Page 1

Models

CSL

CSM

CSB

CSG

HENNY PENNY

Sure Chef®Combi-Steamers

Applications Manual

and Cooking Guide

Page 2

CSL

CSM

CSB

CSG

This manual should be retained in a convenient location for future reference.

Wiring diagram for this appliance is located on the inside access door below the control panel.

Post in a prominent location, instructions to be followed in event user smells gas. This information shall be

obtained by consulting the local gas supplier. (Gas units only)

FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. (Gas units only)

Keep appliance area free and clear from combustibles.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance must be left all around appliance

for sufficient air to the combustion chamber. (Gas units only)

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury

or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this

equipment.

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the original purchaser

only for Henny Penny appliances and replacement parts:

New Equipment Any part of a new appliance, except lamps and fuses, which proves to be defective in material or workmanship

within one year from date of original installation, will be repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or

F.O.B. authorized distributor. To validate this warranty, the registration card for the appliance must be mailed to Henny Penny

within 10 days after installation.

Replacement Parts Any appliance replacement part, except lamps and fuses, which proves to be defective in material or workmanship within 90 days from date of original installation will be repaired or replaced without charge F.O.B. factory, Eaton, Ohio,

or F.O.B. authorized distributor.

This warranty covers only the repair or replacement of the defective par t and does not include any labor charges for the removal

and installation of any parts, travel or other expenses incidental to the repair or replacement of a part.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was purchased. No allowance

will be granted for repairs made by anyone else without Henny Penny’s written consent. If damage occurs during shipping, notify the carrier at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY FOR ANY BREACH OF

WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY (INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSEQUENTAL DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses.

THE ABOVE LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING MERCHANT ABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED. HENNY PENNY

NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Page 3

Dear Customer:

Congratulations on your decision to purchase a new Henny Penny Sure Chef®Combi-Steamer. In our

opinion, you now possess the most advanced combi-steamer in the industry. As you begin to become

familiar with its operation and more confident in the results, you will see the incredible potential for

quality, variety and productivity this unit has to offer. In fact, this new concept in cooking may change

your entire approach to hot food production.

The Sure Chef Combi-Steamer is not difficult to operate. But it is a fairly complex piece of equipment.

We recommend a thorough study of this Application Manual. It is filled with information, suggestions

and explanations that will help you achieve the potential of the unit. Keep the manual in a safe place,

but accessible for easy reference.

Henny Penny products are known for their outstanding craftsmanship, leading edge technology and

user-friendly operation. As a company, we believe in establishing a partnership with our customers that

leads both parties to long-term success. In that spirit, we remain interested in any questions, comments, suggestions or ideas you may have concerning the combi-steamer you have purchased, as well

as this manual.

We hope you enjoy good food and good profits with your new Sure Chef Combi-Steamer. Welcome to

the world of imaginative cooking!

Henny Penny Corporation

800-417-8417

Page 4

Table of Contents

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Features at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Loading and Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control Panel Functions at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Basic Operation

Cooking Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Steam Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Convection Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Combination Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Tender Steaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Rethermalizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Forced Steaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SDHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Probe Cooking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Cool Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Steam Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Half Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Half Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Pulse Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Delta-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Quick Guide To Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Installation – Electric Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Installation – Gas Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Cooking Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Page 5

Indication of Safety Warnings

Throughout this manual you will see the following words and symbols relating to important issues

of personal safety and proper operation. Their usage is described here:

DANGER

The word DANGER indicates an imminent hazard which

will result in highly serious injury, such as severe burns.

WARNING

The word WARNING is used to alert you to a procedure,

that if not performed properly, may cause personal injury.

CAUTION

The word CAUTION is used to alert you to a procedure

that, if not performed properly, may damage the equipment.

IMPORTANT

The word IMPORTANT is used to highlight especially important information

NOTE

The word NOTE is used to separate additional useful subject matter for the sake of clarity.

Page 6

Glossary of Terms

for Sure Chef®Combi-Steamers

CSL

CSM

CSB

CSG

For a better understanding of the settings, functions and general operation of Sure Chef CombiSteamers as described in this manual, please familiarize yourself with the following terms, definitions and symbols.

Auto Flush–A built-in feature that periodically and automatically drains, flushes and

refills the steam generator.

Cooking Mode–Any of several settings that produce a particular cooking medium or

environment.

Steam Mode–Cooking by pressureless steam produced in the built-in steam generator

and circulated by the high-speed fan.

Convection Mode–Dry heat produced by heating elements and circulated by the

high speed fan.

Combination Mode–A cooking mode that combines steam and convection heat to

produce a controlled environment.

Temperature Control–The method in which the cooking temperature in the cabinet

is selected or changed.

Timer–A switch that sets and measures cooking time in the cabinet and stops the

cooking process when time has elapsed.

Digital Readout (LED)–A lighted panel that displays the mode, function or other

information about the operation of the unit.

Food Probe–A device that monitors the internal temperature of food product during

cooking and stops the cooking process at a preselected temperature.

Probe Cooking–Any cooking method that utilizes the food probe.

Hand Held Sprayer–A spray nozzle for cleaning the unit that is attached to a

retractable hose built into the unit and connected to the unit’s water line.

Tender Steaming–A low temperature cooking method used to produce delicate foods

with less air turbulence at temperatures between 86° (30°C) to 212°F (100°C).

Rethermalizing Mode–A cooking mode that quickly brings precooked (chilled)

product back to serving temperatures and conditions.

5

Page 7

Programming–A function that allows the storing of up to 99 sets of cooking steps (recipes

in the unit’s memory.

Steam Injection–A feature of the Convection mode that sprays a 4-second burst of water onto

the heating elements to create a small amount of steam momentarily. Often used to help in the

browning of certain foods.

Half-Energy–A function that shuts off half the heating elements in order to extend the

cooking time for slow-cooked product.

Half-Fan Speed–A function that reduces fan speed by one-half for less turbulence.

Pulse Fan–A function that operates the fan intermittently: On for 10 seconds, off for 110

seconds. Often used in cooking delicate items.

Fully Digital–All control panel functions are controlled by computer and activated by touch

pad buttons.

Delta T Cooking–A cooking technique that raises the cooking temperature in the cabinet

in direct relationship to the rise in product’s internal temperature. Often used in preparing

large fresh or cured meat roasts.

Auto Reverse Fan–A function that operates the fan 2 minutes forward then 2 minutes

reverse. Helps produce even browning.

Filterless Grease Extraction–A feature of the Auto Reverse Fan that removes grease from

the air centrifugally, eliminating the need for grease filters.

SDHC–The acronym for Smart Digital Humidity Control. This is a control technology that

automatically measures and regulates the level of humidity in the cooking cabinet.

Cool Down–A feature that quickly reduces the cabinet temperature by allowing the fan to

operate while the door is open.

Forced Steaming–A cooking method in which convection heat is used to drive up cabinet

temperatures, allowing steaming at temperatures between: 213° (101°C) and 265°F (130°C).

6

Page 8

Sure Chef®Combi-Steamers – Features

at a glance

CSL

CSM

CSB

CSG

Models

Sure Chef Combi-Steamers come in three electric models: CSB, CSM, and CSL;

and one gas model, CSG.

Sizes

• Model Sizes are designated by the number of 12” x 20” x 2

of holding.

• Electric models come in five sizes: 6 (6-pan, counter model), 10 (10-pan, counter

model), 1020 (20-pan, counter model*), 20 (20-pan, floor model) and 40 (40-pan,

floor model**).

• Gas models come in three sizes: 10 (10-pan, counter model), 12 (12-pan, counter

model), and 20 (20-pan, floor model).

NOTE: Features vary according to model type. Accessories tend to vary according to unit

size. You may occasionally see references such as CSB/M/L-6. This means that the reference

applies to all electric models in that size. A reference such as CSL-6/10/20/40 applies to the

CSL model in all sizes.

1

⁄2” pans each is capable

* The 1020 model is designed for holding up to (10) full size 18” x 26” bun pans with adaptor,

as well as (20) 12” x 20” x 2

** The 40 model is designed to hold up to (20) 18” x 26” bun pans with adaptor.

1

⁄2“ steam pans.

