INSTALLATION MANUAL

FlexFuison® GOLD GAS COMBI

FGG-615

FGG-621

FGG-115

FGG-121

FGG-215

FGG-221

Directory of contents

2

1

Introduction

5

1.1

About this manual

5

1.1.1

Explanation of signs

5

1.2

Use of the unit

7

1.3

Warranty

7

2

Safety information

8

3

Description of the unit

11

3.1

Overview of the unit

11

3.2

Planning drawing

13

3.3

Equipment and connection data

14

3.3.1

Connection pressure

16

3.3.2

Speed of the fan-assisted gas burner

17

3.3.3

Exhaust gas values

17

3.3.4

Gas orifice diameter

18

3.3.5

Status messages

19

4

Transporting the unit

22

4.1

Transport information

22

4.2

Transporting to the installation site

22

4.2.1

Transporting on a pallet

23

4.2.2

Transporting without a pallet

23

4.2.3

Transporting by raising and lowering

25

4.3

Unpacking the unit

25

5

Setting up the unit

26

5.1

Lifting the unit off the pallet

26

Directory of contents

Directory of contents

3

5.2

Placing the unit on the equipment legs

27

5.3

Setting up the unit on a work surface

27

5.4

Aligning the unit

28

5.4.1

Aligning countertop units

29

5.4.2

Aligning floor-standing units

29

5.5

Maintaining minimum clearances

31

6

Connecting the unit

32

6.1

Opening and closing the housing

32

6.1.1

Removing and attaching the side panel

32

6.2

Checking the supply air and exhaust gas routing

33

6.2.1

Description of the supply air and exhaust gas routing

34

6.3

Making the electrical connection

36

6.3.1

Notes regarding the electrical connection

36

6.3.2

Connecting the electric power cable to the unit

37

6.3.3

Connecting to the potential equalisation circuit

39

6.4

Making the basic control settings

39

6.4.1

Opening the Setting menu

39

6.4.2

Changing the basic control settings

40

6.5

Making the water connection

41

6.5.1

Connecting hard and soft water

42

6.5.2

Connecting soft water twice

43

6.6

Making the wastewater connection

44

6.6.1

Identifying the cleaning system

44

6.6.2

Connecting the wastewater line to a permanent connection

45

6.6.3

Connecting the wastewater line to the discharge funnel

46

6.7

Connecting the gas

47

6.7.1

Notes about the gas connection

47

6.7.2

Description of the gas connection

48

Directory of contents

4

6.7.3

Connecting the gas connection line

49

6.7.4

Checking for leaks

50

6.7.5

Checking the connection pressure

52

6.7.6

Checking the basic gas setting

54

6.7.7

Adjusting the basic gas setting

60

6.8

Converting the gas type

65

6.9

Making the exhaust air connection

67

6.10

Checking operation

68

6.10.1

Checking the exhaust gas routing for leaks

69

6.10.2

Checking the monitoring of the exhaust gas routing

69

6.10.3

Checking the ignition behaviour

70

6.10.4

Checking the flame pattern

70

6.10.5

Checking the flame monitoring

71

6.10.6

Checking the controls

72

6.10.7

Checking the monitoring of the cooking zone door

72

7

Putting the unit into service

73

7.1

Filling out the commissioning report

73

Introduction

1

About this manual

5

DANGER

Imminent threat of danger

Failure to comply will lead to death or very severe injuries.

WARNING

Possible threat of danger

Failure to comply can lead to death or very severe injuries.

CAUTION

Dangerous situation

Failure to comply can cause minor or moderate injuries.

1

1.1

Target group

Figures

1.1.1

Introduction

About this manual

The instruction manual is part of the unit and contains information on safe

installation of the unit.

Observe and adhere to the following instructions:

▪ Read the instruction manual in its entirety prior to installation.

▪ Make the instruction manual available to the installer at the operating site

at all times.

▪ Preserve the installation manual throughout the service life of the unit.

▪ Insert any supplements from the manufacturer.

▪ Pass on the installation manual to any subsequent operator of the unit.

The target group for the installation manual is trained technical personnel

that is familiar with installing and operating the unit.

All figures in this manual are intended as examples. Discrepancies between

these and the actual unit can arise.

Explanation of signs

1

Introduction

About this manual

6

SAFETY INSTRUCTIONS

Material damage

Failure to comply can cause material damage.

NOTICE

Information

Notes for better understanding and operation of the unit.

Symbol / sign

Meaning

▪

Listing of information.

Action steps, which can be

performed in any sequence.

1.

2.

Action steps, which must be

performed in the prescribed

sequence.

Result of a listed action.

Introduction

1

Use of the unit

7

1.2

1.3

Use of the unit

This unit is intended to be used solely for commercial purposes, particularly

in commercial kitchens.

This unit is certified in the following:

Warranty

The warranty is void and safety is no longer assured in the event of:

▪ Modifications or technical changes to the unit,

▪ Improper use,

▪ Incorrect startup, operation or maintenance of the unit,

▪ Problems resulting from failure to observe these instructions.

2

Safety information

8

2

Ensuring conformity with

standards

Improper installation

Transportation and storage

Fire prevention

Organisational measures

Safety information

Observe applicable international, European and national laws, regulations,

standards and directives for the unit when transporting, setting up and

connecting it.

Risk of property damage and personal injury from improper

installation

▪ Install the unit only as specified in these installation instructions.

▪ Do not add anything to the unit or modify the unit.

▪ Use only original spare parts.

Risk of personal injury and property damage from improper

transportation and improper storage.

▪ Store the unit in a dry, frost-free environment.

▪ Observe the safety regulations for the lifting gear used.

▪ Attach the unit to the lifting gear securely during transport and setup, and

prevent it from dropping.

▪ Transport the unit in an upright position, do not tilt or stack.

▪ Pay attention to protruding parts when transporting the unit without

packaging.

Risk of fire from combustible surfaces

▪ Observe general fire prevention regulations.

▪ When setting up the unit in close proximity to heat-sensitive substances

or substances that pose a risk of fire, observe fire prevention regulations.

▪ The room's ceiling above the unit must be non-combustible.

Risk of fire from objects

▪ Do not obstruct the exhaust gas duct.

Risk of property damage and personal injury from lack of

organizational measures

▪ Identify hazard areas when transporting, setting up and connecting the

unit.

Safety information

2

9

Setup

Electrical connection

Gas connection

▪ Prior to starting the installation work, notify any operators present about

the procedure.

▪ Prior to starting the installation work, discuss how to behave in an

emergency.

▪ Use equipment and protective gear suitable for the activity.

▪ Brace housing components to prevent them from falling over and

dropping.

Risk of property damage and personal injury from improper

setup

▪ Ensure that the installation area has adequate load-bearing capacity.

▪ Where safety shoes and protective gloves.

Risk of fire from improper connection

▪ Observe applicable regional regulations of the electrical utility.

▪ Ensure that only licensed electricians connect the unit.

▪ Ensure that the electrical system is earthed by a protective earthing

conductor.

▪ Note the information on the nameplate.

Risk of electric shock from live components.

▪ Prior to working on the electrical system, switch off the unit, disconnect

the electrical system from the mains and prevent power from being

switched on again. Check to ensure absence of voltage.

▪ Use only insulated tools.

Risk of explosion and fire from improper connection

▪ Observe applicable regional regulations of the gas utility.

▪ Ensure that only a licensed tradesman connects the unit to the gas

supply.

▪ Prior to working on the gas system, switch off the unit, close the gas

supply from the gas system and secure it against being reopened. When

bleeding air or degassing, ensure that the air and gas are discharged to

the outside in a technically correct manner and without creating a risk.

▪ Observe the information on the nameplate and

label.

Gas type

supplemental

2

Safety information

10

Additional connection work

Commissioning

▪ Check for leaks.

▪ When working on the gas system and units in buildings, ensure that a

hazardous gas-air mixture cannot form in the rooms.

