Henny Penny HC 900 Service Manual

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT: Any part of a new appliance, except lamps and fuses, which proves to be defective

in material or workmanship within two (2) years from date of original installation, will be repaired or replaced

without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To validate this warranty, the

registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

REPLACEMENT PARTS: Any appliance replacement part, except lamps and fuses, which proves to be

defective in material or workmanship within ninety (90) days from date of original installation will be repaired

or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new

frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for the frypot only . Any freight charges and labor costs to install

the new frypot as well as the cost of any other parts replaced, such as insulation, thermal sensors,

high limits, fittings, and hardware, will be the responsibility of the owner.

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If

damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse;

(b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED.

HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY

OTHER OBLIGATION OR LIABILITY.

FM01-286

Revised 2-23-06

ecti

Section 1.

Section 2.

Section 3.

NTRODUCTION

l-l.

::g*

1-4:

1-5.

eated Holding Cabinet

~,,:::::::::::::::::::::::::::::::::

sistance

Safety

.....................................................

INSTALLATION.

2-1.

2-2.

2-3.

2-4.

2.5.

2-6.

Introduction

Unpacking

Location

Electrical Connection

Cabinet Dimensions.

Water Supply Connection.

ON

3-1.

3-2.

3-3.

Introduction

Operating Controls and Components

Start-Up

................................................

..................................................

................................................

................................................

.................................................

...................................................

....................................................

................................................

...................................................

3-4. Operation with

3-5. Cleaning Proce

......................................

........................................

.........................................

....................................

...........................

.......................

.. !.

uct

.........................................

...............

...............

.; .“.*.

......

l-1

l-l

l-l

l-l

l-2

1-2

2-l

2-l

2-1

2-2

2-2

2-3

2-4

3-1

3-l

3-l

3-4

,: -.3:5

3-5

. _

Section 4.

Section 5.

2:;:

NTENANCE

............................................

NG

ction ................................................

shooting

.............................................

................................................

duction

Instruments

oval of Module Access Panel

................................................

............................................

..............................

............................................

al

odule Housing

..................................

.....................................................

r S~tch

...............................................

................................................

ights

............................................

..............................................

....................................................

mit .................................................

4-l

4-l

5-l

5-l

5-l

5-l

5-l

5-2

5-2

555-5

5-6

;:;

Model HC-900

TABLE OF CONTENTS (Continued)

Section Page

5-13. Blower ................................................................................................................ 5-9

5-14. Door Gasket Replacement................................................................................... 5-10

5-15. Cleaning Water Strainer....................................................................................... 5-10

5-16. Replacing Water Strainer ..................................................................................... 5-11

5-17. Cleaning Water Valve .......................................................................................... 5-11

5-18. Replacing Water Valve......................................................................................... 5-13

5-19. Float Switch ........................................................................................................ 5-13

5-20. Time Delay Relay ................................................................................................ 5-14

5-21. Infinite Regulator ................................................................................................. 5-15

5-22. Water Heater ...................................................................................................... 5-15

5-23. Wiring Diagram ................................................................................................... 5-17

Section 6. PAR TS INFORMATION ............................................................................................. 6-1

6-1. Introduction......................................................................................................... 6-1

6-2. Genuine Parts...................................................................................................... 6-1

6-3. How to Find Parts............................................................................................... 6-1

6-4. How to Order ..................................................................................................... 6-1

6-5. Prices.................................................................................................................. 6-1

6-6. Delivery .............................................................................................................. 6-2

6-7. Warranty ............................................................................................................. 6-2

6-8. Recommended Spare Parts for Distributors.......................................................... 6-2

Parts List............................................................................................................. 6-3