7

Page 9

Feature CSL CSM CSB CSG

Auto Flush

Auto-Reverse Fan

Cooking Modes

Combination

Convection

Rethermalizing In Combination

Steam

Tender Steaming In Steam

Cool-Down

Delta-T Cooking

Digital Readout

Dual Glass Door

Electro-Mechanical Controls

Electronic Touch Pad Controls

Filterless Grease Extraction

••••

•••

••••

••••

••

••••

••

•••

•

•• •

•••

•••

••

•••

Hand Held Sprayer

Half Energy

Half Fan

Probe Cooking

Programmable Operation

Pulse Fan

SDHC Full Limited

Steam Injection

All units require drain and water source.

Units can be ordered with left-hand hinged door, optional.

Please specify phase and voltage with order. These cannot be changed in the field.

••

••

••

••

••

•

••

Optional

Optional

•

•

8

Page 10

Loading & Unloading

CSL

CSM

CSB

CSG

Your Sure Chef Combi-Steamer includes a Mobile Oven Rack that is integral to the unit’s

operation. All food product is loaded onto the oven rack which is then loaded into the

cooking cabinet.

• Floor Models–CSB/M/L-20 and 40, and CSG-20, use Mobile Oven

Racks designed to roll directly into cabinets. Door closes and seals

around Mobile Oven Rack.

• Counter Models–CSB/M/L-6, 10 and 1020, and CSG-10 and 12

utilize Transport Carts upon which Mobile Oven Racks may be

placed. The Transport Cart is rolled up to the unit, and the Mobile

Oven Rack rolls directly into the cabinet.

IMPORTANT: During the loading and unloading process for counter

models, lock front casters of Transport Cart when car t is stationary. Lock

front wheels on Mobile Oven Rack with locking lever near right front wheel.

Unlock wheels of Mobile Oven Rack ONLY when rolling in or out of unit.

This will keep Mobile Oven Rack stable on Transport Cart.

Full Loads

To Load

• Place food product on appropriate grids, pans and racks. Load onto Mobile Oven Rack.

• Preheat unit to desired temperature.

•Open door slightly until fan stops and heat dissipates. Open door fully with care.

• (Floor models) Roll loaded Mobile Oven Rack directly into unit.

(Counter models) Roll loaded Mobile Oven Rack on Transport Cart up to unit.

Lock front casters on Transport Cart to prevent movement. Release wheel lock on

Mobile Oven Transport Cart and roll into unit.

• Shut door and begin cooking.

To Unload

• Signal will sound when cooking cycle is complete

• Open door slightly until fan stops and heat dissipates. Open door fully with care.

• (Floor models) Roll Mobile Oven Rack straight out of unit and to appropriate location.

(Counter models) Roll Transport Cart up to unit, lock front casters on Transport Cart

and roll Mobile Oven Rack out of unit and onto Transport Cart. Lock front wheel of

Mobile Oven Rack. Release locked front caster on Transport Cart and roll away from

unit to appropriate location.

9

Page 11

Partial Loads

Individual pans or racks of product can be easily loaded or unloaded while the unit is in

operation.

•Open door slightly until fan stops and heat dissipates. Open door fully with care.

• Load or unload pans or racks directly to or from Mobile Oven Rack in unit. It is not

necessary to remove Mobile Oven Rack.

• Shut door. Cooking process continues automatically.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or vapors to escape. KEEP FACE AND HANDS AWAY FROM OPENING or

burns could result. When steam and/or heat has dissipated open door fully with care. Escaping hot steam and/or vapors

can cause serious burns. Interior surfaces extremely hot, including pans, grids and oven racks. To prevent burns, allow

unit to cool, or use appropriate heat resistant protective mitt or pad when handling.

Tips

• No flavor transfer occurs during cooking, so consider load by the type of cooking mode

(Steam, Convection, Combination) being used.

•When cooking for longer periods, or on Continous cooking, load items that will be done

sooner toward the front of the rack. These can be removed individually when done.

• For greatest efficiency, try to cook with full loads. In general, cooking times and temperatures are not affected by the quantity of product in the cooking cabinet.

•When loading roasts, or large cuts of meat, place product directly on racks and load near

the bottom of the Mobile Oven Rack. Load an empty pan directly beneath roast to catch

drippings and roast bones.

• For counter models, consider ordering Combi-Steamer Base Units. Several styles are

available that include enclosed pan storage for convenient access to pans, grids and racks.

10

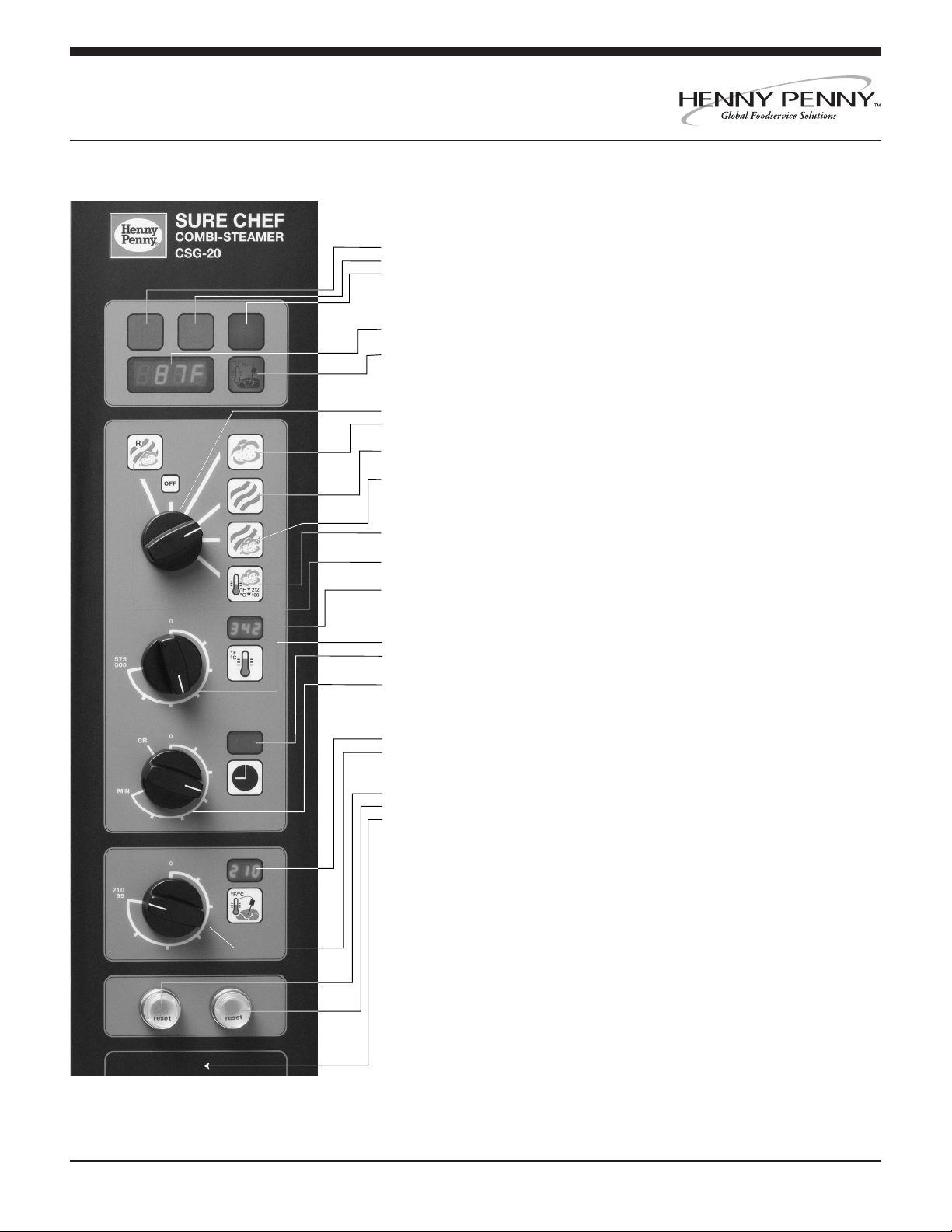

Page 12

Sure Chef

®

Combi-Steamer models CSL-6/10/1020/20/40

1 ON/OFF switch

2 ON indicator light (green)

3Message display

• NO WATER warning–check water supply

• Displays steam exhaust flap position

• Displays SDHC humidity level

Cooking mode selection key (lighted display indicates the selected mode)

4 STEAM mode–86°F to 266°F (30°C to 130°C)

•Normal steaming, pre-set at 212°F (100°C)

