Page 1

Henny Penny

Heated Holding Cabinet

Model HHC-900

Model HHC-902

Model HHC-903

Model HHC-906

Model HHC-908

Model HC-15

TECHNICAL MANUAL

Page 2

Page 3

Models HHC-90X/HC-15

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING ............................................................................................. 1-1

1-1. Introduction ...................................................................................................... 1-1

1-2. Safety ............................................................................................................... 1-1

1-3. Troubleshooting ............................................................................................... 1-1

Section 2. MAINTENANCE ...................................................................................................... 2-1

2-1. Introduction ...................................................................................................... 2-1

2-2. Test Instruments ............................................................................................... 2-1

2-3. Removal of Module Access Panel ................................................................... 2-1

2-4. Module Removal .............................................................................................. 2-1

2-5. Removal of Module Housing .......................................................................... 2-2

2-6. Fuse .................................................................................................................. 2-3

2-7. Power Switch ................................................................................................... 2-4

2-8. Thermostat ....................................................................................................... 2-5

2-9. Indicating Lights .............................................................................................. 2-6

2-10. Thermometer .................................................................................................... 2-7

2-11. Heater ............................................................................................................... 2-8

2-12. High Limit ....................................................................................................... 2-9

2-13. Blower ............................................................................................................. 2-10

2-14. Door Gasket Replacement ............................................................................... 2-12

2-15. Wiring Diagrams ............................................................................................. 2-13

Section 3. PARTS INFORMATION ........................................................................................... 3-1

3-1. Introduction ...................................................................................................... 3-1

3-2. Genuine Parts ................................................................................................... 3-1

3-3. How to Find Parts ............................................................................................ 3-1

3-4. How to Order ................................................................................................... 3-1

3-5. Prices ................................................................................................................ 3-2

3-6. Delivery ............................................................................................................ 3-2

3-7. Warranty ........................................................................................................... 3-2

3-8. Recommended Spare Parts for Distributors ..................................................... 3-2

106 FM06-021 i

Revised 5-28-10

Page 4

Page 5

Models HHC-90X/HC-15

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION

This section provides troubleshooting information in the form of

an easy to read list.

If a problem occurs during the fi rst operation of a new cabinet,

recheck the Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the Operation Section of

the Operator’s Manual.

1-2. SAFETY Where information is of particular importance or is safety related,

the words NOTICE, CAUTION, or WARNING are used. Their

usage is described below.

SAFETY ALERT SYMBOL is used with DANGER,

WARNING, or CAUTION which indicates a personal

injury type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

The word WARNING is used to alert you to a

procedure, that if not performed properly, might

cause personal injury.

1-3. TROUBLESHOOTING To isolate a malfunction proceed as follows:

1. Clearly defi ne the problem or symptom and when it occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes, then one at a time work

through the list of corrections until the problem is solved.

If maintenance procedures are not followed correctly,

injuries and/or property damage could result.

203 1-1

Page 6

Models HHC-90X/HC-15

1-3. TROUBLESHOOTING (Continued)

PROBLEM CAUSE CORRECTION

OPERATION

A. Product not • Doors are left open • Keep doors closed except to

holding load and unload product

temperature

• Thermostat set too low • Increase thermostat setting by moving

the knob to a higher number setting

• Gasket torn or worn • Replace gasket per Door Gasket

Replacement Section

• Heater not working • Check heater; replace per Heater

Section

• Blower not working • Check blower; replace per Blower

Section

• Product held too long • Hold product only for recommended

time

• Low or improper voltage • Using meter, compare receptacle

voltage to data plate voltage

B. Cabinet • Too much humidity inside the cabinet • Empty water from the water pan

steaming -

product • Holding product too long • Hold product for recommended time

becoming

soggy • Vent not set properly (units • Adjust vent per Operator’s Manual

with vent adjustment only)

C. Product dry • No water in pan • Remove pan and put in approximately

1” of hot water

HEATING SYSTEM

A. Unit will • Faulty thermostat • Check thermostat per Thermostat

not heat Section

• Faulty high limit • Check high limit per High Limit

Section

• Faulty heater • Check heater; replace per Heater

Section

• Faulty wiring • Check wiring for loose connections

or broken wires and repair as needed

1-2 203

Page 7

Models HHC-90X/HC-15

1-3. TROUBLESHOOTING (Continued)

PROBLEM CAUSE CORRECTION

HEATING SYSTEM (Continued)

B. Unit will not heat • Faulty blower • Check blower; replace per Blower

to desired temp- Section

erature

• Thermometer not indicating • Check cabinet temperature with

true temperature another thermometer; if necessary,

replace per Thermometer Section

• One of heaters defective • Check heater; replace per Heater

Section

• Doors being left open too much • Only open doors as necessary

• Gaskets torn or worn • Replace gasket per Door Gasket

Replacement Section

• Defective high limit on one of heaters • Check high limit; replace per High

Limit Section

C. Unit overheating • Faulty thermostat • Check thermostat; replace per

Thermostat Section

• Faulty blower • Check blowers; replace per Blower

Section

VENTILATING SYSTEM

A. Both blowers • Faulty blowers • Check blowers; replace per Blower

not working Section

• Faulty fuse (if equipped) • Check fuse; replace per Fuse Section

203 1-3

Page 8

Page 9

Models HHC-90X/HC-15

SECTION 2. MAINTENANCE

2-1. INTRODUCTION

This section provides procedures for the testing and replacement

of the various parts used within the cabinet. Before replacing any

parts, refer to the Troubleshooting Section. It will aid you in determining the cause of the malfunction.

2-2. TEST INSTRUMENTS You may use two test instruments to check the electric

components.

1. A continuity light

2. An ohmmeter

When the manual refers to the circuit being closed, the continuity

light illuminates or the ohmmeter reads zero unless otherwise noted.

When the manual refers to the circuit being open, the continuity

light will not illuminate or the ohmmeter will read 1 (one) or

infi nite resistance.

A continuity tester cannot be used to check coils.

