Page 1

Applications Manual

and Cooking Guide

Henny Penny Combis

All MCS, MCG

and BCS Models

Page 2

This manual should be retained in a convenient location for future reference.

Wiring diagram for this appliance is located inside the unit, behind the control panel.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or

servicing this equipment.

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the original purchaser only for Henny Penny appliances

and replacement parts:

New Equipment Any part of a new appliance, except lamps and fuses, which proves to be defective in material or workmanship within two (2) years from

date of original installation, will be repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To validate this warranty, the

registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

Replacement Parts Any appliance replacement part, except lamps and fuses, which proves to be defective in material or workmanship within ninety (90) days

from date of original installation will be repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective part and does not include any labor charges for

the removal and installation of any parts, travel or other expenses incidental to the repair or replacement of a part.

Extended Frypot Warranty Henny Penny will replace any frypot that fails due to manufacturing or workmanship issues for a period of up to seven (7) years

from date of manufacture. This warranty shall not cover any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 to 3 Years During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for parts, labor, or freight.

Henny Penny will either install a new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

4 to 7 Years During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for the frypot only.

Any freight charges and labor costs to install a new frypot as well as the cost of any other parts replaced, such as insulation, thermal sensors, high limits,

fittings, and hardware, will be the responsibility of the owner.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was purchased. No allowance will be granted for repairs made

by anyone else without Henny Penny’s written consent. If damage occurs during shipping, notify the carrier at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES

THAT NO OTHER REMEDY (INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse; (b) if the equipment’s serial number is removed

or defaced; or (c) to lamps and fuses. THE ABOVE LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

MERCHANT ABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO

ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Indication of Safety Warnings

Throughout this manual you will see the following words and symbols relating to

important issues of personal safety and proper operation. Their usage is described here:

The word DANGER indicates an imminent hazard

which will result in highly serious injury, such as severe burns.

The word WARNING is used to alert you to a procedure, that if not performed properly, may

cause personal injury.

The word CAUTION is used to alert you to a procedure, that if not performed properly, may

damage the equipment.

The word IMPORTANT is used to highlight especially important information.

The word NOTE is used to separate additional useful subject matter for the sake of clarity.

1

Page 3

Dear Customer:

Congratulations on your decision to purchase a new Henny Penny

MCS, MCG, or BCS Combi. In our opinion, you now possess one in

the family of the most advanced combis in the industry. As you become

familiar with its operation and more confident in the results, you will

see the outstanding potential for quality, variety and productivity these

units have to offer.

The Henny Penny Combi is not difficult to operate, but it is a fairly

sophisticated piece of equipment. We recommend a thorough study

of this Applications Manual. It is filled with information, suggestions,

and explanations that will help you achieve the potential of the unit.

Keep the manual in a safe place, but accessible for easy reference.

Henny Penny products are known for their outstanding craftsmanship,

leading edge technology and user-friendly operation. As a company, we

believe in establishing a partnership with our customers that leads both

parties to long-term success. In that spirit, we remain interested in any

questions, comments, suggestions or ideas you may have concerning

your new combi or this manual.

We hope you enjoy good food and good profits with your new Henny

Penny Combi. Welcome to the world of imaginative cooking.

Henny Penny Corporation

+1 937 456.8400

Toll free in USA

800 417.8417

www.hennypenny.com

2

Page 4

Table of Contents

General Information

Models and Features ................................................................................................5

Control Panel Functions ..........................................................................................8

Loading and Unloading..........................................................................................10

Cooking Modes ..............................................................................................................13

Moist Heat Mode ..................................................................................................14

Dry Heat Mode ....................................................................................................16

Combination Mode ..............................................................................................18

Forced Steaming ....................................................................................................20

Tender Steaming ....................................................................................................22

Rethermalizing ......................................................................................................24

Probe Cooking................................................................................................................26

Additional Functions

Cool Down ............................................................................................................28

Steam Injection ......................................................................................................29

HACCP Interface ..................................................................................................30

Programming ..................................................................................................................32

Cleaning..........................................................................................................................35

Installation – Electric and Gas Units ..............................................................................37

Cooking Guides..............................................................................................................45

Distributors ....................................................................................................................59

3

Page 5

General Information

The Combi Advantage

The Henny Penny MCS, MCG and BCS Combis have the potential to make

your entire approach to foodservice production simpler, more consistent and

more productive.

Simpler because, ultimately, you will use fewer appliances as you become more

adept at utilizing the Combi for different applications.

More consistent because the Henny Penny Combi precisely generates specific

cooking climates for up to five different modes over a wide range of temperatures

to handle just about any type of food.

More productive because it is versatile, easy to use, cooks faster with less food

shrinkage then conventional appliances, and practically cleans itself.

The Combi Concept

The Henny Penny Combi uses pressure-less steam and hot-air convection,

individually, in sequence, or in combination regulated by the unit’s control system,

to help you create the right conditions for cooking perfect foods. There are plenty of

other features and functions, all designed to make this effort easier and more precise.

As you become more familiar with the way the machine operates and the cooking

concepts it employs, experiment! Try different settings. Change modes and settings

at any time in the cooking cycle (you can.) Observe the results, adjust your

approach. In short, learn and use the capabilities of the Combi to create the kind

of food you want to create.

The Family

Henny Penny Combis are available in two versions, the MCS electric and MCG

gas models, and the BCS electric model. All models accept mobile oven racks

(optional on some sizes) and feature rugged stainless steel construction and a host

of high-performance features (see next page.) The BCS is considered the basic

model. The MCS/G models offer additional cooking modes as well as touch pad

controls, digital displays and programmable functions. As a result, certain sections,

pages, or operating instructions in this manual may apply only to MCS/G units.

This distinction is clearly noted in each case.

Please note that Henny Penny also offers the (LCS/LCG) Combi, a high-end unit

that employs a completely different and technologically advanced control system.

The ClimaPlus Combi allows precise control of a nearly infinite combination of

moist and dry heat, offers up to 99 separate custom cooking programs, and features

IQT Intelligent Cooking Technology. If you would like to learn more about the

ClimaPlus Combis, please contact your Henny Penny distributor.

4

Page 6

GENERAL

INFORMATION

Models and Featuresat a glance

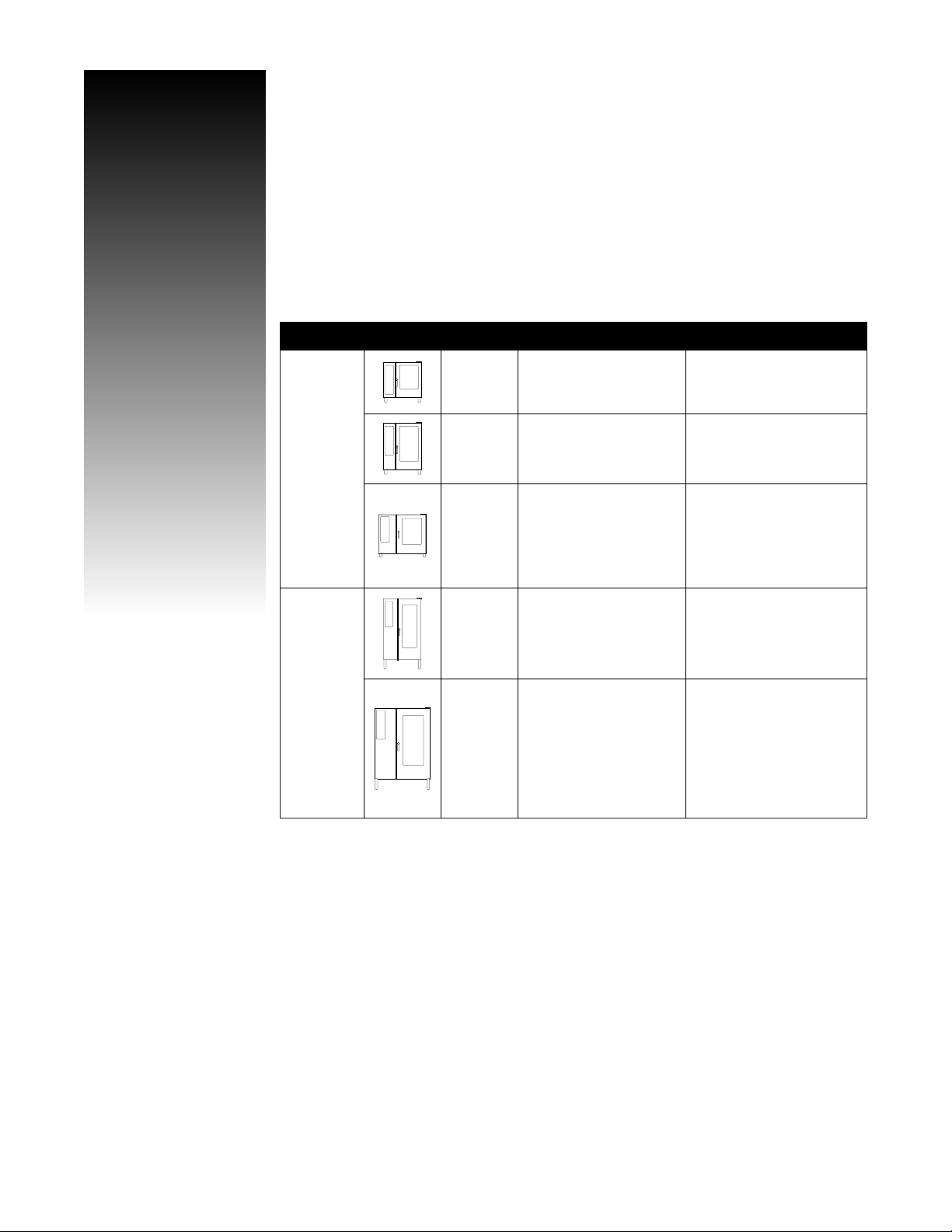

Models and sizes available

Model numbers are designated according to pan capacity. Units are available

in either electric (MCS, BCS) or gas (MCG, only.)

Model Designation Pan Capacity Pan size inches (mm)

Base-top

models

Floor

models

MCS-6

MCG-6

BCS-6

MCS-10

MCG-10

BCS-10

MCS-1020

MCG-1020

BCS-1020

MCS-20

MCG-20

BCS-20

MCS-40

MCG-40

BCS-40

6 steam table pans (1/1 GN) or

6 half sheet pans

10 steam table pans (1/1 GN)

or 10 half sheet pans

10 full sheet pans with

rack adapter or

20 steam table pans (1/1 GN)

or 10 steam table pans (2/1 GN)

20 steam table pans (1/1 GN)

or 20 half sheet pans

40 steam table pans (1/1 GN)

or 20 steam table pans (2/1 GN)

or

40 half sheet pans or

20 full sheet pans with

rack adapter

1

12 x 20 x 2

13 x 18 (330 x 457)

12 x 20 x 2

13 x 18 (330 x 457)

18 x 26 (457 x 660)

12 x 20 x 2

20 x 24 x 2

12 x 20 x 2

13 x 18 (330 x 457)

12 x 20 x 2

20 x 24 x 2

13 x 18 (330 x 457)

18 x 26 (457 x 660)

⁄2 (325 x 530 x 65)

1

⁄2 (325 x 530 x 65)

1

⁄2 (325 x 530 x 65)

1

⁄

2 (530 x 650 x 65)

1

⁄2 (325 x 530 x 65)

1

⁄2 (325 x 530 x 65)

1

⁄2 (530 x 650 x 65)

NOTE: Features may vary between gas and electric models. Accessories may vary

according to unit size.

