Henny Penny FGE 621, FGE 215, FGE 115, FGE 121, FGE 221 Service Instructions Manual

...

Service instructions

Translation from the original document • FM05-115---DE • 1/31/2018

10013864-0ASAE-D

en-US

Copyright

All rights to text, graphics and pictures in this documentation are held by MKN Maschinenfabrik Kurt

Neubauer GmbH & Co. KG. Distribution or duplication is exclusively permissible subject to a written

consent of MKN.

Copyright by MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG

Manufacturer

Copyright by MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG

Halberstaedter Strasse 2a

D-38300 Wolfenbuettel

Telephone 0 53 31 / 89-0

Telefax 0 53 31 / 89-280

2 Service instructions

Directory of contents

3Service instructions

1Introduction......................................................................... 7

1.1About this manual ............................................................................ 7

1.2Warranty............................................................................................ 7

2Safety information.............................................................. 8

3Function descriptions........................................................ 9

3.1WaveClean ........................................................................................ 9

4Opening the unit............................................................... 11

4.1Control panel .................................................................................. 11

5Service menu - unit test................................................... 12

5.1Service menu .................................................................................. 12

5.1.1Calling service menu ............................................................................... 12

5.1.2Service menu - overview ......................................................................... 12

5.2Software display (Sof).................................................................... 13

5.3Buttons and display test (bdS)...................................................... 14

5.4Relay test (rEL) ............................................................................... 15

5.5WaveClean test (CLe)..................................................................... 17

5.6DynaSteamTest (H2O).................................................................... 18

5.7100°C + KT calibration (CAL)......................................................... 19

5.7.1Check calibration - single chamber 6.x / 10.x.......................................... 19

5.7.2Check calibration - double chamber unit 20.x ......................................... 20

5.7.3Calibrate cooking chamber sensor - single chamber unit 6.x / 10.x........ 22

5.7.4Calibrate cooking chamber sensor - double chamber unit 20.x .............. 23

5.8Draining water (-H2) ....................................................................... 25

5.9Exporting error memory (EEP)...................................................... 25

5.10Deleting the error memory (ECL)................................................ 26

5.11Software update (SFL) ................................................................. 26

5.12Diagnostic memory (dia) ............................................................. 27

5.13Equipment settings (Opt)............................................................. 27

5.14Backup of (PEP) ........................................................................... 29

5.15Recovering data (PIP) .................................................................. 30

5.16Configuration settings (Con)....................................................... 30

6Software update ............................................................... 32

7Exhibition mode................................................................ 34

8Electronics ........................................................................ 35

8.1Overview of the control ................................................................. 35

8.2Layout of control board ................................................................. 36

8.3Assignment of control board ........................................................ 37

8.4Overview of fuses........................................................................... 39

10013864-0ASAE-D

Directory of contents

4 Service instructions

8.5Use of spare relay K6..................................................................... 40

9Gas technology ................................................................ 42

9.1Basics.............................................................................................. 42

9.2CO2 setting ..................................................................................... 43

9.2.1Checking the settings .............................................................................. 43

9.2.2Adjusting the settings .............................................................................. 44

9.3Converting the gas type ................................................................ 49

9.4Checking the connection pressure .............................................. 52

9.5Checking the offset pressure........................................................ 53

10Gas orifices and C02 values up to S/N 16212355........ 55

11Gas orifices and C02 values after S/N 16212356......... 56

12Error messages .............................................................. 57

12.1Description.................................................................................... 57

12.2Overview of fault messages ........................................................ 57

12.3Err 01-23 (not possible to start fan)............................................ 62

12.4Err 01-24 (not possible to start upper fan)................................. 63

12.5Err 01-25 (not possible to start lower fan) ................................. 63

12.6Err 06-13 (emergency rinse not possible).................................. 63

12.7Err 07-10 (cooking sensor defective) ......................................... 64

12.8Err 07-11 (top cooking chamber sensor defective)................... 64

12.9Err 07-12 (bottom cooking chamber sensor defective) ............ 65

12.10Err 07-13 ((cooking chamber sensor emergency program) ... 65

12.11Err 07-14 ((cooking chamber top sensor emergency program)...

