OPERATOR’S

MANUAL

FlexFusionTM GAS GOLD COMBI

MODEL

FGG-615

FGG-621

FGG-115

FGG-121

FGG-215

FGG-221

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

Read instructions before operating the appliance

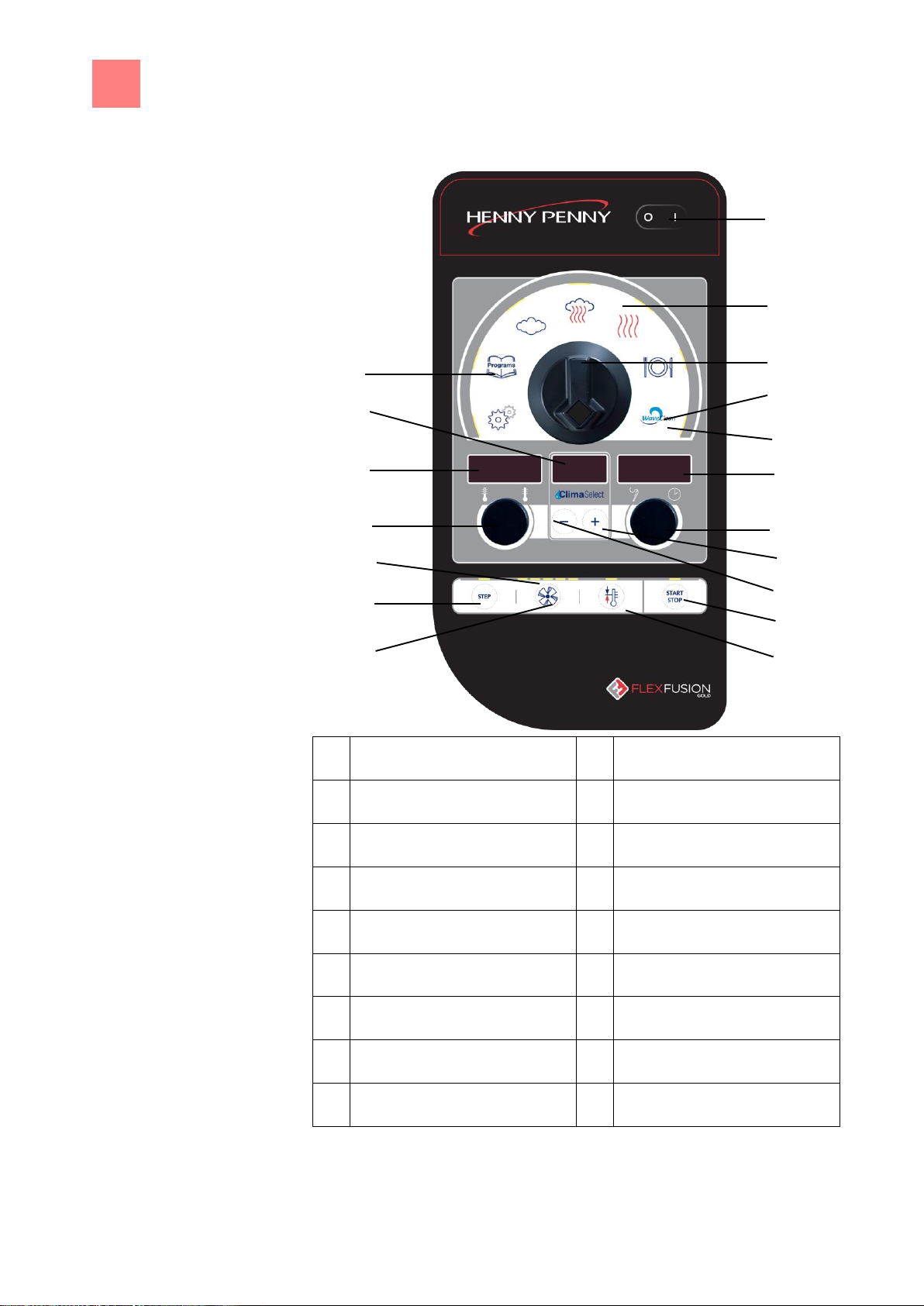

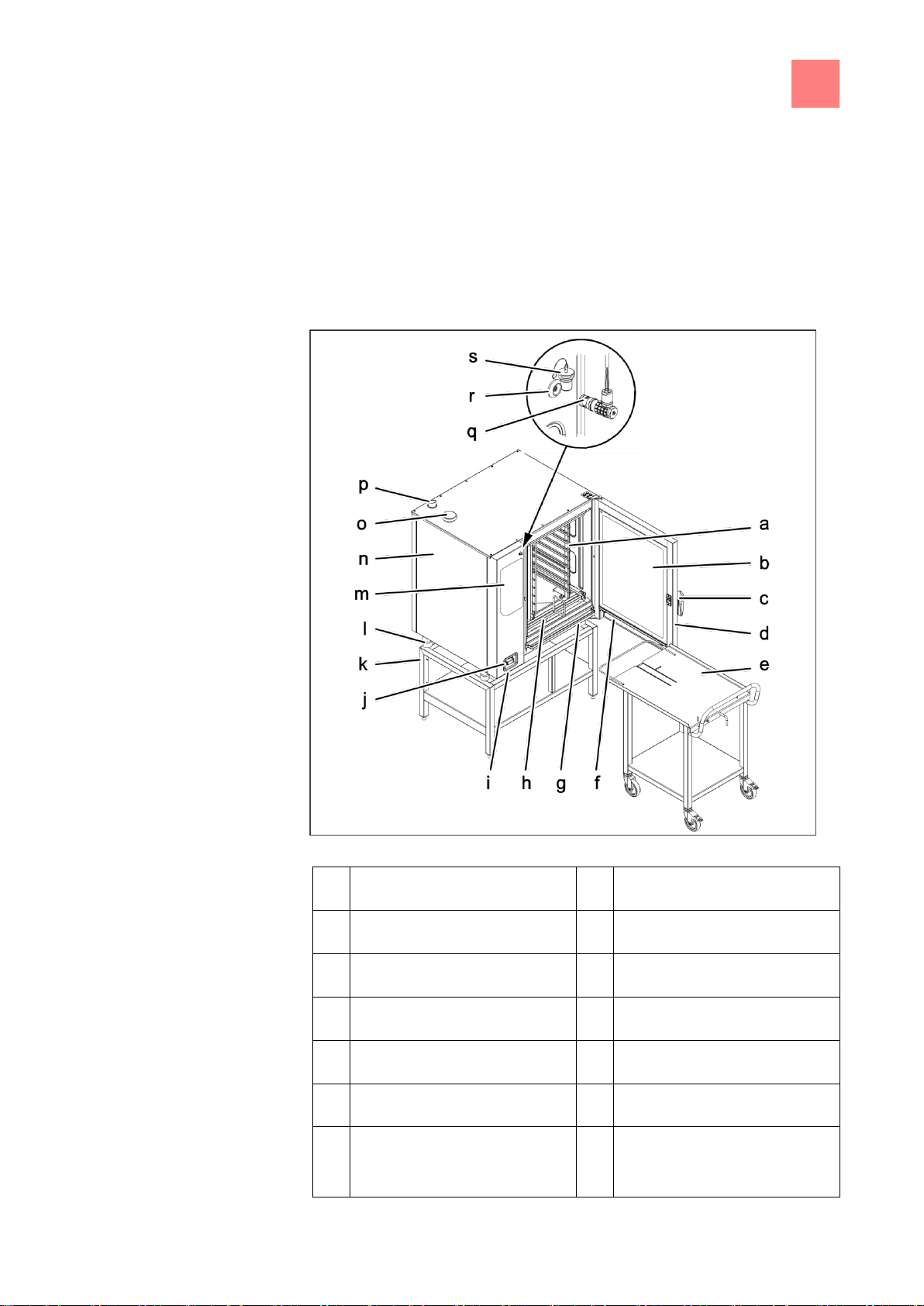

Operating and display elements

2

a

On Off

button

j

"START STOP" button

b

Selection range

k

Ready2Cook

button

c

Select

knob

l

Fan speed

button

d

HandClean

symbol

m

"STEP" button

e

WaveClean

symbol

n

Indicator light

f

Right display

o

Left knob

g

Right knob

p

Left display

h

Plus

button

q

Center display

i

Minus

button

r

"Programs" button

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

Operating and display elements

Directory of contents

3

1

Introduction

8

1.1

About this manual

8

1.1.1

Explanation of signs

9

1.2

Intended use

11

1.3

Warranty

11

2

Safety information

12

Rules of conduct when the smell of gas is detected

3

Description of the unit

17

3.1

Overview of the unit

17

3.1.1

Countertop unit

17

3.1.2

Floor-standing unit

18

3.2

Features

19

3.2.1

Characteristics

19

3.2.2

Operating modes

19

3.2.3

Types of cooking

20

3.2.4

Expanded cooking functions

20

3.2.5

Core temperature measurement

21

3.2.6

HACCP log

22

3.2.7

USB port

22

3.2.8

WaveClean automatic cleaning (optional)

22

3.3

Operating, control and display element functions

23

3.4

Application

25

3.4.1

Abbreviations in the displays

25

3.4.2

Temperature standard setting

26

Directory of contents

#Inhaltsverzeichnis

4

3.4.3

Cooking zone humidity standard setting

27

3.4.4

Core temperature standard-setting

27

3.4.5

Loading capacity

28

3.4.6

Plate capacity during regeneration

28

4

Putting the unit into service

29

5

Operating the unit

30

5.1

Switching the unit on and off

30

5.1.1

Switching on

30

5.1.2

Switching off

30

5.2

Opening and closing the cooking zone door

31

5.2.1

Opening the single-stage door latch

31

5.2.2

Closing the single stage door latch

32

5.2.3

Opening the two-stage door latch

32

5.2.4

Closing the two-stage door latch

33

5.3

Loading and emptying the unit