• Tender Steaming 86°F to 212°F (30°C to 100°C)

• Forced steaming, 213°F to 266°F (101°C to 130°C)

• Light ring around Steam key flashes when cabinet temperature exceeds

pre-selected temperature by 20°F (10°C)

5 COMBINATION mode–86°F to 575°F (30°C to 300°C)

• Pre-set to 320°F (160°C) and 100% SDHC

• Control humidity with SDHC function (7)

• Rethermalize in this mode

6 CONVECTION mode–86°F to 575°F (30°C to 300°C)

• Pre-set to 320°F (160°C) and 100% SDHC

• Reduce humidity with SDHC function (7)

7 SDHC Smart Digital Humidity Control

• Six possible moisture levels from 100% to 0%

• Control humidity in Combination mode

• Reduce humidity (from cooking product) in Convection mode

8 CABINET TEMPERATURE indicator key

• Press to indicate temperature selection. Adjust and select with SELECT arrow keys (16)

• Press and hold to display actual cabinet temperature

• Key lights up during preheating

9 Interior cabinet temperature display

10 TIMER activation key

• Press to activate cook time. Adjust and select with SELECT arrow keys (16)

11 COOKING TIME display

• Selected time (0 to 24 hr) displayed with period between hours and minutes. When

timer selection is activated, period flashes. Actual cooking time remaining is displayed

with flashing colon between hours and minutes.

12 PROBE COOKING activation key

• Press to activate Probe Cooking function. Adjust and select food internal “done”

temperature range from 68°F to 210°F (20°C to 99°C) using SELECT arrow keys (16).

• Upon reaching “done” temperature, audio signal sounds and unit shuts off automatically

13 Actual food probe temperature display

14 Pre-selected “done” temperature display

15 Continuous Run key

16 SELECT arrow keys for temperature, time and food probe temperature

17 PROGRAM activation key

• Press to enter programming function and display program number

18 Program number (1 to 98 for cooking programs, plus number 99 pre-programmed for cleaning)

19 Program stage (1 to 9 intervals)

20 Program START key

21 Program SELECT arrow keys

22 SPECIAL FUNCTIONS activation key (press to display)

23 STEAM INJECTION

• Four-second burst of steam in Convection mode between 250°F (120°C) and 480°F (250°C)

24 PULSE FAN

• Fan runs ON 10 seconds, OFF 110 seconds

25 HALF-FAN SPEED

26 COOL DOWN

• Fan continues to operate when door is open, reducing cabinet temperature rapidly

27 DELTA-T Cooking

28 HALF-ENERGY

29 Unit serial number

Please refer to this number when requesting service

Control Panel Functions

at a glance

11

Page 13

Sure Chef

®

Combi-Steamer models CSM-6/10/1020/20/40

1 ON indicator light (green)

2 Message display

•NO WATER warning–check water supply

•Displays steam exhaust flap position

3 Mode selection switch (lighted display indicates the selected mode)

4 STEAM mode–212°F (100°C)

• For steaming, stewing, blanching, preserving, etc.

• 212°F (100°C), and 100% humidity

• Steam Mode LED flashes when cabinet temperature exceeds 239°F (115°C) in Steam mode

5 CONVECTION mode–86°F to 575°F (30°C to 300°C)

• For roasting, baking grilling, etc

• Pre-setting: flap closed

6 COMBINATION mode–86°F to 575°F (30°C to 300°C)

• For Combi-Steaming instead of roasting and glazing or baking with moisture

• Forced Steaming between 213°F to 266°F (101°C to 130°C)–firm vegetables

or potatoes are cooked more quickly

• Pre-setting: flap closed

7 TENDER STEAMING mode–86°F to 210°F (30°C to 99°C)

• For blanching, poaching, simmering, soaking, vacuum cooking

• Pre-setting: flap closed

•Message display flashes when cabinet temperature exceeds pre-selected

temperature by 20°F (10°C)

8 RETHERMALIZING mode–86°F to 575°F (30°C to 300°C)

• For reheating pre-cooked (chilled) food

• Pre-setting: Flap closed

9 PROGRAM function

• Create and store up to 99 cooking programs of 9 steps each

10 CABINET TEMPERATURE indicator key

• Key lights up during preheating

• Press key to display cabinet temperature

11 TEMPERATURE SELECTION dial

12 TEMPERATURE DISPLAY

•Displays selected cooking temperature

•Displays cabinet temperature when CABINET TEMPERATURE key is pressed

13 TIMER activation key

• Select time using the TIMER/PROBE COOKING dial (15)

• Press key to activate timer

14 COOKING TIME display

• Shows actual cooking time remaining

15 TIMER/PROBE COOKING dial

• Set TIMER for 0 minutes to 120 minutes, press TIMER activation key (13)

• Set PROBE temperature from 68°F to 210°F (20°C to 99°C), press PROBE

COOKING key (16)

• Select “CR” for Continuous Run

16 PROBE COOKING key

• Select food internal “done” temperature using TIMER/PROBE COOKING dial (15)

• Press key to select Probe Cooking function

17 PROBE COOKING display

• Upper display indicates actual internal food temperature

• Lower display shows pre-selected “done” temperature

Additional functions

18 HALF-FAN SPEED

19 STEAM INJECTION

• Four-second burst of steam in Convection mode between 250°F (120°C) and 480°F (250°C)

20 COOL DOWN

• Fan continues to operate when door is open, reducing cabinet temperature rapidly

21 HALF-ENERGY

22 SDHC (Smart Digital Humidity Control) operational in Convection, Combination and

Rethermalizing modes

• Pre-setting for all modes: flap closed

• Lighted display: Left–moisture removed to 50% humidity. Right–all moisture removed (0%),

flap open. No display–no moisture removed (100%), flap closed.

Programming (press and display)

23 Program number (1 to 99)

24 Program stage (1 to 9 intervals)

25 Program START key

26 Program SELECT arrow keys

27 Unit serial number

Please refer to this number when requesting service

Control Panel Functions

at a glance

12

Page 14

Sure Chef

®

Combi-Steamer models CSB-6/10/1020/20/40

1 Warning light– lights red when cabinet temperature exceeds 239°F (115°C)

in Steam mode

2 NO WATER Warning light–check water supply

3 ON indicator light (green)

4 Mode selection switch

5 STEAM mode–212°F (100°C)

• For steaming, stewing, blanching, preserving...

6 CONVECTION mode–140°F to 575°F (60°C to 300°C)

• For roasting, baking grilling, etc.

7 COMBINATION mode–140°F to 575°F (60°C to 300°C)

• For Combi-Steaming instead of roasting and glazing or baking with

moisture rethermalizing

• Forced Steaming between 213°F to 266°F (101°C to 130°C)–firm vegetables

or potatoes are cooked more quickly

8 Additional function COOL DOWN

• Fan continues to operate when door is open, reducing cabinet

temperature rapidly

9 TEMPERATURE selection dial

• For convection and combination modes

10 HEAT ON indicator

• Lights during preheating

11 TIMER (0 to 100 minutes)

• Set on “D” for Continuous Run

12 FOOD PROBE DISPLAY 68°F to 210°F (20°C to 99°C)–(optional feature)

• Indicates pre-selected food probe temperature

• Indicates internal temperature of food

13 FOOD PROBE pre-selected TEMPERATURE

switch–(optional feature)

14 Unit serial number

Please refer to this number when requesting service.

Control Panel Functions

at a glance

13

Page 15

Sure Chef

®

Combi-Steamer models CSG-10/12/20

1Warning light–lights red when cabinet temperature exceeds 239°F (115°C)

2 NO WATER warning light (red)–check water supply

3 ON indicator light (green)

4Digital COOKING/PROBE TEMPERATURE display–actual cabinet

or internal food/probe temperature

5 PROBE COOKING indicator display

6Mode selection switch (lighted display indicates the selected mode)

7 STEAM mode–212°F (100°C)

• For steaming, stewing, blanching, preserving, etc.