66

12.12Err 07-15 ((cooking chamber bottom sensor emergency

program)................................................................................................ 66

12.13Err 07-16 (water vapor sensor defective) ................................. 67

12.14Err 07-18 (cooking chamber temperature too high)................ 67

12.15Err 07-40 (core temperature sensor defective)........................ 68

12.16Err 07-50 (control board temperature too high) ...................... 68

12.17Err 07-51 (risk of frost)............................................................... 68

12.18Err 07-60 (fan defective or temperature limiter triggered)...... 69

12.19Err 07-61 (upper fan fault or temperature limiter triggered.).. 70

12.20Err 07-62 (lower fan fault or temperature limiter triggered) ... 71

12.21Err 07-70 (water pressure too low) ........................................... 73

12.22Err 07-72 (water pressure during WaveClean too low) ........... 74

12.23Con (configuration required)..................................................... 74

12.24SFL (CAN connection faulty / update required)....................... 75

12.25SHO in right-hand display ......................................................... 75

12.26SHO in center display ................................................................ 75

10013864-0ASAE-D

Directory of contents

5Service instructions

13Gas faults and error messages..................................... 76

13.1Err 08-01 (no gas) ......................................................................... 76

13.2Err 08-02 (no gas 1 - upper burner) ............................................ 77

13.3Err 08-03 (no gas 2 - lower burner) ............................................. 77

13.4Err 08-04 (no flame)...................................................................... 77

13.5Err 08-05 (no flame 1 - upper burner) ......................................... 77

13.6Err 08-06 (no flame 2 - lower burner).......................................... 78

13.7Err 08-07 (gas fan fault) ............................................................... 78

13.8Err 08-08 (fault in gas fan 1 - upper burner)............................... 78

13.9Err 08-09 (fault in gas fan 2 - lower burner) ............................... 78

13.10Checking the electrodes............................................................ 79

13.10.1Glow electrode .................................................................................... 79

13.10.2Ionization electrode ............................................................................. 80

13.11Checking the gas magnetic valve and gas heat exchanger... 80

10013864-0ASAE-D

Directory of contents

6 Service instructions

10013864-0ASAE-D

Introduction

7Service instructions

1 Introduction

1.1 About this manual

This service manual contains information needed by the service

technician for professional and correct fault isolation, repair and

maintenance of the unit. The service technician must also observe

the contents of the installation instructions and the user manual.

Target group Target group for this service manual is qualified personnel who are

familiar with the technical functioning and operation of the unit.

Figures All figures in this service manual are intended as examples.

Discrepancies can arise between this and the actual unit.

Spare parts To ensure the reliability of the unit and the individual components, it is

essential that only genuine OEM parts be used.

Spare parts can be identified exactly with the aid of the online

database.

1.2 Warranty

The warranty is void and safety is no longer assured in the event of:

• Modifications or technical changes to the unit,

• Improper use,

• Incorrect startup, operation or maintenance of the unit,

• Problems resulting from failure to observe these instructions.

10013864-0ASAE-D

Safety information

8 Service instructions

2 Safety information

For servicing tasks, the service technician must be familiar with and

observe regional regulations.

In addition, the notes in the service manual must be observed.

DANGER

Danger to life due to electric current

ü Disconnect power prior to performing gas and electrical work.

• Disconnect unit from the mains supply and secure it against restart.

• Check to ensure absence of voltage.

DANGER

Risk of fatal injury from gas

ü Disconnect the unit from gas supply prior to performing gas installation

tasks.

• Lock site gas supply and secure it against restart.

10013864-0ASAE-D

Function descriptions

9Service instructions

3 Function descriptions

3.1 WaveClean

Overview of functions

a b c

a Solenoid valve K12 c Pump G24

b Pump G16

The following purification stages are available on the fully automatic

cleaning WaveClean:

• Short: duration of about one hour

• Normal: duration about two hours

• Extra: duration approximately three hours

Description 1. Testing the cooking chamber temperature.

Automatic cooling of the cooking chamber, if > 55°C.

2. Inserting the WaveClean cartridge.

3. Water exchange of siphon content by the siphon pump G24 and

solenoid valve K12.

