Henny Penny GSC-115 Gas, ESC-115 Electric User Manual

PROJECT QUANTITY ITEM NO

SmartCombi™ Combi-steamer

Electric and gas

General Information

Henny Penny SmartCombi combi

ovens use moist heat and dry heat,

either separately or in combination,

to produce the ideal cooking

conditions for a wide variety of foods.

Four basic cooking modes employ

a variety of built-in functions in

different ways.

• Steaming/Moist heat:

86-266°F (30-130°C)

Low and high-temperature

steaming.

• Convection cooking/Dry heat:

SmartCombi model ESC-115

The ESC/GSC-115 has a capacity

of (10) full-size steam table pans

2 ½ in. (65 mm) or (10) Crosswise

Plus pans and grids.

Standard Features

• Patented Advanced Steam

Technology for effective steam

generation without boilers.

• ClimaSelect climate control allows

the selection of humidity levels

between 0% and 100% relative

humidity. ClimaMonitor feature

measures and maintains selected

level automatically.

• Digital control panel features easyto-read LED displays and icons.

Operators can choose automatic

cooking from pre-programmed

menu items or select and input

cooking parameters manually.

• Simple CombiDial control—rotate

Electric: 86-572°F (30-300°C)

Gas: 86-482°F (30-250°C)

Active humidity reduction

• Combination/Dry and moist heat:

86-482°F (30-250°C)

Individual or automatic humidity

control between 0 and 100% RH.

• Rethermalizing/Dry and moist heat:

86-356°F (30-180°C)

Special fan speed function and

banqueting programs.

to select, push to confirm and start.

• Temperatures can be displayed in

either °F or °C. Operations and

service diagnostics programs offer

a choice of languages.

• Auto-reverse fan for fast, even

cooking throughout the cabinet.

• WaveClean™ self-cleaning system

significantly reduces water and

detergent consumption.

• Filterless grease extraction.

• Rethermalizing and plated banquet

system utilizes specific settings

including fan speed function for

easy, high quality banquet cooking.

• Auto-retractable hose shower for

MODEL ESC-115

electric

GSC-115 gas

Henny Penny bridges the gap

between boiler and boilerless combis

with patented Advanced Steam

Technology.™ This system

introduces large amounts of steam

into the cooking cabinet quickly

without the deliming and maintenance

issues of a boiler.

Operator can select humidity levels

from 0-100% relative humidity. Digital

humidity control continuously

measures the humidity level in the

cabinet and maintains the selected

level by automatically adding steam

or venting excess humidity. The

SmartCombi is fully programmable

and includes a wide range of preprogrammed menu selections for fully

automated cooking.

Units include a multi-sensor core

temperature probe for automatic

probe cooking.

Lengthwise rack available for either

crosswise or lengthwise loading of

standard steam table pans.

easy, quick rinsing.

• Seamless interior cabinet of

corrosion-resistant chrome nickel

steel. Exterior made from 1 mm

chrome nickel stainless steel.

• Full seal door with triple-pane glass.

