Henny Penny HEC-103 Service Manual

Henny Penny

Heated Express

Model HEC-103

Model HEC-104

Model HEC-123

Model HEC-124

Cabinet

TECHNICAL MANUAL

LIMITED WARRANTY FOR HENNY PENNY EQUIPMENT

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the original

purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT: Any part of a new appliance, except baskets, lamps, and fuses, which proves to be defective in

material or workmanship within two (2) years from date of original installation, will be repaired or replaced without

charge F .O.B. factory , Eaton, Ohio, or F .O.B. authorized distributor . Baskets will be repaired or replaced for ninety (90)

days from date of original installation. Lamps and fuses are not covered under this Limited W arranty. To validate this

warranty, the registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

FILTER SYSTEM: Failure of any parts within a fryer filter system caused by the use of the non-OEM filters or

other unapproved filters is not covered under this Limited Warranty.

REPLACEMENT PARTS: Any appliance replacement part, except lamps and fuses, which proves to be defective in

material or workmanship within ninety (90) days from date of original installation will be repaired or replaced without

charge F .O.B. factory , Eaton, Ohio, or F .O.B. authorized distributor .

The warranty for new equipment covers the repair or replacement of the defective part and includes labor charges and

maximum mileage charges of 200 miles round trip for a period of one (1) year from the date of original installation.

The warranty for replacement parts covers only the repair or replacement of the defective part and does not include any

labor charges for the removal and installation of any parts, travel, or other expenses incidental to the repair or replacement of

a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or workmanship

issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover any frypot that fails due to

any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new frypot at no cost or

provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for the frypot only . Any freight charges and labor costs to install the new frypot as

well as the cost of any other parts replaced, such as insulation, thermal sensors, high limits, fittings, and

hardware, will be the responsibility of the owner.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was purchased. No

allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If damage occurs during

shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FOR TH THE SOLE REMEDY AGAINST HENNY PENNY FOR ANY BREACH

OF W ARRANTY OR OTHER TERM. BUYER AGREES THA T NO OTHER REMEDY (INCLUDING CLAIMS FOR ANY INCIDENT AL OR CONSEQUENTIAL DAMAGES) SHALL BE AV AILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) if the

equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED W ARRANTY IS EXPRESSL Y IN LIEU OF ALL OTHER W ARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANT ABILITY AND FITNESS, AND ALL OTHER W ARRANTIES ARE EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY

PERSON TO ASSUME FOR IT ANY OTHER OBLIGA TION OR LIABILITY.

Revised 01/01/07

FM06-031

Revised 2-17-11

Model HEC-103/104/123/124

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING

1-1. Introduction ........................................................................................................... 1-1

1-2 Safety.................................................................................................................... 1-1

1-3. Troubleshooting ..................................................................................................... 1-1

1-4. Error Codes and Warnings.................................................................................... 1-3

Section 2. MAINTENANCE

2-1. Introduction ........................................................................................................... 2-1

2-2. Maintenance Hints ................................................................................................ 2-1

2-3. Lamp Socket Replacement ................................................................................... 2-1

2-4. Ballast Replacement ............................................................................................. 2-4

2-5. Base Heaters ........................................................................................................ 2-5

2-6. Transformers......................................................................................................... 2-5

2-7. Relays ................................................................................................................... 2-6

2-8. Fuse and Fuse Holder Replacement ..................................................................... 2-8

2-9. Power Switch Replacement ................................................................................. 2-9

2-10. Contactor Replacement ........................................................................................ 2-10

2-11. PC Board Replacement ........................................................................................ 2-10

2-12. Heated Shelf Replacement ................................................................................... 2-12

Wiring Diagrams ................................................................................................... 2-13

Section 3. PAR TS INFORMATION

3-1. Introduction ........................................................................................................... 3-1

3-2. Genuine Parts ....................................................................................................... 3-1

3-3. How to Order ....................................................................................................... 3-1

3-4. Prices .................................................................................................................... 3-1

3-5. Delivery ................................................................................................................ 3-1

3-6. Warranty ............................................................................................................... 3-1

3-7. Recommended Spare Parts for Distributors ......................................................... 3-1

206 i

Model HEC-103/104/123/124

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION This section provides troubleshooting information in the form of

and easy to read table.