4. Circulation of water by means of pump G16. Thus pre-cleaning of

the cooking chamber. Then anew siphon water exchange.

The heater heats the oven to 55°C.

10013864-0ASAE-D

Function descriptions

10 Service instructions

5. Start cleaning.

Fan motor and WaveClean pump G16 active.

Heating active. Heating the cooking chamber to about 70°C.

The first layer of wax melts in the WaveClean cartridge. The

cleaner falls into the cooking chamber and mixes with water.

The fan motor operates in both directions of rotation and at

different speeds.

The cleaning phase duration depends on the selected

program.

6. A new water exchange of siphon content by means of the siphon

pump G24 and solenoid valve K12.

7. Start of rinsing.

Identical to step 5 (cleaning).

Differences: Heating of the cooking chamber to 92°C. The

second layer of wax melts in the WaveClean cartridge. The

rinse agent drops into the cooking chamber and mixes with

water.

Final rinse to bring the pH value to the normal level.

8. In the programs "normal" and "extra" additional drying of the

interior occurs by means of hot air.

9. Finally, an indicator for withdrawing the WaveClean cartridge

appears, and has to be confirmed.

INFORMATION

Despite different cleaning durations, all cleaning steps require the same

amount of water.

During the cleaning process about 3 liters of water are provided by the steam-

ing unit into the oven.

WaveClean termination

INFORMATION

WaveClean forced rinsing

The WaveClean forced rinse is automatically started by the operator in case of

failure or premature termination. The duration is 12 minutes. An entry is made

into the HACCP and in the diagnostic memory.

10013864-0ASAE-D

Opening the unit

11Service instructions

4 Opening the unit

4.1 Control panel

Opening the control panel Unlock the control panel with an Allen wrench, size 5. The control

panel pops up automatically.

Closing the control panel Close the control panel by repeatedly pressing the left side

(particularly in the upper left). The control panel locks noticeably at

multiple points.

NOTICE

Damage due to vapor / moisture

There should be no gap between the control panel and housing.

10013864-0ASAE-D

Service menu - unit test

12 Service instructions

5 Service menu - unit test

5.1 Service menu

Description • Functional testing of individual components

• Error analysis

• Maintenance

• Change basic settings

• Software update

The graphics shown may deviate due to changes and different

software versions.

