559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

6299Air Suspension Kit (pat. pending)

2009+ Dodge 1500 Pickup with Rear Coil Springs

Thank you for purchasing a quality Hellwig Product.

PLEASE READ THIS INSTRUCTION SHEET COMPLETELYBEFORE STARTING

YOUR INSTALLATION

IMPORTANT NOTES

IF EQUIPPED WITH FACTORY PREMIUM RIDE OR

AUTOLEVELSUSPENSION, CONTACT HELLWIG

PRODUCTS CO. FOR FURTHER INSTRUCTIONS.

DO NOT INFLATE ANYAIR SPRINGASSEMBLYUNLESS IT HAS BEEN

PROPERLY INSTALLED ON VEHICLE.

DO NOT INFLATE AIR SPRINGS OVER 100 PSI

AMINIMUM OF 5-10 PSI MUSTBE MAINTAINED INAIR SPRINGS

AFTER INSTALLATION FOR WARRANTYTO BE VALID. FAILURE TO

KEEPMINIMUM PRESSURE INAIR SPRINGS WILLVOID WARRANTY.

THIS UNIT IS DESIGNED TO INCREASE THE LEVEL LOAD CARRYING

CAPACITY OF YOUR VEHICLE. NEVER LOAD THE VEHICLE THIS

UNIT IS INSTALLED ON BEYOND THE MANUFACTURER’S MAXIMUM

GROSS VEHICLE WEIGHT RATING.

OVERINFLATIONAND IMPROPER USE MAY RESULT IN PERSONAL

INJURYAND/OR DAMAGE TO YOUR VEHICLEAND PROPERTY.

6299 ( R-6299) 02/26/2010

559-734-7451 800-367-5480 FAX 559-734-7460

BEFORE STARTINGYOUR PROJECT

WHEN LIFTING A VEHICLE WITH A JACK, BE SURE TO SET THE PARKING BRAKE AND USE SAFETY STANDS.

ENSURE THAT THE INSTALLATION OF COMPONENTS WILL NOT CRUSH OR DAMAGE FUEL AND BRAKE

LINES OR ELECTRICAL HARNESSES.

BEFORE DRILLING ANYHOLES, ENSURE THAT ALL ELECTRICAL WIRES, FUELLINES, BRAKE LINES, BRAKE

HOSES AND ANY OTHER COMPONENTS ARE MOVED OR PROTECTED TO AVOID DAMAGE FROM DRILLING

ANY HOLES .

DO NOT ATTEMPT ANY MODIFICATIONS TO THE VEHICLE OTHER THAN THOSE OUTLINED IN THIS

INSTRUCTION SHEET. IF ANY INTERFERENCE WITH THEGAS TANK, FUEL LINES, BRAKE LINES, EXHAUST

PIPE, ETC. EXISTS, STOP YOUR INSTALLATIONAND CALL HELLWIG PRODUCTS FOR TECHNICAL HELP.

IF WHEELS ARE REMOVED FOR INSTALLATIONOF KIT, CHECK MANUFACTURERS SPECIFICATIONS FOR

PROPER LUG NUT TORQUE BEFORE REINSTALLING WHEELS.

WHEN CUTTING AIRBRAKE TUBING, A SQUARE CUT IS REQUIRED AND THE HOSE END MUST NOT BE

DEFORMED OR LEAKAGEMAY RESULT. IF DEFORMATION OF THE HOSE END OCCURS, THE HOSE END

MUST BE REWORKED SO THAT IT IS ROUND.

ENGAGEMENTOF THE SEALING O-RING WILL BE FELT WHEN THE AIR LINE HAS BEEN INSERTED

PROPERLY INTO THE FITTING. FITTINGS MAY BE DISCONNECTED IF REQUIREDBY PUSHING DOWN ON THE

OUTER RING WHILE PULLING FIRMLY ON THE AIR LINE.