Risk of poisoning from exhaust gases

▪ Ensure that exhaust gases are discharged properly and that the

necessary amount of combustion air is supplied.

▪ Ensure that a maximum CO value of < 0.1 vol. % or < 1000 ppm is

achieved in undiluted exhaust gas.

Risk of fire from combustion gases and hot surfaces

▪ Maintain an adequate distance from grease filters on ventilation systems.

Risk of physical damage and personal injury from improper

connection

▪ Prior to working on the unit, switch off the unit, disconnect the unit from

the mains and prevent power from being switched on again. Check to

ensure absence of voltage.

▪ Prior to working on the unit, switch off the unit, close the gas supply and

secure it against being reopened.

▪ Route connection lines such that they cannot be damaged from heat.

Risk of property damage and personal injury from improper

commissioning

▪ Read the operating instructions prior to commissioning. Observe the

safety instructions in this installation manual and in the "Safety

information" chapter of the operating instructions.

▪ Put the unit into service only after a successful function test following

assembly.

▪ Put the unit into service only after it has reached room temperature.

▪ Observe the units during operation.

Description of the unit

3

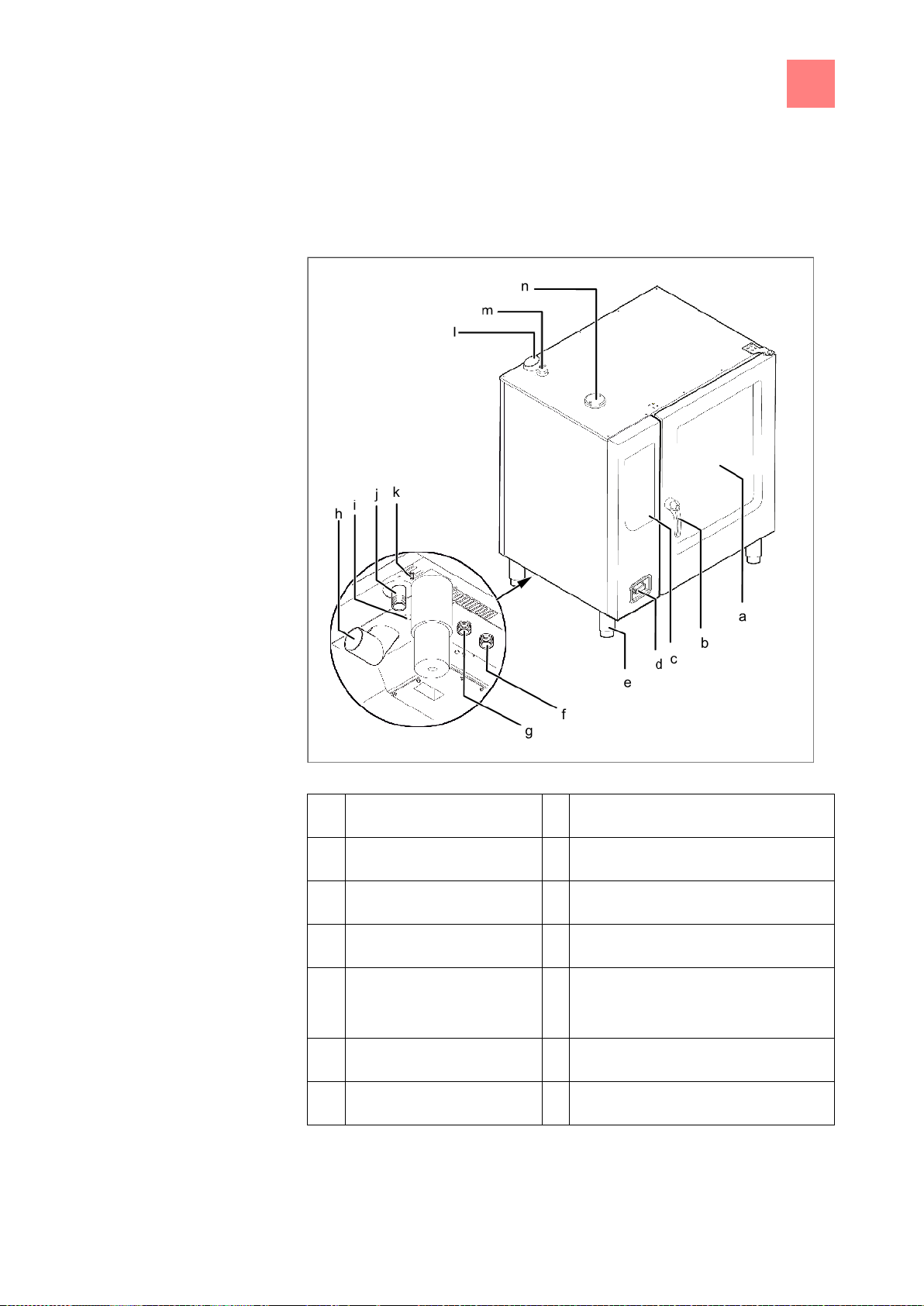

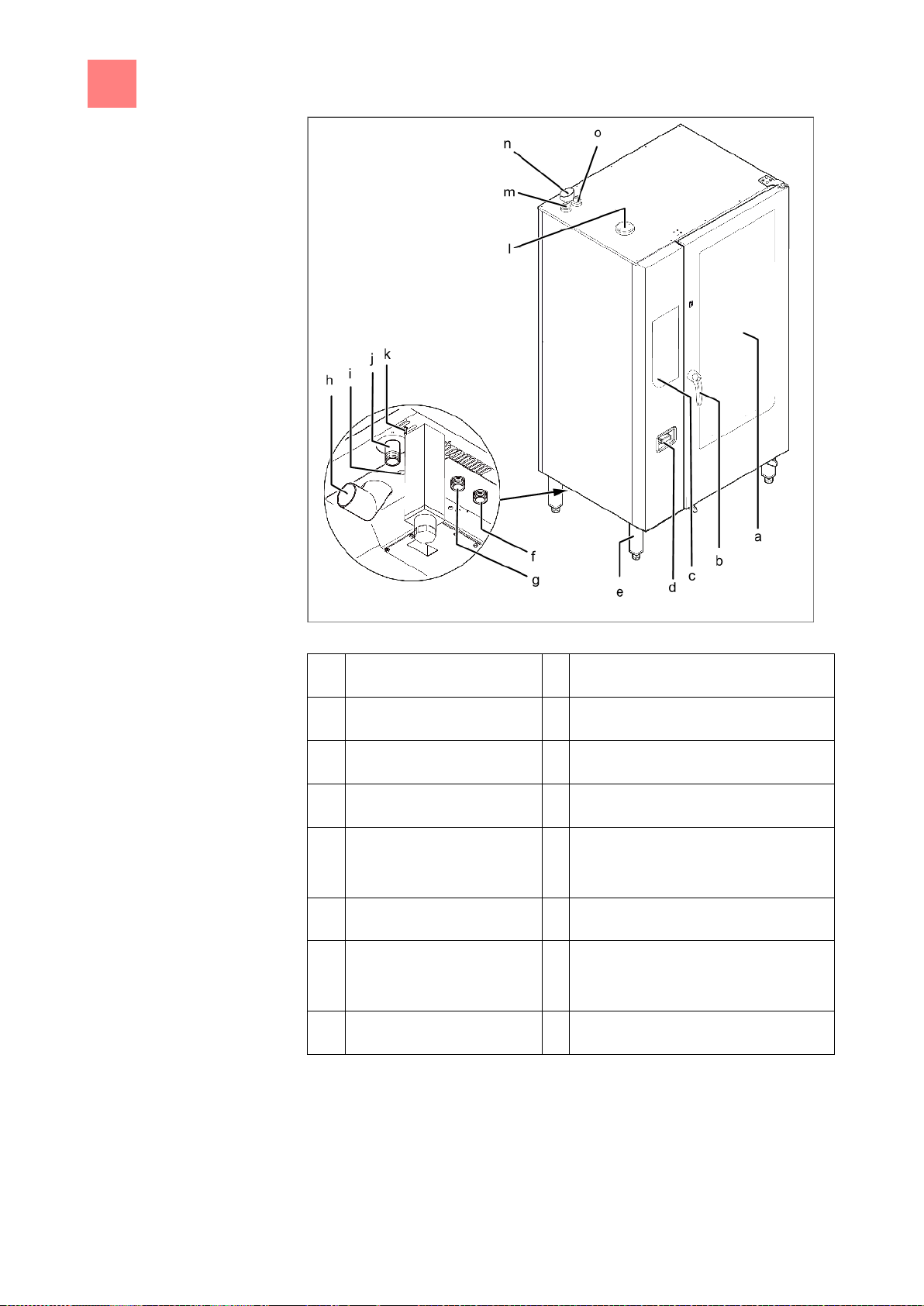

Overview of the unit

11