A reference such as “MCS models” or “MCS-6/10/1020/20/40” designates the

MCS electric model in all sizes. A reference such as “MCG base-top models” or

“MCG-6/10/1020” designates only MCG gas models of those sizes.

5

Page 7

GENERAL

INFORMATION

Models and

Features

continued

Features

MCS/G BCS

Cooking Modes Cooking Modes

■ Moist Heat ■ Moist Heat

■ Dry Heat ■ Dry Heat

■ Combination Moist and Dry ■ Combination Moist and Dry

■ Tender Steaming

■ Rethermalizing

Control Control

■ Touchpad and electromechanical ■ Electromechanical controls for

controls for mode, time, temperature mode, time, temperature

mode, time, temperature ■ Lighted indicators

■ LED readouts ■ Cool Down

■ Forced Steaming ■ Forced Steaming

■ Steam Injection

■ Cool Down

■ Probe cooking

■ Programmable operation with (9)

three-step custom cooking program

capacity

■ Custom cleaning program

Design and operation Design and operation

■ Auto-reverse fan ■ Auto-reverse fan

■ Filterless grease extraction ■ Filterless grease extraction

■ Dual glass door ■ Dual glass door

■ Safety latch handle (Standard on all ■ Safety latch handle (Standard on all

floor models, available as option on floor models, available as option on

all base-top models) all base-top models)

■ HACCP interface and serial port ■ Auto flush

■ Auto flush ■ Built-in retractable hand shower

■ Built-in retractable hand shower

6

Page 8

GENERAL

INFORMATION

Models and

Features

continued

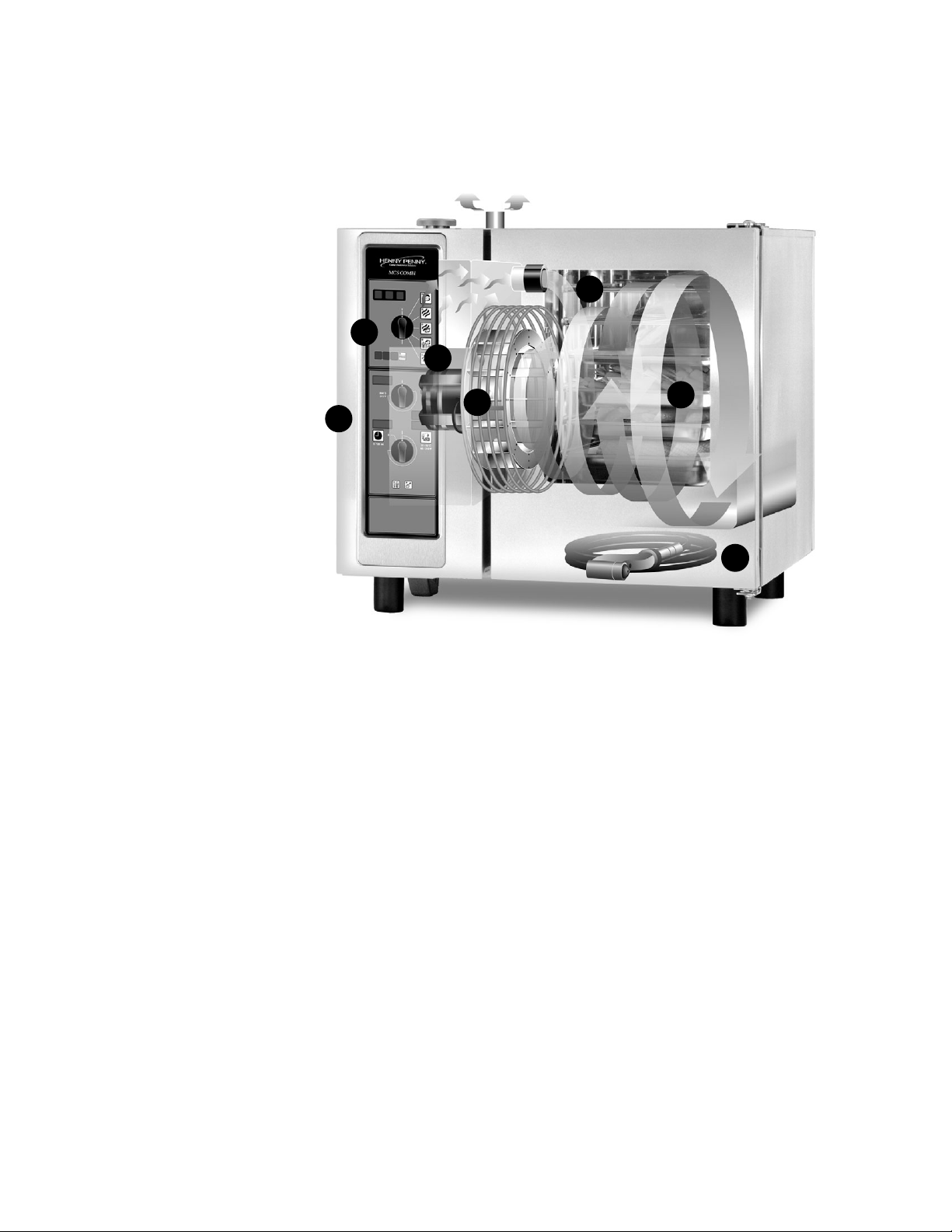

How it works

3

4

6

1

2

5

7

1. Moist heat is created and dispersed

rapidly from the self-cleaning

steam generator.

2. Dry heat up to 575°F (300°C)

is produced by tubular electrical

elements or gas burners.

3. Select cooking mode: Moist Heat,

Dry Heat, or Combination modes.

With MCS/G models you have

the additional selection of Tender

Steaming and Rethermalizing modes.

4. Set and select desired cabinet

temperature and cooking time.

With MCS/G models you may

select probe cooking and set

desired “done temperature.

5. Auto-reverse fan and air circulation

system keep temperatures precise

and heat distribution uniform

throughout the cabinet, even when

cooking full loads.

6. Hinged racking system or mobile

oven rack accepts a wide range of

pans and grids.

7. Coved corners, filterless grease

extraction system, and built-in

handshower minimize cleaning

labor.