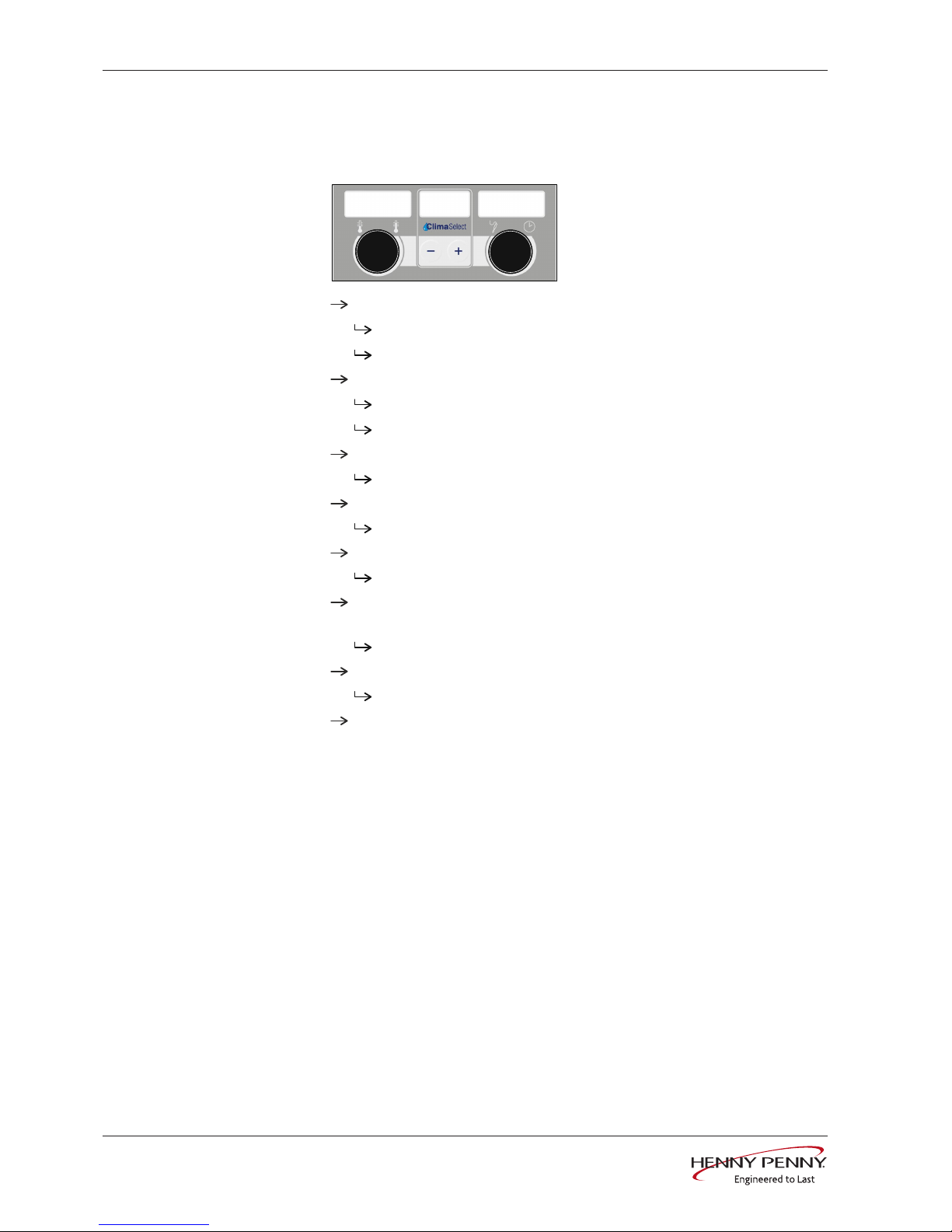

5.1.1 Calling service menu

Overview

Calling service menu

Switch on unit "I"

Turn the

Select

knob to the Settings symbol.

Press the "START STOP" button.

The left display shows "PASS".

The right display flashes "----".

Turn the right knob and select pass word.

Press the "START STOP" button.

Jump to the service menu.

Quit the service menu

Turn the

Select

knob to a different position.