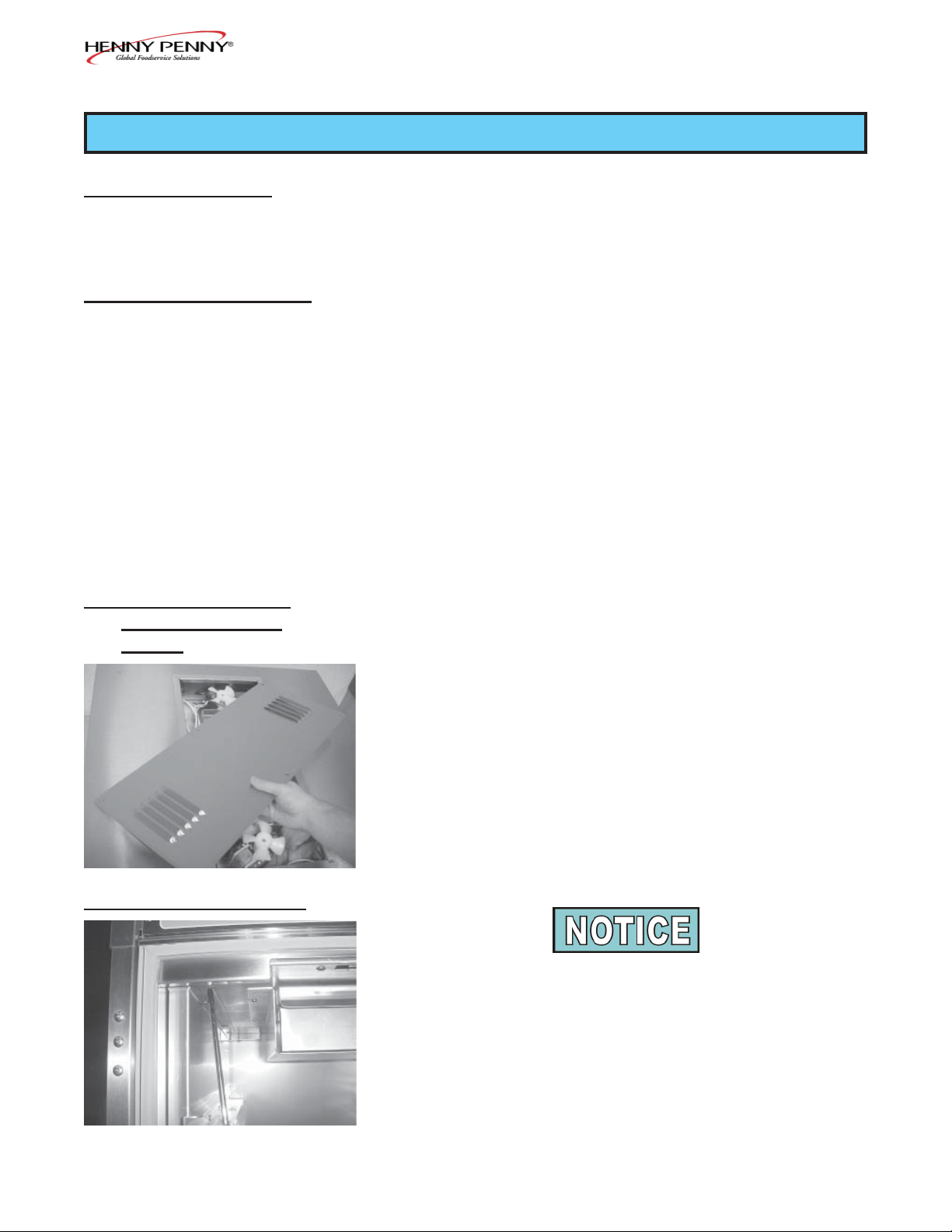

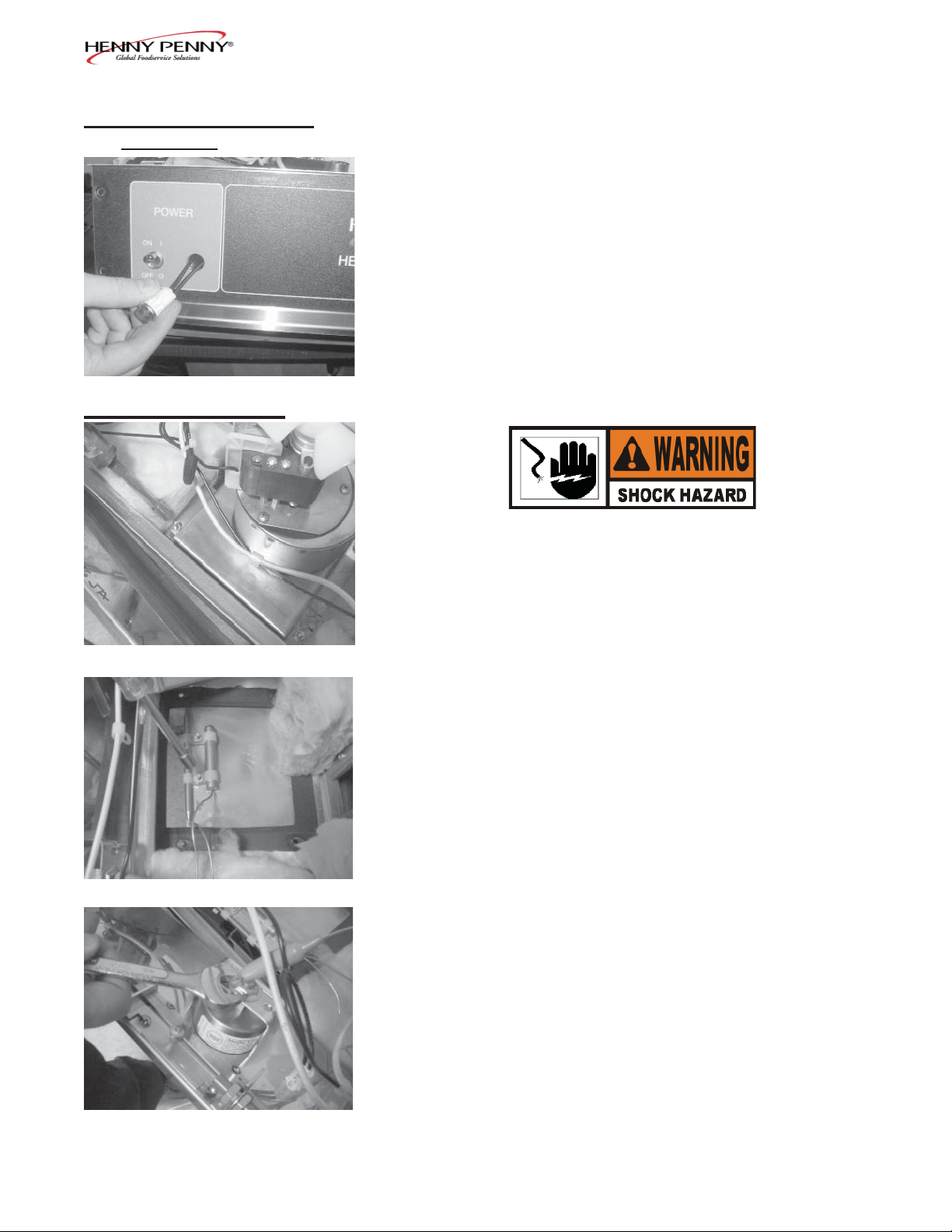

2-3. REMOVAL OF THE

MODULE ACCESS

PANEL

In most procedures of the maintenance section, the access panel

must be removed from the top of the module. This access panel

can easily be removed by taking out the four screws that fasten it

to the module shell.

2-4. MODULE REMOVAL

If the component module of the cabinet has to be removed,

be sure to remove the four screws (one at each corner) before

lifting it from the unit. Also, when work has been completed

on the module, be sure to relocate it properly and reinstall the

screws that fasten the module to the cabinet. Failure to do so

might cause the unit to perform inadequately.

203 2-1

Page 10

Models HHC-90X/HC-15

2-5. REMOVAL OF

MODULE HOUSING

Step 2

Step 3

If the need for extensive service is required on the module components, the entire outer shell of the module can be removed to make

servicing easier. To remove the outer shell of the module, follow

these procedures:

1. Remove the module from the cabinet per Module Removal

Section.

2. Remove the six (6) screws that are located on the sides of the

module.

3. Remove the four (4) screws located at the corners of the

module top.

4. Remove the screws from the control panel and the back

panel, that fasten them to the module housing.

5. Lift the shell of the module off the unit.

6. When work is completed, reassemble in reverse order.

Step 4

Step 5

2-2 803

Page 11

2-6. FUSE

Models HHC-90X/HC-15

All units are not equipped with fuses.

If both blowers quit working at the same time:

1. Remove electrical power supplied to the cabinet.

Step 2

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the cap from the fuse holder by turning it counterclockwise. (Located above the power cord.)

Step 3

Step 4

3. Pull the fuse from the holder.

4. Check the fuse for defectiveness by putting both leads of the

ohmmeter or continuity light on opposite ends of the fuse.

The fuse should be closed, or read no resistance. If the fuse

is found to be defective, replace it with a new one. Be sure to

use an identical fuse as the one being replaced.

5. Replace the cap to the fuse holder.

6. Reconnect the electrical supply to the cabinet.

203 2-3

Page 12

Models HHC-90X/HC-15

2-7. POWER SWITCH

Step 3

1. Disconnect the electrical supply to the cabinet.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the four (4) screws from the control panel and pull it

down.

3. Remove all wires from the switch. Check across the two

terminals of the switch for continuity. With the switch in the

ON position, the circuit should be closed. With the switch in

the OFF position, the circuit should be open. If the switch is

found to be defective, replace it by continuing with the following instructions in this section.

4. Loosen the nut holding the switch on the back side of the control panel and then remove the nut on the front of the control

panel.

Step 4

5. Remove the switch.

6. Install a new switch in reverse order.

7. Reconnect the wires to the switch on the same terminals that

they were previously on.