ROUTE AIRLINES AWAY FROM EXHAUST PIPES OR ANY OTHER SOURCESOF HEAT AND ENSURE THAT THE

AIR LINES ARE PROTECTED FROM SHARP EDGES.

6299 ( R-6299) 02/26/2010

PartA Air Spring Installation

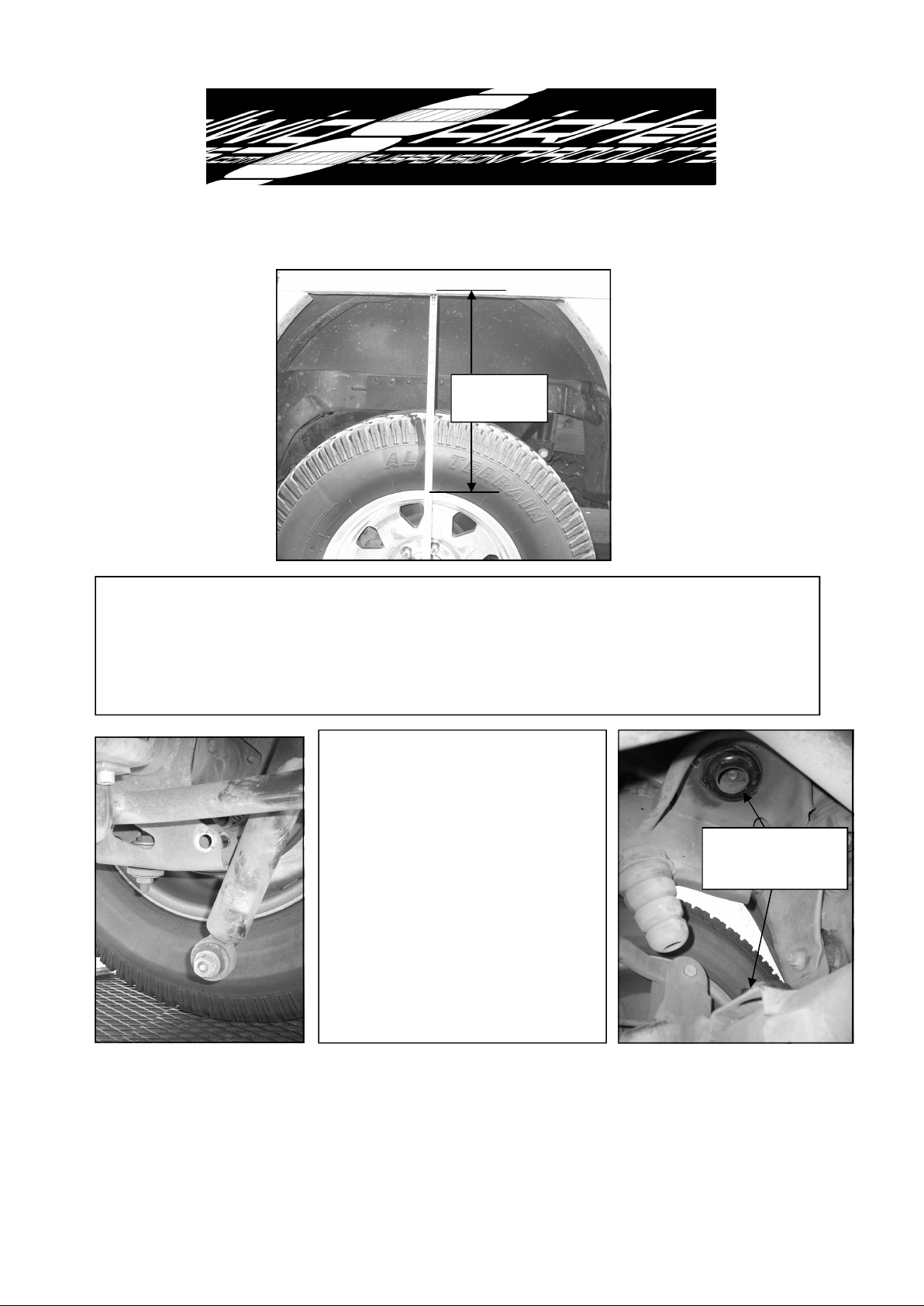

Measure this

distance

1. Prepare vehicle for installation by chocking front tires and setting emergency

brake. Before starting installation, measure the distance from the top of rear

wheel to fender lip as shown. This is the original ride height of the vehicle.