INFORMATION

The password for the service menu is 1967

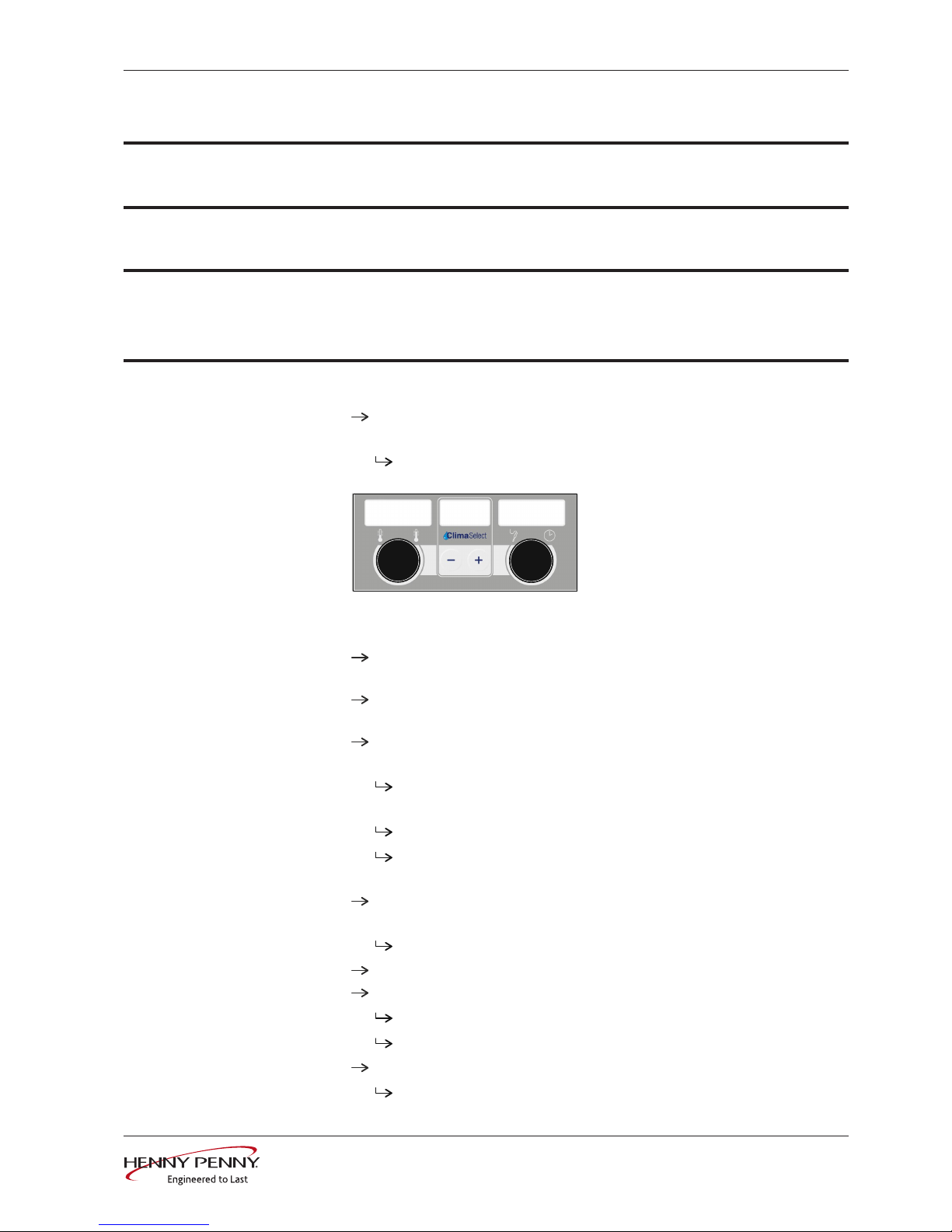

5.1.2 Service menu - overview

Overview

Selecting a menu element

Select the menu item using the left rotary knob.

Left display shows the selected menu item.

Press the "START STOP" button.

Menu item is selected.

10013864-0ASAE-D

Service menu - unit test

13Service instructions

Exit menu item

Press the "STEP" button.

Service menu overview

Designation Description Function

Sof Software display Displays the installed software

bdS Buttons and display test Individual testing of buttons, dials and displays

rEL Relay test Individual control of the relays on the I/O board. Check of the

connected actuators as well as relays.

CLt WaveClean test Option. Test program for automatic cleaning.

CO2 CO2 – calibration Only for gas version. See CO2 – calibration

H2O DynaSteam test Functional test of the DynaSteam steaming unit

CAL 100°C calibration Calibration function for cooking chamber and core temperature sensor

-H2 Drain the water Water draining by means of the connected compressed air on both

water connections.

EEP Export error memory Export error memory to USB stick

ECL Delete the error memory Delete the entire error memory

HCL Delete the HACCP memory Delete the entire HACCP memory

SFL Software update Software update via USB

dIA Display the error memory Display the fault messages from error memory

Con Configuration area Internal configuration level

PEP Export I/O parameters Export I/O parameters from USB stick

PIP Import I/O parameters Import I/O parameters from USB stick

5.2 Software display (Sof)

Description Query about installed software versions.

Overview

SOF1 1

Display Software version

Press the "START STOP" button.

Display on the left shows the software version of the unit.

Display on the right shows the software version of the control

board.

Exit selection

Press the "STEP" button.

10013864-0ASAE-D

Service menu - unit test

14 Service instructions

5.3 Buttons and display test (bdS)

Description Individual check of all buttons, knobs, and indicator lights.

Overview

8888 8888888

Start checking

Turn the left and right knob one after another.

The values on corresponding display changes.

The decimal points of corresponding display go out.

Press the

PLUS

and

MINUS

buttons in succession.

The value in the center display changes.

The decimal points in the middle display go out.

Turn control knob

Selection

fully to the right.

The indicator lights of the 6 positions go off one by one.

Turn the

Select

knob to the

Settings

symbol.

The indicator light of the symbol

Settings

goes off.