Henny Penny Distributor List

206 i

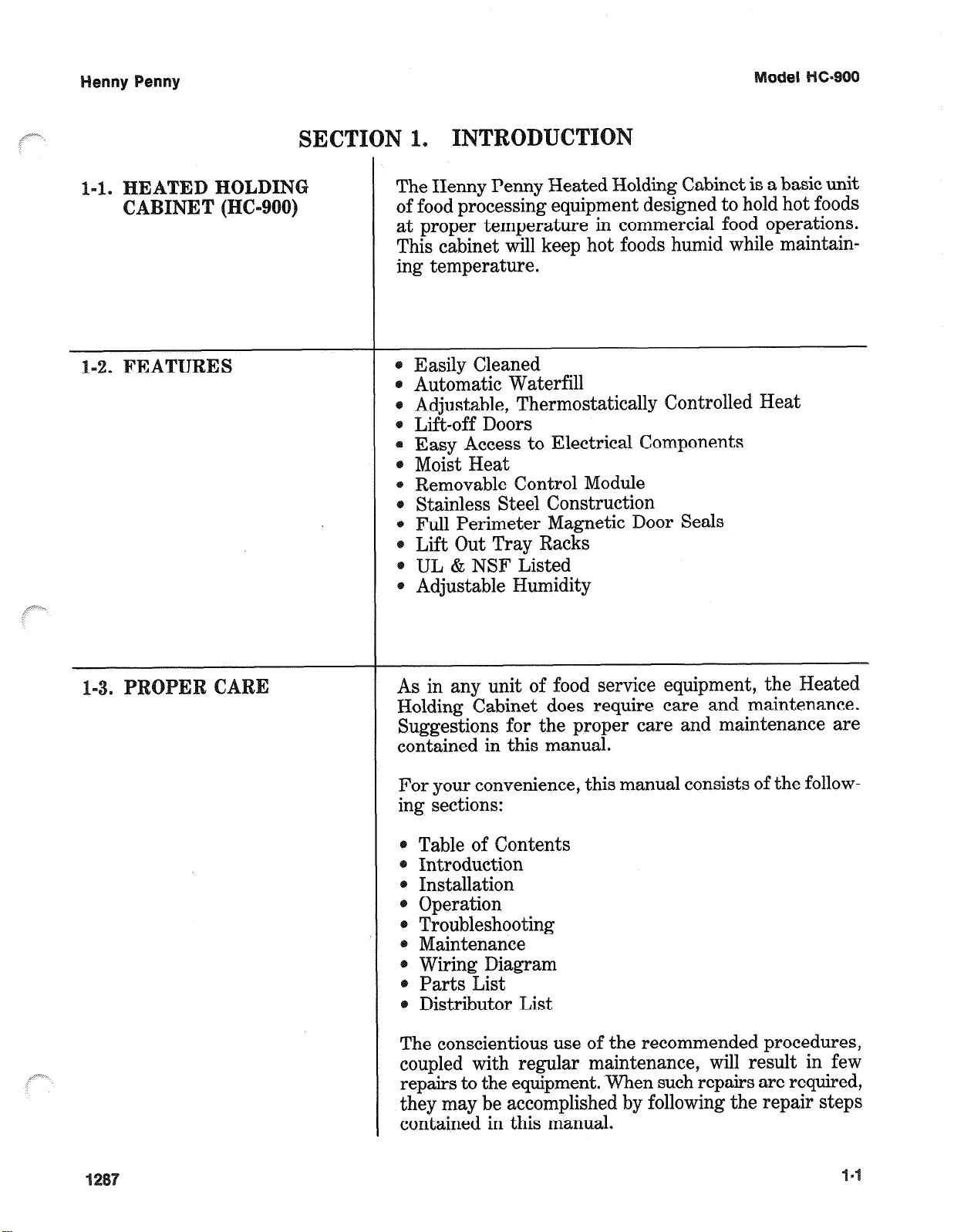

el

enny Heated Holding Cabinet is a basic unit

of food processing equipment designed to hold hot foods

at proper temperature in commercial food operations.

This cabinet will keep hot foods humid while maintaining temperature.

Adjustable, Thermostatically Controlled Heat

Lift-off Doors

s to Electrical Components

Stainless Steel Construction

Full Perimeter Magnetic Door Seals

As in any unit of food service equipment, the

Holding Cabinet does require care and maintenance.

Suggestions for the proper care and maintenance are

contained in this manual.

or your convenience, this manual consists of the follow-

ing sections:

he conscientious use of the recommended procedures,

coupled with regular m

repairs to the equipment..

ante, will result in few

such repairs are required,

they may be accomplished by following the repair steps

contained in this manual.