34

5.3.1

Loading and emptying

34

5.3.2

Loading and emptying with a tray rack trolley

35

5.3.3

Loading and emptying with a tray trolley

36

5.4

Using the core temperature sensor

38

5.4.1

Measuring with the 1- and 4-point core temperature sensor

38

5.4.2

Measuring with a sous-vide core temperature sensor

39

5.4.3

Measuring the core temperature when cooking frozen food

40

5.5

Making the basic settings

40

5.5.1

Opening the Setting menu

40

5.5.2

Changing the basic setting

41

5.6

Basic functions

43

5.6.1

Starting the cooking program

43

5.6.2

Ending the cooking program

44

Directory of contents

5

5.6.3

Cancelling the cooking program

44

5.6.4

Saving the cooking program

44

5.6.5

Selecting the cooking program

45

5.6.6

Changing the cooking program while cooking

46

5.6.7

Setting the cooking temperature

46

5.6.8

Setting the cooking time

47

5.6.9

Setting the core temperature

47

5.6.10

Setting the fan speed

48

5.6.11

Displaying actual values

48

5.6.12

Inserting and removing a USB flash drive

48

5.6.13

Displaying the HAACP log number

49

5.6.14

Exporting the HACCP log

49

5.7

Creating and starting a multi-step cooking program

49

5.7.1

Creating a program

49

5.7.2

Starting

50

5.8

Manual cooking

51

5.8.1

Starting the type of cooking

51

5.9

Expanded cooking functions

51

5.9.1

Manual humidification

51

5.9.2

Setting the start time delay

52

5.9.3

Cancelling the start time delay

52

5.9.4

Starting Ready2Cook

53

5.9.5

Cancelling Ready2Cook

53

5.9.6

Setting the cooking zone humidity level

54

5.10

Pausing and finishing use

54

5.10.1

Perform a hygiene flush after an extended period of idleness

54

6

Cleaning and caring for the unit

55

6.1

Preventing corrosion

55

6.2

Remove rust spots

56

#Inhaltsverzeichnis

6

6.3

Cleaning the housing

56

6.4

Cleaning the door handle, operating elements and control panel

56

6.5

Cleaning the door seal

57

6.6

Cleaning the cooking zone door

58

6.6.1

Cleaning the door with hygienic glazing

58

6.6.2

Cleaning the door with a back-ventilated window

58

6.7

Cleaning the steam outlet

59

6.8

Cleaning the condensation hood (optional)

