Page 1

Henny Penny

Evolution Elite™

Reduced Oil Cap acity Open Fryers

(Split Vat & Full V at–

Model EEE-141

Model EEE-142

Model EEE-143

Model EEE-144

Electric)

OPERA TOR’S MANUAL

REGISTER WARRANTY ONLINE A T WWW .HENNYPENNY .COM

Page 2

Page 3

LIMITED WARRANTY FOR HENNY PENNY EQUIPMENT

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the original

purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT : Any part of a new appliance, except baskets, lamps, and fuses, which proves to be defective in

material or workmanship within two (2) years from date of original installation, will be repaired or replaced without

charge F .O.B. factory , Eaton, Ohio, or F .O.B. authorized distributor . Baskets will be repaired or replaced for ninety (90)

days from date of original installation. Lamps and fuses are not covered under this Limited W arranty. T o validate this

warranty, the registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

FIL TER SYSTEM: Failure of any parts within a fryer filter system caused by the use of the non-OEM filters or

other unapproved filters is not covered under this Limited Warranty.

REPLACEMENT P A R TS: Any appliance replacement part, except lamps and fuses, which proves to be defective in

material or workmanship within ninety (90) days from date of original installation will be repaired or replaced without

charge F .O.B. factory , Eaton, Ohio, or F .O.B. authorized distributor .

The warranty for new equipment covers the repair or replacement of the defective part and includes labor charges and

maximum mileage charges of 200 miles round trip for a period of one (1) year from the date of original installation.

The warranty for replacement parts covers only the repair or replacement of the defective part and does not include any

labor charges for the removal and installation of any parts, travel, or other expenses incidental to the repair or replacement of

a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or workmanship

issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover any frypot that fails due to

any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new frypot at no cost or

provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will

be replaced at no charge for the frypot only . Any freight charges and labor costs to install the new frypot as

well as the cost of any other parts replaced, such as insulation, thermal sensors, high limits, fittings, and

hardware, will be the responsibility of the owner.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was purchased. No

allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If damage occurs during

shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY FOR ANY BREACH

OF W ARRANTY OR OTHER TERM. BUYER AGREES THA T NO OTHER REMEDY (INCLUDING CLAIMS FOR ANY INCIDENT AL OR CONSEQUENTIAL DAMAGES) SHALL BE AV AILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) if the

equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED WARRANTY IS EXPRESSL Y IN LIEU OF ALL OTHER W ARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANT ABILITY AND FITNESS, AND ALL OTHER W ARRANTIES ARE EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY

PERSON TO ASSUME FOR IT ANY OTHER OBLIGA TION OR LIABILITY.

Revised 01/01/07

FM05-053-F

5-19-10

Page 4

Model EEE-141,142, 143, 144

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION ..........................................................................................1-1

1-1 Introduction...........................................................................................1-1

1-2 Proper Care ..........................................................................................1-1

1-3 Assistance .............................................................................................1-1

1-4 Safety ...................................................................................................1-2

Section 2. INST ALLATION.............................................................................................2-1

2-1 Introduction...........................................................................................2-1

2-2 Unpacking .............................................................................................2-1

2-3 Selecting the Fryer Location ..................................................................2-2

2-4 Leveling the Fryer ..................................................................................2-2

2-5 V entilation of Fryer ................................................................................2-3

2-6 Electrical Requirements ..........................................................................2-3

2-7 Dimensions ............................................................................................2-5

Section 3. OPERA TION ..................................................................................................3-1

3-1 Operating Components..........................................................................3-1

3-2 Set-Up Mode .......................................................................................3-5

3-3 Filling or Adding Oil...............................................................................3-6

3-4 Morning Start-Up Procedures ...............................................................3-7

3-5 Basic Operation ....................................................................................3-8

3-6 Idle Mode.............................................................................................3-8

3-7 Oil Guardian™ (Auto T op-Off) .............................................................3-9

3-8 Selecting Product with Different Setpoint................................................3-9

3-9 Replacing the JIB ..................................................................................3-9

3-10 Model EEE-141 Oil Reservoir...............................................................3-10

3-11 SmartFilter Express™ ...........................................................................3-11

3-12 Daily Filtering ........................................................................................3-13

3-13 Discarding Oil from V at Using Optional Discard Shuttle ..........................3-16

3-14 Operation Instructions for Optional Bulk Oil Disposal System.................3-17

3-15 Changing the Filter Pad..........................................................................3-18

3-16 Removing and Cleaning Basket Rest ......................................................3-20

3-17 Clean-Out Mode...................................................................................3-21

3-18 Check/Replace Filter Drain Pan O-Rings ...............................................3-24

3-19 Info Button Stats ...................................................................................3-25

3-20 Filter Button Stats..................................................................................3-25

3-21 Preventive Maintenance Schedule ..........................................................3-26

Section 4. INFORMA TION MODE ................................................................................4-1

4-1 Information Mode Details ......................................................................4-1

Section 5. PRODUCT PROGRAM MODE .....................................................................5-1

5-1 Modifying Product Settings ....................................................................5-1

i 510

Page 5

Model EEE-141,142, 143, 144

T ABLE OF CONTENTS (Continued)

Section Page

Section 6. LEVEL 2 PROGRAMMING ...........................................................................6-1

6-1 Special Program Mode .........................................................................6-1

6-2 Clock Set.............................................................................................. 6-10

6-3 Data Logging, Heat Control, T ech, Stat and Filter Control Modes ..........6-10

Section 7. TROUBLESHOOTING ..................................................................................7-1

7-1 Troubleshooting Guide ...........................................................................7-1

7-2 Error Codes ..........................................................................................7-3

909 ii

Page 6

SECTION 1. INTRODUCTION

Model EEE-141,142, 143, 144

1-1. INTRODUCTION

1-2. PROPER CARE

The Henny Penny reduced oil capacity open fryer is a basic unit of

food processing equipment. This unit is used only in institutional and

commercial food service operations.

As of August 16, 2005, the W aste Electrical and Electronic

Equipment directive went into effect for the European Union. Our

products have been evaluated to the WEEE directive. W e have

also reviewed our products to determine if they comply with the

Restriction of Hazardous Substances directive (RoHS) and have

redesigned our products as needed in order to comply . T o continue

compliance with these directives, this unit must not be disposed as

unsorted municipal waste. For proper disposal, please contact

your nearest Henny Penny distributor .

As in any unit of food service equipment, the Henny Penny open

fryer does require care and maintenance. Requirements for the

maintenance and cleaning are contained in this manual and must

become a regular part of the operation of the unit at all times.

1-3. ASSISTANCE

Should you require outside assistance, call your local independent

distributor in your area, or call Henny Penny Corp. at

1-800-417-8405 or 1-937-456-8405.

1-1 1108

Page 7

Model EEE-141,142, 143, 144

1-4. SAFETY The Henny Penny open fryer has many safety features incorporated.

However, the only way to ensure a safe operation is to fully under stand the proper installation, operation, and maintenance procedures. The instructions in this manual have been prepared to aid you

in learning the proper procedures. Where information is of particular importance or safety related, the words DANGER, W ARNING,

CAUTION, and NOTICE are used. Their usage is described

below .

SAFETY ALER T SYMBOLS are used with DANGER,

W ARNING, or CAUTION which indicates a personal injury

OR type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICA TES AN IMMINENTL Y

HAZARDOUS SITUA TION WHICH, IF NOT

AVOIDED, WILL RESULT IN DEA TH OR SERIOUS

INJURY.

1108 1-2

Page 8

1-4. SAFETY

(Continued)

Model EEE-141,142, 143, 144

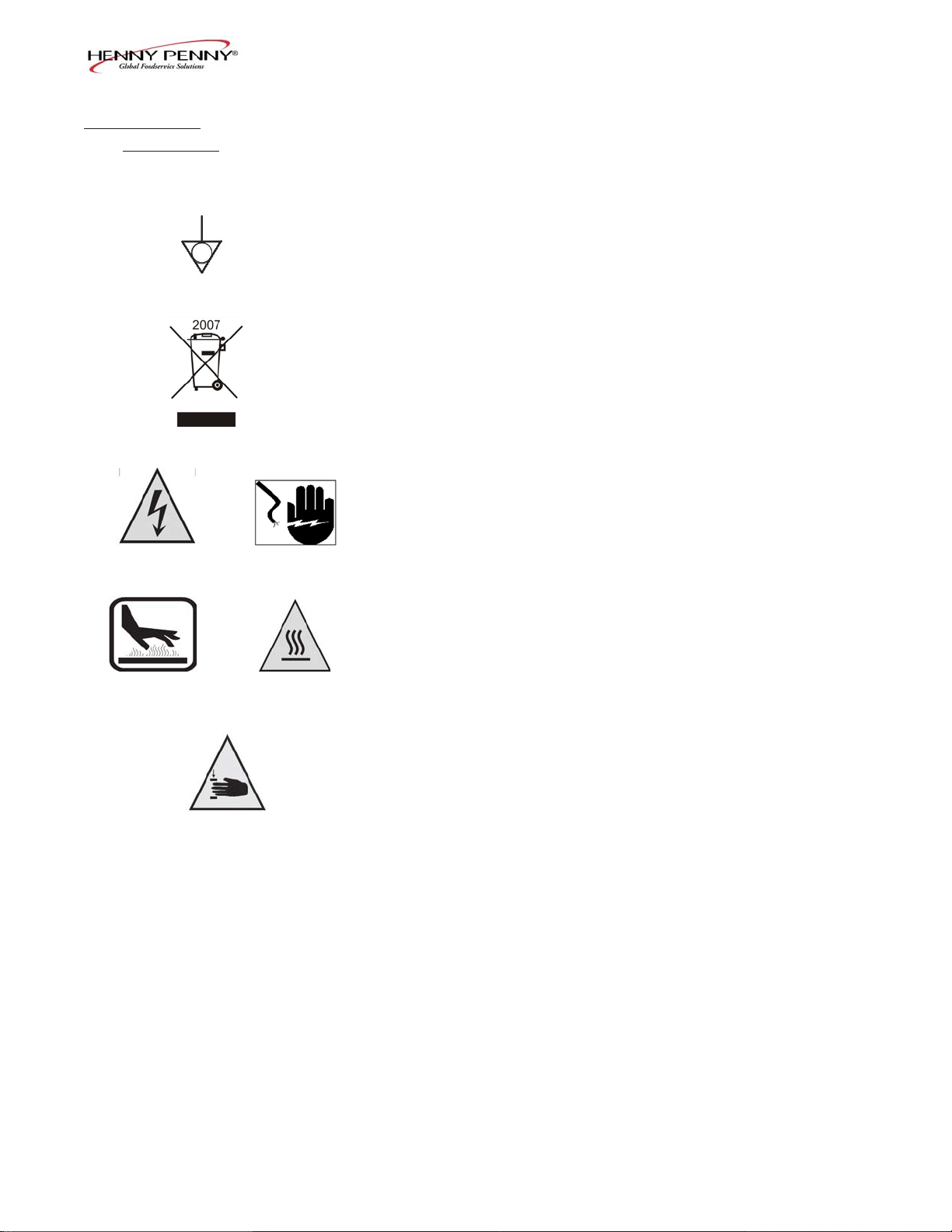

Equipotential Ground Symbol

W aste Electrical and Electronic Equipment (WEEE) Symbol

Shock Hazard Symbols

OR

OR

Hot Surface Symbols

Pinch-Point Symbol (Auto-Lift Fryers)

1-3

310

Page 9

SECTION 2. INST ALLA TION

2

1

4

5

3

Model EEE-141,142, 143, 144

2-1. INTRODUCTION

2-2. UNP ACKING

INSTRUCTIONS

This section provides the installation and unpacking instructions for

the Henny Penny open fryer.

Installation of this unit should be performed only by a qualified

service technician.

Do not puncture the fryer with any objects such as drills

or screws as component damage or electrical shock

could result.

Any shipping damage should be noted in the presence of the

delivery agent and signed prior to his or her departure.