Henny Penny Model HC-900

1-4. ASSISTANCE Should you require outside assistance, just call your local

independent distributor maintained by Henny Penny Corporation.

In addition, feel free to contact our corporate headquarters in

Eaton, Ohio. Dial 1-800-417-8405 toll free, or 937-456-8405.

1-5. SAFETY The only way to insure safe operation of the Henny Penny

Heated Display Cabinet is to fully understand the proper installation,

operation and maintenance procedures. The instructions in this

manual have been prepared to aid you in learning the proper

procedures. Where information is of particular importance or is

safetyrelated, the words NOTE, CAUTION, or WARNING are

used. Their usage is described below.

NOTE

The word NOTE is used to highlight especially important

information.

The word CAUTION is used to alert you to a procedure

that, if not performed properly, may damage the unit.

The word WARNING is used to alert you to a procedure

that, if not performed properly, may cause personal injury.

1-2 1287

5. Peel off any protective covering from the exterior

of the cabinet.

eated Holding Cabinet is now ready for

location and set up.

e certain to save any literature that is packed inside the

cabinet.

The HC-900 should be placed in an area where the doors

can be opened without interruption and loading and

unloading of product is easy.

cabinet must be level.

Do not set anything on top of the cabinet that might close

off the vent holes.

or proper operation, the

eated Holding Cabinet is available from the factory

20 VAC unit. The data plate, located on the side

of the module, will specify the correct electrical supply.

e unit requires a grounded receptacle with a separate

ctrical line protected by a fuse or circuit breaker of

the proper rating.