60

6.9

Removing calcium deposits from the unit

61

6.10

Cleaning the cooking zone automatically

61

6.10.1

Preparing for cleaning

61

6.10.2

Selecting the cleaning level

62

6.10.3

Inserting the cleaning cartridge

62

6.10.4

Starting automatic cleaning

63

6.10.5

Cancelling automatic cleaning

64

6.10.6

Ending automatic cleaning

64

6.11

Cleaning the cooking zone semi-automatically

65

6.11.1

Preparing the cooking zone

65

6.11.2

Starting the cleaning program

65

6.11.3

Rinsing the cooking zone

66

6.11.4

Drying the cooking zone

67

6.12

Swinging the air diverter open and closed

67

6.13

Inspecting the unit

68

6.13.1

Performing a visual inspection

68

7

Troubleshooting

69

7.1

Causes of errors and remedies

69

Directory of contents

7

7.2

Nameplate

71

8

Dispose of unit in an environmentally responsible manner

72

1

Introduction

About this manual

8

1

1.1

Target group

Figures

Introduction

About this manual

The instruction manual is part of the unit and contains information:

▪ on safe operation

▪ on cleaning and care

▪ on remedial actions in case of faults

Observe and adhere to the following instructions:

▪ Read the instruction manual completely before operating the unit for the

first time.

▪ Make the instruction manual available to the operator at all times at the

operating site of the unit.

▪ Insert any supplements from the manufacturer.

▪ Preserve the instruction manual throughout the service life of the unit.

▪ Pass on the instruction manual to any subsequent operator of the unit.

The target group of the instruction manual is the operator, who is entrusted

with the operation, cleaning and care of the unit.

All figures in this manual are intended as examples. Discrepancies between

these and the actual unit can arise.

Introduction

1

About this manual

9

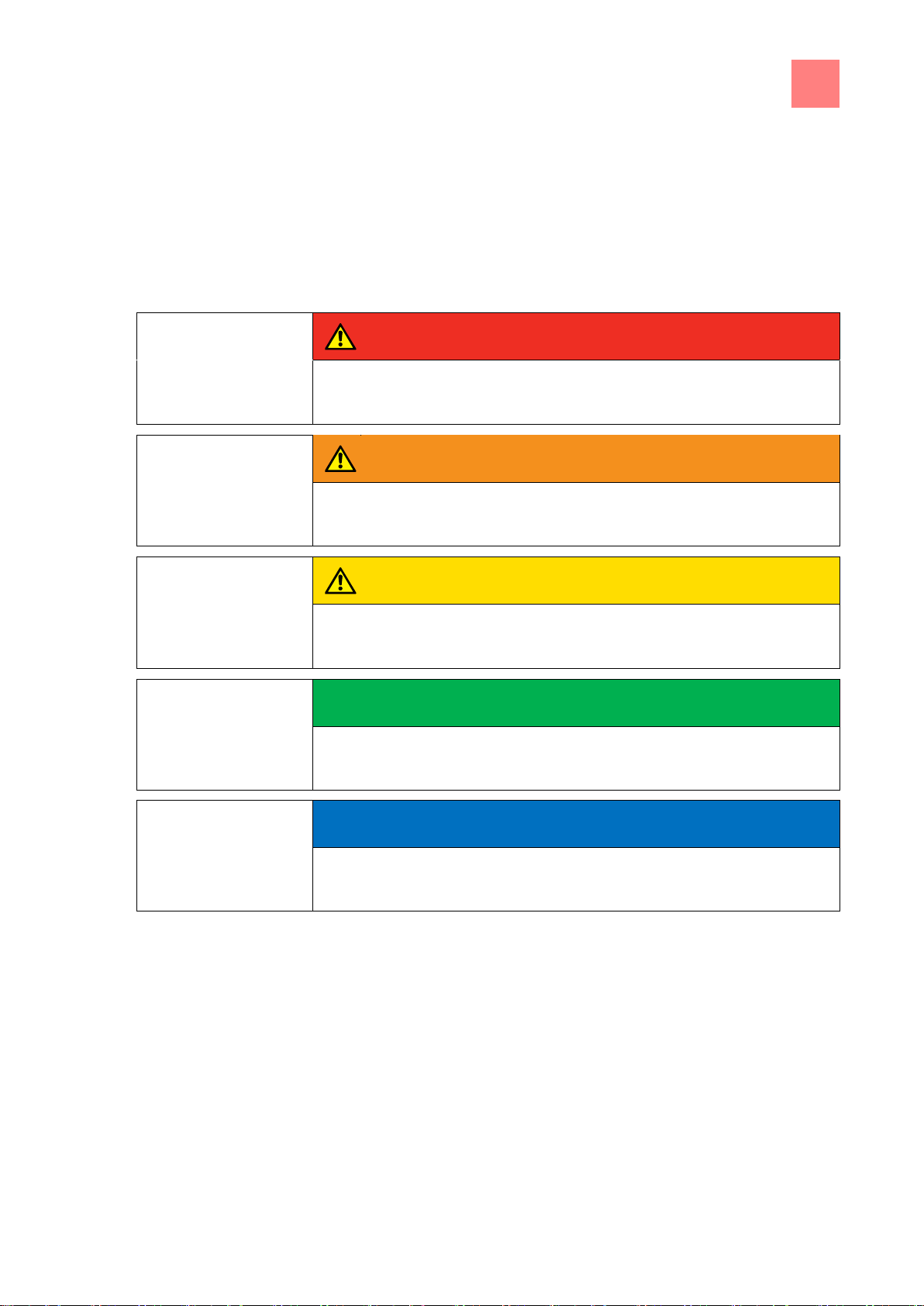

DANGER

Imminent threat of danger

Failure to comply will lead to death or very severe injuries.