Write this measurement down as this will be used to set the height of the air

springs later in the installation.

2. For ease of installation, position the rear wheels on automotive ramps. Ensure vehicle is

secure and disconnect shock

absorbers from rear axle. Raise

Remove insulators

from frame and axle

vehicle frame until coil springs

are unloaded. Support frame

with jack stands and remove

coil springs and insulators from

vehicle. Do not remove bump

stops from frame.

6299 ( R-6299) 02/26/2010

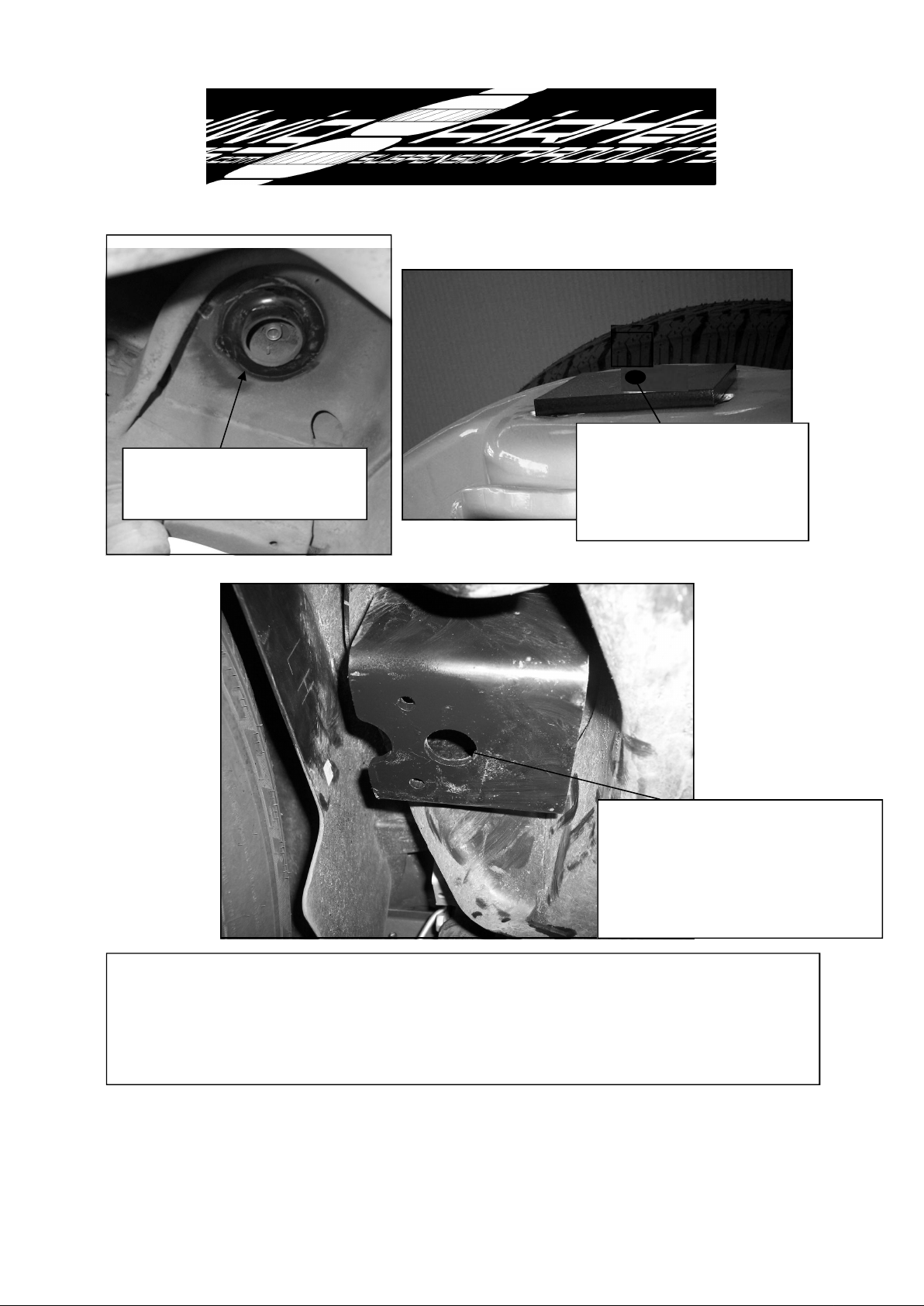

Place frame bracket over

coil spring seat

Place retainer plate on

top of frame so that axle

bracket can be retained

by 1/2” bolt

Attach frame bracket to retainer plate with 1/2x2-1/2”

bolt through hole in bracket

and engage threaded hole in

plate.

3. Place retaining plate on top of rail as shown. Locate frame bracket on coil

spring seat as shown with the notch pointing outboard. Insert 1/2 x 2-1/2 UNC

bolt through hole in frame bracket and tighten into threads in frame plate. Align

bracket to be square with the frame and axle and tighten bolt to 35 ft-lb.

