Hellwig 6400, R-6400 Installation Instructions Manual

559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

Thank you for purchasing a quality Hellwig Product.

PLEASE READ THIS INSTRUCTION SHEET COMPLETELY BEFORE STARTING

YOUR INSTALLATION

IMPORTANT NOTES

DO NOT INSTALL THIS UNIT ON CAB AND CHASSIS TRUCKS. THIS UNIT WILL

INTERFERE WITH THE REAR TIRES ON CAB AND CHASSIS TRUCKS CAUSING

DAMAGE TO THE AIR SPRING OR TIRES, OR TO BOTH. THIS KIT IS DESIGNED

FOR USE ON PICKUP TRUCKS ONLY

DO NOT ATTEMPT ANY MODIFICATIONS TO THE VEHICLE OTHER THAN

THOSE OUTLINED IN THIS INSTRUCTION AND WARNING SHEET. IF ANY

INTERFERENCE WITH THE GAS TANK , FUEL OR BRAKE LINES, EXHAUST

PIPE ETC.. STOP YOUR INSTALLATION AND CALL HELLWIG PRODUCTS FOR

TECHNICAL HELP OR INSTRUCTIONS.

NEVER LOAD THE VEHICLE THIS UNIT IS INSTALLED ON BEYOND THE

VEHICLES MANUFACTURER’S MAXIMUM GROSS WEIGHT RATING.

TORQUE TABLE BOLT SIZE:

3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs.

½” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.-5/8”=120 ft. lbs.