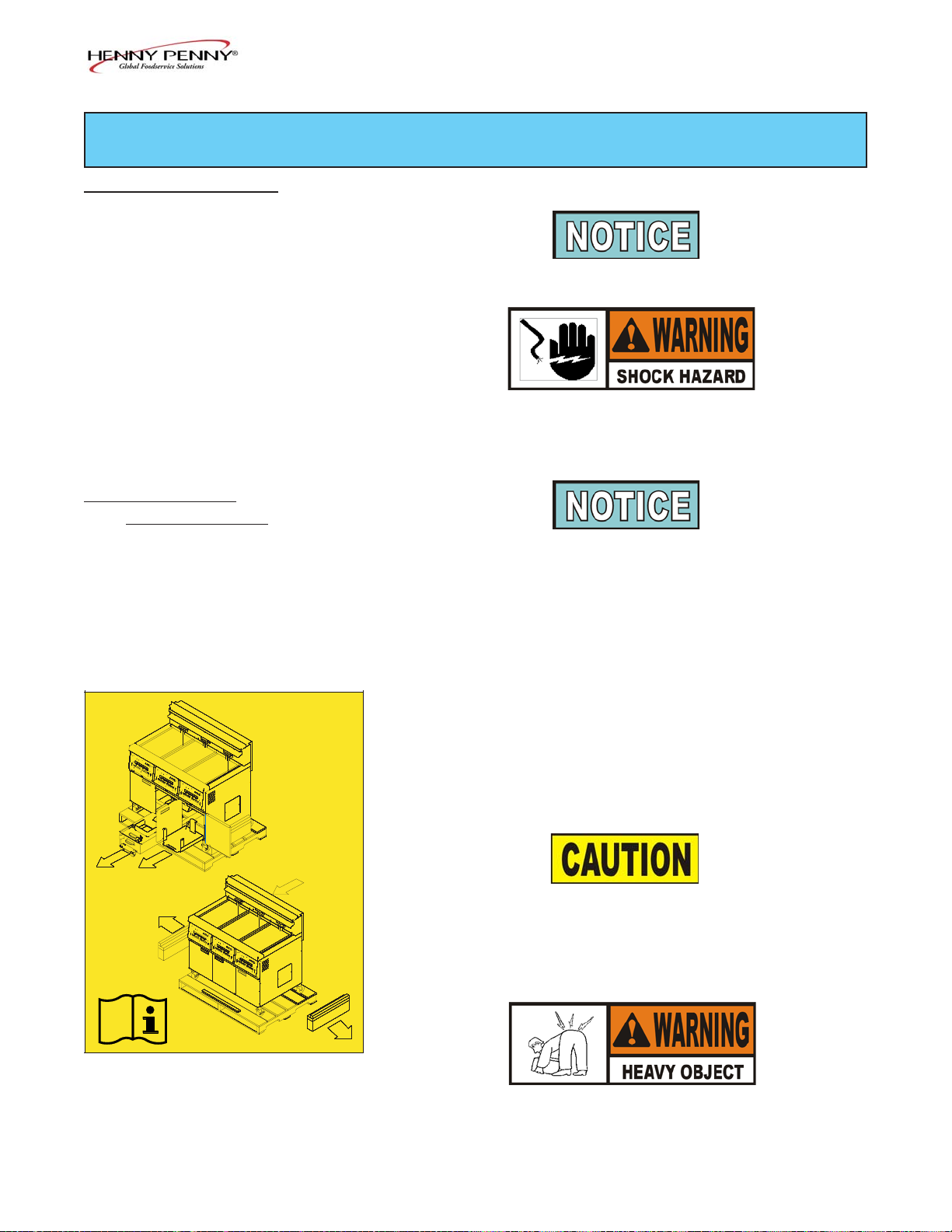

1. Cut and remove the metal bands from the carton.

2. Remove the carton lid and lift the main carton off the fryer .

3. Remove corner packing supports (4).

4. Cut the stretch film from around the carrier/rack box and

remove it from the top of the fryer lid.

5. Cut and remove the metal bands holding the fryer to the

pallet.

Remove filter drain pan and JIB shelf from fryer before

removing fryer from pallet or damage to the unit could

result. Figur e 1

6. Remove the fryer from the pallet.

Figure 1

T ake care when moving the fryer to prevent personal

injury . The fryer can weigh up to 800 lbs. (363 kg).

510 2-1

Page 10

Model EEE-141,142, 143, 144

2-3. SELECTING THE FRYER

LOCATION

The proper location of the fryer is very important for operation,

speed, and convenience. The location of the open fryer should

allow clearances for servicing and proper operation. Choose a

location which will provide easy loading and unloading without

interfering with the final assembly of food orders. Operators have

found that frying from raw to finish, and holding the product in

warmers provides fast continuous service. Keep in mind, the best

efficiency will be obtained by a straight line operation, i.e. raw in

one side and finished out the other side. Order assembly can be

moved away with only a slight loss of efficiency .

To avoid fire and ruined supplies, the area under the

fryer should not be used to store supplies.

T o prevent sever e burns from splashing hot oil,

position and install fryer to prevent tipping or movement.

Restraining ties may be used for stabilization.

2-4. LEVELING THE FRYER

For proper operation, the open fryer should be level from

side-to-side and front to back. Using a level placed on the flat

areas around the vat collar, on the middle well, and then adjust the

casters until the unit is level.

2-2 1108

Page 11

Model EEE-141,142, 143, 144

2-5. VENTILATION OF FR YER

2-6. ELECTRICAL

REQUIREMENTS

The fryer should be located with provision for venting into adequate

exhaust hood or ventilation system. This is essential to permit

efficient removal of steam exhaust and frying odors. Special

precaution must be taken in designing an exhaust canopy to avoid

interference with the operation of the fryer. W e recommend you

consult a local ventilation or heating company to help in designing an

adequate system.

V entilation must conform to local, state, and national codes.

Consult your local fire department or building authorities.

Check the data plate, mounted on the inside of the doors, to

determine the correct power supply .

This fryer must be adequately and safely grounded

(earthed) or electrical shock could result. Refer to local

electrical codes for correct grounding (earthing) procedures or in absence of local codes, with The National

Electrical Code, ANSI/NFPA No. 70-(the current edition). In Canada, all electrical connections are to be

made in accordance with CSA C22.1, Canadian Electrical Code Part 1, and/or local codes.

T o avoid electrical shock, this appliance must be

equipped with an external circuit breaker which will

disconnect all ungrounded (unearthed) conductors. The

main power switch on this appliance does not disconnect

all line conductors.

(FOR EQUIPMENT WITH CE MARK ONL Y!)

T o prevent electric shock hazard this appliance must be

bonded to other appliances or touchable metal surfaces in

close proximity to this appliance with an equipotential

bonding conductor . This appliance is equipped with an

equipotential lug for this purpose. The equipotential lug is

marked with the following symbol .

1108 2-3

Page 12

Model EEE-141,142, 143, 144

2-6. ELECTRICAL

REQUIREMENTS

(Continued)

An all pole, separate disconnect switch, with proper capacity

fuses or breakers must be installed at a convenient location

between the fryer and the power source, and must be installed

according to national and local codes. It should be an insulated

copper conductor rated for 600 volts and 90o C. For runs

longer than 50 feet (15.24 m), use the next larger wire size. CE

units require a minimum wire size of 6 mm to be wired to the

terminal block.

It is recommended that a 30 mA rated protective device such as a

residual current circuit breaker (RCCB), or ground fault circuit

interrupter (GFCI), be used on the fryer circuit.

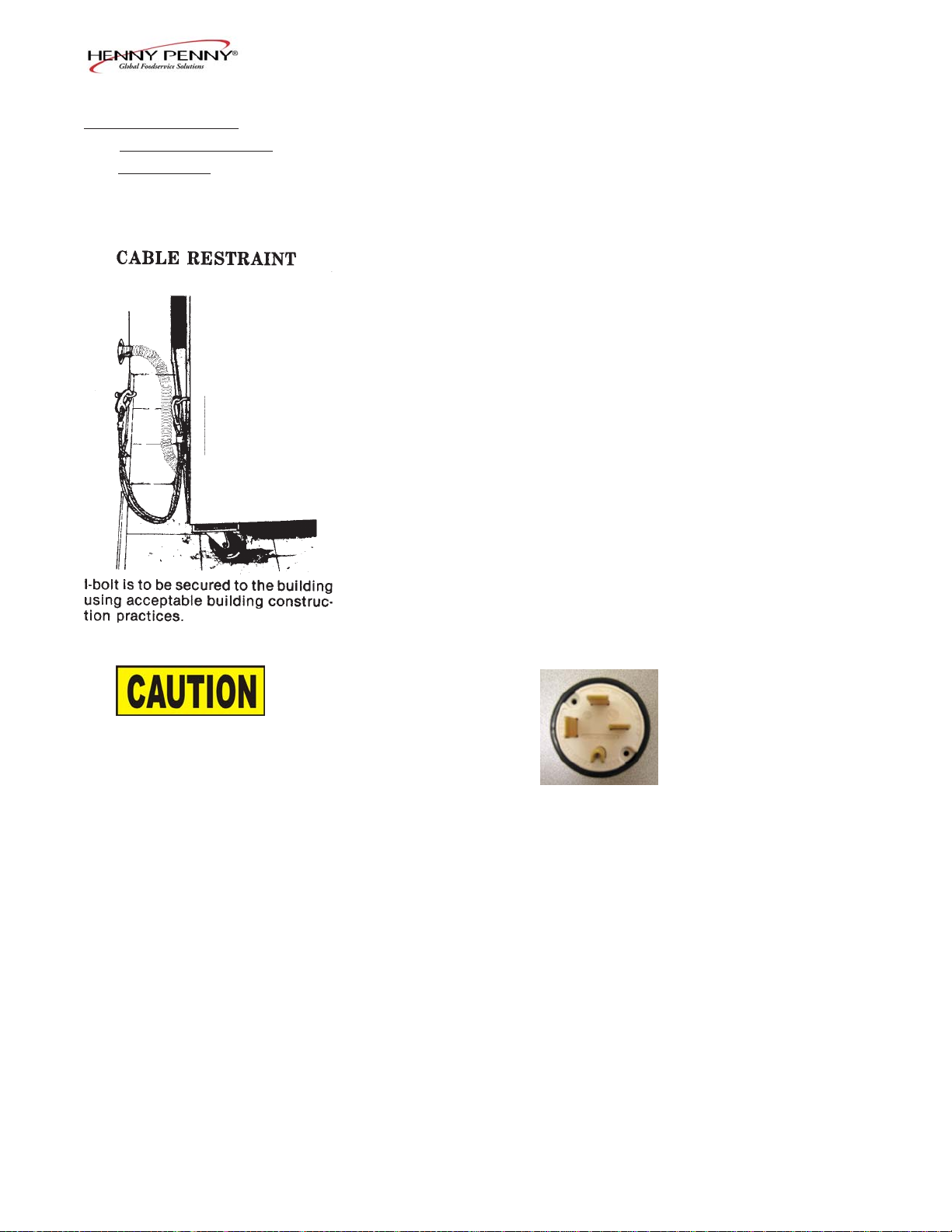

Permanently connected electric fryers with casters must be installed

with flexible conduit and a cable restraint, when installed in the

United States. See illustration at left. Holes are available in the rear

fryer frame for securing the cable restraint to the fryer . The cable

restraint does not prevent the fryer from tipping.

DRYWALL CONSTRUCTION

Secure I-bolt to a building stud. Do

not attach to drywall only . Preferred

installation is approximately six

inches to either side of service.

Cable restraint must be at least six

inches shorter than flexible conduit.

Each vat has it’s own power cord assembly , and uses

NEMA 15-50 S traight Plug or NEMA 15-60P.

The supply power cords shall be oil-resistant, sheathed flexible

cable, no lighter than ordinary polychloroprene or other equivalent

synthetic elastomer-sheathed cord.