If a problem occurs during the first operation of a new unit,

recheck the Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the operating

procedure per the Operation Section of the Operator’s Manual.

1-2. SAFETY

Where information is of particular importance or is safety related,

the words, NOTICE, CAUTION, or WARNING are used.

Their usage is described below .

SAFETY ALER T SYMBOL is used with DANGER, W ARNING,

or CAUTION which indicates a personal injury type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury .

1-3. TROUBLESHOOTING T o isolate a malfunction, proceed as follows:

1. Clearly define the problem (or symptom) and when it

occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes. Then, one-at-a-time work

through the list of corrections until the problem is solved.

1-1 104

Model HEC-103/104/123/124

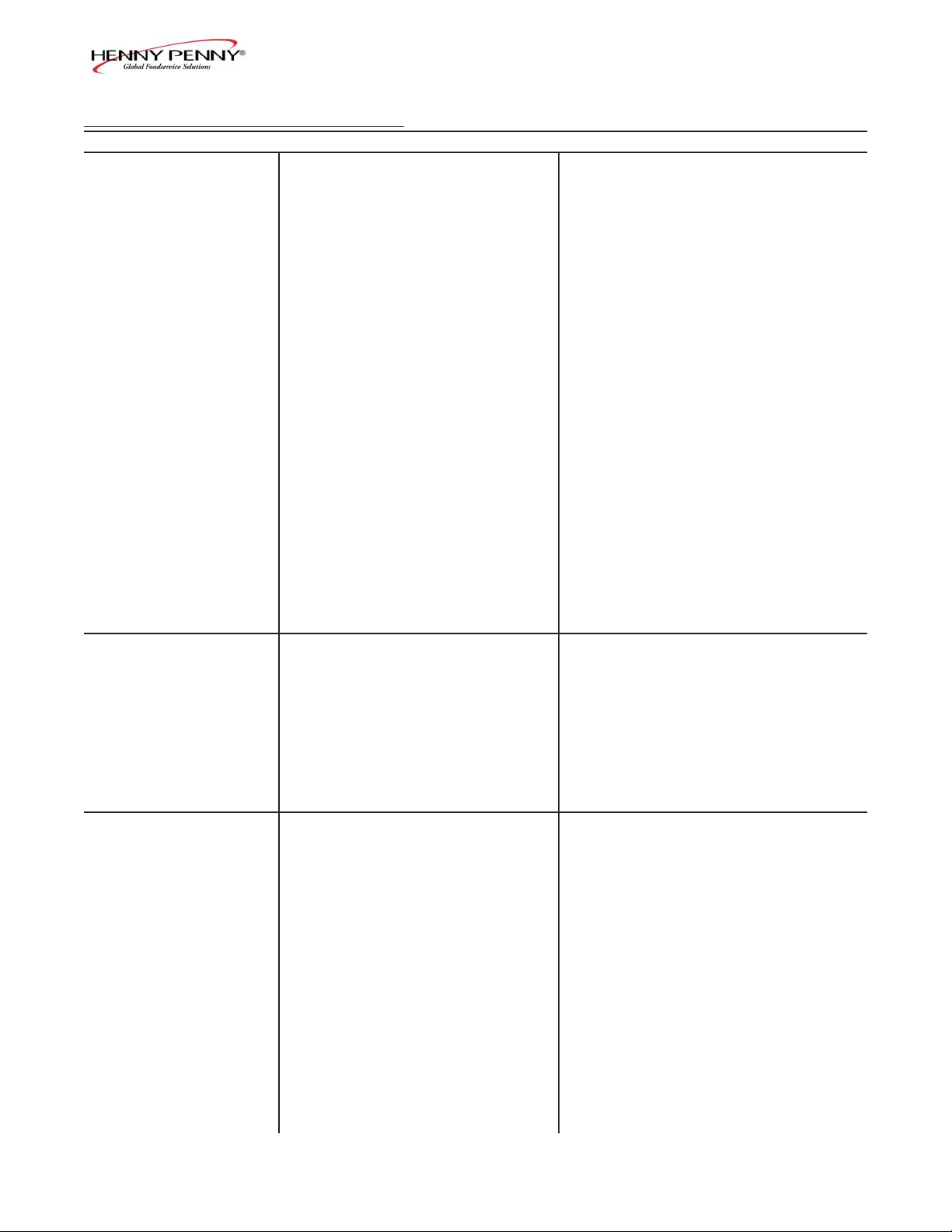

1-3. TROUBLESHOOTING (Continued)

PROBLEM CAUSE CORRECTION

With power switch in • Open circuit • Check to see that unit is

POWER position, unit plugged in

is completely

inoperative (no power) • Check breaker or fuse at supply box

• Check control panel fuses per Fuse

and Fuse Holder Replacement Section

• Check voltage at wall receptacle

• Check POWER switch;

replace if defective

• Check cord and plug for loose

connections

• Control board defective • Check for 12 volt input from

transformer; replace if defective

• Transformer defective • Check input and output voltage;

replace if defective

Unit will not heat • Control board not calling • Check set point reading; if unit

for heat below setpoint and not calling

for heat, control board

defective

• Faulty contactor • Check contactor and replace if

necessary

No shelf heat • Faulty shelf heat relay • Check and replace if necessary

• Faulty shelf heater • Check and replace if necessary

• Unit not preheated • Preheat unit before loading product

• Faulty PC board • Replace PC board

• T emperature setting “OFF” • Remove front cover and increase shelf

heat setting

