Henny Penny CW-216, CW-114 General Manual

- -

FM01 -276

Revised 7-99

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

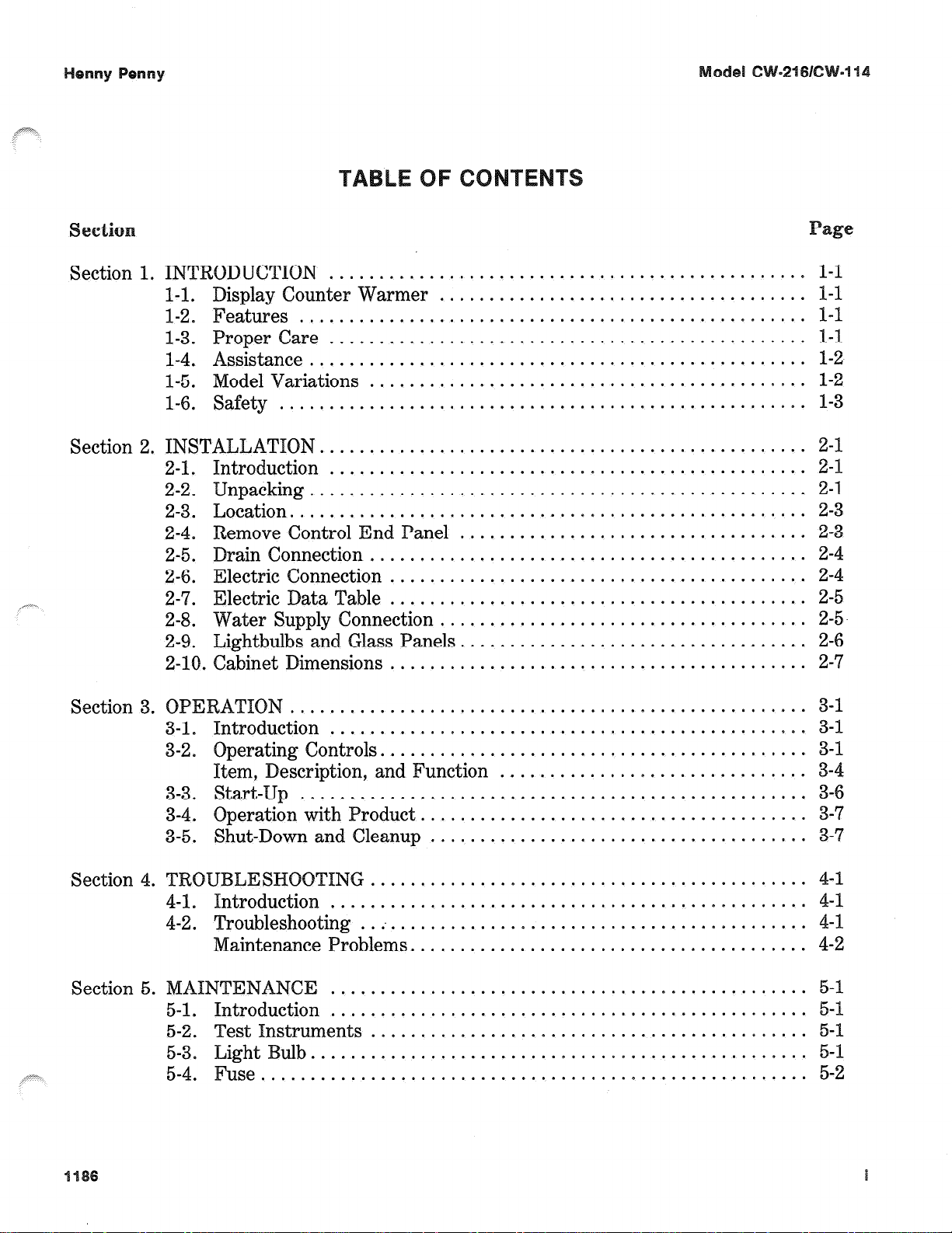

Section 1. IN

1-3. Proper Care

1-4. Assistance

1-5. Model Variations

l-6. Safety .....................................................

ION ................................................

isplay Counter Warmer

.....................................

eatures ...................................................

................................................