The cabinet must be adequately and safely grounded

according to local

possibility of electrical

for electrical ratings for t

er

05148

el

120 1940

to prevent the

o the table below

16.2

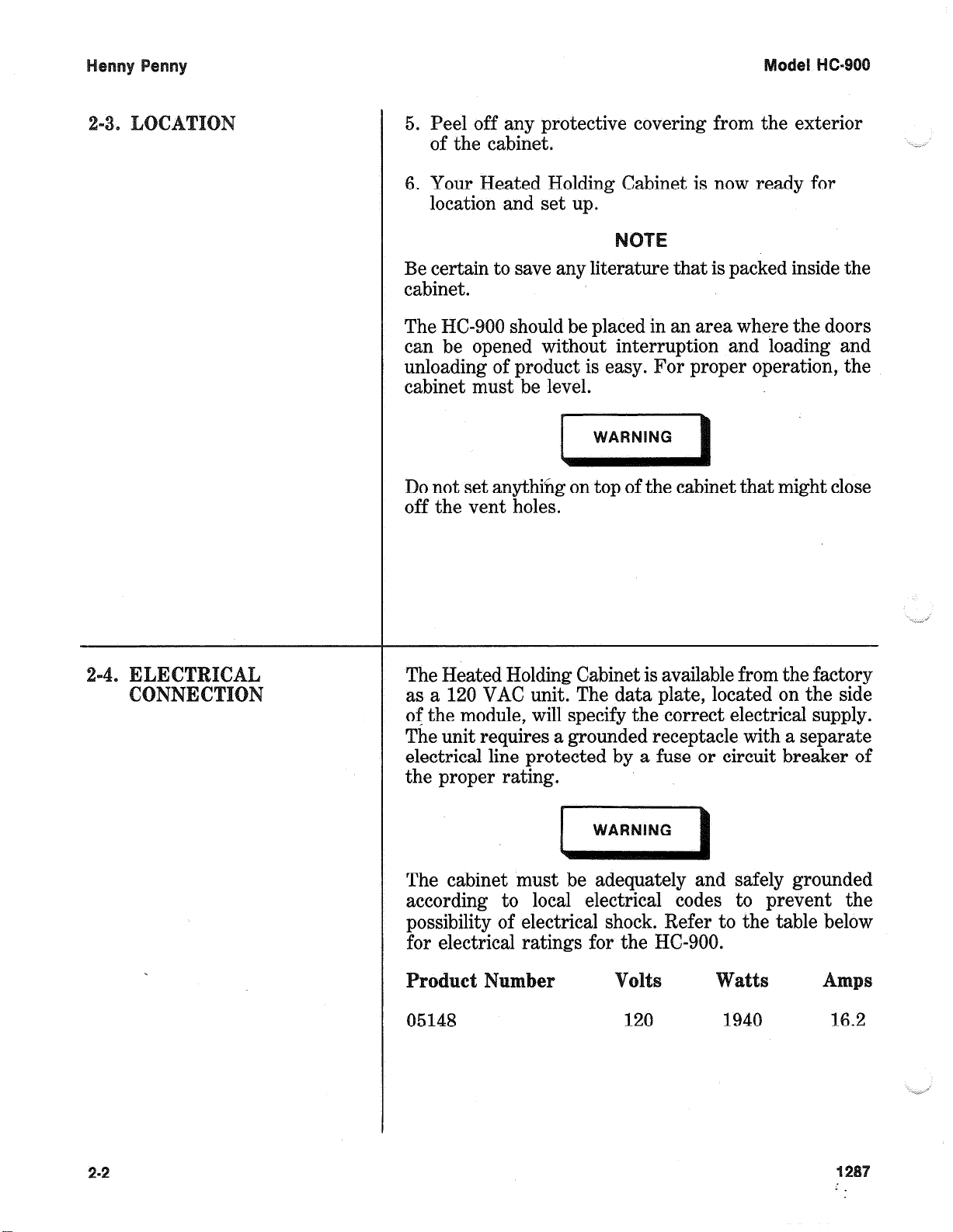

24

(62.8

=h”

Cm)

Model

Adjust

0 with

umidity

Product No. 05148

(181 cm)

The automatic water fill system requires a water supply.

he unit is equipped with a water strainer and clamp for

a hose connection. It i

nylabraid hose tubing.

tion, providing enough tubing to allow movement of the

unit for cleaning or maintenance. The use of a water

conditioner or filter is recommended. A shut-off valve

should be installed in the supply line.

rate this unit without water connected to

mage to components will result.

To install water supply connection, follow these steps:

lush the incoming water line.

2. Slide tubing over end of water strainer.

3. Tighten tubing clamp.

o equipped with an eight foot

the tubing to the cabinet loca-

4. Check for leaks.

This section provides operating procedures for the

C-900. Sections 1, 2 and 3 should be read, and all

instructions should be followed before operating the

cabinet.

his section contains an explanation of all controls and

components and information on operating procedures and

daily maintenance.