a

Cooking zone door

h

Wastewater connection

b

Door handle

i

Opening for power connection

c

Operating elements

j

Gas connection on unit

d

Hand shower

k

Potential equalisation connection

e

Equipment leg, vertically

adjustable

l

Steam outlet connection fitting

f

Hard water connection

m

Waste gas connection

g

Soft water connection

n

Air intake connection fitting

3

3.1

Description of the unit

Overview of the unit

Gas-FlexFusion Gold, unit size 10

3

Description of the unit

Overview of the unit

12

a

Cooking zone door

i

Opening for power connection

b

Door handle

j

Gas connection on unit

c

Operating elements

k

Potential equalisation connection

d

Hand shower

l

Air intake connection fitting

e

Equipment leg, vertically

adjustable

m

Waste gas connection, burner 2

f

Hard water connection

n

Steam outlet connection fitting

g

Soft water connection

o

Waste gas connection, upper fanassisted gas burner

h

Wastewater connection

Gas-FlexFusion Gold, size 20

Description of the unit

3

Planning drawing

13

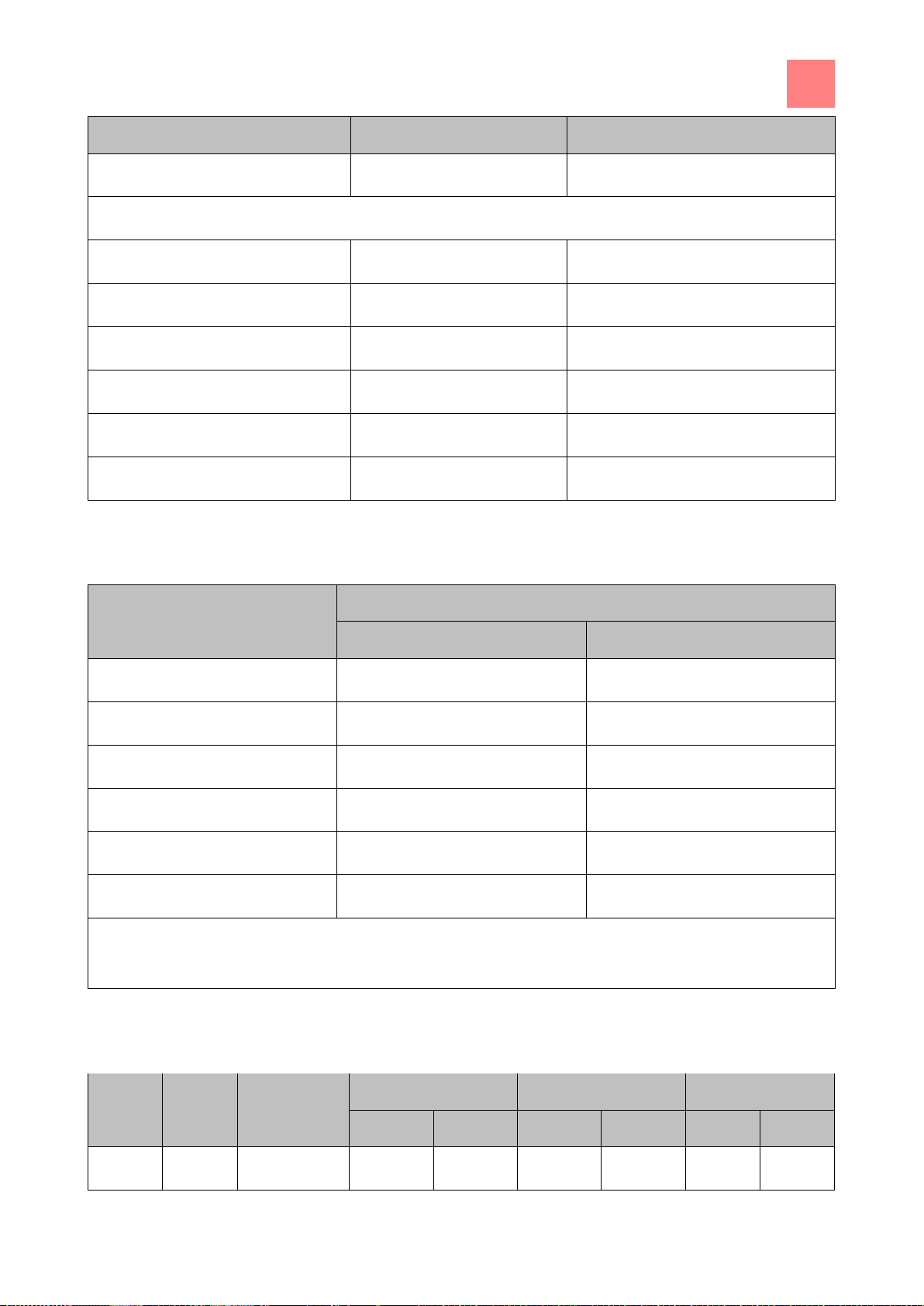

Unit size

a b c d e f g h 6.15, 6.21

500 (20)

1020 (40)

50 (2)

50 (2)

799 (31)

790 (31)

850 (33)

1640 (65)

10.15, 10.21

500 (20)

1020 (40)

50 (2)

50 (2)

799 (31)

1060 (42)

580 (23)

1640 (65)

20.15, 20.21

500 (20)

1075 (42)

50 (2)

50 (2)

813 (32)

---

---

1960 (77)

a-h= mm (in)