.................................................. l-2

............................................ 1-2

1-l

1-l

1-l

l-l

1-3

Section 2. INSTA N .................................................

2-1. Introduction

2-2. Unpacking.

................................................ 2-l

................................................. 2-1

2-3. Location ....................................................

emove Control anel ................................... 2-3

rain Connectio

...........................................

ion ..........................................

ble

..........................................

ater Supply Conne on .....................................

lghtbulbs and Glas anels ...................................

imensions ..........................................

Section 3.

....................................................

ion ................................................

g Controls. ........................................

escription, and unction ...............................

.............................................

roduct .......................................

n and Cleanup ......................................

Section 4.

ction

NG ............................................

................................................

shooting ..; ..........................................

Maintenance Problems.

.......................................

2-1

2-3

2-4

2-4

2-5

2-5

2-6

2-7

3-1

3-1

3-l

3-4

3-7

4-1

4-l

4-2

Section 5. MA

5-l.

5-2.

5-3.

5-4. use.....................................~

NANCE

................................................

reduction ................................................

truments ............................................

ulb...............................~ ..................

.................

5-l

5-1

5-I

5-l

5-2

&ion 5.

ainer

................................................

...............................................

ch

ermometer

ntactor ...................................................

...............................................

eater

er ..............................................

iii-iostat

...........................................

............................................

......................................

.................................

.......................................

.......................................

.................................

.......................................

.......................................

.......................................

.......................................

.......................................

..........................

..........................

.::::::::::::::::::::::::::

..

..........................

..........................

..........................

.............................

5-2

5-4

555-1

5-7

5-e:

5-9

55-

5-P P

5-12

5-12

5-U

5-13

5-14

5-15

5-16

5-17

5-l

5-1

5-2

5-2

5-2

5-2

-

..........................................

N

................................................

............................................

arts......................................”

...............................................

er

.....................................................

....................................................

y

...................................................

............................................

....