2-4 109

Page 13

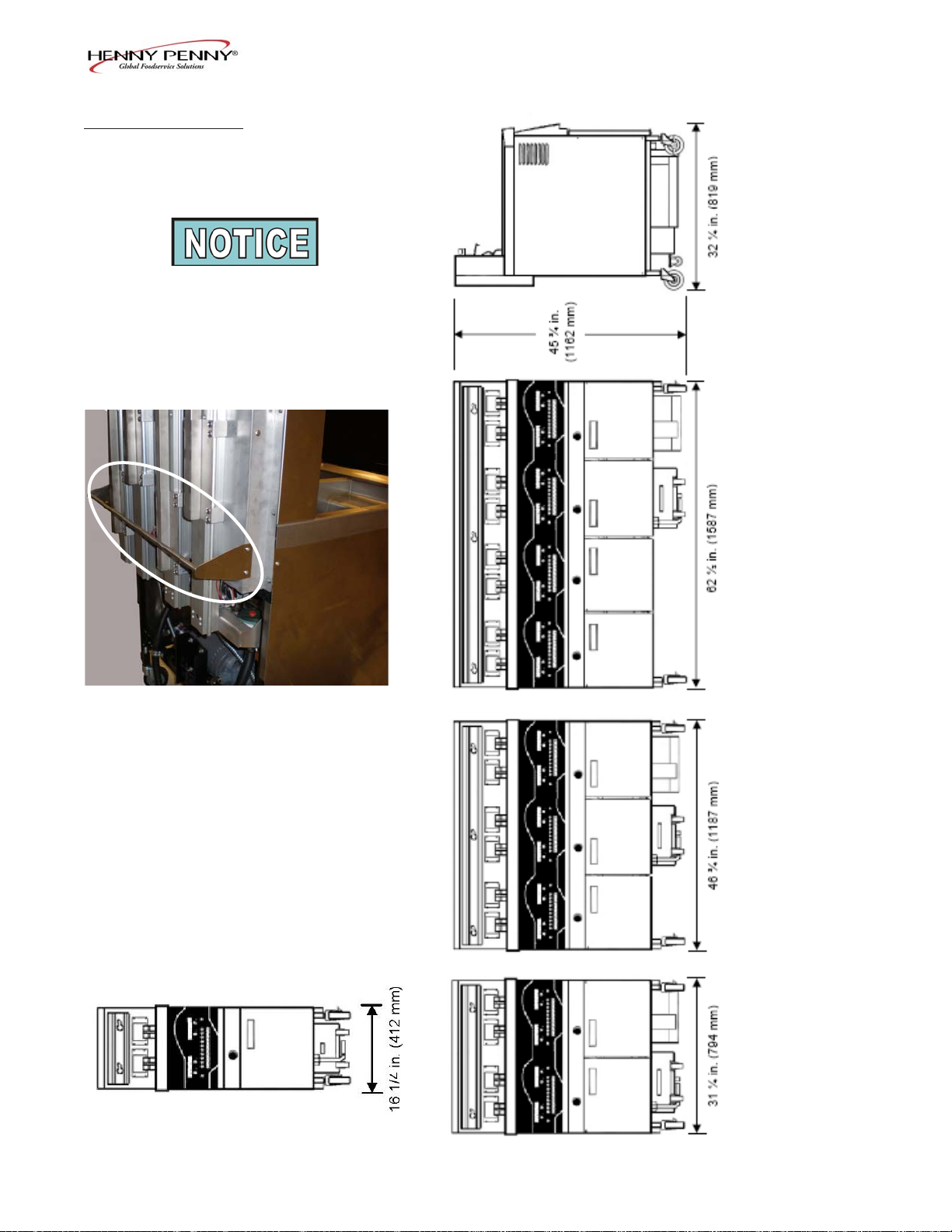

2-7. DIMENSIONS

Auto-Lift Fryers

Front to rear dimension is 36-7/8 (93.66 cm).

For doorways 36 in. (91.44 cm) or less, the

protective bumper bar on rear of the fryer

needs removed. See photo at below .

Model EEE-141,142, 143, 144

510 2-5

Page 14

Model EEE-141,142, 143, 144

SECTION 3. OPERA TION

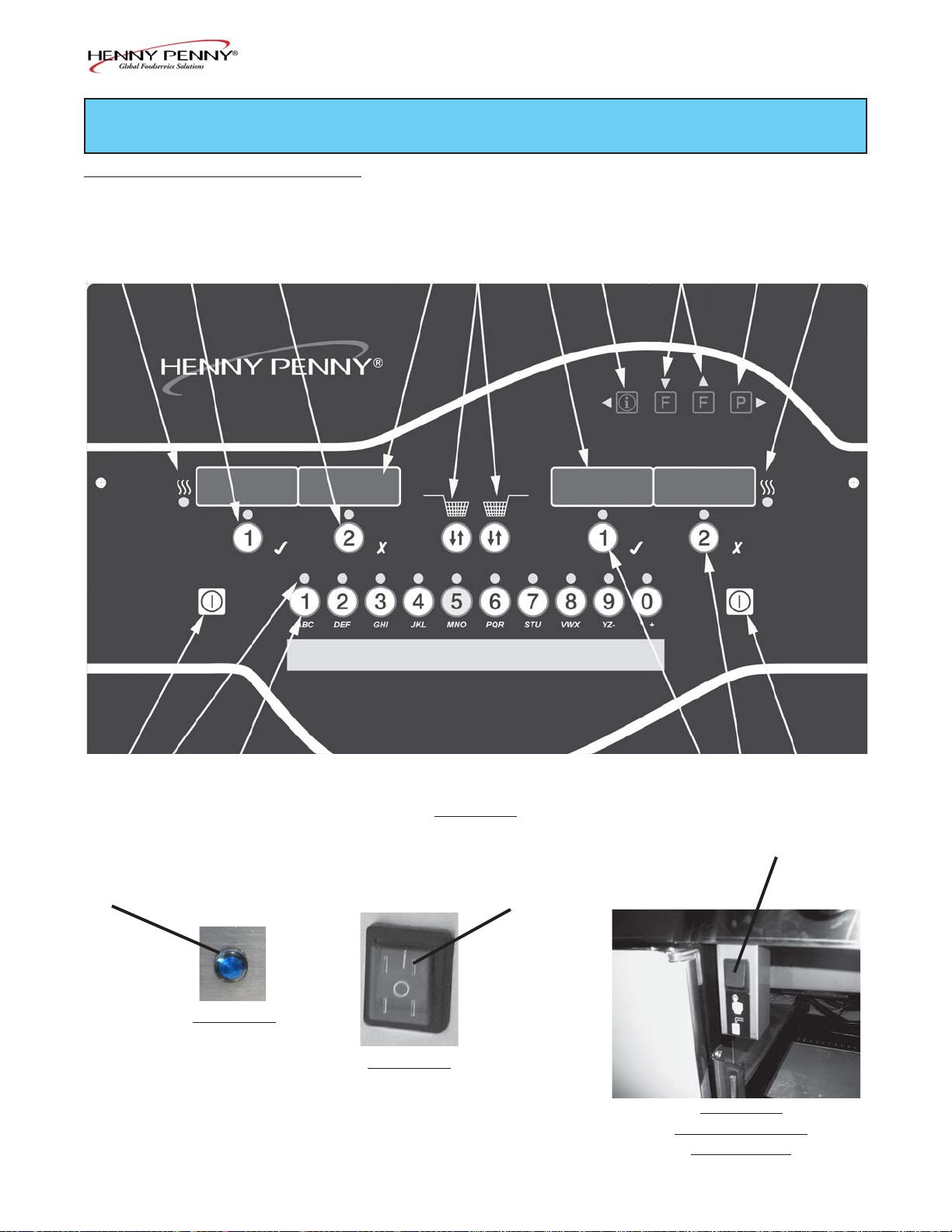

3-1. OPERA TING COMPONENTS Refer to explanations on the next pages.

12 645738

15

4

13

9

10

11

Figure 3-1

12 14

18

16

Figure 3-2

Figure 3-3

3-1 110

17

Figure 3-4

(Bulk Oil Supply

Fryers Only)

Page 15

Model EEE-141,142, 143, 144

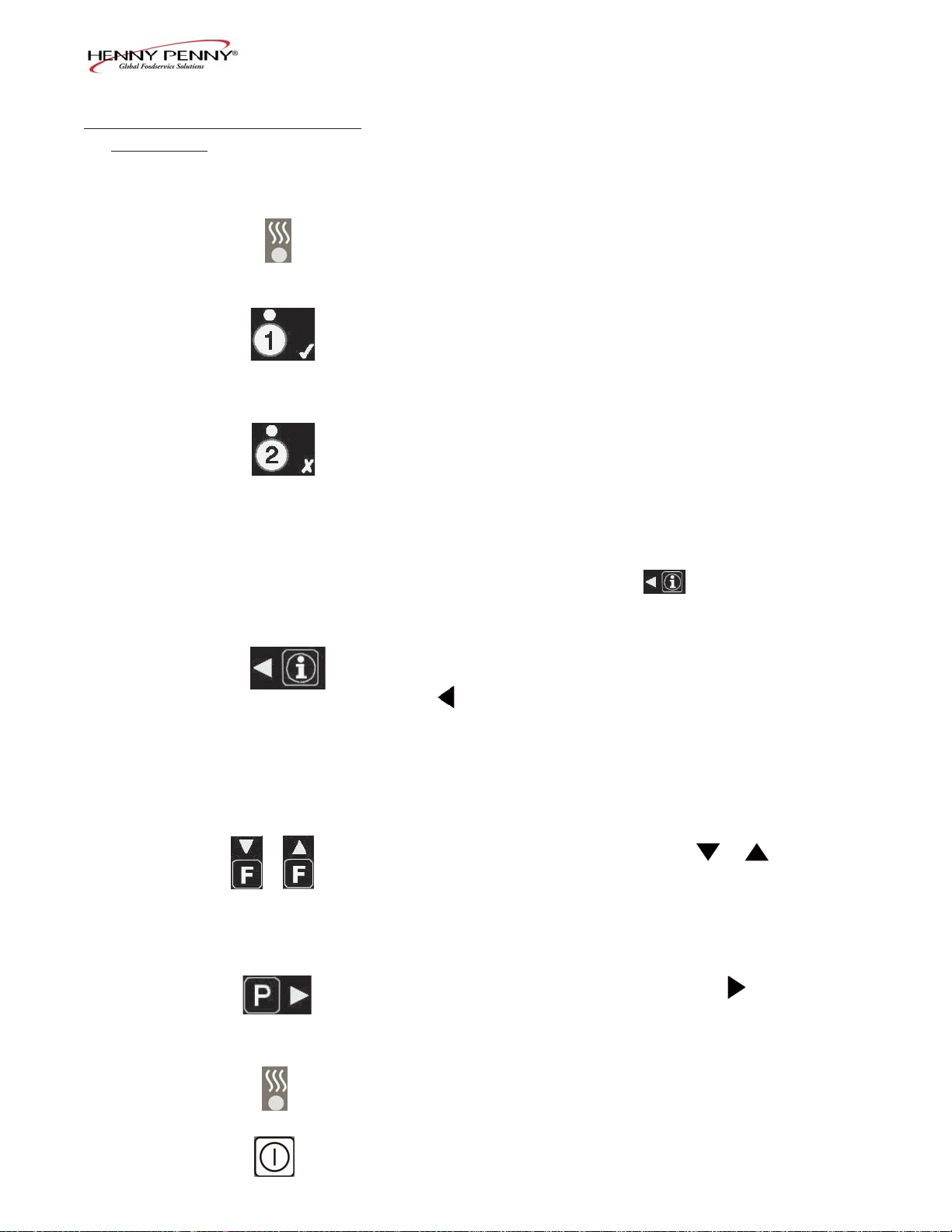

3-1. OPERA TING COMPONENTS

(Continued)

Refer to Figures 3-1, 3-2 & 3-3 in conjunction with the description

of the functions below .

Fig. Item Description Function

No. No.

3-1 1 This LED lights when the control calls for heat for the left

vat(s), and the elements come on and heat the oil

3-1 2 During normal operation, press this button to start and stop

cook cycles for the left basket; press to change displayed

product; also used for

√ √

√ to indicate YES or to confirm

√ √

3-1 3 During normal operation, press this button to start and stop

cook cycles for the left basket; press to change displayed

product; also used for X to indicate NO or cancel

3-1 4 Digital Display Shows the product codes; shows the timer countdown during

cook cycles; shows the prompts during the filter modes;

shows the selections in the Program Mode; shows the

temperature of the oil by pressing ; shows error codes

(also displays in several languages)

3-1 5 Press once to view oil temperature; press twice to vew the

setpoint temperature; Used in the Programming Modes; also used

for button; press to display the following fryer information

status:

a. actual oil temperature

b. oil setpoint temperature

c. recovery information for each vat

3-1 6 Used in the Programming and Filtering Modes; left button used

for left split vatand right button used for or buttons;

press to view the following filtering stats:

a. number of cook cycles before next filter-Global Filter Mode or

percentage of filter allowance-Mixed Mode

b. time and date of the most recent filter on each vat

3-1 7 Used to access the Program Modes; used as button to

advance to the next parameters in Program and Filter Modes;

press to select 2nd languages and volumes

3-1 8 This LED lights when the control calls for heat for the right

vat(s), and the elements come on and heat the oil

3-1 9 Press to turn on and off the heat system for the left vat(s)

110 3-2

Page 16

Model EEE-141,142, 143, 144

3-1. OPERA TING COMPONENTS (Continued)

Fig. Item Description Function

No. No.

