Hellwig Air 6290 User Manual

559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

6090Air Suspension Kit (pat. pending)

1999-2006 Tahoe, Suburban, Avalanche, Yukon

Thank you for purchasing a quality Hellwig Product.

PLEASE READ THIS INSTRUCTION SHEET COMPLETELYBEFORE STARTING

YOUR INSTALLATION

IMPORTANT NOTES

IF EQUIPPED WITH FACTORY PREMIUM RIDE OR

AUTOLEVELSUSPENSION, CONTACT HELLWIG

PRODUCTS CO. FOR FURTHER INSTRUCTIONS.

DO NOT INFLATE ANYAIR SPRINGASSEMBLY UNLESS IT HAS BEEN

PROPERLY INSTALLED ON VEHICLE.

DO NOT INFLATE AIR SPRINGS OVER 100 PSI

AMINIMUM OF 5-10 PSI MUSTBE MAINTAINED INAIR SPRINGS

AFTER INSTALLATION FOR WARRANTYTO BE VALID. FAILURE TO

KEEPMINIMUM PRESSURE INAIR SPRINGS WILLVOID WARRANTY.

THIS UNIT IS DESIGNED TO INCREASE THE LEVEL LOAD CARRYING

CAPACITY OF YOUR VEHICLE. NEVER LOAD THE VEHICLE THIS

UNIT IS INSTALLED ON BEYOND THE MANUFACTURER’S MAXIMUM

GROSS VEHICLE WEIGHT RATING.

OVERINFLATIONAND IMPROPER USE MAY RESULT IN PERSONAL

INJURYAND/OR DAMAGE TO YOUR VEHICLEAND PROPERTY.

6090 ( R-6090) 03/09/07

559-734-7451 800-367-5480 FAX 559-734-7460

BEFORE STARTINGYOUR PROJECT

WHEN LIFTING A VEHICLE WITH A JACK, BE SURE TO SET THE PARKING BRAKE AND USE SAFETY STANDS.

ENSURE THAT THE INSTALLATION OF COMPONENTS WILL NOT CRUSH OR DAMAGE FUEL AND BRAKE

LINES OR ELECTRICAL HARNESSES.

BEFORE DRILLING ANYHOLES, ENSURE THAT ALL ELECTRICAL WIRES, FUELLINES, BRAKE LINES, BRAKE

HOSES AND ANY OTHER COMPONENTS ARE MOVED OR PROTECTED TO AVOID DAMAGE FROM DRILLING

ANY HOLES .

DO NOT ATTEMPT ANY MODIFICATIONS TO THE VEHICLE OTHER THAN THOSE OUTLINED IN THIS

INSTRUCTION SHEET. IF ANY INTERFERENCE WITH THEGAS TANK, FUEL LINES, BRAKE LINES, EXHAUST

PIPE, ETC. EXISTS, STOP YOUR INSTALLATIONAND CALL HELLWIG PRODUCTS FOR TECHNICAL HELP.

IF WHEELS ARE REMOVED FOR INSTALLATIONOF KIT, CHECK MANUFACTURERS SPECIFICATIONS FOR

PROPER LUG NUT TORQUE BEFORE REINSTALLING WHEELS.

WHEN CUTTING AIRBRAKE TUBING, A SQUARE CUT IS REQUIRED AND THE HOSE END MUST NOT BE

DEFORMED OR LEAKAGEMAY RESULT. IF DEFORMATION OF THE HOSE END OCCURS, THE HOSE END

MUST BE REWORKED SO THAT IT IS ROUND.

ENGAGEMENTOF THE SEALING O-RING WILL BE FELT WHEN THE AIR LINE HAS BEEN INSERTED

PROPERLY INTO THE FITTING. FITTINGS MAY BE DISCONNECTED IF REQUIREDBY PUSHING DOWN ON THE

OUTER RING WHILE PULLING FIRMLY ON THE AIR LINE.

ROUTE AIRLINES AWAY FROM EXHAUST PIPES OR ANY OTHER SOURCESOF HEAT AND ENSURE THAT THE

AIR LINES ARE PROTECTED FROM SHARP EDGES.