6-1

6-l

6-1

6-2

6-2

6-2

6-3

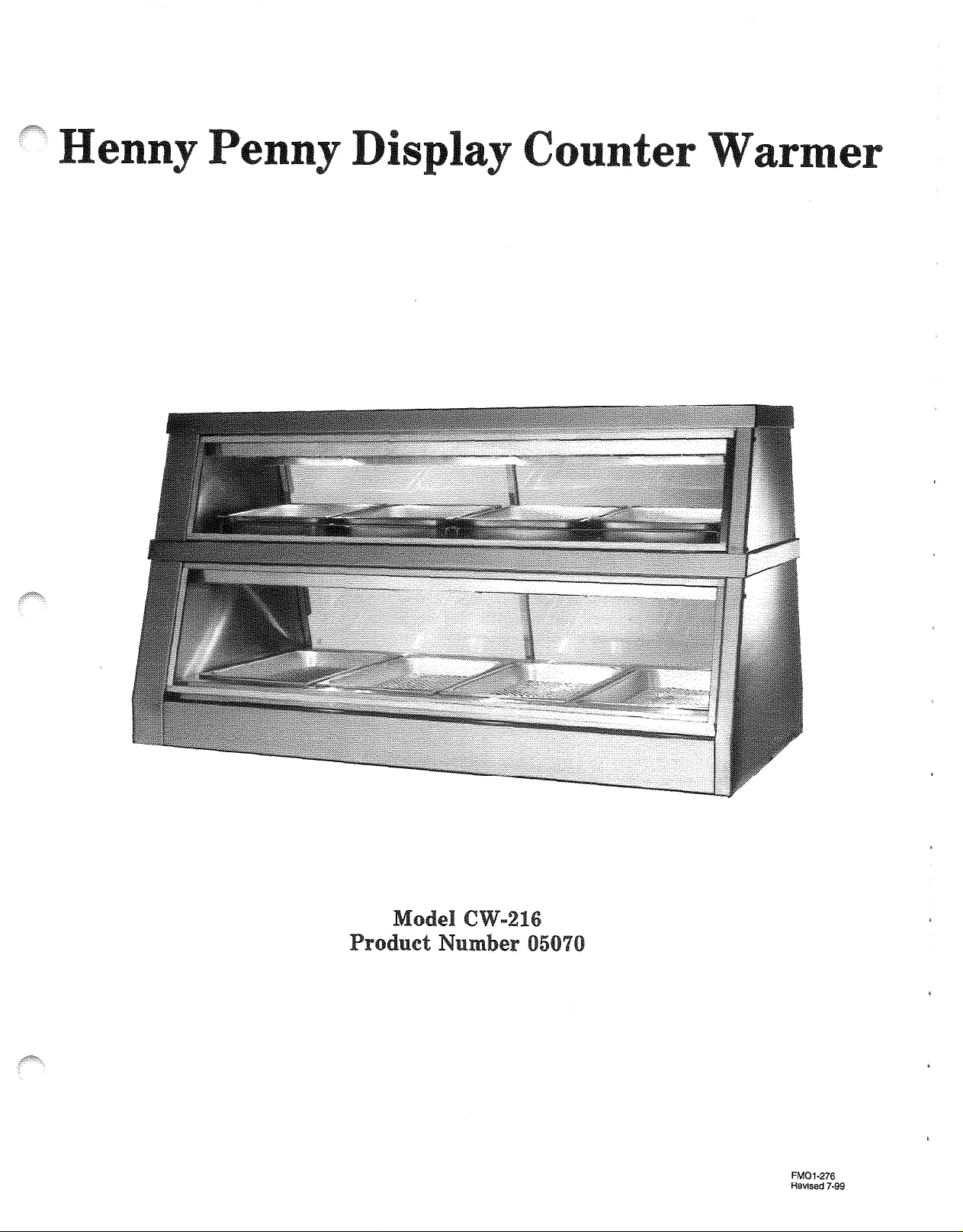

UNTE

The Henny Penny Display Counter unit of food processing

equipment used to display the food product and maintain the

temperature of hot foods in the commercial food service

operation. This highly efficient, quality-built cabinet will keep

hot foods at proper holding temperature with controlled

humidity. The Henny Penny Display Counter Warmer has

see-thru doors which allow viewing and also access to the hot

foods.

Large, ten gallon water well.

0 Automatic water fill system with manual bypass.

Four removable sliding glass doors.

Stainless steel four pan display well (bottom).

Thermostatic and thermometer water control.

Easy to keep clean.

@ Individual heater controls.

* Removable access panels for easy maintenance.

As in any unit of food service equipment, the Display Counter

Warmer does require care and maintenance. Suggestions for

this maintenance are contained in this manual.

Henny Penny Model CW-216/CW-114

1-3. PROPER CARE (continued) For your convenience, this manual consists of the following sections:

• Table of Contents

• Introduction

• Installation

• Operation

• Troubleshooting

• Maintenance

• Wiring Diagrams

• Parts List

• Distributor List

The conscientious use of the recommended procedures, coupled

with regular maintenance, will result in few repairs to the equipment.

When such repairs are required, they may be accomplished by

following the repair steps contained in this manual.

1-4. ASSISTANCE Should you require outside assistance, just call your local

independent Henny Penny distributor.

In addition, feel free to contact our corporate headquarters in

Eaton, Ohio. Dial 1-800-417-8405 toll free, or 937-456-8405.

1-5. MODEL VARIATIONS This manual covers both the CW-216 two tier cabinet and the

CW114 single base cabinet.

Model Number Product Number

CW-216 05070

CW-114 05089

1-2 296

The only way to insure safe operation of the

nny Penny

Display Counter Warmer is to fully understa the proper

installation, operation, and maintenance procedures. The

instructions in this manual have been prepared to aid you in

learning the proper procedures. Where information is of

particular importance or is safety related, the words N

CAUTION, or WARNING are used. Their usage is described

below.

The word NOT is used to highlight especially important

information.

The word CAUTION is used to alert you to a procedure that,

if not performed properly, may damage the unit.

NING is used to alert you to a procedure, that

if not performed properly, might cause personal injury.

enny Penn

This section provides the installation instructions for the Henny

Penny Display Counter Warmer.

Installation of this unit should be performed only by

a qualified service technician.