7

Page 9

0

300°C

575°F

20 - 99°C0 -120 mi

65 - 210°F

D

°C °F

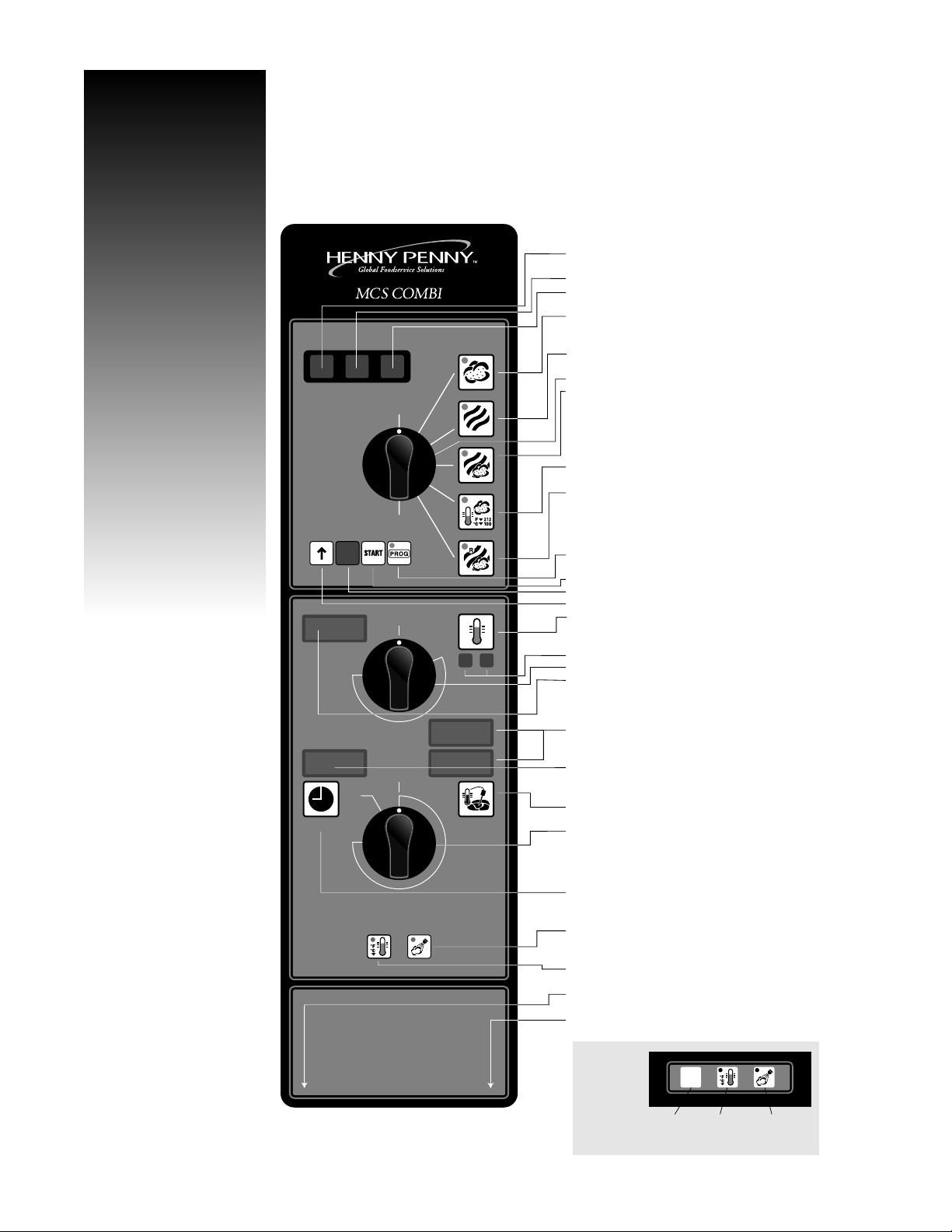

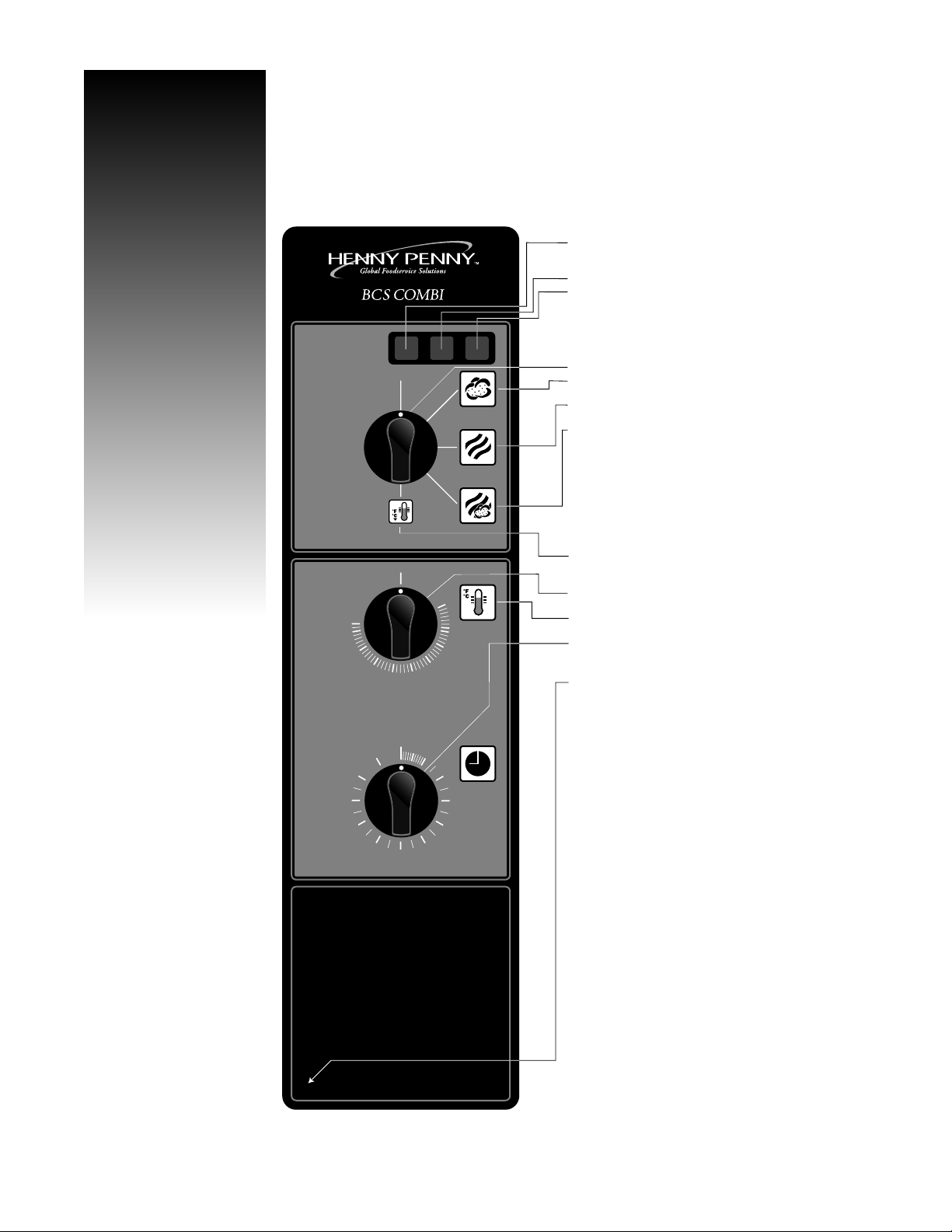

1 Warning light - lights red when steam generator temperature

exceeds 302°F (150°C)

2 NO WATER warning light - check water supply

3 ON indicator light (green)

4 MOIST HEAT mode–212°F (100°C)

• For steaming, stewing, blanching, preserving, etc.

• Mode light blinks when temperature exceeds 40°F (5°C) over set point

5 DRY HEAT mode–85°F to 575°F (30°C to 300°C)

• For roasting, baking grilling, etc

6 Mode selection switch

7 COMBINATION mode–85°F to 575°F (30°C to 300°C)

• For Combi-Steaming instead of roasting and glazing or baking

• Forced Steaming between 213°F to 266°F (101°C to 130°C)–

firm vegetables or potatoes are cooked more quickly

8 TENDER STEAMING mode–85°F to 210°F (30°C to 99°C)

• For blanching, poaching, simmering, soaking, vacuum cooking

9 RETHERMALIZING mode–85°F to 575°F (30°C to 300°C)

• For reheating pre-cooked (chilled) food

10 PROGRAM function

• Create and store up to 9, three-step cooking programs

11 Program START key

12 Program NUMBER display (1 to 9 programs)

13 Program ADVANCE key display (1 to 9 stages)

14 CABINET TEMPERATURE indicator key

• Key lights up when elements heat

• Press key to display cabinet temperature

15 Temperature indicator (°F or °C)

16 TEMPERATURE selection dial

17 TEMPERATURE display

• Displays selected cooking temperature

• Displays cabinet temperature when CABINET TEMPERATURE

indicator key (14) is pressed

18 PROBE COOKING displays

• Upper display indicates actual internal food temperature

• Lower display shows pre-selected “done” temperature

19 COOKING TIME display

• Shows actual cooking time remaining

• Press key to activate probe

20 PROBE COOKING key

• Select food internal “done” temperature using TIMER/PROBE COOKING dial (21)

21 TIMER/PROBE COOKING dial

• Set TIMER for 0 minutes to 120 minutes, press TIMER activation key (22)

• Set PROBE temperature from 65°F to 210°F (20°C to 99°C), press PROBE

COOKING key (20)

• Select “D” for Continuous Run

22 TIMER activation key

• Press key to switch from PROBE COOKING

• Select time using the TIMER/PROBE COOKING dial (21)

23 STEAM INJECTION

• Four-second burst of steam in DRY HEAT mode between

248°F (120°C) and 480°F (250°C)

24 COOL DOWN

• Fan continues to operate when door is open, reducing cabinet temperature rapidly

25 Unit serial number (located on the left side of cabinet in the lower right hand corner)

• Please refer to this number when requesting service

26 HACCP printer port

reset

MCG gas models

will have this

key pad display

IGNITION

RESET

COOL

DOWN

key

STEAM

INJECTION

key

GENERAL

INFORMATION

MCS MODELS

6/10/1020/20/40

Control Panel Functionsat a glance

8

Page 10

0

575

550

500

450

400

350

300

250

212

140

5

10

20

30

40

50

60

70

80

90

100

D

4 Mode selection switch

5 MOIST HEAT mode–212°F (100°C)

• For steaming, stewing, blanching, preserving...

6 DRY HEAT mode–140°F to 575°F (60°C to 300°C)

• For roasting, baking grilling, etc.

7 COMBINATION mode–140°F to 575°F (60°C to 300°C)

• For combi-steaming instead of roasting and glazing or baking

• Forced steaming between 213°F to 266°F (101°C to 130°C)–

firm vegetables or potatoes are cooked more quickly

8 COOL DOWN function

• Fan continues to operate when door is open, reducing cabinet

temperature rapidly

9 TEMPERATURE selection dial

• For convection and combination modes

10 HEAT ON indicator

• Lights during DRY HEAT mode

11 TIMER (0 to 120 minutes)

(UL -approved units: 0 to 100 minutes, CE-approved units: 0 to 120 minutes)

• Set on “D” for Continuous Run

12 Unit serial number (located on the left side of cabinet in the lower right hand corner)

• Please refer to this number when requesting service

1 Warning light– lights red when cabinet

temperature exceeds 239°F (115°C)

in steam mode

2 NO WATER warning light–check water supply/steam generator

3 ON indicator light (green)

GENERAL

INFORMATION

Control Panel Functionsat a glance

BCS MODELS

6/10/1020/20/40

9

Page 11

GENERAL

INFORMATION

Loading and Unloading

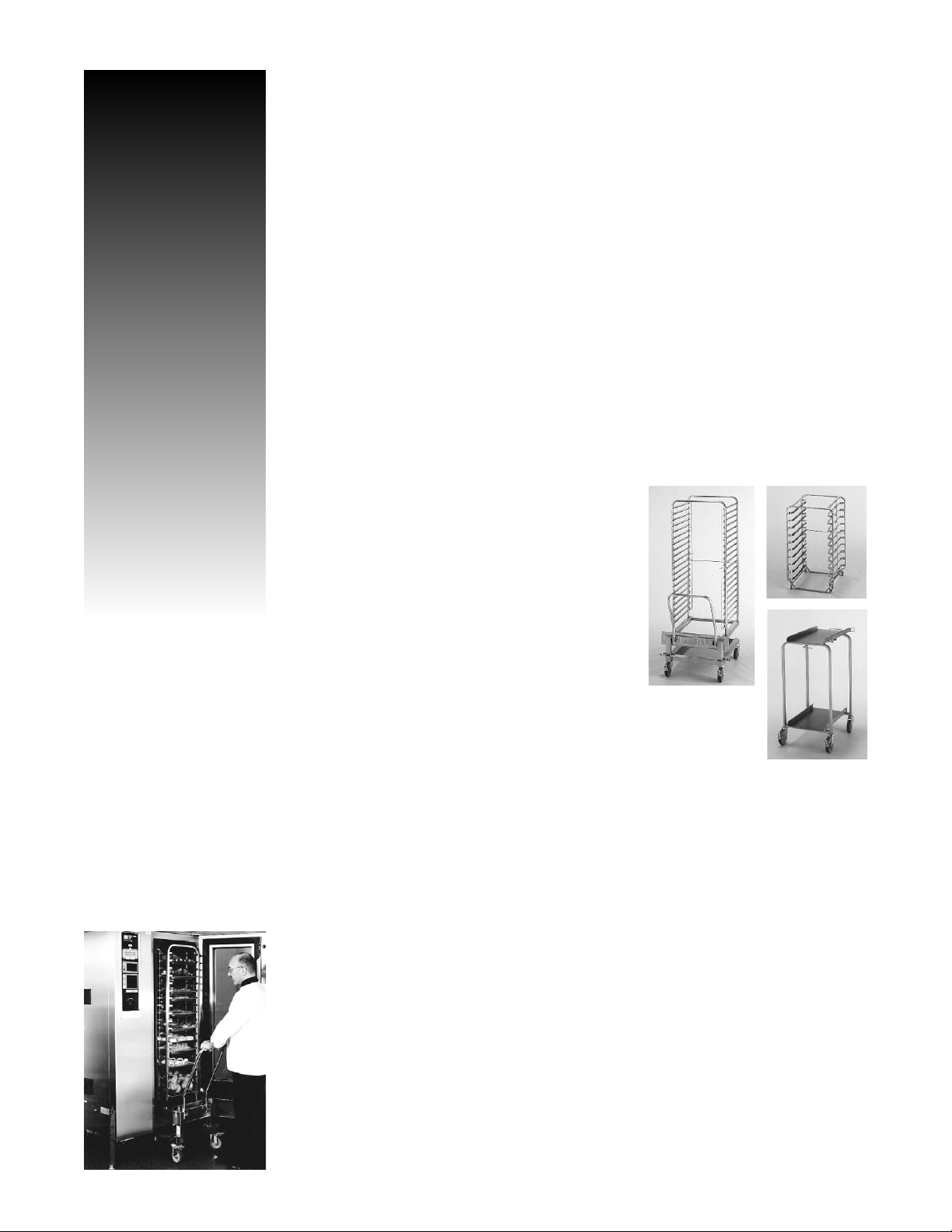

Your Henny Penny Combi includes either a removable hinged racking system

(standard with 6 and 10-pan units) or a mobile oven rack that is integral

to the equipment’s operation. All pans and grids are loaded directly onto the

hinged racking system, or onto the mobile oven rack which is then rolled into

the cooking cabinet.

