Heatmaster HM2-RO-18, HM2-RO-24, HM2-RO-33, HM2-SO-18, HM2-SO-24 Installation And Operating Instructions Manual

...Page 1

UNVENTED (GAS LOG) ROOM HEATER

INSTALLATION AND OPERATING INSTRUCTIONS

This heater is equipped with a PILOT LIGHT SAFETY SYSTEM designed to turn off the heater

if not enough fresh air is available.

Models HM2-MAN, HM2-T and HM2-MIL-18”, 24” and 33” Burner Units

with HM2-RO and HM2-SO Log Sets

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

+ Do not try to light any appliance.

+ Do not touch any electrical switch; do not use any phone in your building.

+ Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

+ If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, personal injury or loss of life. Refer to

this manual for information. Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

16-1010 (04/01)

This is an unvented gas-fired heater. It uses air (oxygen) from the room

in which it is installed. Provisions for adequate combustion and

ventilation air must be provided. Refer to page 5 of these instructions.

This appliance is for supplemental heating only. It should not

be used as a primary heat source for a dwelling.

DO NOT TAMPER WITH PILOT LIGHT SAFETY SYSTEM

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

Page 2

WARNING!

When used without fresh air, heater may give off CARBON MONOXIDE, an

odorless poisonous gas.

This heater is equipped with a PILOT LIGHT SAFETY SYSTEM designed to turn off the heater if not

enough fresh air is available.

If heater shuts off, do not relight until you provide fresh air.

If heater keeps shutting off, have it serviced by a qualified installer, service agency or the gas supplier.

Keep burner and control compartment clean.

2

IMPORTANT: BEFORE BEGINNING INSTALLATION

READ COMPLETE INSTRUCTIONS

CAREFULLY.

DO NOT TAMPER WITH PILOT LIGHT SAFETY SYSTEM

WARNING

+

Before installing in a solid fuel burning fireplace, the chimney flue and firebox must be cleaned

of soot, creosote, ashes and loose paint by a qualified chimney installer.

+ This appliance is for installation only in a solid-fuel burning fireplace or approved ventless

firebox enclosure.

+ Do not allow fans to blow directly into the fireplace. Avoid any drafts that alter the burner flame

patterns.

+ Do not use a blower insert, heat exchanger or other accessory not approved for use with this

burner.

ATTENTION INSTALLER:

REVIEW AND LEAVE THESE INSTRUCTIONS WITH CUSTOMER FOR FUTURE

REFERENCE.

Page 3

3

WARNING: This appliance is for installation only in a solid-fuel burning fireplace or approved

ventless firebox enclosure.

+ Do not use this room heater if any part has been under water. Immediately call a qualified

service technician to inspect the room heater and to replace any part of the control system

and any gas control which has been under water.

+ Early signs of carbon monoxide poisoning resemble the flu, with headache, dizziness and/or

nausea. If you have these signs, heater may not be working properly. Get fresh air at

once! Have heater serviced.

+ Some people - pregnant women, persons with heart or lung disease, anemia, those under

the influence of alcohol and those at high altitudes are more affected by carbon monoxide

than others.

+ WARNING: When used without fresh air, heater may give off CARBON MONOXIDE, an

odorless poisonous gas.

+ If heater shuts off, do not relight until you provide fresh air.

+ If heater keeps shutting off, have it serviced. Keep burner and control compartment clean.

WARNING

A. Due to high surface temperatures, the appliance should be located out of traffic and away

from furniture and draperies.

B. Children and adults should be alerted to the hazard of high surface temperature and should

stay away to avoid burns or clothing ignition.

C. Young children should be carefully supervised when they are in the same room as the

appliance.

D. Adults must be present at all times while operating this appliance.

E. Do not place clothing or other flammable material near the appliance.

F. Do not leave this appliance operating while unattended or while occupants are sleeping.

G. Any safety screen or guard removed for servicing the appliance must be replaced prior to

operating the appliance.

