Page 1

HENNY PENNY

Humidity Control Adjustable

Model HCA910/905

2011/12/09

FM05-058-B

12/09/11

Page 2

HENNY PENNY

Humidity Control Adjustable

Model HCA910

Page 3

LIMITED WARRANTY FOR HENNY PENNY EQUIPMENT

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties

to the original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

proves to be defective in material or workmanship within one (1) year from date of original

installation, will be repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B.

authorized distributor. Baskets will be repaired or replaced for ninety (90) days from date of

original installation. Lamps and fuses are not covered under this Limited Warranty. To validate

this warranty, the registration card for the appliance must be mailed to Henny Penny within ten (10)

days after installation.

FILTER SYSTEM

non-OEM filters or other unapproved filters is not

REPLACEMENT PARTS:

proves to be defective in material or workmanship within ninety (90) days from date of original

installation will be repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B.

authorized distributor.

The warranty for new equipment covers the repair or replacement of the defective part and includes

labor charges and maximum mileage charges of 200 miles round trip for a period of one (90) days from the

date of original installation.

The warranty for replacement parts covers only the repair or replacement of the defective part and does

not include any labor charges for the removal and installation of any parts, travel, or other expenses

incidental to the repair or replacement of a part.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY

PENNY FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO

OTHER REMEDY (INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE

ABOVE LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER

WARRANTIES ARE EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES

ANY PERSON TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIAB ILITY.

Any part of a new appliance, except baskets, lamps, and fuses, which

: Failure of an y parts within a fryer filter system caused by the use of the

covered under this Limited Warranty.

Any appliance replacement part, except lamps and fuses, which

Revised 5/13/10

Page 4

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION………………………………………………………..1-1

1-1. Heated Holding Cabinet...........................................................1-1

1-2. Features...................................................................................1-1

1-3. Proper Care.............................................................................1-1

1-4. Assistance................................................................................1-1

1-5. Safety.......................................................................................1-2

Section 2. INSTALLATION................................................................................2-1

2-1. Introduction..............................................................................2-1

2-2. Unpacking................................................................................2-1

2-3. Location....................................................................................2-2

2-4. Electrical Connection................................................................2-2

2-5. Cabinet Dimensions..................................................................2-3

2-6. Water Supply Connection..........................................................2-4

2-7. Wire diagram……………………………………………………….2-5

Section 3. OPERATION......................................................................................3-1

3-1. Introduction................................................................................3-1

3-2. Operating Controls and Components........................................3-1

3-3. Start-Up.....................................................................................3-6

3-4. Operation with product..............................................................3-7

3-5. Cleaning Procedures.................................................................3-7

Page 5

1-1. HUMIDITY CONTROL

ADJUSTABLE (HCA910/905)

1-2. FEATURES

1-3. PROPER CARE

1-4. ASSISTANCE

The Henny Penny humidity control adjustable is a basic

unit of food processing equipment designed to hold hot

foods at proper temperature in commercial food operations.

This cabinet will keep hot foods humid while maintaining

temperature.

•Easily cleaned

•Automatic water fill

•Adjustable, thermostatically controlled heat

•Lift-off doors

•Easy access to electrical components

•Moist heat

•Removable control module

•Stainless steel construction

•Full perimeter magnetic door seals

•Lift out tray racks

•UL & NSF listed

•Adjustable humidity

As in any unit of food service equipment, the Henny

Penny heated holding cabinet does require care and

maintenance. Requirements for the maintenance and

cleaning are contained in this manual and must

become a regular part of the operation of the unit at

all times.

Should you require outside assistance, just call your

local independent Henny Penny distributor in your

area, or call Henny Penny Corp.1-800-417-8405 toll

free or 1-937-456-8405.