Base-top Models

Removable Hinged Racking–Standard MCS/G/BCS- 6 & 10

To remove, simply lift rack upward and out of mountings. Reverse the action to

replace the rack. To move rack laterally on hinges, lift front of rack slightly to clear

mounting and swivel rack.

Mobile Oven Racks (Standard on 1020)

Oven rack on transport cart rolls up to the front

of the unit. Oven rack rolls completely into the

cabinet. Standard with MCS/G/BCS-1020,

available separately (rail system required) for

MCS/G/BCS-6 and10.

Mobile Oven Racks

* Additional racking systems optional.

Floor Models

Mobile Oven Racks (20 and 40)

Mobile oven rack rolls directly into unit. Specially designed oven

rack allows cabinet door to close easily and completely around the

rack. Standard with MCS/G/BCS-20 and 40. Additional mobile

oven racks or specially designed oven plate racks are available

separately.

Transport Cart

(optional)

IMPORTANT!

When using the oven rack on transport cart, be sure to lock the front casters of

the transport cart when it is in the loading or unloading position at the front of

the cabinet. Keep the front wheels of the oven rack locked at all times (using the

locking lever near the right front wheel) except when rolling it into or out of the

cabinet and onto the transport cart itself. Following this procedure stabilizes the

load. To keep pans in place lock both vertical hinged bars.

To Load

■ Preheat unit to set temperature or above.

■ Place food product on appropriate grids, pans and racks.

■ If using mobile oven rack, slide full grids, pans and racks into shelves on mobile

oven rack. Be sure containers are secure on both sides.

Opening door during operation

■ Open door slightly until fan stops and heat dissipates. Open door fully with care.

10

Page 12

GENERAL

INFORMATION

Loading and

Unloading

continued

NOTE: MCS/G and BCS models 20 & 40 have a built-in safety latch that lets

steam and heat out before door fully opens. Safety latch is optional on models 6, 10

and 1020. If your ClimaPlus Combi is NOT equipped with this feature, open door

slightly until fan stops and steam dissipates. Open door fully with care to unload.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or vapors to escape. KEEP FACE

AND HANDS AWAY FROM OPENING or burns could result. When

steam and/or heat has dissipated open door fully with care. Escaping hot steam

and/or vapors can cause serious burns. Interior surfaces, including pans, grids

and oven racks, can be extremely hot. To prevent burns, allow unit to cool or

use appropriate heat resistant protective mitt or pad when handling. Do not

use built-in retractable hand shower when cabinet temperature is above 150°F

(65°C) or burns could result.

■ Load hinged racking system with food containers or roll loaded mobile oven rack

directly into unit.

■ Remove handle

■ Shut door and begin cooking.

To unload

■ Open door slightly until fan stops and heat and steam dissipates. Open door

fully with care.

■ Insert cart handle. (MOR only)

■ Using oven mitts or pads, remove food containers carefully from shelves in

hinged racking system.

■ With floor units, roll mobile oven rack straight out of unit to appropriate location.

■ With base-top models using transport cart, roll transport cart up to front of

unit and lock front casters. Roll oven rack out of unit and onto transport cart.

Be sure wheels on oven rack are locked to stabilize load and reduce the chances

of spills.

WARNING: Surfaces of food containers, mobile oven racks and inside

cabinet surfaces may be extremely hot. Always use insulated oven mitts or

pads when removing food containers or handling mobile oven racks or

burns could result.

11

Page 13

GENERAL

INFORMATION

Loading and

Unloading

continued

Partial Loads

Individual pans or racks of product can be easily loaded or unloaded while the unit

is in operation.

■ Open door slightly until fan stops and heat and steam dissipates. Open door

fully with care.

■ Using oven mitts or pads, load or unload individual containers.

■ Shut door. Cooking process continues automatically.

Tips

■ Preheat cooking cabinet prior to loading for full loads.

■ Since no flavor transfer occurs during cooking, try to plan full loads based on

similar cooking climates (Moist, Dry, Combination) rather than food compatibility.

■ When cooking for longer periods, or on continuous run cooking, load items

that will be done sooner toward the front of the oven. These can be removed

individually when done.

■ For the greatest efficiency, try to cook with full loads. In general, cooking times

and temperatures are not affected by the quantity of product in the cooking

cabinet.

■ When loading roasts or large cuts of meat, place product on grids and load grids

directly onto shelves near the bottom of the unit. Load an empty pan directly

beneath the roast to catch drippings and roast bones.

■ For base-top models, consider the purchase of Combi Base Units. Several styles

are available that offer storage for convenient access to pans, grids, and racks.

■ If rethermalizing plated portions is a frequent part of your production, consider

the purchase of special plate racks and thermal covers.

12

Page 14

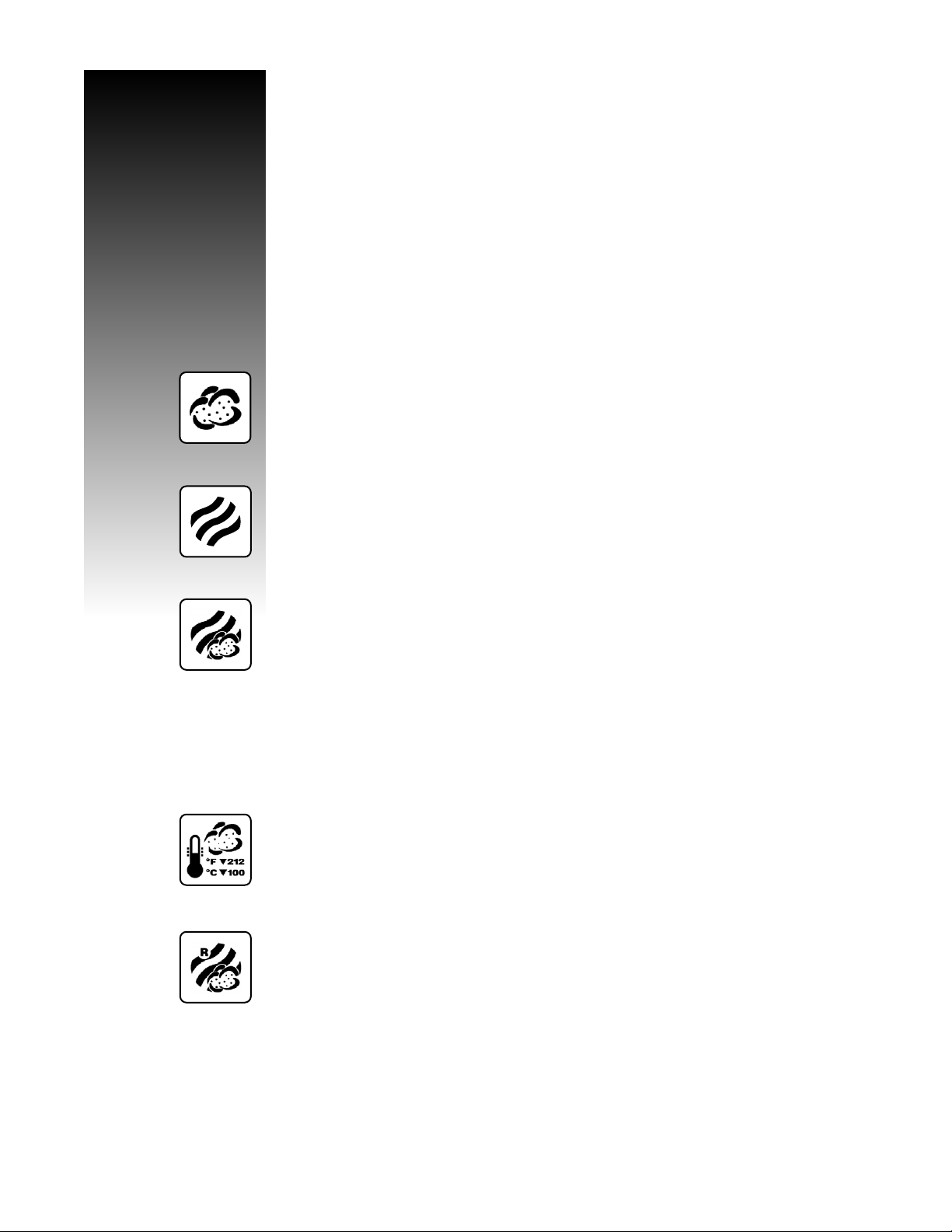

Cooking Modes

Henny Penny Combis operate with three basic cooking modes: Moist Heat,

Dry Heat and Combination. The MCS/G model also incorporates two additional modes: Tender Steaming and Rethermalizing. Almost all traditional

cooking processes can be accomplished in these modes. Cooking modes can be

used exclusively or in any sequence or combination to achieve desired results.

Moist Heat Mode

The steam generator produces hygienic steam and releases it (without pressure)

into the cooking cabinet where it is circulated at high speeds by the fan. The cooking

temperature in this mode is fixed at 212°F (110°C). This mode is used for steaming.

for steaming

Dry Heat Mode for baking or roasting

Powerful heating elements heat the air inside the cabinet. The fan circulates this

hot, dry air evenly throughout the interior. Temperature can be regulated precisely

between 85-575°F (30-300°C)*.

Combination Mode for maintaining a moist environment at high temperatures

The unit’s control system combines both Moist Heat and Dry Heat modes to

create a humid cooking environment at temperatures even above 212°F (100°C).

Selected temperatures can range from 85-575°F (30-300°C)*. The cooking environment retains all humidity generated from the unit and from the moisture released

by food as it cooks.

*Lowest temperature on BCS - 140°F (60°C)

MCS/G models, only

Tender Steaming mode for low temperature steaming

13

In this mode an automatic sensor maintains the selected temperature lower than

212°F (100°C) within a moist environment. Temperatures can be selected from

85-210°F (30-99°C).