3.2

Planning drawing

Unit sizes 6 and 10

Unit size 20

3

Description of the unit

Equipment and connection data

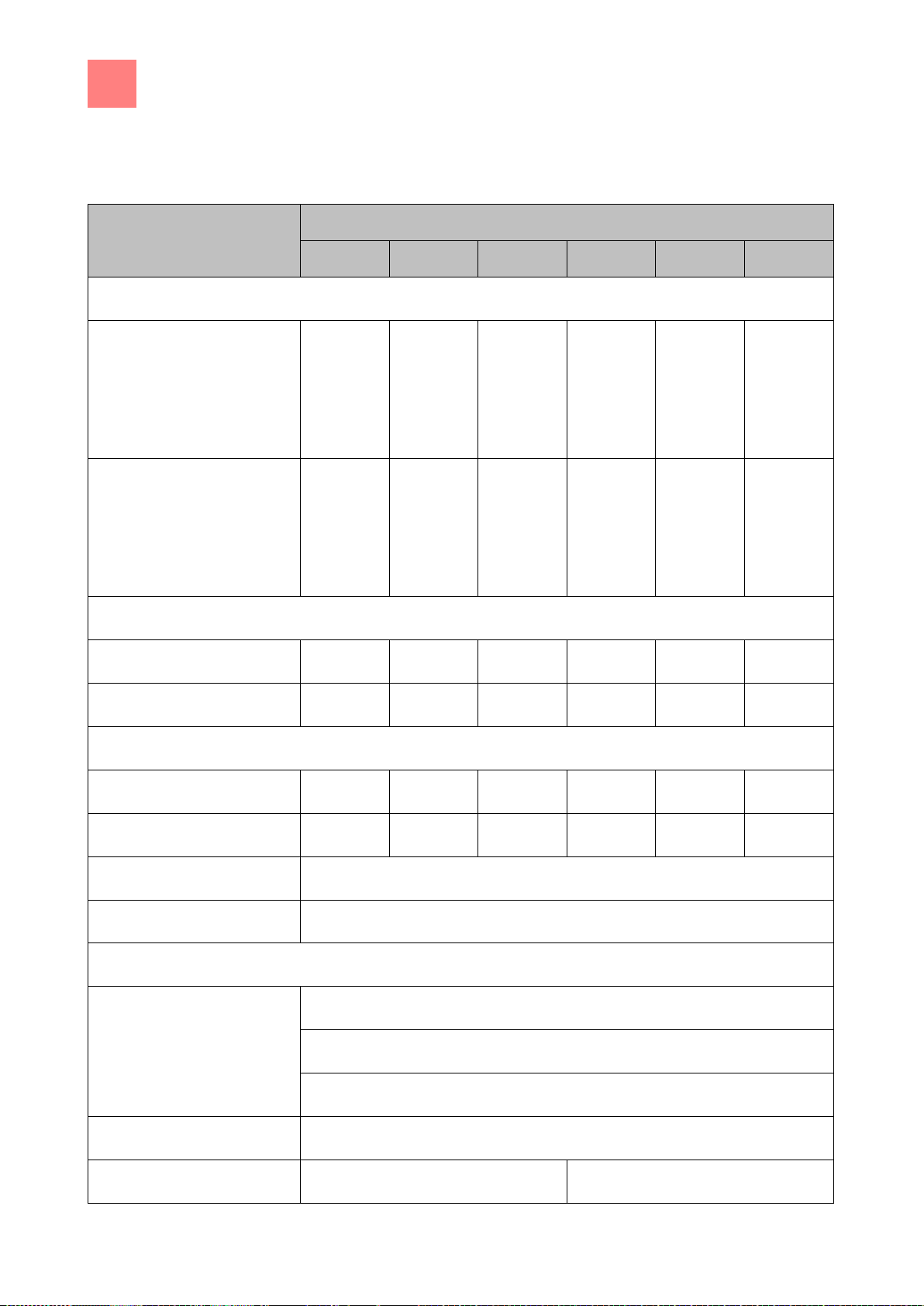

14

Unit size

6.15

6.21

10.15

10.21

20.15

20.21

Dimensions

Unpacked unit

Length x width x height

cm

(in)

102 x 80 x

79

(40 x 31 x

31)

102 x 80 x

79

(40 x 31 x

31)

102 x 80 x

106

(40 x 31 x

41)

102 x 80 x

106

(40 x 31 x

41)

108 x 82 x

196

(42 x 32 x

77)

108 x 82 x

196

(42 x 32 x

77)

Packaged unit

Length x width x height

cm

(in)

96 x 108 x

102

(38 x 43 x

40)

96 x 108 x

102

(38 x 43 x

40)

96 x 108 x

128

(38 x 43 x

50)

96 x 108 x

128

(38 x 43 x

50)

96 x 116 x

220

(38 x 46 x

87)

96 x 116 x

220

(38 x 46 x

87)

Weight

Unpacked unit kg (lbs)

137 (302)

142 (313)

167 (368)

187 (412)

355 (783)

355 (783)

Packaged unit kg (lbs)

170 (375)

170 (375)

195 (430)

195 (430)

375 (827)

375 (827)

Heat loss

Latent (W)

2200

3400

3600

5200

7200

10400

Sensible (W)

1700

2600

2700

3900

5400

7800

Noise level (db (A))

<70

Ambient climate

5 – 40 °C (5 – 104°F), 95 % relative humidity, non-condensing

Electrical connection

Type of connection

1NPE 220-240 V AC 50/60 Hz

2PE 220-240 V AC 50/60 Hz

1NPE 100 V AC 50/60 Hz

Protection class

IPX5

Connected load (kW)