• Shelf not plugged into receptacle • Check that the shelf plug is firmly

properly pushed into receptacle, in the

interior of the cabinet

104 1-2

Model HEC-103/104/123/124

1-3. TROUBLESHOOTING (Continued)

PROBLEM CAUSE CORRECTION

No base heat • Faulty base heat relay • Check and replace if necessary

• Faulty base heater • Check and replace if necessary

• Unit not preheated • Preheat unit before loading product

• Faulty PC board • Replace PC board

No light(s) • Faulty contactor • Check contactor and replace if

necessary

• Light socket shorted • Replace light socket

• Faulty fluourescent light bulb • Replace fluourescent light bulb

• Faulty lamp ballast • Replace ballast

Product not holding

temperature • Heat settings too low • Remove front cover and adjust shelf

and base heat settings

• Low or improper voltage • Using meter, compare receptacle

voltage to data plate voltage

• Product held too long • Hold product for recommended time

• Product not placed correctly in unit • Place product in unit as per

Operation with Product Section of

Operator’s Manual

• Product not hot when placed in • Place prepackaged hot food in

cabinet

1-4. ERROR CODES AND The display shows the following error codes and warnings when a

WARNINGS fault is detected, along with an alarm sound. Both the heat and

humidity systems shut down, except when specified otherwise.

DISPLAY

“E04”

CAUSE

• Control board temperature above

140o F (60o C)

• Check unit for overheating; if not

CORRECTION

overheating and “E04” persists,

replace PC board

“E41

• Scrambled PC board memory

• Press UP button to clear “E41”; if

“E41” persists, replace PC board

1-3 104

SECTION 2. MAINTENANCE

Model HEC-103/104/123/124

2-1. INTRODUCTION

2-2. MAINTENANCE HINTS

2-3. LAMP SOCKET REPLACEMENT

This section provides procedures for the checkout and replacement of the various parts used within the heated merchandiser. Before replacing any parts, refer to the Troubleshooting Section. It will aid you in determining the cause of

the malfunction.