8. Push the control panel back in place and put in screws.

9. Reconnect the electrical supply to the cabinet.

2-4 803

Page 13

Models HHC-90X/HC-15

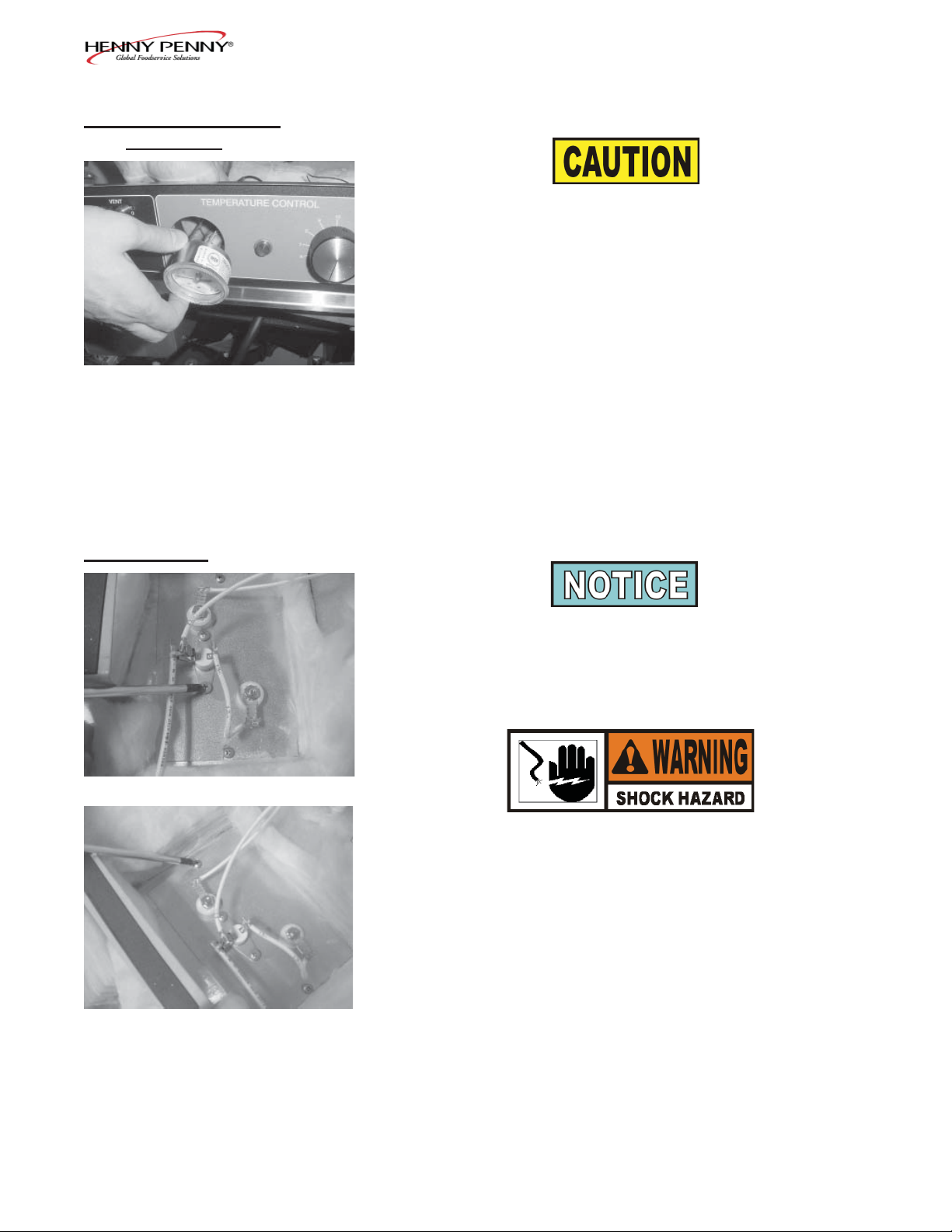

2-8. THERMOSTAT

Step 5

1. Disconnect the electrical supply to the cabinet.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the access panel from the top of the module.

3. Remove the four (4) screws from the control panel and pull it

down.

4. Remove the wires from the thermostat. With the thermostat set at the maximum setting (all the way clockwise), the

circuit should be closed. With the thermostat in the 0, or OFF,

position (all the way counterclockwise), the circuit should be

open. If the thermostat is found to be defective, replace it by

continuing with the following instructions in this section.

Step 7

Step 8

Step 11

5. Remove the four (4) nuts that hold the blower box to the cabinet.

6. Lift the blower box up to expose the thermometer and

thermostat bulbs.

7. While holding the blower box, remove the two (2) nuts that

secure the bulb retaining clamps and remove the thermostat

bulb from the clamps.

8. Using a 5/64” Allen wrench, loosen the two (2) set screws in

the thermostat knob and remove the knob.

9. Remove the two (2) nuts that hold the thermostat bracket to

the control panel.

10. Remove the thermostat shaft extension with a 1/16” Allen

wrench.

11. Remove the two (2) screws that hold the thermostat to the

bracket.

12. Remove the thermostat from the unit.

203 2-5

Page 14

Models HHC-90X/HC-15

2-8. THERMOSTAT

(Continued)

13. Install a new thermostat in reverse order.

14. Reposition the blower box and secure it with the four (4)

nuts previously removed.

Be sure that both the thermometer and thermostat capillary

tubes pass through the notches in the front corners of the

blower box. Failure to do so could permanently damage the

thermometer or thermostat and cause improper operation of

the cabinet.

15. Reseal the notches in the blower box corners with silicone

rubber sealant.

16. Push the control panel back in place and put in screws.

17. Replace the access panel to the module.

2-9. INDICATING LIGHTS

18. Reconnect the electrical supply to the cabinet.

This section should be followed when replacing either of the

two (2) indicating lights in the control panel.

1. Disconnect the electrical supply to the cabinet.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the four (4) screws from the control panel and pull it

down.

3. Cut the light wires just behind the body of the light.

2-6 203

Page 15

Models HHC-90X/HC-15

2-9. INDICATING LIGHTS

(Continued)

2-10. THERMOMETER

4. Remove the light by squeezing the retainers on the body and

pushing the light out through the control panel.

5. Install a new light by pushing it through the front of the control panel until it snaps securely in place.

6. Strip the ends of the cut wires and connect them to the new

light with wire nuts.

7. Push the control panel back in place and put in screws.

8. Reconnect the electrical supply to the cabinet.

Step 4

1. Disconnect the electrical supply to the cabinet.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

Step 4

Step 6

2. Remove the access panel from the top of the module.

3. Remove the four (4) screws from the control panel and pull

it down.

4. Remove the four (4) nuts that hold the blower box to the

cabinet.

5. Lift the blower box up to expose thermometer and thermostat

bulbs.

6. While holding the blower box, remove the two nuts that

secure the bulb retaining clamps and remove the thermometer

bulb from the clamps.

7. Remove the two (2) nuts that hold the mounting brackets

on the back of the thermometer body.

8. Remove the thermometer by pulling the body and capillary

tube through the control panel.

9. Install a new thermometer in reverse order.

Step 7

10. Reposition the blower box and secure it with the four (4)

nuts previously removed.

203 2-7

Page 16

2-10. THERMOMETER

(Continued)

Models HHC-90X/HC-15

Be sure that both the thermometer and thermostat capillary

tubes pass through the notches in the front corners of the

blower box. Failure to do so could permanently damage the

thermometer or thermostat and cause improper operation of

the cabinet.

11. Reseal the notches in the blower box corners with silicone

rubber sealant.

2-11. HEATER

Step 8

Step 3

12. Replace the access panel to the top of the module.

13. Push the control panel back in place and put in screws.

14. Reconnect the electrical supply to the cabinet.

This section should be followed when replacing either of the

two (2) heaters in the cabinet. If there is a heating problem,

both heaters should be checked.

1. Disconnect the electrical supply to the cabinet.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the access panel from the top of the cabinet.

3. Remove the two (2) screws holding the high limit to the

heater.

Step 5

4. Remove the wires attached to the two (2) heater terminals.

5. Remove the two (2) screws holding the heater to the module.

2-8 203

Page 17

Models HHC-90X/HC-15

2-11. HEATER

(Continued)

2-12. HIGH LIMIT

Step 6

6. Remove the heater.

7. Install a new beater in reverse order.

If you have a 240V, 3,000 W unit, you must install the new

heater so that the coils are spread furthest apart where air

from the blower enters the heater.

8. Reattach the heater wires.

9. Refasten the high limit to the new heater.

10. Replace the access panel to the module.

11. Reconnect the electrical supply to the cabinet.

This section should be followed when replacing either of the

two (2) high limits in the cabinet. If there is a heating problem in the cabinet, both high limits should be tested.

Step 5

1. Disconnect the electrical supply to the cabinet.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the access panel from the top of the cabinet.

3. Remove the wires attached to the high limit.

4. Check across high limit terminals for continuity. As long

as cabinet temperature is below 210°F and blower has been

operating properly, high limit should be closed, or read no

resistance. If high limit is found to be defective, replace it by

continuing with the following instructions.

5. Remove two (2) screws that hold high limit to the heater.

203 2-9

Page 18

Models HHC-90X/HC-15

2-12. HIGH LIMIT

(Continued)