Options, accessories

Stands and cabinets

Stacking kit

Two-stage safety door lock

Alternative voltages

Chicken grids

Marine version

Henny Penny Corporation

PO Box 60 Eaton OH 45320 USA

+1 937 456.8400 800 417.8417

+1 937 456.8434 Fax 800 417.8434 Fax

www.hennypenny.com

© 2007Henny Penny Corporation, Eaton, OH 45320 USA Revised 8/24/07

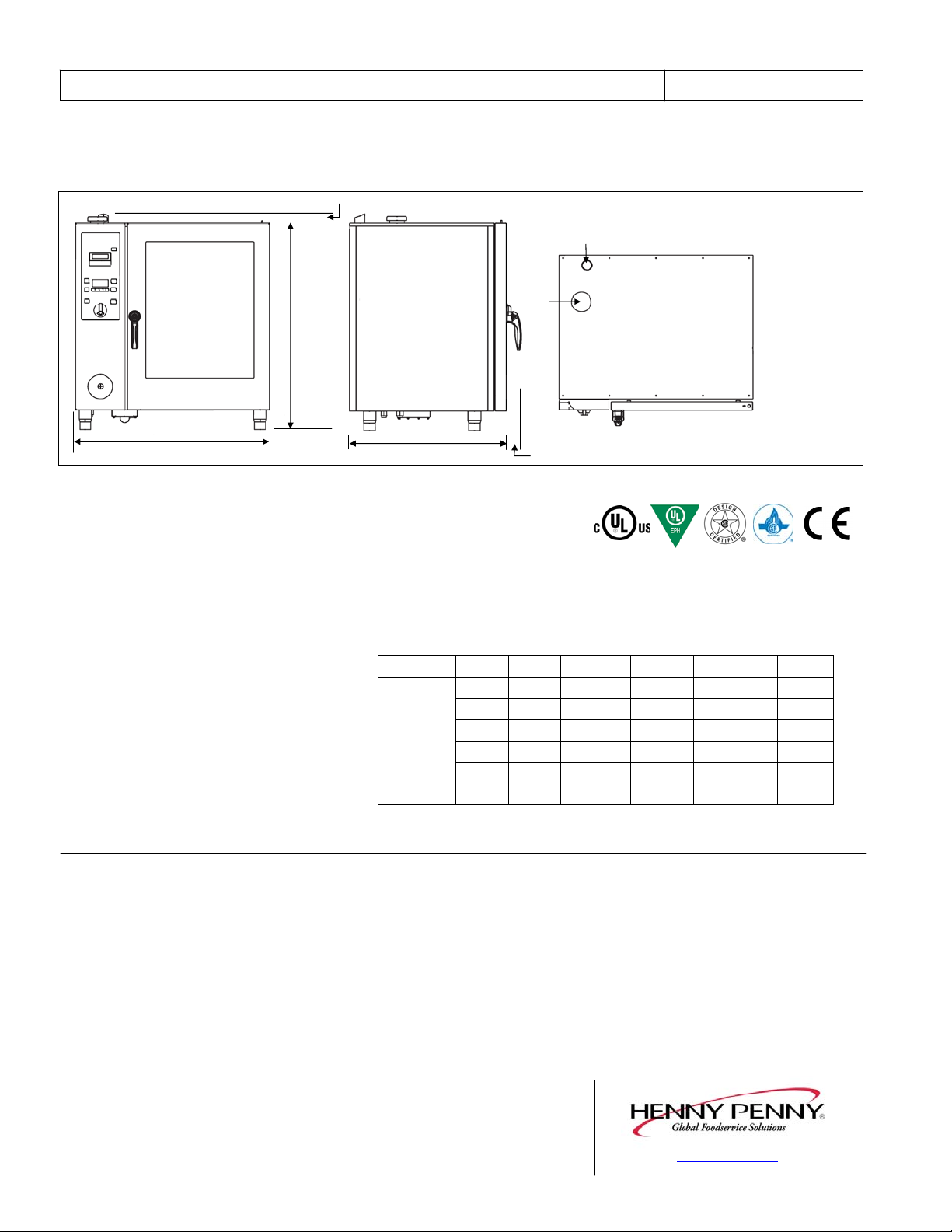

PROJECT QUANTITY ITEM NO

MODEL ESC-115 electric

GSC-115 gas

1 ¾ in. (44 mm) to top of stack

41 ¾ in.

(1060 mm)

39 ¼ in. (997 mm)

Dimensions

Height: 41 ¾ in. (1060 mm)

Width: 39 ¼ in. (997 mm)

Depth: 31 ½ in. (799 mm)

Required Clearances

Left: 20 in. (500 mm) service access:

Right: 2 in. (50 mm) air flow

Back: 2 in. (50 mm) air flow, utility connections:

Front: 28 in. (700 mm) door open

Crated dimensions

Length: 42 ½ in. (1080 mm)

Depth: 37 7/8 in. (962 mm)

Height: 50 ½ in. (1283 mm)

Volume: 47 cu. ft. (1.33 m³)

Net weight: 355 lbs. (160 kg)

Crated weight: 430 lbs. (195 kg)

Pan capacity

10 full-size steam table pans, 2 ½ in. (65 mm)

crosswise or lengthwise.

10 Crosswise Plus pans and grids.

3 standard chicken grids, 18 chickens per load.

6 Crosswise Plus chicken grids, 36 chickens per load.

SmartCombi™ Combi-steamer

Electric and gas

E

Utility locations

A B

C

D

31 ½ in. (799 mm)

Water connections

¾ in. standard cold water connection

¾ in. soft water connection

2 in. (50 mm) drain

Power

Electric units: Connected load 16.5 kW

Gas units: Output:

Electrical Volts Phase Cycle/Hz Watts Amps Wire

Electric

units

Gas units 120 1 60 800 N/A 1NG

Connection: R 3/4" NPT

external thread

Options: Natural Gas or LP

208 3 60 15900

240 3 60 15900 41.8 3+G

400 3 50/60 15900 23.6 3NG

440 3 60 15900 22.0 3+G

480 3 60 15900 20.3 3+G

Add 3 in. (76 mm) for door handle

Laboratory certifications

61500 BTU/hr

A Electrical

B Gas line

C Water connections

D Drain

E Exhaust air

F Exhaust steam

47.6 3+G

Bidding Specifications

• Provide Henny Penny Model ESC-115

(electric) or GSC-115 (gas) combination

oven/steamer. Models enable the selection

of convection (hot air), gentle or regular

steam or a combination of these cooking

modes.

• Units shall have an LED clear-text display

that provides optimal viewing of programs,

time, temperature and other data.

• Units shall have a condensate drip pan with

central direct drain.

• Units shall have patented Advanced Steam

Technology.

• Units shall have a cabinet fan with two

speeds, as well as two rotation directions, to

enable autoreverse operations.

• Units shall have “AutoShower,” integrated

flushing function.

• Units shall have “WaveClean” automatic selfcleaning system.

• Units shall have seamless stainless steel

cooking chamber, a hygiene-supporting door

with isolated window, integrated door

contact switch, electrical door lock and

pluggable door seal. Unit also will have 0%

to 100% humidity control within the cooking

chamber.

• Units shall have 572°F maximum operating

temperature using hot air convection with

accurate temperature controls at all

operating temperatures.

• Units shall accommodate up to (10) full-size

steam table pans, 2 ½ in. deep.

Continuing product improvement may subject specifications to change without notice.

www.hennypenny.com

© 2007Henny Penny Corporation, Eaton, OH 45320 USA Revised 8/24/07

Loading...

Loading...