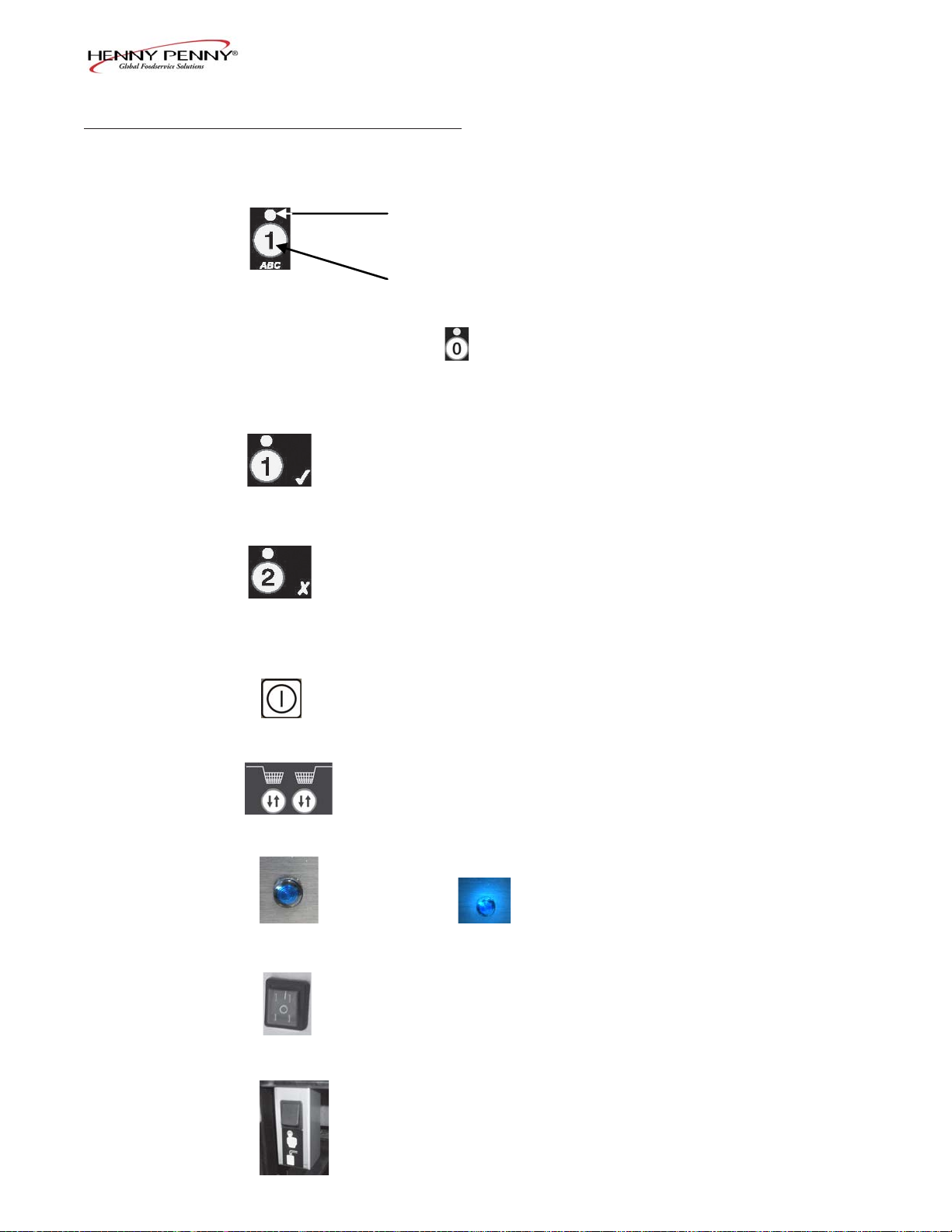

3-1 10 & 11 Each product button LED lights when that particular product has

been selected, or when it is compatible with cook temperature

Press to select the desired product; press to place the letters

under the button, during naming a product in Program Mode

T he can be used to start an Idle Mode if enabled in Special

Program Mode

3-1 12 During normal operation, press this button to start and stop

cook cycles for the right basket; press to change displayed

product; press to confirm prompts in the filter modes; also

used for

√ √

√ to indicate YES or confirmation

√ √

3-1 13 During normal operation, press this button to start and stop

cook cycles for the right basket; press to change displayed

product; press to deny prompts in the filter modes; also

used for X to indicate NO or cancel

3-1 14 Press to turn on and off the heat system for the right vat(s)

3-1 15 Auto-lift equipped fryers ONLY . Press to raise or lower baskets.

3-2 16 A Filter Beacon® is found beside each black drain knob; when

lit blue , indicates the oil should be filtered at this time;

beacon flashes when the drain needs opened or closed

3-3 17 When the power switch is turned to the ON position, power is

supplied to the controls and pumps

3-4 18 For fryers with a bulk oil supply , press this button to fill the JIB

3-3 110

Page 17

2

Model EEE-141,142, 143, 144

3

1

4

5

Figure 3-5

Fig. Item Description Function

No. No.

3-5 1 Filter Drain Pan Assy. Oil is drained into this pan and then is pumped

through filters to help prolong the use of the oil

3-5 2 Basket Rest The baskets hang on this when not in use, or to drain the

product after a cook cycle

3-5 3 V at Covers Covers the vat when not in use

3-5 4 Drain Knob Pull-out on black knobs to open drain valve and oil drains

from vat; Push-in to close drain valve and oil can be

pumped into vat

3-5 5 JIB Jug-in-a-Box; holds oil to be pumped into vats to top-off

the oil level by the Oil Guardian™ process

909 3-4

Page 18

Model EEE-141,142, 143, 144

3-2. SET -UP MODE

Upon initial start-up, the controls will ask to confirm the settings for

the fryer.

When the main power switch is turned on, “OFF” shows in both

displays. Press on either side and *SETUP* *ENTER

CODE* shows in the displays. Press 1, 2, 3, and “LANGUAGE”

shows on the left display , “ENGLISH” on the right display.

Use or buttons to change the operation display to,

“FRANCAIS”, “ESPANOL”, “PORTUG”, “DEUTSCHE”,

“SVENSKI”, “RUSSIAN”.

Press to continue with the other set-up items which include:

• TEMP FORMAT -

o

F or oC

• TIME FORMAT - 12-HR OR 24-HR

• ENTER TIME - Time of day (use product buttons to change)

• ENTER TIME - AM OR PM

• DATE FORMAT - US (MM-DD-YY) or

INTERNATIONAL (DD-MM-YY)

• ENTER DATE - Today’s date (use product buttons to change)

• DAYLIGHT SAVING TIME - 1.OFF; 2.US (2007 & after);

3.EURO; 4.FSA (US before 2007)

• FRYER TYPE - ELEC or GAS

• VAT TYPE - FULL OR SPLIT

• AUTOLIFT ENABLED? - NO LIFT or YES LIFT

• BULK OIL SUPPLY - YES or NO

• BULK OIL DISPOSE? - YES or NO

• S/N - Shows serial number of the unit or can be recorded (THIS

SERIAL NUMBER SHOULD MATCH THE SERIAL

NUMBER ON THE DATA PLATE, ON THE DOORS.)

• 2nd LANGUAGE - By setting a second language in the controls,

2 languages can now be easily chosen by pressing during

normal operation.

One language shows in the left display and the second language

shows in the right display . Pressing the

√√

√ button under the desired

√√

language, selects that language seen in displays.

• 2nd VOLUME - By setting a second volume in the controls,

2 volumes can now be easily chosen by pressing twice

during normal operation.

One volume setting shows in the left display (NONE to 10; 10

being the loudest) and the second volume shows in the right

display. To select the volume, press the

√√

√ button under the desired

√√

volume .

• SETUP COMPLETE

Unless otherwise indicated, use or to change settings.

The Setup Mode can also be accessed by re-initializing the controls,

in Special Program Mode, in Level 2 programming (SP-3).

3-5 909

Page 19

3-3. FILLING OR

ADDING OIL

Figure 1

Model EEE-141,142, 143, 144

The oil level must always be above the heating elements

when the fryer is heating and at the oil level indicators on

the rear of the vat. Failure to follow these instructions

could result in a fire and/or damage to the fryer.

Solid oil is not recommended. Solid oil could cause

clogging and pump failures.

1. It is recommended that a high quality liquid frying oil be used in

the open fryer. Some low grade oils have a high moisture

content which causes foaming and boiling over.

Wear gloves to avoid severe burns when pouring hot oil

into vat. Oil and all metal parts that are in contact with

the oil are extremely hot; take care to avoid splashing.

Figure 2

2. Oil Capacities:

Full-size vats = 15 quarts/30 lbs (14.2 liters/13.6 kg)

Split-vats = 7.5 quarts/15 lbs (7.1 liters/6.8 kg).

All vats have 2 level indicator lines inscribed on the rear wall of

the vat, in which, the upper-most line shows the oil at the

proper level when heated. Figures 1 & 2.

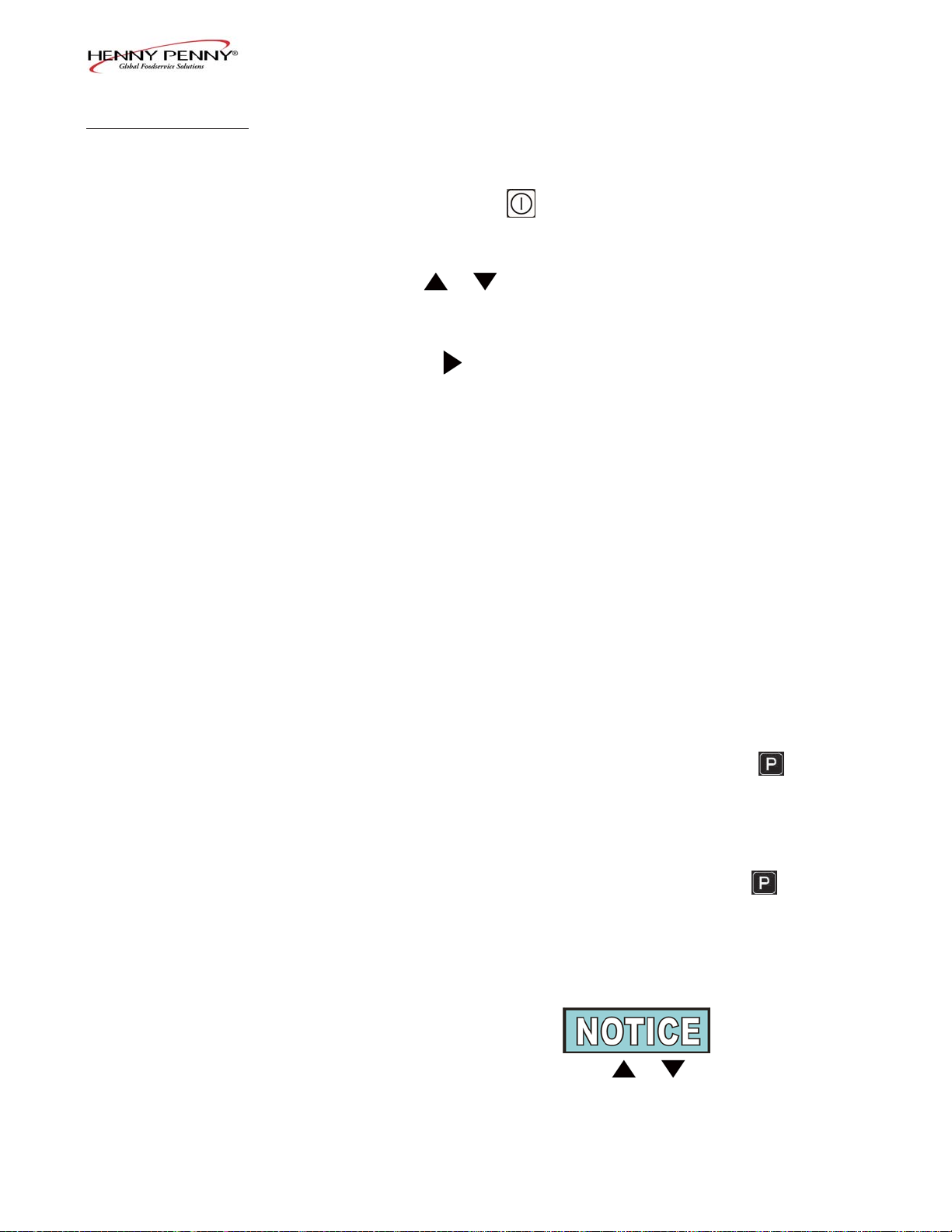

3. Place basket support inside of vat and fill vat with cold oil to the

lower indicator. Figure 3.