6090 ( R-6090) 03/09/07

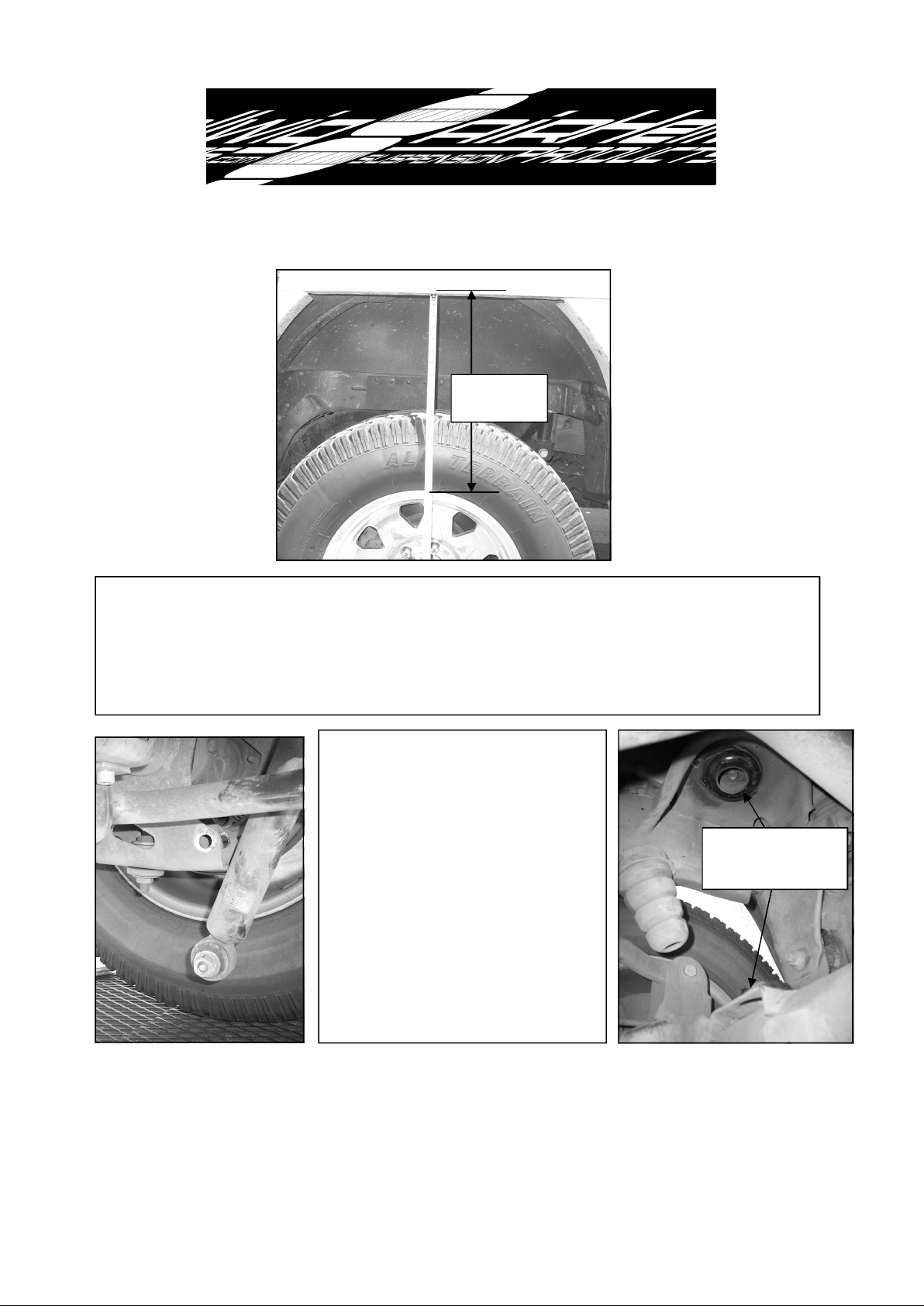

PartA Air Spring Installation

Measure this

distance

1. Prepare vehicle for installation by chocking front tires and setting emergency

brake. Before starting installation, measure the distance from the top of rear

wheel to fender lip as shown. This is the original ride height of the vehicle.

Write this measurement down as this will be used to set the height of the air

springs later in the installation.

