Henn

enny

umidifie m

FMOl-170

Revised 100

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Henny Penny

Section

.I

L’r

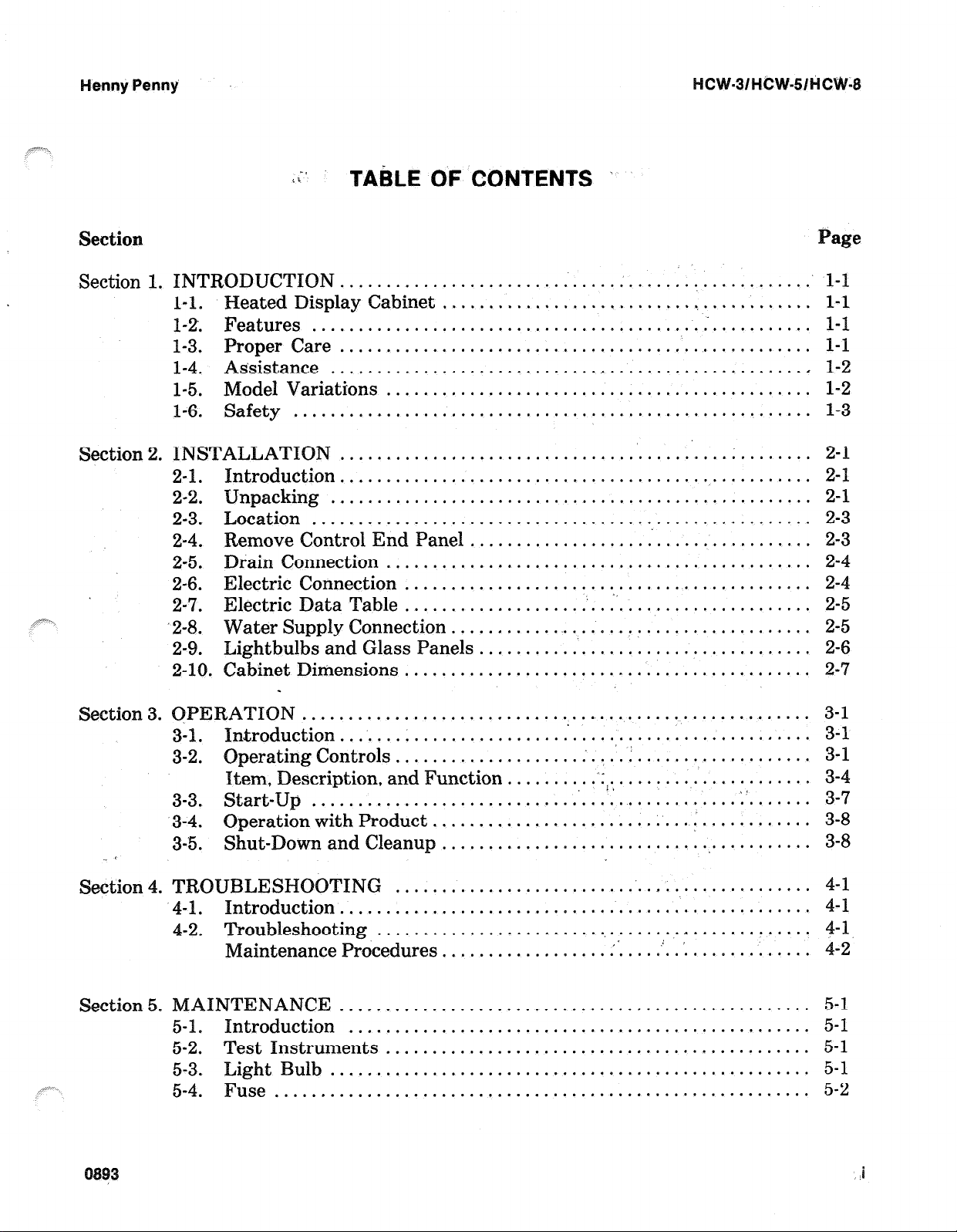

TABLE OF CONTENTS

Section 1. INTRODUCTION

l-l. Heated Display Cabinet

l-2, Features

1-3. Proper Care

1-4. Assistance

1.5. Model Variations

-6. Safety

Section 2. INSTALLATION

2-1. Introduction

2.2. Unpacking ....................................................

2-3. Location

2-4. ove Control End Panel

2-5. Connection.. ............................................

2-6. ctric Connection

.,>-y

2-7. Electric

‘2-8. Water Supply Connection

2-9. Lightbulbs and Glass Panels

2-10. Cabinet imensions

Section 3.

ERATION .......................................................

Introduction

.

.................................................... l-l

......................................... l-l

...................................................... l-l

...................................................

....................................................

.............................................. 1-2

........................................................

...................................................

...................................................

......................................................

......................................

............................................

1.

............................................

........................................

.....................................

............................................ 2-7

-

.....................................................

gcontrols..

scription, and Function

..................

.........

......................................................

with Product

............................ I.

;.., ..:.

‘“ii.

.................. 3-

.....................

*

L I

...........