WARNING

Possible threat of danger

Failure to comply can lead to death or very severe injuries.

CAUTION

Dangerous situation

Failure to comply can cause minor or moderate injuries.

SAFETY INSTRUCTIONS

Material damage

Failure to comply can cause material damage.

NOTICE

Information

Notes for better understanding and operation of the unit.

1.1.1

Explanation of signs

1

Introduction

About this manual

10

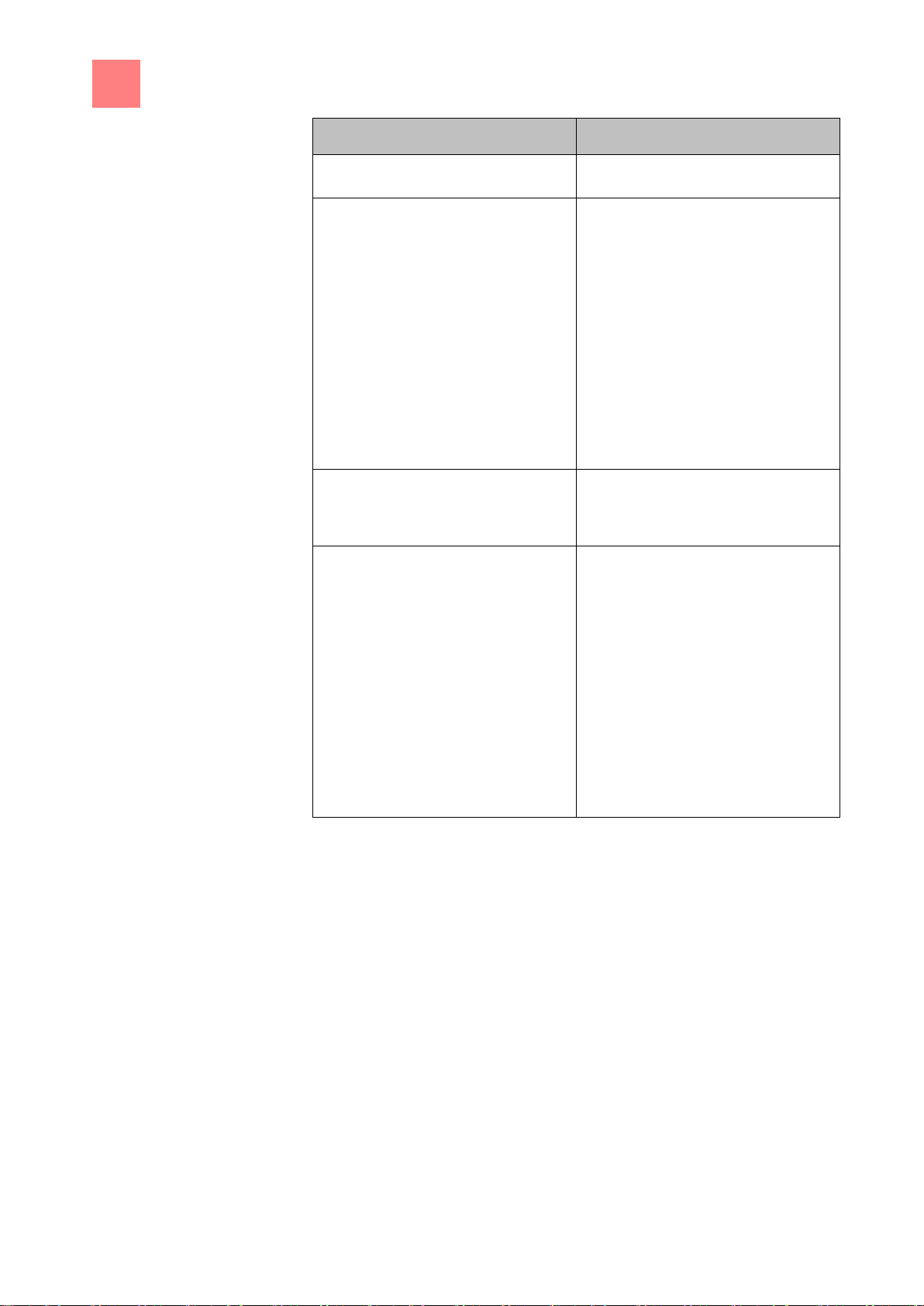

Symbol / sign

Meaning

▪

Listing of information.

Action steps, which can be per-

formed in any sequence.

1.

2.

Action steps, which must be per-

formed in the prescribed sequence.

Result of a listed action.

Introduction

1

Intended use

11

1.2

1.3

Intended use

This unit is intended to be used solely for commercial purposes, particularly

in commercial kitchens.

This unit may only be used with suitable accessories and for the cooking of

food.

It is forbidden to use the unit for purposes, which include the following:

▪ Washing dishes

▪ Storing supplies

▪ Drying cloths, paper or dishes

▪ Heating acids, alkaline solutions or other chemicals

▪ Heating preserved food

▪ Heating flammable liquids

▪ Heating rooms

▪ Cleaning air filters

This unit is certified in the following:

Warranty

The warranty is void and safety is no longer assured in the event of:

▪ Modifications or technical changes to the unit,

▪ Improper use,

▪ Incorrect startup, operation or maintenance of the unit,

▪ Problems resulting from failure to observe these instructions.