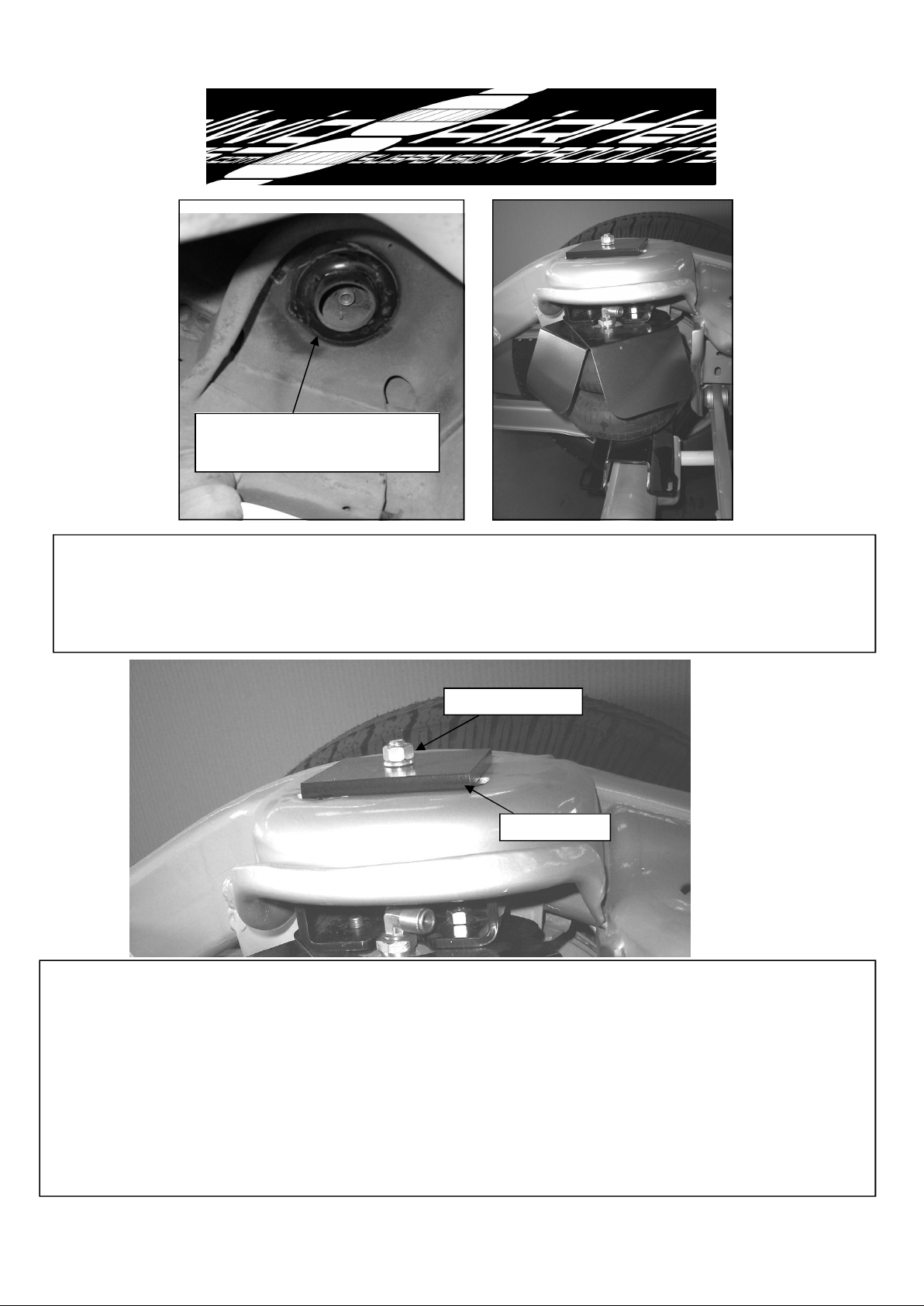

2. For ease of installation, position the rear wheels on automotive ramps. Ensure vehicle is

secure and disconnect shock

absorbers from rear axle. Raise

Remove insulators

from frame and axle

vehicle frame until coil springs

are unloaded. Support frame

with jack stands and remove

coil springs and insulators from

vehicle. Do not remove bump

stops from frame.