Press the "Programs" button.

A signal is output.

Press the button

Ready2Cook

, "START STOP" and "STEP" in

succession.

The corresponding indicator light goes off.

Press the

Fan speed

button several times.

The indicator lights of the 5 positions go off one by one.

Exit selection

Press the "STEP" button.

10013864-0ASAE-D

Service menu - unit test

15Service instructions

5.4 Relay test (rEL)

Description

Separate control of the relay.

Testing the relay.

Testing the connected components.

INFORMATION

Relays K1 and K16 are switched on permanently.

A plurality of relays are switched on simultaneously.

Overview

r1 ONreL

Select relay

Use the left knob to select relay.

Display on the left shows selected relay.

Display on the right shows the switching state of the selected

relay (ON / OFF).

Switch on relay Relay with push-button switch

Press the "START STOP" button.

Relay is switched on.

Display on the right shows the relay count divided by 100.

Switch on the relay long-lasting

Press the "START STOP" button for 3 seconds.

Relay is switched-on permanently until "START STOP" button

is pressed again.

Display on the right shows the switching state of the selected

relay (ON / OFF).

• More relays can be additionally selected and switched on.

Switch on the time-controlled relay

Setting the switch with rotary knob right. Display on the right

shows the set time in seconds.

Press the "START STOP" button.

That is, the relay is switched on for the set time.

Press the "START STOP" button to turn off relay prematurely.

Exit selection

Press the "STEP" button.

10013864-0ASAE-D

Service menu - unit test

16 Service instructions

Relay overview

Relay ConnectorNo. Description Informatio

n

K1 X10 2 Main contactor Q1 230V AC

K1 X11 1 POS A 230V AC

K2 X11 2 POS B 230V AC

K3 Solenoid valve for manual rinse 230V AC

K4 X12 3 Solenoid valve for vapor

quenching K12

230V AC

K5 X12 4 Siphon pump G24 230V AC

K6 X12 5 Backup relay K6 230V AC

K7

Not in use

K8 X17 1 Lift magnet fresh air M8 230V AC

K9 Junior fan left / right direction

K10 X13 1/2 Control for condensation hood Potential

free

K10 Junior fan on/off

K11 X14 2 Cooling fan G7 230V AC

K13

Not in use

K14

Not in use

K15 X1 2 Cooking chamber light 230V AC

K16 X9 1/2 Supply for control panel (MMI) 24V DC

K17 X12 1 Circulating pump G16 230V AC

K18 X31 1 -4 Steaming unit (switched directly,

not via relay)

24V DC

10013864-0ASAE-D

Service menu - unit test

17Service instructions

5.5 WaveClean test (CLe)

Description

INFORMATION

The WaveClean test is included only in the selection, if the unit has Wave-

Clean option features.

WaveClean test program for function check.

Circulating pump

Siphon pump

Solenoid valve for filling water

Door gasket / door area sealing

Overview

0:30CLt

Starting test

Press the "START STOP" button.

Testing the cooking chamber temperature.

Automatic cooling of cooking chamber, if > 70°C.

The right display indicates the remaining time.

Siphon flush and fill.

Discharged by pump G24.

Filling by means of solenoid valve K12.

Recirculating and heating.

The circulating pump G16 is switched on.

Heating the cooking chamber to 55°C.

DynaSteam and siphon flush

DynaSteam steaming unit is switched on.

Anew siphon water exchange.

The test is completed after 30 minutes.

Abort test

Press the "START STOP" button.

Automatic flushing of the siphon and test abortion.

Exit selection

Press the "STEP" button.

10013864-0ASAE-D

Service menu - unit test

18 Service instructions

5.6 DynaSteamTest (H2O)

Description The DynaSteam test allows the function test of the DynaSteam

steaming unit.

Calibration of the steaming unit is not possible / necessary.

Requirement

Access to the water supply pipe in the cooking chamber.

Left hooking-in point or tray trolley removed.

Air baffle in the cooking chamber unlocked and unfolded.

Overview

140 0H20

Starting water test

Press the "START STOP" button.

Display on the left shows "INI".

An automatic pre-purge begins.

