Page 1

TECHNICAL

MANUAL

Wendy’s Evolution Elite™ Gas Open Fryer

MODEL

EEG-252

EEG-253

EEG-254

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

Page 2

Page 3

SECTION 1. TROUBLESHOOTING

Model EEG- 252, 253, 254

1-1. INTRODUCTION

1-2. SAFETY

This section provides troubleshooting information in the form

of an easy to read table.

If a problem occurs during the rst operation of a new fryer,

recheck the installation per the Installation Section of this

manual.

Before troubleshooting, always recheck the operation

procedures per Section 3 of this manual.

Where information is of particular importance or safety related,

the words DANGER, WARNING, CAUTION, and NOTICE

are used. Their usage is described below.

SAFETY ALERT SYMBOL is used with DANGER,

WARNING, or CAUTION which indicates a personal

injury type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICATES AN IMMINENTLY

HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, WILL RESULT IN DEATH OR SERIOUS

INJURY.

3Oct 2014

Page 4

Model EEG- 252, 253, 254

1-3. TROUBLESHOOTING

To isolate a malfunction, proceed as follows:

1. Clearly dene the problem (or symptom) and when it

occurs.

2. Locate the problem in the Troubleshooting table.

3. Review all possible causes. Then, one-at-a-time work

through the list of corrections until the problem is solved.

4. Refer to the maintenance procedures in the Maintenance

Section to safely and properly make the checkout and repair

needed.

If maintenance procedures are not

followed correctly, injuries and/or

property damage could result.

4Oct 2014

Page 5

7-1. TROUBLE SHOOTING

(Continued)

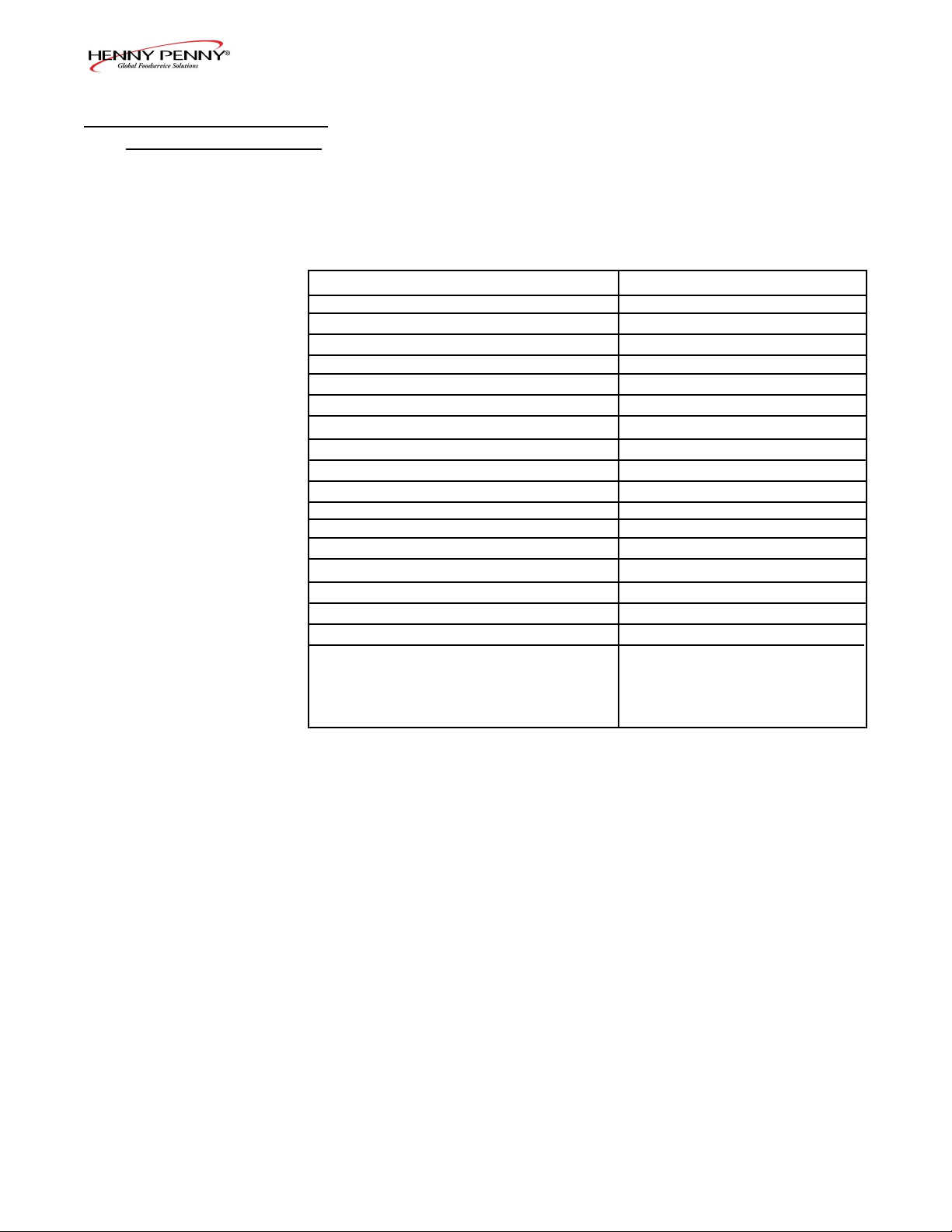

Problem Cause Correction

POWER switch ON

• Open circuit • Plug fryer in

but fryer completely

inoperative

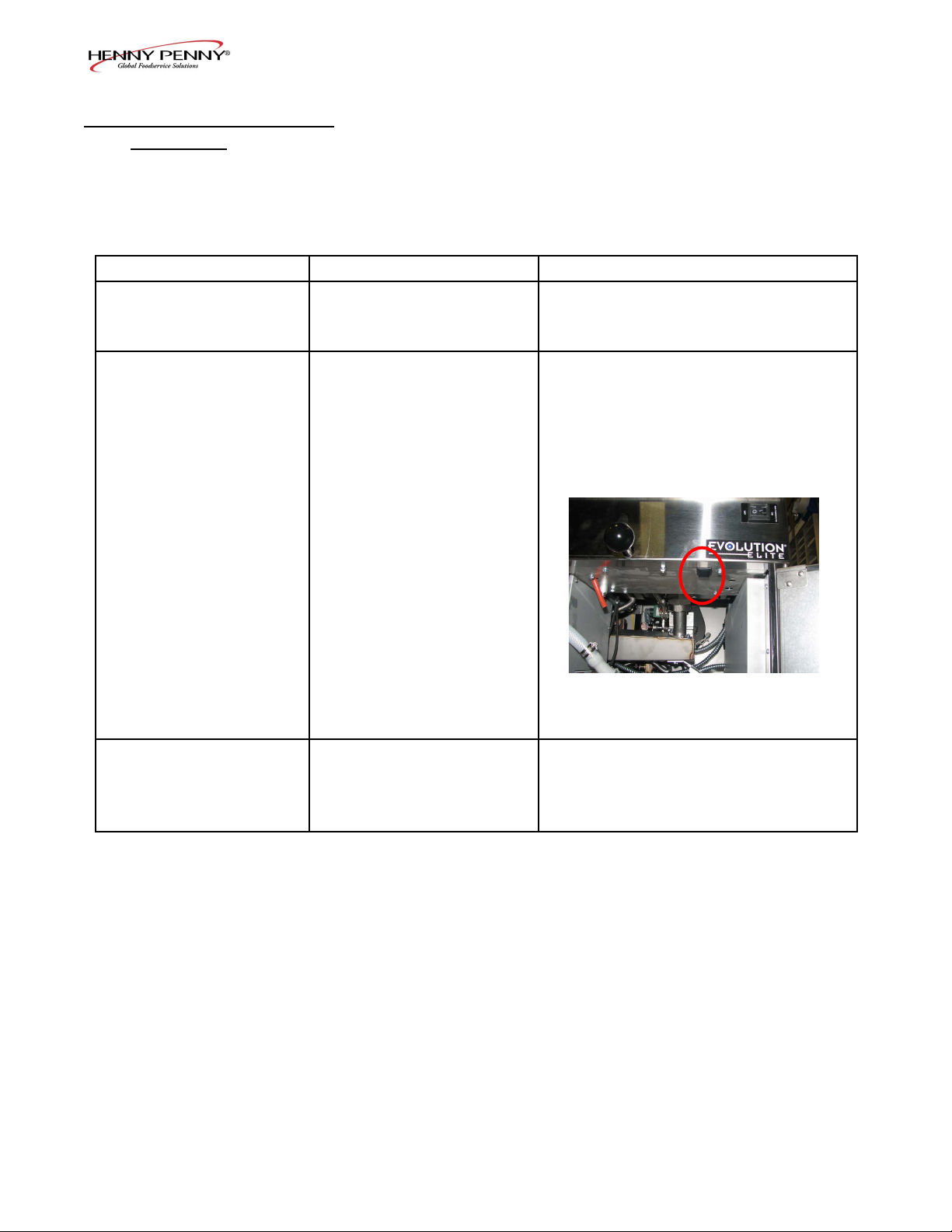

“E-10”

• Hight limit

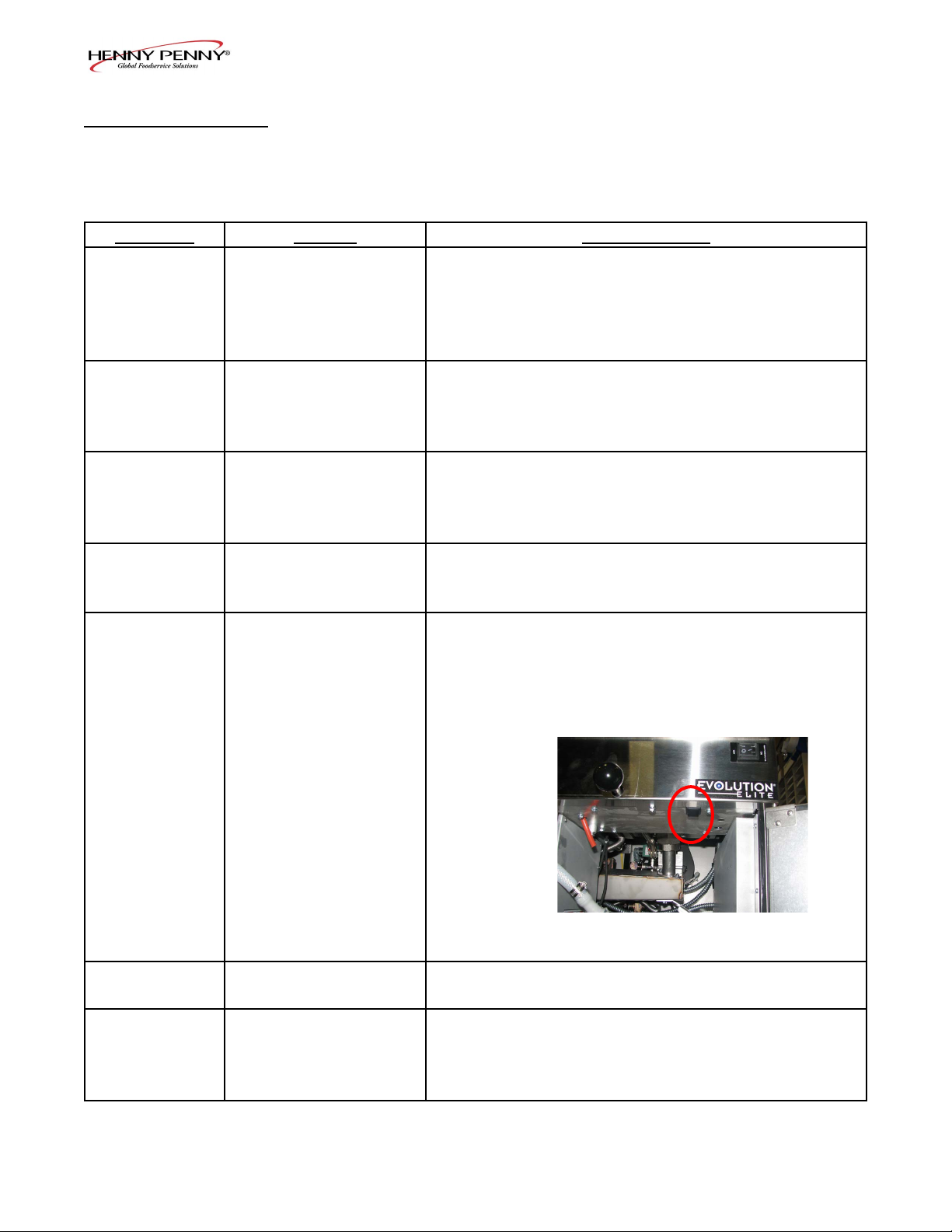

Model EEG- 252, 253, 254

• Check breaker or fuse at supply box

Let unit cool down (15-20 minutes),

push up on metal reset button under

right side of the controls; if high limit

does not reset, high limit must be

replaced

Vat is under-lled • JIB is low or empty

• JIB oil line is clogged or

collapsed

• Filter pan needs cleaned

5Oct 2014

• Fill the JIB

• Check JIB line

• Clean lter pan and change paper or

pad

Page 6

7-1. TROUBLE SHOOTING

(Continued)