2

Safety information

12

2

Operation

Hot surfaces

Hot liquids

Defective unit

Safety information

The unit complies with applicable safety standards. Residual risks associ-

ated with operation or risks resulting from incorrect operation cannot be ruled

out and are mentioned specifically in the safety instructions and warnings.

The operator must be familiar with regional regulations and observe them.

During operation, the following group of individuals must be supervised by

an individual who is responsible for safety:

▪ Individuals with physical, sensory, or mental handicaps, or who lack the

knowledge and experience to operate the unit properly.

The supervising individual must be familiar with the unit and the risks associ-

ated with it.

Risk of burns from hot surfaces

▪ Protect arms and hands by wearing suitable protective gloves.

▪ Allow surfaces to cool prior to cleaning.

▪ Remove hot cookware only with suitable protective gloves or potholders.

▪ Remove containers and baking sheets only with suitable protective

gloves or potholders.

Risk of burns from hot liquids

▪ Protect arms and hands by wearing suitable protective gloves.

▪ Remove, transport and empty containers carefully.

Risk of chemical burns from evaporating cleaners

▪ Follow the instructions of the cleaning agent manufacturer.

▪ Allow the cooking so to clean to a temperature below 60 °C (140 °F) and

then clean.

Risk of burns from steam

▪ Protect arms and hands by wearing protective gloves.

▪ Do not hold hands in front of the extractor hood.

▪ Dry unit completely after cleaning it.

Risk of injury from a defective unit

▪ Disconnect a defective unit from the electric mains.

Safety information

2

13

Fire prevention

Unit on casters

Escaping gas

▪ Do not operate a defective unit.

▪ Allow only an authorized technician to repair the unit.

Risk of asphyxiation and explosion from escaping gas

▪ Follow the rules of conduct when the smell of gas is detected (see

"Rules of conduct when the smell of gas is detected").

Risk of fire from dirt and grease accumulation.

▪ Clean the unit when finished using it.

▪ Do not use the unit as a deep fat fryer.

▪ Do not store any combustible objects or plastic containers in the cooking

zone.

Risk of fire from objects

▪ Do not obstruct the exhaust gas duct.

Firefighting

▪ In the event of a fire, disconnect the unit from the electric mains.

▪ In the event of a fire, use the gas shut-off valve to isolate the unit from

the gas supply.

▪ Use a Fire Class F fire extinguisher, never water, to extinguish grease

fires. Other fires, for instance, can be extinguished with fire extinguishers

suitable for Fire Classes A, B, C, CO2 fire extinguishers or extinguishing

media suitable for the fire class confronted.

Risk of injury from a unit on casters

▪ Move the unit only for cleaning or maintenance

▪ Lock casters during operation.

▪ Only move an empty unit.

Risk of electric shock from live components

▪ Security electric power cable to the wall at the installation location by

means of a chain as strain relief.

2

Safety information

14

Improper cleaning

Core temperature

measurement

Improper use

Risk of chemical burns from cleaning agent

▪ Follow the instructions of the cleaning agent manufacturer.

▪ Take appropriate protective measures when handling aggressive clean-

ing agents.

Risk of falling on smooth floors

▪ Keep the floor in front of the unit clean and dry.

Risk of injury from improper cleaning

▪ Clean the cooking zone carefully. The cooking zone sensor protrudes

into the cooking zone.

Risk of physical damage from improper cleaning

▪ Clean the unit after using it.

▪ Do not clean the unit with a high-pressure cleaner.

▪ Do not clean the housing with highly abrasive or chemically aggressive

cleaning agents.

▪ Do not clean the housing with highly abrasive sponges.

▪ Follow the instructions of the cleaning agent manufacturer.

▪ Do not cool shock the unit by cooling it abruptly.

▪ Clean the cooking zone carefully. The cooking zone sensor protrudes

into the cooking zone.

▪ Do not use any bleaching or chlorine-containing cleaners.

▪ Remove rust spots with an abrasive.

▪ Keep the unit free of calcium deposits.

Health risk from insufficient hygiene

▪ Observe applicable regional hygiene regulations.

Risk of injury from overheated core temperature sensor.

▪ Do not heat the core temperature sensor over an open flame.

Risk of physical damage from improper use

▪ Use only original accessories.

Safety information

2

15

DANGER

Risk of asphyxiation and explosion from escaping gas

Follow the rules of conduct when the smell of gas is detected.

▪ Train operators regularly.

▪ Do not heat food warmer plates or tins of preserved food.

▪ Do not cover air inlet and outlet openings.

▪ Do not operate the unit at temperatures below 4° C (39 °F).

▪ Remove the core temperature sensor before the cooked food is re-

moved.

▪ Insert the core temperature sensor back into the holder after use.

Rules of conduct when the smell of gas is detected

▪ Remain calm.

▪ Open windows and doors and ventilate rooms.

▪ Avoid rooms with the smell of gas.

▪ Do not smoke.

▪ Do not ignite any flames. Extinguish flames.

▪ Do not strike any sparks. Do not operate any switches, electrical devices

or use telephones.

▪ Remove mobile phones and radio-controlled devices from the hazard

area.

▪ Close gas shut-off valves at the gas meter, at the main feed and, if pos-

sible, at the units.

▪ Warn other individuals in the building. Call out and knock, do not ring

doorbells.

▪ Leave the building and prevent entry by others.

▪ Observed the safety instructions of the gas utility.

▪ Once outside the building, notify responsible parties:

– If the smell of gas comes from the unit, notify customer service.

– If the source of the smell of gas cannot be localized immediately, no-

tify the gas utility.

2

Safety information

16

– If the escaping gas is audible, leave the building immediately, pre-

vent others from entering and notify the fire brigade, police and gas

utility.