1-1

Page 6

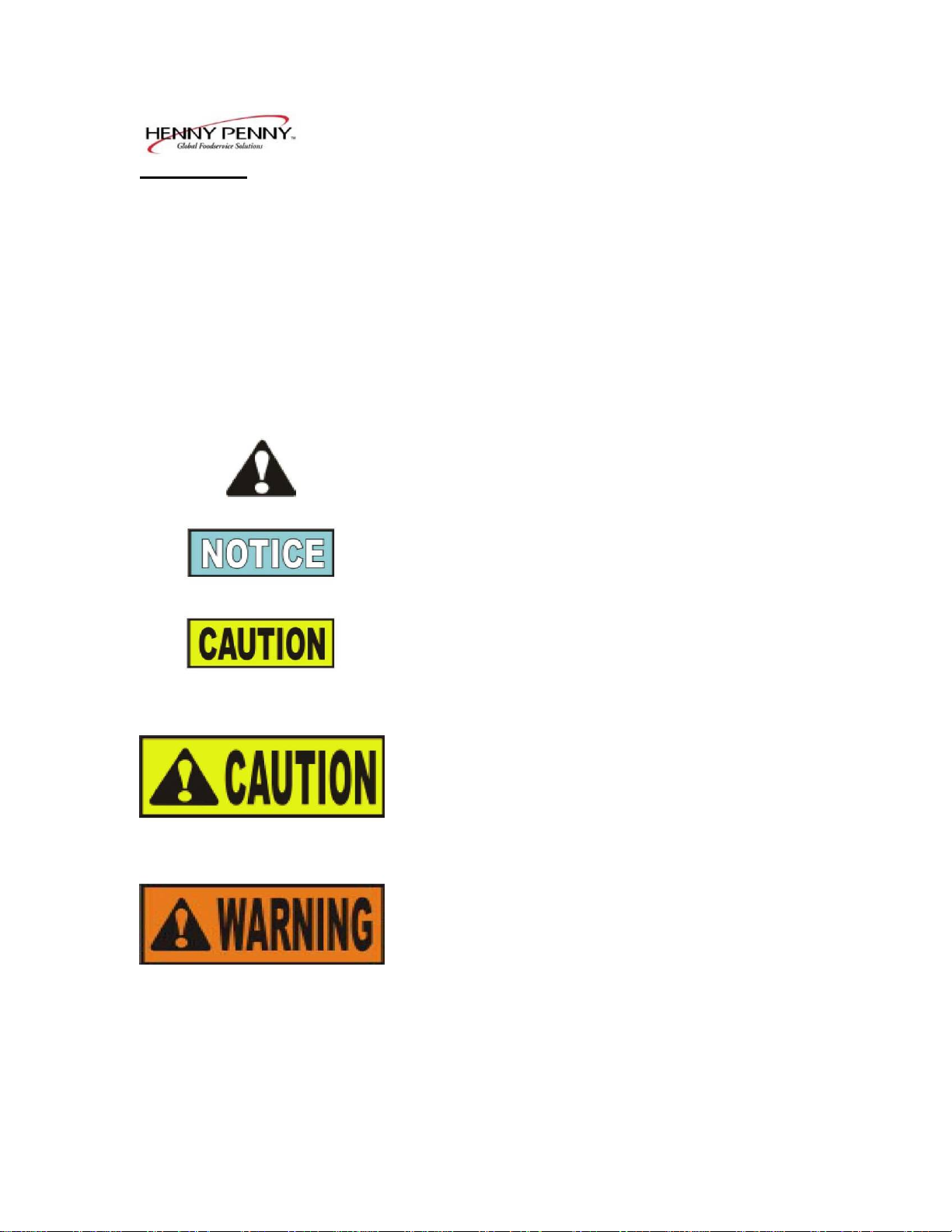

1-5. SAFETY

The only way to insure safe operation of the Henny Penny

heated holding cabinet is to fully understand the proper

installation, operation, and maintenance procedures. The

instructions in this manual have been prepared to aid you in

learning the proper procedures. Where information is of

particular importance or is safety related, the words

NOTICE, CAUTION, or WARNING are used . Their usage

is described below.

SAFETYALERT SYMBOL is used with DANGER,

WARNING, or CAUTION which indicates a personal

injury type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, may result in

property damage.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

The word WARNING is used to alert you to

a procedure, that if not performed properly,

might cause personal injury.

1-2

Page 7

2-1. INTRODUCTION

2-2. UNPACKING

This section provides the installation instructions for the

Henny Penny Humidity Control Adjustable.

Installation of this unit should be performed only by

a qualified service technician.

Do not puncture the skin of the unit with drills or

screws as component damage or electrical shock

could result.

The Henny Penny humidity control adjustable has

been tested, inspected, and expertly packed to

ensure arrival at its destination in the best possible

condition. The cabinet rests on cardboard pads that

sit on a wooden skid. The racks inside the cabinet

are secured with cardboard packing. The unit is then

packed inside a heavy cardboard carton with

sufficient padding to withstand normal shipping

treatment.