Problem Cause Correction

Oil foaming or boiling over

top of vat

Oil will not drain from vat • Drain valve clogged with

Filter motor runs but pumps

oil slowly

Bubbles in oil during entire

ltering process

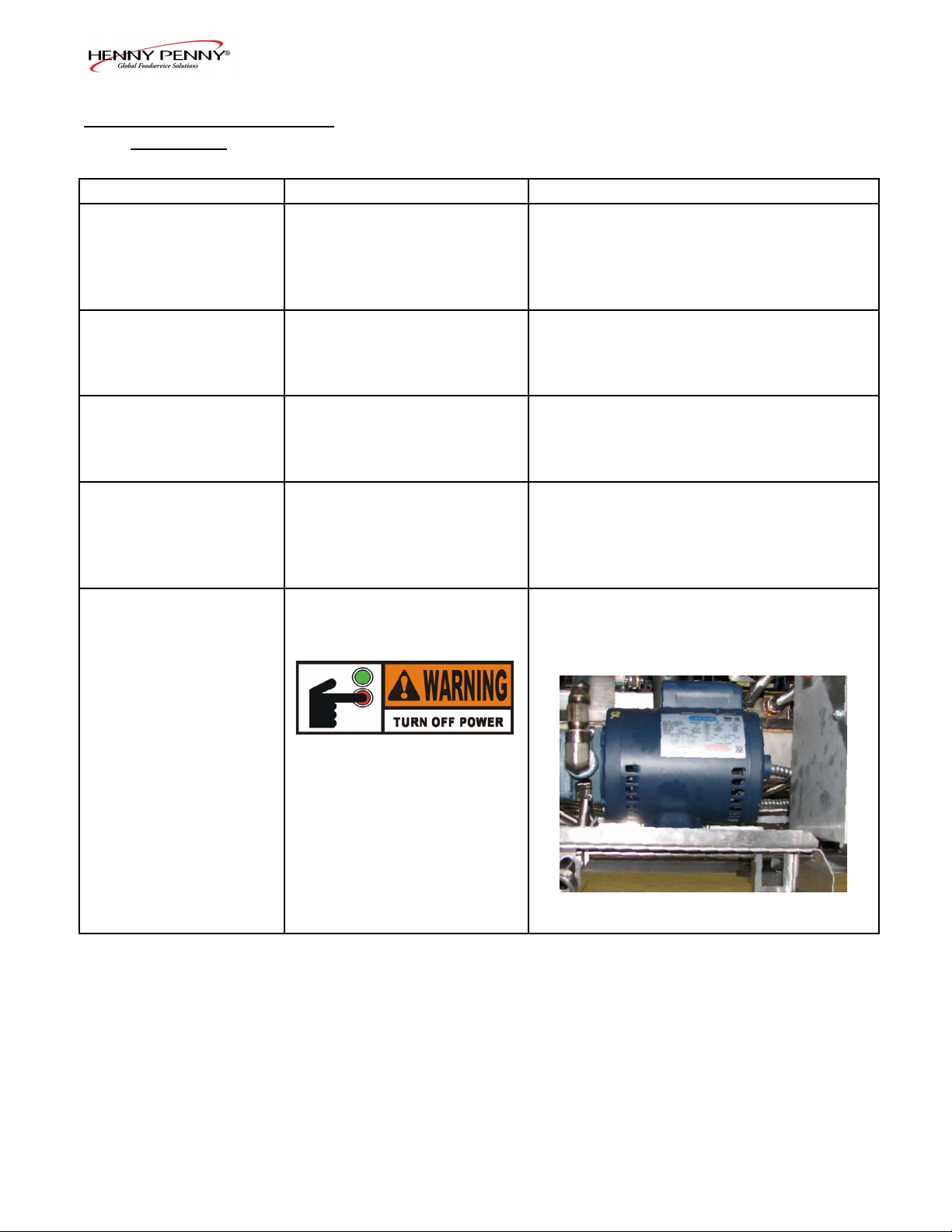

Filter motor will not run • The thermal reset button on

• Water in oil

• Improper or bad oil

• Improper ltering

• Improper rinsing after

cleaning the vat

crumbs

• Drain trough clogged

• Filter line connections loose

• Filter paper or pad clogged

• Filter not reassembled

correctly

• Filter pan not completel

engaged

• Filter pan clogged

• Damaged O-ring on lter line

receiver on fryer

the rear of the pump motor is

tripped

Model EEG- 252, 253, 254

• Drain and clean oil

• Use recommended oil

• Refer to ltering procedures

• Clean and rinse vat and then dry thoroughly

• Open valve, force cleaning brush through

drain

• Remove right side panel and remove plug

from end of trough and clean trough

• Tighten all lter line connections

• Change lter paper or pad

• Refer to assembly instructions on inside door

• Make sure lter pan return line is pushed

completely into the receiver on the fryer

• Clean pan and change paper or pad

• Change O-ring

• Allow time for the motor to cool and

then, using a screwdriver, press hard

against the button until it clicks

To prevent burns caused by

splashing shortening, turn

the unit’s POWER switch

to the OFF position before

resetting the lter pump

motor’s manual reset

protection device.

6Oct 2014

Page 7

Model EEG- 252, 253, 254

1-4. ERROR CODES

In the event of a control system failure, the digital display

shows an error message. The message codes are shown in the

DISPLAY column below. A constant tone is heard when an error code is displayed, and to silence this tone, press any button.

DISPLAY CAUSE CORRECTION

“E-4”

• Control board

overheating

Turn switch to OFF position, then turn switch back

to ON; if display shows “E-4”, the control board is

getting too hot; check the louvers on each side of

the unit for obstructions

“E-5”

• Oil overheating

Turn switch to OFF position, then turn switch back

to ON; if display shows “E-5”, the heating circuits

and temperature probe should be checked

“E-6A”

• Temperature probe

open

Turn switch to OFF position, then turn switch back

to ON; if display shows “E-6A”, the temperature

probe should be checked

“E-6B”

• Temperature probe

shorted

Turn switch to OFF position, then turn switch back

to ON; if display shows “E-6B”, the temperature

probe should be checked

“E-10”

• Hight limit

Let unit cool down (15-20 minutes), push up on

metal reset button under right side of the controls;

if high limit does not reset, high limit must be

replaced

“E-15” • Drain switch Make sure drain knob is completely pushed-in; if E-15

persists, have drain switch checked

“E-18-A”

“E-18-B”

“E-18-C”

• LH level sensor open

• RH level sensor open

• Both sensors open

Turn switch to OFF position, then turn switch back to

ON; if display still indicates a failed sensor, have the

connectors checked at the control board; have sensor

checked & replace if necessary

7Oct 2014

Page 8

1-4. ERROR CODES (Continued)

Model EEG- 252, 253, 254

“E-20-A”

“FAN SENSOR

STUCK

CLOSED”

“E-20-B”

“NO DRAFT”

“CHECK FAN”

“E-20-D”

“IGNITION”

“FAILURE”

• Pressure Switch

failure

• Wiring problem

• I/O board failure

• Pressure switch

failure/ hose loose

• Draft fan failure/ low

voltage

• Flue or hood

obstruction

• Failure to ignite/ no

ame sense

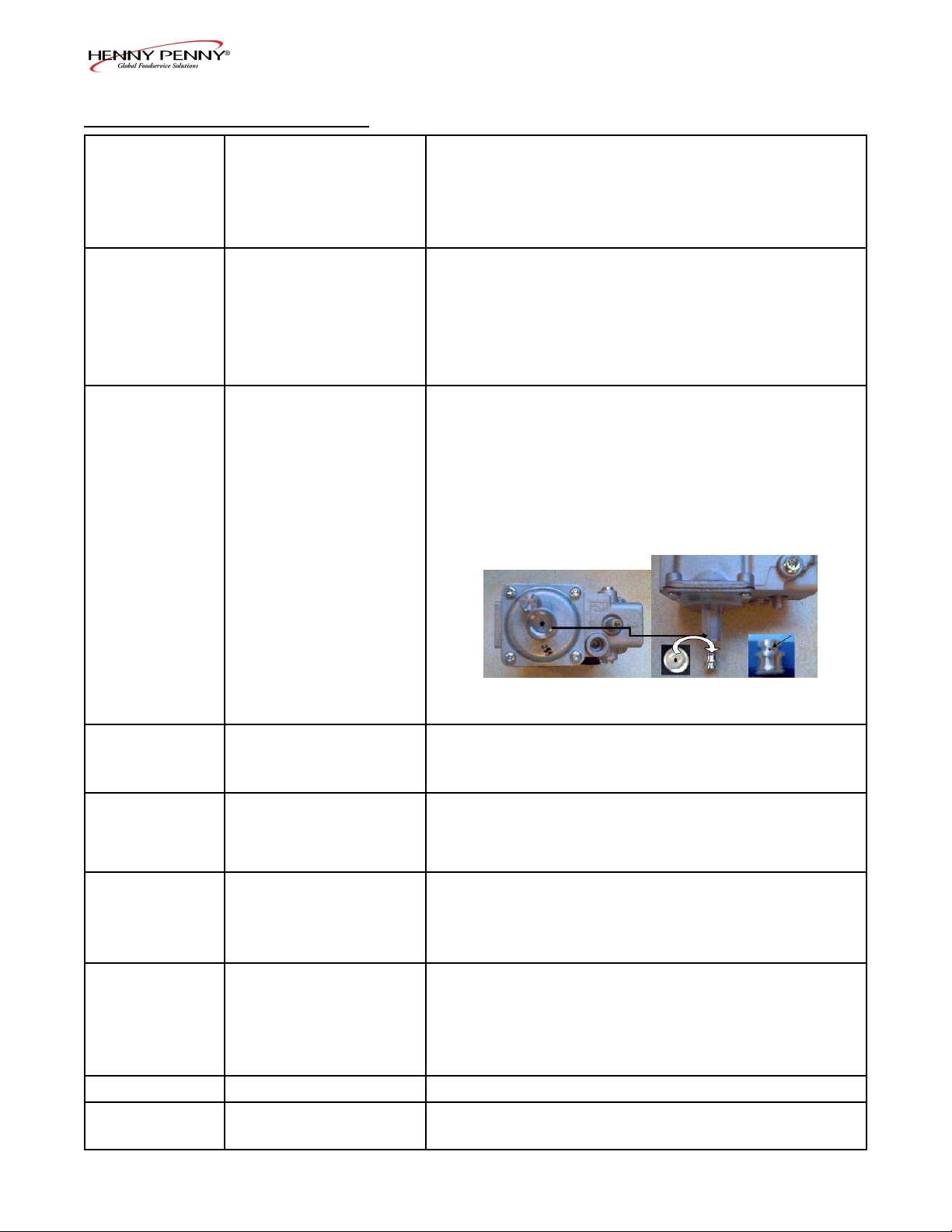

• Plugged atmospheric

equalization hole

in regulator cap

resulting in pilot

ame slowly fading

• If fan is not running, have pressure switch

checked; should be open circuit if no air

pressure

• If fan is running, wiring error, or relay on I/O board

closed

• Press power button to vat off and back on again,

if E-20-B persists, have pressure switch checked;

should be open circuit if no air pressure; make sure

hose is connected to fan and pressure switch

• Have draft fan checked; low voltage going to fan

• Check the fryer ue and hood system for obstructions

• Press power button to vat off and back on again, if

E-20-D persists, check gas line connections; check

gas shutoff valve; check ignition module; check gas

valve; check ame sensor gap; check gas valve, and

check ignition module wiring

• Clear obstruction from hole

“E-21”

“E-22”

“NO HEAT”

“CHECK GAS

VALVE”

“E-41 “ / “E-46”

“E-47”

“E-48”

“E-54-C”

• Slow heat recovery • Have a certied service technician check the fryer for

correct voltage to the unit; have heat circuit checked;

have unit checked for loose or burnt wire

• Burner not igniting

• Have gas valve and heat circuit checked

• Programming failure • Press power button to vat off and back on again,

if any of the error codes, have the controls re-

initialized; if error code persists, have the control

board replaced

• Analog converter

chip or 12 volt

supply failure

• Press power button to vat off and back on again,

if “E-47” persists, have the I/O board, or the

PC board replaced; if speaker tones are quiet,

probably I/O board failure; have the I/O board

replaced

• Input system error

• Temperature input

error

• Have PC board replaced

• Turn switch to OFF, then back to ON; have

control PC board replaced if “E-54C” persists

8Oct 2014

Page 9

1-4. ERROR CODES (Continued)

Model EEG- 252, 253, 254

“E-60”

“FILTER IN USE”

“E-70C”

“E-83-A”

“E-83-B”

“E-83-C”

“E-83-D”

“E-83-E”

“E-83-J”

“E-83-R”

“E-93-1”

“24 VDC SUPPLY

TRIPPED”

• AIF PC board not

communitcating with

control PC board

• Press power button to turn vat off, wait 15 seconds,

and turn back on again. If “E-60” persists, have

connector between the PC boards checked; replace

AIF PC board or control PC board, if necessary

• Drain valve jumper

wire missing or

• Have the jumper wire checked on the PC board at

drain switch interlock position

disconnected

• Pressure too high • Check lter system in Vat #1

• Pressure too high

• Check lter system in Vat #2

• Pressure too high • Check lter system in Vat #3

• Pressure too high

• Check lter system in Vat #4

• Pressure too high • Check lter system in Vat #5

• Bulk JIB FILL

• Check JIB ll valves

switch ON when

pressure too high

• Bulk Dispose switch

ON when pressure

• Check Bulk Dispose quick-disconnect behind

fryer

too high

• Autolift motor

malfunction or

• If AutoLift feature is not operating, have each of the

AutoLift motors checked.

failure

9Oct 2014

Page 10

SECTION 2. INFO & FILTER BUTTON STATS

Model EEG- 252, 253, 254

2-1. INFO BUTTON STATS

Actual Oil Temperature

1. Press and the actual oil temperature shows in the

display, for each vat.