IMPORTANT WARNING

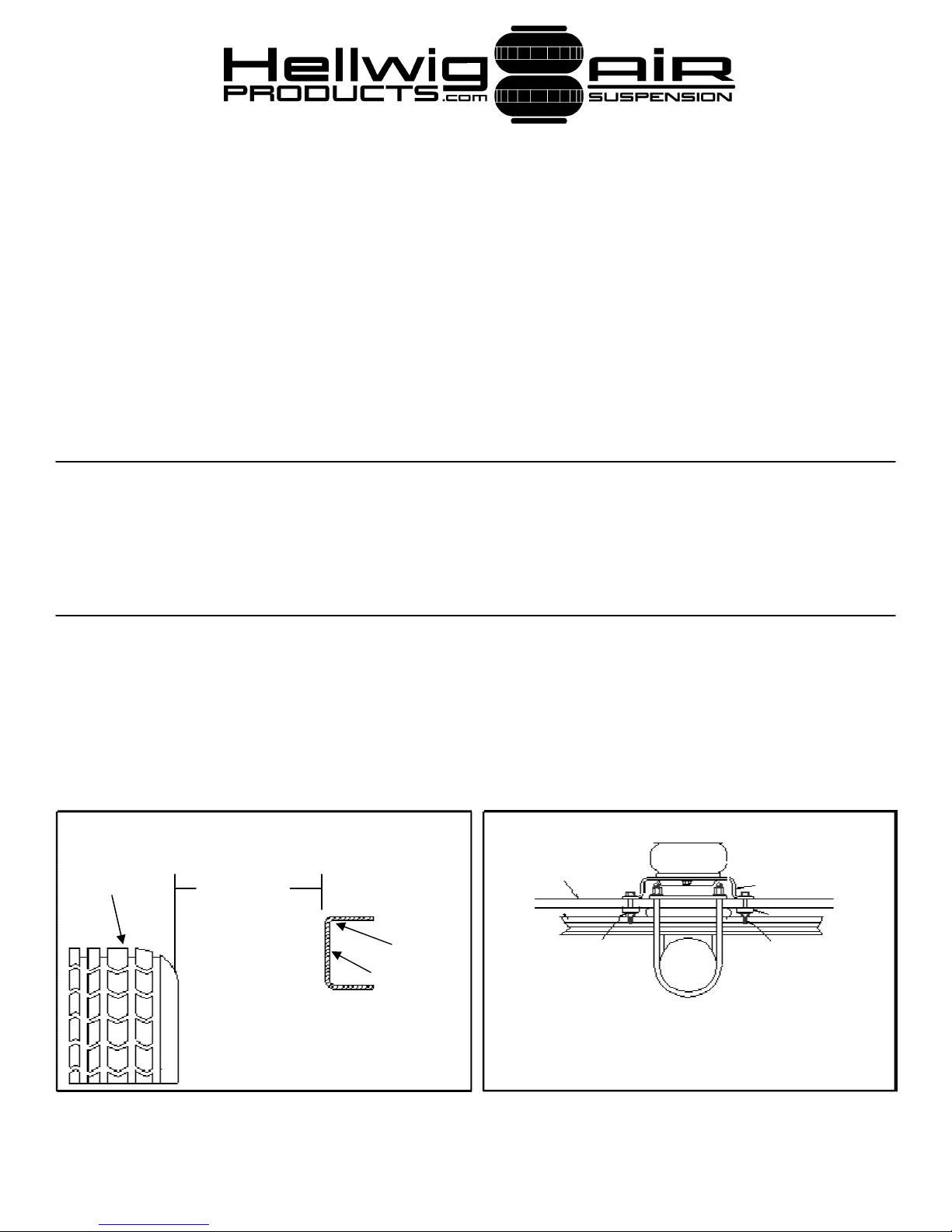

TIRE

MINIMUM CLEARANCE

REQUIRED BETWEEN

OUTSIDE OF FRAME

AND INSIDE OF TIRE

(7) SEVEN INCHES

SEVERE TIRE AND AIR SPRING

FRAME

MOVE ANY

WIRES,

LINES OR

HOSES

PRIOR TO

DAMAGE WILL OCCUR IF THIS

DISTANCE IS NOT PRESENT

FIG # 1 TIRE TO WHEEL CLEARANCE FIG # 2 CONTACT OVERLAOD INSTALLATION

AIR SPRING

CONTACT OVERLOAD ASSY

LEAF SPRING ASSY CROSSBAR

WASHER AND LOCKNUTS

SIDE VIEW

ON VEHICLES WITH CONTACT OVERLOAD LEAVES, MOUNT THIS UNIT TO THE

TOP OF THE CONTACT LEAF, IF YOUR VEHICLE DOES NOT HAVE ENOUGH SPACE

FOR THE AIR SPRING ASSY,REMOVAL OF THE CONTACT OVERLOAD LEAF MAY

BE NECESSARY.

AXLE ASSY

LOWER STEP BRACKET

(REVERSE FOR CLEARANCE)

LONG BOLTS AND LOCKNUTS

(TRIM TO LENGTH AS NEEDED)

6400 ( R-6400 ) 12/19/2013

559-734-7451 800-367-5480 FAX 559-734-7460

NOTE:

SPRING ABOVE THE AXLE. DRILLING HOLES IN THE SIDE OF THE FRAME WILL BE

NECESSARY. IT WILL BE NECESSARY TO REMOVE THE TIRES, SUPPORT THE VEHICLE

BY THE AXLE WITH SAFETY STANDS AND BLOCK THE FRONT TIRES.

IMPORTANT:

CLEARANCE BETWEEN THE FRAME AND THE TIRE FOR THIS ASSEMBLY. 1994

AND NEWER DODGE 4-WHEEL DRIVE PICKUPS MINIMUM CLEARNACE DISTANCE

IS (7) INCHES. SEE DIAGRAM DETAILING FENDER WELL MODIFICATIONS NECES SARY FOR THIS INSTALLATION. ( SEE FIG # 7 )

TH

IS UNIT IS DESIGNED TO MOUNT TO THE SIDE OF THE FRAME AND TO THE LEAF

BEFORE BEGINNING THE INSTALLATION, CHECK TO BE SURE THERE IS ENOUGH

1. This unit is designed to be fully adjustable, the upper frame brackets and top air spring plate are

made up from three different brackets. Attach the air spring to the top plate with the 3/8” locknuts provided. Be sure the air line fitting hole aligns with the large hole on the plate, the bent

lips on the upper plate go upwards away from the air spring. Tighten to 20 ft. lbs. max.. Install

the air line fitting into the large hole in the top of the air spring. Tighten completely so that

some of the red sealant is down inside the threaded hole. Align the hose port on the fitting to

point towards the expected air line route. Be careful not to damage the hose nut or the inner

hose sleeve when tightening the fittings. ( SEE FIG # 3 OR # 5 )

2. Attach the lower step bracket to the bottom of the air spring. Use the small bolt and lock washer

provided. A variety of slots are provided to assure proper air spring alignment. Tighten to be

snug. 20 ft lbs. max.. Reverse direction or switch holes or positions as to best fit your particular

vehicle. ( SEE FIG # 3 OR # 5 )

3. Place the assembly onto the leaf springs above the axle. The frame mount brackets are reversible above or below the top plate, however, there is a right and a left side. The left side below the

plate is the right side above the plate. Position the mount brackets to attach to the top of the upper air spring plate and so the frame mounting holes are against the side of the frame rail. Attach the frame mount brackets to the upper plate with the shortest 3/8” bolts provided. Be sure

to place the heads of the bolts on the air spring side of the bracket. Adjust the frame brackets to

compensate for any contours on your particular frame. Snug these bolts, DO NOT TIGHTEN.

( SEE FIG # 4 OR # 6 )

4. Adjust the upper brackets on the frame so the air spring is as straight up and down as possible.

Set the air spring to be between 5 and 6-1/2 inches between the brackets. The air springs come

shipped at approximately 6”, this is a good set up height. Use the (4) extra crossbars provided

as spacers to elevate one end of the step brackets on the leaf springs to make the assembly as

level as possible. ( SEE FIG # 3 )

5. With the air spring straight and at the desired setup height, use the holes in the frame brackets

and mark the locations to drill the holes, make the mark in the center of the slots to allow for

adjustment. Be sure to double check all dimensions. ( SEE FIG # 3 OR # 5 )

6. Being sure to move any lines or wires inside the frame to avoid damaging with the drill. Drill

the (4) mount holes with a 7/16” drill bit. Repeat this process for the other side.

7. Place the remaining short 3/8” bolts provided through the frame brackets and frame so the

threads are under the vehicle. Place the flat plates inside the frame on the bolts and attach with

the locknuts provided. Tighten only to be snug. Be sure not to pinch any lines, hoses or wires

inside the frame with the flat plates. ( SEE FIGURE # 4 OR # 6 )

6400 ( R-6400 ) 12/19/2013

Loading...

Loading...