Any shipping damage should be noted in the

presence of the delivery agent and signed prior to

his or her departure.

To remove the Henny Penny heated holding cabinet

from the carton, you should:

1. Carefully cut banding straps.

2. Lift the carton off the unit.

2-1

Page 8

2-3. LOCATION

2-4. ELECTRICAL

CONNECTION

3. Lift the unit off the cardboard padding and skid.

Take care when moving the fryer to prevent

personal injury. The unit weighs 379 lbs. (172 kg.).

4. Open doors and remove packing from behind

racks.

5. Peel off any protective covering from the exterior

of the cabinet.

6. The unit is now ready for location and set up.

The HCA910/905 should be placed in an area where

the doors can be opened without interruption and

loading and unloading of product is easy. For proper

operation, the cabinet must be level.

To prevent damaging the unit, do not set anything

on top of the cabinet that might close off the vent

holes.

The heated holding cabinet is available from the

factory as a 240 VAC unit. The data plate, located

on the side of the module, will specify the correct

electrical supply. The unit requires a grounded

receptacle with a separate electrical line protected

by a fuse or circuit breaker of the proper rating.

This unit must be adequately and safely grounded.

Refer to local electrical codes for correct

grounding procedures. If unit is not adequately

grounded, electrical shock could result.

2-2

Page 9

2-5. CABINET DIMENSIONS

Model Number Volts(V) Watts (W) Amps (A) Cycle(HZ)

HCA910/905 240 2524 10.8 50/60

2-3

Page 10

2-6. WATER SUPPLY

CONNECTION

The automatic water fill system requires a water

supply. The unit is equipped with a water strainer

and clamp for a hose connection. It is also equipped

with an eight foot nylabraid hose tubing. Run the

tubing to the cabinet location, providing enough

tubing to allow movement of the unit for cleaning or

maintenance. The use of a water condition or filter

is recommended. A shut-on valve should be

installed in the supply line.

Do not operate this unit without water connected to

cabinet, or damage to components will result.

To install water supply connection, follow these

steps:

1. Flush the incoming water line.

2. Slide tubing over end of water strainer.

3. Tighten tubing clamp.

4. Check for leaks.

2-4

Page 11

2-7. Wire Diagram

2-5

Page 12

3-1. INTRODUCTION

3-2.OPERATING CONTROLS

AND COMPONENTS

This section provides operating procedures for

the HCA910/905. The Introduction, Installation,

and Operation Sections should be read, and all

instructions should be followed before operating

the cabinet.

This section contains an explanation of all controls

and components and information on operating

procedures and daily maintenance.

Figures 3-1 through 3-9 identify and describe the

function of all the operating controls and the

major components of the cabinet.

1 2 3 4 5 6 7 8 9 10

3-1

Page 13

11 12 13 14

15 16 17

18 3 19

3-2

Page 14

20 21

3-3

Page 15

HCA910/905 Components List

Part. No.

16624 1 Power Light

Item

No.

Description

Function

When illuminated, it indicates that the power

switch is in the ON position and the components

are energized

70046 2 Power Switch

73928 3 Infinite Regulator

16624 4 Water Heater Light

70046 5 Choose Switch

25183 6 Thermometer

16624 7 Temperature Light

26244 8 Thermostat Control

18201 9 High Limit

A toggle switch that switches electrical current to

the unit

This control, located on the front control panel,

regulates the water heater; clockwise rotation

increases the amount of humidity,

counterclockwise rotation decreases the amount of

humidity within the cabinet

When illuminated, the water heater light indicates

the water heater is working

When the Switch is turn left, it means

hand-operated fill the water.

When the Switch is turn right, it will autofill

water.

Indicates the air temperature inside the cabinet

When illuminated, it indicates that the thermostat

has turned the heaters on

An electromechanical device that controls the

temperature inside the cabinet

A safety device mounted next to the heater which

protects the unit from overheating

51279 10 Heater

76729 11 Water Valve

77593 12 Copper Tubing Pass through the water

EF02-006

EF02-007

76629 14 Power Cord

13 Fuse

Two, 1000 watt, open-resistance, wire type

heaters that provide heat throughout the cabinet

The water valve is an electro-magnetic valve that

is opened by the float switch. When open, the

valve allows water to flow to the water pan.