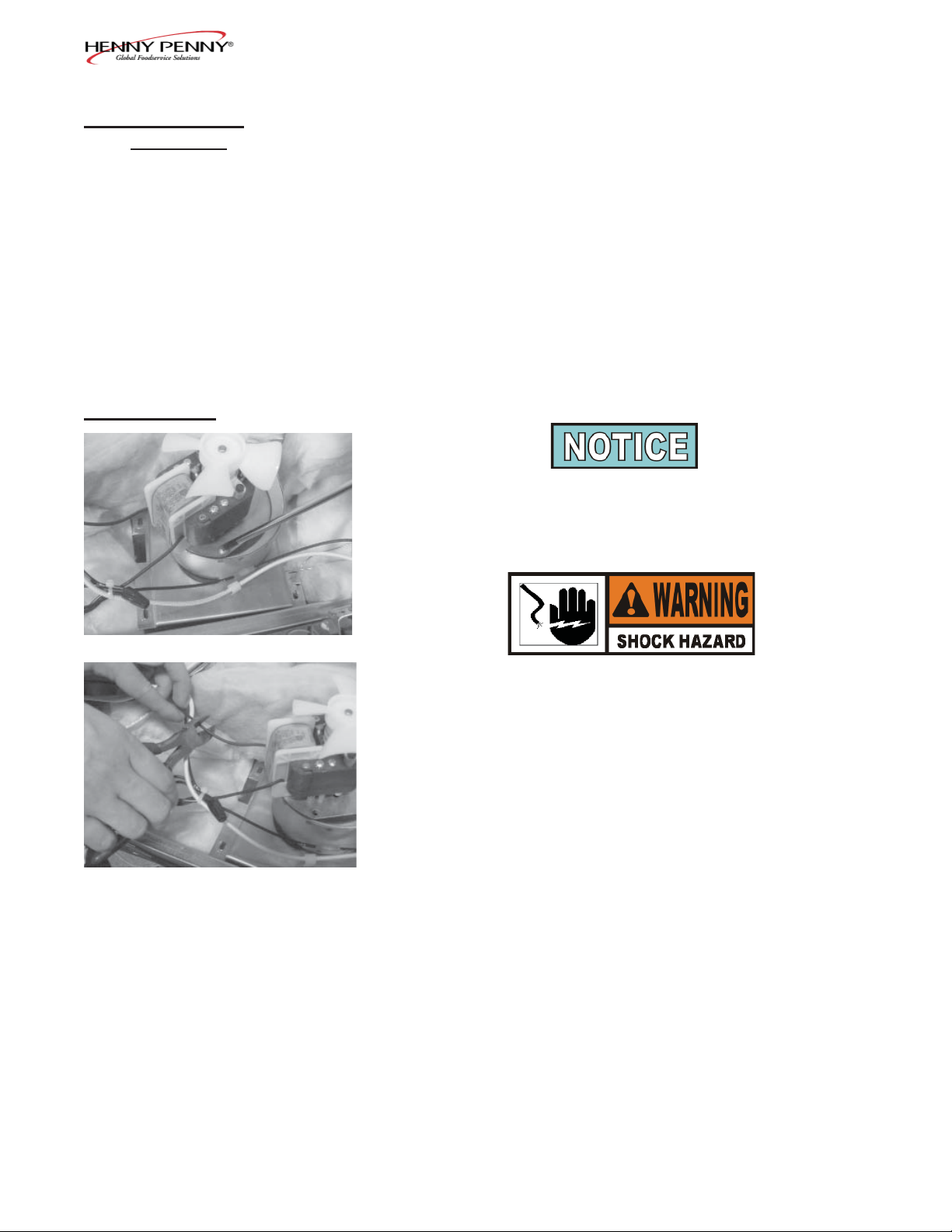

2-13. BLOWER

6. Remove the high limit.

7. Install a new high limit in reverse order.

8. Reconnect the two wires to the high limit.

9. Replace the access panel to the module.

10. Reconnect the electrical supply to the cabinet.

Procedures for blower motor replacement are the same on

both blowers.

1. Disconnect the electrical supply to the cabinet.

Step 3

Step 4

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the access panel from the top of the cabinet.

3. Remove the three (3) screws that fasten the blower motor to

the blower housing.

4. Cut the two (2) blower wires approximately 2” away from the

blower.

5. Lift the blower motor and wheel out of the blower housing.

6. If replacing motor, fan, and wheel as an assembly, install new

assembly in reverse order. If replacing just the motor, continue onto step 7.

2-10 203

Page 19

2-13. BLOWER

(Continued)

Models HHC-90X/HC-15

The blower motor can be ordered as an assembly. This will

include the motor, the fan, and the wheel. Normally, just

the motor would need replacing if found to be defective. If

you are just replacing the motor, continue with the following

procedures.

7. The fan can be pulled off the shaft of the motor.

8. With a 5/64” Allen wrench, loosen the set screw that holds

Step 7

the blower wheel to the motor shaft and remove the wheel.

9. Remove the four (4) screws that hold the blower cover to the

motor.

10. Install a new blower motor in reverse order.

11. Be sure to put the spacers back between the blower cover and

the motor.

Step 8

When replacing a blower motor, be sure that the motor coil is

positioned away from the heater when reinstalling.

12. Reconnect the two wires to the new blower by stripping the

wire ends and fastening with wire nuts.

13. Replace the access panel to the module.

14. Reconnect the electrical supply to the cabinet.

203 2-11

Page 20

Models HHC-90X/HC-15

2-14. DOOR GASKET

REPLACEMENT

1. Pull the gasket to the side to expose the screws that hold the

retainer to the cabinet.

2. Loosen the screws around the full outside perimeter of the

gasket.

3. With the screws loose, the gasket should slide out from under

the retainer.

4. Remove the gasket and replace with a new one by reversing

the above procedures.

Steps 1 & 2

2-12 203

Page 21

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS

803 2-13

Page 22

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

2-14 807

Page 23

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

807 2-15

Page 24

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

2-16 807

Page 25

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

506 2-17

Page 26

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

2-18 803

Page 27

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

807 2-19

Page 28

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

2-20 510

Page 29

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

803 2-21

Page 30

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

2-22 807

Page 31

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

807 2-23

Page 32

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

2-24 506

Page 33

Models HHC-90X/HC-15

2-15. WIRING DIAGRAMS (Continued)

506 2-25

Page 34

Models HHC-90X/HC-15

2-26 807

Page 35

Models HHC-90X/HC-15

807 2-27

Page 36

Models HHC-90X/HC-15

2-28 1209

Page 37

Models HHC-90X/HC-15

510 2-29

Page 38

Models HHC-90X/HC-15

HHC-900 EM & HC-15, 208-240V/50 or 60 Hz/1 Phase, Non-UL, Non-CE

2-30 510

Page 39

Models HHC-90X/HC-15

HHC-900 CDT, 208-240V/50 or 60 Hz/1 Phase, Non-UL, Non-CE

510 2-31

Page 40

Models HHC-90X/HC-15

LIMITED WARRANTY FOR HENNY PENNY EQUIPMENT

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the original pur-

chaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT: Any part of a new appliance, except baskets, lamps, and fuses, which proves to be defective in

material or workmanship within two (2) years from date of original installation, will be repaired or replaced without

charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. Baskets will be repaired or replaced for ninety (90)

days from date of original installation. Lamps and fuses are not covered under this Limited Warranty. To validate this

warranty, the registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

FILTER SYSTEM: Failure of any parts within a fryer fi lter system caused by the use of the non-OEM fi lters or

other unapproved fi lters is not covered under this Limited Warranty.

REPLACEMENT PARTS: Any appliance replacement part, except lamps and fuses, which proves to be defective in

material or workmanship within ninety (90) days from date of original installation will be repaired or replaced without

charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment covers the repair or replacement of the defective part and includes labor charges and

maximum mileage charges of 200 miles round trip for a period of one (1) year from the date of original installation.

The warranty for replacement parts covers only the repair or replacement of the defective part and does not include any

labor charges for the removal and installation of any parts, travel, or other expenses incidental to the repair or replacement of

a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or workmanship

issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover any frypot that fails due to

any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new frypot at no cost

or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for the frypot only. Any freight charges and labor costs to install the new frypot

as well as the cost of any other parts replaced, such as insulation, thermal sensors, high limits, fi ttings, and

hardware, will be the responsibility of the owner.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If damage occurs during shipping,

notify the sender at once so that a claim may be fi led.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY FOR ANY

BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY (INCLUDING CLAIMS

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) if the

equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND

FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Revised 01/01/07

2-30 107

Page 41

Models HHC-90X/HC-15

SECTION 3. PARTS INFORMATION

3-1. INTRODUCTION

3-2. GENUINE PARTS

3-3. HOW TO FIND PARTS

3-4. HOW TO ORDER

This section identifi es and lists the replaceable parts of the Henny

Penny Model HHC-900 heated holding cabinet.

Use only genuine Henny Penny parts in your cabinet. Using a part

of lesser quality or substitute design may result in cabinet damage

or personal injury.

To fi nd items you want to order from the Parts List, proceed

as follows:

1. Referring to the illustration in this section, fi nd the part item

number of the part needed.

2. Find the item number in the parts list, which shows the Henny

Penny part number, a description of the part, any model or

usage limitations, and the quantity of parts used.

Once the parts you want to order have been found in the Parts

List, write down the following information:

Example:

Item number 44

Part number 14635

Description Power Switch

From the data plate list the following information:

Example:

Product number HHC-900.0

Serial number 00179

Voltage 120

803 3-1

Page 42

Models HHC-90X/HC-15

3-4. HOW TO ORDER

(Continued)

The following table has been provided as a sample format for you

to use in preparing your spare parts orders. By providing all the

entries, your distributor will be able to ensure the correct parts

will be sent to you. Also, by prepayment your order will be

expedited.

FROM PARTS LIST YOUR ORDER

Item Part Quantity

Number Number Description Ordered Price Each Total

46 25183 Thermometer

Product No. HHC-900.0 Serial No. 00179 Voltage 120

3-5. PRICES

Your distributor has a priced parts list and will be glad to inform

you of the cost of your parts order.

3-6. DELIVERY

Commonly replaced items are stocked by your distributor and

will be sent out when your order is received. Other parts will be

ordered by your distributor from Henny Penny Corporation. Normally, these will be sent to your distributor within three working

days.

3-7. WARRANTY

All replacement parts (except lamps and fuses) are warranted

for 90 days against manufacturing defects and workmanship. If

damage occurs during shipping, notify the sender and the carrier

at once so that a claim may be properly fi led. Refer to warranty in

the front of this section for other rights and limitations.

3-8. RECOMMENDED

SPARE PARTS FOR

DISTRIBUTORS

Recommended replacement parts, stocked by your distributor, are

indicated with in the parts lists. Please use care when order-

ing recommended parts, because all voltages and variations are

marked. Distributors should order parts based upon common

voltages and equipment sold in their territory.

3-2 106

Page 43

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Figure 3-1. Control Module Assembly - UL & CE Approved

104 3-3

Page 44

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Figure No.