0.6

1.0

3.3

Equipment and connection data

Description of the unit

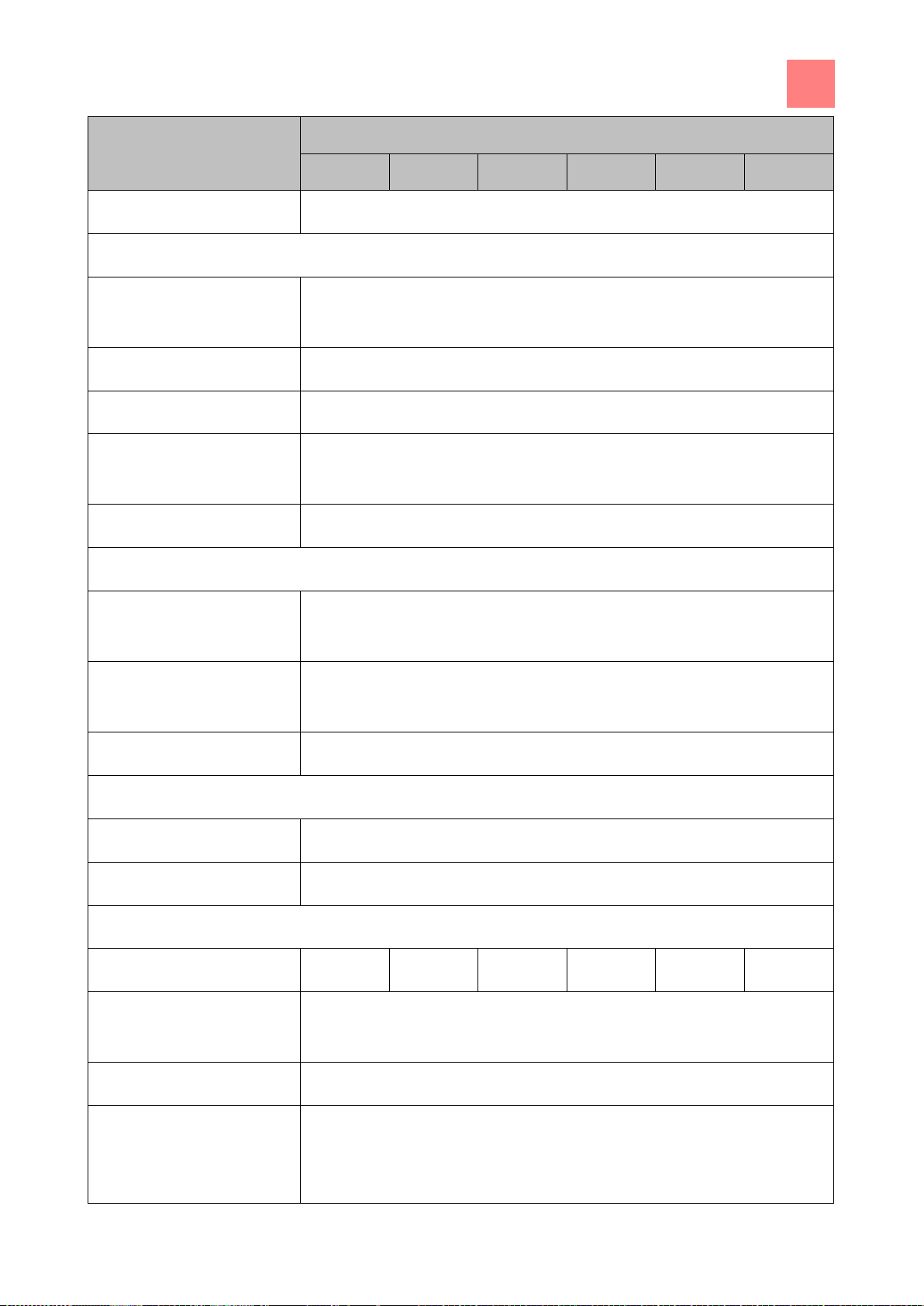

3

Equipment and connection data

15

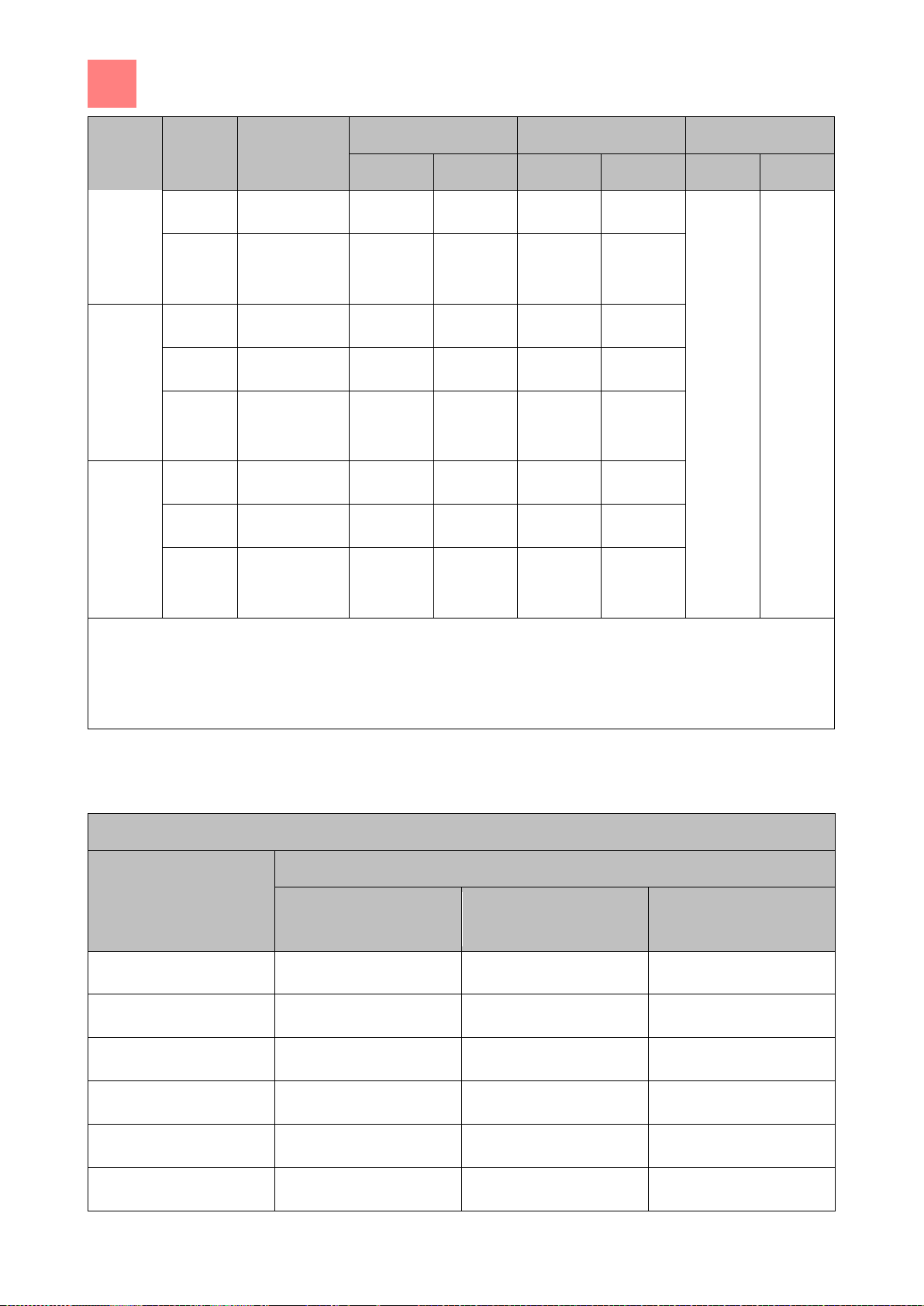

Unit size

6.15

6.21

10.15

10.21

20.15

20.21

Recommended fusing (A)

16

Soft water connection

Carbonate hardness CaCO3

(mmol/l)

<0.9

Chloride Cl (mg/l)

<50

Iron Fe (mg/l)

<0.1

Connection pressure (hPa),

(bar)

200 - 600, 2 - 6

Connection (inches)

R ¾", male thread

Hard water connection

Carbonate hardness CaCO3

(mmol/l)

<4

Connection pressure (hPa),

(bar)

200 - 600, 2 - 6

Connection (inches)

R ¾", male thread

Wastewater connection

Discharge temperature (°C)

<80 (176°F)

Connection (mm)

Connection fitting, 50 mm (2in) diameter

Gas connection

Rated heat input (kW)

11

17

18

26

36

52

Gas type

The gas type for which the unit is set is indicated on the gas type

supplemental label.

Gas connection (inches)

R ¾", male thread EN10226-1

Connection pressure (mbar)

Natural gas 2H, 2E, 2L, 2LL

**

20

3

Description of the unit

Equipment and connection data

16

Unit size

6.15

6.21

10.15

10.21

20.15

20.21

Connection pressure (mbar)

Liquefied gas (LPG) 3B/P, 3P

**

50

Natural gas E/H, G20 (m3/h) *

1.14

1.76

1.87

2.70

3.74

5.40

Natural gas LL/L, G25 (m3/h)

*

1.33

2.05

2.17

3.14

4.35

6.28

Liquefied gas (LPG) B, G30

(kg/h) *

0.87

1.34

1.42

2.05

2.84

4.10

Liquefied gas (LPG) P G31

(kg/h) *

0.85

1.32

1.40

2.02

2.80

4.04

Combustion air (m3/h) *

15.0

22.5

22.5

32.5

45.0

65.0

Supply air and exhaust gas routing

Required delivery pressure

B

13BS

(Pa)

0 - 5

Exhaust gas temperature

B

13BS

°C (°F)

170

(338)

230

(446)

195

(383)

240

(464)

205

(401)

250

(482)

Exhaust gas mass flow rate

B

13BS

(kg/h)

30

47

49

71

99

142

Primary air gap cm (in)

3 – 5 (1-2)

*) Information applies at 15 °C (59°F) and 1013.25 mbar

**) Information is country-specific and applies in Germany; for further information, see "Checking the

connection pressure"

Gas type

Connection pressure (mbar)

Connection pressure range (mbar)

Germany:

Natural gas 2H, 2E, 2L (LL)

20

17 (18) - 25

3.3.1

Connection pressure

Description of the unit

3

Equipment and connection data

17

Gas type

Connection pressure (mbar)

Connection pressure range (mbar)

Liquefied gas (LPG) 3B/P, 3P

50

42.5 - 57.5

Europe:

Natural gas 2E, 2H, (LL)

20

17 (18) - 25

Natural gas 2E+, (2L)

20/25 (25)

17 (20) - 30

Liquefied gas (LPG) 3B/P, 3P

50

42.5 - 57.5

Liquefied gas (LPG) 3B/P (3P)

29 (30)

25 - 35

Liquefied gas (LPG) 3+ (3P)

28 - 30/37 (37)