.................................. 3-8

l-l

l-2

1-3

2-l

2-1

2-1

2-3

2-3

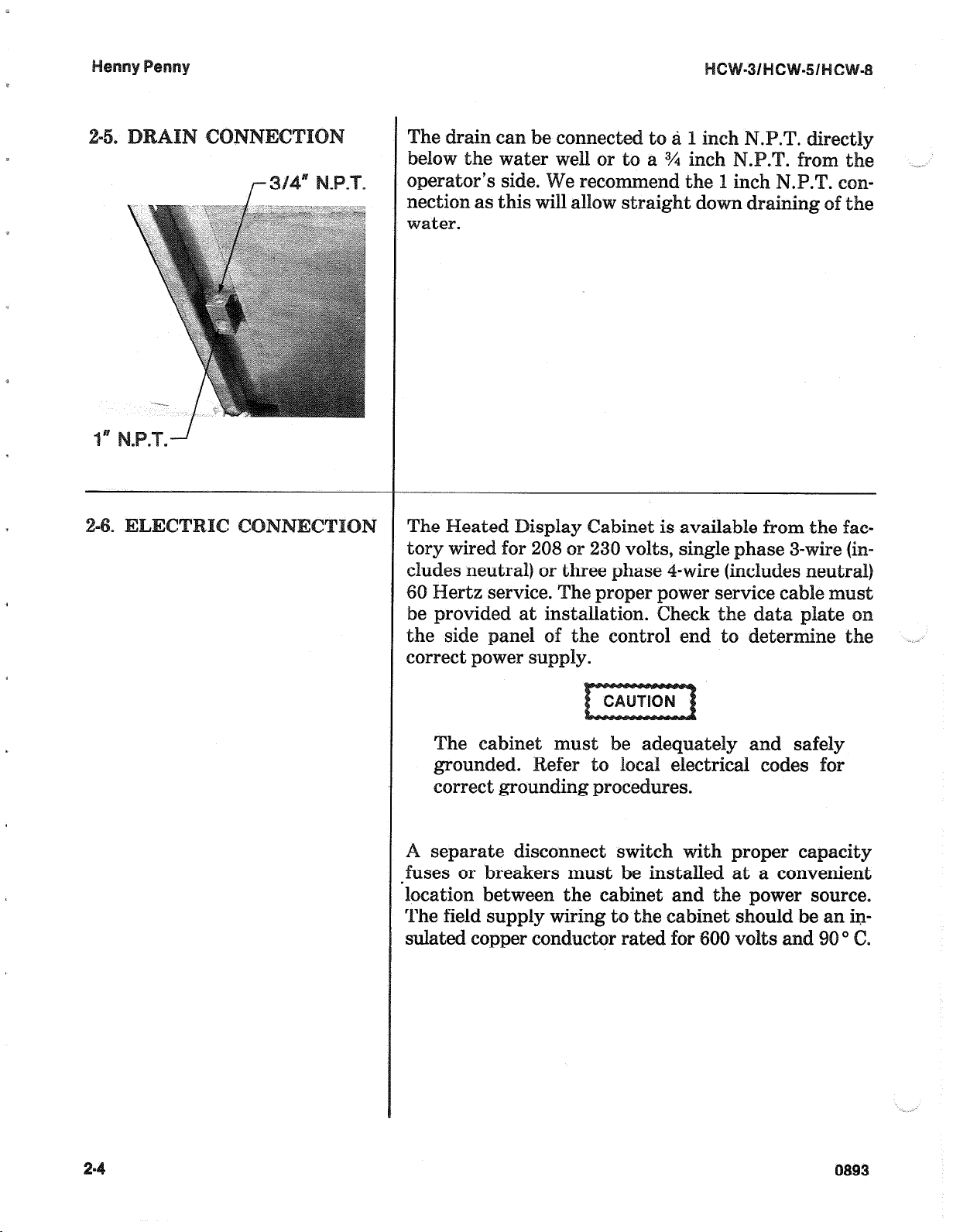

222-5

2-5

2-6

3-1

3-l

33-7

3-8

Section 4. TROU OTING

4-1.

4-2.

ubleshooting .........................

n ...................................................

aintenance Procedures.

Section 5.

AINTENANCE

5-1. Introduction

...................................................

..................................................

5-2. Test Instruments

ulb

....................................................

5-4. Fuse.. ........................................................

..............................................

......................

.

.‘..

.................

.......

..............................................

.

.............

5-l

5-l

5-l

5-l

5-2

em

enn

HCW-3IHCW-51HC

NTENTS (Continued)

ection

Section 5.

AINTENANCE (continued)

5-5.

5-6.

5-7.

5-8.

Cleaning Water Strainer.

Water Strainer.

Water Valve

Float Switch

ight Switch

ower

Switch

............................................

...............................................

...............................................

...............................................

...............................................

5-11. Water Control Switch

5-12. Infinite Switch

5-13. Thermostat

5-14. Indicating Light

5-15. Thermometer

5-16. Contactor

5-17. Terminal Block.

5-18. Water P

5-19. Radiant

5-20.

Light Socket

5-21. High Limit Switch

5-22. Conversion

5-23. Wiring Diagrams

.............................................

................................................

............................................

..............................................

.................................................

............................................

Heater ..........................................

ater .............................................

...............................................

..........................................

................................................

............................

....................................

.......................................

...............

f

e

5-2

5-4

5-4

5-6

5-7

5-8

5-9

5-9

5-10

5-11

5-12

5-13

5-14

5-15

5-16

5-17

5-17

5-18

,5-21

._

Section 6. PARTS INFORMATION.

6-l.

6-2.

6-3.

6-4.

6-5. Prices

Introduction

Genuine Parts.

ow to Find Parts.

owto Order

.....................................................

6-6. Delivery

6-7. Warranty

6.8.

Parts List

...............................................

.............................................

..............................................

...................................................

..................................................

..................................................

Henny Penny Distributor List

.........................................

.........................................

6-l

6-l

6-l

6-l

6-l

6-2

6-2

6-3

6-3

ii

0893

Henny Penny

SECTION 1. INTRODUCTION

1-I. HEATED DISPLAY

CABINET

The Henny Penny Heated Display Cabinet is a basic

unit

of

food processing equipment used to display the

food product and maintain the temperature of hot

foods in the commercial food service operation. This

highly efficient,

foods at proper holding te

umidity. The Henny Pe

e see-thru doors whi

hot foods from both

0 Dry heat in top section ( CW-5 and HCW-8 only).

* Easy to keep clean.

quality-built cabinet w

CW-3 and lower section HCW-5 and

,“*.

. PROPER CARE

Automatic water fill system with manual bypass.

@ Lower section HCW-5 and HCW-3 holds three trays

of product.

+9 Lower section CW-8 holds five trays.

0 Top section HCW-5 holds two trays of product.

0 Top section

@ All heat sources are adjustable.

0 Flip-up, see-through, door panels.

As in any unit of food service equipment,

Display Cabinet does require care

Suggestions for this maintenance

manual.

CW-8 holds three trays.

t

a

Henny Penny HCW-3/HCW-5/HCW-8

1-3. PROPER CARE (continued) For your convenience, this manual consists of the following sections:

• Table of Contents

• Introduction

• Installation

• Operation

• Troubleshooting

• Maintenance

• Wiring Diagrams

• Parts List

• Distributor List

The conscientious use of the recommended procedures, coupled

with regular maintenance, will result in few repairs to the equipment.

When such repairs are required, they may be accomplished by

following the repair steps contained in this manual.

1-4. ASSISTANCE Should you require outside assistance, just call your local

independent distributor maintained by Henny Penny Corporation.

In addition, feel free to contact our corporate headquarters in

Eaton, Ohio. Dial 1-800-417-8405, or 937-456-8405.