Filling Vat from Bulk Supply (Must be equipped with optional

accessories & controls set to “YES” for “Bulk Oil Supply?”

in Set-Up Mode)

1. Turn the main power switch to the ON position.

2. Place basket support inside of vat. Figure 3.

3. Press and hold (on either side) until display shows

*FILTER MENU*, along with 1.AUTO FILTER?

4. Press and release button 6 times until display shows

“7. FILL POT FROM BULK”.

5. Press

“

vat and display shows “FILLING”.

6. Once oil is to the lower fill line, release

returns to “FILL VAT” “

button twice to return to normal operation.

√√

√ button and display shows “FILL VAT” and then

√√

√√

√=PUMP” “X=DONE”. Press and hold

√√

√√

√=PUMP” “X=DONE”. Press X

√√

√√

√ button again to fill

√√

√√

√ button and display

√√

Figure 3

Press and hold the black button behind the right door to fill the

JIB from the Bulk Supply as needed. Figure 3.

1009 3-6

Page 20

Model EEE-141,142, 143, 144

3-4. MORNING START-UP

PROCEDURES

1. Make sure basket support is in vat and the vat is filled with oil

to the proper level.

Model EEE-141, fill the oil reservoir. See Section 3-10.

2. Move power switch to the ON position and then press

to turn on heat for the desired vat. If display shows “IS POT

FILLED?” make sure oil is at the proper level (see Section

√√

3-3) and then press

button for “YES”.

√

√√

Unit automatically goes into the Melt Cycle until the oil temperature reaches 180°F (82°C) and then control automatically

exits the Melt Cycle.

The Melt Cycle may be bypassed, if desired, by pressing

√√

√

√√

button or X button and holding it for 5 seconds.

The control then shows “EXIT MEL T” “YES NO”.

√√

Press

√ button for “YES” and vat heats continuously until the

√√

set-point temperature is reached.

Do not bypass the Melt Cycle unless enough oil has melted

to completely cover all of the elements. If the Melt Cycle is

bypassed before all elements ar e covered, excessive

smoking of oil, or a fire will r esult.

DO NOT OVERLOAD, OR PLACE PRODUCT WITH

EXTREME MOISTURE CONTENT INTO THE

BASKETS. 3 LBS. (1.4 KG.) IS THE MAXIMUM

AMOUNT OF PRODUCT PER FULL VAT AND 1-1/2

LBS. (.68 KG.) FOR THE SPLIT VATS. FAILURE T O

FOLLOW THESE INSTRUCTIONS CAN RESUL T IN

OIL OVERFLOWING THE VAT WHICH COULD

CAUSE SERIOUS BURNS, PERSONAL INJUR Y , FIRE

AND/OR PROPERTY DAMAGE.

3-7 510

Page 21

Model EEE-141,142, 143, 144

3-5. BASIC OPERA TION

The Evolution Elite fryer is availalble as non-auto-lift and auto-lift

models. The auto-lift controls, allow the baskets to be automatically

lowered into the shortening at the beginning of the cook cycle, and

raised from the shortening at the end of the cycle.

1. Once out of the Melt Cycle, LOW TEMP flashes until the set-

point temperature has been reached. No cook cycles can be

started while “LOW TEMP” shows in the display. Once the

set-point temperature has been reached, the product name now

shows in the display , ex: FRY, and product now can be

placed in the oil.

2. Press a timer button or . (Auto-lift fryers, the

basket automatically lowers into the shortening.)

3. Display shows the name of the product cooking (ex: “FRY”)

and the timer counting down.

4. When cook cycle is complete, and alarm sounds and display

shows “DONE”.

5. Press the timer button under “DONE” to stop the alarm, and lift

basket from vat. (Auto-lift fryers, the basket automatically rises

out of the shortening.)

3-6. IDLE MODE

6. If a Quality Timer (hold timer) has been programmed, the hold

time starts automatically when the user presses the timer button

to end the cook cycle. While the quality timer counts down,

the display shows the three-digit product abbreviation followed

by “Qn”, where “n” is the number of minutes remaining.

ex: “FRY” / “Q5” / “FRY” / “Q5” / “FRY” / “Q4”, etc.

At the end of the timer countdown, the control beeps and the

display shows “QUAL” followed by the three-digit product

name: “QUAL” / “FRY” / “QUAL”/ “FRY”. Press the timer

button to cancel the timer.

To stop a cook cycle at any time, press and hold the timer

button or .

Once programmed, an Idle Mode can help to save on oil and

utility costs. If the fryer is not being used for several minutes,

the controls can be set to automatically lower the oil temperature, or

press the button to start the Idle Mode.

The oil is maintained at a lower temperature until the button

is pressed, and then the oil is heated to cooking temperature. See

Special Program Modes, SP-12, SP-13 & SP-14.

110 3-8

Page 22

Model EEE-141,142, 143, 144

3-7. OIL GUARDIAN™

(Auto Top-Off)

During normal operation, the control automatically monitors the

oil level in the vat. If the control senses the oil level too low , the

unit automatically pumps oil from the JIB into the vat to keep

the oil at the proper level.

Manual T op-Off

If the oil level is a little low , oil can be added to the vat at any time

from the JIB to raise the oil level to the proper level by following the

steps below . This procedure is NOT to be used to fill an empty vat

1. Press and hold until display shows

“*FIL TER MENU*”, along with “1.EXPRESS FIL TER”.

2. Press 5 times until “6.FILL FROM JIB” shows in

the display .

3. Press

4. Press and hold

√√

√ button and display shows “*PUMP” and “EXIT”.

√√

√√

√ button and display shows “FILLING” and

√√

the oil is pumped from the JIB to the vat.

5. Once frypot is full, release

√√

√ button and display returns to

√√

“*PUMP” and “EXIT”. Press X button twice to return to

normal operation.

3-8. SELECTING A PRODUCT

WITH A DIFFERENT

SETPOINT

3-9. REPLACING THE JIB

When selecting a product, if “XXX XXX” shows in the display , the

setpoint temperature is not correct for this product.

T o change the setpoint temperature for the desired product:

1. Press product button, for ex: (FRY).

2. Display shows “XXX XXX”.

3. Press and hold a timer button or for 5

seconds and then “FRY” shows in display .

4. Allow oil temperature to reach setpoint temperature before

dropping product.

1. Control displays “JIB IS LOW” and an alarm sounds.

2. Open right door and pull JIB from unit. Pull the cap from top

o f JIB and discard empty JIB and replace with full one.

Figure 1

Model EEE-141 (single-well) see next section.

Figure 1

3-9 510

Page 23

Model EEE-141,142, 143, 144

3-10. MODEL EEE-141 OIL

RESERVOIR

Figure 1

Filling Oil Reservoir

1. Control displays “JIB IS LOW” and an alarm sounds.

2. Open door and pull reservoir forward and remove reservoir

cover. Figure 1.

3. Place on bracket on door. Figure 2.

Figure 2

Figure 3

4. Pour oil into reservoir upto the fill lines (13 lbs. (6.12 kg.)) and

then replace cover and push reservoir back into position.

Figure 3.

Removing/Cleaning Reservoir

1. Open door and pull reservoir forward.

2. Slide reservoir to the left and lift from fryer . Figure 4.

3. Clean reservoir at a sink with soap and water .

Before placing the reservoir back into position, lubricate the

o-rings (below) on the filter tube with cold oil. Check o-rings

for tears or nicks and replace if necessary .

T o replace o-ring, use a small, flat-bladed screwdriver, pry up

on the o-ring and pull off of end of tube. See below .

Figure 4

510 3-10

Page 24

Model EEE-141,142, 143, 144

3-11. SMAR TFILTER EXPRESS™ 1. During normal operation and after a certain number of

®

cook cycles, the Filter Beacon

illuminates on the front of the

fryer (Figure 1), and the control periodically shows “FL TR

NOW?”“YES NO”.

If X for NO is pressed, fryer resumes normal operation and

control suggests filter later.

Figure 1

2. Check Filter Pan: If the filter drain pan or cover is not inplace,

the display shows “CHK P AN”. Make sure that thefilter pipe

is tightly connected, and that the filter drain pan is asfar back

under fryer as it will go and the filter pan cover is in place.

Figure 2

Figure 3

3. Press

√√

√ button for YES and display shows *SKIM VA T*

√√

followed by “CONFIRM” “YES NO”. Press

√√

√ button for

√√

YES and display shows “OPEN DRAIN”.Pull-out on thedrain

knob (Figure 2), the display shows “DRAINING” and theoil

drains from the vat.

T o avoid overfilling the drain pan, drain only 1 vat at a

time. The drain pan holds 1 full vat, or 2 split vats of oil.

Overfilling the drain pan may cause slippery floors, which

may result in personal injury .

If filtering is NOT desired, press , the display shows

“STOPPED” and the SmartFilter is cancelled. The blue light

goes out and the controls return to normal operation. The

controls will suggest filtering after several more cook cycles.

If display shows “V AT EMTY”, followed by , “YES NO”, that

means the drain is clogged. Use the straight white brush to

clear drain and then press

√√

√ button. Display shows

√√

“DRAINING”, and then controls proceed with the filtering

process.

4. Once the control has completed the filtering process, display

shows “CLOSE DRAIN”. Push-in on the drain knob to close

the drain (Figure 3). The vat then re-fills with oil.

5. Once vat is filled, display shows “IS POT FILLED?” “YES

NO”. Make sure vat is full and then press

√√

√ button for YES

√√

and the control returns to normal operation.

3-11 1009

Page 25

Model EEE-141,142, 143, 144

3-11. SMAR TFILTER EXPRESS™

(Continued)

7. If the oil has not pumped back to the proper level in the vat

during the SmartFilter Express™ process, press X button for

NO and pump runs for another 30 seconds.

9. Display shows “IS POT FILLED?” “YES NO”. Make sure

vat is full and then press

√√

√ button and display shows and the

√√

control returns to normal operation. Press X button and pump

runs for another 30 seconds. You can try to fill the vat 3 times.

Filter Error

10. After trying to fill the vat 3 times without success, the controls

then shows “CHANGE FIL TER P AD?” “YES NO”. If

changing the filter pad at this time, press

√√

√ and change filter pad

√√

following the procedures in the Changing the Filter Pad Section.

Controls return to normal operation.

If filter pad is to be changed at a later time, press X button and

“CHANGE FIL TER P AD?” reminder shows 15 minutes later .

11. During the next SmartFilter Express™ with a new filter pad, if

the vat is not filled after 3 tries, the display shows “FIL TER

SER VICE REQUIRED-SEE TROUBLESHOOTING

GUIDE”.

If the “Service Required” message appears, then every 15

minutes the display shows “FIL TER PROBLEM FIXED? YES

NO”. If the problem has not been fixed, press X button. Once

the problem has been resolved, press

√√

√ and controls return to

√√

normal operation.

T o help ensure the vat fills completely, make sure filter pan is

cleaned at least daily , filter pad is changed, make sure JIB is full

and that “O” rings on the filter pan are in good condition.

209 3-12

Page 26

Model EEE-141,142, 143, 144

3-12. DAIL Y FIL TERING

This filtering procedure allows for a more thorough cleaning of the

vat and should be done once a day . The vat can be filtered during

any non-frying times.

T o avoid burns from hot oil, use approved safety equipment including, apron, face shield and gloves before

starting filtering procedure.

Also, to avoid overfilling the drain pan, drain only 1 vat at

a time. The drain pan holds 1 full vat, or 2 split vats of

oil. Overfilling the drain pan may cause slippery floors,

which may result in personal injury .

1. Check Filter Pan: A new filter pad should be used on

the first filter of each day , but the same filter pad can be used

the rest of the day , except for fish vats. After filtering a fish

vat, it is recommended to change the filter pad.

Make sure that the filter pan cover is in place, the filter drain

tube is secured, and the filter drain pan is pushed in and locked

into place. If the filter drain pan and cover are not latched into

place, the display shows “CHK P AN”.

Figure 1

2. Press and hold until display shows “1.EXPRESS

FILTER?” Split vat units, use the left button for the

left vat and the right button for the right vat.

3. Press button and display shows “2.DAIL Y FIL TER?”

4. Press

√√

√ button for YES and display shows “CONFIRM”,

√√

followed by “YES NO”.

5. Press

√√

√ button for YES and display shows “OPEN DRAIN”

√√

Pull-out on the drain knob (Figure 1), the display shows

“DRAINING” and the oil drains from the vat, or press

X button for NO and controls return to normal operation.