8CONVECTION mode–86°F to 575°F (30°C to 300°C)

• For roasting, baking grilling, etc

9COMBINATION mode–86°F to 575°F (30°C to 300°C)

• For Combi-Steaming instead of roasting and glazing or baking with moisture

• Forced Steaming between 213°F to 266°F (101°C to 130°C)–firm vegetables

or potatoes are cooked more quickly

10 TENDER STEAMING mode–86°F to 210°F (30°C to 99°C)

• For blanching, poaching, simmering, soaking, vacuum cooking

11 RETHERMALIZING mode–86°F to 575°F (30°C to 300°C)

• For reheating pre-cooked (chilled) food

12 SELECTED TEMPERATURE display

13 TEMPERATURE SELECTION dial

14 COOKING TIME display

• Shows actual cooking time remaining

15 TIMER dial (0 to 120 minutes)

• Select “CR” for Continuous Run

16 PROBE pre-selected “DONE” TEMPERATURE display

17 PROBE TEMPERATURE SELECTION dial

• Select from 68°F to 210°F (20°C to 99°C)

• Unit shuts off automatically when “done” temperature is reached

18 Warning light–Steam burner malfunction

19 Warning light–Convection burner malfunction

20 Unit serial number

Please refer to this number when requesting service

Control Panel Functions

at a glance

14

Page 16

Basic

Operations

15

Page 17

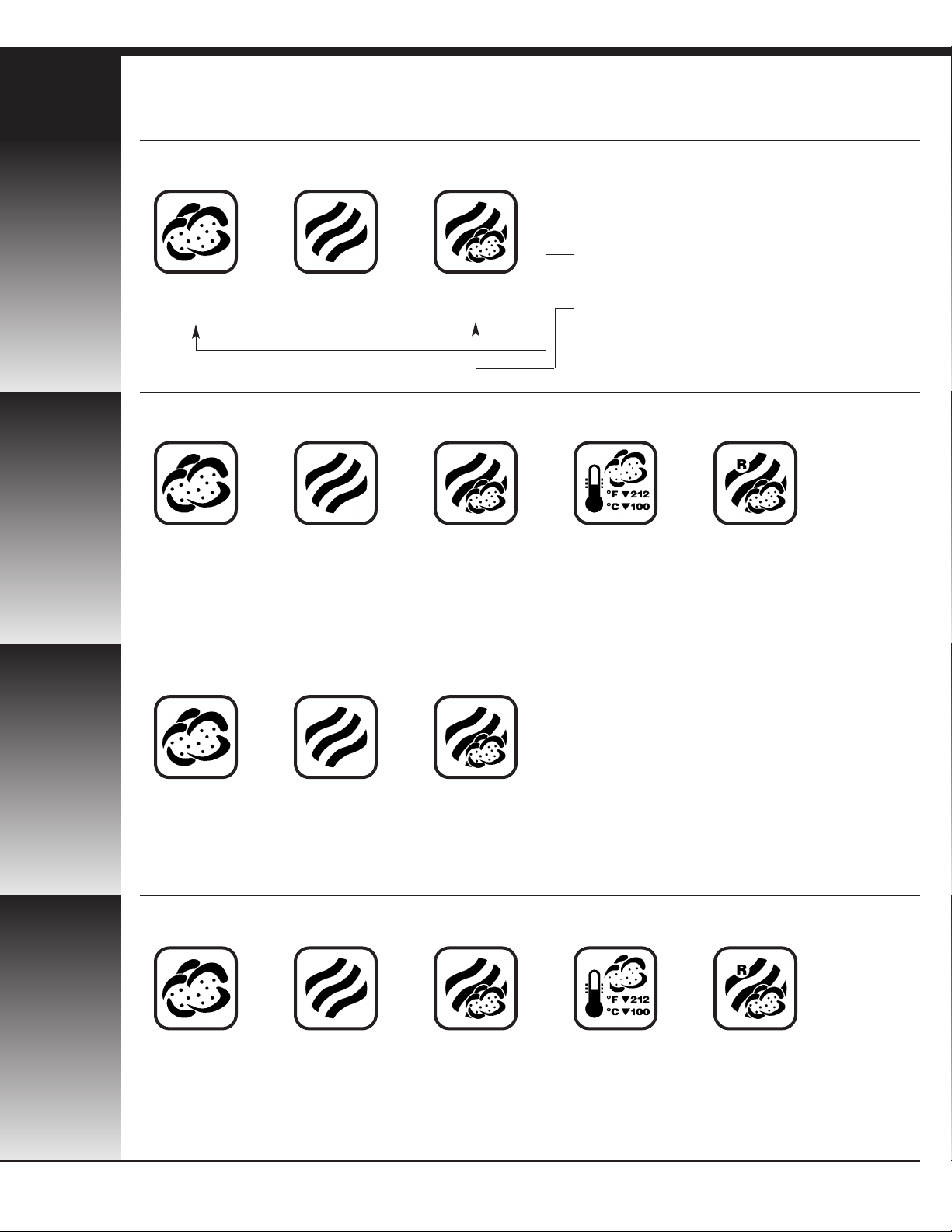

Cooking Modes

CSL

CSM

CSL models have three basic cooking modes:

Steam

Mode

Convection

Mode

Combination

Mode

CSM models have five basic cooking modes:

Steam

Mode

Convection

Mode

Combination

Mode

Fully digital operation of the CSL offers a wider

range of control within these modes. Therefore...

Tender Steaming

is accomplished in the Steam Mode.

Rethermalizing

is accomplished in the Combination Mode.

Tender

Steaming

Mode

Rethermalizing

Mode

CSB

CSG

CSB models have three basic cooking modes:

Steam

Mode

Convection

Mode

Combination

Mode

CSG models have five basic cooking modes:

Steam

Mode

Convection

Mode

Combination

Mode

Tender

Steaming

Mode

Rethermalizing

Mode

16

Page 18

Cooking Modes

(continued)

CSL

CSM

Steam mode–for moist heat

The steam generator produces hygienic steam and releases it pressureless into the cooking cabinet

where it is is circulated at high speeds by the fan. The unit’s control system allows only as much steam

into the cabinet as the food is able to absorb. The cooking temperature in this mode can be regulated

from 86°F (30°C) to 265°F (130°C) to accomplish Tender Steaming as well as normal steaming.

Convection mode–for dry heat

Powerful heating elements heat the air inside the cabinet. The fan circulates this hot, dry air evenly

throughout the interior. Temperature can be regulated precisely between 86°F (30°C) to 575°F

(300°C)

• Cooking environment can be manipulated extensively with additional functions and SDHC.

Steam mode–for moist heat

The steam generator produces hygienic steam and releases it pressureless into the cooking cabinet

where it is is circulated at high speeds by the fan. The unit’s control system allows only as much steam

into the cabinet as the food is able to absorb. The cooking temperature in this mode is fixed at 212°F

(100°C).

Convection mode–for dry heat

Powerful heating elements heat the air inside the cabinet. The fan circulates this hot, dry air evenly

throughout the interior. Temperature can be regulated precisely between 86°F (30°C) to 575°F

(300°C)

• Cooking environment can be manipulated extensively with additional functions and SDHC.

CSB

CSG

Steam mode–for moist heat

The steam generator produces hygienic steam and releases it pressureless into the cooking cabinet

where it is is circulated at high speeds by the fan. The unit’s control system allows only as much steam

into the cabinet as the food is able to absorb. The cooking temperature in this mode is fixed at 212°F

(100°C).

Convection mode–for dry heat

Powerful heating elements heat the air inside the cabinet. The fan circulates this hot, dry air evenly

throughout the interior. Temperature can be regulated precisely between 140°F (60°C) to 575°F

(300°C)

Steam mode–for moist heat

The steam generator produces hygienic steam and releases it pressureless into the cooking cabinet

where it is is circulated at high speeds by the fan. The unit’s control system allows only as much steam

into the cabinet as the food is able to absorb. The cooking temperature in this mode is fixed at 212°F

(100°C).

Convection mode–for dry heat

A powerful heat exchanger heats air through an indirect process–exhaust fumes cannot enter the

cooking cabinet. The fan circulates this hot, dry air evenly throughout the interior. Temperature can

be regulated precisely between 86°F (30°C) to 575°F (300°C).

17

Page 19

Combination mode–for variable temperature moist heat

The unit’s control system combines both Steam and Convection modes to create a humid cooking environment at

temperatures higher or lower than 212°F (100°C). Temperatures can be selected from 86°F (30°C)

to 575°F (300°). Cooking environment remains at optimal humidity to prevent food from dr ying out.

• Cooking environment can be manipulated extensively with additional functions and SDHC.

• Rethermalizing is accomplished in this mode at 60% SDHC or less.