Set-point Temperature

1. Press twice and SP shows in the display, along with

the set-point (preset) temperature of each vat.

Recovery Information for each Vat

1. Press 3 times and REC shows in the left display and

the recovery time that oil temperature went from 250°F

(121°C) to 300°F (149°C) shows in the right display. For

example, means it took 5 minutes and

REC 5:30

30 seconds for the oil temperature to recover to 300°F

(149°C) from 250°F (121°C).

If no buttons are pressed within 5 seconds in

any of stats modes, the controls revert back to

normal operation.

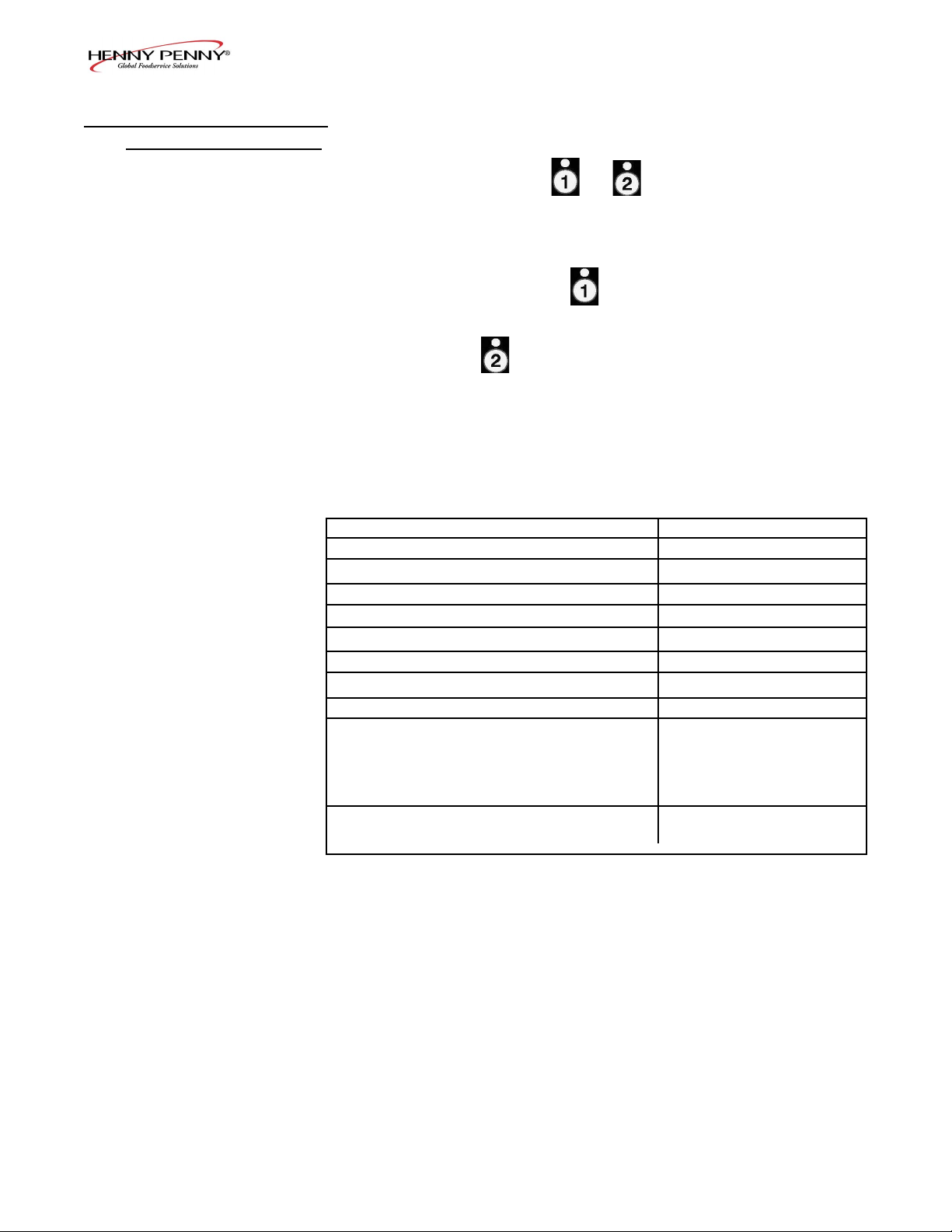

2-2. FILTER BUTTON STATS

Cook Cycles Remaining before Filtering

1. Press and release either button and the left display

shows “COOKSREMAINING” and the right display shows

the number of cook cycles before the next auto lter. For

example.

REMA INING

3 6

means after 3 more cook cycles on the left vat, the controls

asks the operator if they are ready to lter or not. But, 6

more cook cycles remain on the right vat.

Time and Date

2. Press either twice and ‘FILTERED” shows in the

diplays, along with the time-of-day and date of the last

lter.

Filter Pad Hours

3. Press either three times and ‘FLTR PAD XX HRS”

shows in the diplays.

10Oct 2014

Page 11

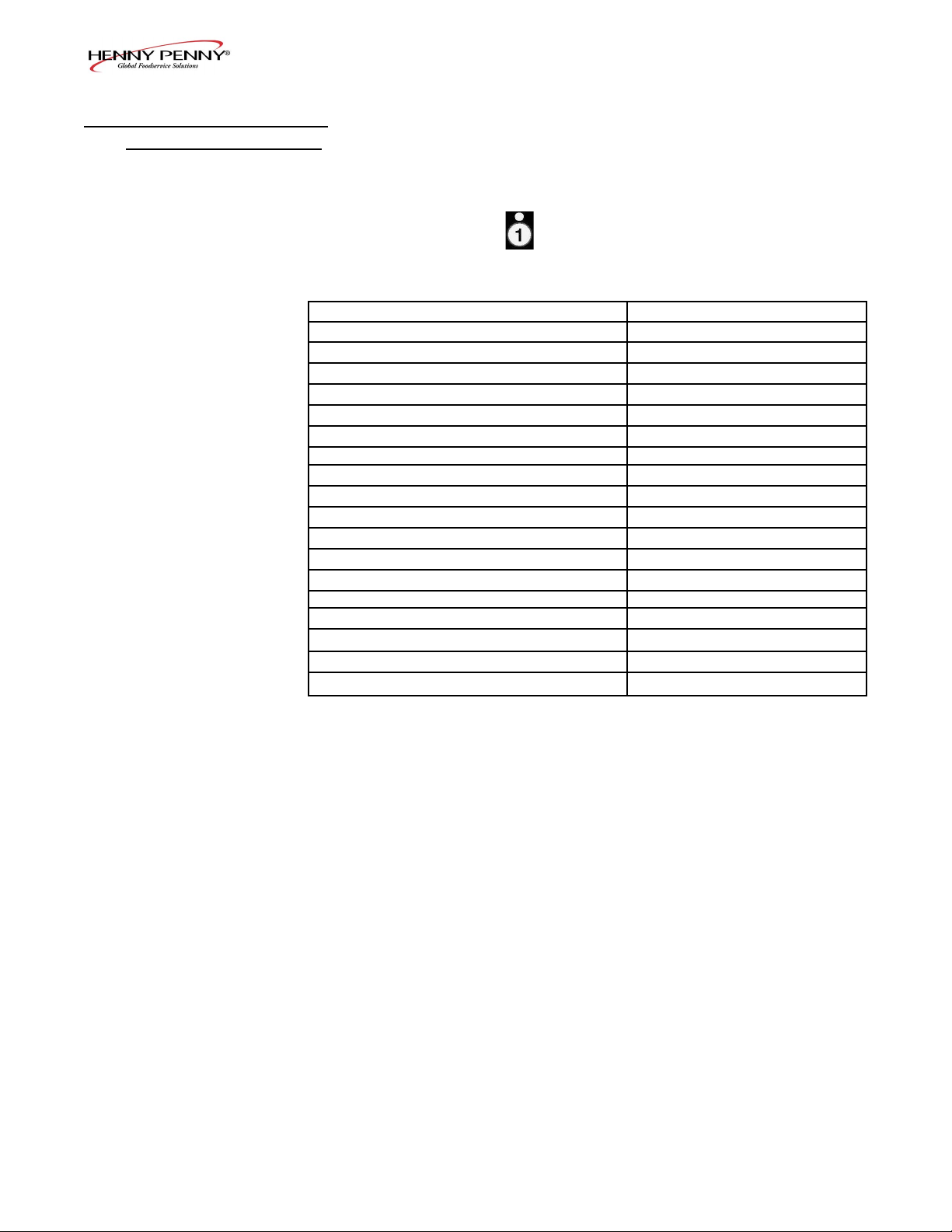

SECTION 3. INFORMATION MODE

This historic information can be recorded and used for

operational and technical help and allows you to view the

following:

• 1. E-LOG • 9. CPU TEMP

• 2. LAST LOAD • 10. COMMUNICATION INFO

• 3. DAILY STATS • 11. ANALOG INFO

• 4. OIL STATS • 12. ACTIVITY LOG

• 5. REVIEW USAGE • 13. OIL LEVELS

• 6. INPUTS • 14. PUMP VALVE INFO

• 7. OUTPUTS • 15. AIF INFO

• 8. OIL TEMP

Not all Information Mode functions are discussed in this

section. To ensure proper operation of fryer, please consult

Henny Penny Corp. before changing any of these settings. For

more information on these functions, contact Technical Support

at 1-800-417- 8405, or 1-937-456-8405.

Model EEG- 252, 253, 254

3-1. INFORMATION MODE

DETAILS

1. E-LOG (error code log)

Press and buttons at the same time and “*INFO

MODE*” shows in the display, followed by “1. E-LOG”.

Press and to exit Information Mode at any time.

Press ▼ and “A. (date & time) *NOW* show in displays.

This is the present date and time.

Press ▼ and if a error was recorded, “B. (date, time, and

error code information)” shows in display. This is the latest

error code that the controls recorded.

Press ▼ and the next latest error code information can be seen.

Up to 10 error codes (B to K) can be stored in the E-LOG

section.

11Oct 2014

Page 12

Model EEG- 252, 253, 254

3-1. INFORMATION MODE

DETAILS (Continued)

2. LAST LOAD (Information on recent cook cycles)

Press ► and “2. LAST LOAD” show in displays.

Press a timer button or for the product you want to

view the cook data and the LED ashes.

Press ▼ button to start viewing the cook data.

For example, if the left LED is ashing, “PRODUCT

FRY L1” show in displays.

If the right LED is ashing, “PRODUCT FRY R2” show

in displays.

Press ▼ button to start viewing the cook data.