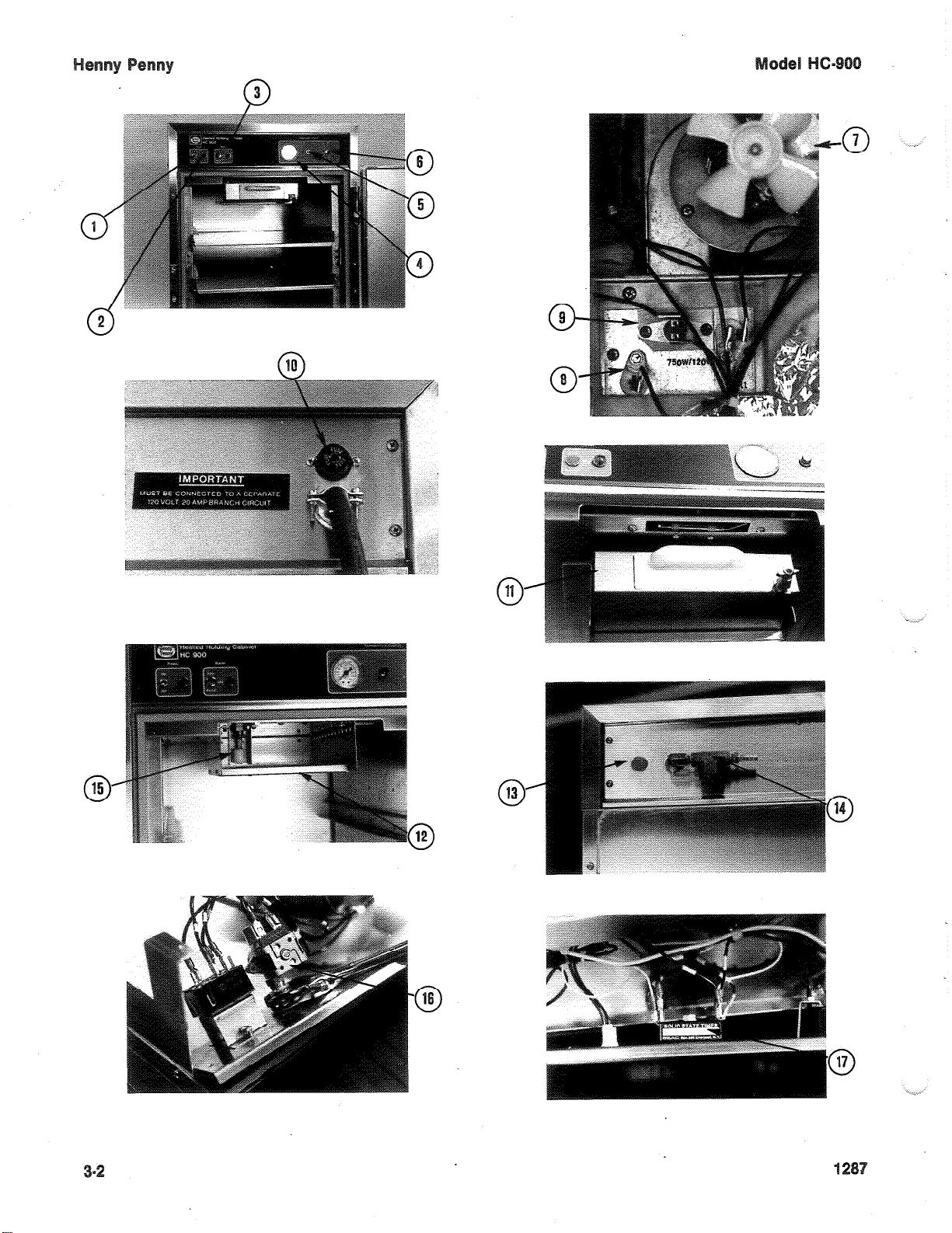

Figures 3-1 through 3-10 identify and describe the

function of all the operating controls and the major

components of the cabinet.