Rethermalizing mode for ideal results when reheating

This special mode combines moist and dry heat to create the ideal climate for

reheating cooked foods. Rethermalizing restores the look, taste and texture of fresh

hot food without drying or marking. Rethermalize works best at temperatures

between 85-575°F (30-300°C).

Page 15

COOKING MODES

Moist Heat Mode 212°F (100°C)

Pressureless steam generation and auto-reverse fan quickly produce a cooking

environment of 100% humidity. Perfect for steaming a wide variety of foods

with no flavor transfer. Also used for stewing, blanching, poaching, simmering,

soaking, thawing, rethermalizing, preserving.

Advantages

■ Extremely short preheating time.

■ Excellent food consistency.

■ Conserves nutrients, color.

■ No added fats or oils.

■ Cook different products at the same time with no flavor transfer.

■ Can be partially unloaded for serving convenience.

■ No need to boil water in pots.

Menu suggestions

■ Ingredient preparations–tomato concasees, garnishes, mushrooms, blanched

vegetables for stuffing, peeling, etc.

■ Starters, appetizers–scrambled, poached or boiled eggs; vegetable pate, asparagus,

stuffed vegetables, cannelloni.

■ Entrees–cooked beef, ham, turkey legs, steamed fish, chicken breasts.

■ Sides–rice, dumplings, pasta, fresh and frozen vegetables, boiled potatoes, and

grains.

Tips

■ Determine which foods can be cooked together for the greatest production

efficiency. This is best done by considering the cooking modes and temperatures.

Keep in mind that fish, meat, vegetables, fruit, etc. can be cooked at the same

time because no flavor transfer occurs.

■ Potatoes should always be cooked in perforated pans. This allows steam to

circulate for faster, more even cooking.

■ In general, two shallower pans are better than one deeper pan. This avoids bruising.

■ Dumplings should be placed in shallow pans not too close together.

■ Rice, dry pasta, beans, and grains are foods to which water must be added prior

to cooking. Longer soaking times mean shorter cooking times.

■ Tomatoes can be skinned easily when steamed for 30 to 60 seconds, then chilled

in cold water.

■ Stock can be collected by inserting a container in the bottom of the oven rack.

14

Page 16

COOKING MODES

Moist Heat

continued

MCS/G units

BCS units

Operation and Settings

■ Set on MOIST HEAT mode and set TIMER on “D” Continuous Run.

■ Preheat until warm-up control light goes out.* Temperature will remain at

212°F (100°C).

* M model only

■ Load oven rack.

■ Set desired cooking time and press TIMER key OR set desired “done”

temperature and press PROBE cooking key. OR set on Continuous Run.

■ Set dial to desired cooking time OR set on Continuous Run.

■ Unload oven when done. Blower and heat automatically stops when door

is opened.

NOTE: MCS/G/BCS models 20 & 40 have a built-in safety latch that

lets steam and heat out before door fully opens. Safety latch is optional on

models 6, 10 and 1020. If your Combi is NOT equipped with this feature,

open door slightly until fan stops and steam dissipates. Open door fully to

unload.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or vapors to escape. KEEP FACE AND

HANDS AWAY FROM OPENING or burns could result. When steam and/or heat

has dissipated open door fully with care. Escaping hot steam and/or vapors can cause

serious burns. Interior surfaces, including pans, grids and oven racks, can be extremely

hot. To prevent burns, allow unit to cool or use appropriate heat resistant protective

mitt or pad when handling. Do not use built-in retractable hand shower when cabinet

temperature is above

150°F (65°C) or burns could result.

15

Page 17

COOKING MODES

Dry Heat Mode MCS/G: 85-575°F (30-300°C)

BCS: 140-575°F (60-300°C)

Powerful convection heating and auto-reverse fan create the ideal environment for

fast, even broiling, roasting, baking, browning, thawing, grilling and sautéing.

Advantages

■ Powerful heating capability up to 575°F (300°C), even when fully loaded.

■ Fast pre-heating.

■ High-speed air circulation creates even heating for high quality food production.

■ Consistent cooking and even browning at all rack levels.

■ No added fats or oils are needed for cooking.

■ Cook different products at the same time.

■ Can be partially unloaded for serving convenience.

Menu suggestions

■ Ingredient preparations–roasted bones for stock, melting butter, thawing

frozen ingredients.

■ Starters, appetizers–meatballs, roast beef, grilled ham, sausage, chicken wings,

quiches, tarts, breadsticks, bread rolls, etc.

■ Entrees–beef and pork roasts, ribs, chicken whole or piece, turkey, frozen lasagna,

pizza, pizza rolls.

■ Sides–baked potatoes, soufflés, casseroles.

■ Desserts–sponge cake, marble cake, puff pastries, frozen fruit puffs, pies, etc.

Tips

Cooking times

Proper cooking times will vary depending on the quality, weight, or size of the

product being cooked. Generally, cooking time is not affected by the size of the

load. However, avoid overloading grids or pans so air will circulate evenly around

all product.

Roasting, broiling

■ Preheat up to 575°F (300°C). Load and set to desired temperature.

1

■ Ideal thickness for steaks, chops, cutlets, or loin cuts:

■ Cook on grids with drip pans underneath. This allows even browning on all sides.

■ Group similarly sized products on the same grids.

⁄2-1 in. (13-25mm).

Sautéing

■ Preheat enamel pan.

■ Shallow pans work best.

Browning, finishing

■ Preheat up to 575°F (300°C). Load and set to desired temperature.

16

Page 18

COOKING MODES

Dry Heat

continued

MCS/G units

Baking

■ Preheat to desired baking temperature. In general, Combi baking temperatures

will be 40-50°F (5-10°C) LOWER than conventional ovens.

■ When baking do NOT preheat pans.

■ For bread, rolls, and muffins use only every second rack. Trays should not be

deeper than 23⁄4 in. (70mm).

■ Defrost frozen bread dough and let rise for a short time before baking.

■ Lightly mist breaded products with water or vegetable oil or brush with eggwash.

■ When baking whole fish, wrap tail in foil and support it from underneath with

raw potatoes.

Operation and settings

■ Set on DRY HEAT mode and set TIMER on “D” Continuous Run.

■ Preheat until set temperature is reached or heat indicator light goes out.

■ Load oven rack.

■ Set desired cooking TEMPERATURE: 85-575°F (30-300°C). Selected cooking

temperature appears in display. Press TEMPERATURE key to display current

cabinet temperature.

BCS units

■ Set desired cooking TIME and press TIMER key OR set desired “done”

temperature and press PROBE cooking key. OR set on Continuous Run.

■ Set dial to desired cooking TEMPERATURE: 140-575°F (60-300°C).

■ Set dial to desired cooking time OR set on Continuous Run.

■ NOTE: Steam generator does not operate during Dry Heat Mode. However,

humidity builds in the cabinet from the moisture escaping food as it cooks.

■ Unload oven when done. Blower and heat automatically shuts off when door

is opened.

NOTE: MCS/G/BCS models 20 & 40 have a built-in safety latch that lets steam

and heat out before door fully opens. Safety latch is optional on models 6, 10

and 1020. If your Combi is NOT equipped with this feature, open door slightly

until fan stops and steam dissipates. Open door fully to unload.

17

Page 19

COOKING MODES

Combination Mode MCS/G: 85-575°F (30-300°C)

BCS: 140-575°F (60-300°C)

Fast, consistent method for cooking foods that require a combination of moist

and dry heat. In Combination Mode, the cabinet may be heated to any temperature in the range shown above. The steam generator introduces moist heat

into the cabinet as needed throughout the cooking cycle. Use when combi-baking,

combi-roasting, combi-steaming, browning, braising, glazing, basting.

Advantages

■ Fast preheating.

■ Cook with steam at temperatures above 212°F (100°C).

■ Less food shrinkage from dehydration.

■ More servings per cooked pound.

■ Automatic basting.

■ Foods retain more nutrients and flavor.

■ No added fats or oils are needed for cooking.

■ Even heating improves cooked quality of large meat portions.

■ Cook different products at the same time with no flavor transfer.

■ Consistent cooking and browning at all rack levels.

■ Can be partially unloaded for serving convenience.

Menu suggestions

■ Ingredients preparations–roasted bones for stock.

■ Starters, appetizers–quiche, pastas, bread, rolls (frozen), etc.

■ Entrees–roasts (beef, veal, pork, lamb) stuffed peppers, whole roast chicken,

turkey legs, casseroles, lasagna, etc.

■ Sides–potatoes au gratin, baked potatoes, frozen vegetables, baked apples, etc.

■ Desserts–yeast dough (choux pastry).

Tips

■ To achieve even cooking and browning, always cook roasts on grids with plenty

of space around each roast for air to circulate.

■ When practical, place roasts on grids with meat grain parallel to airflow for even

better results.

■ Cook large, fat-encrusted roasts in MOIST HEAT mode for the first one-third

of the total cooking time, then switch to COMBINATION mode with desired

settings for the remainder. This technique helps seal in juices, flavors and nutrients

while reducing shrinkage.

■ Condensation and juices can be collected in a pan under the roasts to be used

later with roasted bones for sauce stocks.

■ Use chicken grid to roast whole chickens upright for even cooking, browning.

18

Page 20

COOKING MODES

Combination

continued

NOTE: BCS models do not have a separate mode for rethermalizing. When

reheating items in BCS models, use Combination Mode with temperatures from

280-320°F (138-160°C) for 5-8 minutes, depending on items and load size.

Operation and settings

■ Set on COMBINATION mode and set TIMER on “D” Continuous Run.

■ Preheat until set temperature is reached or heat indicator light goes out.

■ Load oven rack.

MCS/G units

BCS units

■ Set desired cooking TEMPERATURE: 85-575°F (30-300°C). Selected cooking

temperature appears in display. Press TEMPERATURE key to display current

cabinet temperature.

■ Set desired cooking TIME and press TIMER key OR set desired “done”

temperature and press PROBE cooking key. OR set on Continuous Run.

■ Set dial to desired cooking TEMPERATURE: 140-575°F (60-300°C).

■ Set dial to desired cooking time OR set on Continuous Run.

■ Unload oven when done. Blower and heat automatically shuts off when door

is opened.

NOTE: MCS/G/BCS models 20 & 40 have a built-in safety latch that lets

steam and heat out before door fully opens. Safety latch is optional on models

6, 10 and 1020. If your is NOT equipped with this feature, open door slightly

until fan stops and steam dissipates. Open door fully to unload.

19

X

Opening Door During Operation

Open door slightly to allow hot steam and/or vapors to escape. KEEP FACE AND

HANDS AWAY FROM OPENING or burns could result. When steam and/or heat

has dissipated open door fully with care. Escaping hot steam and/or vapors can cause

serious burns. Interior surfaces, including pans, grids and oven racks, can be extremely

hot. To prevent burns, allow unit to cool or use appropriate heat resistant protective

mitt or pad when handling. Do not use built-in retractable hand shower when cabinet

temperature is above

150°F (65°C) or burns could result.