H. Installation and repair should be done by a qualified service person. The appliance should be

inspected before use and at least annually by a professional service person. More frequent

cleaning may be required due to excessive lint from carpeting, bedding material, etc. It is

imperative that control compartments, burners and circulating air passageways of the

appliance be kept clean.

I. Any change to this heater or its controls can be dangerous.

Page 4

IMPORTANT INFORMATION

+ This appliance is design certified by CSA International under the ANSI Z21.11.2b-1998

Unvented Heaters, ANSI Z21.60-1996 CGA 2.26-M96, Decorative Appliances

for Installation in Solid-Fuel Burning Fireplaces. ANSI Z21.60-1996 CGA 2.26-M96

only applies to manual and millivolt control valve units and does not apply to

thermostat control units. State or local codes may only allow operation of this

appliance in a vented configuration. Check your state or local codes.

+ This appliance must have a fireplace screen in place while the appliance is operating

and, unless other provisions for combustion air are provided, the screen shall have an

opening(s) for introduction of combustion air.

+ The flue damper in an existing vented solid-fuel burning fireplace must be closed at all

times when operated as an unvented room heater.

+ No solid-fuels shall be burned in a fireplace where an unvented room heater is

installed.

+ This appliance must not be installed in a bedroom, bathroom or any room where an

occupant could possibly be sleeping.

+ Always have glass fireplace doors open completely and have fireplace screen closed

when operating this appliance.

+ When installing this appliance in a fireplace with a mantle, always follow guidelines

listed in the Installation Clearances section of this brochure.

+ If a hood is required to be installed on your fireplace due to mantle clearances,

contact your dealer or HEATMASTER, INC. for availability of the hood.

Any outside air ducts and/or ash dumps in the fireplace shall be

permanently closed at the time of the appliance installation.

4

WARNING

+

This room heating appliance is factory designed to produce a flame having a clean and

virtually transparent appearance. If at any time the appliance begins to appear

abnormal due to excessive yellow flames, noticeable odor, or any carbon deposits on

the logs, immediately turn the appliance to the “OFF” position and contact a

qualified service technician or the gas company.

+ While operating this appliance using propane (LP) gas, the flame burning

characteristics may vary as the gas level in the LP tank approaches empty or less than

¼ full.

+ Unvented gas logs are intended for supplemental heat and are not to be used as a

primary heating source. When operated for an extended period of time this room

heating appliance can produce moisture that could create condensation, requiring

additional ventilation to the home. (EXAMPLE: Partially open a window, partially

open the fireplace vent, if applicable.)

+ Do not remove from this unit any of the attached metal plates which contain

important safety and operating information.

Page 5

5

COMBUSTION AND VENTILATION PROVISIONS

WARNING: This heater shall not be installed in a confined space or unusually tight construction unless

provisions are provided for adequate combustion and ventilation air.

Confined Space and Unconfined Space

The National Fuel Gas Code, ANSI Z223.1 defines a confined space as a space whose volume is less than

50 cubic feet per 1,000 Btu per hour (4.8m³ per kw) of the aggregate input rating of all appliances

installed in that space and an unconfined space as a space whose volume is not less than 50 cubic feet

per Btu per hour (4.8m³ per kw) of the aggregate input rating of all appliances in that space. Rooms

communicating directly with the space in which the appliances are installed, through openings not

furnished with doors, are considered a part of the unconfined space.

Unusually tight construction is defined as construction where

:

a. Walls and ceilings exposed to the outside atmosphere have a continuous water vapor retarder

with a rating of 1 perm (6 x10-¹¹ kg per pa-sec-m²) or less with openings gasketed or sealed, and

b. Weather stripping has been added to openable windows and doors, and

c. Caulking or sealants are applied to areas such as joints around windows and door frames,

between sole plates and floors, between wall-ceiling joists, between wall panels, at penetrations

for plumbing, electrical and gas lines and at other openings.