1. Y ou may want to use a multimeter to check the electric

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the

multimeter reads infinity .

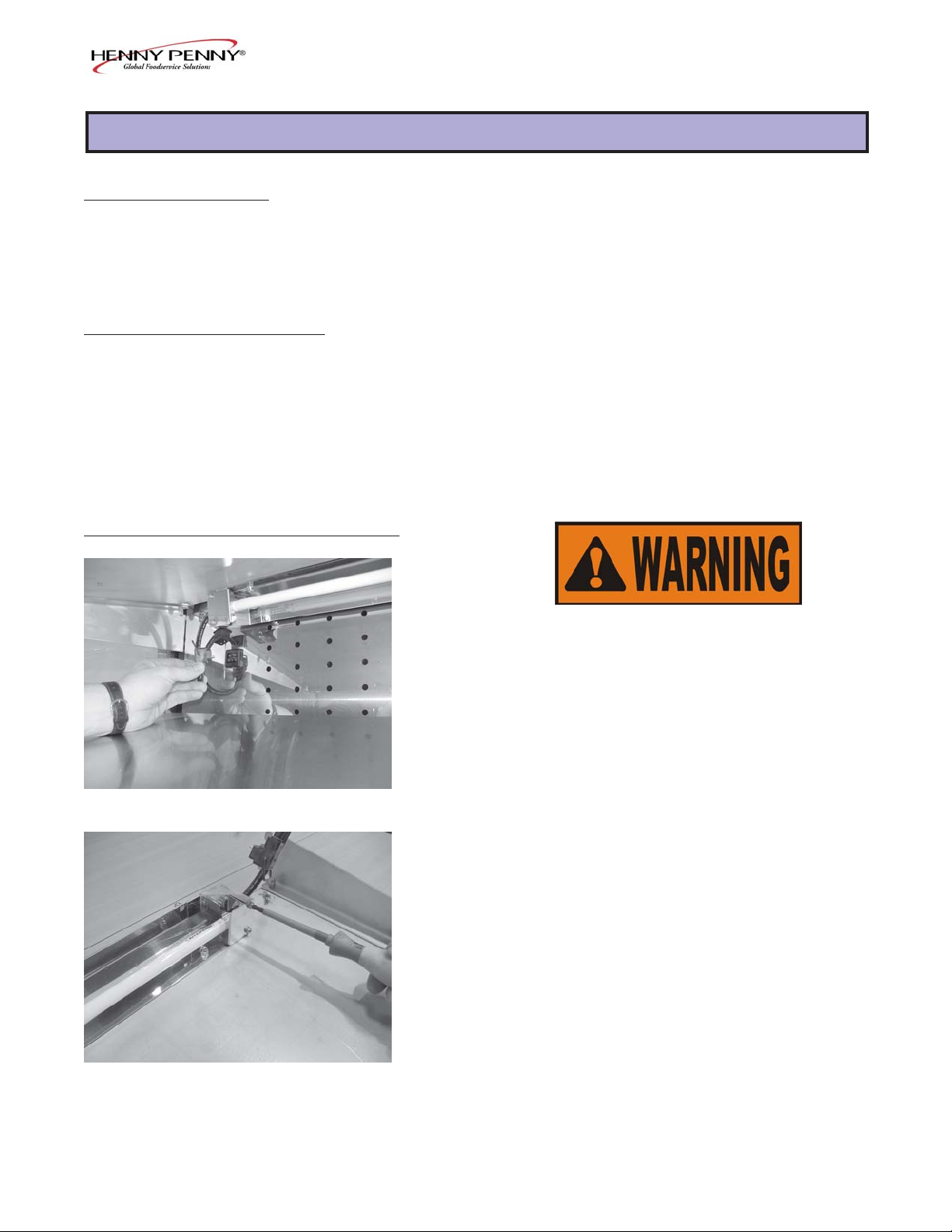

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker , or unplug cord at wall receptacle.