Setting the amount of water with left rotary knob

Display on the left shows the amount of water in ml.

Press the "START STOP" button.

Control of the DynaSteam steaming unit.

The water runs from the water supply pipe into the cooking

chamber.

Check the water quantity Collect the water from the supply pipe with a measuring container.

Starting water test.

After the predetermined amount of water has gone through, the

steaming unit stops automatically.

Compare amount of water with the set value. A deviation of +10% is within tolerance.

Exit water test.

Press the "STEP" button.

INFORMATION

Dual-chamber units (20.x) have two DynaSteam steaming units with parallel

control. The specified quantity of water refers to one chamber. Perform Dy-

naSteam test for each chamber separately.

10013864-0ASAE-D

Service menu - unit test

19Service instructions

5.7 100°C + KT calibration (CAL)

Description

Calibration for cooking chamber sensor and core temperature

sensor.

Testing the calibration.

Performing the calibration.

The cooking chamber sensor and core temperature sensor calibration

is performed in one step.

INFORMATION

The units are factory calibrated. Recalibration is required only in exceptional

cases.

5.7.1 Check calibration - single chamber 6.x / 10.x

Requirement Calibrated temperature digital meter.

The temperature in the cooking chamber is < 100°C.

Fixing the internal core temperature sensor and temperature

sensor from the external instrument in the cooking space.

For this purpose, use a grill.

Align the sensor tips upward in order to avoid measuring

errors.

Overview

96.6 -0.5CAL

Testing the calibration

Press the "START STOP" button.

The cooking chamber is heated to 100°C.

Display on the left shows the current temperature in the

cooking chamber.

Wait until the display to the left indicates 100 °C (± 1°C).

Compare the left display with temperature on the external

meter.

The external meter must indicate a temperature between 99°C

- 99.5°C.

If the value is within the range, terminate checking.

Press the "START STOP" button.

If the value is outside the range, calibration is carried out.

Continue with calibration (see „5.7.3 Calibrate cooking

chamber sensor - single chamber unit 6.x / 10.x‟, Page 22).

10013864-0ASAE-D

Service menu - unit test

20 Service instructions

5.7.2 Check calibration - double chamber unit 20.x

INFORMATION

Two-chamber appliances (20.x) are equipped with two cooking chamber sen-

sors.

Separation of the two

chambers required

INFORMATION

A separation into two regions (chambers) is required for temperature measure-

ments. This can be achieved, for instance, by placing a baking sheet on the

middle shelf of the tray trolley.

Prerequisite Two calibrated digital measurement devices or two-channel

measurement device.

The temperature in the cooking chamber is < 100°C.

Fix the temperature sensor of the two external measurement

devices in the middle of the top and bottom chambers in the

cooking chamber respectively. Fix the core temperature sensor in

the middle of the bottom chamber.

Use a grill rack for this.

Point the sensor tips upward in order to prevent measurement

errors.

Overview

96.6 -0.5CAL

Checking the calibration

Press the "START STOP" button.

The cooking chamber is heated up to 100°C.

Display on the left shows the current temperature in the top

cooking chamber 1.

Display on the right shows the current temperature in the

bottom cooking chamber 2.

Wait until the display to the left and right indicate 100°C (± 1°C).

Compare the left display with temperature on the top external

meter.

Compare the right display with temperature on the bottom

external meter.

Both external meters must indicate a temperature between

99°C - 99.5°C.

If the values are within the range, terminate checking.

Press the "START/STOP" button.

10013864-0ASAE-D

Service menu - unit test

21Service instructions

If one of the values is outside of the range, calibration must be

done.

Continue with calibration (see „5.7.4 Calibrate cooking

chamber sensor - double chamber unit 20.x‟, Page 23).

10013864-0ASAE-D

Service menu - unit test

22 Service instructions

5.7.3 Calibrate cooking chamber sensor - single chamber unit 6.x / 10.x

Requirement

Perform calibration check

and do not turn off the unit.

(see „5.7.1 Check calibration - single chamber 6.x / 10.x‟, Page

19)

Left display on the left shows 100°C.

Display on the right shows the stored offset value.

Overview

96.6 -0.5CAL

Calibration

Adjusting offset value with a rotary knob on the right.