20 (25) - 45

Liquefied gas (LPG) 3B

29

20 - 35

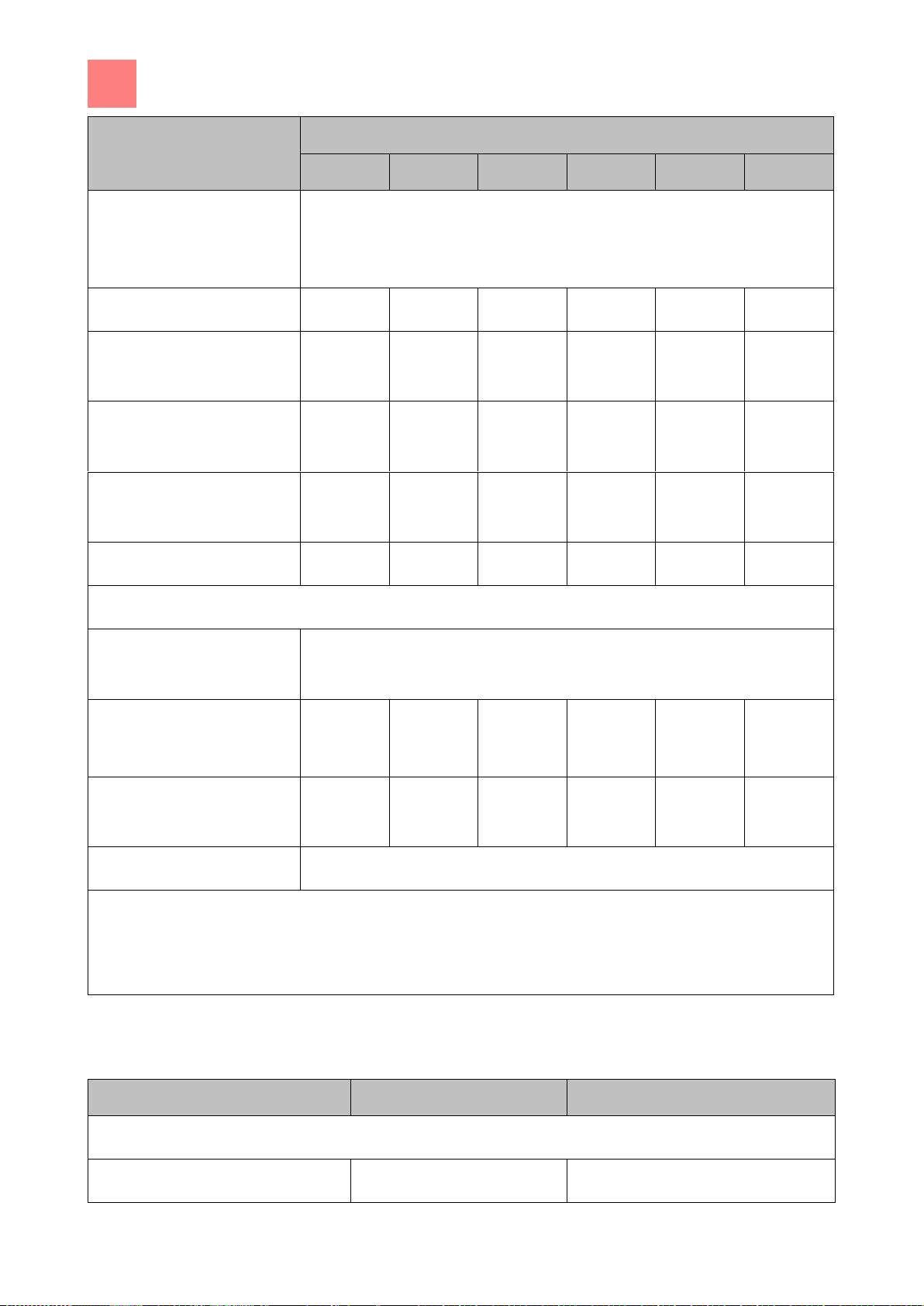

Unit size

Gas blower speed (rpm)

High output (HI)

Low output (LO)

6.15

5050 *

4800

6.21

6700

4800

10.15

5050

2800

10.21

6700

2800

20.15

5050

2800

20.21

6700

2800

* In deviation from the table, for unit size 6.15 the gas blower speed at the described setting and upon

verification of the rated heat input is 5500 rpm.

Gas type

Output

Unit size

CO2 (vol. %) *

p

offset

(hPa) **

CO (ppm) ***

Range

optimal

Range

optimal

Range

optimal

Natural

HI

All units

8.6 - 9.6

9.2

---

---

0 - 1000

<100

3.3.2

3.3.3

Speed of the fan-assisted gas burner

Exhaust gas values

3

Description of the unit

Equipment and connection data

18

Gas type

Output

Unit size

CO2 (vol. %) *

p

offset

(hPa) **

CO (ppm) ***

Range

optimal

Range

optimal

Range

optimal

gas

LO

6.1, 6.2

0.5 - 1.0

0.6

-0.8 - 0

-0.55

LO

10.1, 10.2,

20.1, 20.2

0.5 - 1.0

0.6

-0.4 - 0

-0.15

Liquefied

gas,

propane

HI

All units

10.0 - 10.6

10.3

---

---

LO

6.1, 6.2

0.5 - 1.0

1.0

-0.8 - 0

-0.55

LO

10.1, 10.2,

20.1, 20.2

0.5 - 1.0

1.0

-0.4 - 0

-0.15

Liquefied

gas,

butane

HI

All units

11.5 - 12.5

11.8

---

---

LO

6.1, 6.2

0.5 - 1.0

1.0

-0.8 - 0

-0.55

LO

10.1, 10.2,

20.1, 20.2

0.5 - 1.0

1.0

-0.4 - 0

-0.15

* At low output (LO) 0.5 - 1.0 lower than at high output (HI)

** Adjustment aid, offset pressure applies only at low output (LO)

** Undiluted exhaust gas

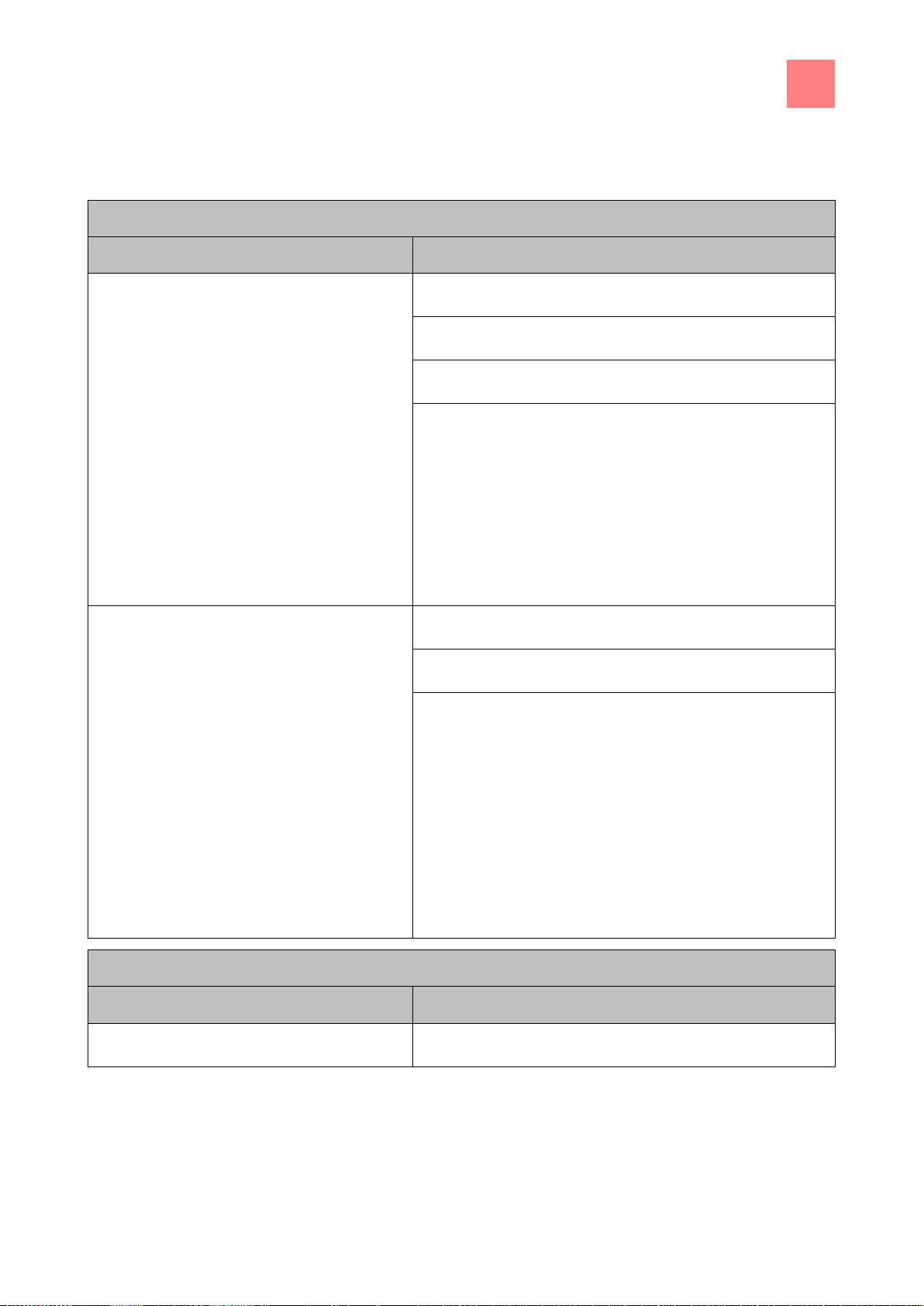

Gas orifices

Unit size

Gas orifice diameters (1/100 mm)