FUNCTION DISPLAY EX:

Product (Last product cooked) PRODUCT FRY L1

Time of day the last Cook Cycle was started STARTED FEB 4

2:25P

Actual Elapsed cook Time (Real seconds) ACTUAL TIME 1:06

Programmed cook Time PROG TIME 1:00

Max Temp during Cook Cycle MAX TEMP 350°F

Min Temp during Cook Cycle MIN TEMP 313°F

Avg Temp during Cook Cycle AVG TEMP 322°F

Heat On (percentage) during Cook Cycle HEAT ON 45%

Ready? (Was fryer Ready before start?) READY? YES

When Cook Cycle was stopped: Early QUIT AT 0:10 REM

After complete Cook Cycle OR

*DONE* +6 SEC

Difference (%) between actual and ACT/PROG 1%

programmed cook time

12Oct 2014

Page 13

Model EEG- 252, 253, 254

3-1. INFORMATION MODE

DETAILS (Continued)

3. DAILY STATS (Operational info of fryer for last 7 days)

Press ► and “3. DAILY STATS” show in displays.

Press ▼ button to start viewing the cook data.

Press the right to view data for other days of week.

FUNCTION DISPLAY EX:

Day this data was recorded for APR-30 TUE*

Number of Hours:Minutes the fryer was on (L/R) ON HRS TUE* 3:45

Number of times ltered (L/R) FILTERED TUE* 4

Number of times lter skipped (L/R) SKIPPED TUE* 4

Number of times oil added (L/R) ADD OIL TUE* 4

Number of times oil discarded (L/R) DISPOSE TUE* 0

Oil temperature recovery time (L/R) RECOVERY TUE*1:45

Total number of cook cycles that day (L/R) TOT CK TUE* 38

Number of cycles stopped before *DONE* QUIT CK TUE* 2

Cook Cycles for Product #1 TUE* COOK -1- 17

Cook Cycles for Product #2 TUE* COOK -2- 9

Cook Cycles for Product #3 TUE* COOK -3- 5

Cook Cycles for Product #4 TUE* COOK -4- 0

Cook Cycles for Product #5 TUE* COOK -5- 0

Cook Cycles for Product #6 TUE* COOK -6- 6

Cook Cycles for Product #7 TUE* COOK -7- 0

Cook Cycles for Product #8 TUE* COOK -8- 0

Cook Cycles for Product #9 TUE* COOK -9- 1

Cook Cycles for Product #0 TUE* COOK -0- 0

13Oct 2014

Page 14

Model EEG- 252, 253, 254

3-1. INFORMATION MODE

DETAILS (Continued)

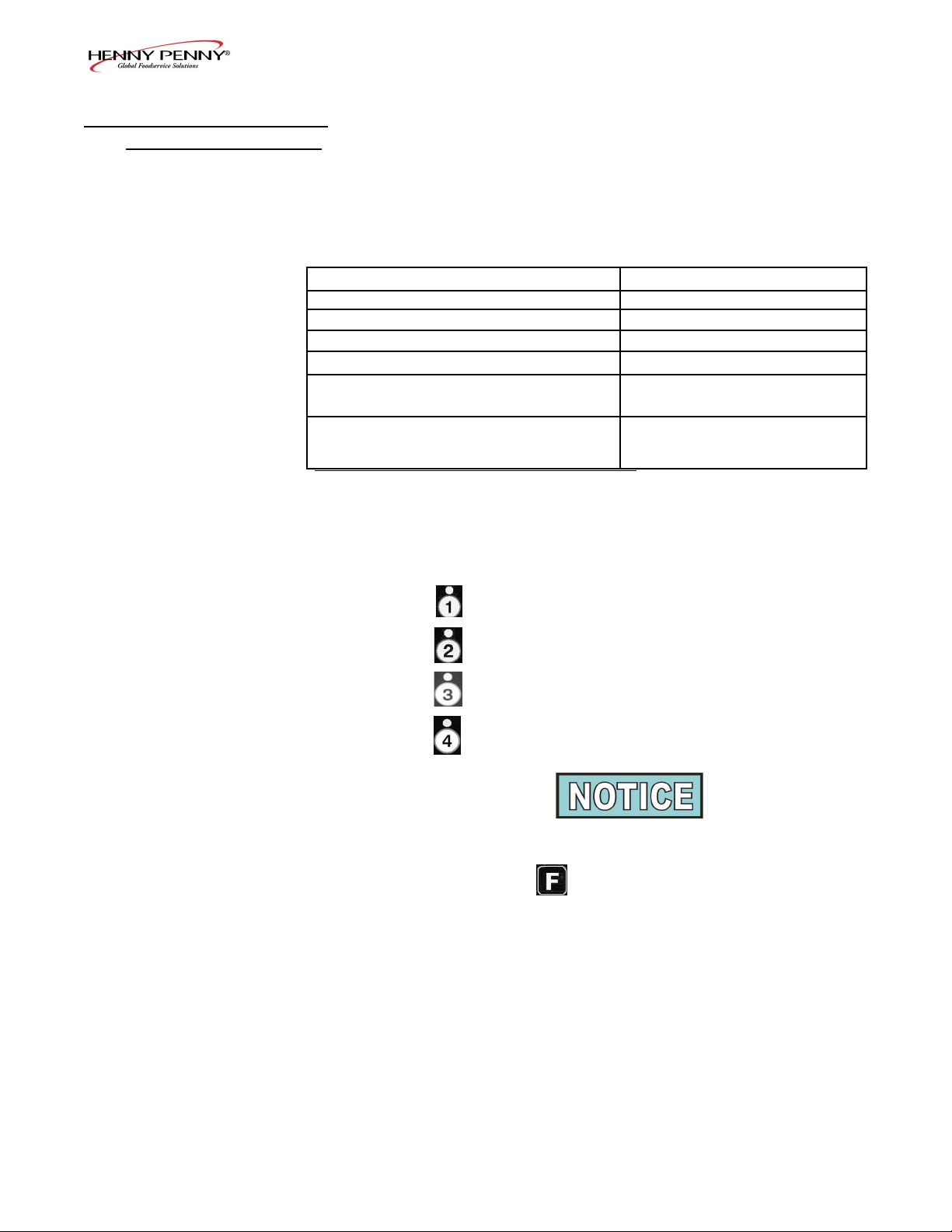

4. OIL STATS

(info of current oil and avg. of last 4 batches of oil)

Press ► and “4. OIL STATS” show in displays.

Press ▼ button to start viewing the cook data.

FUNCTION DISPLAY EX:

Start date of new oil NEW OIL MAR-23

Number of days oil in use (L/R) OIL USE 4 DAYS

Number of lters on this oil (L/R) FILTERED 4

Number of times lter skipped (L/R) SKIPPED 0

Number of cook cycles on this oil (L/R) TOT CK 38

Average number of days per oil change (L/R) AVG DAYS

PER OIL CHANGE 13.8 DAYS

Average number cook cycles per oil change (L/R) AVG CKS PER

OIL CHANGE 388 CKS

Press and hold a product button (1 to 4) to view the data from

one of the previous 4 batches of oil used.

Press to view oldest oil data: Ex: OIL-4 14 DAYS

Press to view 3rd oldest oil data: Ex: OIL-3 12 DAYS

Press to view 2nd oldest oil data: Ex: OIL-2 15 DAYS

Press to view previous batch of oil: Ex: OIL-1 13 DAYS

To obtain the most accurate oil information, use

the “3.DISPOSE” step in the Filter Menu (press

and hold ) to drain the oil from the vat.

14Oct 2014

Page 15

Model EEG- 252, 253, 254

3-1. INFORMATION MODE

DETAILS (Continued)

Day the usage data was previously reset SINCE APR-19 3:00P

Number of Hours the fryer was on (L/R) ON HRS 4

Number of times ltered (L/R) FILTERED 4

Number of times lter skipped (L/R) SKIPPED 0

Number of times oil added (L/R) ADD OIL 4

Number of times oil discarded (L/R) DISPOSE 1

Total number of cook cycles (L/R) TOT CK 38

Number of cycles stopped before *DONE* QUIT CK 2

Cook Cycles for Product #1 COOK -1- 17

Cook Cycles for Product #2 COOK -2- 9

Cook Cycles for Product #3 COOK -3- 5

Cook Cycles for Product #4 COOK -4- 0

Cook Cycles for Product #5 COOK -5- 0

Cook Cycles for Product #6 COOK -6- 6

Cook Cycles for Product #7 COOK -7- 0

Cook Cycles for Product #8 COOK -8- 0

Cook Cycles for Product #9 COOK -9- 1

Cook Cycles for Product #0 COOK -0- 0

Reset usage data:

Enter the Usage Code - 1, 2, 3 RESET USAGE /

on this step to zero out all the ENTER CODE ------

usage information

5. REVIEW USAGE

(accumulated info since the data was reset)

Press ► and “5. REVIEW USAGE” show in displays.

Press ▼ button to start viewing the cook data.

FUNCTION DISPLAY EX:

15Oct 2014

Page 16

Model EEG- 252, 253, 254

3-1. INFORMATION MODE

DETAILS (Continued)

6. INPUTS

Press ► and “6. INPTS” and “HDF” show in displays.

H = HIGH LIMIT - If “H” is present, the high limit is good. If “-”

shows then the high limit is tripped out (overheated) or discon-

nected.

D = DRAIN SWITCH - If “D” is present, the drain handle (when

applicable) is closed. If “-” shows then the drain is open or the

switch is faulty.

F =FAN (PRESSURE SWITCH) - If “F” is present, the pressure

switch is good. If “-” shows in the display, the switch is faulty.

Press ▼ button and an underscore (“_”) indicates the input is not

presently detected. A Checkmark (“

detecting a normal input. A blinking (“X”) indicates the signal is

presently detected, but is detected as a half-wave (partially failed)

input.

The H, D, F signals above are wired in series. The rst signal miss-

ing out of this sequence l generally causes all signals to the right of it

to be missing as well.

√” ) indicates the signal is

7. OUTPUTS

Press ► and “7. OUTP” and “F-S-I-H-” show in displays.

F = FAN (PRESSURE SWITCH)- Press or to open and

close the pressure switches

S = SAFETY GAS VALVE (if available) - Press or to

open and close the gas safety valves

I = IGNITION MODULE - Press or to open and

close the outputs on the ignition modules

H = HEAT OUTPUTS - Press or to turn on and off the

heating outputs (ex: gas valve)

8. OIL TEMPERATURE

Press ► and “8.OIL TMP” shows in the left display and the oil

temperature shows in the right display.

9. CPU TEMPERATURE

Press ► and “9.CPU TMP” shows in the left display and the

current PC board temperature shows in the right display.

16Oct 2014

Page 17

SECTION 4. PRODUCT PROGRAM MODE

This mode allows you to program the following:

• Change Product Name

• Assign Button

• Change Times & Temp

• Change Cook ID

• Alarms

• Quality Timers

• Include in Filter Count (Global)

• Filter at X no. of loads (Mixed)

• Load Compensation

• Load Compensation Reference

• Full Heat

• PC Factor

Model EEG- 252, 253, 254

4-1. MODIFYING PRODUCT

SETTINGS

1. Press and hold button until “PROG” shows in the

display, followed by “ENTER CODE”.

2. Enter code 1, 2, 3 (rst 3 product buttons). “PRODUCT”

and “PROGRAM” show in the displays, followed by

“SELECT PRODUCT’ and “-P 1-” (ex: NUG).

Change Product Names

3. Use the ▲and ▼ buttons to scroll through the 40 products,

or press the desired product button.

4. Press ►button and “NAME” shows in the left display

and the product (ex: NUGGETS) shows in the right display.

5. Press √ button and the rst letter in the name ashes.

Press a product button and the ashing letter changes to

the rst letter under the product button that was pressed.

For example, if is pressed, the ashing letter changes

to an “A”.

Press the same button again and the ashing letter changes

to a “B”. Press it again and the ashing letter changes to

a “C”. Once the desired letter shows in the display, press

► button to continue to the next letter and repeat the

procedure.

Press and hold the right X button to exit Program Mode, or

press ► button to continue on to “COOK TIME”.

Assign Button

6. Press ► button until “ASSIGN BTN” shows in the

display, along with the product (ex: NUGGETS). If this

product already has a product button assigned to it, that

LED will be lit. To assign other product buttons to that

product, press and hold the product button for 3 seconds

and that LED stays lit. To remove a product from a button,

press and hold the product button with a lit LED and the

LED goes out.

17Oct 2014

Page 18

Model EEG- 252, 253, 254

4-1. MODIFYING PRODUCT

SETTINGS (Continued)

To Change Times and Temperatures

7. Press ► button until “COOK TIME” shows in the display,

and then use the product buttons, or the ▲ and ▼buttons,

to change the time in minutes and seconds, to a maximum

of 59:59.

8. Press ► button and “TEMP” shows in the display, along

with the preset temperature on the right side of the display.

Press the product buttons, or the ▲ and ▼ buttons, to

change the temperature. The temperature range is 190°F

(88°C) to 375°F (191°C).