– If the smell of gas comes from inaccessible rooms, notify the fire bri-

gade, police and gas utility.

Description of the unit

3

Overview of the unit

17

a

Tray rack

k

Base frame (optional)

b

Insulated window

l

Equipment foot

c

Door handle

m

Operating control

d

Cooking zone door

n

Housing

e

Tray rack trolley (optional)

o

Air intake connection fitting

f

Steam drain channel, door

p

Steam outlet connection fitting

g

Steam drain channel, unit

q

Core temperature sensor

(optional)

3

3.1

3.1.1

Description of the unit

Overview of the unit

Countertop unit

FlexFusion with tray rack trolley

3

Description of the unit

Overview of the unit

18

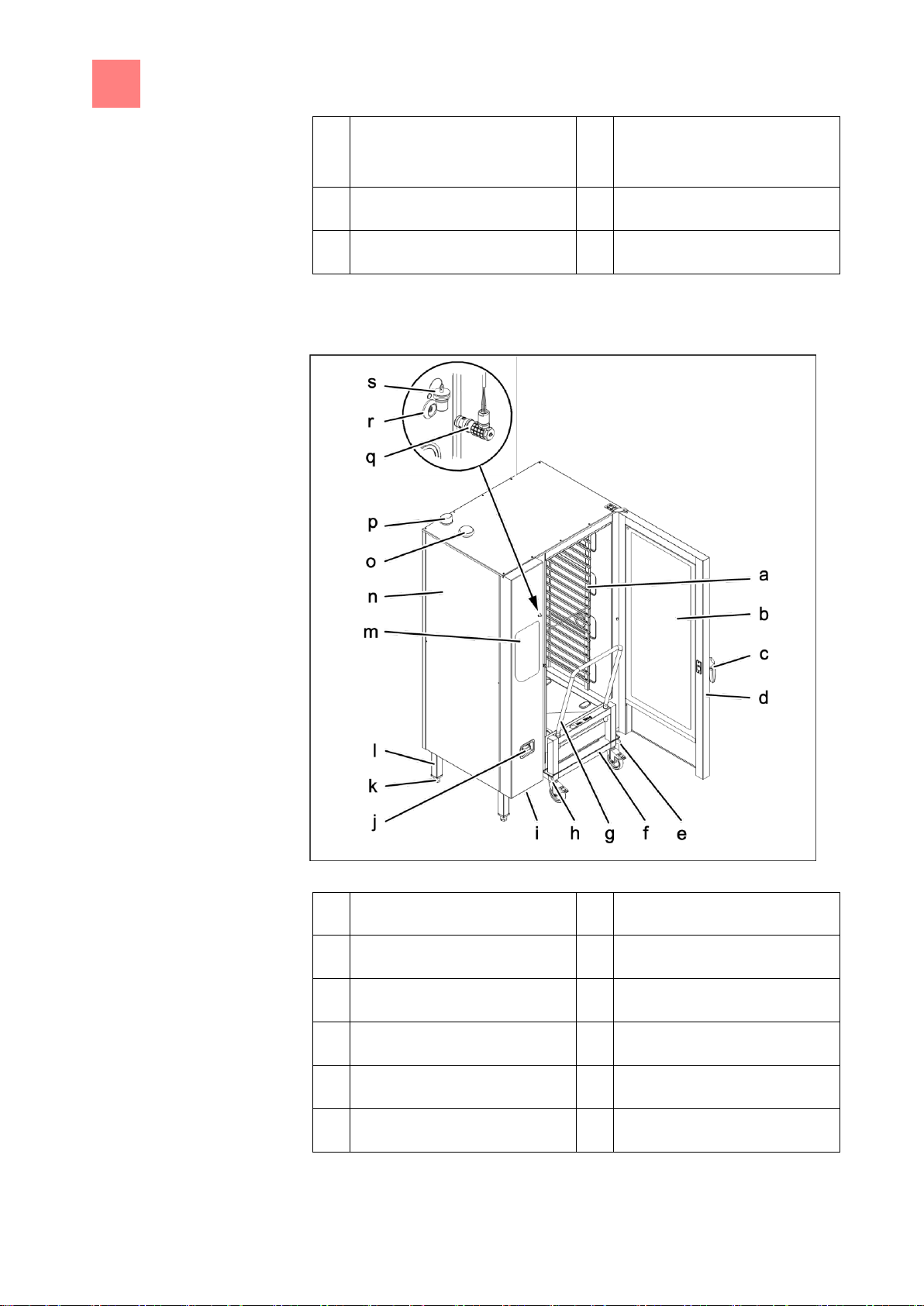

h

Guide rail for tray rack (op-

tional)

r

Connection (optional)

i

USB port (covered)

s

Protective cap (optional)

j

Hand shower (optional)

a

Tray rack

k

Equipment leg

b

Insulated window

l

Equipment foot

c

Door handle

m

Operating control

d

Cooking zone door

n

Housing

e

Guide rail (right)

o

Air intake connection fitting

f

Tray trolley

p

Steam outlet connection fitting

3.1.2

Floor-standing unit

FlexFusion with tray trolley

Description of the unit

3

Features

19

g

Push handle

q

Core temperature sensor

(optional)

h

Guide rail (left)

r

Connection (optional)

i

USB port (covered)

s

Protective cap (optional)

j

Hand shower

3.2

3.2.1

3.2.2

Manual cooking

Automatic cooking

Features

Characteristics

▪ 1-point core temperature sensor

▪ 4-point core temperature sensor (optional)

▪ Sous-vide core temperature sensor (optional)

▪ Hand shower (optional)

▪ Back-ventilated cooking zone door

▪ Cooking zone door with hygienic glazing (optional)

▪ Single-stage door latch

▪ Two-stage door latch (optional); this feature is standard on size 20 units

▪ Power optimizing system (optional)

▪ Cooking zone door hinged at right

▪ Cooking zone door hinged at left (optional)

▪ HandClean

▪ WaveClean (optional)

Operating modes

▪ Manual cooking

▪ Automatic cooking

In the manual cooking mode, individual cooking programs and equipment

functions can be actuated directly. The various types of cooking and equip-

ment functions can be adapted individually.