Page 21

COOKING MODES

Combination/

Forced Steaming

Forced Steaming 213-265°F (101-130°C)

A cooking technique that uses Combination Mode within a certain

temperature range to achieve full-humidity steaming at temperatures well

above boiling. Forced Steaming is excellent for cooking dense products,

such as root vegetables and frozen casseroles.

Advantages

■ Creates an intensified cooking process

■ Shorter cooking times

■ Product retains color, nutrients

■ Less shrinkage

Menu suggestions

■ Potatoes, carrots, celery

■ Frozen prepared foods

Tips

Approximate temperature ranges for some common Forced Steamed items:

Celery 230°F 110°C

Carrots 240°F 115°C

Potatoes 257°F 125°C

Turnips, yams 248°F 120°C

Frozen lasagna 248°F 120°C

Frozen vegetables 248°F 120°C

Rice 248°F 120°C

20

Page 22

COOKING MODES

Combination/

Forced Steaming

continued

MCS/G units

BCS units

Operation and settings

■ Set on COMBINATION mode and set TIMER on “D” Continuous Run.

■ Preheat until set temperature is reached or heat indicator light goes out.

■ Load oven rack.

■ Set desired Forced Steaming TEMPERATURE: 213-265°F (101-130°C).

■ Set desired cooking TIME and press TIMER key OR set desired “done”

temperature and press PROBE cooking key. OR set on Continuous Run.

■ Set dial to desired Forced Steaming TEMPERATURE: 213-265°F (101-130°C).

■ Set dial to desired cooking time OR set on Continuous Run.

■ Unload oven when done. Blower and heat automatically shuts off when door

is opened.

NOTE: MCS/G/BCS models 20 & 40 have a built-in safety latch that lets steam

and heat out before door fully opens. Safety latch is optional on models 6, 10

and 1020. If your Combi is NOT equipped with this feature, open door slightly

until fan stops and steam dissipates. Open door fully to unload.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or vapors to escape. KEEP FACE AND

HANDS AWAY FROM OPENING or burns could result. When steam and/or heat

has dissipated open door fully with care. Escaping hot steam and/or vapors can cause

serious burns. Interior surfaces, including pans, grids and oven racks, can be extremely

hot. To prevent burns, allow unit to cool or use appropriate heat resistant protective

mitt or pad when handling. Do not use built-in retractable hand shower when cabinet

temperature is above

150°F (65°C) or burns could result.

21

Page 23

COOKING MODES MCS/G models, only

Tender Steaming 85-210°F (30-99°C)

A cooking mode that cooks with moist heat at temperatures below the boiling

point. Use Tender Steaming Mode for scalding, poaching, thawing, proofing,

simmering, blanching, soaking, vacuum cooking, and preserving.

Advantages

■ Fast preheating.

■ The ability to select and maintain precise low cooking temperatures.

■ Gentle steaming for a variety of delicate items.

■ Excellent consistency and taste for many kinds of meat and fish.

■ Lower cooking temperatures mean less sticking and crumbling.

■ Less shrinkage resulting in moist, attractive portions for display merchandising.

■ No added fats or oils are needed for cooking.

■ Excellent method for proofing breads and doughs at 95-99°F (35-37°C).

■ Can be partially unloaded for serving convenience.

Menu suggestions

■ Ingredients preparations–blanching bacon and ham, proofing, soups, sauces,

stocks, fish garnishings, etc.

■ Starters, appetizers–Poached eggs, seafood, cakes, patés, etc.

■ Entrees–Fish (salmon, sole, orange roughy), poultry, vacuum cooking items,

boneless chicken and turkey filets, beef filets, sausages, etc.

■ Sides-Vegetable casseroles

■ Desserts–fruit, cheese cakes, delicate moist items, etc.

■ Yeast doughs–breads, rolls, bagels, etc.

Tips

Approximate temperature ranges for some common Tender Steamed items:

Soup garnishings 167-194°F 75-90°C

Fish, seafood 149-194°F 65-90°C

Pork, veal 161-167°F 72-75°C

Chicken/white meat 167-185°F 75-85°C

Chicken/dark meat 176-194°F 80-90°C

Poultry (other) 176°F 80°C

Beef, lamb 135-165°F 58-74°C

Desserts 149-194°F 65-90°C

Breads, doughs 95-99°F 35-37°C

22

Page 24

COOKING MODES

Tender Steaming

continued

MCS/G units

Cooking times

Moist Heat mode principles apply: generally, the lower the cooking temperature the

longer the cooking time.

Seasoning

Season lightly. Low temperature cooking intensifies a food’s natural taste, as well as

the taste of seasonings. For the same reason, use less essences or reducing agents.

Texture, appearance

Tender Steaming imparts excellent characteristics to food for presentation in display

merchandisers:

■ Excellent color

■ Firm structure for clean portioning

■ Less shrinkage for plump, taut skins

■ Fewer and smaller “bursts” even when skin is damaged

Operation and settings

■ Set on TENDER STEAMING mode and set TIMER on “D” Continuous Run.

■ Preheat until set temperature is reached or heat indicator light goes out.

■ Load oven rack.

■ Set desired Tender Steaming TEMPERATURE: 85-210°F (30-99°C).

■ Set desired cooking TIME and press TIMER key OR set desired “done”

temperature and press PROBE cooking key. OR set on Continuous Run.

■ Unload oven when done. Blower and heat automatically shuts off when door

is opened.

■ NOTE: MCS/G/BCS models 20 & 40 have a built-in safety latch that lets

steam and heat out before door fully opens. Safety latch is optional on models

6, 10 and 1020. If your Combi is NOT equipped with this feature, open door

slightly until fan stops and steam dissipates. Open door fully to unload.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or vapors to escape. KEEP FACE AND

HANDS AWAY FROM OPENING or burns could result. When steam and/or heat

has dissipated open door fully with care. Escaping hot steam and/or vapors can cause

serious burns. Interior surfaces, including pans, grids and oven racks, can be extremely

hot. To prevent burns, allow unit to cool or use appropriate heat resistant protective

mitt or pad when handling. Do not use built-in retractable hand shower when cabinet

temperature is above

150°F (65°C) or burns could result.

23

Page 25

COOKING MODES MCS/G models, only

Rethermalizing

Rethermalizing Mode utilizes an optimum combination of moist and dry heat

to maintain flavor and textures when bringing chilled cooked foods back up to

serving temperatures.

Advantages

■ Different food products can be reheated without being covered.

■ Perfect mode for re-heating ingredients, servings or meals previously cooked and

chilled as part of a cook/chill production process.

■ Whole meals can be plated and chilled in quantity on special racks that roll

directly from the blast chiller into the Combi for rethermalizing.

■ Allows more efficient use of time to prepare dishes and trays ahead of time.

■ Less shrinkage.

Menu suggestions

■ Starters, appetizers–pasta, vegetable dishes, macaroni & cheese, casseroles, spring

rolls, etc.

■ Entrees–roasts, pasta, casseroles, chilled or frozen meat and fish, chilled or frozen

prepared entrees, stuffed vegetable dishes.

■ Sides–rice and rice dishes, vegetables, noodles, new potatoes, potatoes au gratin,

potato pancakes, fries, etc.

■ Desserts–fruit pies, cheese cakes, stewed fruit, etc.

Tips

■ Proper rethermalizing temperatures will vary depending on type of food.

■ Rethermalizing times depend on the type of food, the beginning internal

temperature and the number of plates or pans in the load.

■ Use probe cooking when practical. Ideal serving temperatures are easier to achieve.

■ Re-heating plated servings is more efficient, especially when preparing meals

in volume.

■ Use special mobile oven rack designed to hold plates for rethermalizing. Racks

roll from blast chiller or walk-in directly into the ClimaPlus Combi. Fitted

thermal covers are available to keep plates on rack warm for short periods or

during transport.

■ Make sure food is arranged evenly on plates.

■ Apply sauces after rethermalizing.

NOTE: BCS models do not have a separate mode for rethermalizing. When

reheating items in BCS models, use Combination Mode with temperatures from

280-320°F (138-160°C) for 5-8 minutes, depending on items and load size.

24

Page 26

COOKING MODES

Rethermalizing

continued

■ Create a custom cooking program with Rethermalizing settings that can be used

for similar recurring situations.

Operation and settings

■ Set on RETHERMALIZING mode and set TIMER on “D” Continuous Run.

■ Preheat until set temperature is reached or heat indicator light goes out.

■ Load oven rack.

■ Set desired Rethermalizing TEMPERATURE: Generally from 240-280°F (116-

138°C).

■ Set desired cooking TIME and press TIMER key OR set desired “done” temper-

ature and press PROBE cooking key. OR set on Continuous Run.

■ Unload oven when done. Blower and heat automatically shuts off when door

is opened.

NOTE: MCS/G/BCS models 20 & 40 have a built-in safety latch that lets steam

and heat out before door fully opens. Safety latch is optional on models 6, 10 and

1020. If your Combi is NOT equipped with this feature, open door slightly until

fan stops and steam dissipates. Open door fully to unload.

25

X

Opening Door During Operation

Open door slightly to allow hot steam and/or vapors to escape. KEEP FACE AND

HANDS AWAY FROM OPENING or burns could result. When steam and/or heat

has dissipated open door fully with care. Escaping hot steam and/or vapors can cause

serious burns. Interior surfaces, including pans, grids and oven racks, can be extremely

hot. To prevent burns, allow unit to cool or use appropriate heat resistant protective

mitt or pad when handling. Do not use built-in retractable hand shower when cabinet

temperature is above

150°F (65°C) or burns could result.

Page 27

COOKING

FUNCTIONS

MCS/G models, only

Probe Cooking for achieving precise “done” temperatures

The Probe Cooking function allows the operator to select the food’s desired “done”

temperature as well as the cooking temperature. The probe is inserted into the

central part of the product to measure the actual internal temperature of the

food as it cooks. The cooking cycle stops automatically when selected internal

temperature is achieved.

Advantages

■ Cook to proper “doneness” for precise, consistent results with different types

of food.

■ Prevents over cooking, less waste.

■ Does not require constant observation of cooking process.

■ Results in less shrinkage, more portions.

■ Control panel simultaneously displays done temperature and current core

temperature.

■ Eliminates wasteful and unattractive intrusive testing methods such as needle,

fork, or cutting.

When to use

Probe cooking can be used for practically any type of food, most often with roasts,

meats, poultry, casseroles, entreés, soups, rethermalizing plated portions.

Tips

■ When roasting meat for sliced cold servings, set food core temperature about

9°F (5°C) lower than recommended “done” temperature. Roast will continue to

cook as it cools.

■ A hot probe may sear the meat on contact, leaving a hole or scar when probe is

removed. Always cool probe prior to insertion.