Do not puncture the skin of Display Counter Warmer with

drills or screws as component damage or electrical shock could

result.

te

The Henny enny Display Counter Warmer is tested,

inspected, and expertly packed to insure arrival at its

destination in the best possible condition. The cabinet has been

bolted to a wooden skid. All glass items have been packed in

cartons and taped inside the unit. The unit is then packed inside

a triple wall corrugated carton with sufficient padding to

withstand normal shipping treatment. Any shipping damages

should be noted in presence of delivery agent and signed prior

to his or her departure.

To remove the Henny Penny

isplay Counter Warmer from

the carton, you should:

1. Carefully cut banding straps.

2. Open top flaps and remove packing.

3. Lift carton off skid.

set-up.

isplay Counter Warmer is now ready for location and

Place the unit on a table, preferably with a cut-out opening

below the cabinet to allow easy service connections and

serviceability. When setting up the Henny Penny

Counter Warmer, be sure to level the table.

The unit has built-in draining capabilities, but this

becomes ineffective when set on an unlevel table.

After the Henny Penny Display Counter Warmer has been

leveled on the table, run a bead of silicone rubber (or equivalent

sealant) around the perimeter of the unit, sealing it to the table

top. You are now ready to make the electrical and drain

connections to the unit.

,..H-.

1. emove the seven screws fastening the end panel to the

cabinet.

2. Slide bottom of end panel out first allowing top to drop

below shelf edge.

The drain can be connected to a 1 inch N.P.T. directly below

the water well or to a

3/4

inch N.P.T. from the operator’s side.

We recommend the 1 inch N.P.T. connection as this will allow

straight down draining of the water.

The Display Counter Warmer is available from the factory

wired for 208 or 230 volts, single phase 3-wire (includes neutral)

or three phase 4-wire (includes neutral) 60 Hertz service. The

proper power service cable must be provided at installation.

Check the data plate on the side panel of the control end to

determine the correct power supply.

- .’

The cabinet must be adequately and safely grounded.

Refer to local electrical codes for correct grounding

procedures.

A separate disconnect switch with proper capacity fuses or

breakers must be installed at a convenient location between

the cabinet and the power source. The field supply wiring to

the cabinet should be an insulated copper conductor rated for

600 volts and 90” C.

-216/

The electrical power can be connected from the bottom or from

the operator’s side. There is a l-3132 inch diameter hole from

either connection. Again,

we recommend the bottom

connection as this will give a cleaner appearance to the unit.

Please observe the electrical connection information on the

data plate located on the side panel of the control end.

Voltage potential of L1 and Lz to ground cannot exceed

125 volts.