• Cooking Modes can be used individually, in sequence or in any combination to achieve desired results.

Combination mode–for variable temperature moist heat

The unit’s control system combines both Steam and Convection modes to create a humid cooking environment at

temperatures higher or lower than 212°F (100°C). Temperatures can be selected from 86°F (30°C) to 575°F

(300°C). Cooking environment remains at optimal humidity to prevent food from dr ying out.

• Cooking environment can be manipulated extensively with additional functions and SDHC.

Tender Steaming mode–for low temperature moist heat

In this mode, an automatic sensor keeps the pre-selected temperature constant within a moist cooking environment. Temperatures can be selected from 86°F (30°C) to 210°F (99°C). Temperature may vary +/- 31⁄2

°F ( 1°C)

Combination mode–for high temperature moist heat

The unit’s control system combines both Steam and Convection modes to create a humid cooking environment at

temperatures higher than 212°F (100°C). Temperatures can be selected from 140°F (60°C) to 575°F (300°C).

Cooking environment retains 100% humidity to prevent food from dr ying out.

• Cooking Modes can be used individually, in sequence or in any combination to achieve desired results.

Combination mode–for variable temperature moist heat

The unit’s control system combines both Steam and Convection modes to create a humid cooking environment at

temperatures higher than 212°F (100°C). Temperatures can be selected from 86°F (30°C) to 575°F (300°C).

Cooking environment remains at optimal humidity to prevent food from dr ying out.

Tender Steaming mode–for low temperature moist heat

In this mode, an automatic sensor keeps the pre-selected temperature constant within a moist cooking

environment. Temperatures can be selected from 86°F (30°C) to 210°F (99°C). Temperature may vary +/-

1

⁄

2°F

(1°C)

3

18

Page 20

Cooking Modes

(continued)

Rethermalizing mode–for optimum reheating

This is a specialized mode that combines moist and dry heat to create the ideal environment for reheating

previously cooked foods. Rethermalizing restores the look, taste and temperature of food without drying or water

marks. Temperatures can be selected from 86°F (30°C) to 575°F (300°C).

• Cooking environment can be manipulated extensively with additional functions and SDHC.

• Humidity is limited to a maximum of 60%.

• Cooking Modes can be used individually, in sequence or in any combination to achieve desired results.

Rethermalizing mode–for optimum reheating

This is a specialized mode that combines moist and dry heat to create the ideal environment for reheating

previously cooked foods. Rethermalizing restores the look, taste and temperature of food without drying or water

marks. Temperatures can be selected from 86°F (30°C) to 575°F (300°C)

• Cooking Modes can be used individually, in sequence or in any combination to achieve desired results.

• Humidity is controlled to approximately 60%.

19

Page 21

Steam Mode

moist heat at 212°F(100°C)

CSL

CSM

CSB

CSG

Advantages

• Extremely short preheating time

• Excellent food consistency

• Conserves nutrients, color

• No added fats or oils

• Cook different products at same time with no taste transfer

• Can be partially unloaded for serving convenience

• No need to boil water in pots

Cooking examples

• Cooking preparations

Tomatoes concasees, garnish, mushrooms, blanched vegetables for stuffing, peeling, etc.

• Starters, appetizers

Scrambled, poached or boiled eggs; vegetable pate, asparagus, stuffed vegetable, canneloni

• Entrees

Cooked beef, ham, turkey legs, steamed fish, chicken breasts

• Sides

Rice, dumplings, pasta, fresh and frozen vegetables, boiled potatoes

Cooking methods

• Steaming

• Stewing

• Blanching

• Poaching

• Simmering

• Soaking

• Thawing

• Rethermalizing

•Preserving

20

Page 22

Steam Mode

moist heat at 212°F(100°C) – (continued)

CSL

CSM

Operation

•Turn unit on

• Select STEAM mode and select CR

• Preheat until “warm-up” control light goes out.

Temperature will remain at 212°F (100°C).

Operation

• Set on STEAM mode, activate TIMER and set on CR

• Preheat until “warm-up” control light goes out.

Temperature will remain at 212°F (100°C).

• Load mobile oven rack, place or roll into cabinet

Setting

• Select TIMER and set desired cooking time

Setting

• Set desired cooking time and activate TIMER

OR select PROBE COOKING and set desired probe

“done” temperature OR select continuous operation

or or

OR set on continuous operation OR set desired probe

“done” temperature and activate PROBE COOKING

or or

CSB

CSG

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on STEAM mode, and set TIMER

on Continuous Run

• Preheat until window is misted over.

Temperature will remain at 212°F (100°C).

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on STEAM mode, set TIMER on CR

• Preheat until “warm-up” control light goes out.

Temperature will remain at 212°F (100°C).

Setting

• Set desired cooking TIME

OR continuous operation

OR set desired PROBE (optional) “done” temperature

or or

Setting

• Set desired cooking TIME

OR set on continuous operation

OR set desired PROBE “done” temperature

or or

• Load mobile oven rack, place or roll into cabinet

21

Page 23

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or

vapors to escape. KEEP FACE AND HANDS

AWAY FROM OPENING or burns could result.

When steam and/or heat has dissipated open

door fully with care. Escaping hot steam

and/or vapors can cause serious burns. Interior

surfaces extremely hot, including pans, grids

and oven racks. To prevent burns, allow unit to

cool, or use appropriate heat resistant protective

mitt or pad when handling.

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

22

Page 24

Steam Mode

(continued)

CSL

CSM

CSB

CSG

Tips

• Determine which foods can be cooked together for the greatest efficiency. This is best

done by considering the cooking modes and temperatures. Keep in mind that fish,

meat, vegetables, fruit, etc can be cooked at the same time because there is no flavor

transfer.

• Potatoes should always be cooked in perforated pans. This allows steam to circulate

for faster, more even cooking.

• In general, two shallower pans are better than one deeper pan. This avoids bruising.

• Dumplings should be placed in shallow pans not too close together.

• Rice is the only type of food to which water must be added prior to cooking. Longer

soaking times mean shorter cooking times.

•Tomatoes can be skinned easily when steamed for 30 to 60 seconds, then chilled in

cold water.

• Stock can be collected by inserting a container in the bottom of the mobile oven rack.

23

Page 25

Convection Mode

dry heat 86°F to 575°F (30°C to 300°C)

CSL

CSM

CSB

CSG

Advantages

• Powerful heating capability up to 575°F (300°C), even when fully loaded

• Fast pre-heating

• Convection heat for faster cooking than traditional methods

• Even heating for high quality food production

• Consistent cooking and even browning at any rack level

• No added fats or oils

• Cook different products at same time with no taste transfer

• Can be partially unloaded for serving convenience

Cooking examples

• Cooking preparations

Roasted bones for stock, melting butter, thawing frozen prepared foods, etc.

• Starters, appetizers

Meatballs, roast beef, grilled ham, sausage, chicken wings, quiches, tarts,

breadsticks, bread, rolls, etc.

• Entrees

Beef and pork roasts, ribs, chicken whole or piece, turkey, frozen lasagna,

pizza, pizza rolls,

• Sides

Baked potatoes, souffles

• Desserts

Sponge cake, marble cake, puff pastries, frozen fruit puffs, pies, etc.

Cooking methods

•Broiling

• Roasting

• Baking

•Browning

• Thawing

24

Page 26

Convection Mode

dry heat 86°F to 575°F (30°C to 300°C) – (continued)

CSL

CSM

Operation

• Turn unit on

• Select CONVECTION mode and select CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on CONVECTION mode,

activate TIMER and set on CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

Setting

• Select desired cooking TEMPERATURE

• Select TIMER and set desire cooking time

OR select PROBE COOKING and set desired probe

“done” temperature OR select continous operation

or or

Setting

• Set desired cooking TEMPERATURE

• Set desired cooking TIME and activate timer

OR set on continuous operation OR set desired probe

“done” temperature and activate PROBE COOKING

or or

CSB

CSG

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on CONVECTION mode,

and set TIMER on Continuous Run

• Preheat until set temperature is reached

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on CONVECTION mode, set TIMER on CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

Setting

• Set desired cooking TEMPERATURE

140°F to 575°F (60°C to 300°C)

• Set desired cooking TIME

OR continuous operation

OR set desired PROBE (optional) “done” temperature

or or

Setting

• Set desired cooking TEMPERATURE

• Set desired cooking TIME

OR set on continuous operation

OR set desired probe “done” temperature

• Load mobile oven rack, place or roll into cabinet

or or

25

Page 27

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or

vapors to escape. KEEP FACE AND HANDS

AWAY FROM OPENING or burns could result.