3-13 110

Page 27

Model EEE-141,142, 143, 144

3-12. DAIL Y FIL TERING

(Continued)

Figure 2

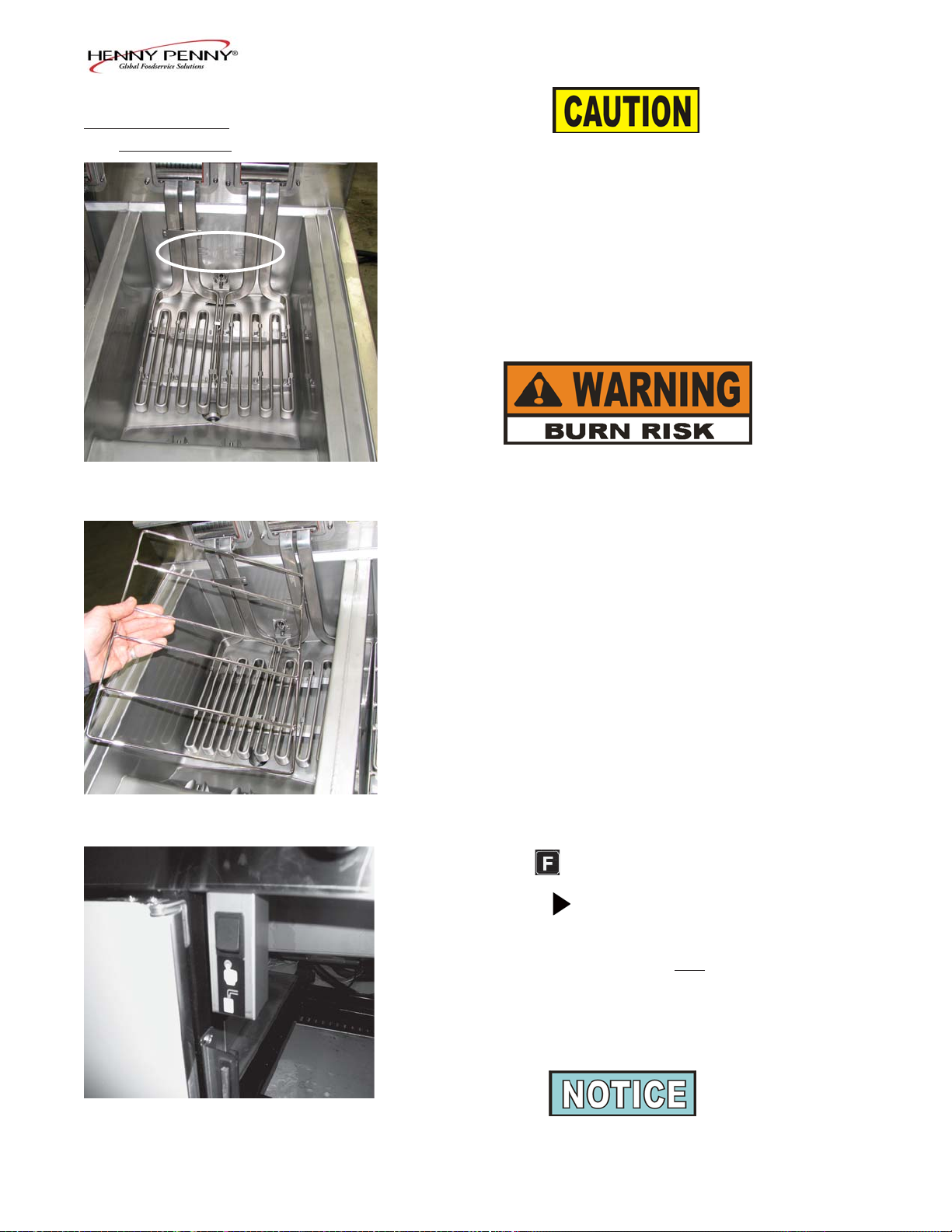

6. Once oil has drained from vat, use the lift tool and lift the hinged

element from the vat to clean the bottom of the vat. Figure 2.

(Auto-lift fryers, hinge back the basket hooks over the top of

the fryer before lifting the elements.)

Use protective cloth or gloves when lifting the element

with the lift tool. The element may be hot and severe

burns could result.

Avoid putting the lift tool in the center of the elements, at

the same area as the high limit bulb, or damage to the high

limit could result.

7. Scrape or brush the sides and the bottom of the vat. Be

careful not to damage the sensing probes.

Do not use steel wool, other abrasive cleaners or cleaners/

sanitizers containing chlorine, bromine, iodine or ammonia

chemicals, as these will deteriorate the stainless steel

material and shorten the life of the unit.

Figure 3

Figure 4

Do not use a water jet (pressure sprayer) to clean the unit,

or component damage could result.

8. Once the vat is clean and the display shows

“SCRUB VA T COMPLETE?” “YES NO”. Press

√√

√ button

√√

for YES and the display shows “WASH V AT” “YES NO”..

9. Lower the element and then press

√√

√ button and display

√√

shows “W ASHING”. The oil circulates through the vat for

several minutes. Once the wash cycle is complete, display

shows “W ASH AGAIN?” “YES NO”.

10. Press

√√

√ button for YES if another wash is needed, otherwise

√√

press X button for NO and the display shows “CLOSE

DRAIN” Push-in on the drain knob to close the drain (Figure

3) and the display shows “RINSING” and vat fills with oil.

11. Once the vat is filled, “OPEN DRAIN” shows in display. Pullout on drain knob to open the drain (Figure 4) and display

shows “RINSING”. When rinsing is complete, display shows

“RINSE AGAIN?” “YES NO”.

110 3-14

Page 28

Model EEE-141,142, 143, 144

3-12. DAIL Y FIL TERING

(Continued)

12. Press

√√

√ button for YES if another rinse is needed, otherwise

√√

press X button for NO. The display shows “POLISH?”

“YES”.

13. Press

√√

√ button for YES and the oil is “polished” by circulating

√√

it through the filtering system. The display shows “5:00 STOP

POLISH”. If desired, press

√√

√ button to stop the polishing,

√√

otherwise the oil is polished for 5 minutes.

14. Once the oil is polished, the display shows “FILL VA T?”

“YES”. Press

√√

√ button and display shows “CLOSE DRAIN”.

√√

Push-in on the drain knob to close the drain (Figure 3), the

display shows “FILLING” and the vat then re-fills with oil.

15. Once full, the display shows “IS POT FILLED?” “YES NO”.

√√

Press

√ button for YES and fryer returns to normal operation.

√√

If X button is pressed, the display shows “FILLING”. You can

try to fill the vat 4 times and then the control shows “ADD

QUIT”. Press

√√

√ button and JIB pump runs 60 seconds, filling

√√

the vat from the JIB. Press X button and controls return to

normal operation.

3-15 110

Page 29

3-13. DISCARDING OIL

FROM VAT USING

OPTIONAL OIL

DISCARD SHUTTLE

Model EEE-141,142, 143, 144

WITH PROLONGED USE, THE FLASHPOINT OF

OIL IS REDUCED. DISCARD OIL IF IT SHOWS

SIGNS OF EXCESSIVE SMOKING OR FOAMING.

SERIOUS BURNS, PERSONAL INJUR Y , FIRE, AND/

OR PROPERTY DAMAGE COULD RESUL T .

1. Open the door, lift-up on the drain pan stop and pull-out the

drain pan assembly , using the handle on the drain pan.

Figures 1 & 2.

Figure 1

Figure 2

2. Press and hold (either one) until display shows

“*FILTER MENU*”, along with “1.EXPRESS FILTER?”.

3. Press and release button twice until display shows

“3.DISPOSE”. Press

“DISPOSE?” “YES NO”.

4. Press

5. With discard shuttle rolled into place (Figure 3), press

6. Display shows “VAT EMTY “YES NO”. Verify that vat is

7. Display shows “CLN VAT COMPLETE” “YES NO”. Once

√√

√ button and “IS DISPOSAL UNIT IN PLACE?

√√

“YES NO”shows in display .

If Bulk Oil Dispose is set to “YES”, “DRAIN VAT?” YES NO”

shows in display

and display shows “OPEN DRAIN”. Pull-out on drain knob

to open drain and display shows “DRAINING”. Oil now

drains from the vat into the shuttle.

empty, and press

vat is clean, press

DRAIN”. Push-in on the drain knob.

√√

√ button and display shows

√√

√√

√ button.

√√

√√

√ button. and display shows “CLOSE

√√

√√

√ button

√√

Figure 3

909 3-16

If Bulk Oil Dispose is set to “YES”, “

shows in the display. Press X button.

8. Display shows “MANUAL FILL POT”, followed by “IS POT

FILLED?”, along with “YES NO”. Fill the vat to the lower

indicator line on the rear of the vat and then press

See Filling or Adding Oil instructions from Section 3-3.

Fryer returns to normal operation.

9. Remove the discard shuttle from under fryer and replace with

the filter pan assembly .

√√

√=PUMP” “X=DONE

√√

√√

√ button.

√√

Page 30

Model EEE-141,142, 143, 144

3-14. OPERA TING INSTRUC-

TIONS FOR OPTIONAL

BULK OIL DISPOSAL

SYSTEM

Figure 1

1. Connect the female quick disconnect, that is attached to the

hose in the rear of the open fryer, to the correct male quick

disconnect at the wall. Once attached, the hose can remain

connected unless the open fryer is moved. Figures 1 & 2.

“BULK OIL DISPOSE?” in the Special Program Mode or

Set-Up Mode, must to set to “YES” for the Bulk Oil Dispose

System to operate. Also, a password code step (1, 2, 3) can

be added in Special Programming, SP-27.

2. Press and hold (left or right for split vats) until display

shows“*FILTER MENU*”, along with

“1.EXPRESS FILTER?”.

3. Press and release button twice until display shows

“3.DISPOSE”. Press

“YES NO”, or enter code 1, 2, 3, if SP-27 is set to YES.

4. Press

√√

√ button and “DRAIN VAT?” YES NO” shows in display

√√

√√

√ button and display shows“DISPOSE?”

√√

Figure 2

Press X button if drain pan already has oil in it. Skip to step 8.

5. Press

6. Display shows “VAT EMTY “YES NO”. Verify that vat is

7. Display shows “CLN VAT COMPLETE” “YES NO”. Once

8. Display shows “DISPOSE” and then “

9. When all the oil is pumped from the pan, press X button(STOP)

10. Display shows “DISPOSE” and then “

11. Display shows “MANUAL FILL VAT” (or “FILL VAT FROM

√√

√ button and display shows “OPEN DRAIN”. Pull-out

√√

on drain knob to open drain and display shows “DRAINING”.

Oil now drains from the vat into drain pan.

empty, and press

vat is clean, press

√√

Press

√ button and oil is pumped from the drain pan to the bulk

√√

oil container.

Press X button and close drain.

BULK if equipped), followed by “IS POT FILLED?”, along with

“YES NO”. Fill the vat to the lower indicator line on the rear of

the vat and then press

instructions from Section 3-3.

√√

√ button.

√√

√√

√ button.

√√

√√

√=PUMP” “X=DONE.

√√

√√

√=PUMP” “X=DONE.

√√

√√

√ button. See Filling or Adding Oil

√√

Fryer returns to normal operation.

3-17 1009

Page 31

Model EEE-141,142, 143, 144

3-15. CHANGING THE FILTER

PAD

Figure 1

In order to assure good oil pumping performance, the filter pad (or

paper) should be changed at least once per day .

If the filter pad has not been changed, a reminder shows on the

display , “CHANGE P AD”. Press

√√

√ button to cancel the

√√

message, but it reappears every 4 minutes until the filter pad has

been changed.

1. Make sure the main power switch is in the ON position.

2. Open the door, lift-up on the drain pan stop and pull-out the

drain pan assembly , using the handle on the drain pan.

Figures 1 & 2.

This pan could be hot! Use protective cloth or glove,

or severe burns could result.

Figure 2

Figure 3

If the filter pan is moved while full of oil, use care to

prevent splashing, or severe burns could result.

3. Lift the pan cover from the drain pan. Figure 3.

4. Lift the crumb basket from the drain pan. Wipe the oil and

crumbs from the crumb basket. Clean the crumb basket with

soap and water, then thoroughly rinse with hot water and dry .

Figure 4.

Figure 4

209 3-18

Page 32

3-15. CHANGING THE FILTER

PAD (Continued)

Figure 5

Model EEE-141,142, 143, 144

5. Remove the filter pad retaining ring and clean thoroughly with

soap and water. Rinse thoroughly with hot water and dry .

Figure 5.