A protective device that breaks the circuit when

current exceeds the rated value. The fuse provides

an overload protection for the electrical

components. To remove the fuse, twist and pull

the cap

Power supply

3-4

Page 16

81084 15 Water Pan

77589 16 Float Switch

Holds the water that, when heated, creates

humidity in the cabinet

The float switch is an electro-mechanical level

switch that controls water level in the water pan.

75689 17 Water Heater

77591 18 Water Strainer

74266 19 Time Delay Relay

77079 20 Relay

25752 21 Blower Motor

FP01-207 22 Nipple Connect to hose

A 438 watt tube heater that heats the water pan to

produce humidity

A filter that prevents particles from entering

through the water line and obstructing the water

valve

The time delay relay is an electrical device used to

reduce the electrical load on the float switch and

provide an automatic time delay of approximately

10 seconds to prevent overflowing.

When the water valve is turn on, the relay will

work in order to turn off the water heater

The 2 blower motors are used to recirculate the

hot humid air throughout the cabinet

FP05-018 23 Elbow Elbow

FP01-208 24 Nipple reducing Nipple reducing 3/8PT TO 1/4PT

FP01-209 25 Bulkhead adaptor Bulkhead adaptor

77592 26 Copper Tubing Pass through the water

FP05-019 27 Connector

Male connector Φ6mm to 1/8 PT pipe

3-5

Page 17

3-3. START UP

Before using the Heated Holding Cabinet, the

unit should be thoroughly cleaned as described

in the “Cleaning Procedures” section of this

manual.

1. To put the HCA910/905 into operation, move the

power switch to the “ON” position. The power light

should now be illuminated and the blowers should

be in operation.

The unit should take approximately 25-35 minutes

STEP 1

STEP 2

to heat to temperature during start up. Be sure that

the temperature light goes out before loading with

product.

2. When the water level lower than the setting

position, the water valve will work. Then the water

is flowing into the water pan. When the pan is filled

to the proper level, the water valve will turn off and

water will stop flowing.

There is a 10 second delay before the float switch

will activate the water valve. This is to eliminate

over-working the components in the event the

cabinet is bumped or moved.

3. The heat light should illuminate indicating the

unit is heating. When heat light goes out, the unit

has reached proper operating temperature.

4. Although the cabinet and water temperature are

factory preset, they are adjustable. If more cabinet

3-6

Page 18

temperature is desired, rotate adjustment shaft

clockwise. If less cabinet temperature is desired,

rotate adjustment shaft counter-clockwise. If more

humidity is required, rotate adjustment shaft

clockwise to increase humidity and

counterclockwise to decrease humidity.

3-4. OPERATING WITH

PRODUCT

3-5. CLEANING

PROCEDURES

1. Place the hot product on pans and insert between

the cabinet racks.

2. Serve the product first that has been in the cabinet

the longest.

3. Open the doors only as necessary to load and

unload product. This will help temperature stay

constant and will save energy.

1. Turn all controls to the “OFF” position.

2. Disconnect the electrical supply to the cabinet.

Allow the unit to cool before cleaning, as the

interior of the cabinet may be hot enough to burn.

3. Open the doors and remove all trays from the

cabinet.

4. Take the trays to a sink and clean them

thoroughly.

Most surfaces of the HC-900 can be clealned with a

soft cloth, soap, and water. DO NOT USE

ABRASIVE CLEANERS.

5. Wipe the control panel with a damp cloth. Do not

splash water around the controls.

6. Clean the exterior of the cabinet with a damp

cloth.

7. Open the doors and remove side racks. Clean the

3-7

Page 19

racks with soap and water.

8. Clean the interior of the cabinet thoroughly with

a cloth and soapy water.

9. Put the side racks and water pan back into the

cabinet.

10. Leave at least one door open over night to

allow the unit to thoroughly dry out.

Water Pan Cleaning For more efficient operation,

the water pan must be cleaned daily.

Before removing water pan, be sure unit has

cooled down. Serve burns will result.

Drain the water pan into a bucket or pan by

rotating the drain cock on the front of the pan.

Remove pan and clean with a soft cloth, soap and

water. Daily cleaning is necessary to avoid lime

build-up on the float switch. Lime build-up on the

float switch will cause improper operation.

3-8

Loading...

Loading...