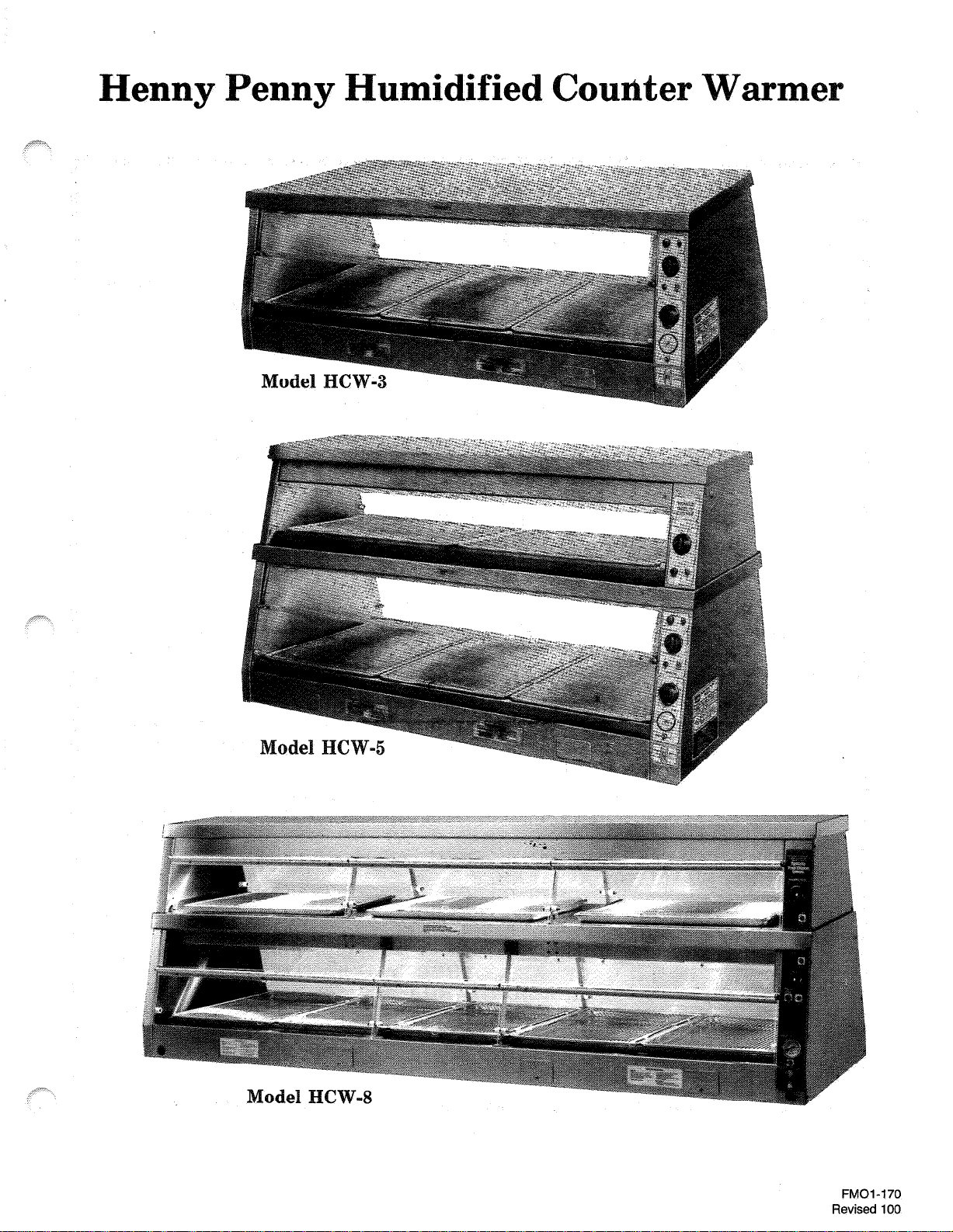

1-5. MODEL VARIATIONS This manual covers the HCW-5 and HCW-8 two tier cabinets, and

the HCW-3 single base cabinet. Also included is the HCW-2

which is the conversion from HCW-3 to HCW-5.

498 1-1

enny Penny

,H--

SAFET

.

The only way to insuke safe operation of the

Penny Heated Display Cabinet is to fully und

flaps and remove p

ft carton offs

-3/HCW-51HC

.

emove

four bolts from under

“.,

s

lay Cabinet is now ready for

.,,

enny Penny

.ee,

2-3. LOCATION

/ Place the unit on a table, preferably with a cut-out

~ opening below the cabinet to allow easy service con~ nections and serviceability. When setting up the

~ Penny Heated Display Cabinet,

e sure to level t

table.

The unit has built-in

aining capabilities,

this becomes ineffective when set on an unl

table.

After the Henny Penny

isplay Counter Warmer has

been leveled on the table, run a bead of silicone rubber

(silicone or equivalent sealant must be a NSF listed

material) around the perimeter of the unit sealing it to

the table top. You are now ready to make the electrical

and drain connections to the unit.

e seven screws fastening t

rst allowing to

ane

893

208 or 230 vo

ses or breakers must be inst .

ation between the

cabinet

and saf

1 codes

an

0893

“_ .

enny Penny

-3/HCW45/

,&m~

~con~~nued~

IC CONNECTION

The electrical power can be connected from the bottom or from the operator’s side. There is a l-3/32 inch

diameter hole for either connection. Again, we

recommend the bottom connection as this will give a

cleaner appearance to the unit. ease observe the

electrical connection information

located on the side anel of the con

Voltage potential of

2 to ground cannot

exceed 125 volts.

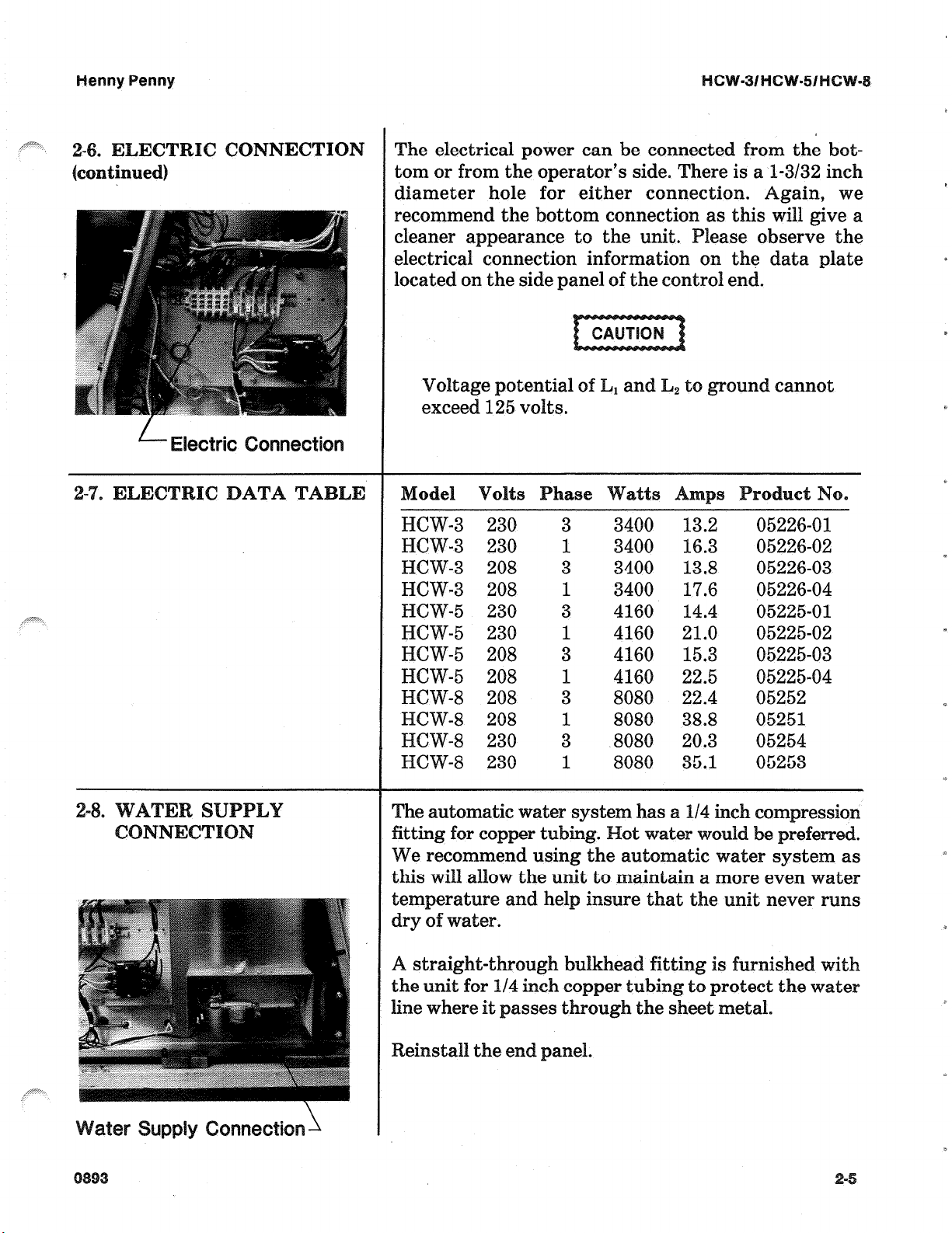

HCW-3

HCW-3

HCW-3

HCW-3

HCW-5

HCW-5

HCW-5

HCW-5

HCW-8

HCW-8

HCW-8

HCW-8

ts

ase

230 3

230 1

208 3

208 1

230 3

230 1

208 3

208 1

208 3

208 1

230 3

230 1

S

3400

3400

3400

3400

4160

4160

4160

4160

8080

8080

8080

8080

13.2

16.3

13.8

17.6

14.4

21.0

15.3

22.5

22.4

38.8

20.3

35.1

S

05226-01

05226-02

05226-03

05226-04

05225-01

05225-02

05225-03

05225-04

05252

05251

05254

05253

ter ectio

The automatic water system

fitting is furnishe

the water

TE

This unit as manufactured requires the installation

of an appropriate back-siphoning device (as per

National Plumbing Code ASA-A40.8-1955) to be

connected to the water inlet line. This device to

be connected in accordance to the basic plumbing

code of the Building Officials and Code

Administrators International, Inc. (BOCA), and

the Food Service Sanitation Manual of the Food

and Drug Administration (FDA).

