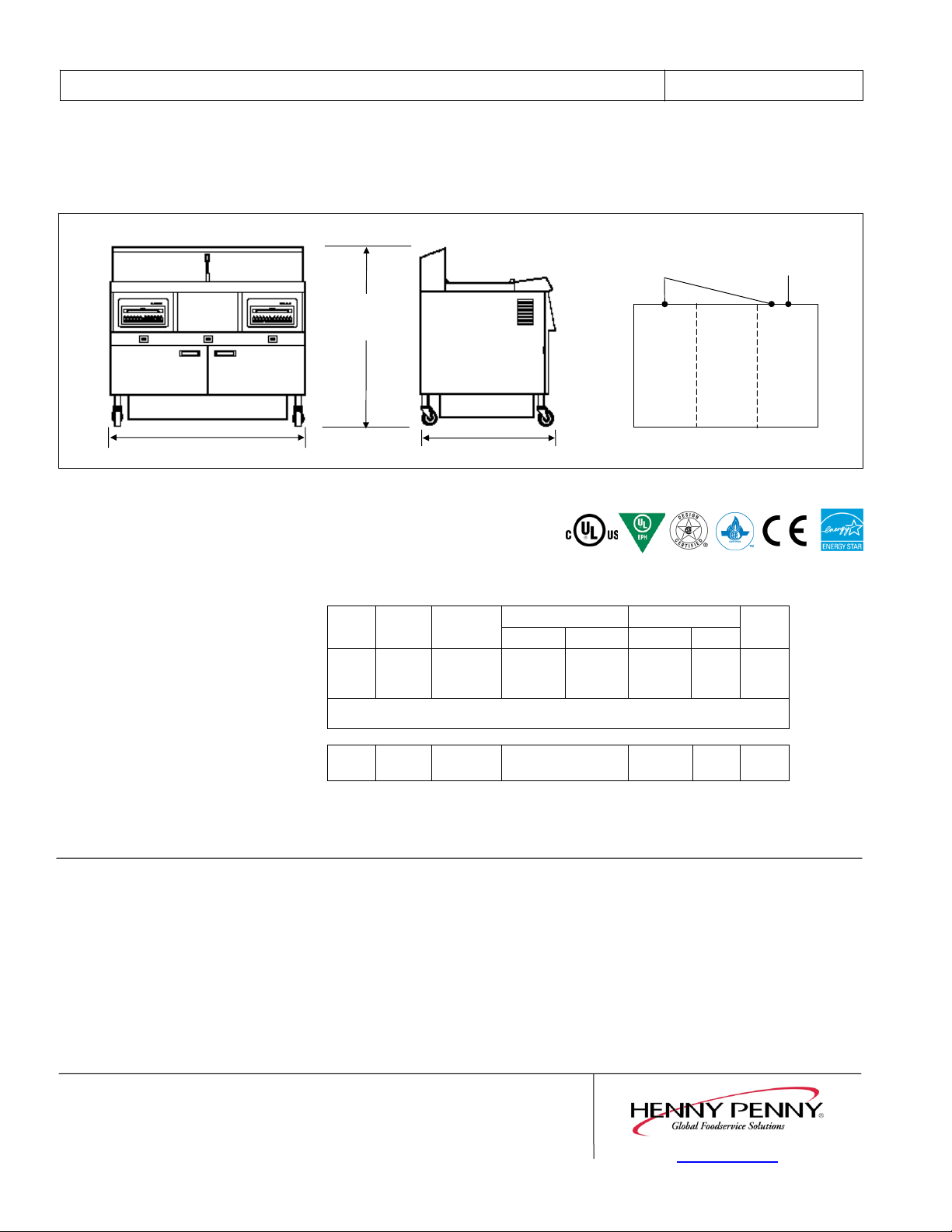

PROJECT ITEM NO

Open fryer with dump station

Two fry wells, one dump well

44 in. (1118 mm)

Height includes

casters

49 3/8 in. (1254 mm)

Dimensions

Width 49 3/8 in. (1254 mm)

Depth 37 3/8 in. (949 mm)

Height 44 in. (1118 mm)

Required clearances

Sides: 6 in. (152 mm) air flow

Back: 6 in. (152 mm) air flow, connections

Front: 30 in. (762 mm) filter pan removal

Crated dimensions

Length 55 in. (1397 mm)

Depth 39 in. (991 mm)

Height 54 in. (1372 mm)

Volume 67.0 cu. ft. (1.90 m³)

Net weight N/A

Crated weight

Electric Please contact Henny Penny

Gas Please contact Henny Penny

Heating

Electric Immersed elements, 28.8 kW

Gas Natural or liquid petroleum

(4) burners,170,000 BTU/hr (50 kW)

(1) ¾ in. connection

Capacity

Product 12.5 lbs. (5.7 kg) per fry well

25 lbs. (11.4 kg) total

Oil 65 lbs. (30.3 l) per fry well

130 lbs. (60.6 l) total

Electrical

Volts Phase Cycle/Hz

208 3 60 14400 28800 39.9 79.8 3+G

240 3 60 14400 28800 37.2 74.4 3+G

480 3 60 14400 28800 17.5 35.0 3+G

Two electrical connections required, one for each well. Power cord and plug must be

installed on site by a qualified electrician.

120 1 60 N/A 12.0 24.0 2+G

230 1 50 N/A 2.5 5.0 1NG

37 3/8 in. (949 mm)

Watts Amps

Per well Total Per well Total

Gas models

ODE-323 electric

MODEL

ODG-323 gas

Electric units:

(2) electrical connections,

one per well

Laboratory certifications

PLAN

FRONT

Gas units:

(1) ¾ inch gas

connection

Wire

Bidding Specifications

• Provide Henny Penny open fryers, models

ODE-323 electric and ODG-323 gas with

integral dump station and available built-in

filtration system (additional charge.)

• Units shall have two-fry wells and one

product dump well located in between or to

the left.

• Units shall incorporate either

COMPUTRON

or COMPUTRON

™

1000 simple digital controls

™

8000 control system

with (additional charge.)

• Materials—cabinet, deck, exhaust stack, filter

drain pan and various fittings are stainless

steel. Dump station is integral stainless steel.

Fry pots are heavy duty stainless steel.

• Units shall incorporate high-efficiency heatexchange design for extremely fast recovery.

• Units qualify for the ENERGY STAR

• Heating elements encircle the fry pot part-

way up the side, and are not located at the

bottom or below the pot. This design

produces a “cold zone” that extends oil life.

• Unit’s controller provides for programmable

Continuing product improvement may subject specifications to change without notice.

© 2006 Henny Penny Corporation, Eaton, O H 45320 USA Revised 09/10/08

®

mark.

or manual operation with press-key controls

and LED digital display. COMPUTRON

™

8000

control offers idle and melt modes, load

compensation, filtration tracking and 7-day

history.

• Units will include four heavy-duty casters, two

locking.

• Units with filtration system ship with stainless

steel Max filtration screen and (2) PHT filter

envelopes. All units ship with choice of (2) full

baskets, (1) full and (2) half baskets, or (4) half

baskets.

www.hennypenny.com

Loading...

Loading...