6090 ( R-6090) 03/09/07

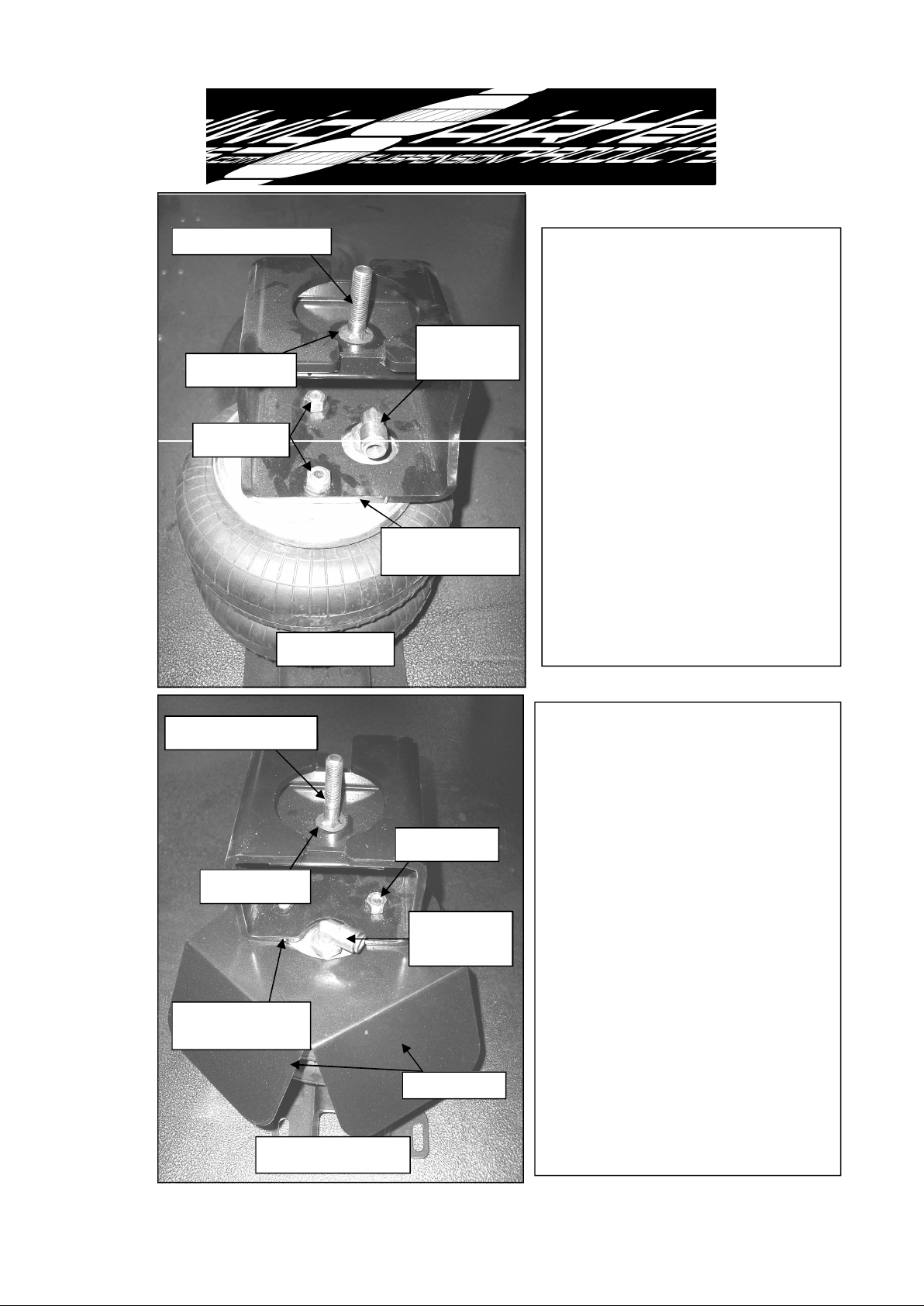

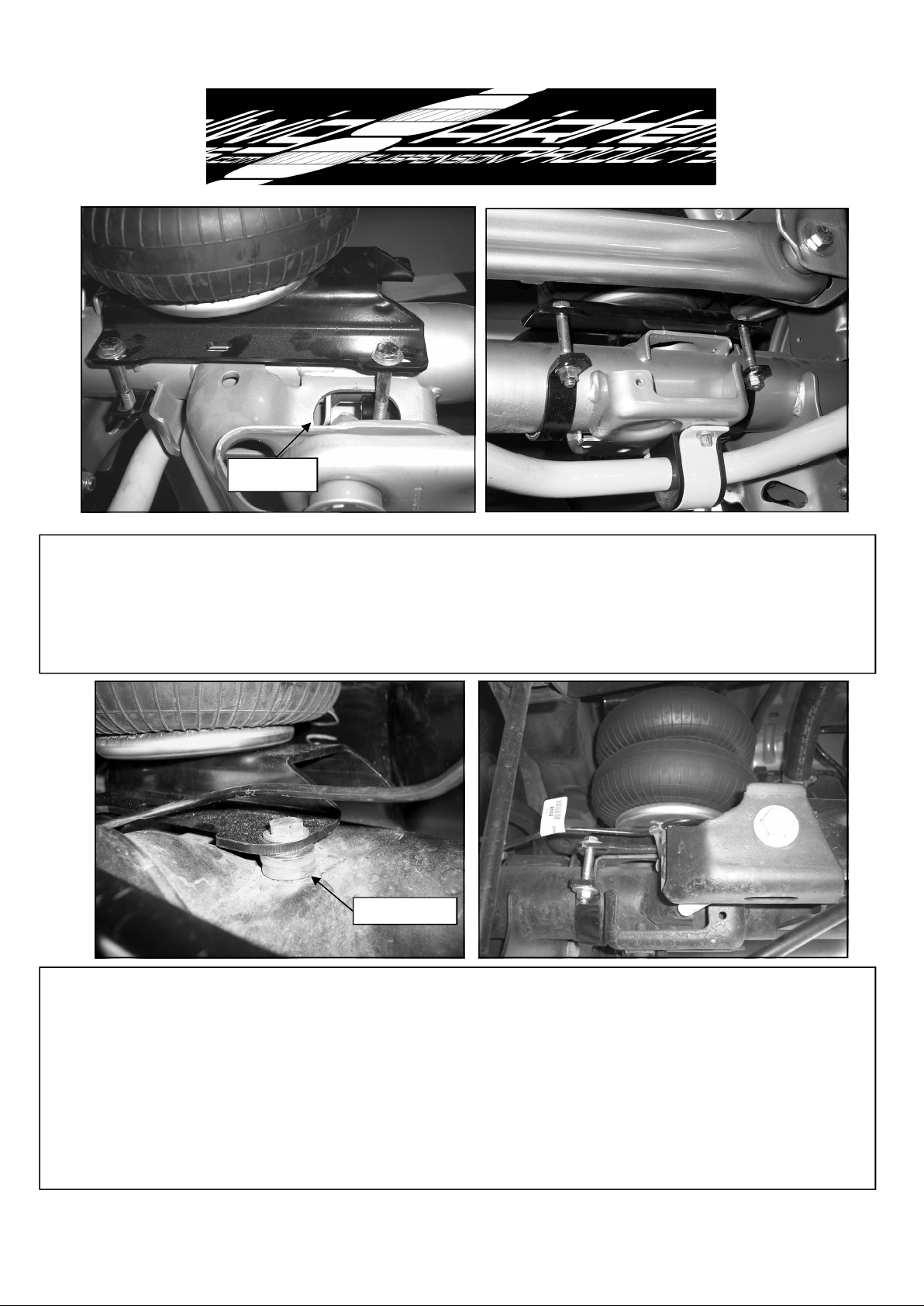

7/16UNF x 2-1/4 Bolt

Push Nut Clip

3/8 UNF Nut

Driver Side

1/2 MPT x 3/8

Hose fitting

This side of bracket

faces inboard

3. Prepare driver side air spring

assembly by installing 1/2” MPT

x 3/8 push to connect fitting into

air spring. Torque to 25-30 ft-lb.

The driver side frame bracket

has a full circle cut out for the

air fitting instead of a cut-out on

the edge. Attach frame bracket

to air spring with 3/8” UNF nuts.

Torque to 20 ft-lb. Place 7/1620x2-1/4” bolt through hole in

frame bracket and retain with

push nut clip. Push nut can be

installed on bolt by pushing on

clip with a deep well socket

while holding head of bolt in

place.