■ Probe cooking temperatures can be changed or reset at any time during the

cooking process. For example, you may wish to change cooking modes or

accelerate the cooking process after a certain core temperature is reached.

Simply make those changes and reset probe “done” temperature to the desire

cooked setting.

26

Page 28

COOKING

FUNCTIONS

Probe Cooking

continued

Operation and settings

■ Set on any desired mode. Set TIMER on “D” Continuous Run.

■ Load oven rack.

■ Insert probe into thickest portion of the meat or other food item on center rack.

NOTE: Be sure probe is clean and cool prior to insertion.

■ Set desired cooking TEMPERATURE.

■ Press PROBE COOKING key and set desired probe “done” temperature.

■ Selected done temperature is displayed. Timer does not operate.

■ No operator control or observation is necessary.

■ A signal sounds when done temperature is reached. Blower and heat shuts off

automatically. (Cabinet will retain heat)

■ Probe done temperature, as well as other settings, can be changed at any time.

Probe Cooking Guide to “Doneness”

Meat Probe “Done Temp” Appearance

Beef Rare 130°F 55°C Dark, blood red

Medium rare 140F 60°C Red meat, blood-red juice

Medium 145°F 63°C Light pink core

Well done 167-189°F 75-65°C Gray-brown throughout

Veal Fully cooked 155-170°F 69-77°C Red-brown to gray-white

Pork Medium 150°F 65°C Light pink

Well done 167-176°F 75-80°C Pale brown to gray-white

Cured 150°F 65°C Pale red-brown or nearly

colorless

Lamb Fully cooked 165°F 74°C Gray to pale-red juice,

clear juice

Mutton Fully cooked 165°F 74°C Pale gray meat, red juice

Poultry Fully cooked 185°F 85°C White meat, nearly colorless

juice

27

X

Probe sensor may be extremely hot

When not in use, always place probe sensor in holder. Do not let probe sensor hang loose outside

the cooking cabinet. Remove probe sensor from food before unloading unit.

Page 29

COOKING

FUNCTIONS

Additional Functions: Cool Down

Cool Down is a keypad function that enables the fan to continue operating

when the door is open. This dissipates heat quickly. (MCS/G only)

Advantages

■ Achieve rapid reduction in cabinet temperature when switching from a high

to a low cooking temperature.

■ Saves time for efficient operation.

■ Prevents overcooking, especially with shorter cooking times.

Operation and control

■ Cool Down can be used in any cooking mode, at any temperature setting, and

at any time during the cooking process.

■ Unit must be in operation with door closed.

MCS/G units

BCS units

■ Cool Down automatically stops after 5 minutes.

■ Press the Cool Down key. Green LED on key will light.

■ Open door with care.

■ Actual cabinet temperature appears with flashing digits in Temperature display.

■ Close door to continue cooking when desired cabinet temperature is achieved.

■ Set mode switch to COOL-DOWN.

■ Open door with care.

■ Close door to continue cooking at a lower cabinet temperature.

X

Opening Door During Operation

Open door slightly to allow hot steam and/or vapors to escape. KEEP FACE AND

HANDS AWAY FROM OPENING or burns could result. When steam and/or heat

has dissipated open door fully with care. Escaping hot steam and/or vapors can cause

serious burns. Interior surfaces, including pans, grids and oven racks, can be extremely

hot. To prevent burns, allow unit to cool or use appropriate heat resistant protective

mitt or pad when handling. Do not use built-in retractable hand shower when cabinet

temperature is above

150°F (65°C) or burns could result.

28

Page 30

COOKING

FUNCTIONS

MCS/G models, only

Additional Functions: Steam Injection

Steam Injection is a keypad function enabled in Dry Heat mode that, when

activated, sprays a four-second burst of water onto heating elements, creating

an immediate and brief humidified environment in the cooking cabinet.

Advantages

■ Improves rising and browning of dough.

■ Adds slight glaze to pastries.

■ Keeps foods, and especially skins and crusts from dehydrating.

■ Additional control for fruit, meat pastries and other items with varied textures,

densities and consistency.

Tips

■ Use Steam Injection sparingly. If ongoing humidity is desired, use Combination

Mode or Forced Steaming.

■ Use early in the baking process to improve dough and pastry rising.

■ Can be used in all program steps that use Dry Heat between 248°F and 482°F

(120-250°C). When programmed, a four-second burst occurs every two minutes.

Operation and settings

■ Steam Injection can only be activated when cooking in Dry Heat mode.

■ Cooking temperature must be between 248°F and 482°F (120-250°C).

NOTE: Steam Injection will not operate until cabinet temperature is 248°F

(120°C) or higher.

■ To activate, press STEAM INJECTION key.

■ Repeat as desired.

29

Page 31

COOKING

FUNCTIONS

MCS/G models, only

Special Functions: HACCP Interface

A special capability that records, prints and/or transmits actual cooking data

for conformance with HACCP procedures.

Henny Penny Combis are equipped with a serial interface to output key cooking

data, core temperature progression, cabinet temperature, start and end times, etc.

This data can be printed out directly in report form or downloaded to a PC

environment.

Set Up

First, connect a printer or PC to the unit using a standard serial cable. The combi

serial port is located on the underside of the unit near the front. Once connected,

follow the instructions below to begin recording data.

Recording data

■ Select any cooking mode.

■ Set desired cooking TEMPERATURE.

■ Press PROBE cooking key and set desired probe “done” temperature. Recording

can only take place when using probe cooking. Be sure food probe is inserted.

■ Simultaneously press and hold TEMPERATURE key and STEAM INJECTION

key for approximately 10 seconds until a flashing dot appears in the cooking

temperature display.

■ Close cabinet door and begin cooking.

■ The function stops at the end of the cooking cycle, or if the unit is turned off

for longer than 4 seconds. Data recording can be terminated prior to completion

of the cooking process by pressing both the Temperature and Steam Injection

keys at the same time again.

Outputting data

Data can be output to the following devices:

■ A standard printer equipped with a serial RS232 interface that can be set

to the specified transmission format.

■ Any PC with Windows 95 or higher operating system. Windows 95 and 98

include a terminal program in the “Hyper Terminal” folder within the

Accessories program group. After launching the "Hypertrm" application

program, the following settings must be made:

30

Page 32

COOKING FUNCTIONS

HACCP Interface

continued

Windows 95 and Windows 98

1. Create a new connection in Hyper Terminal and name it “HACCP.”

2. In the “Phone Number” dialog box, click on Connect Using and select

either COM 1, COM 2, ...OR COM n, depending on which of the PC’s

serial interfaces is connected to the combi steamer. Click “OK.”

3. In the Properties dialog box that appears, select the following settings:

Bits per second:9600

Data Bits: 8

Parity: None

Stop bits:

Flow control: None

Click “OK.”

4. In the Hyper Terminal main window, click File and select Properties from

the pull down menu.

5. Click on the Settings tab and select VT-100 from the Emulation menu.

Click “OK.”

6. In the Hyper Terminal main window, click Transfer and select “Capture Text.”

7. A name must be given for the text file. You must include the “txt” with

your file name. Click “OK.”

■ For Windows NT 4.0 or higher and Windows 2000, please refer to the

appropriate operating manuals or consult your organization’s network

technical support personnel.

31

Evaluating data

Data downloaded from the combi includes a header, the temperature data, and

an end character. Tabs separate the individual temperatures in a data record.

This makes it easy to import data into suitable spreadsheet or database software.

■ A “data record” is comprised of the following three values:

1. Core temperature of food

2. Cabinet temperature

3. Number of minutes elapsed since the start of recording.

■ The current date and the start time (of the cooking process) should be entered

(manually) via the PC.

■ A graphical display of temperature progressions has proved useful.

■ Always ensure that once cooking is over, a clear signal is sent to the staff

operating the unit that the cooking process parameters have been adhered

to (i.e. that the core temperature has been reached).

■ A “non-temperature data record” can be identified by the fact that the first

character is a semicolon.

■ The batch number is automatically numbered from 0 upwards for each

cooking cycle.

■ The temperature data measured is sent at 60-second intervals.

■ The termination time is output in minutes and seconds.

■ The end character consists of the message “end***.”

Page 33

COOKING

FUNCTIONS

MCS/G models, only

Programming

Programming capabilities of the MCS/G Combi allow operators to create custom

cooking programs that automatically operate the unit to programmed parameters.

If you are not already familiar with the MCS or MCG control panel, please review

page 8 before attempting to program your unit.

Memory

■ Up to 9 total custom cooking programs are available to the operator.

An additional program for cleaning has been set by the manufacturer.

■ Each program can contain up to 3 separate steps (sets of parameters).

Control

■ Automatic—Unit begins operation when Program Start key is pressed.

Unit shuts down when last program step has been completed.

C

START

■ Manual Override—Program operation can be interrupted at any time by simply

selecting or setting a new value. The new value affects cooking process only in

the step in which the program was overridden. Overriding the program DOES

NOT cancel it. When the new value or function is achieved, and/or that step

of the program is completed, program operation continues with the next

programmed step, or shuts down unit if program is complete.

■ Program Lock—Cooking programs can be locked to prevent any unauthorized

or undesired changes to the programs. If programming is locked out, only stored

programs will be displayed.

NOTE: When programming is locked you cannot manually override changes to

programs.

Programming the MCS/G Combi

To create custom cooking programs:

■ Unit must be off. Open door.

■ Turn mode selector dial to PROG. The PROG LED will flash for five seconds,

prompting a programming action. The letter “C” (Cleaning program) appears in

the Program Number Display, the middle of three display keys immediately left.

NOTE: If the PROG LED does not flash, the programming function has

been locked (see “To lock/unlock programming”.)

5.

START

■ Select the desired program number (1-9) by pressing the display key farthest left.

This key acts as the Program Selection key. The middle display will show the

program number followed by a decimal point. Flashing program numbers are

available for programming; non-flashing numbers indicate stored programs.

NOTE: If programming is locked, only stored program numbers will be displayed.

■ Program number and first cooking mode must be selected while the PROG

LED is flashing within 5 seconds.

32

Page 34

COOKING

FUNCTIONS

Programming

continued

MCS/G models, only

Step

Number

Program

Number

Program

Selection

5.

C

5.

C

START

Program

Start

START

Program

Start

■ Begin entering cooking parameters for each step of the program by selecting

desired cooking mode.

■ Continue current step by selecting additional parameters, such as cooking

temperature, time or probe “done” temperature, or steam injection.

■ To move on to the next step in the program, select a cooking mode. It can be

the same mode or a different one. If you wish to use the same mode, reset that

mode by quickly turning the mode dial away from and back to its original

setting. The Program Step Display now shows a number “2” with no decimal.

Continue entering parameters.

■ When all steps have been entered in this manner, save the program by switching

the mode dial to PROG.