Figure 1

Figure 2

T o avoid burns, allow the unit to cool before

servicing.

Shelf Lamp Socket

1. Unplug both sides of the shelf with the faulty lamp socket.

Figure 1.

2. Lift shelf from unit.

3. Remove the screws securing the fluorescent bulb guards

on both ends of the bulb, and remove guards. Figure 2.

2-1 104

Model HEC-103/104/123/124

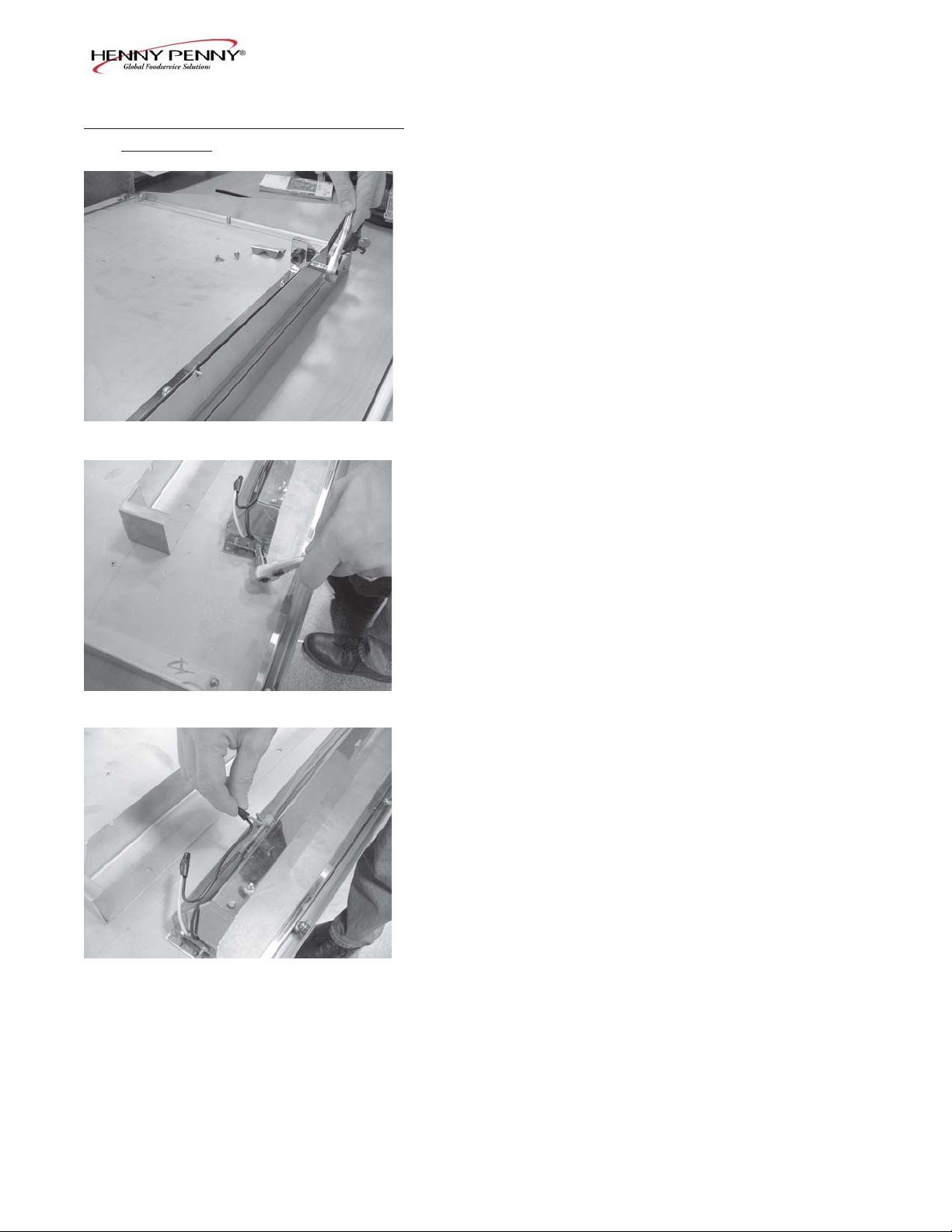

2-3. LAMP SOCKET REPLACEMENT

(Continued)

Figure 3

4. T wist bulb and remove from shelf.

5. Using a 5/16” socket for the rear, and 3/8” socket for

the front, remove all acorn nuts from the lamp reflector.