Cook ID Change

9. Press ► button until “COOK ID” shows in the display

along with the product ID. For example, NUG would be

the ID for nuggets. Use the product buttons, or the ▲ and

▼ buttons, to change the ID.

Alarms (1 & 2)

10. Press ► button until “ALRM 1” shows in the left display,

and an alarm time in the right display. Press the product

buttons, or the ▲ and ▼buttons, to set an alarm.

Ex., If a Cook Cycle was set at 3 minutes, and an alarm

was to go off after 30 seconds into the Cook Cycle, “2:30”

would be set in the display at this time. When the timer

counts down to 2:30 the alarm sounds.

After the alarm time is set, press ► button and “ALRM

2” shows in the display, and a second alarm can be

programmed.

Quality Timer (hold time)

11. Press ► button until “QUAL TMR” shows in the display

along with the preset holding time. Press the product

buttons, or the ▲ and ▼ buttons,to adjust holding time, up

to 59:59.

Global Filter Tracking

Include in Filter Count

12. Press ► button until “INCL IN FLTR CNT” ashes in

the display along with “YES” or “NO”. Using ▲ and ▼

buttons, change the display to “YES” if that product’s Cook

Cycles are to be counted as part of the recommended lter

process. Set to “NO” if it is not to be included. Mixed

Filter Tracking

18Oct 2014

Page 19

Model EEG- 252, 253, 254

4-1. MODIFYING PRODUCT

SETTINGS (Continued)

Filter After X Number of Loads

13. Press ► button until “FILTER AFTER...” ashes in the

left display along, and the number of cook cycles between

lters shows in the right display. Press the product buttons,

or the ▲ and ▼ buttons, to change this value of 0 to 99

loads. This needs set for each product.

>Load Compensation, Load Compensation

Reference, Full Heat, PC Factor<

14. Press ► button until “LD COMP” shows in the

display, along with the load compensation value. This

automatically adjusts the time to account for the size and

temperature of the cooking load.

Press the product buttons, or the ▲ and ▼ buttons, to

change this value of 0 to 20.

15. Press ► button until “LCMP REF” shows in the display

along with the load compensation average temperature.

(if load compensation is set to “OFF”, then “_ _ _” shows

in display and setting cannot be programmed) This is the

average cooking temperature for each product. The timer

speeds up at temperatures above this setting and slows

down at temperatures below this setting. Press the product

button, or the ▲ and ▼ buttons, to change this value.

16. Press ► button until “FULL HT” shows in the display

along with the full heat value in seconds, which means

the heat is on as soon as a timer button is pressed, for the

programmed length of time. Press the product buttons,

or the ▲ and ▼ buttons, to change this value of 0 to 90

seconds.

17. Press ► button until “PC FACTR” shows in the display

along with the proportional temperature, which helps to

keep the oil from over-shooting the setpoint temperature.

Press the product buttons, or the ▲ and ▼ buttons, to

change this value of 0 to 50 degrees.

• Use ◄ button to go back to previous menu items.

• Press ► button when nished with the current

product, to return to the “SELECT PRODUCT”

step.

• Press and hold button to exit PRODUCT

PROGRAM Mode.

19Oct 2014

Page 20

SECTION 5. LEVEL 2 PROGRAMMING

5-1. SPECIAL PROGRAM

MODE

Model EEG- 252, 253, 254

Used to access the following:

• Special Program Mode

• Clock Set

• Data Communication

• Heat Control

The Special Program Mode is used to set more

detailed

programming, such as:

• SP-1 • Degrees Fahrenheit or Celsius

• SP-2 • Language: English, Russian, Swedish

(SVENSKT), German (DEUTSCHE),

Portuguese, Spanish (ESPANOL) and French

(FRANCAIS)

• SP-3 • System Initialization (Factory Presets)

• SP-4 • Audio Volume

• SP-5 • Audio Tone

• SP-6 • Melt Cycle Select - 1.LIQUID; 2.SOLID

• SP-7 • Idle Mode Enabled - YES or NO

• SP-7A • Use “0” for IDLE

• SP-7B • Auto Idle Minutes

• SP-7C • Idle Set-point Temperature

• SP-8 • Filter Tracking Mode - 1.MIXED or

2.GLOBAL

• SP-8A • Suggest Filter At... - 75% to 100%

(MIXED)

• SP-8B • Filter Lockout Enabled? - YES or NO

(MIXED)

• SP-8A • Left Vat Filter Cycles - 0 to 99

(GLOBAL)

• SP-8B • Right Vat Filter Cycles - 0 to 99

(GLOBAL)

• SP-8C • Filter Lockout Enabled? - YES or NO

(GLOBAL)

• SP-9 • Polish Duration - X:XX M:SS

• SP-10 • Change Pad Reminder Time - XX HRS

• SP-11 • Clean-Out Time - XX MIN

• SP-12 • Clean-Out Temperature - XXX

o

F or oC

• SP-13 • Cooking User IO - After Cook Cycle,

display shows previous menu item or “----”

• SP-14 • Number of Baskets - 2-BASKETS or 4

BASKETS

• SP-15 • Show Cooking Indicator - YES or NO

• SP-16 • 2nd Language: English, Russian, Swedish

(SVENSKT), German (DEUTSCHE), Portuguese,

Spanish (ESPANOL) and French (FRANCAIS)

• SP-17 • 2nd AudioVolume

• SP-18 • Energy Save Enabled? - YES or NO

• SP-19 • Fryer Type - GAS or ELECTRIC

• SP-20 • Vat Type - SPLIT or FULL

• SP-21 • Autolift Enabled? - NO LIFT or YES LIFT

• SP-22 • Bulk Oil Supply? - YES or NO

• SP-23 • Bulk Oil Dispose? - NO / FRONT / REAR

• SP-24 • Serial No. of Fryer

• SP-25 • Change Mgr. Code- 1 = YES

• SP-26 • Change Usage Code - 1 = YES

• SP-27 • Dispose Requires Code ? - YES or NO

• SP-28 • Longer Fill Time Enabled - YES or NO

• SP-29 • Let User Exit Fill? - YES or NO

• SP-30 • Skip Skim Prompt? YES or NO

• SP-31 • Skip Exp Fltr Conrm Prompt? YES or NO

• SP-32 • 2-Stage Wash Enabled? YES or NO

• SP-33 • Daily Filter Lockout Enabled? YES or NO

• SP-34 • Daily Filter Period Start Time (ie: 5:00)

• SP-35 • Daily Filter Reminder Time (ie: 21:00)

20Oct 2014

Page 21

Model EEG- 252, 253, 254

5-1. SPECIAL PROGRAM

MODE (Continued)

Press and hold the button for 5 seconds until “LEVEL

2”followed by, “SP PROG” and “ENTER CODE” show in the

display.

Enter code 1,2,3, and “SP-1”, “TEMP”, “FORMAT” show in

the displays.

If a bad code is entered, a tone sounds and “BAD

CODE” shows on the display. Wait a few seconds,

the controls revert back to the cook mode, and repeat

the above steps.

To exit from the Special Program Mode at any time,

press and hold button for 2 seconds.

Degrees Fahrenheit or Celsius (SP-1)

The left display ashes “SP-1” and “TEMP”, “FORMAT”.

Press the ▲ or ▼ buttons to choose ºF or ºC.

• Use ◄ button to go back to previous menu items

• Press ► button when nished with the current Level 2

step

Language (SP-2)

Press ► button and “SP-2” and “LANGUAGE” ash on the

left display. Press the ▲ or ▼ buttons to select the desired

language.

System Initialization (SP-3)

Press ► button and “SP-3” and “DO SYSTEM INIT” ash

in the display, along with “INIT” on the right display. To reset

the controls to factory default settings, press and hold √ button

and control counts down “IN 3”, “IN2”, “IN 1”. Once display

shows “-INIT-” & *DONE* the controls are reset to factory

defaults.

Audio Volume (SP-4)

Press ► button and “SP-4” and “VOLUME” ash in the left

display. Press the ▲ or ▲ or use product buttons, to adjust the

volume of the speaker, 10 being the maximum value and 1 the

minimum.

21Oct 2014

Page 22

Model EEG- 252, 253, 254

5-1. SPECIAL PROGRAM

MODE (Continued)

Audio Tone (SP-5)

Press ► button and “SP-5” and “TONE” ash in the left

display. Press the ▲ or ▼ or use product buttons, to adjust the

tone of the speaker, 2000 being the maximum value and 50 the

minimum.

Liquid or Solid Cooking Oil Used (SP-6)

Press ► button until “SP-6 MELT CYCLE SELECT” scrolls

in the left display. Unless solid oil is being used in the vats the

right display should show “1.LIQUID”.

If solid oil is used, the unit MUST BE equipped to handle solid

oil. Use the ▲ and ▼buttons to change the right display to

“2.SOLID”

Idle Mode Enabled (SP-7)

An Idle Mode allows the oil temperature to drop to a lower

temperature when not in use. This savies on oil and utilities.

Press ► button and “SP-7” and “IDLE MODE ENABLED?”

ash in the left display. Press the ▲ or ▼ buttons to choose

YES” or “NO”.

With “YES” in the display, press ► button and “SP-7A” and

“USE ‘0’ FOR IDLE” ash on the left display. Press the ▲

or ▼ buttons to select “YES” or “NO”. If “YES” is selected,

an Idle Mode can be programmed in product button .

Press ► button and “SP-7B” and “AUTOIDLE MINUTES”

ash in the left display. Press the ▲ or ▼, or use product buttons, to set the time (0 to 60 minutes) fryer stays idle before the

auto-idle is enabled.

Ex.,“30” means, if product is not cooked in that vat for 30 minutes, the control automatically cools the oil down to the idle

setpoint temperature

Press ► button and “SP-7C” and “IDLE SETPT” ash in the

left display. Press the ▲ or ▼ , or use product buttons, to set

o

the idle temperature 200

to 375 oF (93 to 191 oC) .

22Oct 2014

Page 23

Model EEG- 252, 253, 254

5-1. SPECIAL PROGRAM

MODE (Continued)

Product Cycles Count

Fish 2 1/2

French Fries 8 1/8

Chicken 4 1/4

No. Cook Cycle

Filter Tracking Mode (SP-8)

Filter Tracking signals the operator when the oil needs ltering

by counting the number Cook Cycles between lters

Press ► button and “SP-8” and “FILTER TRACKING

MODE” show in the display. Use the ▲ and ▼ buttons to

choose either “1.MIXED” lter tracking or “2.GLOBAL”.

GLOBAL means all the products have the same number

of cook cycles between lters.

MIXED means each product may be set with different number

of cook cycles between lters. The controls adds the cycle

counts (see example at left) and when the counts equal 1 or

greater, ltering is suggested. Ex: 1 load of sh, 2 loads of

french fries, a load of chicken equals 1. 1/2 + 1/8+1/8+1/4=1.

MIXED

If MIXED is selected, press ► button and “SP-8A” and “SUGGEST FILTER AT …” shows in the left display, and a value

between 75% and 100% shows on the right display. Press the ▲

and ▼ buttons to change this value.

The lower the value, the sooner the control recommends to

lter. Ex: If set to 75%, the control suggest ltering after 3/4

of the programmed cook cycles is met, whereas at 100%, all

the cook cycles must be completed before the control suggest

ltering.

Press ► and “SP-8B” and “LOCKOUT ENABLED?” shows in

the left display. Press the ▲ and ▼ buttons to choose YES or

NO.

If set to YES, when the controls suggest ltering, “FILTER

LOCKOUT”/”YOU *MUST* FILTER NOW”, shows in the

display, and it refuses further cook cycles until the vat is l-

tered.

Press ► and “SP-8C” and “LOCKOUT AT...” shows in the

left display and a value between 100% and 250% shows on the

right display. Press the ▲ and ▼ buttons to change this value.

The lower the value, the sooner the “lockout” occurs.

Ex: If set at 100%, “lockout” occurs when the cycle counts

reaches 1 or greater. Set at 200%, twice as many cycles are

counted before “lockout” occurs. See example above.

23Oct 2014

Page 24

Model EEG- 252, 253, 254

5-1. SPECIAL PROGRAM

MODE (Continued)

Filter Tracking Mode (SP-8) (Continued)

GLOBAL

If GLOBAL is selected, press ► button.

Split Vat

If unit is a split vat, “SP-8A” and “LEFT VAT FILTER CYCLES”

shows in the left display, and the number of cook

cycles between lters shows on the right display (0 to 99). Use ▲

and ▼ or product buttons to change this number.

Press ► button and “SP-8B” and “RIGHT VAT FILTER CYCLES”

shows in the left display, and the number of cook cycles between

lters shows on the right display (0 to 99).

Press ► button and “SP-8C” and “LOCKOUT ENABLED?” shows

in the left display. Press the ▲ and ▼ buttons to choose YES or NO.