Natural gas LL

Natural gas H

Liquefied gas, propane /

butane

6.15

720

650

470

6.21

650

565

420

10.15

650

565

420

10.21

680

600

460

20.15

630

565

420

20.21

630

565

420

3.3.4

Gas orifice diameter

Description of the unit

3

Equipment and connection data

19

Burner operation

Display

Meaning

HI = High output

CO2 = CO2 measurement

G1 = Gas supply open (gas solenoid valve open)

F1 = Flame present (burner on)

85°C = Current cooking zone temperature

CO2 = CO2 measurement

2800 = Gas blower speed (rpm)

Burner status messages

Display

Meaning

G0 = Gas supply closed (gas solenoid valve closed)

3.3.5

Status messages

3

Description of the unit

Equipment and connection data

20

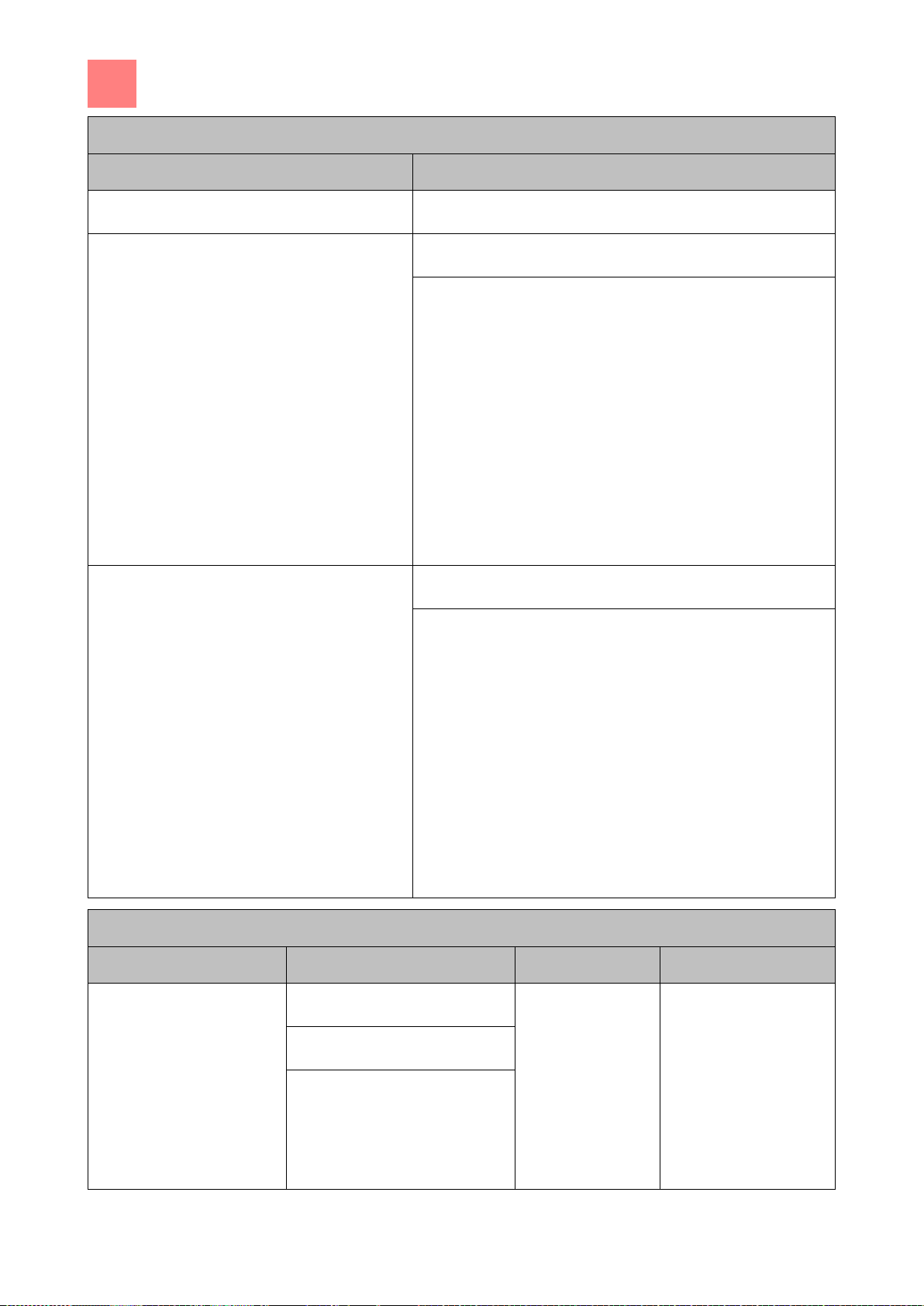

Burner status messages

Display

Meaning

F0 = No flame (burner off)

G1 = Gas supply open (gas solenoid valve open)

F0 = No flame (burner off)

G1 = Gas supply open (gas solenoid valve open)

F1 = Flame present (burner on)

Burner error messages

Display

Meaning

Possible cause

Remedy

Err = Error

Gas valve closed.

Air in the gas line.

Open the gas valve and

repeat ignition.

CO2 = CO2 measurement

71 = No gas

Description of the unit

3

Equipment and connection data

21

Burner error messages

Display

Meaning

Possible cause

Remedy

Err = Error

Power supply

interrupted. Error in

the control

electronics.

Contact customer

service

CO2 = CO2 measurement

72 = Blower not running

Err = Error

Wrong gas quality

Contact customer

service

CO2 = CO2 measurement

73 = General gas error

4

Transporting the unit

Transport information

22

WARNING

Risk of property damage and personnel injury from tipping equipment

a) Do not linger next to or behind raised equipment.

b) Move raised equipment carefully.

SAFETY INSTRUCTIONS

Risk of physical damage from improper transport

a) Transport the unit upright.

b) Do not tilt or stack the unit.

c) Pay attention to protruding parts when transporting the unpacked unit.

4

4.1

4.2

Transporting the unit

Transport information

Crossing a grate with the tray trolley

Prior to transporting the unit to the installation site, ensure that:

▪ The route has adequate load-bearing capacity; place rails or metal plates

underneath if necessary.

▪ Wall openings are large enough. Removing the packaging reduces the

clear width required (see "Equipment and connection data").“

Transporting to the installation site

Transporting the unit

4

Transporting to the installation site

23

SAFETY INSTRUCTIONS

Risk of physical damage from improper lifting of the unit

a) Lift size 6 and size 10 units only with the aid of wooden beams placed

underneath.