Figure 3.

Figure 4

Figure 5

6. Pull reflector apart and using 1/4” socket remove nuts

securing the faulty socket. Figure 4.

7. Disconnect wires and remove faulty socket from

reflector. Figure 5.

8. Install new lamp socket in reverse order .

104 2-2

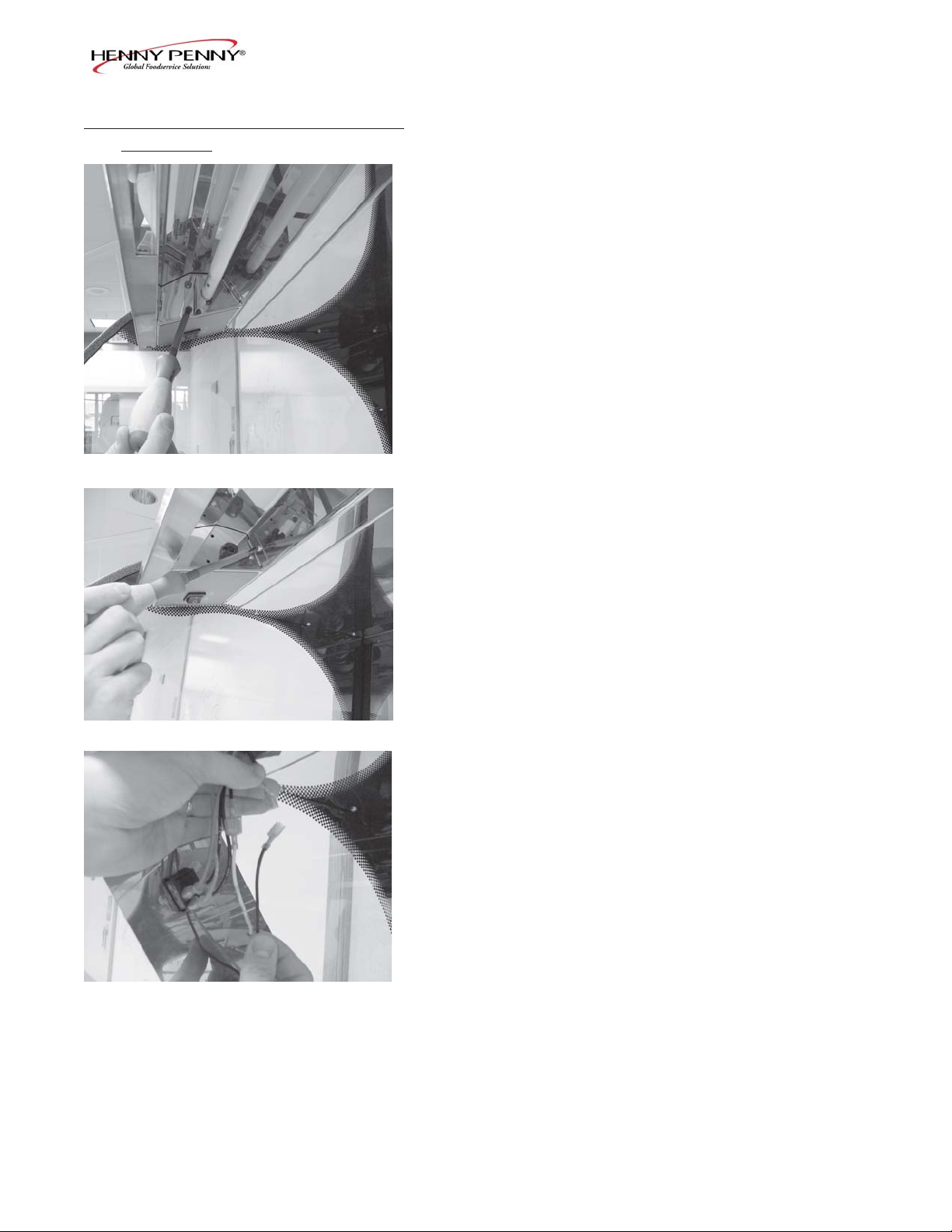

2-3. LAMP SOCKET REPLACEMENT

(Continued)

Figure 6

Model HEC-103/104/123/124

Canopy Lamp Socket

1. Remove the screws securing the fluorescent bulb guards

on both ends of the bulb, and remove guards. Figure 6.

2. T wist bulb and remove from canopy .

Figure 7

3. Remove screws securing both ends of the canopy lamp

reflector, and allow reflector to drop down. Figure 7.

4. Pull wires down from canopy and disconnect the wire

connectors. Figure 8.

5. Using a 1/4” socket, remove nuts securing the faulty

socket, and remove socket from reflector.

Figure 8

6. Install new lamp socket in reverse order .

2-3 104

2-4. BALLAST REPLACEMENT

Figure 1

Model HEC-103/104/123/124

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker , or unplug cord at wall receptacle.

1. Carefully pry out on the front cover of the unit, unsnapping the plastic fasteners, and remove front cover.

Figure 1.

2. Remove the 3 screws securing the control panel and hinge

the panel down. Figure 2.

Figure 2

Figure 3

3. Using a small screwdriver , press down on the wire

retainers on the ends of the ballast and remove wires f

from ballast. Figure 3.

4. Remove screws securing the ends of the faulty ballast

and remove ballast. Figure 4.

5. Install new ballast in reverse order . Use the color coded

chart on the ends of the ballast on re-installing the wires.

Figure 4

104 2-4

2-5. BASE HEA TERS

Figure 1

Model HEC-103/104/123/124

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker , or unplug cord at wall receptacle.