12

0

16

0

13

0

17

0

. ,

-.._,-

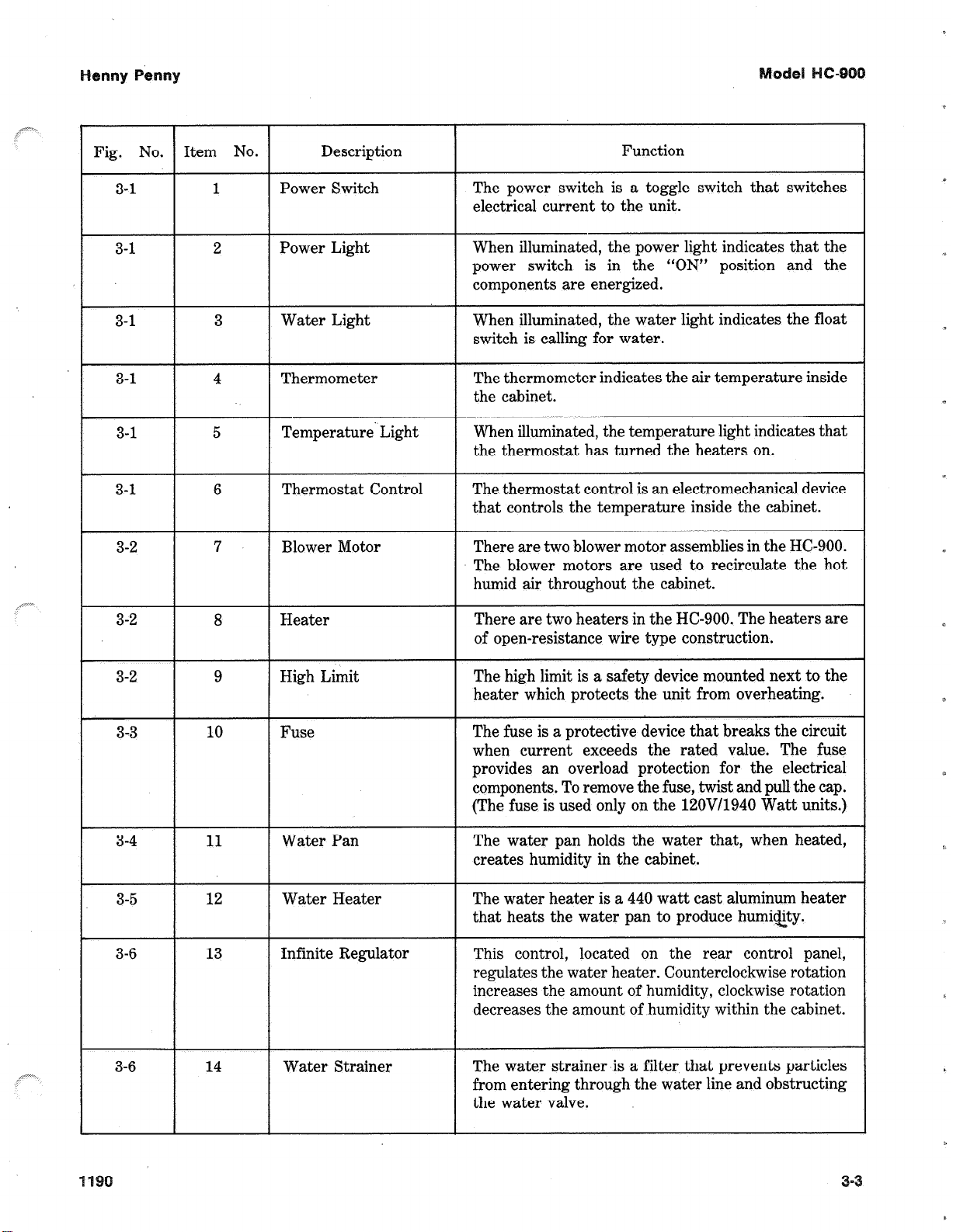

Fig. No.

Item No.

Description Function

3-l

3-l

3-l

3-l 4

3-l

3-l 6

3-2

3-2 8

1 Power Switch

2

3

5

7

The power switch is a toggle switch that switches

electrical current to the unit.

Power Light

Water Light When illuminated, the water light indicates the float

Thermometer

Temperature Light

Thermostat Control The thermostat control is an electromechanical device

Blower Motor There are two blower motor assemblies in the HC-900.

Heater There are two heaters in the HC-900. The heaters are

When illuminated, the power light indicates that the

power switch is in the “ON” position and the

components are energized.

switch is calling for water.

The thermometer indicates the air temperature inside

the cabinet.

When illuminated, the temperature light indicates that

the thermostat has turned the heaters on.

that controls the temperature inside the cabinet.

The blower motors are used to recirculate the hot

humid air throughout the cabinet.

of open-resistance wire type construction.

3-2 9 High Limit The high limit is a safety device mounted next to the

heater which protects the unit from overheating.

3-3

3-4 11 Water Pan The water pan holds the water that, when heated,

3-5 12

3-6 13

3-6 14 Water Strainer

10 Fuse

Water Heater The water heater is a 440 watt cast aluminum heater

Infinite Regulator

The fuse is a protective device that breaks the circuit

when current exceeds the rated value. The fuse

provides an overload protection for the electrical

components. To remove the fuse, twist and pull the cap.

(The fuse is used only on the 12OVl1940 Watt units.)

creates humidity in the cabinet.

that heats the water pan to produce humi@y.

This control, located on the rear control panel,

regulates the water heater. Counterclockwise rotation

increases the amount of humidity, clockwise rotation

decreases the amount of humidity within the cabinet.

The water strainer is a filter that prevents particles

from entering through the water line and obstructing

the water valve.

Loading...

Loading...