TE

A water shut-off valve should be installed in a

convenient location.

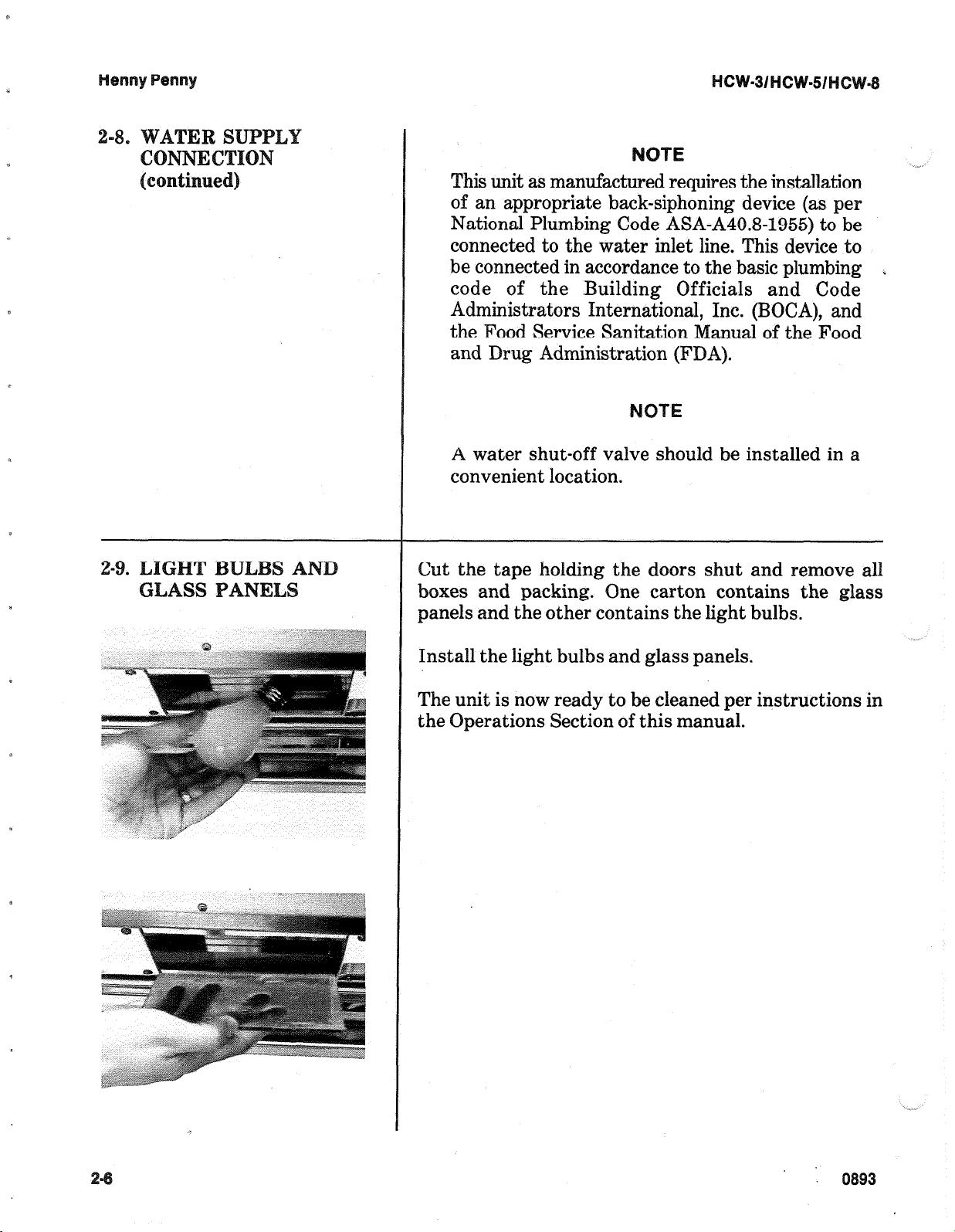

ut the tape holding the doors shut and remove all

boxes and packing. One carton contains the glass

anels and the other contains the light bulbs.

-

1

Install the light bulbs and glass panels.

The unit is now ready to be cleaned per instructions in

the Operations Section of this manual.

