Henny Penny HB-121 General Manual

FMOl-312

Revised 2-97

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Section 1. INTRODU

eatures ...................................................

escription

Assistance ....................................................

l-5.

l-6.

Safety .....................................................

ON ................................................

der/Sifter

........................................... l-l

re ................................................

................................................... l-2

..l- 1

..l- 1

..l- 1

l-2

..l- 2

Section 2. INSTAL

Introduction

2-l.

Unpacking and Assembly ......................................

2.2.

2-3. Electric Requirements

2-4. Cabinet

Principle of Operation and Controls .............................

2-5.

2-6. Cleaning rocedures .........................................

eplacement of Motor

eplacement of Switch ........................................

eplacement of Push

eplacement of Sifter Bearing. .................................

Section 4. PA

SINFORMATION ..........................................

ntroduction ................................................

4-2. Genuine

4-3.

4-7.

How to ndParts.............................................4- 1

Warranty ...................................................

ERATION ...............................

................................................. .2-l

....................................... .2-2

ocation ............................................

..................................................

.................................................. 3-l

dre;:::::::::::::::::::::::::::::::::::::::.3-1

......................................... .3-2

ring................................3- 4

ring ..............................

arts.................................................4- 1

ow to Order Parts. ..........................................

......................................................

S

ery......................................................4- 1

..2- 1

.2-l

..2- 2

.2-3

..2- 3

3-l

.3-l

.3-3

.3-4

.3-5

..4- 1

..4- 1

.4-l

..4- 1

.4-l

reader/Sifter is a compact

xeading table with a high speed sifter which save time,

xeading, and money by separating dough balls from the

xeading. The unit is available with various optional equipnent making it adaptable to each store’s individual needs.

As in any unit of food service equipment, the Hand

reader/Sifter does require care and maintenance. Suggestions for the proper care and maintenance are contained in this manual.

Before using the

cleaned in accordance with the instructions contained in this manual.

owerful l/4 hp totally enclosed motor gives fast,

thorough sifting.

Stainless steel sifting basket under breading lug gently separates dough balls from flour as it sifts uniformly and automatically into the bottom lug.

Stainless steel unit is rugged and can be quickly

disassembled for easy cleaning.

Compact design requires little floor space, yet the work

flow pattern contributes to high production capability.

-121 it should be thoroughly

All moving parts are enclosed for greater safety.

U.L., C.S.A. approved.

Left to right flow of operation available.