6299 ( R-6299) 02/26/2010

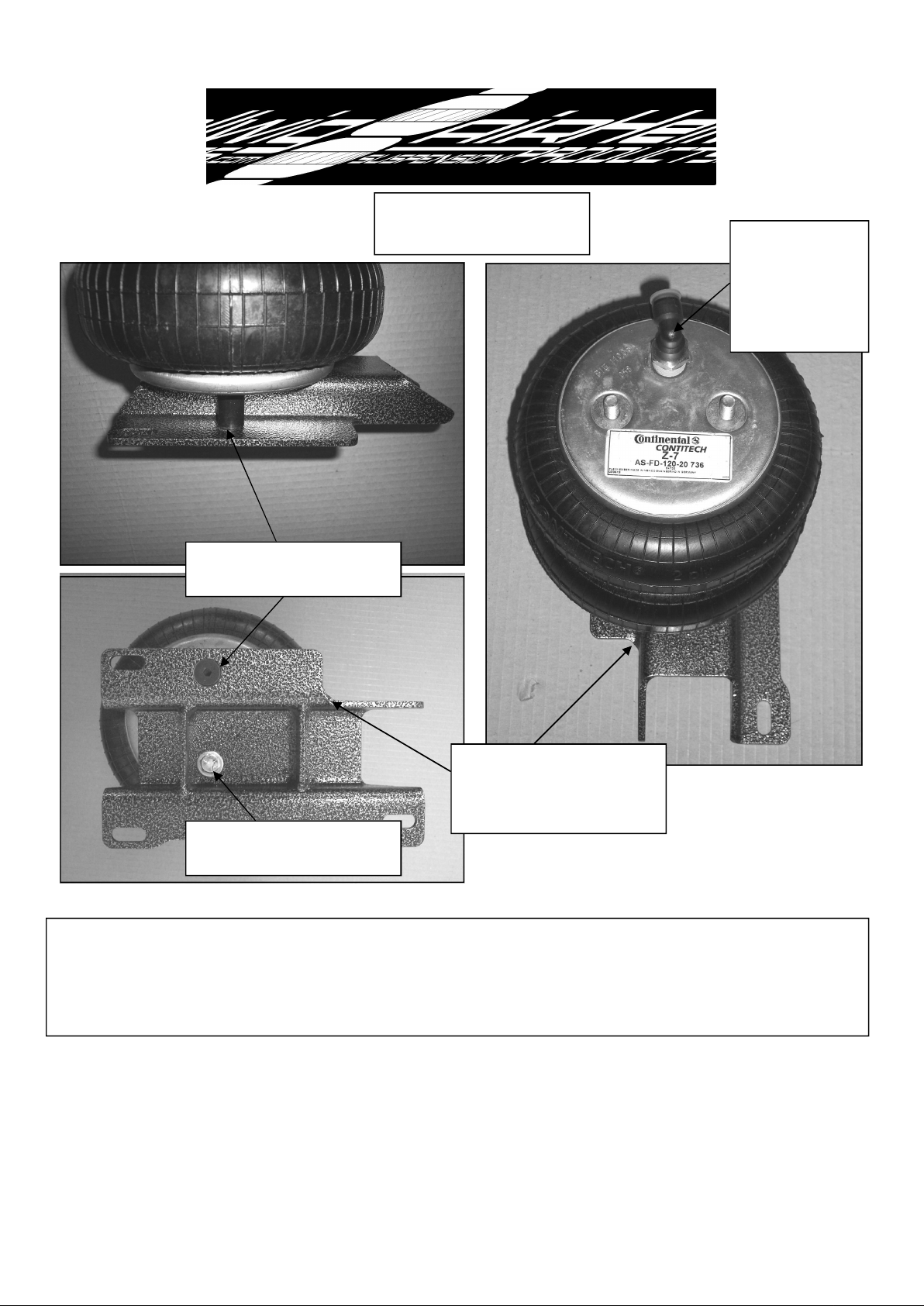

3/8 x 2 Flat head cap screw and

spacer. Torque to 20 ft-lb.

Passenger Side Shown

Driver Side Opposite

Install air spring to

axle bracket as

shown so that fittings will point outboard when installed on vehicle.

Install bracket on air spring so

that notch is located on forward

in board side when installed on

axle.

3/8 x 3/4 bolt and washer.

Torque to 20 ft-lb.

4. Assemble air spring to axle bracket as shown. Make sure to orient axle bracket so that the

notch will clear brackets welded to axle assembly. Install fittings in air spring and torque to

20 ft-lb.

6299 ( R-6299) 02/26/2010

Drill 13/32” (.406) hole in

bump stop flange for 3/8” bolt.