In the automatic cooking mode, stored cooking programs can be actuated

and adapted as necessary.

3

Description of the unit

Features

20

NOTICE

When using the start time delay, temperatures that promote the growth of

harmful microorganisms on the food being cooked can occur in the cooking

zone. Observe food processing regulations.

3.2.3

Steaming

Hot air

Combisteaming

Regeneration

3.2.4

Manual humidification

Start time delay

Types of cooking

▪ Steaming

▪ Hot air

▪ Combisteaming

▪ Regeneration

Steaming is a type of cooking in which the food to be cooked is cooked gen-

tly with the aid of steam in a temperature range of 30°C (86°F) to 130°C

(266°F).

Hot air is a type of cooking in which the food to be cooked is cooked without

additional moisture in a temperature range of 30°C (86°F) to 300°C (572°F).

Combisteaming is a type of cooking in which large roasts, casseroles and

baked goods can be cooked in a temperature range of 30°C (86°F) to

250°C (482°F).

Regeneration is a type of cooking in which the food to be cooked can be

kept warm and prepared in a temperature range of 30°C (86°F) to 150°C

(302°F).

Expanded cooking functions

Expanded cooking functions can be used to adapt individual cooking steps

to the particular food being cooked.

The following expanded cooking functions are available:

▪ Manual humidification

▪ Start time delay

▪ Preheating

Manual humidification allows the cooking zone humidity to be increased dur-

ing operation.

Manual humidification can be used with all types of cooking.

The start time delay can be used to set a waiting period until the program

starts.

Description of the unit

3

Features

21

NOTICE

This function can be started manually as necessary.

Preheating (Ready2Cook)

3.2.5

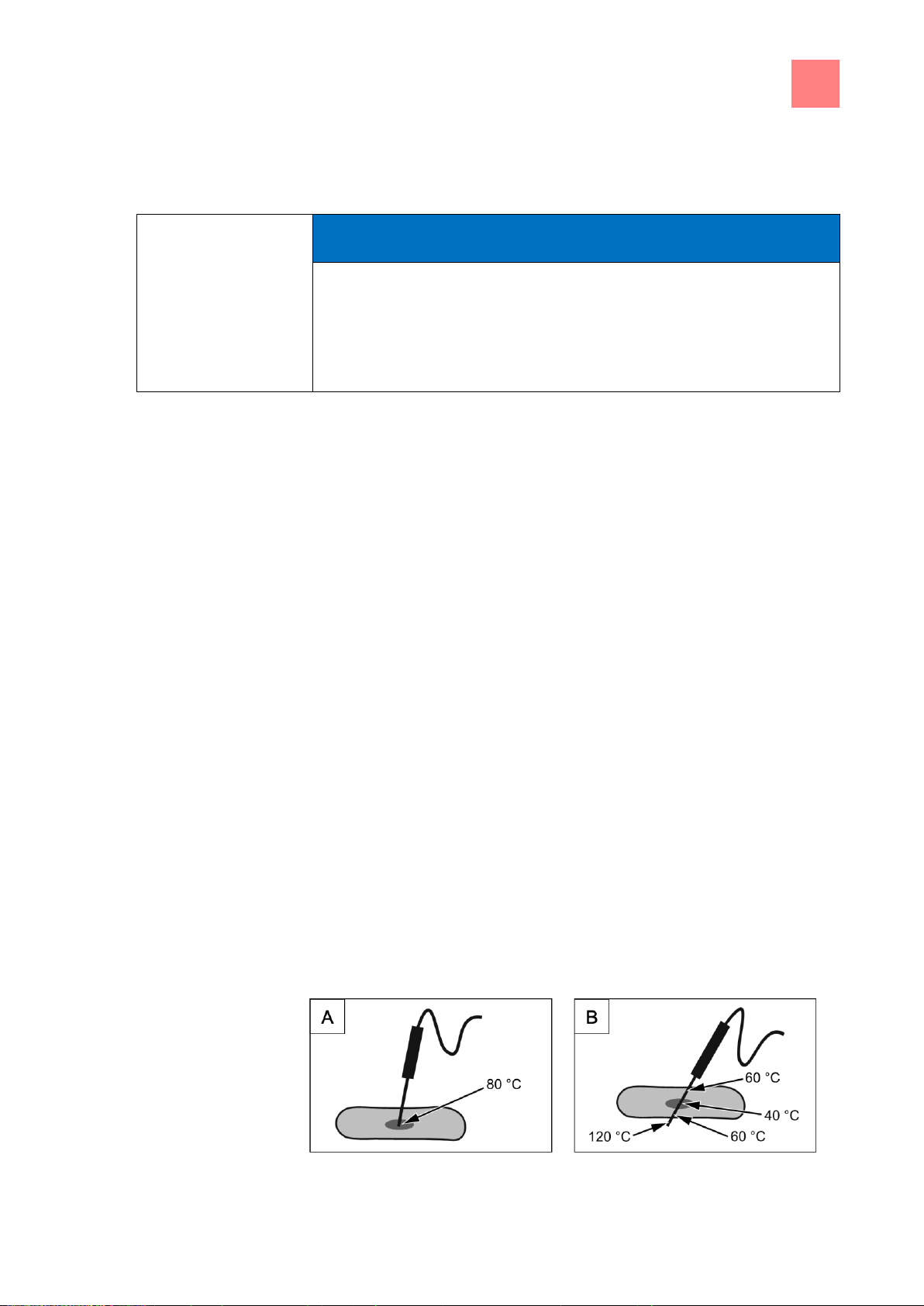

176°F

248°F

104°F

140°F

140°F

In this way, bottlenecks in production and preparation can be avoided.