893

enny Penny

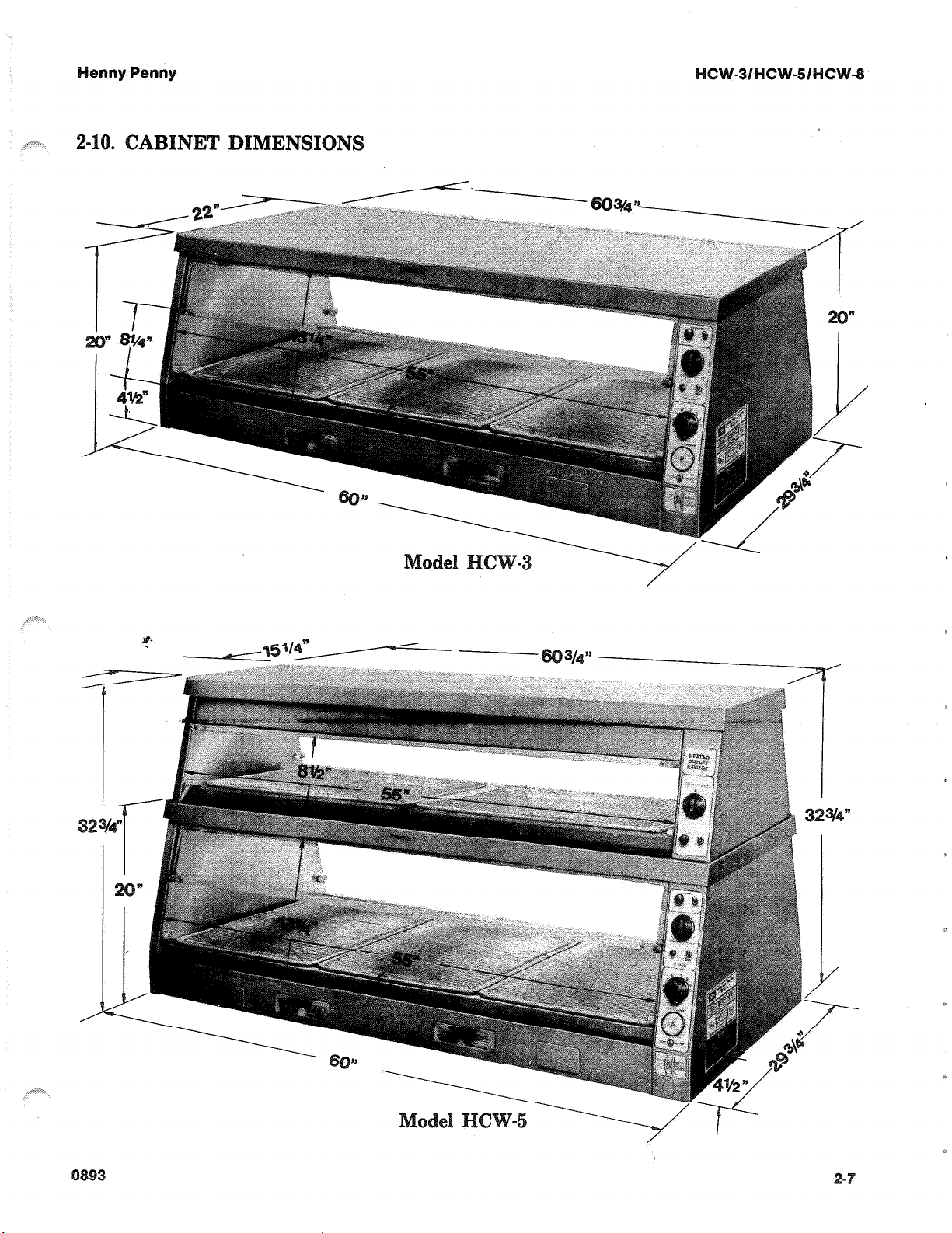

CABINE

IMENSION

.-;:, --” ,.” . .

,. . ,.i . , >

CW-31HCW41HC

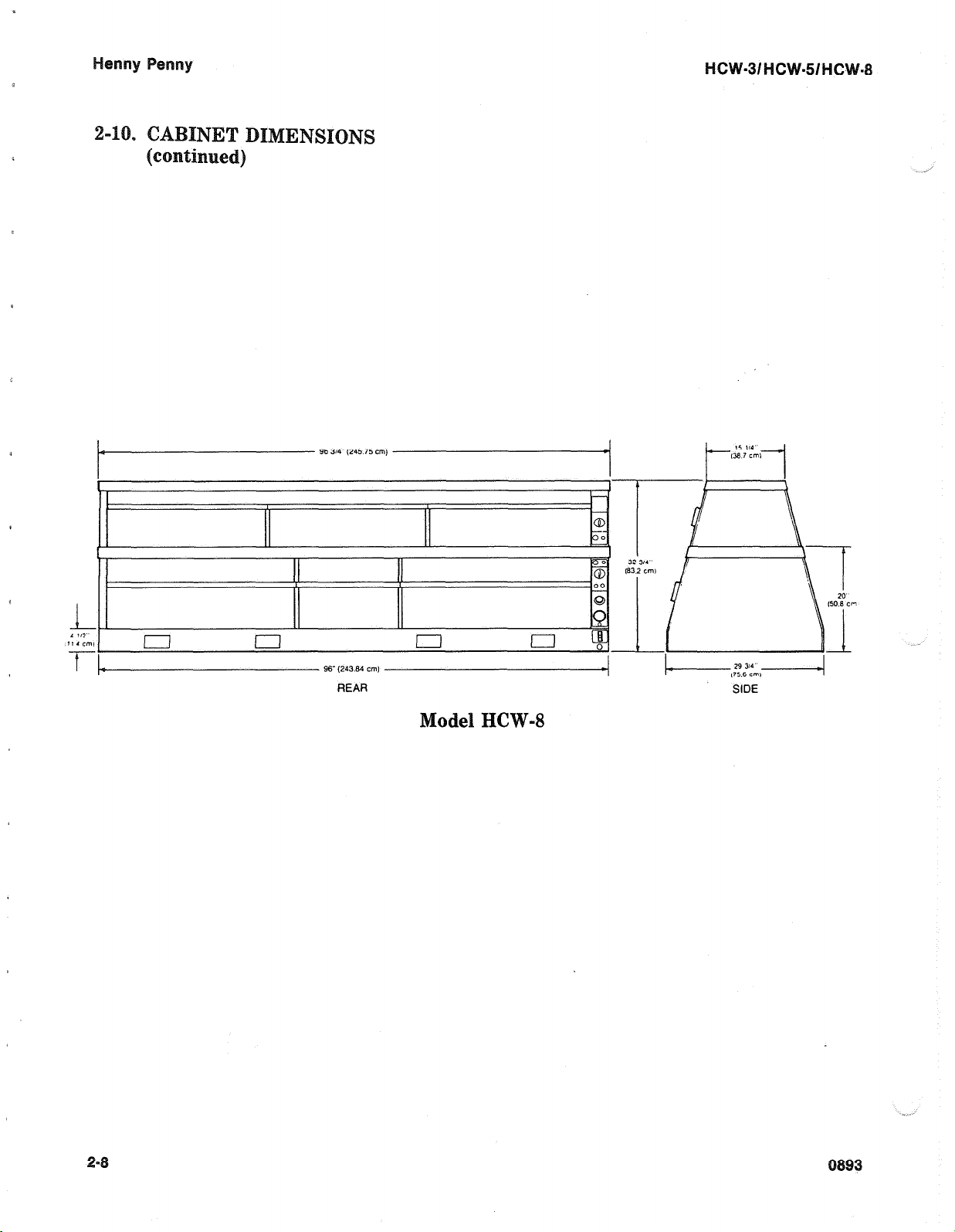

96” (243.84 cm,

REAR

SIDE

ode1 HCW-8

” .,

enny Pen

atio eratin

TR

y-ste

res.