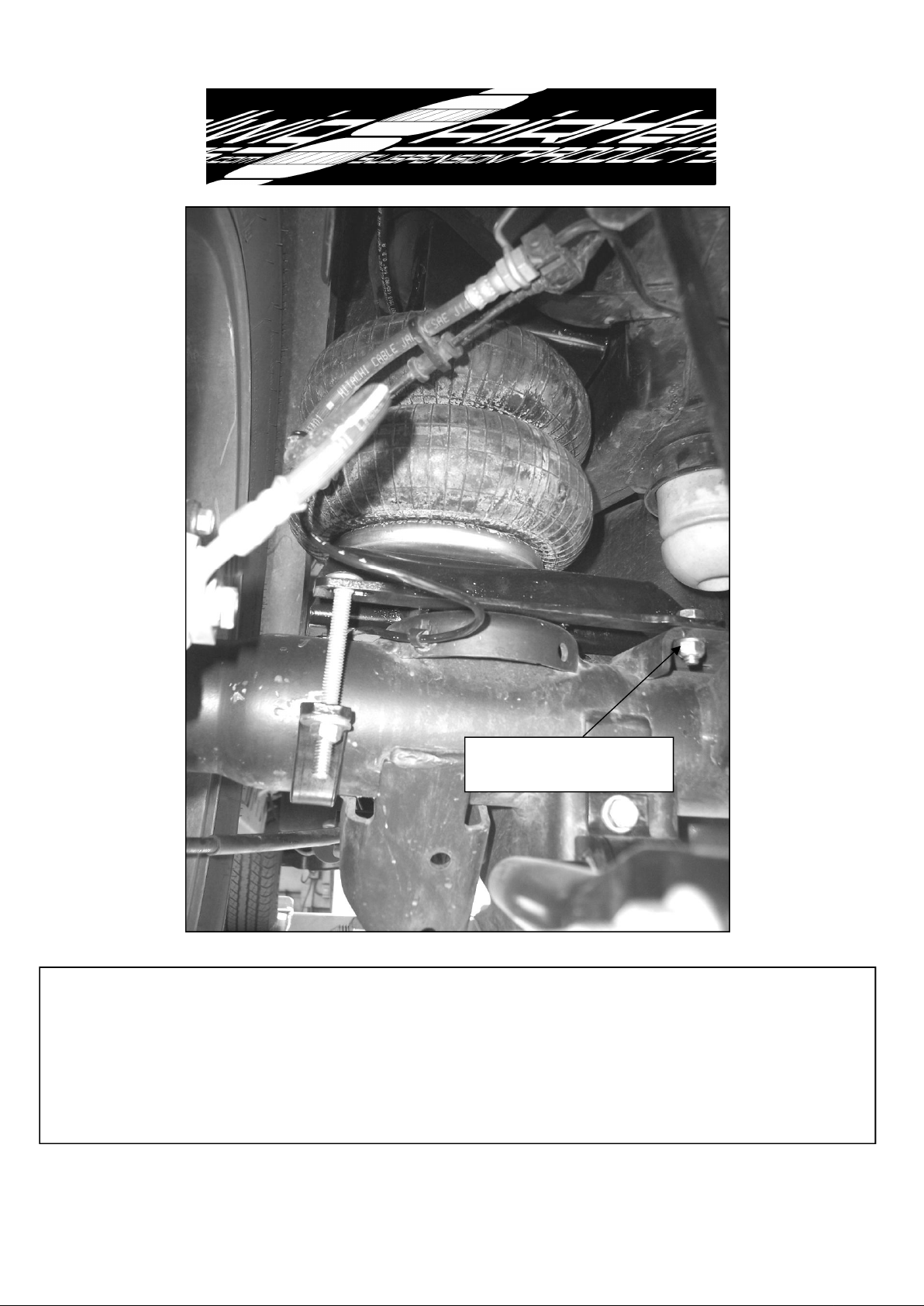

5. Install air spring assembly on axle as shown. Insert studs in air spring through holes in

frame bracket and attach air spring using 3/8” fine thread nuts. Torque to 20 ft-lb. Insert carriage bolts into outer slotted holes and attach strap to axle with 3/8” washers and locknuts.

Leave loose for adjustment later. Align air spring and mark hole for 13/32” (.406) hole to be

drilled in axle bump stop flange as shown. Attach axle bracket to flange using 3/8 X 1” bolt,

washers and locknut. Tighten bolt to 20-25 ft-lb. Tighten carriage bolts to 20 ft-lb.

6299 ( R-6299) 02/26/2010

6. Check installation that all bolts are torqued properly and that there is not interference with

brake lines or cables, electrical wires, fuel lines, exhaust pipes or any other chassis or suspension related component throughout the suspension travel. Reattach shock absorbers to axle

brackets and tighten bolts to factory specification.

6299 ( R-6299) 02/26/2010

559-734-7451 800-367-5480 FAX 559-734-7460

Part B Leveling Valve Installation

Subtract 1” from

reference dimension

7. Reference the ride height from step (1) and subtract 1” from this measurement. Adjust

frame height to the new measurement and place frame on jack stands. This will allow

the vehicle to have a level attitude as Dodge built in rake to accommodate compression

of the coil spring under load. The air suspension will hold ride height regardless of

load. IMPORTANT- You must reduce the rear ride height 1” to prevent the leveling

valve linkage from contacting the bed.

Remove 2 bolts

8. Remove 2 bolts from differential cover as shown. Attach leveling valve axle bracket

as shown using 5/16” X 1-1/4” bolts. Place qty (4) 5/16” washers between differential

cover and bracket at each bolt location to make bracket sit square. Torque to 10-12 ft-lb.