7/16UNF x 2-1/4 Bolt

Push Nut Clip

This side of bracket

faces inboard

Passenger Side

3/8 UNF Nuts

1/2 MPT x 3/8

Hose fitting

Heat Shields

4. Prepare passenger side air

spring assembly by installing

1/2” MPT x 3/8 push to connect

fitting into air spring. Torque to

25-30 ft-lb. The passenger side

frame bracket has a cut-out on the

edge of the bracket for the air fitting. Place two (2) heat shields

on top of air spring as shown and

attach frame bracket to air spring

with 3/8” UNF nuts. Torque to

20 ft-lb. Place 7/16-20x2-1/4”

bolt through hole in frame

bracket and retain with push nut

clip. Push nut can be installed on

bolt by pushing on clip with a

deep well socket while holding

head of bolt in place.

6090 ( R-6090) 03/09/07

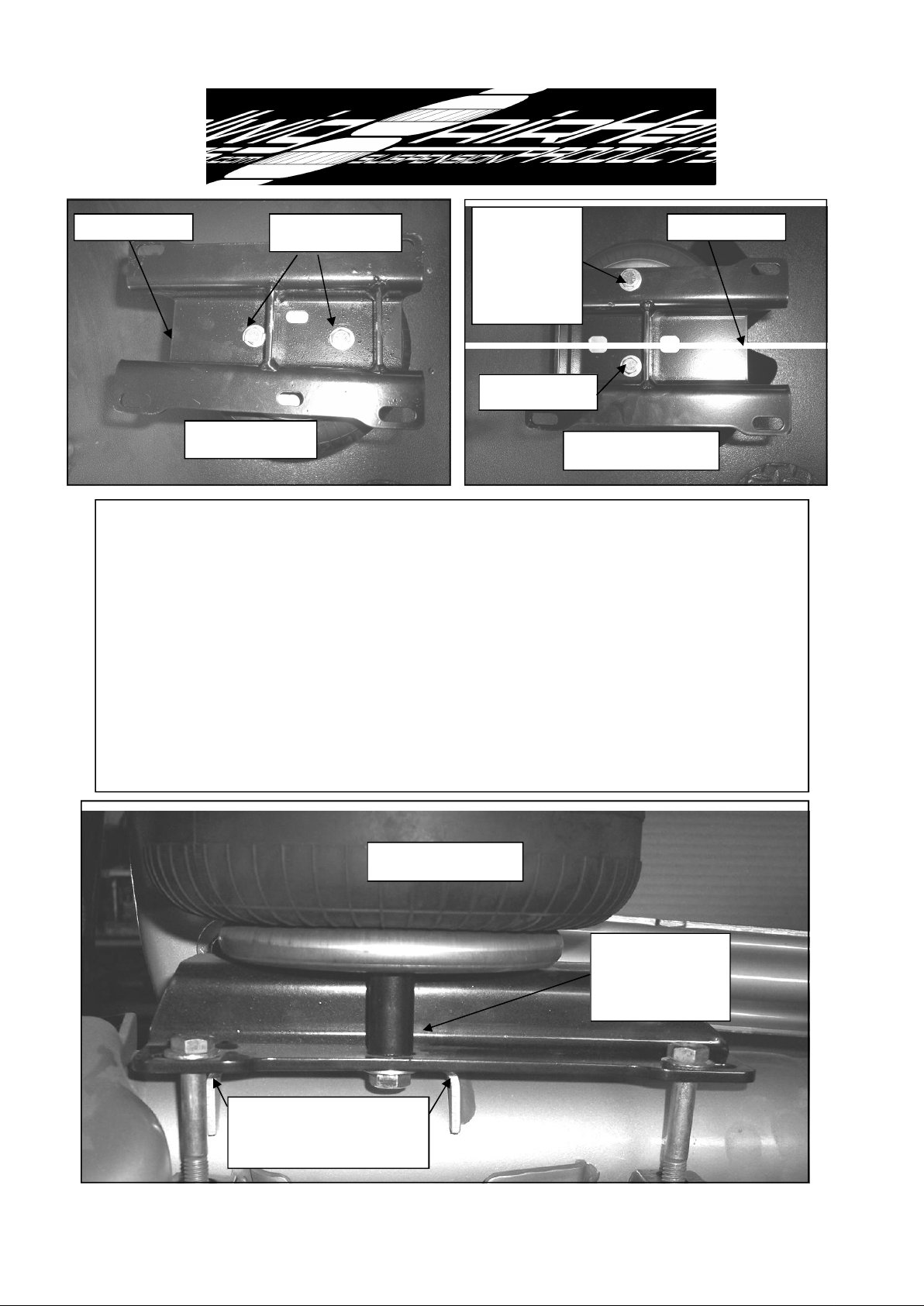

This end inboard This end inboard

3/8-16 x 1” Bolt

3/8-16 x 1-3/4”