Instructions for determining maximum Btu’s for a room

Step 1

This calculation is for combustion and ventilation air provisions only and is not intended to be used for

sizing for heating comfort. To determine the maximum Btu’s allowed for a given room size you will need

to calculate the volume of the room in cubic feet. To perform this calculation, fill in the table below and

multiply the room’s width, length and height to obtain the room volume in cubic feet.

Example:If your room is 20 feet in length, 16 feet wide and has an 8 foot ceiling height, the

calculation would be as follows: 20 x 16 x 8 = 2,560 cubic feet.

Step 2

Divide the room volume by 50 cubic feet to determine the maximum Btu’s per hour the room can

utilize.

Example:Using the above example: 2,560 cubic feet divided by 50 = 51.2 x 1,000 = 51,200 Btu’s.

If the rating of your appliance plus any other gas appliances installed in the space is rated at more Btu’s

than the example calculated above, you must follow instructions for confined space. See shaded

WARNING above. If your appliance is rated at less Btu’s than the example calculated above, then your

area is considered unconfined space.

WARNING: If the area in which the heater may be operated is smaller than that defined as an

unconfined space or if the building is of unusually tight construction, provide adequate

combustion and ventilation air by one of the methods described in the National Fuel Gas

Code, ANSI Z223.1, Section 5.3 or applicable local codes.

ROOM

LENGTH

ROOM

WIDTH

ROOM

HEIGHT

ROOM VOLUME

IN CUBIC FEET

X X =

Page 6

6

INSTALLATION CLEARANCES

To ensure a safe installation in a masonry or approved factory built fireplace, the following instructions must

be carefully followed.

Minimum mantle clearance when unit is installed as a vent free appliance in a pre-existing fireplace.