6299 ( R-6299) 02/26/2010

559-734-7451 800-367-5480 FAX 559-734-7460

Inlet/Exhaust Port Delivery Port

9. Prepare leveling valve for installation. The inlet and exhaust ports have a

screen across the base of the port while the delivery ports to the air springs have a

hole. See photos. Attach fittings to leveling valve as shown below. Torque fittings to 7-8 ft-lb. Do not over tighten.

1/4” tube –1/4” MPT

elbow (fitting may have

plastic elbow)

1/4” tube—1/4” MPT

connector

6299 ( R-6299) 02/26/2010

Assemble leveling valve

with long studs at top of

valve.

Locate slotted holes for valve

as shown. Clamp bracket to

frame forinitial installation.

DO NOT DRILL ANY

HOLES AT THIS TIME.

Center lever arm on

valve with 11/64” drill

10. Attach leveling valve to bracket as shown using 1/4” nylon locknuts and

washers. Tighten to 7 ft-lb. Attach leveling valve linkage pins to valve and axle

bracket in orientation shown. Make sure that the axle bracket and linkage pin

will not interfere with brake lines. Relocate brake lines as required. Tighten nuts

to 8-10 ft-lb. Assemble linkage as shown in photos and clamp leveling valve

bracket to frame crossmember in location shown so that linkage geometry

matches photo. DO NOT drill mounting holes at this time. Center leveling

valve by inserting a 11/64” drill bit through hole in arm and body of leveling

valve. When satisfied with linkage geometry, REMOVE drill bit.

Attach leveling valve to

bracket using long studs

at top of valve.

Linkage to be angled as

shown for initial layout.

Link must be attached as

shown for initial layout.

6299 ( R-6299) 02/26/2010

11. IMPORTANT– BEFORE DRILLING ANY MOUNTING HOLES IN

CROSSMEMBER, remove jack stands and lower frame so that the weight of the

vehicle is on the bump stops. CHECK POSITION OF LEVELING VALVE SO

THAT IT CLEARS AXLE ASSEMBLY AND BRAKE LINES. It will be a close

fit but there should be at least 1/2” of clearance. Relocate brake lines if required.

Also check that the leveling valve arm will not contact the floor of the vehicle or

any other components—evaporative canister, vent tube, exhaust pipe, etc. After

verifying clearances proceed to step 12—DO NOT DRILL HOLES AT THIS

TIME.

Leveling Valve Clearances with vehicle on bump stops

Check position of leveling valve

so that at least 1/2” clearance is

maintained to axle and brake lines.

Maintain at least 1” clearance

to vehicle floor when weight

of vehicle is on bump stops.

Leveling Valve clearance must be checked with weight of vehicle

on bump stops before drilling any mounting holes.

6299 ( R-6299) 02/26/2010

Leveling valve orientation at full extension

Minimum 20 deg Angle between linkage

and lever arm maintained at full extension

Good Installation—Leveling

valve will work correctly

Lever arm and linkage point at

each other at full extension

which will result in damage to

lever arm, valve and linkage.

Correct by moving leveling

valve toward passenger side

frame rail until minimum angle

Bad Installation—Leveling

valve will not work correctly

12. Reconnect shock absorbers to axle brackets and torque bolts to 60-70 ft-lb. IMPORTANT— Raise vehicle frame until the wheels come off the ground and support frame on

jack stands. Note orientation of leveling valve linkage. The leveling valve arm and link

must NOT be in line when the suspension is at full extension or the valve will not operate

properly. Ensure there is at least a 20 degree angle between the lever arm and linkage at

full extension . The leveling valve can be moved toward the passenger side frame rail to

increase this angle. The leveling valve MUST be RECHECKED at compression and nominal ride height if the leveling valve is moved to ensure that the arm and linkage will not

contact the vehicle or any of its components.