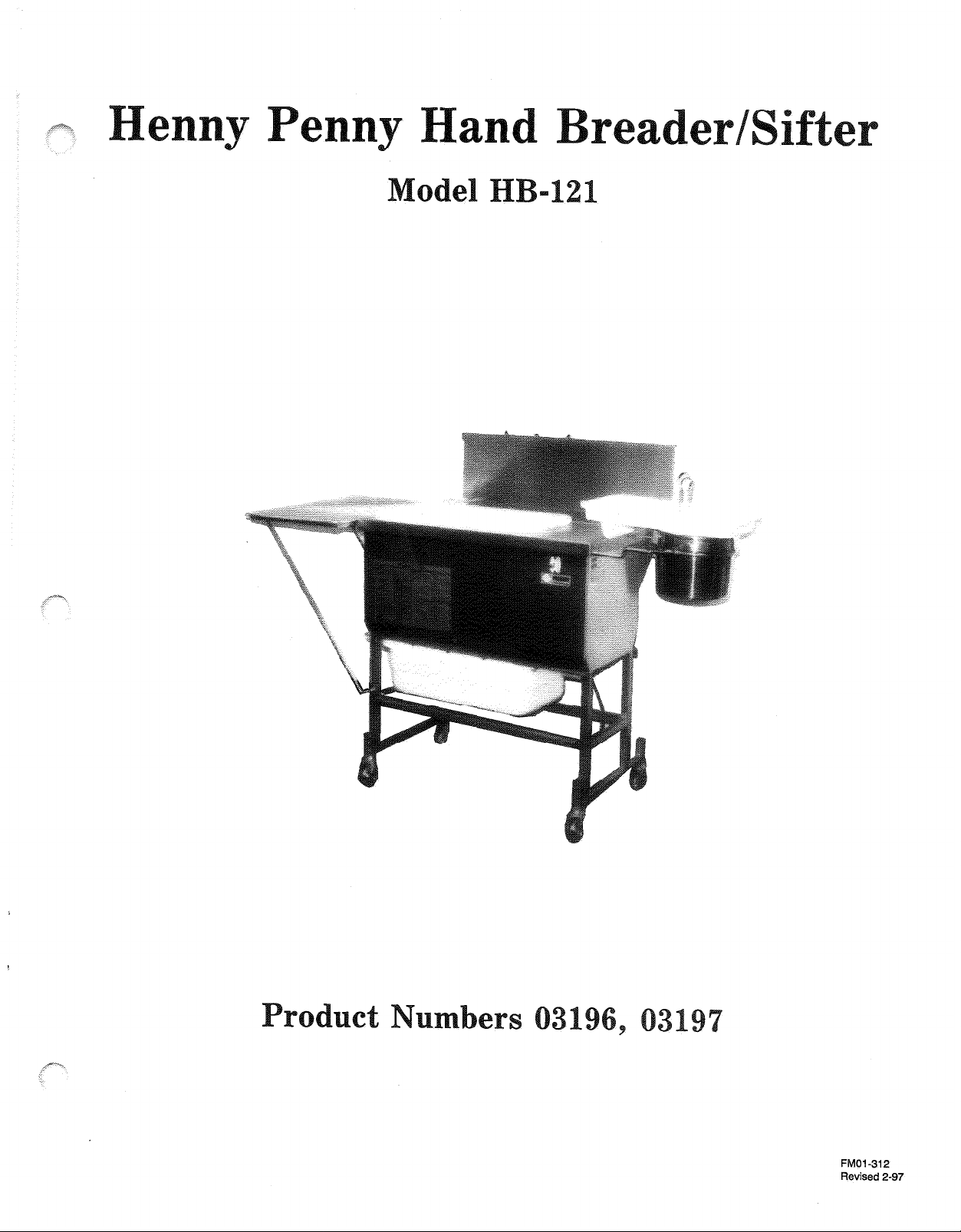

Henny Penny HB-121

1-4. DESCRIPTION The HB-121 is a stainless steel table and cabinet containing a

stainless steel sifting basket. The unit comes with two breading lugs,

tray rack, pan support, dip pot, holder for dip container, plastic dip

tray , and a back splash. It is equipped with dependable drive

mechanism, adjustable casters, and an ON/OFF switch for customer convenience. Dimensions are 36-3/4” (93.35 cm) wide

(top), 67-12” (171.45 cm) overall width from dip pot to fully

extended tray rack, 16-3/4” (42.55 cm) deep (top), 26” (66.00

cm) overall depth from face of top to back of back splash, 35-1/2”

(90.17 cm) high to top, and 46-1/2” (118.1 1 cm) to top of back

splash. Shipping weight is 140 lbs. (63.5 kg.).

1-5. ASSIST ANCE Should you require outside assistance, contact your local indepen-

dent distributor (refer to distributor list in rear of this manual). In

addition, feel free to contact our corporate headquarters in Eaton,

Ohio. Dial 800-417-8405 toll free, or 937-456-8405. It is our

sincere desire that you obtain the maximum benefit from your Hand

Breader/Sifter. If at any time you have questions or require assistance, please do not hesitate to contact us.

1-6. SAFETY The only way to insure safe operation of the Henny Penny Hand

Breader/Sifter is to fully understand the proper installation,

operation, and maintenance procedures. The instructions in this

manual have been prepared to aid you in learning the proper

procedures. Where information is of particular importance or is

safety related, the words NOTE, CAUTION or WARNING are

used. Their usage is described below:

NOTE

The word NOTE is used to highlight especially important infor-0

mation.

The word CAUTION is used to alert you to a procedure

that, if not performed properly , may damage the unit, or

product.

The word WARNING is used to alert you to a procedure,

that if not performed properly , might cause personal injury,

such as burns and/or loss of sight, and damage to the unit.

1-2 601

This section provides the installation and operation instructions for the reader/Sifter.

Installation of th e performed by a

qualified service technician.

o not puncture the

ills or screws as dam

Sifter with

shock could

result.

The Henny Penny

corrugated carton

eaderlsifter is shipped in a

‘cient padding to withstand

normal shipping treatment.

Any shipping damages should be noted in the

presence of the delivery agent and signed prior to

his or her departure.

To remove the HB-121 from the carton follow these

instructions:

1. Carefully cut banding straps.

2. Remove carton from unit.

emove unit from wooden skid.

-ix . . .

Care should be taken when lifting unit to prevent

personal injury.

4. Remove all accessories from unit for assembly.

The Hand

and tested

eaderlsifter

the factory.

etely assembled

easier, some parts are separa

parts should be assembled and installed at this time as

follows. Refer to exploded view in rear of this manual.

1. Assemble gussets (32) to back splash using four lo-24

wing nuts (31) found in plastic bag taped to the

breading table.

olding back splash (33) horizontal with gasket hanger

2.

hooks (35) facing you, hook back splash lip into larger

opening in top (28) of breading table and rotate it back

until gussets rest against back of unit.

3. olding dip pot holder (21) with ring up, insert ends

into holes in side of unit top (28) (switch end) and rotate

down to horizontal position. Slide dip pot holder (21)

into unit top until vertical bend is against top.

nsert ends of tray rack (29) into side of unit top (28)

opposite switch end and rotate to horizontal position,

allowing swinging leg to rest on top of leg cross brace.

5. Pan support (30) sets on tray rack (29).

ne breading lug (25) sets in the large opening in unit

top (28) and the other breading lug (25) slides into a

pair of channels under the bin.

The

a 12

reader/Sifter is available from the factory as

single phase, 60 hertz, 4.2 amp unit. The unit

is also equipped with a nine foot grounded cord and plug.

The unit requires a grounded 15 amp receptacle with a

separate electrical line protected by a fuse or a circuit

breaker of the proper rating.

The cabinet must

ly and safely

grounded according to local electrical codes to prevent the possibility of electrical shock.

uty cycle approved for five minutes on then five minutes

off with a constant load of eighteen pounds.

Cycle d’operation approve’ pour clinq minute et ap’res

ferme pour cinq minute avez une charge de dixhuit livers.

2-2

I

reader/Sifter should be placed so that the

product flow from breading to cooking is han

most efficient manner. For this reason, Henny

duces units designed for left to right operation, as well

as right to left operation.

Loading...

Loading...