& Item No. Part No. Description Quantity

3-1 Control Module Assembly - UL & CE Approved

1 25704 Panel - Access ............................................................................... 1

1 51209 Panel -Access - C E ...................................................................... 1

2 SC01-053 Screw #8-32 x 1/2 PH RHD ......................................................... 4

3 48993 Panel - Rear (208/240V) S/A ........................................................ 1

3 71092 Panel - Rear (120V) S/A .............................................................. 1

3 25944 Panel Rear S/A: HC-903 ............................................................... 1

3 28121 Panel - Rear HHC-906; HHC-908 ................................................ 1

3 49018 Panel - Rear - CE .......................................................................... 1

4 EC04-002 Terminal Flag #10-10-12 Ga. ........................................................ 1

5 MS01-212 Cable #12/3, 2,000W/120V .......................................................... 8 Ft.

5 MS01-175 Cable #14/3; 1500W/120V & 3000W/240V ................................ 8 Ft.

5 67390 Power Cord Assy. - Twist - 120V/20A .......................................... 1

5 67472 Power Cord Assy. - 125V, 20 Amp ............................................... 1

5 44857 Power Cord Assy. - 1.0MM - CE .................................................. 1

5 71119 Power Cord Assy. - 1.5MM - HHC-906 - CE ............................... 1

5 71120 Power Cord Assy. - Canada - 120V/30A-RT Angle ..................... 1

5 68412 Power Cord Assy. - Canada - 208/240/20A .................................. 1

5 68413 Power Cord Assy. - 208/240/20A ................................................. 1

5 71384 Power Cord Assy. - Harmonized - Int’l. - 240V ........................... 1

6 25765 Plug 125V, 20 Amp; Used on 2000W/120V ................................. 1

6 25764 Plug 125V, 15 Amp, Used on 1500W/120V ................................. 1

6 63943 Plug 250V, 20 Amp; Used on 3000W/240V ................................. 1

6 28543 Plug - Twist - 120V/20A ............................................................... 1

6 71717 Plug - 120V, 30 Amp - RT Angle - Canada ................................... 1

7 SC01-010 Screw #6-32 x 112 pH PHD ......................................................... 2

8 EF02-007 Fuse 15 Amp ................................................................................. 1

9 EF02-124 Connector - Cable 3/4 ................................................................... 1

10 SC02-023 Screw 48-B x 3/8 pH THD ........................................................... 15

11 NS02-001 Nut #10-32 Hex Keps ................................................................... 1

12 EF02-006 Fuse Holder ................................................................................... 1

13 NS02 005 Nut #6-32 Hex Keps ..................................................................... 2

14 EC01-010 Wire Nut 12-18 Ga ........................................................................ 2

15 76396 Top - Enclosure ............................................................................. 1

15 28153 Top HHC-906, HHC-908 .............................................................. 1

16 26225 Insulation - Cover ......................................................................... 1

17 SC02-041 Screw #8-18 x 7/16 PH IND XTRNL TORX ............................... 18

18 25620 Seal ................................................................................................ 2

19 25670 Cradle ............................................................................................ 1

20 25624 Seal ................................................................................................ 2

21 25619 Gasket - Blower Outlet ................................................................. 2

22 25618 Gasket Retainer ............................................................................. 2

23 SC02-012 Screw #12-AB x 3/8 Ph PHD ....................................................... 2

24 SC01-055 Screw #1 0-32 x 3/4 Hex HD ........................................................ 2

25 EF02-031 Clamp 1/4 x 3/8” ........................................................................... 2

26 EF02-033 Clamp 7/16 x 3/8” ......................................................................... 2

27 25627 Gasket ........................................................................................... 2

28 25872 Blower Box Assembly (903 and all others) .................................. 1 or 2

29 25616 Box, Blower .............................................................................. 1

recommended parts

3-4 510

Page 45

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Item No. Part No. Description Quantity

30 NS02-001 Nut ............................................................................................ 2

31 25698 Gasket, Blower Plate ................................................................. 2

32 25622 Flange, Inlet .............................................................................. 1

33 25623 Housing, Blower ....................................................................... 1

34 25941 Blower Box Assembly (903 only) ................................................ 1

35 25924 Rear Box, Blower ..................................................................... 1

36* 25942 Hose Coupling .......................................................................... 1

37 NS02-001 Nut ............................................................................................ 2

38 25698 Gasket, Blower Plate ................................................................. 2

39 25622 Flange, Inlet .............................................................................. 1

40 25623 Housing, Blower ....................................................................... 1

41 25753 Blower Motor Assembly (120V) .................................................. 2

42 25621 Wheel, Blower, Std. .................................................................. 2

43 SC01-023 Screw ........................................................................................ 8

44 LW02-010 Lockwasher ............................................................................... 8

45 37157 Plate, Blower ............................................................................. 2

46 81606 Spacer, Motor ............................................................................ 8

47 25751 Motor (120V) ............................................................................ 2

48 SC01-091 Screw ........................................................................................ 4

49 25768 Spacer, Fan ................................................................................ 2

50 25706 Fan, Cooling .............................................................................. 2

51 14249 Blower Motor Assembly (240V) .................................................. 2

52 52240 Wheel, Blower, Int’l. ................................................................. 2

53 SC01-023 Screw ........................................................................................ 8

54 LW02-010 Lockwasher ............................................................................... 8

55 37157 Plate, Blower ............................................................................. 2

56 81606 Spacer, Motor ............................................................................ 8

57 25752 Motor (240V) ............................................................................ 2

58 SC01-091 Screw ........................................................................................ 8

59 25768 Spacer, Fan ................................................................................ 2

60 25706 Fan, Cooling .............................................................................. 2

61 51279 Heater 120V/1000W ..................................................................... 2

61 74870 Heater 100V/1000W ..................................................................... 2

61 67627 Heater 240V/1500W ..................................................................... 2

61 51278 Heater 120V/750W ....................................................................... 2

62 18201 High Limit Thermostat ................................................................. 2

62 59272 High Limit Sensor (manual reset)-CE .......................................... 2

63 14635 Power Switch (toggle) .................................................................. 1

63 72277 Black Rocker Switch - CDT ........................................................ 1

63 52224 Rocker Switch - CDT - CE ........................................................... 1

64 16624 Indicator Light - Red ..................................................................... 2

64 54085 Indicator Light - CE - Green ......................................................... 2

65 14250 Thermometer ................................................................................. 1

66 25863 Knob - Thermostat ........................................................................ 1

67 SC02-030 Screw #8-B x 3/8 PH THD Black Oxide ...................................... 4

68 25717 Label Control Panel ...................................................................... 1

68 44024 Label Control Panel - KFC ........................................................... 1

68 61445 Label Control Panel-Pollo Campero ............................................. 1

68 61523 Label Control Panel-Pollo Campero - HHC-903 .......................... 1

recommended parts/* not shown

510 3-5

Page 46

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Item No. Part No. Description Quantity

68 25948 Label Control Panel; Std. HHC-900 - Vented ........................... 1

68 44023 Label Control Panel KFC- Vented ............................................ 1

68 49119 Label Control Panel; HHC-906/908 (rocker-after Nov. 1, 2005) ...... 1

68 28188 Label Control Panel; HHC-906 (toggle-before Nov. 1, 2005) .. 1

68 28190 Label Control Panel; HHC-908 (toggle-before Nov. 1, 2005) . 1

68 33874 Label Control Panel KFC - CDT Vented .................................. 1

68 45616 Label Control Panel-HHC-906 Auto Water-CE ........................ 1

68 49060 Label Control Panel - CE - Std. HHC-900 ............................... 1

68 61470 Label Control Panel - HHC-903 - Wendy’s .............................. 1

69 25786 Panel Control S/A HHC-900 ..................................................... 1

69 69856 Panel Control S/A HHC-900 - SimpleHold .............................. 1

69 25947 Panel Control S/A HHC-903 ..................................................... 1

69 28182 Panel Control S/A HHC-906/908 (rocker-after Nov. 1, 2005) . 1

69 14684 Panel Control S/A HHC-906/908 (replaces toggle-before Nov. 1, 2005) 1

69 49054 Panel Control S/A - CE - Std. HHC-900................................... 1

71 25241 Bracket Thermostat Mount ....................................................... 1

70 25263 Extension Thermostat Shaft ...................................................... 1

72 14209 Thermostat w/clips .................................................................... 1

73 25734 Insulation 5 x 7 x 1 .................................................................... 2

74 25733 Insulation 6 x 6 1/2 x 1 ............................................................. 4

75 25735 Insulation 5 x 10 1/2 x 1 ........................................................... 2

76* 25950 Control Cable; HHC-903 .......................................................... 1

77* 27849 Actuator HHC-903 .................................................................... 1

78* 51193 Vent Housing - CE .................................................................... 2

79* 04158 Wiring Kit (higher wattage)-E/M-Top Cord ............................. 1

79* 01460 Wiring Kit (higher wattage)-E/M-Rear Cord ............................ 1

79* 01461 Wiring Kit (higher wattage)-S/S Controls ................................ 1