When steam and/or heat has dissipated open

door fully with care. Escaping hot steam

and/or vapors can cause serious burns. Interior

surfaces extremely hot, including pans, grids

and oven racks. To prevent burns, allow unit to

cool, or use appropriate heat resistant protective

mitt or pad when handling.

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

26

Page 28

Convection Mode

(continued)

CSL

CSM

CSB

CSG

Tips

Cooking times

Proper cooking times will vary depending on the quality, weight or size of the product.

Generally, cooking time is not affected by the size of the load. However, avoid overloading

grids or pans so air will circulate evenly around product.

Roasting, broiling

• Always preheat unit at 575°F (300°C), then set to desired temperature.

• For steaks, chops, cutlets, or loin cuts, 1/2” to 1” thickness is ideal.

• Cook on grids with drip pans below. This allows even browning on sides and bottom.

• Try to place similar sized product on same grids.

Browning, finishing

Preheat to 575°F (300°C), or until light goes out. After loading, set to desired temperature.

Fish

Do not cover with flour.

For whole fish, wrap tail in foil and support it from underneath with raw potatoes.

Cook in previously unheated enameled pans.

Baking

• Preheat to baking temperature. In general, Combi-Steamer baking temperatures

will be 70°F to 80°F (20°C to 25°C) LOWER than traditional ovens.

•When baking bread and rolls, use only every second rack. Baking trays should not

be higher than 2 3/4” (7.0 cm).

• When baking frozen prepared food items, preheat to 575°F (300°C), do not defrost.

Then set to desired baking temperature, load and begin.

• Defrost frozen bread dough and let rise for a short time before baking.

• When baking full loads of “wet” product (frozen or dough), remove built-up humidity

with SDHC* or open door briefly.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or vapors to escape. KEEP FACE AND HANDS AWAY FROM

OPENING or burns could result. When steam and/or heat has dissipated open door fully with care. Escaping

hot steam and/or vapors can cause serious burns. Interior surfaces extremely hot, including pans, grids and

oven racks. To prevent burns, allow unit to cool, or use appropriate heat resistant protective mitt or pad when

handling.

*Available on CSL and CSM models, only

27

Page 29

Combination Mode

For variable temperature moist heat, 86°F to 575°F (30°C to 300°C)

CSL

CSM

CSB

CSG

Advantages

• Fast preheating

• The ability to cook with steam at temperatures above 212°F (100°C)

• Less shrinkage of food due to dehydration

• More servings per uncooked pound

• Automatic basting

• Food retains more nutrients and flavor

• No added fats or oils

• Even heating for high quality food production

• Even heating for large meat portions

• Cook different products at same time with no taste transfer

• Consistent cooking and even browning at any rack level

• Can be partially unloaded for serving convenience

Cooking examples

• Cooking preparations

Roasted bones for stock

• Starters, appetizers

Quiche, pastas, bread, rolls (frozen), etc.

• Entrees

Roast (beef, veal, pork, lamb) stuffed peppers, roast whole chicken, turkey legs,

casseroles, lasagna, etc.

• Sides

Potatoes au gratin, baked potatoes, frozen vegetables, baked apples, etc

• Desserts

Yeast dough (choux pastr y)

Cooking methods

• Combi-steaming • Combi-roasting

• Combi-baking • Glazing

•Browning • Basting

• Braising

28

Page 30

Combination Mode

for variable temperature moist heat – 86°F to 575°F (30°C to 300°C)

CSL

CSM

Operation

• Turn unit on

• Select COMBINATION mode and select CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on COMBINATION mode,

activate TIMER and set on CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Setting

• Select desired cooking TEMPERATURE

• Select TIMER and set desired cooking time OR select

PROBE COOKING and set desired probe “done”

temperature OR select continuous operation

or or

Setting

• Set desired cooking TEMPERATURE

• Set desired cooking TIME and activate timer

OR set on continuous operation

OR set desired probe “done” temperature

and activate PROBE COOKING

or or

CSB

CSG

Operation

• Set on COMBINATION mode, and set TIMER

on Continuous Run

• Preheat until set temperature is reached

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on COMBINATION mode, set TIMER on CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Setting

• Set desired cooking TEMPERATURE

212°F to 575°F (100°C to 300°C)

• Set desired cooking TIME

OR continuous operation,

OR set desired PROBE (optional) “done” temperature

or or

Setting

• Set desired cooking TEMPERATURE

• Set desired cooking TIME

OR set on continuous operation

OR set desired PROBE “done” temperature

or or

29

Page 31

(continued)

• Use SDHC to achieve desired humidity, if necessary

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

• Use SDHC to achieve desired humidity, if necessary

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or

vapors to escape. KEEP FACE AND HANDS

AWAY FROM OPENING or burns could result.

When steam and/or heat has dissipated open

door fully with care. Escaping hot steam

and/or vapors can cause serious burns. Interior

surfaces extremely hot, including pans, grids

and oven racks. To prevent burns, allow unit to

cool, or use appropriate heat resistant protective

mitt or pad when handling.

In Combination Mode steam is not visible.

Cabinet looks dry, but is full of steam. KEEP

FACE AND HANDS AWAY FROM OPENING

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

Unload

When done, open door slightly until fan stops and

steam dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

or burns could result.

30

Page 32

Combination Mode

(continued)

CSL

CSM

CSB

CSG

Tips

•To ensure even cooking and browning, always cook roasts on grids with plenty of

space around each roast for air to circulate.

• When practical, place meat grain parallel to the air circulation for even better results.

• Cook large, fat encrusted roasts in STEAM mode for the first one-third of the total

cooking time. This helps seal in juices, flavors and nutrients, and reduces shrinkage.

• Condensation and juices can be collected in a pan under the roasts, to be used later

with roasted bones for sauce stocks.

• Use chicken grid to roast whole chickens upright for even cooking and browning.

• When combi-steaming poultry and other juicy items, use SDHC* to regulate humidity

in the cooking environment (CSL, CSM models, only).

*Available on CSL and CSM models, only

31

Page 33

Tender Steaming

Low temperature steaming, 86°F to 210°F (30°C to 99°C)

CSL

CSM

CSG

NOTE: Tender Steaming not available on CSB models.

Advantages

• Fast preheating

• Gentle steaming for a variety of delicate items.

• Excellent consistency and taste for different many kinds of meat and fish.

• Lower cooking temperatures mean less sticking and crumbling.

• Less shrinkage results in juicier, more attractive portions, especially when held

in display merchandisers.

• No added fats or oils.

• Less cooking time required than traditional methods.

• The ability to select and maintain desired cooking temperature at lower levels.

• Can be partially unloaded for serving convenience

Cooking examples

• Cooking preparations

Blanching bacon and ham, soups, sauces, stocks, fish garnishings, etc.

• Starters, appetizers

Poached eggs, seafood, cakes, pates, etc.

• Entrees

Fish (salmon, sole, orange roughy), poultry, vacuum cooking items,

boneless chicken and turkey filets, beef filets, sausages, etc...

• Sides

Vegetable casseroles

• Desserts

Fruit, cheese cakes, delicate moist items, etc.

Cooking methods

• Scalding • Simmering • Soaking

• Poaching • Blanching • Vacuum cooking

• Thawing • Rethermalizing • Preserving

•Proofing

32

Page 34

Tender Steaming

Low temperature steaming – 86°F to 210°F (30°C to 99°C)

CSL

CSM

Operation

•Turn unit on

• Select STEAM mode and select CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on TENDER STEAMING mode, activate TIMER

and set on CR

Setting

• Set desired Tender Steaming TEMPERATURE

• Select TIMER and set desired cooking time

Setting

• Set desired Tender Steaming TEMPERATURE

86°F to 210°F(30°C to 99°C)

OR select PROBE COOKING and set desired probe

“done” temperature OR select continuous operation

or or

86°F to 210°F(30°C to 99°C)

CSG

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on TENDER STEAMING mode,

set TIMER on CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

• Set desired cooking time and activate TIMER

OR set on continuous operation OR set desired probe

“done” temperature and activate PROBE COOKING

or or

Setting

• Set desired Tender Steaming TEMPERATURE

86°F to 210°F(30°C to 99°C)

• Set desired cooking TIME

OR set on continuous operation

OR set desired PROBE “done” temperature

or or

33

Page 35

(continued)

Unload

When done, open door slightly until fan stops and steam

dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

Notes

• When Tender Steaming, fan will operate intermittently

in order to slow down the cooking process and maintain the selected cooking temperature (+/- 1/2°F).