Checkout:

1. Carefully pry out on the front cover of the unit, unsnapping the plastic fasteners, and remove front cover.

2. Remove the 3 screws securing the control panel and

hinge the panel down.

3. Disconnect the wires from the heater terminals, and

using a multimeter, or ohm meter , check ohm rating.

Figure 1. The ohm ratings should be:

Figure 2

2-6. TRANSFORMERS

HEC-103 - 208V - Cold - 39 ohms

HEC-103 - 240V - Cold - 52 ohms

HEC-104 - 208V - Cold - 49 ohms

HEC-104 - 240V - Cold - 70 ohms

Replacement:

4. If heater proves faulty , remove the well covers.

5. Remove the screws securing the heater to the unit and

pull the heater from the unit. Figure 2.

6. Install new heater in reverse order .

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker , or unplug cord at wall receptacle.

Checkout:

1. Carefully pry out on the front cover of the unit, unsnapping the plastic fasteners, and remove front cover.

2. Remove the 3 screws securing the control panel and

hinge the panel down.

2-5 704

2-6. TRANSFORMERS (Continued)

Figure 1

Model HEC-103/104/123/124

3. Label and disconnect the wires from the transformer

terminals, and using a multimeter, or ohm meter, check

ohm rating. Figure 1. The ohm ratings should be:

Secondary: 1 ohm

Primary: 234 ohms - 208V

200 ohms - 240V

Replacement:

4. If transformer proves faulty , remove screws securing

transformer to the unit and remove transformer.

Figure 2.

Figure 2

2-7. RELAYS

5. Install new transformer in reverse order .

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker , or unplug cord at wall receptacle.

Checkout:

1. Carefully pry out on the front cover of the unit, unsnapping the plastic fasteners, and remove front cover.

2. Remove the 3 screws securing the control panel and

hinge the panel down.