■ Check the program by pressing the Program Start key (the display key next

to PROG) repeatedly. Each step will be displayed in sequence with the

corresponding LEDs and values indicating the various parameters of that

stage. After the last step, the program number will be displayed.

To run a saved program

■ Do not open door. Turn the mode selector dial to PROG.

■ Select the desired program number by pressing the Program Selection display key.

■ Press the Program Start display key. Cooking program will begin.

33

110

START

START

To lock/unlock programming

■ Open door. Turn mode selector dial to PROG

■ Press TIMER activation key. Set TIMER to 110 minutes.

■ Press Program Start display key. When locking programming, display will show

a dash. When unlocking programming, display will show “P”.

Page 35

COOKING

FUNCTIONS

MCS/G models, only

To delete a program (must be unlocked)

5.

0

START

■ Open door. Turn mode selector dial to PROG.

■ Select program number to delete by pressing Program Selection display key.

Then select any cooking mode.

NOTE: both of these actions must be taken while PROG LED is flashing.

■ Set TIMER to “0”.

■ Turn mode selector dial back to PROG. The program has now been deleted

and the program number is available for a new cooking program.

0C0

To change temperature scale °F/°C

■ Open door. Turn mode selector dial to any cooking mode.

■ Simultaneously press and hold cooking TEMPERATURE key and COOL

DOWN keys for about 10 seconds until Temperature Scale Indicator changes

to the desired format. All temperatures will automatically be displayed in the

new temperature scale.

F

34

Page 36

C

Cleaning

Your Henny Penny Combi MUST be cleaned at least once a day to ensure proper

sanitation and continued trouble-free operation.

All models are equipped with a built-in retractable hand shower for rinsing. The

unit uses its own built-in water supply, plus heat and steam from Moist Heat mode

operation to do most of the work. MCS/G models are equipped with a preset

cleaning program that requires less operator time.

For best results, use Henny Penny Oven and Grill Cleaner and follow the procedures outlined below:

To clean:

1. Allow cooking cabinet to cool down below 130°F (55°C). (Cool Down

function can be used)

2. Turn unit off and disconnect electrical power to unit.

3. Swivel left hinged rack inward. (If using mobile oven rack, remove rack and

guide frame.)

4. Using a flat-head screwdriver, turn the two quick fastening locks one-quarter

turn counterclockwise. Baffle will swing open for cleaning.

NOTE: Floor units have 1 air baffle that opens in this manner.

5. Spray all interior cabinet surfaces (even behind the pivoted air baffle).

6. Replace air baffle and racking system, load grids and stainless steel pans and

spray thoroughly with Henny Penny Oven and Grill/Combi Cleaner.

Reconnect power.

To initiate factory pre-set cleaning program (MCS/G models only):

7. Set mode selector dial to PROG. The letter “C” appears in the program

number display.

8. Press the Program Start display key and skip steps 6-8.

NOTE: If you do not wish to use pre-set cleaning program, skip steps 7-8.

9. Let cleaner act for approximately 20 minutes.

10. Select Moist Heat mode.

11. Select TIMER and set for 15 minutes.

12. Repeat process for heavily soiled cabinet.

13. Rinse thoroughly with built-in hand shower.

NOTE: To activate the hand shower water flow, pull hose to full extension and

release to rest position. Press spray gun button.

35

Page 37

CLEANING

continued

Hand cleaning accessibility

■ The hinged racks can be removed for cleaning by lifting up on the racks,

swiveling them inward, and lifting them off their mountings.

■ If using the mobile oven rack system, roll the rack out of the unit and remove

the guide frame from the bottom of the unit by lifting it upward out of its

mountings.

■ The air baffle, covering the left side of the interior cabinet, provides even airflow

and protects operator from heating elements and fan.

NOTE: Wipe door gasket with clean cloth.

Safety protection (gloves, goggles, etc.) is required when working with

cleaning products. Please refer to cleaning product guidelines before use.

Descaling Maintenance

Limescale deposits occur naturally inside the steam generator. Time, heavy use,

and hard water conditions result in a gradual build-up of these deposits, eventually

affecting the performance of, and potentially damaging, your combi. Periodic,

professional descaling of the steam generator must be performed on a regular basis

to ensure peak performance of your Henny Penny Combi.

Auto Flush

Auto Flush is an automatic feature in all models that drains and flushes the steam

generator on a regular basis in order to keep the unit operating reliably between

descalings. While it extends the time between service calls, the Auto Flush feature is

not meant to make descaling unnecessary.

IMPORTANT

Descaling should ALWAYS be performed by a certified Henny Penny service tech-

nician, or a similarly qualified individual.

36

Page 38

Installation

Refer to the following pages for important information regarding the

installation of MCS/G and BCS Combis. It is recommended that

installation be accomplished by a certified and properly trained technician.

Site, leveling

Minimum clearance sides and back:

2 in. (50 mm)

Service clearance, left side:

20 in. (500 mm)

Clearance for door opening:

1

Model 6 & 10: 20

Model 1020: 29

Model 20: 28

Model 40: 30

⁄2 in. (521 mm)

1

⁄2 in. (749 mm)

3

⁄4 in. (730 mm)

3

⁄4 in. (781 mm)

fig. 1

fig. 2

1) Check for any transport damages. Should there be any signs of transport

damage immediately inform your dealer/freight forwarder.

2) Check installation site. Check entrance clearance.

Minimum entrance space needed without pallet:

Model 6 & 10: 351⁄2 in. (902 mm)

Model 1020: 495⁄8 in. (1262 mm)

Model 20: 397⁄8 in. (1012 mm)

Model 40: 521⁄2 in. (1332 mm)

■ Floor at installation site must be level.

■ Cold water line should be in place. (page 40)

■ 2 in. (50 mm) drain connection installed.

■ Max. drain height for floor units: 4 in. (100mm)

■ Electrical power supply/protective measures installed and sized correctly.

(page 38-39)

3) Remove all cartons, packing materials, documents etc. from the interior cabinet.

4) Remove grid shelves/mobile rack from cabinet.

5) Take unit off the pallet.

■ Moving unit without pallet: Models 6, 10, 1020 (fig. 1)

37

■ Moving unit without pallet: Models 20, 40 (fig. 2)

Page 39

INSTALLATION

continued

Unit weights:

MCS/BCS 6 270 lbs. (123 kg) MCG 6 335 lbs. (152 kg)

MCS/BCS 10 334 lbs. (152kg) MCG 10 384 lbs. (174 kg)

MCS/BCS 1020 484 lbs. (220 kg) MCG 1020 584 lbs. (265 kg)

MCS/BCS 20 686 lbs. (312 kg) MCG 20 798 lbs. (362 kg

MCS/BCS 40 972 lbs. (442 kg) MCG 40 888 lbs. (403 kg)

Fig. 3

Fig. 4

Fig. 5

6) Installation models 6, 10, 1020

■ Place floor stand at the installation place and level by adjusting legs (fig. 3).

■ Minimum clearance required to neighboring equipment or walls (page 36)

■ Place the unit on top of the stand. The unit’s legs must be centered on

the locating pins of the stand (fig. 4).

■ Unit must be level (fig. 5).

7) Installation models 20, 40

■ The unit must be secured against shifting on the floor by means of floor

fixtures (fig. 6). If floor fixtures are glued to the floor (use polyurethane

glue or similar), remove all grease from the floor first.

■ Place the unit at its final location and level by adjusting legs (fig. 5).

■ Minimum clearance required to neighboring equipment or walls (page 36)

■ The area of floor under the unit where Mobile Oven Racks will roll in

must be level or door will not seal (fig. 7).

Electrical

8) Electrical connection

Fig. 6

Fig. 7

■ Connect the unit only according to the information given on the data plate.

■ Observe all regulations of your local Electrical Code.

■ The appliance may only be connected by a licensed electrician.

■ Each appliance requires an independent fused power supply line.

■ Connection via GFI circuit breaker is advisable.

■ On-site installation: provide accessible all-pole disconnection device with

minimum of

1

⁄8 in. (3 mm) contact gap (not required for 120v gas units.)

■ Connect appliance to ground.

■ Special voltages on request. Circuit diagram is located behind the operator

panel.

Connected load for electric units:

Model KW

208v 3Phase 240v 3 Phase 208v 1 Phase 240v 1 Phase

MCS/BCS-6 10 28 24 48 42

MCS/BCS-10 19 53 45.8

MCS/BCS-1020 31.5 87.5 75.9

MCS/BCS-20 38 105.6 91.5

MCS/BCS-40 63 175.1 151.8

Amps

38

Page 40

INSTALLATION

12

11

10

9

8

7

6

5

4

3

2

1

fig. 8

N

L

L

L

3

2

1

Electrical requirements of gas units:

Model Voltage Phase Cycle/Hz KW

MCG-6 120 1 60 1

MCG-10 120 1 60 1

MCG-1020 208/240 1 60 1.5

MCG-20 208/240 1 60 1.6

MCG-40 208/240 1 60 3.5

Choose conductor size according above tables and your local regulations.

IMPORTANT

fig. 9

Cable

Inlet

Gas units are voltage specific. Supply voltage must match voltage rated on data plate.

■ Gas units are supplied with grounded power cord and plug.

■ Electric units are NOT supplied with power cord.

To connect power supply for electric units, models 6, 10:

■ Open the operator panel. (fig. 8)

(Electric)(Gas)

■ Insert power cord through cable inlet under left side of unit to desired

length and secure the cable connection tight. (fig. 9)

■ The circuit diagram is located behind the control panel.

To connect power supply for electric units, models 1020, 20, 40:

■ Access power connection terminals by removing left side panel.

■ Insert power supply cable through cable inlet under left side of unit to desired

length and secure the cable connection tight. (fig. 9)

■ Connect supply wires as follows:

Gray terminals: L1, L2, L3, phase sequence

does not need to be observed

Blue terminal: Neutral (if applicable)

Yellow/Green terminal: Ground

240 Volt

208 Volt

Common

39

IMPORTANT/MCS Only

Henny Penny Combi Ovens are shipped set up for 240 volts, but can be changed

to operate on 208 volt by proceeding with the following steps:

1. Disconnect unit from power supply source.

2. Open service door (fig. 8) by loosening fastener at top of the unit over the

control panel using a 5 mm Allen wrench. A rubber grommet must first be

removed to access the bolt.

3. Remove jumper between pins 8 and 9 of connector shown at left. The jumper is

removed for 208 volt supply, it stays in place between pins 8 and 9 for 240 volt.

4. Move transformer primary lead from the 240 volt terminal to the 208 volt

terminal.

5. Secure all panels and covers.

NOTE: BCS electric units are voltage specific. Only MCS electric units

are convertible.

Page 41

INSTALLATION

fig. 10

WA

Water supply

9) Drain Connection (WA)

■ For drain connection (fig. 10) use only steam temperature resistant pipe,