If set to YES, press ► button and the left display shows “SP-8D” and

“LEFT VAT LOCKOUT CYCLES” and the number of cook

cycles before lter lock-out shows on the right display (0 to 99). Use

▲ and ▼ or product buttons to change this number.

Press ► button and the left display shows “SP-8E” and “RGHT

VAT LOCKOUT CYCLES” and the number of cook cycles before

lter lock-out shows on the right display (0 to 99). Use ▲ and ▼ or

product numbers to change this number.

Once this number of cook cycles is reached, “FILTER LOCKOUT”/”YOU *MUST* FILTER NOW”, shows in the display, and it

refuses further cook cycles until the vat is ltered.

Full Vat

If unit is a full vat, “SP-8A” and “FULL VAT FILTER CYCLES”

shows in the left display, and the number of cook cycles between

lters shows on the right display (0 to 99). Use ▲ and ▼ or product

numbers to change this number.

Press ► button and “SP-8B” and “LOCKOUT ENABLED?” shows

in the left display. Press the ▲ and ▼ buttons to choose YES or NO.

If set to YES, press ► button and the left display shows “SP-8C” and

“FULL VAT LOCKOUT CYCLES” and the number of cook cycles

before lter lock-out shows on the right display (0 to 99). Use and

or product buttons to change this number.

Once this number of cook cycles is reached, “FILTER LOCKOUT”/”YOU *MUST* FILTER NOW”, shows in the display, and it

refuses further cook cycles until the vat is ltered.

24Oct 2014

Page 25

Model EEG- 252, 253, 254

5-1. SPECIAL PROGRAM

MODE (Continued)

Polish Duration (SP-9)

Press ► button and “SP-9” and “POLISH TIME” ash in the

left display. Press the ▲ or ▼ , or use product buttons, to

change the polish time, from 0 to 10 minutes.

Change Filter Pad Reminder Time (SP-10)

Press ► button and “SP-10 “CHANGE PAD’ REMINDER”

ash in the left display. Press the ▲ or ▼ , or use product

buttons, to change the time, from 0 hours to a maximum of 100

hours.

Clean-Out Time (SP-11)

Press ► button and “SP-11 CLEAN-OUT TIME” ashes in

the left display. Press the ▲ or ▼ or use product buttons, to

change the time from 0 to 99 minutes.

Clean-Out Temperature (SP-12)

Press ► button and “SP-12 CLEAN-OUT TEMP” ashes in

the left display. Press the ▲ or ▼ or use product buttons, to

change the temperature from 0 to 195o F (90o C).

Cooking User IO (SP-13)

Press ► button and “SP-11” and “COOKING USER IO” ash

in the display. Press the ▲ or ▼ buttons to choose “SHOWPREV” or “SHOW----”.

Setting SP-11 to SHOWPREV means after a cook cycle the

display shows the last menu item cooked. SHOW---- means

after a cook cycle “----” shows in the display and a menu item

needs selected before starting the next cook cycle.

Number of Baskets (SP-14)

Press ► button and “SP-14 NUMBER OF BASKETS” ashes

in the left display. Press the ▲ or ▼ buttons to choose 2 or 4

baskets per well.

Cooking Indicator (SP-15)

Press ► button and “SP-15 SHOW COOKING INDICATOR”

ashes in the left display. Press the ▲ or ▼ buttons to choose

YES, and during a cook cycle, “*” shows which timer is counting-down. Choose NO and “*” will not show during a cook

cycle.

25Oct 2014

Page 26

Model EEG- 252, 253, 254

5-1. SPECIAL PROGRAM

MODE (Continued)

2nd Language (SP-16)

Press ► button and “SP-16 2ND LANGUAGE” ashes on the

left display. Press the ▲ or ▼ buttons to select the desired 2nd

language.

By setting a 2nd language in the controls, 2 languages can

now be chosen by pressing button during normal opera-

tion.

One language shows in the left display and the second language shows in the right display. Pressing the √ button selects

the language in the displays.

2nd Volume (SP-17)

Press ► button and “SP-17 2ND VOLUME” ashes on the

left display. Press the ▲ or ▼ buttons, or the product buttons

to select the desired 2nd volume.

By setting a 2nd volume in the controls, 2 volumes can now be

chosen by pressing button twice during normal opera-

tion.

One volume setting shows in the left display (NONE to 10; 10

being the loudest) and the second volume shows in the right

display. To select the volume, press the √ button under the

desired volume .

Engery Save Mode (SP-18)

Press ► button and “SP-18 ENERGY SAVE ENABLED?”

ashes in the left display. Press the ▲ or ▼ buttons to choose

“YES” or “NO”.

If set to YES, during times of non-use the fryer automatically starts an Energy Save Mode, which turns-off the blowers. Then once a product is selected to start a cook cycle, the

blowers and heat come back on. If set to NO, the blowers are

on constantly.

Fryer Type (SP-19)

Press ► button and “SP-19 FRYER TYPE” ashes in the

left display. Press the ▲ or ▼ buttons to choose “GAS” or

“ELEC”.

Vat Type (SP-20)

Press ► button and “SP-20 VAT TYPE” ashes in the left

display. Press the ▲ or ▼ buttons to choose “SPLIT” or

“FULL”.

26Oct 2014

Page 27

Model EEG- 252, 253, 254

5-1. SPECIAL PROGRAM

MODE (Continued)

Autolift Enabled (SP-21)

Press ► button and “SP-21 AUTOLIFT ENABLED?” ashes

in the left display. Press the ▲ or ▼ buttons to choose “YES

LIFT” or “NO LIFT”. If fryer is tted with the auto-lift option,

SP-21 must be set to“YES LIFT”, otherwise, set SP-21 to “NO

LIFT”.

Bulk Oil Supply (SP-22)

Press ► button and “SP-22 BULK OIL SUPPLY?” ashes

in the left display. Press the ▲ or ▼ buttons to choose “YES

SUPL” or “NO SUPL”. Set to YES if the oil is pumped

into the vats from an outside oil reservoir. Otherwise, set SP22 to NO.

Bulk Oil Disposal (SP-23)

Press ► button and “SP-23 BULK OIL DISPOSE?” ashes

in the left display. Press the ▲ or ▼ buttons to choose “YES

DISP” or “NO DISP”.Set to “YES DISP” if the oil is pumped

from the vats to an outside oil reservoir when disarding the oil.

Otherwise, set SP-23 to “NO DISP”.

Serial Number Log (SP-24)

Press ► button and “SP-24” and “S/N √EDIT” ash in the

displays, along with the serial number of the unit. THIS SERIAL NUMBER SHOULD MATCH THE SERIAL NUMBER

ON THE DATA PLATE, ON THE DOORS. IF NOT, IT CAN

BE RECORDED.

Program Code Change (SP-25)

This allows the operator to change the program code (factory

set at 1, 2, 3) used to access Product Programming and Level 2

Program Mode.

Press ► button and “SP-25” and “CHANGE MGR CODE?

1=YES” ash in the display. Press and “ENTER NEW

CODE, P=DONE, I=QUIT show scrolls through the display.

Press the product buttons for new code.

If satised with code, press and “REPEAT NEW CODE,

P=DONE, I=QUIT, shows in display. Press same code buttons.

27Oct 2014

Page 28

Model EEG- 252, 253, 254

5-1. SPECIAL PROGRAM

MODE (Continued)

Program Code Change (SP-25) (Continued)

If satised with code, press and “*CODE CHANGED*”

shows in display.

If not satised with code, press and “*CANCEL” shows

in display, then reverts back to “SP-25” and “CHANGE, MGR

CODE? 1=YES”. Now the above steps can be repeated.

Usage Code Change (SP-26)

This allows the operator to change the reset usage code (factory

set at 1, 2, 3) to reset the usage amounts of each product. See

Review Usage step in Information Mode.

Press ► button and “SP-26 CHANGE USAGE CODE?

1=YES” ashes in the display. Press and “ENTER NEW

CODE, P=DONE, I=QUIT show scrolls through the display.

Press the product buttons for new code.

If satised with code, press and “REPEAT NEW CODE,

P=DONE, I=QUIT, shows in display. Press same code buttons.

If satised with code, press “*CODE CHANGED*” shows

in display.

If not satised with code, press and “*CANCEL” shows in

display, then reverts back to “SP-26” and “CHANGE,

USAGE CODE? 1=YES”. Now the above steps can be repeat-

ed.

Dispose Requires Code ? (SP-27)

Press ► button and “SP-27 DISPOSE REQUIRES CODE ?”

ashes in the left display. Press the ▲ or ▼ buttons to choose

YES or NO. If set to YES, code 1, 2, 3 must be entered to discard the oil from the vat, using the Dispose Mode.

Longer Fill Time (SP-28)

Press ► button and “SP-28 LONGER FILLTIME EN-

ABLED?” ashes in the left display. Press the ▲ or ▼ buttons

to choose YES or NO.

Let User Exit Fill (SP-29)

Press ► button and “SP-29 LET USER EXIT FILL” ashes

in the left display. Press the ▲ or ▼ buttons to choose YES or

TM

NO. If YES is chosen, the user can exit the Express Filter

ll operation.

28Oct 2014

Page 29

Model EEG- 252, 253, 254

5-2. CLOCK SET

1. Press and hold the button for 5 seconds until “LEVEL

2”, followed by, “SP PROG” and “ENTER CODE” show in

the display.

2. Press the button 2 times and “CLK SET” and “ENTER

CODE” ash in the left display.

3. Enter code 1, 2, 3 (rst 3 product buttons).

4. “CS-1 ENTER DATE MM-DD-YY” ashes in the left

display. Use the product buttons to set the date in the right

display.

5. Press ► button and “CS-2 ENTER TIME” ashes in the

left display and the time ashes in the right display. Press

the ▲ or ▼ , or use product buttons, to change the time.

6. Press ► button and “CS-2 ENTER TIME” ashes in the

left display and “AM” or “PM” ashes in the right display.

Use the ▲ or ▼ buttons to choose AM or PM.

5-3. DATA LOGGING, HEAT

CONTROL, TECH, STAT,

AND FILTER CONTROL

MODES

7. Press ► button and “CS-3 TIME FORMAT” ashes in the

left display and “12-HR” or “24-HR” shows in the right

display.Use the ▲ or ▼ buttons to choose a 12 hour time

format or a 24 hour time format.

8. Press ► button and “CS-4 DAYLIGHT SAVING TIME”

ashes in the left display. Use the ▲ or ▼ buttons to

choose daylight saving time for your area:1.OFF; 2.US

(2007 & after); 3.EURO; or 4.FSA (US before 2007).

The Data Logging, Heat Control, Tech, Stat and Filter Control

Modes are advanced diagnostic and program modes, mainly for

Henny Penny use only. For more information on these modes,

contact the Service Department at 1-800-417-8405 or 1-937456-8405.

29Oct 2014

Page 30

Model EEG- 252, 253, 254

5-4. TECH MODE

The TECH Mode has self-diagnostic information, which can be

used by certied technicians for troubleshooting purposes, such

as:

T-1 • Software

T-2 • Fryer Type (Gas or Elec.)

T-3 • Push Button Test

T-4 • All On Display Test

T-5 • Display Segment Test

T-6 • Display Digits Test

T-7 • Display Decimal Point Test

T-8 • LED’s Test

T-9 • Left Temp. Probe Calibration & Offset

T-10 • Left Level 1 Probe Calibration & Offset

T-11 • Left Level 2 Probe Calibration & Offset

T-12 • Right Temp. Probe Calibration & Offset

T-13 • Right Level 1 Probe Calibration & Offset

T-14 • Right Level 2 Probe Calibration & Offset

T-15 • CPU Control Temp. Calibration/Offset/Highest

T-16 • View A - D Channel

T-17 • Inputs

T-18 • Outputs S-H-S-H

T-19 • Basket Lifts

T-20 • AIF Info

T-21 • Pumps and Valves

T-22 • Recovery Test Valves

T-23 • Heat Err Enabled?

T-24 • Change Tech Code?

T-25 • Total Initialization

Not all Tech Mode functions are discussed in this section. To

ensure proper operation of fryer, please consult Henny Penny

Corp. before changing any of these settings. For more information on these functions, contact the Service Department at

1-800-417- 8405, or 1-937-456-8405.

30Oct 2014

Page 31

Model EEG- 252, 253, 254

5-4. TECH MODE (Continued)

1. Press and hold the button for 5 seconds until “LEVEL

2”, followed by, “SP PROG” and “ENTER CODE” show in

the display.

2. Press the button 4 times and “TECH” and “ENTER

CODE” ash in the left display.