13. When satisfied with position of leveling valve and linkage has been checked for

proper operation and clearance, mark hole

location to attach leveling valve bracket to

crossmember. Drill (2) 1/4” holes and

install (2) 5/16” self tapping bolts to attach

bracket to crossmember. Torque bolts to

10 ft-lb

6299 ( R-6299) 02/26/2010

559-734-7451 800-367-5480 FAX 559-734-7460

Part C Compressor Installation

Air Filter

14. Prepare the compressor for mounting by HAND-TIGHTENING the air filter

into the port on the compressor. If necessary, adapters are provided with the

compressor to connect nylon hose from the tank to the compressor hose. Do

not remove the braided hose or check valve from the compressor. If the vehi-

cle will be operated in a manner where the compressor may draw in water,

the air filter should be remotely mounted in the cab with components included with compressor.

Blowoff Valve

3/8” Tube X 1/4”

MPT Connector

Reducer

1/4” Street Tee

Drain Valve

Relay

15. Prepare air tank as shown. Apply pipe sealant or Teflon tape to all fittings

before tightening. .

6299 ( R-6299) 02/26/2010

559-734-7451 800-367-5480 FAX 559-734-7460

Compressor hose installed to tank. Do not

tighten check valve.

16. Mount compressor to mounting plate

using fasteners supplied with compressor

as shown in photo. Connect compressor

mounting plate to the passenger side frame

rail using two of the supplied U-bolts

washers and locknuts. Mount tank to tank

bracket as shown using 3/8 x 1-1/4 bolts

and mount to frame using supplied U-bolt.

Torque nuts on U-bolts to 30-35 ft-lb.

Torque bolts to 20-25 ft-lb. Connect compressor hose to tank fitting as shown

above. Take care to tighten only the specified fitting to avoid damaging check valve

6299 ( R-6299) 02/26/2010

559-734-7451 800-367-5480 FAX 559-734-7460

Plumbing and Wiring Diagram

6299 ( R-6299) 02/26/2010

559-734-7451 800-367-5480 FAX 559-734-7460

17. Route 12 ga and 16 ga electrical wires from compressor to engine compartment along driver’s side frame rail. Make sure to fasten wires securely to existing

wire harness. Follow plumbing and wiring diagram for connection of leveling valve,

compressor, and relay. Take care when routing air and electrical lines that they will

not be crimped or chafed during installation or use. Deviation from the electrical diagram and failure to use an inline fuse holder (supplied) will void warranty. DO NOT

install fuse in inline fuse holder until all connections and circuits are verified to be completed correctly.

From air tank

To Air Springs

18. Connect air springs to leveling valve as shown. Tie strap hoses as required to avoid contact with exhaust and chafing on frame.

6299 ( R-6299) 02/26/2010

559-734-7451 800-367-5480 FAX 559-734-7460

28. After all connections have been verified, install fuse in inline fuse holder, apply park

brake and start engine with shifter in park or neutral. Due to the amperage draw of the

compressor, failure to turn engine on during initial startup may drain the battery enough to

require a jump start.

29. Test system by adding air to air springs. Disconnect linkage from arm and rotate arm

up to fill air springs. Check all connections with soapy water for leaks. After the integrity of the system is verified, reconnect linkage to valve. A MINIMUM OF 5-10 PSI

MUST BE MAINTAINED IN AIR SPRINGS AFTER INSTALLATION FOR WARRANTY TO BE VALID. FAILURE TO KEEP MINIMUM PRESSURE IN AIR

SPRINGS WILL VOID WARRANTY.

30. Recheck all components and test drive vehicle. Re-check all components for mounting and proper torque. Check clearance to all vehicle components including suspension

components, exhaust pipe, brake lines, fuel lines, hoses, etc. Re-check installation on a

regular basis afterward. The air tank MUST be drained at least every couple of weeks to

prevent condensation buildup, FAILURE TO REGULARLY DRAIN AIR TANK WILL

VOID WARRANTY.

6299 ( R-6299) 02/26/2010

Loading...

Loading...