tS

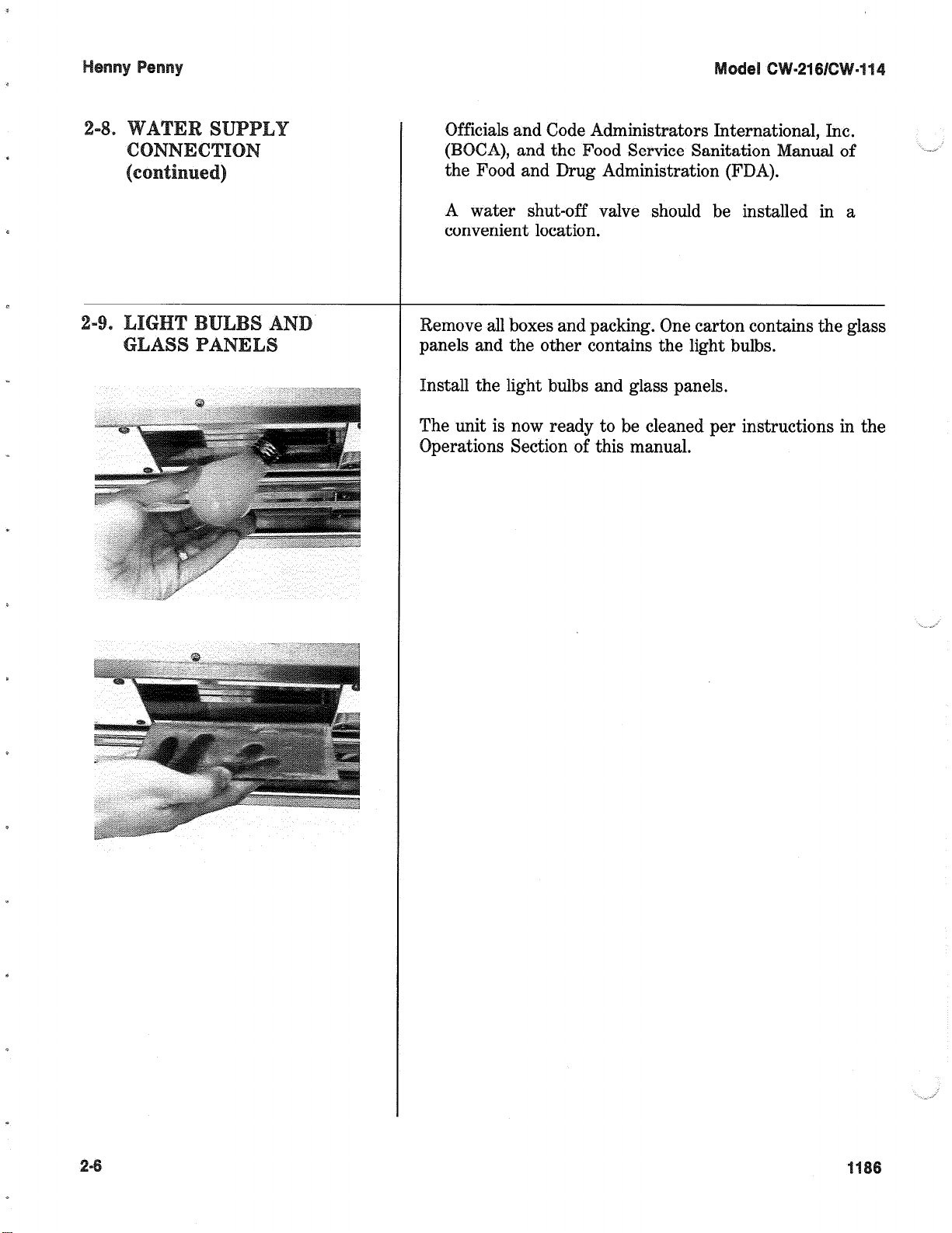

cw-114

CW-114

230

230

cw-114 208

CW-114 208

CW-216

230

CW-216 230

CW-216 208

C W-216

208

as6 S

3400 13.2

3400 16.3

3400

3400 17.6

4160 14.4

4160

4160

4160 22.5 05070

The automatic water system has a

11’4

inch compression fitting

s

05089

05089

13.8

05089

05089

05070

21.0 05070

15.3 05070

for copper tubing. Hot water would be preferred. We

recommend using the automatic water system as this will allow

the unit to maintain a more even water temperature and help

insure that the unit never runs dry of water.

A straight-through bulkhead fitting is furnished with the unit

for l/4 inch copper tubing to protect the water line where it

passes through the sheet metal.

.

Reinstall the end panel.

This unit as manufactured requires the installation of

an appropriate back-siphoning device (as per National

lumbing Code ASA-A40: 8-1955) to be connected to

the water inlet line. This device to be connected in

accordance with the basic plumbing code of the Building

fficials and Code Administrators International, Inc.

(BOCA), and the Food Service Sanit

Manual of -d

the Food and Drug Administration (

A water shut-off valve should be installed in a

convenient location.

Install the light bulbs and glass panels.

The unit is now ready to be cleaned per instructions in the

Operations Section of this manual.

c

-

-

I

-

envy

This section provides the daily operating procedure for your

Display Counter Warmer. Read Section 1 and this Section

before operating the cabinet. Also, refer to Section 2 to be sure

the cabinet has been properly installed. The arrangement of

this Section is:

An illustration and explanation of all operating conrols.

Step-by-step operating procedures.

Daily maintenance procedures.