• To maintain selected cooking temperatures below

149°F (65°C), fan operates at half-speed.

• When cabinet temperature falls below any selected

Tender Steaming temperature, fan will automatically

adjust to full speed until selected temperature is

regained.

Unload

When done, open door slightly until fan stops and steam

dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

Notes

• When Tender Steaming, fan will operate intermittently

in order to slow down the cooking process and maintain the selected cooking temperature (+/- 1/2°F).

• To maintain selected cooking temperatures below

149°F (65°C), fan operates at half-speed.

• When cabinet temperature falls below any selected

Tender Steaming temperature, fan will automatically

adjust to full speed until selected temperature is

regained.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or

vapors to escape. KEEP FACE AND HANDS

AWAY FROM OPENING or burns could result.

When steam and/or heat has dissipated open

door fully with care. Escaping hot steam

and/or vapors can cause serious burns. Interior

surfaces extremely hot, including pans, grids

and oven racks. To prevent burns, allow unit to

cool, or use appropriate heat resistant protective

mitt or pad when handling.

Unload

When done, open door slightly until fan stops and steam

dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

34

Page 36

Tender Steaming

Low temperature steaming – (continued)

CSL

CSM

CSG

Tips

Cooking times

The same principles for Steam mode apply. Generally, the lower the cooking temperature, the longer the cooking time.

Cooking temperatures

Approximate temperature ranges for some common items that can be Tender Steamed:

Soup garnishings: 167°F to 194°F (75°C to 90°C)

Fish, seafood: 149°F to 194°F (65°C to 90°C)

Pork, veal: 161°F to 167°F (72°C to 75°C)

Chicken/white meat: 167°F to 185°F (75°C to 85°C)

Chicken/dark meat: 176°F to 194°F (80°C to 90°C)

Poultry (other): 176°F (80°C)

Beef, lamb: 135°F to 165°F (58°C to 74°C)

Desserts: 149°F to 194°F (65°C to 90°C)

Seasoning

Season lightly. A food’s natural food taste, as well as the taste of seasonings, is intensified

by low temperature cooking. For this reason, also use less essences or reducing agents.

Texture, appearance

Tender Steaming is especially valuable in preparing certain foods for presentation in

display merchandisers.

• Excellent color

• Firm structure for clean portioning

• Less shrinkage, for plump, taught skins

• Fewer and smaller “bursts”, even when skin is damaged

35

Page 37

Rethermalizing

CSL

CSM

CSB

CSG

Advantages

• Different food products can be reheated without being covered.

• Food can be cooked and then reheated and served hours later.

• Allows more time to prepare dishes and trays.

• Allows foodservice operation to run more efficiently.

• Perfect function for handling large, catered orders in off-peak hours.

• Rethermalize directly on plates or in pans.

• Reduced humidity prevents water drops from forming on plated food when rethermalized.

Cooking examples

• Starters, appetizers

Pasta, vegetable dishes, macaroni & cheese, casseroles, spring rolls, etc

• Entrees

Roasts, casseroles, frozen meat and fish, frozen entrees, ribs, leg of veal,

stuffed vegetable dishes, etc.

• Sides

Rice, potatoe pancakes, noodles, vegetables, potatoes, fries, etc.

• Desserts

Fruit pies, cheese cakes, stewed fruit, etc.

36

Page 38

Rethermalizing

(continued)

CSL

CSM

Operation

• Turn unit on

• Select COMBINATION mode and select CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on RETHERMALIZING mode,

activate TIMER and set on CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Setting

• Select Rethermalizing TEMPERATURE

• Select TIMER and set desired cooking time OR select

PROBE COOKING and set desired probe “done”

temperature OR select continuous operation

or or

Setting

• Set Rethermalizing TEMPERATURE

Generally between 280°F (140°C) and 320°F (160°C)

• Set desired cooking TIME and activate timer OR set on

continuous operation OR set desired probe “done”

temperature and activate PROBE COOKING

or or

CSB

CSG

Operation

NOTE: CSB models do not have Rethermalizing mode.

REHEATING is possible in any of the three operating

modes – STEAM, CONVECTION, COMBINATION

• Set desired cooking MODE.

This will depend on the type of food being reheated.

or or

Operation

• Set on RETHERMALIZING mode, set TIMER on CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

• Set TIMER on Continuous Run

• PREHEAT to the selected mode temperature

• Load mobile oven rack, place or roll into cabinet

Setting

• Set Rethermalizing TEMPERATURE

• Set desired cooking TIME

Generally between 280°F (140°C) and 320°F (160°C)

OR set on continuous operation

OR set desired PROBE “done” temperature

or or

37

Page 39

• Use SDHC to achieve desired humidity, if necessary

Notes

•Proper rethermalizing temperatures will vary

according type of food.

• Normally, a setting of 60% SDHC or lower is preferred

for Rethermalizing.

•Proper rethermalizing times depend on type of food,

starting internal food temperature and number of

plates or pans. Times should average from 5 to 8 minutes.

• When practical, consider using probe cooking to

rethermalize. Ideal ser ving temperatures are easier

to achieve.

• Use SDHC to achieve desired humidity, if necessary

Setting

• Set reheating TEMPERATURE

Generally between 280°F (140°C) and 320°F (160°C)

• Set desired cooking TIME

OR set on continuous operation,

OR set desired PROBE (optional) “done” temperature

or or

Notes

•Proper rethermalizing temperatures will vary

according type of food.

• Rethermalizing mode limits humidity to maximum of 60%.

Therefore, SDHC range is limited to 60%, 30% or 0%.

•Proper rethermalizing times depend on type of food,

starting internal food temperature and number of

plates or pans. Times should average from 5 to 8 minutes.

• When practical, consider using probe cooking to

rethermalize. Ideal ser ving temperatures are easier

to achieve.

Notes

•Proper rethermalizing temperatures will vary

according type of food.

• Humidity levels in both Steam and Combination modes will

be 100%.

•Proper rethermalizing times depend on type of food,

starting internal food temperature and number of

plates or pans. Times should average from 5 to 8 minutes.

• When practical, consider using probe cooking to

rethermalize. Ideal ser ving temperatures are easier

to achieve.

Notes

•Proper rethermalizing temperatures will vary

according type of food.

• Rethermalizing mode controls humidity to approximately 60%.

•Proper rethermalizing times depend on type of food,

starting internal food temperature and number of

plates or pans. Times should average from 5 to 8 minutes.

• When practical, consider using probe cooking to

rethermalize. Ideal ser ving temperatures are easier

to achieve.

38

Page 40

CSL

CSM

CSB

CSG

Rethermalizing

Unload

When done, open door slightly until fan stops and

heat dissipates. Open door fully to remove pans.

Unit automatically shuts off when door is opened.

(continued)

X

Opening Door During Operation

Open door slightly to allow hot steam and/or

vapors to escape. KEEP FACE AND HANDS

AWAY FROM OPENING or burns could result.

When steam and/or heat has dissipated open

door fully with care. Escaping hot steam

and/or vapors can cause serious burns. Interior

surfaces extremely hot, including pans, grids

and oven racks. To prevent burns, allow unit to

cool, or use appropriate heat resistant protective

mitt or pad when handling.