c

93

at

ncti

ter

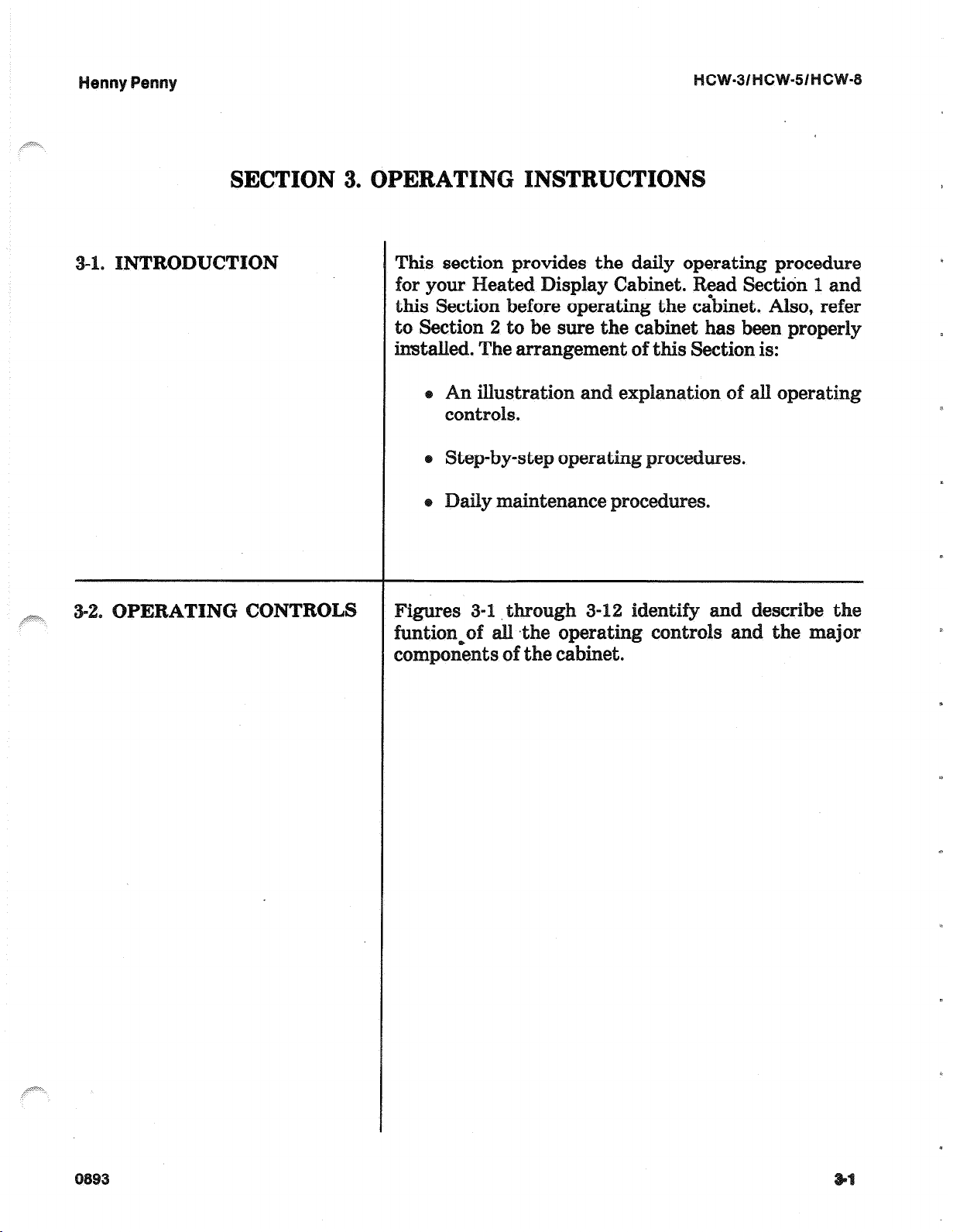

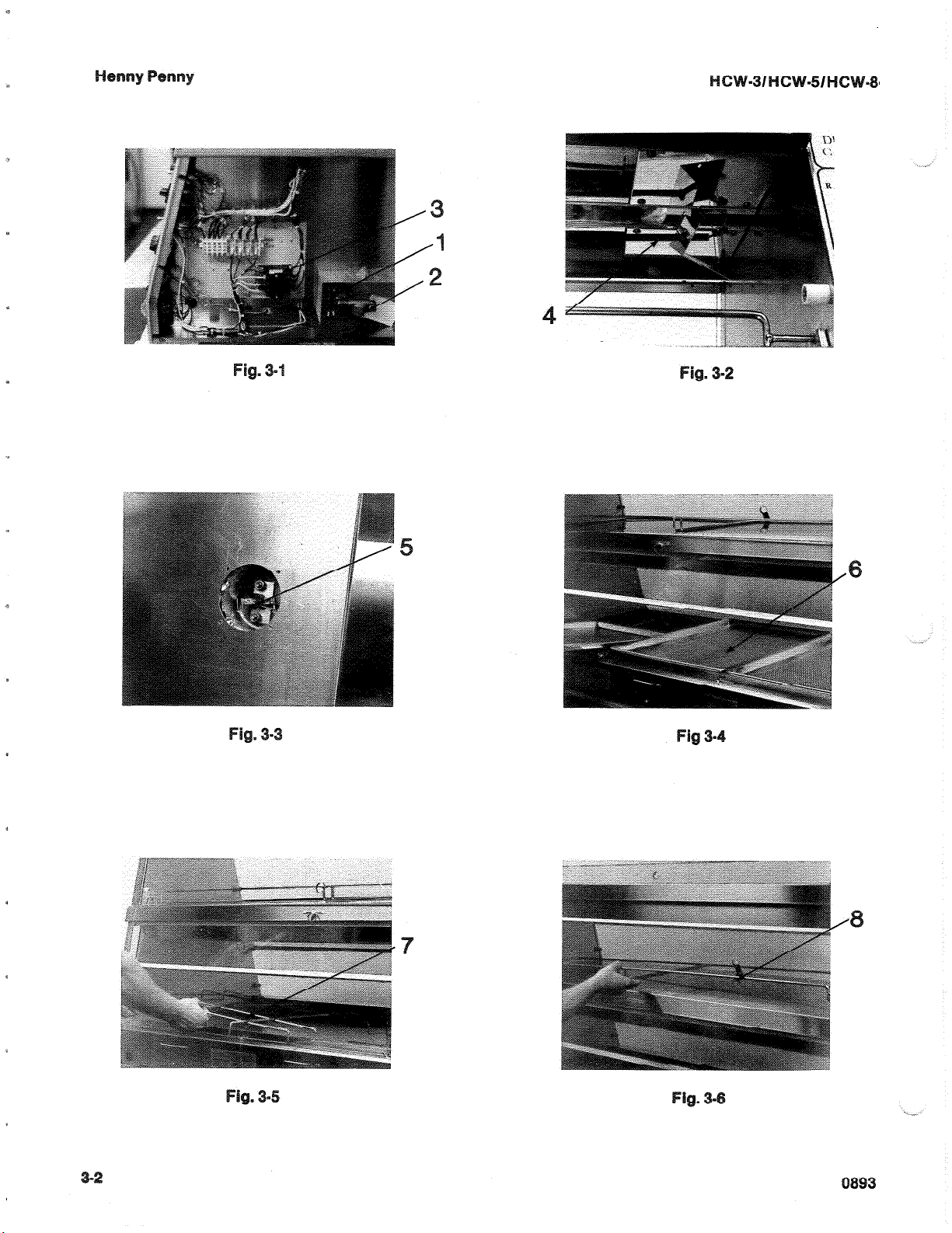

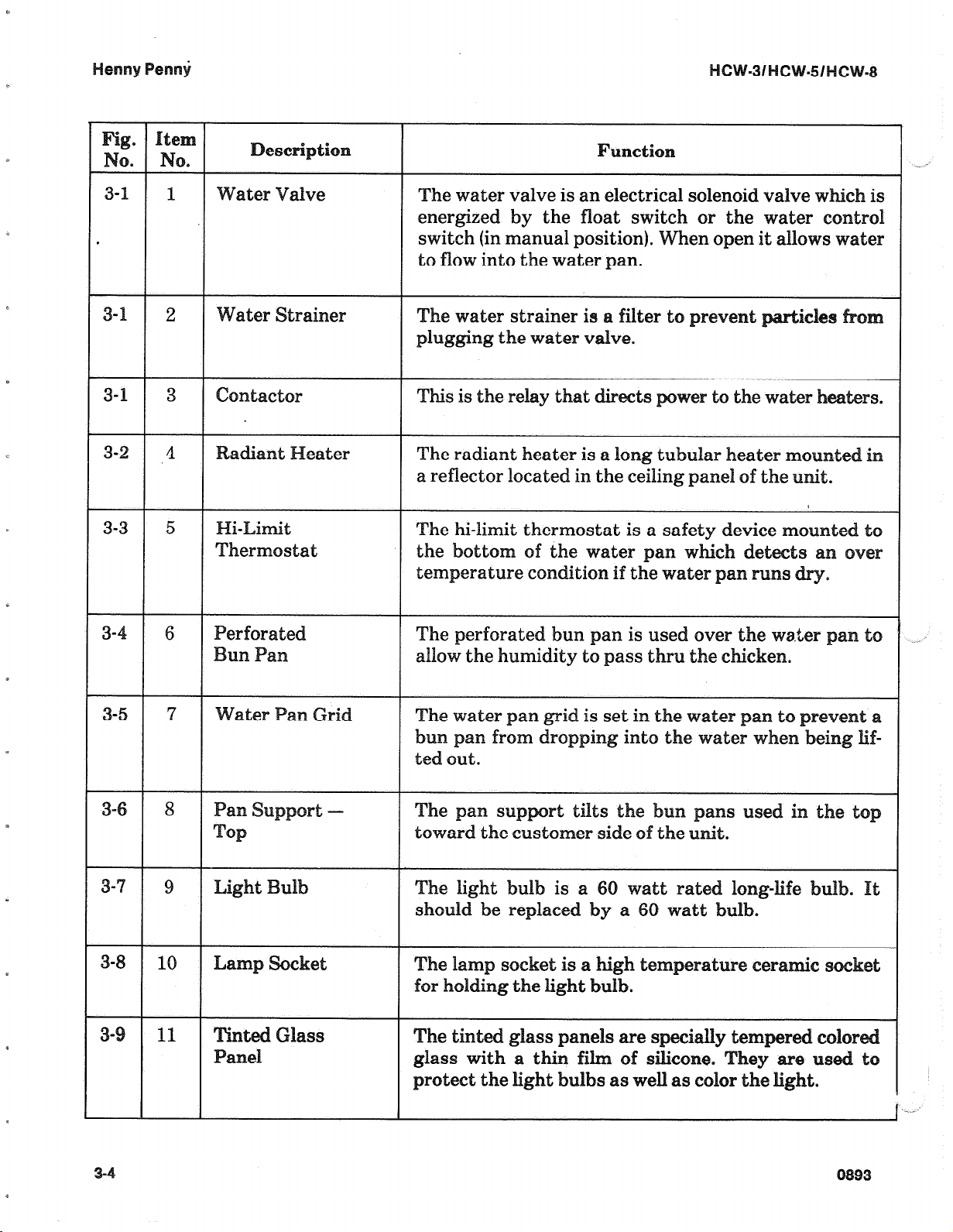