3. Enter code 1, 1, 2, 2, 1, 1, 2, 2 (rst 2 product buttons).

4. “T-1 SOFTWARE” ashes in the left display and “EV-

ELITE” shows in the right display. Use the ◄ and ►

buttons to select the steps.

If a bad code is entered, a tone sounds and “BAD

CODE” shows on the display. Wait a few seconds,

the controls revert back to the cook mode, and repeat

the above steps.Press and hold button at anytime to

return to normal operation.

T-1 - SOFTWARE

• Press to view HP Part No. of eprom

• Press to view software ID

• Press to view software version

T-2 - FRYER TYPE - GAS or ELEC

T-3 - PUSH-BUTTON TEST

Press any of the control buttons to test operation. You should hear a

beep, and the LED should light and/or a display.

T-4 - ALL ON DISPLAY TEST

Press any of the product buttons and all the LEDs and display

segments should light.

T-5 - SEGMENTS TEST

Press button to view the different segments of the display

characters.

T-6 - DIGITS TEST

Press button to view all segments of each digit across the

displays.

31Oct 2014

Page 32

Model EEG- 252, 253, 254

5-4. TECH MODE (Continued)

T-7 - DECIMAL PTS TEST

Press button to view all decimal points across the displays.

T-8 - LED’S TEST

Press buttons to view each LED across the control panel.

T-17 - INPUTS - HDF

H = HIGH LIMIT - If “H” is present, the high limit is good. If “-”

shows then the high limit is tripped out (overheated) or

disconnected.

D = DRAIN SWITCH - If “D” is present, the drain handle (when

applicable) is closed. If “-” shows then the drain is open or the

switch is faulty.

F = FAN (PRESSURE SWITCH) - If “F” is present, the pressure

switch is good. If “-” shows in the display, the switch is faulty.

Press ▼ button and an underscore (“_”) indicates the input is not

presently detected. A Checkmark (“

detecting a normal input. A blinking (“X”) indicates the signal is

presently detected, but is detected as a half-wave (partially failed)

input.

√” ) indicates the signal is

The H, D, F signals above are wired in series. The rst signal miss-

ing out of this sequence l generally causes all signals to the right of it

to be missing as well.

T-18 - OUTPUTS

S = SAFETY GAS VALVE (if available) - Press to open and

close the gas safety valves

H = HEAT OUTPUTS - Press to turn on and off theheating

outputs (ex: gas valve)

32Oct 2014

Page 33

Model EEG- 252, 253, 254

5-4. TECH MODE (Continued)

T-20 - AIF Board Inputs:

E = Stop button Ex = E-Stop pressed.

P = Drain Pan Px = drain pan is missing.

JL = JIB Jx = JIB oil level is low.

R = RTI Rx = RTI System NOT Detected

DT = Discard Tank DTx = tank full

T-21 - PUMPS & VALVES

Press ▼ button and “LIGHTS” “DLT_” shows in displays.

Press and left Filter Beacon lights (split vats) and press

button and right Filter Beacon lights (display shows “DLTo”

when on)

Press ▼ button and “VALVES” “DcRc” shows in displays.

Press to open and close the return valve.

“DcRc” means valve is closed, “DcRo” means valve is open.

(Driven by the control board)

Press ▼ button and “DISCARDc” and “JIBFILLc” shows in

the displays. (Driven by the AIF board)

Press to open and close the RTI discard valve (display

shows “DISCARDo” when open)

Press to open and close the RTI JIB ll valve (display

shows “JIBFILLo” when open)

Press ▼ button and “PUMP FP_” and “JP_ NP_” shows in the

displays. (Driven by the AIF board)

Press to turn off and on the lter pump (display shows

“FP*” when on)

Press to turn off and on the JIB pump (display shows

“JP*” when on)

Press to turn off and on the new oil pump (if available display shows “NP*” when on)

33Oct 2014

Page 34

Model EEG- 252, 253, 254

5-4. TECH MODE (Continued)

Press ▼ button and “AIF REQ” and “RQ=Y OK=Y” shows in

the displays.

REQ=Y” means that this particular control is currently requesting control of the AIF Board outputs.

“OK=Y” means that the AIF Board has granted this control the

authority to control the AIF Board outputs.

Press ▼ button and “FILR IN” and “USE BY 1(ex)” shows in

the displays. These displays shows which controls are using the

ltering system.

“USE = 0” = not in use

“USE = 7” = used by AIF

“USE = 1 to 5” = used by control PCB

Press ▼ button and “CPU POSN” and “1 OF 3(ex)” shows in

the displays. These displays shows which controls are plugged

into which port on the AIF board.

For example, the left control should be plugged into port 1, and

on a 3 control fryer, shows “1 OF 3” on the display.

If the right control is unplugged, then the left control would show

“1 OF 2” instead of “1 OF 3”.

Press ▼ button and “INP E_P_” and “JL_Rx DF_” shows in

the displays.

34Oct 2014

Page 35

Model EEG- 252, 253, 254

5-4. TECH MODE (Continued)

Press ▼ button and “OUT F_J_” and “N_DI_oJF_” shows in

the displays.

AIF Board Outputs:

Current outputs status from AIF board.

F = Filter Pump. (Fx = Filter pump is on)

J = JIB Pump. (Jx = JIB pump is on)

N = New Oil Pump. (Nx = RTI new oil pump on)

(if present)

DI = Discard Valve. (DIo = Disc. valve open/DIc=closed)

(if present)

JF = JIB Fill Valve. (JFo = JIB ll valve open/JFc=closed)

Press ▼ button and “REQ F_J_” and “N_DI_JF_” shows in

the displays.

AIF Board Outputs Requested by the Control Board:

Current outputs status from AIF board.

F = Filter Pump. (Fx = Filter pump is on)

J = JIB Pump. (Jx = JIB pump is on)

N = New Oil Pump. (Nx = New oil pump on)

(if present)

DI = Discard Valve. (DIo = Disc. valve open/DIc=closed)

(if present)

JF = JIB Fill Valve. (JFo = RTI JIB ll valve open/JFc=closed)

35Oct 2014

Page 36

Model EEG- 252, 253, 254

5-5. STATS MODE

This mode allows a technician to view advanced information on

the operation of the fryer and controls.

1. Press and hold the button for 5 seconds until “LEVEL

2”, followed by, “SP PROG” and “ENTER CODE” show in

the display.

2. Press the button 5 times and “STATS” and “ENTER

CODE” ash in the left display.

3. Enter code 1, 1, 2, 2, 1, 1, 2, 2 (rst 2 product buttons).

4. “ST-1 STATS LAST RESET ON...” ashes in the left dis-

play and the date shows in the right display. Use the

◄ and ► buttons to select the steps.

If a bad code is entered, a tone sounds and “BAD CODE”

shows on the display. Wait a few seconds, the controls

revert back to the cook mode, and repeat the above steps.

Press and hold button at anytime to return to normal operation.

ST-1 • Stats Last Reset Date

ST-2 • Fryer Total Running Hours

ST-3 • Left Vat Melt Cycle Hours

ST-4 • Left Vat Cook Cycle Hours

ST-5 • Left Vat Idle Hours

ST-6 • Right Vat Melt Cycle Hours

ST-7 • Right Vat Cook Cycle Hours

ST-8 • Right Vat Idle Hours

ST-9 • Power-Ups Count

ST-10 • Error Counts

ST-11 • Left Vat Heat On Hours

ST-12 • Right Vat Heat On Hours

ST-13 • Highest Left Vat Oil Temperature

ST-14 • Highest Right Vat Oil Temperature

ST-15 • Highest CPU Temperature

ST-16 • System RAM Fade Count

ST-17 • Cook RAM Fade Count

ST-18 • Product RAM Fade Count

ST-19 • Stat RAM Fade Count

ST-20 • RAM Data Error Count

ST-21 • Data Total Loss Count

ST-22 • User Intialization Count

ST-23 • Automatic Initialization Count

ST-24 • Cooks Count per Product

ST-25 • Cook Cycle Stop Counts

- “A” = number of stops in the rst 30 sec.

- “B” = 0

- “C” = 0

- “D” = complete cook cycles counted

ST-26 • Reset All Stats

36Oct 2014

Page 37

Model EEG- 252, 253, 254

5-6. DO NOT DISTURB

Time periods of peak operations during which the “FILTER

NOW?” message will not appear, may be programmed into the

fryer. There are three groupings of days - Monday thru Friday

(M-F), Saturday (SAT), and Sunday (SUN). Within each day

grouping, up to 4 time periods (M-F 1 thru M-F 4, SAT 1 thru

SAT 4, and SUN 1 thru SUN 4) may be programmed. A time

period may be anywhere from 1 to 180 minutes in length.

1. Press and hold the

button for 5 seconds until “LEVEL

2”, followed by, “SP PROG” and “ENTER CODE” show in

the display.

2. Press

button once more and “DO NOT DISTURB” and

“ENTER CODE” ash in the left display.

3. Enter code 1, 2, 3 (rst 3 product buttons).

4. “DO NOT DISTURB ENABLED?” ashes in the left display

and YES or NO appears in the right display. Press the ▲ or

▼ buttons to choose YES or NO.

5. Press

button and “M-F 1” shows in the left display and

the time ashes in the right display. Press the ▲ or ▼, or use

product buttons, to change the time.

6. Press

button and “M-F 1” shows in the left display and

“A” or “P” ashes in the right display. Use the ▲ or ▼

buttons to choose AM or PM.

7. Press

button and “M-F 1” shows in left display and far

right character display ashes. Press product buttons to enter

amount of time (up to 180 minutes) during which ltering

will be inhibited, after time entered in step 5.

8. Press

button to move to the next timer period, M-F 2.

9. Repeat steps 5, 6, 7, and 8 for other desired time periods.

37Oct 2014

Page 38

SECTION 6. MAINTENANCE

Model EEG- 252, 253, 254

6-1. INTRODUCTION

6-2. MAINTENANCE

HINTS

6-3. PREVENTIVE

MAINTENANCE

This section provides checkout and replacement procedures,

for various parts of the fryer. Before replacing any parts, refer

to the Troubleshooting Section to aid you in nding the cause

of the malfunction.

1. A multimeter will help you to check the electric

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the

multimeter should read innity.

Do not move the fryer with hot oil in the vat or lter pan.

Severe burns can result from splashing hot oil.

To ensure a long life of the fryers and their components, regular

maintenance should be performed. Refer to the chart below.

Frequency Action

Daily Filter the oil (See Daily

Filtering Instructions Section in

Operator’s Manual)

Daily Change Filter Pad (See

Changing Filter Pad Section in

Operator’s Manual)

Every lter pad change Lubricate lter pan o-rings

Quarterly Inspect/Change Filter Pan

O-Rings (See Check/Replace

Filter Drain Pan O-Ring

Section)

When oil smokes, foams-up

Change oil

violently, or tastes bad

Every change of oil Clean Vat (See Clean-Out Mode

Section in Operator’s Manual)

Semi-Annually Clean blowers & Vents (See

Section 3-21 in Operator’s

Manual)

38Oct 2014

Page 39

Model EEG- 252, 253, 254

6-4. CONTROL PANEL &

MENU CARD

REPLACEMENT

Should the control panel become inoperative, or the menu card

needs changed, follow these instructions:

1. Remove electrical power supplied to the vat.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit breaker,

or unplug cord at wall receptacle.

2. Remove the two screws securing the control panel.

3. Pull the top of the panel down, allowing the panel to be

supported by the 2 brackets in the slots in the control

shroud. (If changing control panel, continue onto step 5.)

4. If changing the menu card, loosen the tape securing the

menu card at the bottom, side of the control panel and pull

menu card from panel. Carefully, slide changed menu card

back into slot in panel and secure with tape.

5. Unplug the connectors going to the control board.

6. Install a new control panel in reverse order.

39Oct 2014

Page 40

Model EEG- 252, 253, 254

6-5. HIGH TEMPERATURE

LIMIT CONTROL

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker, or unplug cord at wall receptacle.

2. Lower the control board (refer to the Control Board

section).

3. Remove the heat shield which covers the high limit control.

4. Mark and disconnect the wires located on the high limit

control.

5. Using a 3/8” wrench, remove the nuts.

6. Remove the clamp bars.

7. Slide the high limit control off of mounting studs.

8. Install the new control in reverse order.

40Oct 2014

Page 41

Model EEG- 252, 253, 254

6-6. MAIN POWER SWITCH

1. Lower the control board (see Control Board Replacement).

2. Press on the switch from the inside of the fryer to release

from the metal shroud.

3. Mark and disconnect the wires from the switch.

4. Connect the wires onto the new switch on the correct

terminals.