Tips on Rethermalizing

• Reheat servings on plates, especially for large functions

• Special mobile oven rack

• Designed to hold plates for rethermalization

• Rolls in and out easily

• Thermal cover available to keep plates warm for short periods, or during transport

•Make sure food is arranged evenly on plates

• Sauces–pour over product before reheating, or on side after reheating

• Program rethermalization settings for similar, recurring situations*

• Use SDHC to “fine tune” rethermalization to achieve desired results*

*Available on CSL and CSM models, only

39

Page 41

Forced Steaming

High temperature steaming, 213°F to 266°F (101°C to 130°C)

CSL

CSM

CSB

CSG

Advantages

• Creates an intensified cooking process

• Shorter cooking times

• Retains color, nutrients

• Less shrinkage

Cooking examples

• Potatoes, carrots, celery

• Frozen prepared foods

Tips

Cooking temperatures

Approximate temperatures for Forced Steaming items:

Celery: 230°F (110°C)

Carrots: 240°F (115°C)

Potatoes: 257°F (125°C)

Turnips, yams: 248°F (120°C)

Frozen lasagna: 248°F (120°C)

Frozen vegetables: 248°F (120°C)

Rice 248°F (120°C)

40

Page 42

Forced Steaming

High temperature steaming, 213°F to 266°F (101°C to 130°C)

CSL

CSM

Operation

•Turn unit on

• Select STEAM mode and select CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on COMBINATION mode, activate TIMER

and set on CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Setting

• Select desired Forced Steaming TEMPERATURE

213°F to 266°F (101°C to 130°C)

• Select TIMER and set desired cooking time

OR select PROBE COOKING and set desired probe

“done” temperature OR select continuous operation

or or

Setting

• Select desired Forced Steaming TEMPERATURE

213°F to 266°F (101°C to 130°C)

• Set desired cooking time and activate TIMER

OR set on continuous operation OR set desired probe

“done” temperature and activate PROBE COOKING

or or

CSB

CSG

Operation

• Set on COMBINATION mode, and set TIMER

on Continuous Run

• Preheat until set temperature is reached

• Load mobile oven rack, place or roll into cabinet

Operation

• Set on COMBINATION mode, set TIMER on CR

• Preheat until set temperature is reached

or “warm-up” control light goes out

• Load mobile oven rack, place or roll into cabinet

Setting

• Select desired Forced Steaming TEMPERATURE

213°F to 266°F (101°C to 130°C)

• Set desired cooking TIME

OR continuous operation

OR set desired PROBE (optional) “done” temperature

or or

Setting

• Select desired Forced Steaming TEMPERATURE

213°F to 266°F (101°C to 130°C)

• Set desired cooking TIME

OR set on continuous operation

OR set desired PROBE “done” temperature

or or

41

Page 43

Cooking Functions: SDHC

For controlling humidity in the cooking environment

CSL

CSM

Advantages

Control humidity to:

• Improve quality of foods with different textures and consistency

• Enable precise finishing of delicate items

• Cook a wide variety of foods at the same time, including sauces, stocks

• Achieve proper cooking intensity for doughy pastries

Increase humidity to:

• Achieve basting

• Retain foods natural flavors and nutrients

• Prevent dehydration for increased portions

Remove humidity to:

• Achieve browning

• Increase crispness and texture

• Maintain consistent environment when baking or roasting “wet” foods

Cooking examples

• Crisp crusts for roast chicken

• Tender consistency for beef and pork roasts, ribs, casseroles, meat loaf, etc.

• Even consistency for light breads, cakes, pastries, etc.

• Perfect browning for au gratin dishes, casseroles, fruit pastries, dumplings, etc.

Full SDHC – CSL Models Limited SDHC – CSM Models

Using the SDHC function gives you the ability to maintain

or adjust the humidity level when cooking in Convection or

Combination modes. With this flexibility, you can create the

ideal cooking environment for a wide range of items, at any

stage in the cooking process.

42

Page 44

Cooking Functions: SDHC

(continued)

For controlling humidity in the cooking environment

CSL

CSM

Operation

• Select mode–either CONVECTION

or COMBINATION

or

• Select desired SDHC level.

Six levels are available:

%%%%%%

100% 80% 60% 40% 20% 0%

Operation

• Select from CONVECTION, COMBINATION

or RETHERMALIZING modes

• Message display indicates exhaust flap position

or

Open

Closed

Setting

• Set desired cooking TEMPERATURE

• Select timer, probe cooking or continuous operation

or or

• Message display indicates exhaust flap position

or

or or

• Set SDHC at 0%, 50% or 100%.

Message display indicates selection as follows:

100% 0%50%

60% 30% 0%

(When Rethermalizing)

Open

Closed

Setting

• Set desired cooking temperature

• Set desired cooking TIME and activate timer

OR set desired PROBE “done” temperature and activate

probe cooking OR set on continuous operation

or or

43

Page 45

Control

%%%%%%

100% 80% 60% 40% 20% 0%

• Press selected SDHC to display the actual humidity in

the cooking cabinet

• Select SDHC function and/or change levels at any stage

of the cooking process to achieve desired results

• Input SDHC levels along with times and temperatures

when programming cooking procedures

Tips

• SDHC is most effective with food items that have high

• One of the best approaches to using SDHC is to obser ve

• SDHC is also well suited to controlling the variable

• Use SDHC benefits, such as faster cooking times–

moisture content

the cooking process and react with

the appropriate SDHC level. Use SDHC when:

• Food perspires

• Condensation forms on the pans

• When browning needs to proceed more rapidly

• Any situation in which humidity needs to be

maintained or adjusted

humidity that occurs when cooking fully or partially

frozen meats, casseroles, entrees or side dishes.

especially for frozen items–to make your foodservice

production schedule more efficient.

Control

• Select SDHC function and/or change levels at any

stage of the cooking process to achieve desired results

0% Moist 50% Moist 100% Moist

• Input SDHC levels along with times and temperatures

when programming cooking procedures

Tips

• SDHC is most effective with food items that have high

moisture content

• One of the best approaches to using SDHC is to obser ve

the cooking process and react with

the appropriate SDHC level. Use SDHC when:

• Food perspires

• Condensation forms on the pans

• When browning needs to proceed more rapidly

• Any situation in which humidity needs to be

maintained or adjusted

• SDHC is also well suited to controlling the variable

humidity that occurs when cooking fully or partially

frozen meats, casseroles, entrees or side dishes.

• Use SDHC benefits, such as faster cooking times–

especially for frozen items–to make your foodservice

production schedule more efficient.

44

Page 46

Cooking Functions: Probe Cooking

For achieving precise “done” temperatures

CSL

CSM

CSB

CSG

Using the Probe Cooking function allows you to select the desired “done” temperature

as well as the cooking temperature. The probe measures the food’s actual internal

temperature and displays it on the control panel.

Advantages

• Achieve precise, repeatable cooking results

• Prevents overcooking, less waste

• Results in less shrinkage, more portions

• Requires no constant obser vation of cooking process

• High food quality with improved production efficiency

• Eliminates the need for wasteful intrusive testing methods, such as needle, finger,

fork or cut

• Built-in probe and control panel display makes Probe Cooking easy to accomplish

Cooking methods

Probe Cooking function can be used in all modes

Cooking examples

Roasts, meats, poultry, casseroles, frozen entrees, soups, etc. rethermalizing plated

portions

45

Page 47

CSL

Operation

Probe Cooking possible in all modes.

• Load mobile oven rack, place or roll into cabinet.

• Insert probe tip into the thickest portion of the meat

or other food item on center rack

NOTE: Be sure probe is clean and cool prior to inser tion

Setting

• Select desired cooking TEMPERATURE

• Select PROBE COOKING and set desired

probe “done” temperature–68°F to 210°F

(20°C to 99°C)

• Selected “done” temperature is displayed–

timer does not operate

Control

• No operator control or observation is necessary

• Completion signal sounds when “done” temperature is

reached. Unit shuts off automatically.

• Change previous settings when necessar y

CSM

CSB

Operation

Probe Cooking possible in all modes.

• Load mobile oven rack, place or roll into cabinet.

• Insert probe tip into the thickest portion of the meat

or other food item on center rack

NOTE: Be sure probe is clean and cool prior to inser tion

Setting

• Set desired cooking TEMPERATURE

Operation

NOTE: Probe Cooking function and Food Probe are

optional on model CSB

Probe Cooking possible in all modes.

• Load mobile oven rack, place or roll into cabinet.

• Insert probe tip into the thickest portion of the meat

or other food item on center rack

NOTE: Be sure probe is clean and cool prior to inser tion

• Set desired probe “done” temperature and

activate PROBE COOKING

• Selected “done” temperature is displayed–

timer does not operate

Control

• No operator control or observation is necessary

• Completion signal sounds when “done” temperature is

reached. Unit shuts off automatically.

• Change previous settings when necessar y

Setting

• Set desired cooking TEMPERATURE

• Set desired PROBE “done” temperature

• Selected “done” temperature is displayed–

timer does not operate

Control

• No operator control or observation is necessary

• Completion signal sounds when “done” temperature is

reached. Unit shuts off automatically.