Bolt Install 11/4” spacer

tube between

bracket and air

spring

3/8-16 x 1” Bolt

Driver Side

Passenger Side

5. Attach axle bracket to air spring as shown. The reinforcement braces are to be

installed over the coil seat on the axle. Note that the bracket is installed so that

the braces are under the air spring. The section of the axle bracket without

braces will be installed so that it faces inboard toward the center of the axle.

There are differences in how the brackets attach to the air spring for the driver

and passenger assemblies. On the passenger side assembly attach the 3/8-16 x

1-3/4” bolt and 1-1/4” spacer to air spring and axle bracket as shown. Then attach 3/8-16 x 1” bolt to air spring through middle hole of axle bracket as shown.

Snug bolts but do not tighten to allow for adjustment. On the driver side assembly attach the axle bracket to the air spring using the slotted holes as shown using 3/8-16 x1” bolts. Snug bolts but do not tighten to allow for adjustment.

Passenger Side

3/8-16 x 1-3/4” Bolt

Install 1-1/4” spacer

tube between

bracket and air

Coil spring seat—install

bracket so that reinforcement

braces center bracket on seat.

6090 ( R-6090) 03/09/07

Place frame bracket over coil spring

seat

6. Compress air spring assembly and install between axle and frame. Place brackets over

coil spring seats so that the cut-out in the frame bracket and the reinforcements in the axle

bracket fit over the raised lip of the seat. Adjust axle brackets so that air springs sit square

and tighten bolts to 20 ft-lb. Heat shields may need to be bent slightly to clear exhaust pipe.

Nut and lock washer

Frame Washer

7. To aid assembly of brackets to frame, lower frame of vehicle slightly so that the air spring

assembly holds itself in place between the axle and frame. While lowering frame, DO NOT

get under vehicle or place hands between axle and frame. Place frame on jack stands before

continuing work. Attach frame bracket by placing frame bracket over coil spring seat so that

the cut-out in the frame bracket fits over the raised lip of the seat. Place frame washer over

bolt and attach bracket with 7/16”nut and lock washer. Tighten 7/16” bolt to 35-40 ft-lb.

Due to the close quarters of the body and frame it is advised to hold the nut in place with a

wrench and tighten the bolt head. To gain additional clearance to tighten the nut, the plastic

inner fender wells can be unbolted.

6090 ( R-6090) 03/09/07

Slotted hole

8a. 1999– early 2006 models—Driver side panhard axle bracket has a large slotted hole to

insert bolt through as shown. Place 3/8-16x2-3/4” bolts through slotted holes in axle bracket

as shown and attach qty 2 axle straps per side to axle using washers and 3/8” locknuts.

Tighten nuts until legs of axle straps bend slightly. Relocate brake lines so that they do not

interfere with axle brackets, bolts, straps and air springs.

Thick washers

8b. Late 2006 models - Driver side panhard axle bracket does not have a large slotted hole.

Place 3/8-16x2-3/4” bolts through slotted holes in axle bracket as shown and attach qty 2 axle

straps to passenger side axle bracket using washers and 3/8” locknuts. Attach 1 axle strap to

outboard side of axle bracket only as shown for early models. Place qty (2) 1/4” thick washers between axle bracket and panhard axle bracket as shown. Shim axle bracket with additional flat washers until bracket is parallel with axle. Insert 3/8-16 x 1-1/2 bolt and tighten

locknut to 20 ft-lb. Tighten nuts on axle straps until legs of axle straps bend slightly. Relocate brake lines so that they do not interfere with axle brackets, bolts, straps and air springs.

6090 ( R-6090) 03/09/07

Loading...

Loading...