79* 14903 KIT - 900 SW ASSY 100V EM Top CD .................................. 1

79* 14904 KIT - 900 SW ASSY 100V EM Rear CD ................................. 1

79* 14905 KIT - 900 Switch ASSY 100V EM ........................................... 1

79* 14906 KIT - 900M Wiring 100V CDT ................................................ 1

83* ME90-003 Relay - 12V Coil 20A 240Vac - CE .......................................... 1

HHC-900/903 CDT Only - 13, 10, 6 & 5 Timers

3 37147 Rear Panel Assy. ........................................................................ 1

5 37556 Power Cord Assy. ...................................................................... 1

63 43768 Power Switch ............................................................................ 1

69 37395 Control Panel Weld Assy - 903 - 6 Timer ................................. 1

69 37285 Control Panel Weld Assy - Vented ............................................ 1

69 30951 Control Panel Weld Assy - Not Vented ..................................... 1

72 29523 Probe Assy. ................................................................................ 1

80* 51040RB Display PC Board Assy - 3 digit - 13 Timer; GV083IE and above ... 1

80* 31910RB Display PC Board Assy - 2 digit - 13 Timer; GV082IE and below... 1

80* 37374RB Display PC Board Assy - 2 digit - 6 Timer; GV082IE and below..... 1

80* 51117RB Display PC Board Assy - 3 digit - 5 Timer; GV083IE and above ..... 1

(discontinued 6 timer controls)

80* 73970RB Display PC Board Assy - 3 digit - 10 Timer (McD’s 903)........ 1

recommended parts/*not shown

3-6 908

Page 47

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Item No. Part No. Description Quantity

81* 78082RB Control PC Board Assy - 3 digit - 10 Timer (McD’s 903) ........ 1

81* 39167RB Control PC Board Assy-3 digit-5 & 13 Timer; GV083IE and above 1

81* 73968RB Control PC Board Assy-2 digit-5 & 13 Timer; GV082IE and below 1

81* 70047RB Control PC Board Assy - 2 digit - 6 Timer; GV082IE and below ..... 1

82* 40500 Replaceable Beeper-3 Digit; GV083IE and above ................... 1

82* 36210 Replaceable Beeper-2 Digit; GV082IE and below ................... 1

83* ME90-003 Relay 12V coil ......................................................................... 1

84* 30978 Transformer 115V ..................................................................... 1

84* 28979 Transformer 240V ..................................................................... 1

98* 14871 KIT - 903 CVSRN 5CDT to 10CDT (Front to Back) ............... 2

99* 14885 KIT - 903 CVSRN 5CDT to 10CDT (Front to Front) .............. 2

100* 14774 KIT - 900 120V KFC PRGM THERM ..................................... 1

101* 14775 KIT - 900 230/240V KFC PRGM THERM .............................. 1

102* 14918 KIT - 903 CVSRN - STACKED ............................................... 1

HHC-900 CDT Decals

68 33874 Decal - KFC Vented - 3 digit .................................................... 1

68 43952 Decal - KFC Non Vented - 3 digit............................................. 1

68 30950 Decal - GM 900 - 3 digit ........................................................... 1

68 31901 Decal - 903 - 6 Timer - Vented - 2 digit .................................... 1

68 31931 Decal - 903 - 6 Timer - Non Vented - 2 digit ............................ 1

68 52347 Decal - GM 903 - 5 Timer - 3 digit ........................................... 1

68 55180 Decal - 13 Timer - 903 - 3 digit (Churches) .............................. 1

68 61443 Decal - 900 Pollo Campero ....................................................... 1

HHC-900 CDT-5 Timers-KFC

68 43073 Control Panel Decal .................................................................. 1

80* 51117RB Display PC Board ..................................................................... 1

81* 39167RB Control PC Board ...................................................................... 1

82* 40500 Replaceable Beeper ................................................................... 1

84* 30978 Transformer ............................................................................... 1

Boston Market HHC-900

68 54511 Decal ......................................................................................... 1

72 54577 Temperature Sensor Assy. ......................................................... 1

81* 54571 PC Board Assy. ......................................................................... 1

83* 40645 Relay ......................................................................................... 1

84* 30978 Transformer ............................................................................... 1

SimpleHold - HHC-900

61 51278 Heater 120V/750W ................................................................... 1

68 69894 Decal ......................................................................................... 1

72 29523 Temperature Sensor Assy. ......................................................... 1

81* 69843 PC Board Assy. ......................................................................... 1

83* 40645 Relay ......................................................................................... 1

84* 30978 Transformer ............................................................................... 1

recommended parts/*not shown

908 3-7

Page 48

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Item No. Part No. Description Quantity

C.E. Parts

5 44857 Power Cord Assy....................................................................... 1

63 52224 Rocker Switch - CDT - CE ....................................................... 1

63 43768 Power Switch - Plastic .............................................................. 1

68 49038 Decal - Control Panel - HHC-900 ............................................. 1

68 49060 Decal - Control Panel-Vented-HHC-903 .................................. 1

68 49086 Decal - Control Panel-KFC-HHC-900 ...................................... 1

68 49118 Decal - Control Panel-w/Vent-HHC-906/908 ........................... 1

Vented Control Module

85* 48990 Rear Panel Studweld Assy (Full) 900 ....................................... 1

85* 25944 Rr Pnl Studweld Assy (1/3) 903 (SN: DA0506014 & below) .. 1

85* 68859 Rear Panel Studweld Assy (1/3) 903 (SN: DA0506015 & up) . 1

85* 28123 Rear Panel Studweld Assy-906/908 .......................................... 1

86* 28155 Cable - E/M ............................................................................... 1

86* 25950 Cable - CDT .............................................................................. 1

87* 25964 Hose - Intake ............................................................................. 1

88* 25963 Hose - Exhaust .......................................................................... 1

89* 25977 Hose Clamp ............................................................................... 4

90* 25942 Coupling - Hose ........................................................................ 1

91* 25999 Control Panel Stud Assy ........................................................... 1

92* 38429 Vent Control Arm ...................................................................... 1

93* 38367 Knob - Vented Module .............................................................. 1

94* 27927 Spacer - Slide Vent (SN: DA0506014 & below) ...................... 1

94* 68574 Spacer - Slide Vent (SN: DA0506015 & above)....................... 1

95* 27828 Slide - Vent - Back (SN: DA0506014 & below) ....................... 1

96* 28092 Slide - Vent - Blower - Box (SN: DA0506014 & below) ......... 1

97* 25919 Slide - Vent (SN: DA0506014 & below) .................................. 1

97* 68573 Slide - Vent (SN: DA0506015 & above) .................................. 1

recommended parts/*not shown

3-8 1207

Page 49

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Figure 3-2. Cabinet Assembly - UL & CE Approved

908 3-9

Page 50

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Figure No.

& Item No. Part No. Description Quantity

3-2 Cabinet Assembly - UL & CE Approved

1 31023 Control Module 120V, 2,000W ................................................. 1

1 31031 Control Module 120V, 1,500W, HHC-903 ............................... 1

1 28180 Control Module 120V, 2,000W, HHC-906, HHC-908.............. 1

2 SC01-170 Screw #10-32 x 2-1/2 PH PHD ................................................. 4

3 28816 Right Hand Top Door Assembly ............................................... 1

3 28817 Right Hand Bottom Door Assembly ......................................... 1

3 28818 Left Hand Top Door Assembly ................................................. 1

3 28819 Left Hand Bottom Door Assembly ........................................... 1

3 27033 Right Door Assembly, HHC-903 .............................................. 1

3 27034 Left Door Assembly, HHC-903 ................................................ 1

3 28158 Right Hand Top Door Assembly, HHC-906 ............................. 1

3 85644 Left Hand Top Door Assembly, HHC-906 ................................ 1

3 85645 Right Hand Bottom Door Assembly, HHC-906 ....................... 1

3 85646 Left Hand Bottom Door Assembly, HHC-906 .......................... 1

3 28166 Right Hand Door Assembly, HHC-908 .................................... 1

3 28168 Left Hand Door Assembly, HHC-908 ....................................... 1

4 14271 Kit - HHC-900 Hinge ............................................................... 8

5a SC01-086 Screw #10-32 x 1 PH TH S ................................................. 16

5b SC01-225 Screw #10-32 x 3/4 PH TH S ............................................. 24

5c 27146 Cover - Hinge Pin - Chrome ............................................... 8

6 SC01-074 Screw #10-32 x 1/2 PH TH ....................................................... 16

7a LW01-002 Lockwasher Split 1/4” ............................................................... 8

7b* WA01-013 Flat Washer 1/4” ........................................................................ 8

8a SC01-039 Screw 1/4-20 x 1 Hex Head ...................................................... 8

8b SC01-193 Screw 1/4-20 x 3/4” Hex Head ................................................. 8

9a 27155 Caster 5” (See item 52) ............................................................. 2

9b 40948 Caster-4”; Rigid (See item 51) .................................................. 2

9c 58139 Caster-3” Dia.; 4” Height; Rigid (See item 50) ........................ 2

9d 18645 Caster 2-1/2” ............................................................................. 2

9e 68804 Caster 5” - CE ........................................................................... 2