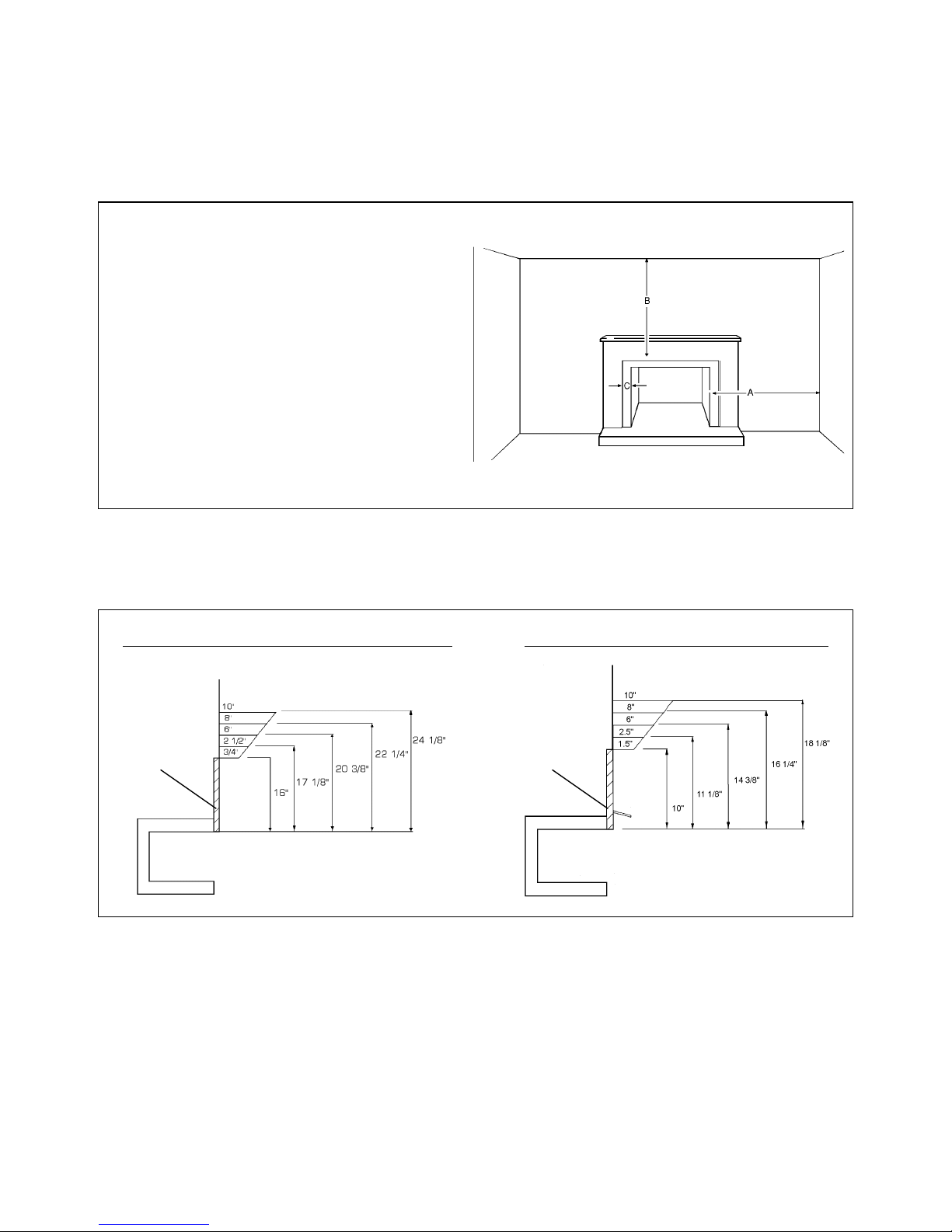

+ A) Minimum clearance from the

side of the fireplace opening to

any combustible wall should

not be less than 15 inches.

+ B) Minimum clearance from the top

of the fireplace opening to any

combustible ceiling should not be

less than 42 inches.

+ C) Minimum clearance from the

side of the fireplace opening to

part of a mantle piece should not

be less than 6 inches. See figure

at right.