Figure 6

Figure 7

6. Pull the filter pad from the pan and discard pad. Figure 6.

7. Remove the bottom screen from pan and clean thoroughly with

soap and water. Rinse thoroughly with hot water and allow to

air dry . Figure 7.

8. Wipe the oil and crumbs from the drain pan. Clean the drain

pan with soap and water, then thoroughly rinse with hot water

and dry . Figure 8.

Figure 8

3-19 209

Page 33

3-15. CHANGING THE FILTER

PAD (Continued)

Figure 9

Model EEE-141,142, 143, 144

Be sure that the drain pan, bottom screen, crumb catcher,

and the retaining ring are thoroughly dry before placing filter

pad into pan as water will dissolve the filter pad.

9. Reassemble in reverse order, placing the bottom screen into the

filter pan first, followed by the filter pad, retaining ring and the

crumb catcher.

Before pushing the filter drain pan back into position, lubricate

the o-rings (Figure 9) on the filter tube with cold oil. Check

o-rings for tears or nicks and replace if necessary .

See Section 3-16.

Figure 10

3-16. REMOVING AND

CLEANING BASKET

REST

10. Push the filter pan assembly back underneath the fryer, making

sure the filter tube on the pan makes a good connection with the

fitting underneath the fryer . Figure 9.

11. Make sure the drain pan stop is engaged and the fryer is now

ready for normal operation. Figure 10.

The basket rest, on the rear shroud of the fryer, should be removed

and cleaned periodically .

Use protective gloves when removing the basket rest. The

basket rest may be hot and burns could result.

Grasp the basket rest with 2 hands and pull it off the “key-ways”.

T ake it to a sink and clean it with soap and water. Dry thoroughly .

Clean the area behind the basket rest and then reinstall the basket

rest.

209 3-20

Page 34

3-17. CLEAN-OUT MODE

Model EEE-141,142, 143, 144

The filter drain pan must be as far back under fryer as it

will go, and the cover in place. Be sure the filter drain pan

is latched into place and the hole in the cover lines up with

the drain before opening the drain. Failure to follow these

instructions causes splashing of shortening and could

result in personal injury.

Moving the fryer or filter drain pan while containing hot

shortening is not recommended. Hot shortening can

splash out and severe burns could result.

Always wear chemical splash goggles or face shield and

protective rubber gloves when cleaning the frypot as the

cleaning solution is high in alkaline. Avoid splashing or

other contact of the solution with your eyes or skins.

Severe burns may result. Carefully read the instructions

on the cleaner. If the solution comes in contact with your

eyes rinse thoroughly with cool water and see a physician

immediately.

Also, to avoid overfilling the drain pan, drain only 1 vat at

a time. The drain pan holds 1 full vat, or 2 split vats of

oil. Overfilling the drain pan may cause slippery floors

which may result in personal injury.

1. Cover adjoining vats to avoid accidentally contaminating oil

with fryer cleaning solution.

Do not cook product in an adjoining vat when the cleaning

process is in progress to avoid contaminating the oil and product.

2. Press and hold until display shows “1.EXPRESS FILTER?”.

Split vat units, use the left button for the left vat and the

right button for the right vat.

3. Press and release button 6 times and display shows

“7.CLEAN-OUT”.

4. Press

√√

√ button and display shows

√√

“OIL RMVD” “YES NO”

5. If oil has already been removed, press

√√

√ button and control skips

√√

down to “Solution Added?” step.

3-21 109

Page 35

Model EEE-141,142, 143, 144

3-17. CLEAN-OUT MODE

(Continued)

If vat still has oil, press X button and display shows “DISPOSE”

“YES NO”. Press

button to exit Clean-Out Mode.

Display shows “IS DISPOSAL UNIT IN PLACE?” “YES

NO”. If “NO” is selected, display shows “INSERT DISPOSAL

UNIT”. Once disposal unit is in place press

open drain, and display shows “DRAINING” and oil drains

from vat. Display then shows “VAT EMTY”, “YES NO”.

√√

Press

√ button when ready and close drain.

√√

Bulk Oil Systems Only! Display shows “CHK PAN” if the

filter drain pan is missing. Once pan is in place, display shows

“OPEN DRAIN”. Pull-out drain knob and display shows

“DRAINING” and oil drains from vat. Display then shows

√√

“

√=PUMP” “X=DONE. Press

√√

“DISPOSING” and oil is pumped from drain pan. Once pan is

empty , press X button twice and close drain.

6. Display shows “SOLUTION ADDED?” “YES NO”. Fill the

vat to 1 in. (25 mm) above the top fill line with hot water andadd

4 ozs. (0.12 liters) of open fryer cleaner and mix thoroughly .

Then press

“YES NO”

√√

√ button and display shows “START CLEAN”

√√

√√

√ button to dispose of the oil, or press X

√√

√√

√ button for YES,

√√

√√

√ button, display shows

√√

7. Press

8. Using the open fryer brush (never use steel wool), scrub the

9. Empty filter drain pan of internal filtering components and take

√√

√ button and display shows “CLEANING” and a count-

√√

down timer. Heat regulates to 195°F (91°C) for this step for one

hour.

Add water as needed during cleaning process to keep solution

1 in. (25 mm) above the top fill line.

T o stop the cleaning cycle early, press X button. The display

shows “QUIT DEEP CLN” “YES NO”. Press the

cancel the rest of the countdown time and proceed to the rinse

steps.

inside of the vat. At the end of the one hour, display shows

“CLEAN DONE” and beeps. Press

shows “REMOVE SOLUTION FROM VAT”.

the components to a sink to be cleaned. Return the empty filter

drain pan and cover to the fryer, making sure it is pushed into

placed and the latch engaged.

√√

√ button and display then

√√

√√

√ button to

√√

10. Drain cleaning solution into the filter drain pan and pull drain pan

from unit and dispose of the solution.

909 3-22

Page 36

3-17. CLEAN-OUT MODE

(Continued)

Model EEE-141,142, 143, 144

To avoid burns when pouring hot solution, wear gloves

and protective gear and take care to avoid splashing.

Figure 1

11. Return empty filter drain pan to fryer and press

Display then shows “VAT EMTY” “YES NO”.

12. Once vat is empty, press

VAT COMPLETE” “YES NO”. Use brush to clean element

and scour pad to clean vat, if needed.

Do not scrape the electric fryer elements, or use scouring

pads on the elements. This produces scratches on the

surface of the element causing breading to stick and burn.

Do not use steel wool, other abrasive cleaners, or cleaners/

sanitizers containing chlorine, bromine, iodine, or ammonia

chemicals as these will deteriorate the stainless steel material

and shorten the life of the unit.

Do not use a water jet (pressure sprayer) to clean unit or

component damage could result.

Use the lift tool and lift the elements from the vat as needed.

(Auto-lift fryers, hinge back the basket hooks over the top of the

fryer before lifting the elements.)

√√

√ button and display shows “SCRUB

√√

√√

√ button.

√√

13. Once vat is clean, press the

VAT”. (If drain is not open, display shows “OPEN DRAIN”

Open the drain.)

14. Pour clean water and approximately 8 ozs. (0.24 liters) of

distilled vinegar solution into vat to rinse vat and allow rinse

water to drain into drain pan. Rinse at least 3 times, but be

careful not tooverfill the drain pan. Display now shows

“RINSE COMPLETE” “YES NO”

15. Once vat is completely rinsed, press the

shows “CLEAR SOLUTION FROM OIL LINES”

√ √

“

√ =PUMP” “X =DONE”

√ √

T o make sure no cleaning solution remains in the oil lines, press

and hold

X button and display shows VAT DRY?” “YES NO”. Push

drain knob and close drain.

16. Pull drain pan from under fryer and dispose of rinse water.

3-23 110

√√

√ button for a few seconds. Once lines are clear, press

√√

√√

√ button and display shows “RINSE

√√

√√

√ button and display

√√

Page 37

Model EEE-141,142, 143, 144

3-17. CLEAN-OUT MODE

(Continued)

3-18. CHECK/REPLACE FIL TER

DRAIN PAN O-RINGS

17. Thoroughly dry the vat with a towel, and then press the

√√

√

√√

button. Controls return to normal operations.

Make sure the inside of the vat, the drain valve opening,

and all the parts that come in contact with the new oil are

as dry as possible.

18. Make sure the drain is closed and return the filter pan assembly,

with new filter pad, to the fryer. Fill vat with oil following the

Filling or Adding Oil instructions from Section 3-3.

T o prevent oil leaking, and to keep filtering process operating

properly , the filter drain pan o-rings should be inspected for nicks

and tears at least every 3 months. Figure 1

1. Open the door, lift-up on the drain pan stop and pull-out the

filter drain pan assembly , using the handle on the drain pan.

Figures 2 & 3

Figure 1

Figure 2

This pan could be hot! Use protective cloth or glove, or

severe burns could result.

2. Visually check the 3 o-rings on the tube of the filter drain pan

for any cracks or breaks and replace if necessary .

3. To replace o-ring, use a small, flat-bladed screwdriver , pry up

on the o-ring and pull off of end of tube. Roll new o-ring into

notch on tube. Before pushing the filter drain pan back into

position, lubricate the o-rings on the filter tube with fresh, cold

oil.

Figure 3

110 3-24

Figure 4

Page 38

3-19. INFO BUTTON ST ATS Actual Oil T emperature

1. Press and the actual oil temperature shows in the

display , for each vat.

Set-point T emperature

2. Press twice and SP shows in the display , along with

the set-point (preset) temperature of each vat.

Recovery Information for each Vat

1. Press 3 times and REC shows in the left display and

the recovery time that oil temperature went from 250°F

(121°C) to 300°F (149°C) shows in the right display . For

example, means it took 5 minutes and

REC 5:30

30 seconds for the oil temperature to recover to 300°F

(149°C) from 250°F (121°C).

Model EEE-141,142, 143, 144

3-20. FIL TER BUTTON ST ATS

If no buttons are pressed within 5 seconds in any of stats

modes, the controls revert back to normal operation.

Cook Cycles Remaining before Filtering

1. Press and release either button and the left display

shows “COOKS REMAINING” and the right display shows

the number of cook cycles before the next auto filter. For

example,

REMA INING

3 6

means after 3 more cook cycles on the left vat, the controls

asks the operator if they are ready to filter or not. But, 6 more

cook cycles remain on the right vat.

Time and Date

2. Press either twice and ‘FIL TERED” shows in the

diplays, along with the time-of-day and date of the last filter .

3-25 309

Page 39

Model EEE-141,142, 143, 144

3-21. PREVENTIVE

MAINTENANCE

SCHEDULE

As in all food service equipment, the Henny Penny open fryer does

require care and proper maintenance. The table below provides a

summary of scheduled maintenance procedures to be performed by

the operator .

Procedure Frequency

Filtering of shortening Daily

(Section 3-11)

Changing the filter pad Daily

(Section 3-13)

Lubricate filter pan o-rings Every filter pad change

Lubricate EEE-141 oil reservoir When reservoir is

o-rings removed

Changing of oil When oil smokes,

foams up violently , or

tastes bad

Cleaning the vat Every change of oil

(Section 3-15)

Inspect filter pan o-rings Quarterly

(Section 3-16)

Inspect EEE-141 reservoir Quarterly

o-rings (Section 3-10)

510 3-26

Page 40

SECTION 4. INFORMA TION MODE

This historic information can be recorded and used for operational

and technical help and allows you to view the following:

Model EEE-141,142, 143, 144

4-1. INFORMATION MODE

DETAILS

• 1. E-LOG

• 2. LAST LOAD

• 3. DAIL Y ST A TS

• 4. OIL STATS

• 5. REVIEW USAGE

• 6. INPUTS

• 7. OUTPUTS

• 9. CPU TEMP

• 10. COMMUNICATION INFO

• 11. ANALOG INFO

• 12. ACTIVITY LOG

• 13. OIL LEVELS

• 14. PUMP VALVE INFO

• 15. AIF INFO

• 8. OIL TEMP

Not all Information Mode functions are discussed in this

section. T o ensure proper operation of fryer, please consult

Henny Penny Corp. before changing any of these settings. For

more information on these functions, contact T echnical Support

at 1-800-417- 8405, or 1-937-456-8405.

1. E-LOG (error code log)

Press and buttons at the same time and “*INFO

MODE*” shows in the display , followed by “1. E-LOG”.

Press and to exit Information Mode at any time.

Press and “A. (date & time) *NOW* show in displays.

This is the present date and time.

Press and if a error was recorded, “B. (date, time, and

error code information)” shows in display . This is the latest error

code that the controls recorded.