704 2-6

2-7. RELA YS (Continued)

Model HEC-103/104/123/124

T o avoid electrical shock, make connections

before applying power , take r eading, and remove

power before removing meter leads. The following checks are performed with the wall circuit

breaker closed and the main power switch in the

ON position.

3. With power reapplied, let unit start heating up, and

with the component energized, 0 volts should show on

the output side of the relay , and 12 volts on the input.

4. If voltage varies from steps 4 and 5, remove power to

unit, pull input wires from relay and place leads of

meter onto input wires. Reapply power to unit. If the

input wires to relay shows 12 vdc volts, the relay is

faulty .

Figure 1

Replacement:

5. Label and remove the wires from the relay , using a

Phillip’s head screwdriver . Figure 1.

6. Using a Phillip’s head screwdriver , remove the 2

screws securing the relay and remove faulty relay .

Figure 2.

7. Install new relay in reverse order.

Figure 2

2-7 204

2-8. FUSE AND FUSE HOLDER

REPLACEMENT

Figure 1

Model HEC-103/104/123/124

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker, or unplug cord at wall receptacle.

Fuse Replacement:

1. Carefully pry out on the front cover of the unit, unsnapping the plastic fasteners, and remove front cover.

2. Unscrew fuse holder cap counterclockwise to access

fuse. Figure 1.

T o check fuse, use a multimeter, or continuity tester , and put

leads on each end of fuse. If meter shows circuit is closed,

fuse is good. Replace fuse with a 15 amp fuse, (20 amp

fuse-CE), if meter shows circuit is open.

Figure 2

Fuse Holder Replacement:

1. W ith the front cover removed, remove the 3 screws securing the control panel and hinge the panel down.

2. Label wires and pull wires from the terminals of the faulty

fuse holder. Figure 2.

3. Remove the nuts securing the fuse holder and pull the

fuse holder from the unit. Figure 3.

4. Replace with new fuse holder in reverse order .

Figure 3

204 2-8

2-9. POWER SWITCH REPLACEMENT

Model HEC-103/104/123/124

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker, or unplug cord at wall receptacle.

1. Remove the screws securing the fluorescent bulb guards

on both ends of the bulb, and remove guards. Figure 1.

2. T wist bulb and remove from canopy .

Figure 1

Figure 2

3. Using a Phillip’ s head screwdriver, remove the screws s

securing the POWER switch plate, and pull plate down

from canopy . Figure 2.

3. Label and remove wires from POWER switch.

Figure 3.

4. Pushing in on the tabs on the sides of the POWER switch,

push switch through, to the outside of the plate, and

then replace with new switch in reverse order. Figure 4.

Figure 3

Figure 4

2-9 204

2-10. CONT ACTOR REPLACEMENT

Figure 1

Model HEC-103/104/123/124

T o avoid electrical shock or pr operty damage,

move the POWER switch to OFF and disconnect

main circuit breaker , or unplug cord at wall

receptacle.

1. Carefully pry out on the front cover of the unit, unsnapping the plastic fasteners, and remove front cover.

2. Remove the 3 screws securing the control panel and

hinge the panel down.

3. Label and disconnect the wires from the contactor

coil, and using a multimeter or ohm meter check

ohm rating. The ohm rating should be 540 ohms.

Figure 2

2-11. PC BOARD REPLACEMENT

4. If contactor proves faulty , remove screws securing the

wires to the contactor. Figure 1.

5. Using a Phillip’ s head screwdriver, remove the screws

securing the relay and remove faulty contactor.

Figure 2

6. Install new contactor in reverse order .

T o avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker, or unplug cord at wall receptacle.

1. Carefully pry out on the front cover of the unit, unsnapping the plastic fasteners, and remove front cover.

2. Remove the 3 screws securing the control panel and

hinge the panel down.

704 2-10

Loading...

Loading...