5. Press back into factory location.

41Oct 2014

Page 42

Model EEG- 252, 253, 254

6-7. PROBE REPLACEMENT

Oil

level

probe

Temperature

probe

Oil

level

probe

The temperature probe is the center probe inside the vat (see

photo at left) and it relays the actual oil temperature to the control. If it becomes disabled, “E-6A or B” shows in the display.

The oil level probes (left & right-see photo at left) monitor the

oil level by temperature differences. If they becomes disabled,

the display shows: “E-18A”= left probe; “E18-B”= right probe;

“E18C”= both.

Also, if any of the probes are out of calibration more than 5°F,

or 5°C, the probe should be replaced. An Ohm check can be

performed also. See chart below.

Checkout:

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

1. Using a Phillip’s-head screwdriver, or cordless drill, loosen

the screw securing the top of the control panel and secure

control panel in the slots of the shroud.

2. Pull the probe connector from the control panel and locate the

terminals in the connector for the probe being tested. Attach

meter leads onto those terminals and refer to the chart at left

to determine if probe is good or not. (Probe wires are labeled,

with #1 being the far left probe.)

42Oct 2014

Page 43

Model EEG- 252, 253, 254

6-7. TEMPERATURE PROBE

REPLACEMENT

(Continued)

Replacement:

1. Pull-out on the drain valve knob and drain the oil from the

vat.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Using a 3/8” socket, remove the 2 screws securing the

burner jet bracket and remove bracket.

3. Pull both burner jets from unit.

4. Using a 1/2” wrench, remove the nut on the compression

tting, and remove the temperature probe from the vat.

5. Using a terminal extractor, remove the probe terminals from

the connector and pull remove probe from unit

43Oct 2014

Page 44

Model EEG- 252, 253, 254

6-7. TEMPERATURE PROBE

REPLACEMENT

(Continued)

6. Place the nut and new ferrule on the new temperature probe

and insert the temperature probe into the compression tting.

See drawing below.

7. Using the probe gauge in the kit, follow the instructions on

drawing below.

8. Hand-tighten compression nut and then a half turn with

wrench.

Excess force will damage temperature probe.

44Oct 2014

Page 45

Model EEG- 252, 253, 254

6-7. TEMPERATURE PROBE

REPLACEMENT

(Continued)

6-8. SOLENOID VALVES

9. Connect new temperature probe to the connector and fasten

connector onto control panel.

10. Replace control panel and reconnect power to vat.

11. Fill vat by pressing and holding button until *FIL-

TER* *MENU* shows in the display. Then once “1.EXPRESS FILTER” shows in the display, press ►4 times until

“5.FILL FROM PAN” shows in the display. Press √ button

and “PUMP” “EXIT” shows in the display. Press √ button

again, and oil lls vat. Once vat is full, press X twice to

return to normal operation.

Each vat has a solenoid plumbed-into the oil return lines. They

are normally closed, but open when power is supplied, such as,

the controls are lling the vats.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

1. Remove both top and bottom rear panels, or a side panel,

depending upon the location of the solenoid.

Checkout

2. Follow the wires from the solenoid and through the conduit

and then cut the wires. Strip the wires back and take an

ohm reading:

120 Volts - 60Hertz 50 Ohms

220-240 Volts -50/60 Hertz 230 Ohms

45Oct 2014

Page 46

6-8. SOLENOID VALVES

(Continued)

Model EEG- 252, 253, 254

Replacement:

1. Using an adjustable wrench, loosen the front and rear t-

tings to solenoid.

2. Remove the conduit from the fryer and pull the solenoid

assembly from the fryer.

3. Remove the conduit from the solenoid.

46Oct 2014

Page 47

Model EEG- 252, 253, 254

6-8. SOLENOID VALVES

(Continued)

4. Remove elbow and ttings from solenoid stem assembly

and attach them to the new solenoid, using pipe sealent on

the threads.

5. Reattach the conduit to the new solenoid, threading the

wires through the conduit.

6. Reattach the solenoid assembly to the fryer.

7. Reattach the conduit to the fryer and connect the wires to

the fryer using wire nuts.

8. Replace rear side panels or rear panels and reconnect power

to the fryer.

47Oct 2014

Page 48

Model EEG- 252, 253, 254

6-10. JIB PUMP

REPLACEMENT

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker, or unplug cord at wall receptacle.

2. Remove the lower back shroud (See back shroud removal).

3. Remove blower (see blower removal sections).

4. Using an adjustable wrench, remove the ex line from the

elbow.

5. Loosen the hose clamp with a at blade screw driver and

disconnect the hose.

6. Use a 3/8 socket or wrench and remove the four nuts and

washers from the pumps feet.

7. Pull the pump off of the studs.

8. Remove the wire nuts.

9. Wire the new pump into the existing wires.

10. Place the pump onto the studs. Be sure to have the shield

box in place on the studs before placing the pump onto

studs.

11. Tighten the pump nuts and washers onto the feet of the

pump.

12. Reconnect ttings.

13. Replace blower.

48Oct 2014

Page 49

Model EEG- 252, 253, 254

6-11. BLOWER REPLACEMENT

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move

the POWER switch to OFF and disconnect main

circuit breaker, or unplug cord at wall receptacle.

2. Remove the lower back shroud (See back shroud removal).

3. Using a phillips head screw, remove the two screws that

secures the blower to the ue. One screw is located on the

back side of the ue.

4. Cut zip ties that are holding the wires to the blower.

Remove the wire nuts from the wires.

5. Remove blower.

6. Reconnect new blower wires to the existing wires with wire

nuts.

7. Tighten the new blower onto the ue with the two screws.

8. Zip tie wires back to the blower.

49Oct 2014

Page 50

Model EEG- 252, 253, 254

6-12. FILTER BEACON™

Replacement

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit breaker,

or unplug cord at wall receptacle.

1. Remove right or left side panel for end vats, or hinge-down

the control panel for center vats.

2. Pull apart the light by pulling on the rear of the light and removing the front part of the light from the front of the fryer.

3. Locate and cut the light wires and pull the light from unit.

4. Connect new light wires, using wirenuts and install light in

reverse order.

5. Restore power to the unit.

50Oct 2014

Page 51

6-13. AIR PRESSURE

SWITCHES

Model EEG- 252, 253, 254

1. Remove electrical power supplied to the unit.

2. Remove the lower back shroud (See back shroud removal).

3. Remove the pressure switch mounting cover from the

frame.

4. Remove the vacuum hose from switch.

5. Using a phillips bit or screwdriver, remove the two screws

securing switch to the cover.

6. Disconnect the wires on the switch.

7. Replace switch in reverse order.

51Oct 2014

Page 52

Model EEG- 252, 253, 254

6-14. PILOT REPLACEMENT

1. Remove electrical power supplied to the unit.

2. Lower the control board (refer to the Control Board

section).

3. Remove burner tubes (refer to the Burner Tube Removal

section).

4. Remove the ame sensor wire.

5. Remove the two screws securing the pilot to the burner

assembly. The right hand screw will have the ground wire.

6. Disconnect the pilot wire located in the orange rubber

sleeve.

7. Using a 7/16” wrench, loosen the pilot tube from the pilot.

8. Disconnect the ame sensor.

9. Replace pilot in reverse order.

10. When screwing the pilot back to the burner assembly, be

sure to connect the ground wire to the right hand screw.

52Oct. 2014

Page 53

Model EEG- 252, 253, 254

SECTION 7: PARTS

7-1. INTRODUCTION This section lists the replaceable parts of the Henny Penny

®

Evolution Elite

7-2. GENUINE PARTS Use only genuine Henny Penny parts in your fryer. Using a

part of lesser quality or substitute design may result in damage

to the unit or personal injury.

7-3. WHEN ORDERING PARTS Once the parts that you want to order have been found in the

parts list, write down the following information:

Item Number 2

Part Number 60241 Example:

Description High Limit

fryer.

From the data plate, list the following information:

Product Number 01100

Serial Number 0001 Example:

Voltage 208

7-4. PRICES Your distributor has a price parts list and will be glad to inform

you of the cost of your parts order.

7-5. DELIVERY Commonly replaced items are stocked by your distributor and

will be sent out when your order is received. Other parts will

be ordered, by your distributor, from Henny Penny Corpora tion. Normally, these will be sent to your distributor within

three working days.

7-6. WARRANTY All replacement parts (except lamps and fuses) are warranted

for 90 days against manufacturing defects and workmanship.

If damage occurs during shipping, notify the carrier at once so

that a claim may be properly led. Refer to warranty in the

front of this manual for other rights and limitations.

Recommended replacement parts are indicated with A or B

in the parts lists:

A = parts to be stocked on service vans or trucks

B = parts to be stocked at the distributor/KES location.

Inventory on all other parts not identif ed, should be based

upon usage in the territory. Please use care when ordering

recommended parts, because all voltages and variations a

marked. Distributors should order parts based upon comm

voltages and equipment sold in their territory.

Oct. 2014

53

Page 54

Model EEG- 252, 253, 254

1

2

9

11

3

8

4

6

7

5

10

12

Item No. Part No. Description Quantity

1

2 76555 WELD ASSY-COVER FULL ..................................................................... 1/vat

3 81980 LED-5MM BLUE ....................................................................................... 1/vat

4 -------- DRAIN KNOB ASSEMBLY ...................................................................... 1/vat

--See DRAIN KNOB drawing for breakdown

5 77575 CASTER-SWIVEL W/ BRAKE (front) ..................................................... 2

6 77679 CASTER-SWIVEL W/O BRAKE (back) ................................................... 2

7 151704 STUD ASSY-JIB SHELF ............................................................................ 1

8 52224 COVERED POWER SWITCH ................................................................... 1

9 81915 BASKET-1/2 SIZE BLK FRONT SUPP .................................................... A/R

9 85136 BASKET-FULL SIZE BLACK FR SPRT .................................................. A/R

10 152634 DRAIN PAN ASSY ..................................................................................... 1

11 97581 ASSY-EE CONTROL-25X ......................................................................... 1/well

11 140402 KIT-EEX CONTROL W/THUMB DRIVE (Smart Touch) ........................ 1/vat

81354 --DECAL-EVOLUTION ELITE CONTROL ............................................. 1/well

26974 --ASSY-SPEAKER ..................................................................................... 1/well

12 152487 CABLE-USB PORT AND .......................................................................... 1/vat

12 152488 CAP-USB .................................................................................................... 1/vat

13* 154068 ASSY-JIB TUBE QIK DISC-EEX25X ....................................................... 1

151171 WELD ASSY-WENDYS BASKET HANGER .......................................... 1/well

Recommend Parts: A=Truck Stock/B=Dist. Stock / *not shown/ A/R=As Required

54Jan. 2016

Page 55

12

11

Model EEG- 252, 253, 254

2

3

4

1

1

10

13

14

9

8

15

7

EEG-15X Filter Pan Assembly, Brushes & Accessory Holder

5

6

Item No. Part No. Description Quantity

1 91130 ASSY - WIDE DRAIN PAN .......................................... 1

2 82673 ASSY-DRAIN PAN COVER ..................................... 1

3 76259 WELD ASSY-CRUMB CATCHER .......................... 1

4 89416 WELD ASSY-FILTER WEIGHT .............................. 1

5 89420 FILTER-SECTION .................................................... 1

6 93128 WELD ASSY-WIDE DRAIN PAN ........................... 1

7 52487 CASTER - FILTER PAN ........................................... 4

8 85397 ADAPTOR - PUMP TO PICKUP TUBE .................. 1

A 9 86349 O-RING-PICKUP TUBE ........................................... 3

10 ** SPECIAL PLEATED FILTER ........................................ 1

**(Ordered through Wendy’s supplier)

11 83790 Bracket - Accessory Holder ............................................. 1

12 83791 Holder - Accessory ........................................................... 1

B 13 12116 BRUSH - FRYER - LONG HANDLE ............................ 1

B 14 12112 BRUSH - STRAIGHT WHITE ....................................... 1

B 15 12126 BRUSH - BLACK L ........................................................ 1

Recommend Parts: A=Truck Stock/B=Dist. Stock / *not shown/ A/R=As Required

55Oct 2014

Page 56

Model EEG- 252, 253, 254

1.

2.

Item No. Part No. Description Quantity

A 1 92717 THERMOCOUPLE- HIGH LIMIT ........................................ 1/vat

2 140098 ASSY-PROBE ......................................................................... 1/well

150300

ASSY-LH DOOR

(long)

ASSY-LH DOOR

Door

150300 93370 93369 150624 39752

93355 93370 93369 85409 39752

93355 93370 93369 85409 39752

93356 93369 93370 150625 39752

150300

(long)

EEG-164 Door Break Down

93355

ASSY-LH DOOR

(short)

EEG-163 Door Break Down

Door Hinge Chart

Top Hinge

(Door)

ASSY-LH DOOR

93355

ASSY-LH DOOR

(short)