9f 28170 Caster 5” Non-Swivel HHC-906, HHC-908 ............................. 2

9g 19004 Caster 2” .................................................................................... 4

9h 78671 Caster 1.5” - Swivel .................................................................. 4

10a 27154 Caster 5” W/Brake (See item 52) .............................................. 2

10b 40947 Caster-4”; Swivel W/Brake (See item 51) ................................ 2

10c 58138 Caster-3” Dia.; 4” Height; Swivel W/Brake (See item 50) ....... 2

10d 18646 Caster 3” W/Brake .................................................................... 2

10e 68803 Caster 5” W/Brake - CE ............................................................ 2

11 SC01-075 Screw #10-32 x 3/. PHT TH ................................................... 12

12 25695 Washer ....................................................................................... 12

recommended parts/*not shown

3-10 510

Page 51

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Item No. Part No. Description Quantity

13 25644 Spacer ........................................................................................ 12

14 25687 Retainer, HHC-900; HHC-903 ................................................. 8 & 4

14 28117 Retainer, HHC-906; HHC-908 ................................................. 8 & 4

15 SC02-041 Screw #8-18 x 7/16 PH IND XTRNL TORX ........................... 24

16 25689 Retainer, HHC-900 ................................................................... 8

16 25690 Retainer, HHC-903 ................................................................... 4

17 NS01-008 Nut #8-32 Hex S ....................................................................... 10

18 LW02-006 Lockwasher Internal #8 S ......................................................... 10

19 SC01 -053 Screw #8-32 x 1/2 PH RHD ...................................................... 10

20 25643 Gasket Door .............................................................................. 4

20 25793 Gasket - Door, HHC-903 .......................................................... 4

20 28147 Gasket - Door, HHC-906 .......................................................... 2

20 28143 Gasket - Door, HHC-908 .......................................................... 1

21 71478 Water Box Assembly with Handle - HHC-903 - Flip Doors .... 1

21 25879 Water Box Assembly with Handle ............................................ 1

22 25707 Water Box and Stud Assembly ........................................... 1

22 70381 Water Box and Stud Assembly - HHC-903 - Flip Doors .... 1

23 25646 Wiper................................................................................... 1

24 25685 Pull ...................................................................................... 1

25 LW02-005 Lockwasher Internal #10 .................................................... 2

26 NS03-030 Nut Acorn #10-32 ............................................................... 2

27 27895 Air Duct Assembly - Upper ...................................................... 2

27 42964 Air Duct Assembly - Upper - HHC-900K ( SIB ) .................... 2

27 52345 Air Duct -Upper-KFC-Int’l-CDT-15 Tray ................................ 2

27 25956 Air Duct Assembly - HHC-903 ................................................. 2

27 70387 Air Duct Assembly - HHC-903 - Flip Doors ............................ 2

27 70032 Air Duct Assembly - HHC-903 - Pollo Campero ..................... 2

27 34928 Air Duct Assembly- Upper - Boston Mkt. ................................ 2

27 55181 Air Duct Assembly- Upper- Churches ...................................... 2

27 55087 Air Duct Assembly-Upper-Wendy’s #10 .................................. 2

27 28129 Air Duct-Upper ONLY-NO SLIDES HHC-906

27 34519

Air Duct-Upper ONLY-NO SLIDES-Knotts Berry-HC-906 (uses 34536 slides) 2

(uses 28133 slides) 2

28 55088 Air Duct Assembly-Lower-Wendy’s #10 .................................. 2

28 55084 Air Duct Assembly-Wendy’s-903 Plast. ................................... 2

28 27811 Air Duct Assembly - Lower ...................................................... 2

28 55187 Air Duct Assembly- Lower-Churches....................................... 2

28 34929 Air Duct Assembly-Lower-Boston Mkt. ................................... 2

28 52346 Air Duct-Lower-KFC-Int’l-CDT-15 Tray ................................. 2

28 42965 Air Duct Assembly - Lower HHC-900K(SIB) ......................... 2

28 28130

28 34517

Air Duct ONLY-NO SLIDES - Lower HHC-906 (uses 28133 slides) 2

Air Duct -Lower ONLY-NO SLIDES-Knotts Berry-HC-906 (uses 34536 slides) 2

28 28128 Air Duct ONLY-NO SLIDES - HHC-908 (uses 28133 slides) . 2

28 34553

Air Duct ONLY-NO SLIDES-Knotts Berry-HC-908 (uses 34536 slides) 2

recommended parts

908 3-11

Page 52

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

Item No. Part No. Description Quantity

29 25696 Hanger ....................................................................................... 16

30 SC02-023 Screw #8-B x 3/8 PH THD S .................................................... 8

31 14272 Latch/Screw Kit ........................................................................ 4

32 SC01-186 Screw #10-32 x 1-3/4 PH .................................................... 16

33 34536 Slides ONLY - HHC-906, HHC-908 ........................................ 22 & 8

34 28133 Slides ONLY, HHC-906, HHC-908 .......................................... 22 & 8

35 34544 Air Duct Assembly Complete - HHC-908, ............................... 2

35 34545 Air Duct Assembly Complete - Lower - HHC-906 ................. 2

35 34550 Air Duct Assembly Complete - Upper - HHC-906 .................. 2

36 14647 Kit - Leg Adjustable - 4 inch (Set of 4 legs) ............................. 1

36 68946 Legs - Adjustable - 4 inch ................................................... 4

37 68937 Weld Assy - Mtg. Plate & Leg - 4 inch ............................... 4

38 26120 Foot - Adjustable ................................................................. 4

39 27149 Stop - Door ................................................................................ 4

39 34949 Door Stop - Boston Mkt. .......................................................... 4

40* 27146 Chrome Hinge Cover ................................................................ 1

41* 27912 Handle, HHC-906, HHC-908 ................................................... 1

42* 27939 Brkt. Handle, HHC-906, HHC-908 .......................................... 2

43* 58116 Hinge Plate (Tap Bar) HHC-900 ............................................... 4

44* 58274 Hinge Plate (Tap Bar) HHC-903 ........................... 4

45* 03182 Worktop - HHC-903.................................................................. 1

46* 56179 Worktop - HHC-908.................................................................. 1

47* 14853 Kit - 903 Undercounter CVSRN ............................................... 1

48* 58047 Insulation - Side ........................................................................ 2

49* 03559 Accessory - Storage Bin ............................................................ 1

50* 86832 3” Caster Set (Incluides items 7a, 7b, 8b, 9b, & 10b) ............... 1

51* 86833 4” Caster Set (Incluides items 7a, 7b, 8b, 9c, & 10c) ............... 1

52* 86850 5” Caster Set (Incluides items 7a, 8a, 9a, & 10a) ..................... 1

Glass Doors Only

3 54353 Glass Door Assembly - 1/3 size(LH) ........................................ 1

3 54352 Glass Door Assembly - 1/3 size(RH) ........................................ 1

-- 30517* Nut - Glass Retainer .................................................................. 4

3 59257 Glass Door Assy.-Left, Top ....................................................... 1

3 59258 Glass Door Assy.-Left, Bottom ................................................. 1

3 59260 Glass Door Assy.-Right, Top ..................................................... 1

3 59261 Glass Door Assy.-Right, Bottom ............................................... 1

3 76480 Glass Door Assy. - 1/2 size (McD’s) ......................................... 1

Church’s HHC-903

3 54353 Glass Door Assembly - 1/3 size (LH) ........................... 1

3 54352 Glass Door Assembly - 1/3 size (RH) ....................................... 1

* not shown

3-12 510

Page 53

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

20

Figure 3-3. Flip-Up Door Assemblies (HHC-903 - SN: DA0511040 & Above)

908 3-13

Page 54

Models HHC-90X/HC-15

UL & CE Approved - HHC-900/902/903/904/906/908

• HHC-903’s (1/3-size) with SN: DA0511039 & below, SN required.

• HHC-900 (full-size) with SN: DA0511039 & below, no parts available.

Complete door assembly must be ordered.