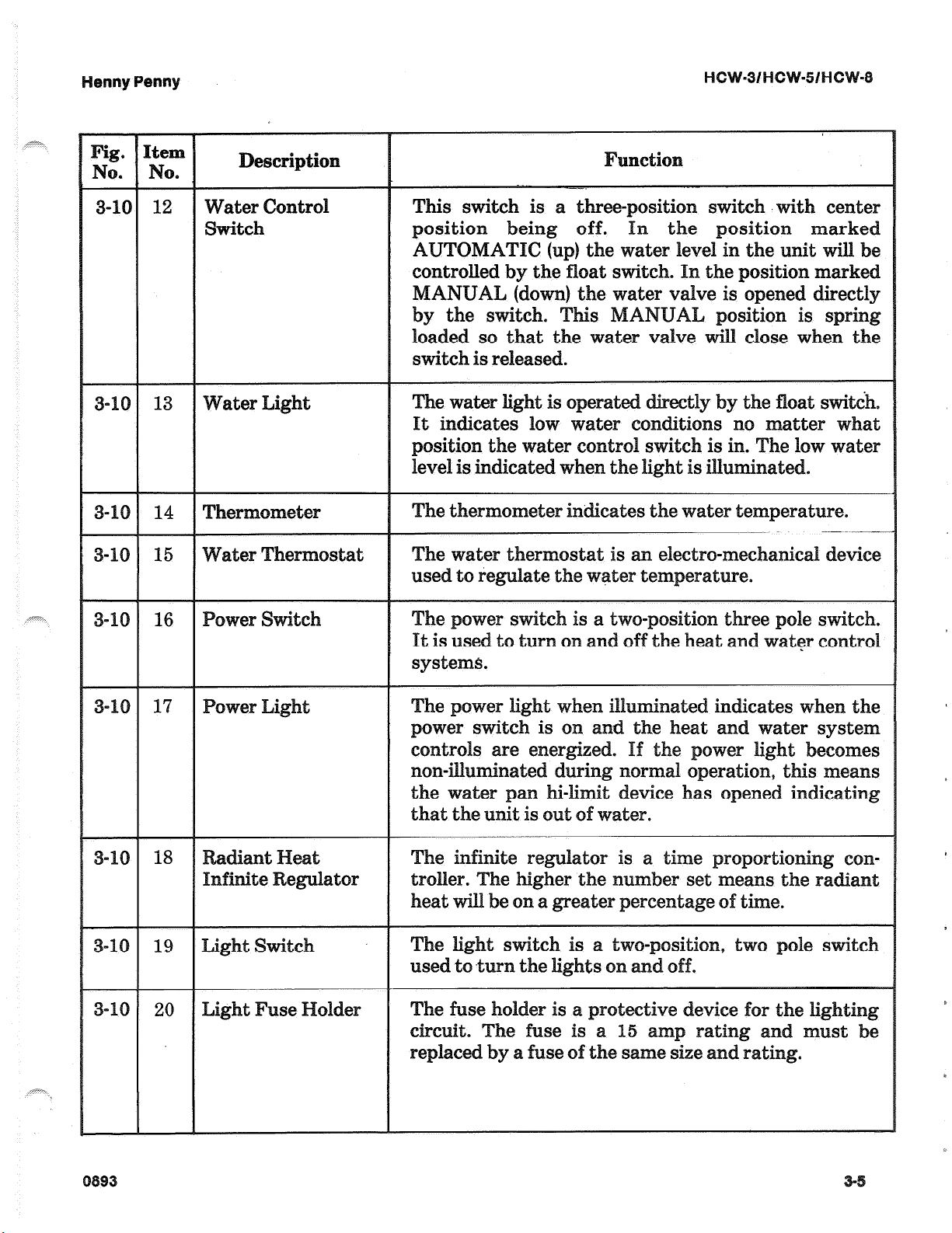

3

.4

5

ter

ater

he radia eater is

a reflector locate

.ter

enny Penny

-3lHC

controlled by the

ted at 1020 watts

ong.