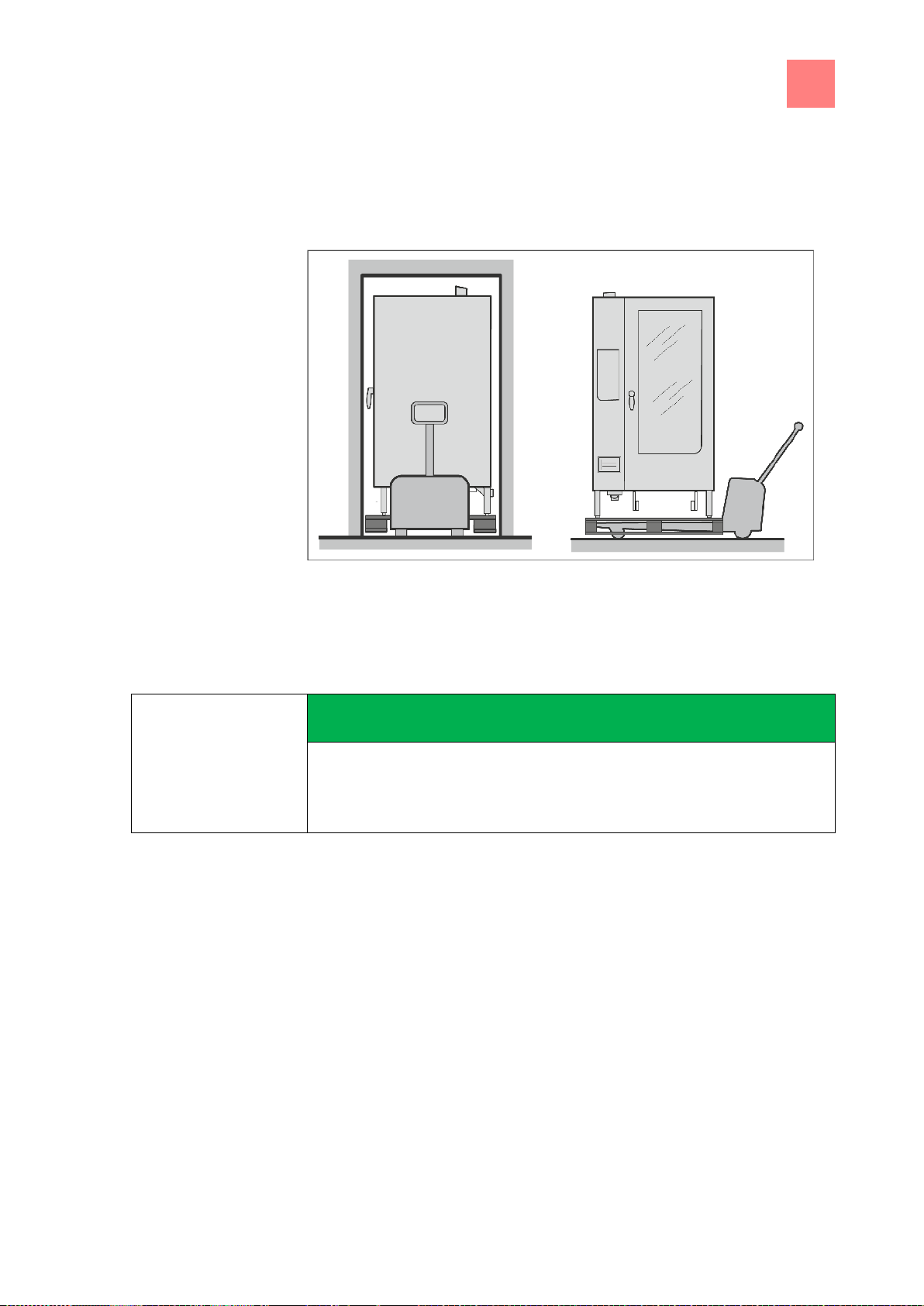

4.2.1

4.2.2

Requirement

Transporting on a pallet

a) Move the pallet truck under the pallet.

b) Raise the unit on the pallet.

Transporting the unit on a pallet

c) Move the unit to the installation site.

Transporting without a pallet

Unit sizes 6 and 10

➢ Packaging removed except for the pallet

a) Move the pallet truck under the unit from the right.

b) Place the wooden beams on the lift forks and slide under the unit.

c) Lift the unit off the pallet.

4

Transporting the unit

Transporting to the installation site

24

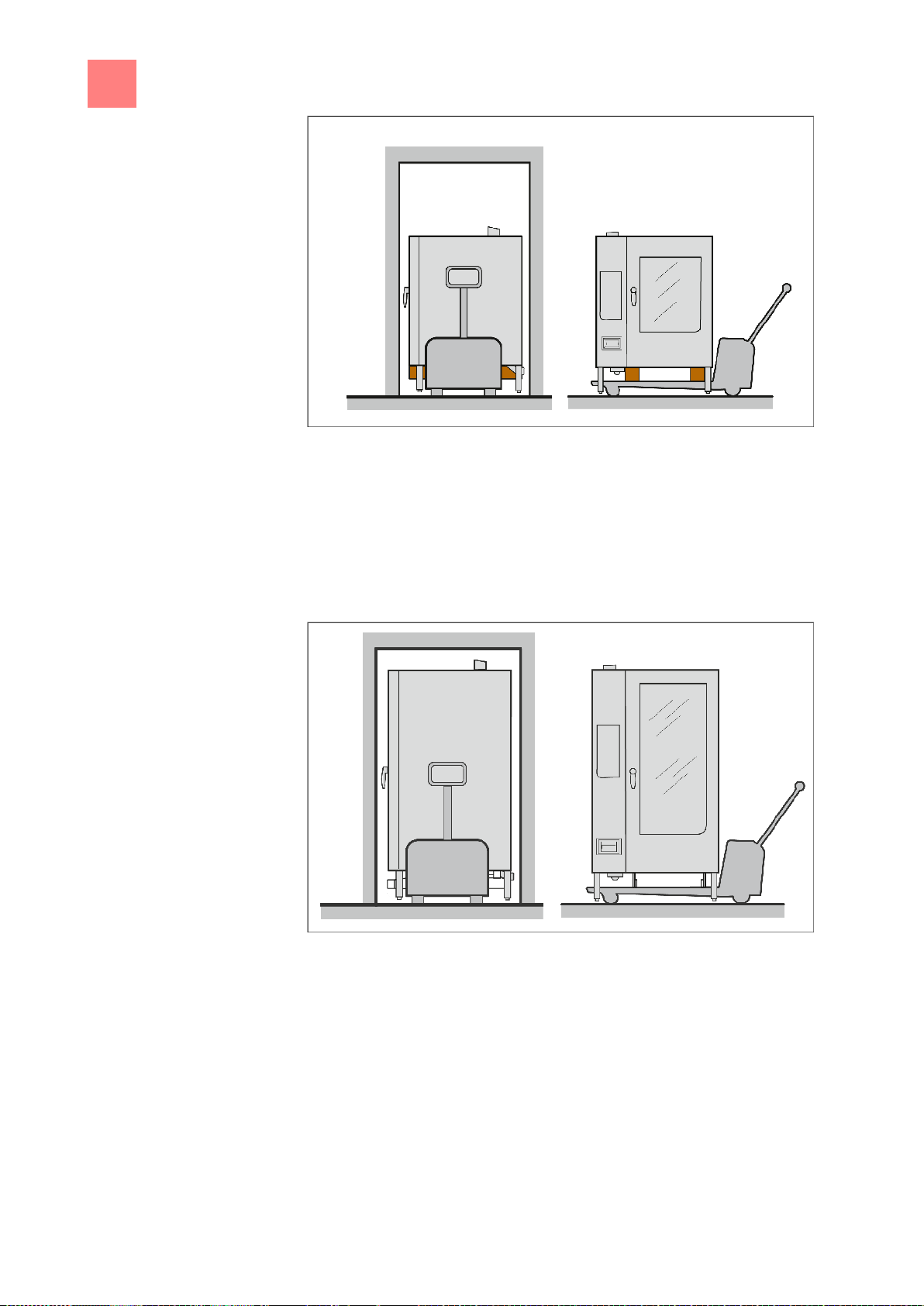

Requirement

Transporting unit sizes 6 and 10 without a pallet

d) Move the unit to the installation site.

Unit size 20

➢ Packaging removed except for the pallet

a) Move the pallet truck under the guide rails of the unit from the right.

b) Lift the unit off the pallet.

Transporting unit size 20 without a pallet

c) Move the unit to the installation site.

Loading...

Loading...