Figure No. Qty per Door

& Item No. Part No. Description 900 903

3-3 Flip-Up Door Assemblies

1 71309 Assy - Door - Flip - RH - Full Size .................................................. 1 -

1 71403 Assy - Door - Flip - LH - Full Size ................................................... 1 -

1 71466 Assy - Door - Flip - RH - 1/3 Size (DA0511040 & Above) .............. - 1

1 71467 Assy - Door - Flip - LH - 1/3 Size (DA0511040 & Above) .............. - 1

2 75544-004 Panel - Flip Door - 9.562 HGT .......................................................... 1 -

3 75544-003 Panel - Flip Door - 6.860 HGT .......................................................... 1 -

4 75544-005 Panel - Flip Door - 6.735 HGT .......................................................... 1 -

5 75544-001 Panel - Upper Flip Door - 1/3 Size .................................................... - 1

6 75544-002 Panel - Lower Flip Door - 8.108 HGT .............................................. - 1

7 71308 Assy - Hinge - Panel - Door - Flip..................................................... 3 2

8 71067 Rod - Flip Door ........................................................................... 3 2

9 71316 Spring - Flip Door ....................................................................... 3 2

10 70768 Cam - Flip Door - RH .................................................................. 3 2

10 70769 Cam - Flip Door - LH .................................................................. 3 2

11 73320 Extrusion - Flip Door .................................................................. 3 2

12 SC01-032 Screw - #8-32 x 5/8 PH 100 FHD SS ................................................ 6 4

13 LW02-006 Lockwasher - Internal - #8 S ............................................................. 6 4

14 NS03-024 Nut - #8-32 Low Crown Acorn - B P ................................................ 6 4

15 14272 Kit - HC-900 Door Handle ................................................................ 1 1

16 SC01-186 Screw - #10-32 x 1-3/4 PH FHD SS ........................................... 4 4

17 14271 Kit - HC-900 Door Hinge .................................................................. 2 2

18 SC01-086 Screw - #8-32 x 1 PH FHD S ...................................................... 4 4

19 71310 Weld Assy - Flip Door Frame - RH - Full Size ................................. 1 -

19 71404 Weld Assy - Flip Door Frame - LH - Full Size.................................. 1 -

19 71056 Weld Assy - Flip Door Frame - RH - 1/3 Size ................................... - 1

19 71057 Weld Assy - Flip Door Frame - LH - 1/3 Size ................................... - 1

20 03557 Accessory - Flip Door Tray ............................................................... - 1

3-14 908

Page 55

Models HHC-90X/HC-15

Non-UL & Non-CE Approved - HHC-900 EM, HHC-900 CDT, & HC-15

Figure 3-4. Control Module Assembly - Non-UL, Non-CE

510 3-15

Page 56

Models HHC-90X/HC-15

Non-UL & Non-CE Approved - HHC-900 EM, HHC-900 CDT, & HC-15

Figure No.

& Item No. Part No. Description Quantity

3-4 Control Module Assembly - Non-UL, Non-CE

1 72312 Panel - Access Louvers (HHC-900EM & HC-15) .................... 1

1 80890 Panel -Access Louvers (HHC-900CDT) .................................. 1

2 SC02-023 Screw #8-32 x 1/2 PH RHD ...................................................... 4

3 28029 Panel - Rear (208/240V) S/A (HHC-900EM) ........................... 1

3 72404 Panel - Rear (120V) S/A (HHC-900CDT) ................................ 1

3 72317 Panel Rear S/A (HC-15) ............................................................ 1

4 EC04-004 Terminal Flag #10-10-12 Ga. .................................................... 1

5 31584 Power Cord Assy (HHC-900CDT) ........................................... 1

5 71384 Power Cord Assy-240V (HHC-900EM & HC-15) ................... 1

7 SC01-010 Screw #6-32 x 112 pH PHD ..................................................... 2

8 EF02-007 Fuse 15 Amp ............................................................................. 1

9 49778 Connector - Cable 3/4 ............................................................... 1

10 SC02-023 Screw 48-B x 3/8 pH THD ....................................................... 15

11 NS02-001 Nut #10-32 Hex Keps ............................................................... 1

12 EF02-006 Fuse Holder ............................................................................... 1

13 NS02 005 Nut #6-32 Hex Keps ................................................................. 2

14 EC01-010 Wire Nut 12-18 Ga .................................................................... 2

15 72305 Top - Enclosure (HHC-900EM & HC-15) ................................ 1

15 84607 Top - Enclosure (HHC-900CDT) .............................................. 1

16 26225 Insulation - Cover ..................................................................... 1

17 SC02-041 Screw #8-18 x 7/16 PH IND XTRNL TORX ........................... 18

18 25620 Seal ............................................................................................ 2

19 25670 Cradle ........................................................................................ 1

20 25624 Seal ............................................................................................ 2

21 25619 Gasket - Blower Outlet ............................................................. 2

22 25618 Gasket Retainer ......................................................................... 2

23 SC02-041 Screw #8-18 x 7/16 PH IND XTRNL TORX ........................... 2

24 SC01-074 Screw #10-32 x 3/4 Hex HD ..................................................... 2

25 EF02-031 Clamp 1/4 x 3/8” (HC-15) ........................................................ 2

26 EF02-003 Wire Tie ..................................................................................... 4

27 25627 Gasket ....................................................................................... 2

28 72915 Blower Box Assembly (HHC-900 EM & CDT) ....................... 2

29 72914 Box, Blower (HHC-900 EM & CDT) .................................. 1

30 NS02-001 Nut......................................................................................... 2

31 25698 Gasket, Blower Plate (HHC-900 EM & CDT) ..................... 1

32 25622 Flange, Inlet (HHC-900 EM & CDT) ................................... 1

33 25623 Housing, Blower (HHC-900 EM & CDT) ............................ 1

34 87097 Blower Box Assembly (HC-15) ................................................ 2

35 72914 Rear Box, Blower (HC-15) .................................................. 1

37 NS02-001 Nut......................................................................................... 2

38 25698 Gasket, Blower Plate (HC-15) ............................................. 2

39 25622 Flange, Inlet (HC-15) ........................................................... 1

40 25623 Housing, Blower (HC-15) ..................................................... 1

recommended parts

3-16 510

Page 57

Models HHC-90X/HC-15

Non-UL & Non-CE Approved - HHC-900 EM, HHC-900 CDT, & HC-15

Item No. Part No. Description Quantity

51 14249 Blower Motor Assembly (240V) .............................................. 2

52 52240 Wheel, Blower, Int’l. ............................................................. 1

53 SC01-023 Screw ..................................................................................... 4

54 LW02-010 Lockwasher ........................................................................... 4

55 37157 Plate, Blower ......................................................................... 1

56 81606 Spacer, Motor ........................................................................ 4

57 25752 Motor (240V) ........................................................................ 1

58 SC01-091 Screw ..................................................................................... 4

59 25768 Spacer, Fan ............................................................................ 1

60 25706 Fan, Cooling .......................................................................... 1

61 51279 Heater 120V/1000W ................................................................. 2

62 18201 High Limit Thermostat.............................................................. 2

63 70046 Power Switch (HHC-900EM & HC-15) ................................... 1

63 72277 Black Rocker Switch (HHC-900CDT) ..................................... 1

64 16624 Indicator Light - Red (HHC-900EM & HC-15) ...................... 2

65 14250 Thermometer (HHC-900 EM & HC-15) ................................. 1

66 25863 Knob - Thermostat .................................................................... 1

67 SC02-030 Screw #8-B x 3/8 PH THD Black Oxide .................................. 4

68 44204 Decal-Control (HHC-900EM) .................................................. 1

68 85249 Decal-Control (HHC-900CDT) ................................................ 1

68 87065 Decal-Control (HC-15) ............................................................. 1

69 72440 Panel Control S/A (HHC-900EM & HC-15) ............................ 1

69 81307 Panel Control S/A (HHC-900CDT) .......................................... 1

71 25241 Bracket Thermostat Mount ....................................................... 1

72 14209 Thermostat w/clips .................................................................... 1

73 25734 Insulation 5 x 7 x 1 .................................................................... 2

74 25733 Insulation 6 x 6 1/2 x 1 ............................................................. 4

75 25735 Insulation 5 x 10 1/2 x 1 ........................................................... 2

80* 83758 Control & Display PCB Assy - 13 Timer (HHC-900CDT) ...... 1

83* ME90-009 Relay 240V coil, 30A (HHC-900CDT) .................................... 1

84* 28979 Transformer 240V (HHC-900CDT) ......................................... 1

103* 27870 Insulator, Fan Motor ................................................................. 1

recommended parts/* not shown

510 3-17

Page 58

Models HHC-90X/HC-15

Non-UL & Non-CE Approved - HHC-900 EM, HHC-900 CDT, & HC-15

Figure 3-5. Cabinet Assembly - Non-UL, Non-CE

3-18 510

Page 59

Models HHC-90X/HC-15

Non-UL & Non-CE Approved - HHC-900 EM, HHC-900 CDT, & HC-15

Figure No.

& Item No. Part No. Description Quantity

3-5 Cabinet Assembly - Non-UL, Non-CE

2 SC01-170 Screw #10-32 x 2-1/2 PH PHD ..................................................... 4

2* LW02-004 Lockwasher ................................................................................... 4

2* WA01-022 Flat Washer ................................................................................... 2

2* 37151 Spacer (HHC-900EM & HC-15) ................................................. 2

3 59257 Glass Door Assy.-Left, Top ........................................................... 1

3 59258 Glass Door Assy.-Left, Bottom ..................................................... 1

3 59260 Glass Door Assy.-Right, Top......................................................... 1

3 59261 Glass Door Assy.-Right, Bottom ................................................... 1

4 14271 Kit - Hinge ................................................................................... 8

5a SC01-086 Screw #10-32 x 1 PH TH S .................................................... 16

5b SC01-225 Screw #10-32 x 3/4 PH TH S ................................................. 24

5c 27146 Cover - Hinge Pin - Chrome ......................................................... 8

6 SC01-074 Screw #10-32 x 1/2 PH TH ........................................................... 16

7 LW01-002 Lockwasher Split 1/4” .................................................................. 8

8 SC01-104 Screw 1/4-20 x 1-1/2” Hex Head .................................................. 8