There are two

each attached to the bot-

a93

Henny Penny

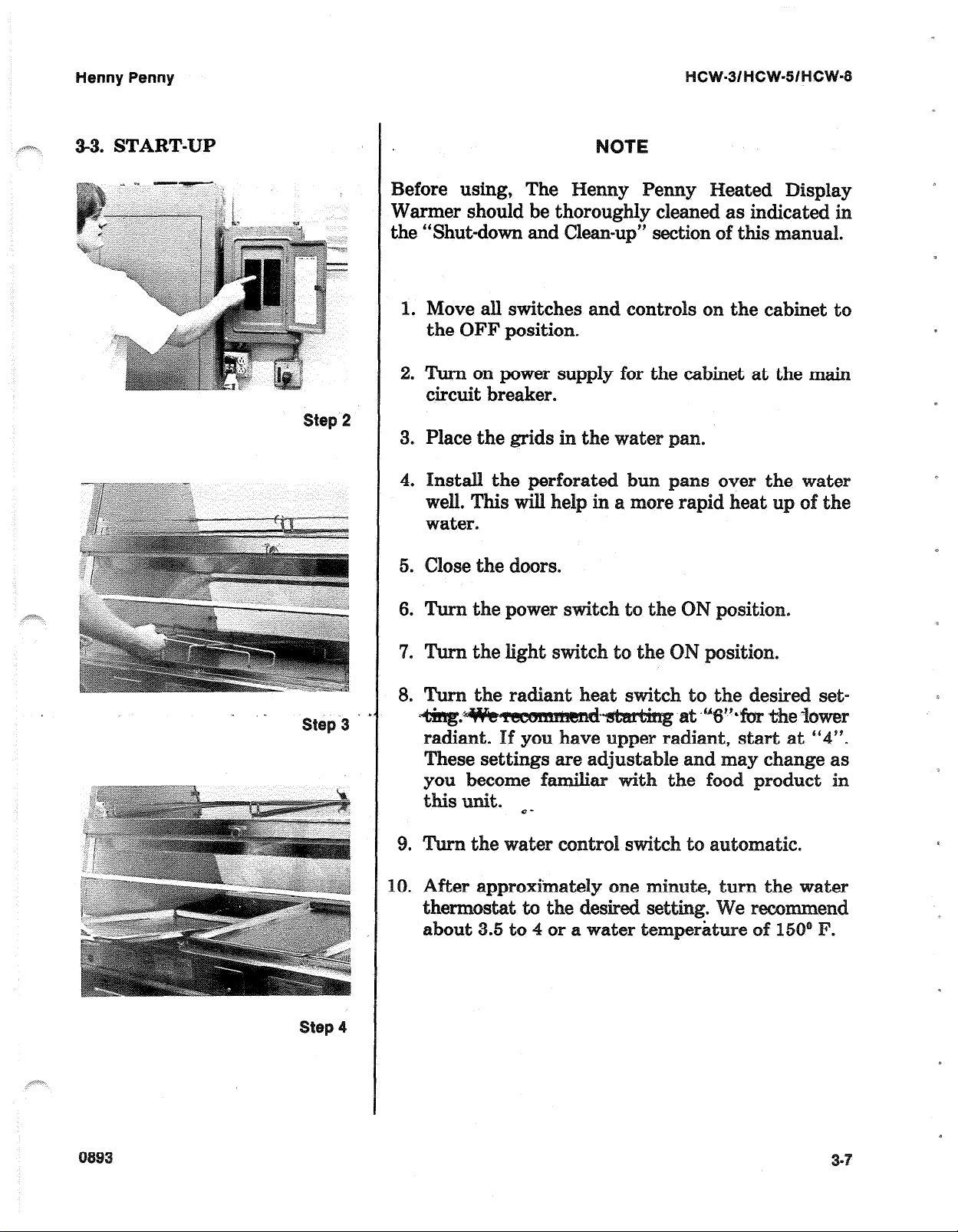

3. START-UP

Before using, The

Warmer should be thoroughly cleane

the “Shut-down and Clean-up”

set

1. Move all switches an

e OFF position.

water.

ower 8

8.

rt

s on the cabinet to

inet at the

e

atic.

roduct on wire

e water contr

001s.

ids in t

ans.

when demand requ

_d

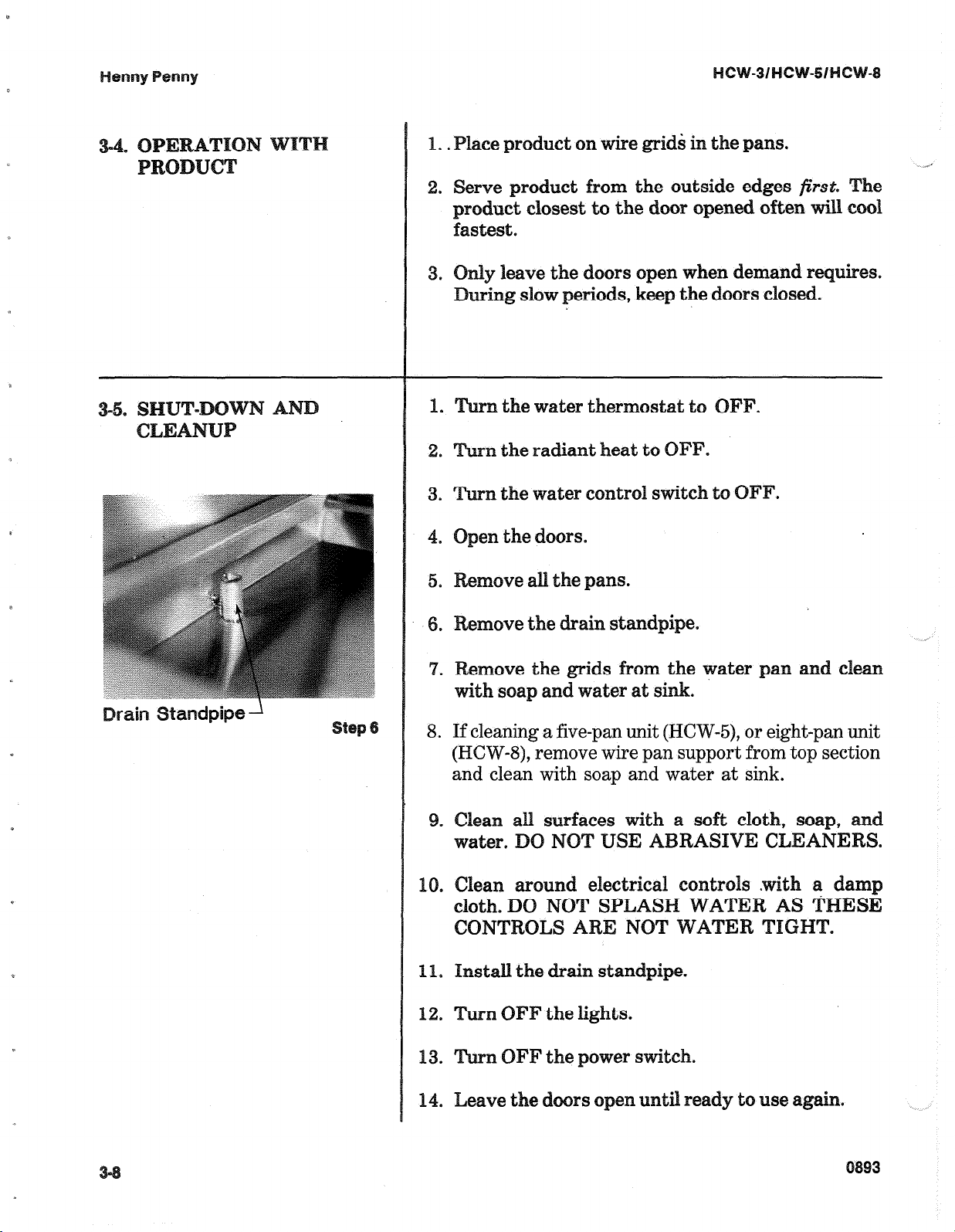

ove a

813s.

ove t

s from the water

8. If cleaning a five-pan unit (HCW-5), or eight-pan unit

(HCW-S), remove wire pan support from top section

and clean with soap and water at sink.

1

eave t

a93

Henny Penny

F

a

SECTION : TROUBLESHOO

1. INTRODUCTION

LESHOOTIN

This section provides troubleshooting information i

the form of an easy to read table.

If a problem occurs ring the first operation of a new

cabinet, recheck the installatio

er section 2 of this

manual.

efore troubles

procedure per se

0 isolate a malfunction

e tro

I

Loading...

Loading...