Allow 10 minutes adaptation time to pass.

The external meter must indicate a temperature between 99°C

- 99.5°C.

If necessary, adjust offset value with a rotary knob on the right.

Allow 10 minutes adaptation time to pass.

If the value is within the range, store calibration.

Storing calibration

Press the "START STOP" button.

Termination of calibration and storage of offset value.

Automatic calibration of core temperature sensor.

Aborting calibration

Press the "STEP" button.

The calibration is terminated.

Exit calibration

Press the "STEP" button.

10013864-0ASAE-D

Service menu - unit test

23Service instructions

5.7.4 Calibrate cooking chamber sensor - double chamber unit 20.x

INFORMATION

Two-chamber appliances (20.x) are equipped with two cooking chamber sen-

sors.

Separation of the two

chambers required

INFORMATION

A separation into two regions (chambers) is required for temperature measure-

ments. This can be achieved, for instance, by placing a baking sheet on the

middle shelf of the tray trolley.

Prerequisite Execute

Check calibration

and do not switch appliance off.

(see „5.7.2 Check calibration - double chamber unit 20.x‟, Page

20)

Display to the left and right indicate 100°C.

Overview

-0.5 -0.5CAL

Calibration Press the

Ready2Cook

button to switch between the display of

cooking chamber temperature, offset value, and PWM value.

Press the Ready2Cook button until the display of the offset

values appears.

Adjust the offset value for top cooking chamber 1 with rotary knob

on the left.

Adjust the offset value for bottom cooking chamber 2 with rotary

knob on the right.

Press the Ready2Cook button until the display of the cooking

chamber temperatures appears.

Let 10 minutes adjustment time elapse.

Both external meters must indicate a temperature between

99°C - 99.5°C.

If necessary, adjust offset anew with a rotary knob on the left and/

or right.

Let 10 minutes adjustment time elapse.

If the values are within the range, store calibration.

Saving the calibration

Press the "START/STOP" button.

Termination of calibration and storage of offset values.

Automatic calibration of core temperature sensor.

Canceling the calibration

Press the "STEP" button.

The calibration ends.

10013864-0ASAE-D

Service menu - unit test

24 Service instructions

Exiting the calibration

Press the "STEP" button.

10013864-0ASAE-D

Service menu - unit test

25Service instructions

5.8 Draining water (-H2)

Description Water drainage removes water residue from the unit to prevent frost

damage during transport and idle period.

Requirement

Both water connections are connected to compressed air.

The pressure may not exceed 6 bar.

The cooking chamber temperature is < 130°C.

Overview

120°C 02:00-H2

Start water drainage

Press the "START STOP" button for 3 seconds.

Start automatic water drainage.

Display on the left shows cooking chamber temperature.

Display on the right shows the remaining time.

Aborting water drainage

Press the "START STOP" button.

Exit water drainage

Press the "STEP" button.

5.9 Exporting error memory (EEP)

Description Export function of the error memory on a USB stick.

Requirement

USB flash drive is in the USB interface.

Overview

USb

---EEP

Exporting data

Press the "START STOP" button.

Left display shows "USb".

The right display shows "---" continuously.

The right display shows "

End

" after complete transmission.

The right display shows "no" when USB stick was not detected.

Exit selection

Press the "STEP" button.

10013864-0ASAE-D

Service menu - unit test

26 Service instructions

5.10 Deleting the error memory (ECL)

Description Deleting the entire error memory.

Overview

CLr

rdyECL

Deleting the memory

Press the "START STOP" button for 3 seconds.

The right display shows "rdy".

Exit selection

Press the "STEP" button.

5.11 Software update (SFL)

Description

Upgrade of the software using the USB interface.

Overview

USb

SFL

no

Image: USB stick or software update not detected

USb

SFL

Image: USB stick with software update detected

---

Image: Software update active - do not turn off unit

Perform update

Implementation as described (see „6 Software update‟, Page

32).

Press the "START STOP" button for 3 seconds.

Update begins.

The middle display shows "---".

The update can take up to 20 minutes to complete.

Automatic restart of the software.

10013864-0ASAE-D

Loading...

Loading...