The prepared food can be loaded into the unit and the desired cooking pro-

gram selected.

For many cooking programs such as baking, for instance, the correct starting

temperature is important.

The preheating function can be used to warm the cooking zone to the cor-

rect starting temperature.

Core temperature measurement

When using core temperature measurement, the temperature inside the food

being cooked is measured by means of a sensor.

The core temperature sensor measures the core temperature at one or more

points, depending on the version. The temperature measured at the coldest

spot is used to control the cooking process.

As soon as the target core temperature has been reached, the cooking pro-

cess is ended automatically or, in the case of a multi-step cooking program,

advances to the next cooking step.

The use of core temperature measurement offers the following benefits:

▪ Reduced energy and water consumption

▪ No overcooking

▪ Less weight lost by the food being cooked

The following core temperature sensors are available:

Core temperature measurement with 1- or 4-point core temperature sensor

▪ 1-point core temperature sensor

3

Description of the unit

Features

22

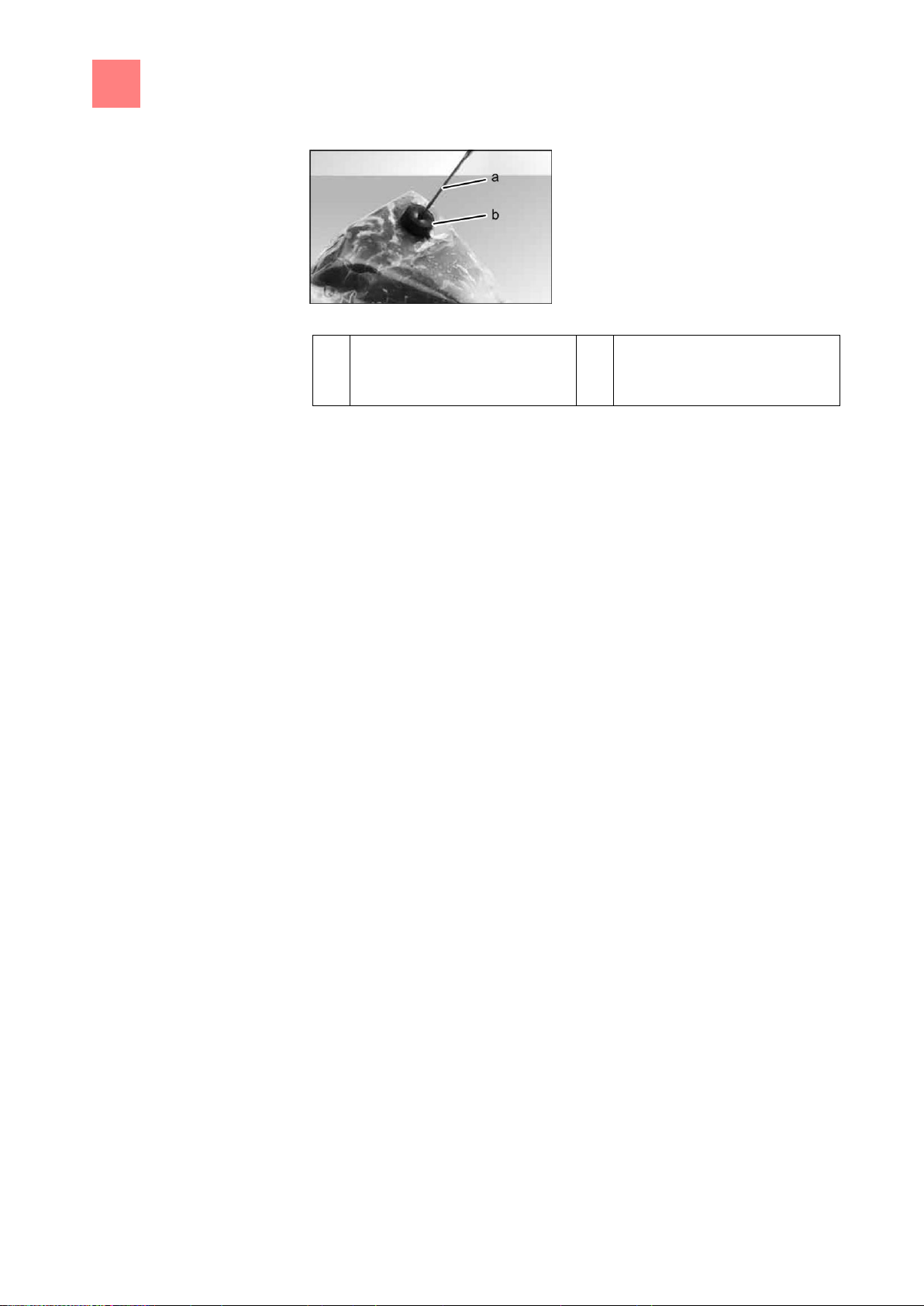

a

Sous-vide core temperature

sensor

b

Foam rubber

3.2.6

3.2.7

3.2.8

▪ 4-point core temperature sensor (optional)

Core temperature measurement with Sous-Vide core temperature sensor

▪ Sous-vide core temperature sensor (optional)

HACCP log

All cooking steps are recorded with a log number in the HACCP log.

A single log or several logs can be exported in a certain area.

The data are exported via the USB port.

USB port

The unit is equipped with a USB port (USB 2.0).

HACCP logs can be exported to the USB flash drive and archived on an ex-

ternal PC as necessary.

WaveClean automatic cleaning (optional)

With WaveClean automatic cleaning, the cooking zone is cleaned with the

aid of a cleaning cartridge intended specifically for the program and then

rinsed clean.

Loading...

Loading...