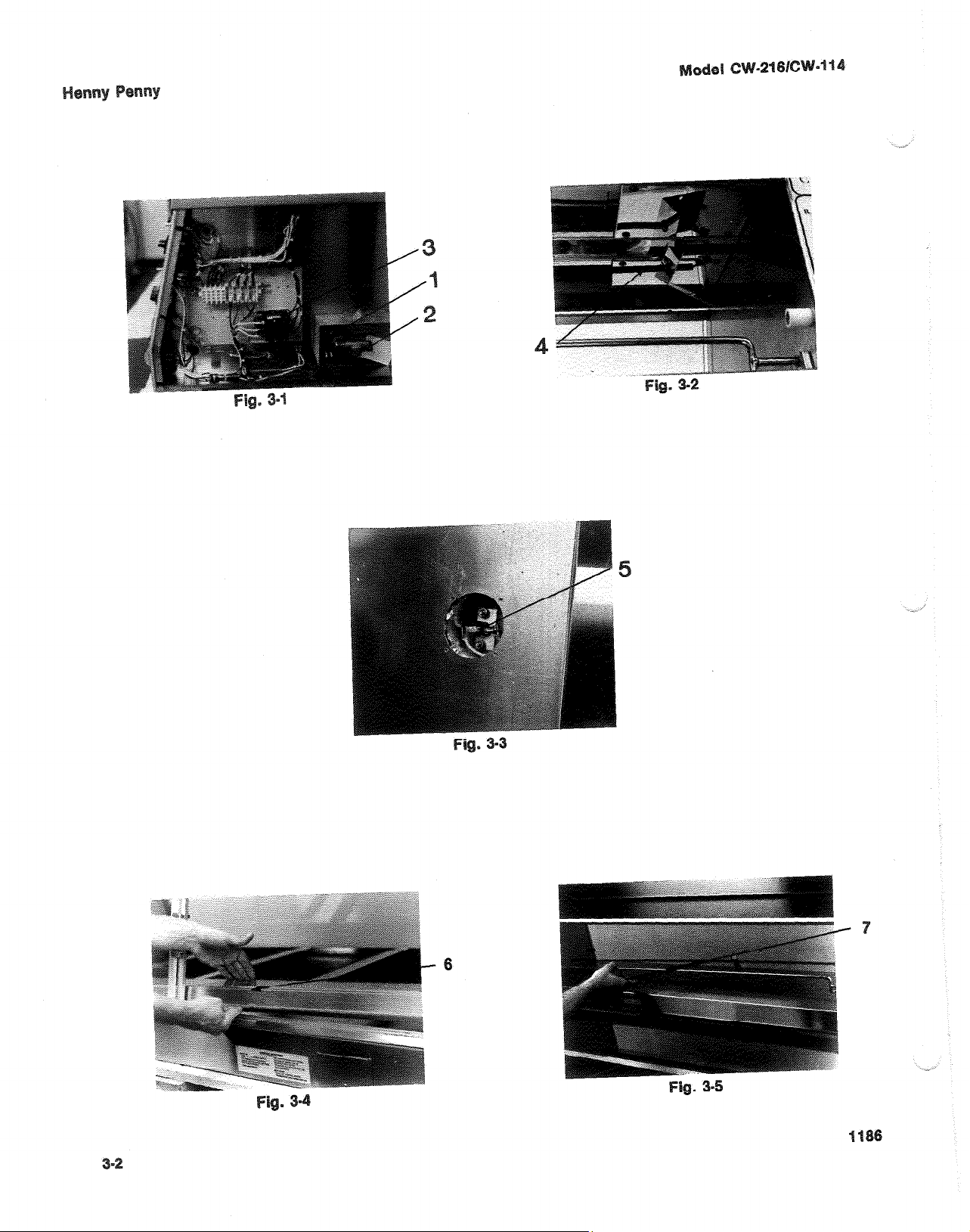

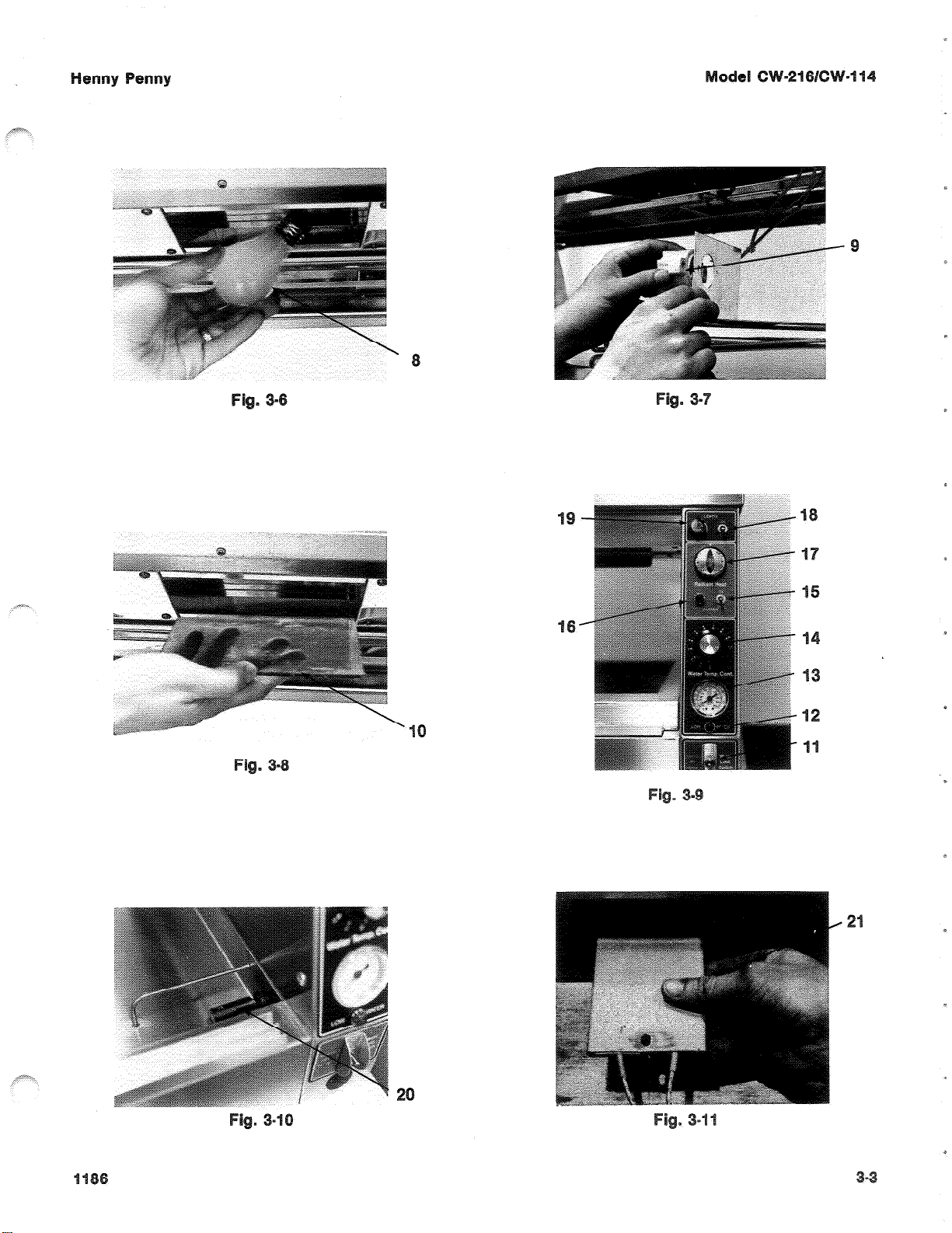

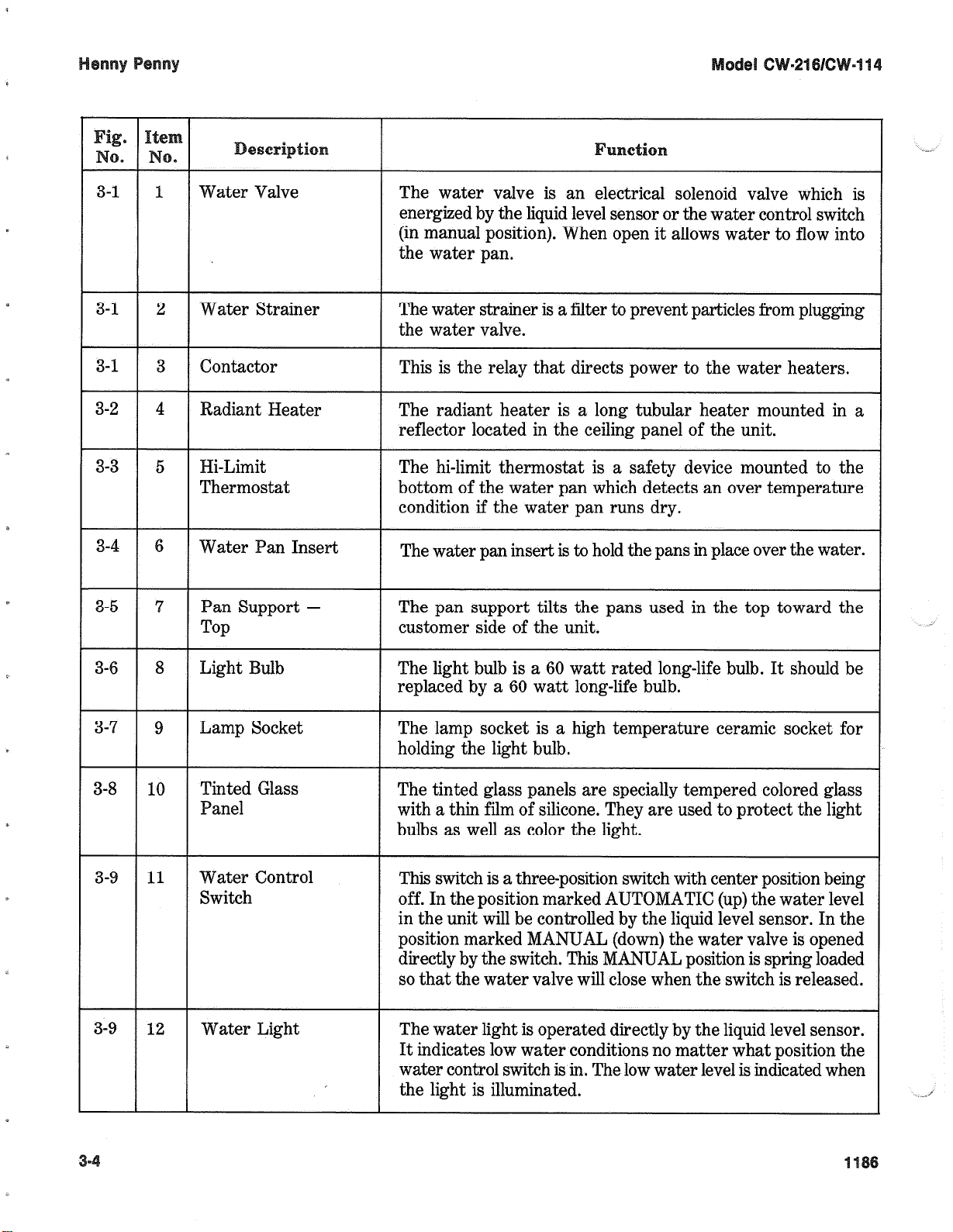

Figures 3-1 through 3-11 identify and describe the function

of all the operating controls and the major components of the

cabinet.

-_

c

._.i

The water valve is an electrical solenoid valve which is

3-2 4

3-3 5

3-4 6

3-5 7

3-6 8

3-7 9

3-8 10

Radiant Heater

Hi-Limit

Thermostat

Water Pan Insert

Pan Support Top

Lamp Socket

inted Glass

anel

The radiant heater is a long tubular heater mounted in a

reflector located in the ceiling panel of the unit.

The hi-limit thermostat is a safety device mounted to the

bottom of the water pan which detects an over temperature

condition if the water pan runs dry.

The water pan insert is to hold the pans in place over the water.

The pan support tilts the pans used in the top toward the

customer side of the unit.

The light bulb is a 60 watt rated long-life bulb. It should be

replaced by a 60 watt long-life bulb.

The lamp socket is a high temperature ceramic socket for

holding the light bulb.

The tinted glass panels are specially tempered colored glass

with a thin film of silicone. They are used to protect the light

bulbs as well as color the light.

3-9 11

3-9 12

Water Control

This switch is a three-position switch with center position being

Switch off. In the position marked AUTOMATIC (up) the water level

in the unit will be controlled by the liquid level sensor. In the

position marked MANUAL (down) the water valve is opened

directly by the switch. This MANUAL position is spring loaded

so that the water valve will close when the switch is released.

Water Light

The water light is operated directly by the liquid level sensor.

It indicates low water conditions no matter what position the

water control switch is in. The low water level is indicated when

the light is illuminated.

Loading...

Loading...