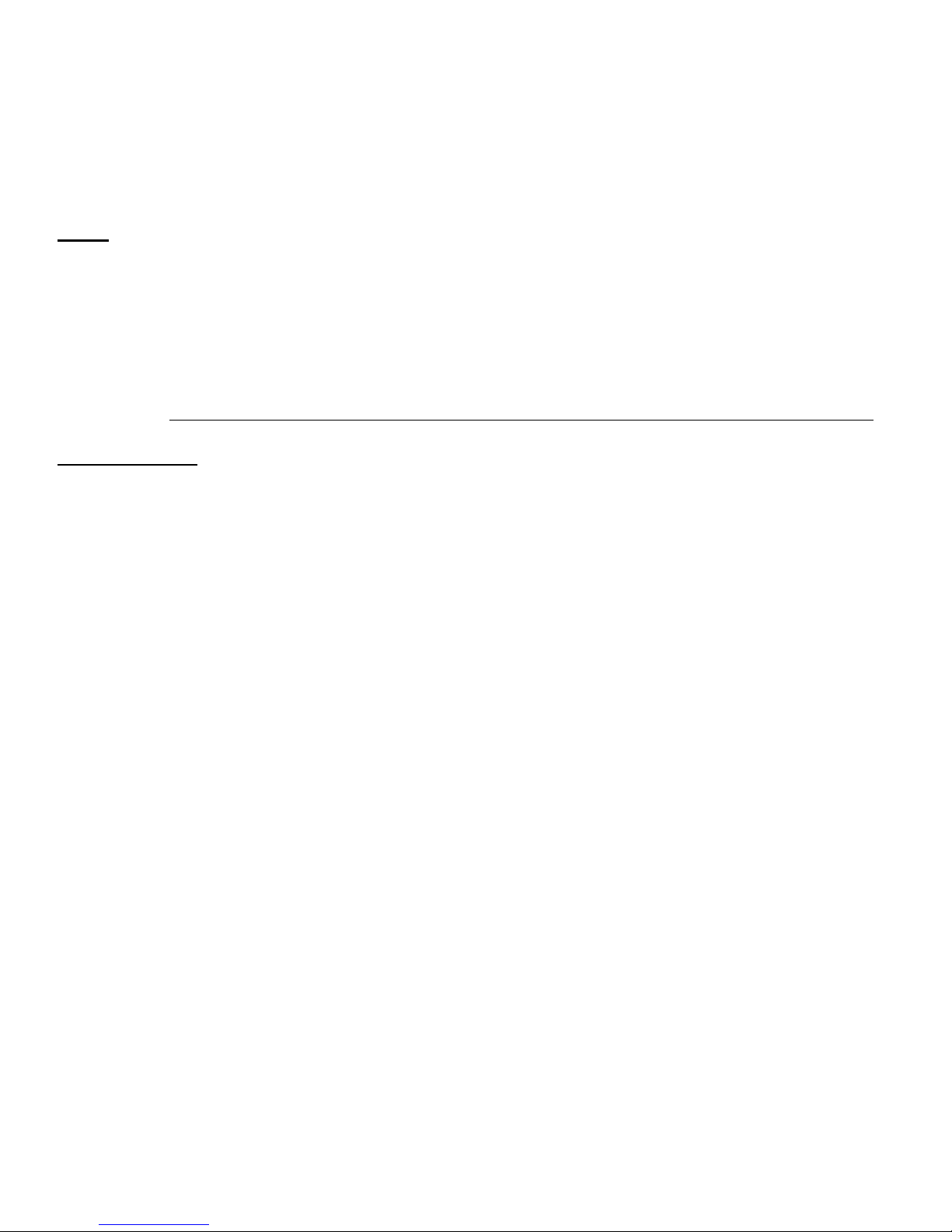

Minimum Mantle Clearance Without Hood Minimum Mantle Clearance With Hood

HEAT

RESISTANT

MATERIAL

12”

MINIMUM

HEAT

RESISTANT

MATERIAL

8”

MINIMUM

NOTE: The stated installation clearances provide the safest distance for combustible materials to

ensure that walls, ceilings and mantle components will not be affected by heat discoloration,

warpage, or possible fire. Each appliance installation presents a different set of variables which

can create problems beyond the control of the gas log manufacturer. It is the responsibility of

the installer to stay within the minimum clearances stated and set forth by the manufacturer

within this instruction manual.

Page 7

INSTALLATION INSTRUCTIONS WHEN

INSTALLING AS A VENT FREE APPLIANCE

The installation of this appliance must conform with local codes or, in the absence of local codes with

the National Fuel Gas Code, ANSI Z223.1.

NOTE: Before the unit is connected to any gas line, check the name plate on the unit for the proper

gas type you will be using.

The appliance regulator furnished on the appliance is not intended to regulate any gas pressure above ½psig.

If using LP gas, a low pressure regulator (not furnished) must be installed in the gas line between the tank

and appliance. Do not connect the appliance to the gas line if this regulator is not in place. If using natural

gas, check with the gas company to insure that proper gas pressure is available.

WARNING: An explosion could occur if a connection is made directly to an unregulated LP gas tank.

GAS

PRESSURE: Minimum inlet gas supply pressure must be 5.0” WC for natural gas or 11” WC for

LP gas for the purpose of input adjustment. Maximum inlet gas supply pressure must not exceed 10.5”

WC for natural gas, or 14” WC for LP gas. The gas line supplying the appliance must be sufficient size

to furnish the appropriate supply pressure to the appliance when being operated on the high setting.

+ The appliance and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of ½

psig (3.5kPa).

+ The appliance must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ½psig (3.5kPa).

+ Always keep appliance area clear and free from combustible materials, gasoline and other

flammable vapors and liquids.