Press and the next latest error code information can be seen.

Up to 10 error codes (B to K) can be stored in the E-LOG section.

4-1 309

Page 41

Model EEE-141,142, 143, 144

4-1. INFORMATION MODE

DETAILS (Continued)

2. LAST LOAD (Information on recent cook cycles)

Press and “2. LAST LOAD” show in displays.

Press a timer button or for the product you want to

view the cook data and the LED flashes.

Press button to start viewing the cook data.

For example, if the left LED is flashing, “PRODUCT FR Y

L1” show in displays.

If the right LED is flashing, “PRODUCT FRY R2” show in

displays.

Press button to start viewing the cook data.

FUNCTION DISPLAY EX:

Product (Last product cooked) PRODUCT FRY L1

Time of day the last Cook Cycle was started STAR TED FEB 4 2:25P

Actual Elapsed cook Time (Real seconds) ACTUAL TIME 1:06

Programmed cook Ti me PROG TIME 1:00

Max T emp during Cook Cycle MAX TEMP 350°F

Min T emp during Cook Cycle MIN TEMP 313°F

A vg Temp during Cook Cycle A VG TEMP 322°F

Heat On (percentage) during Cook Cycle HEAT ON 45%

Ready? (W as fryer Ready before start?) READY? YES

When Cook Cycle was stopped: Early QUIT AT 0:10 REM

OR

After complete Cook Cycle *DONE* +6 SEC

Difference (%) between actual and ACT/PROG 1%

programmed cook time

109 4-2

Page 42

Model EEE-141,142, 143, 144

4-1. INFORMATION MODE

DETAILS (Continued)

3. DAIL Y ST A TS (Operational info of fryer for last 7 days)

Press and “3. DAIL Y ST ATS” show in displays.

Press button to start viewing the cook data.

Press the right to view data for other days of week.

FUNCTION DISPLAY EX:

Day this data was recorded for APR-30 TUE*

Number of Hours:Minutes the fryer was on (L/R) ON HRS TUE* 3:45

Number of times filtered (L/R) FIL TERED TUE* 4

Number of times filter skipped (L/R) SKIPPED TUE* 4

Number of times oil added (L/R) ADD OIL TUE* 4

Number of times oil discarded (L/R) DISPOSE TUE* 0

Oil temperature recovery time (L/R) RECOVERY TUE*1:45

Total number of cook cycles that day (L/R) TOT CK TUE* 38

Number of cycles stopped before *DONE* QUIT CK TUE* 2

Cook Cycles for Product #1 TUE* COOK -1- 17

Cook Cycles for Product #2 TUE* COOK -2- 9

Cook Cycles for Product #3 TUE* COOK -3- 5

Cook Cycles for Product #4 TUE* COOK -4- 0

Cook Cycles for Product #5 TUE* COOK -5- 0

Cook Cycles for Product #6 TUE* COOK -6- 6

Cook Cycles for Product #7 TUE* COOK -7- 0

Cook Cycles for Product #8 TUE* COOK -8- 0

Cook Cycles for Product #9 TUE* COOK -9- 1

Cook Cycles for Product #0 TUE* COOK -0- 0

4-3 309

Page 43

Model EEE-141,142, 143, 144

4-1. INFORMATION MODE

DETAILS (Continued)

Start date of new oil NEW OIL MAR-23

Number of days oil in use (L/R) OIL USE 4 DAYS

Number of filters on this oil (L/R) FIL TERED 4

Number of times filter skipped (L/R) SKIPPED 0

Number of cook cycles on this oil (L/R) TOT CK 38

Average number of days per oil change (L/R) AVG DAYS

Average number cook cycles per oil change (L/R) AVG CKS PER

4. OIL ST A TS (info of current oil and avg. of last 4 batches of oil)

Press and “4. OIL STA TS” show in displays.

Press button to start viewing the cook data.

FUNCTION DISPLAY EX:

PER OIL CHANGE 13.8 DAYS

OIL CHANGE 388 CKS

Press and hold a product button (1 to 4) to view the data from one

of the previous 4 batches of oil used.

Press to view oldest oil data: Ex: OIL-4 14 DAYS

Press to view 3rd oldest oil data: Ex: OIL-3 12 DA YS

Press to view 2nd oldest oil data: Ex: OIL-2 15 DAYS

Press to view previous batch of oil: Ex: OIL-1 13 DAYS

309 4-4

Page 44

Model EEE-141,142, 143, 144

4-1. INFORMATION MODE

DETAILS (Continued)

Day the usage data was previously reset SINCE APR-19 3:00P

Number of Hours the fryer was on (L/R) ON HRS 4

Number of times filtered (L/R) FILTERED 4

Number of times filter skipped (L/R) SKIPPED 0

Number of times oil added (L/R) ADD OIL 4

Number of times oil discarded (L/R) DISPOSE 1

T otal number of cook cycles (L/R) TOT CK 38

Number of cycles stopped before *DONE* QUIT CK 2

Cook Cycles for Product #1 COOK -1- 17

Cook Cycles for Product #2 COOK -2- 9

Cook Cycles for Product #3 COOK -3- 5

Cook Cycles for Product #4 COOK -4- 0

Cook Cycles for Product #5 COOK -5- 0

Cook Cycles for Product #6 COOK -6- 6

Cook Cycles for Product #7 COOK -7- 0

Cook Cycles for Product #8 COOK -8- 0

Cook Cycles for Product #9 COOK -9- 1

Cook Cycles for Product #0 COOK -0- 0

Reset usage data:

Enter the Usage Code - 1, 2, 3 RESET USAGE /

on this step to zero out all the ENTER CODE -----usage information

5. REVIEW USAGE(accumulated info since the data was reset)

Press and “4. REVIEW USAGE” show in displays.

Press button to start viewing the cook data.

FUNCTION DISPLAY EX:

4-5 309

Page 45

SECTION 5. PRODUCT PROGRAM MODE

This mode allows you to program the following:

• Change Product Name

• Assign Button

• Change Times & T emp

• Change Cook ID

• Alarms

• Quality Timers

• Include in Filter Count (Global)

• Filter at X no. of loads (Mixed)

• Load Compensation

• Load Compensation Reference

• Full Heat

• PC Factor

Model EEE-141,142, 143, 144

5-1. MODIFYING PRODUCT

SETTINGS

1. Press and hold button until “PROG” shows in the

display , followed by “ENTER CODE”.

2. Enter code 1, 2, 3 (first 3 product buttons). “PRODUCT”

and “PROGRAM” show in the displays, followed by

“SELECT PRODUCT’ and “-P 1-” (ex: NUG).

Change Product Names

3. Use the and buttons to scroll through the 40 products,

or press the desired product button.

4. Press

button and “NAME” shows in the left display and

the product (ex: NUGGETS) shows in the right display .

5. Press

√√

√ button and the first letter in the name flashes. Press a

√√

product button and the flashing letter changes to the first letter

under the product button that was pressed. For example, if

is pressed, the flashing letter changes to an “A”.

Press the same button again and the flashing letter changes to a

“B”. Press it again and the flashing letter changes to a “C”.

Once the desired letter shows in the display , press button

to continue to the next letter and repeat the procedure.

Press and hold the right X button to exit Program Mode, or

press button to continue on to “COOK TIME”.

Assign Button

6. Press button until “ASSIGN BTN” shows in the display ,

along with the product (ex: NUGGETS). If this product

already has a product button assigned to it, that LED will be lit.

T o assign other product buttons to that product, press and hold

the product button for 3 seconds and that LED stays lit. T o

remove a product from a button, press and hold the product

button with a lit LED and the LED goes out.

309 5-1

Page 46

Model EEE-141,142, 143, 144

5-1. MODIFYING PRODUCT

SETTINGS (Continued)

T o Change Times and T emperatures

7. Press button until “COOK TIME” shows in the display ,

and then use the product buttons, or the and buttons, to

change the time in minutes and seconds, to a maximum of

59:59.

8. Press button and “TEMP” shows in the display , along with

the preset temperature on the right side of the display .

Press the product buttons, or the and buttons, to

change the temperature. The temperature range is 190°F

(88°C) to 375°F (191°C).

Cook ID Change

9. Press button until “COOK ID” shows in the display

along with the product ID. For example, NUG would be the

ID for nuggets. Use the product buttons, or the and

buttons, to change the ID.

Alarms (1 & 2)

11. Press button until “ALRM 1” shows in the left display,

and an alarm time in the right display . Press the product buttons,

or the and buttons, to set an alarm.

Ex., If a Cook Cycle was set at 3 minutes, and an alarm was to

go off after 30 seconds into the Cook Cycle, “2:30” would be

set in the display at this time. When the timer counts down to

2:30 the alarm sounds.

After the alarm time is set, press button and “ALRM 2”

shows in the display , and a second alarm can be programmed.

Quality Timer (hold time)

12. Press button until “QUAL TMR” shows in the display

along with the preset holding time. Press the product buttons,

or the and buttons,to adjust holding time, up to

59:59.

Global Filter Tracking

Include in Filter Count

13a. Press button until “INCL IN FLTR CNT” flashes in the

display along with “YES” or “NO”. Using and

buttons, change the display to “YES” if that product’s Cook

Cycles are to be counted as part of the recommended filter

process. Set to “NO” if it is not to be included.

5-2 309

Page 47

Model EEE-141,142, 143, 144

5-1. MODIFYING PRODUCT

SETTINGS (Continued)

Mixed Filter Tracking

Filter After X Number of Loads

13b. Press button until “FIL TER AFTER...” flashes in the

left display along, and the number of cook cycles between filters

shows in the right display . Press the product buttons, or the

and buttons, to change this value of 0 to 99 loads. This

needs set for each product.

>Load Compensation, Load Compensation

Reference, Full Heat, PC Factor<

14. Press button until “LD COMP” shows in the display ,

along with the load compensation value. This automatically

adjusts the time to account for the size and temperature of the

cooking load.

Press the product buttons, or the and buttons, to

change this value of 0 to 20.

15. Press button until “LCMP REF” shows in the display

along with the load compensation average temperature. (if

load compensation is set to “OFF”, then “_ _ _” shows in

display and setting cannot be programmed) This is the average

cooking temperature for each product. The timer speeds up at

temperatures above this setting and slows down at temperatures

below this setting. Press the product button, or the and

buttons, to change this value.

16. Press button until “FULL HT” shows in the display along

with the full heat value in seconds, which means the heat is on as

soon as a timer button is pressed, for the programmed length of

time. Press the product buttons, or the and buttons,

to change this value of 0 to 90 seconds.

17. Press button until “PC F ACTR” shows in the display along

with the proportional temperature, which helps to keep the oil

from over-shooting the setpoint temperature. Press the product

buttons, or the and buttons, to change this value of 0

to 50 degrees.

• Use button to go back to previous menu items.

• Press button when finished with the current product, to

return to the “SELECT PRODUCT” step.

• Press and hold button to exit PRODUCT PROGRAM

Mode.

309 5-3

Page 48

SECTION 6. LEVEL 2 PROGRAMMING

Used to access the following:

• Special Program Mode

• Clock Set

• Data Communication

• Heat Control

Model EEE-141,142, 143, 144

• T ech Mode

• Stats

• Filter Control

6-1. SPECIAL PROGRAM

MODE

6-1 1009

The Special Program Mode is used to set more detailed

programming, such as:

SP-1 • Degrees Fahrenheit or Celsius

SP-2 • Language: English, Russian, Swedish (SVENSKT),

German (DEUTSCHE), Portuguese, Spanish (ESPANOL)

and French (FRANCAIS)

SP-3 • System Initialization (Factory Presets)

SP-4 • Audio Volume

SP-5 • Audio T one

SP-6 • Melt Cycle Select - 1.LIQUID; 2.SOLID

SP-7 • Idle Mode Enabled - YES or NO

SP-7A • Use “0” for IDLE

SP-7B • Auto Idle Minutes

SP-7C • Idle Set-point Temperature

SP-8 • Filter Tracking Mode - 1.MIXED or 2.GLOBAL

SP-8A • Suggest Filter At... - 75% to 100% (MIXED)

SP-8B • Filter Lockout Enabled? - YES or NO (MIXED)

SP-8A • Left Vat Filter Cycles - 0 to 99 (GLOBAL)

SP-8B • Right Vat Filter Cycles - 0 to 99 (GLOBAL)

SP-8C • Filter Lockout Enabled? - YES or NO (GLOBAL)

SP-9 • Polish Duration - X:XX M:SS

SP-10 • Change Pad Reminder Time - XX HRS