+ Pressure tap screws must be closed before turning on gas to appliance.

+ Any outside air ducts and/or ash dumps in the fireplace shall be permanently closed at the

time of the appliance installation.

+ Special provisions should be made if the unit is to be installed into a sunken fireplace by

raising the floor of the fireplace using non-combustible materials to ensure adequate

airflow.

7

Page 8

8

ASSEMBLY INSTRUCTIONS

1. Remove grate/burner assembly from the box and place in the center of the fireplace.

2. Connect the gas line to the appliance regulator located under the grate. NOTE: The manual and

thermostat valve units will have this appliance regulator. The millivolt valve will not have this

regulator. The appliance regulator is built into the millivolt valve and the gas line is connected to the

valve.

3. Make sure the gas connections are tight. Turn on the gas and coat each joint with a soap and water

solution and watch for air bubbles, which will indicate leaks. Any leaks must be corrected before

proceeding with installation. DO NOT USE A FLAME OR ANY IGNITION SOURCE TO

CHECK FOR LEAKS.

4. Remove logs from the box. Notice the notches in the larger logs and the numbers on the bottom of

the same logs. The log placement is very important to the safe operation of the appliance.

NOTE: Match the log placement photo in this instruction manual with the model number of your log set

for correct log placement. The logs MUST be placed exactly as shown. If there is any evidence of carbon or

blackening on the logs, they may be incorrectly placed. There should not be any carbon or blackening on

the logs at any time.

5. Place the back log in the grooves on the elevated cradle toward the back of the grate making sure

the grooves in the bottom of the log fit on the cradle.

6. Place the middle log in the grooves on the center elevated section of the cradle making sure the

grooves in the bottom of the log fit on the cradle. This will position this log between the burner.

7. Place the front log on the front of the grate in front of the cradle making sure the grooves on the

bottom and front of the log fit the bars on the grate.

8. Place the small top logs in the grooves on top of the front and back log, making sure these logs lay

across the middle log in the appropriate groove.

9. Match the model number of your log set with the log set on pages 13 and 14 of this instruction

manual. Your log set should look like this. If it doesn’t, follow steps 5 through 8 above.

This appliance may be installed in an aftermarket *permanently located, manufactured (mobile)

home, where not prohibited by state or local codes.

*Aftermarket: Completion of sale, not for the purpose of resale, from the manufacturer.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is

not convertible for use with other gases.

Page 9

9

OPERATING INSTRUCTIONS

for

LOG SET AS IT COMES FROM THE FACTORY

If a wall switch, thermostat or remote control has been purchased, you must follow installation and operating

instructions on pages 11and 12 of this instruction manual.

HM2-MAN 18,24 & 33 LP and Natural Gas (See FIG. 1)

1. Notice the white marker line between the igniter button and the control knob. This white marker

line is the line-up mark for the control knob.

2. Follow the safety information on page 15 of this instruction manual.

3. Follow the lighting instructions on page 15 of this instruction manual.

4. NOTE: Your log set main burner will ignite when you complete the next step.

5. Once the pilot is lit, rotate the control knob counterclockwise . As you rotate the control knob

counterclockwise , the main burner will ignite on the minimum heat setting. Continuing to

rotate the knob counterclockwise will allow the burner to increase to the highest setting. You

can leave the control knob where you prefer, either at the low or high setting.

6. To turn the main burner OFF, simply rotate the control knob clockwise to the “PILOT”

position. This will allow the pilot to continue to burn, until you are ready to burn the set again.

7. Your log set has two settings, HI and LOW. You can burn your log set at the range you prefer.

8. To turn you log set completely off, simply rotate the control knob clockwise to the “OFF”

position. If this is done, the pilot must be re-ignited the next time you use your log set.

HM2-T 18,24 & 33 LP and Natural GAS (See FIG. 1)

1. Notice the white marker line between the igniter button and the control knob. This white marker

line is the line-up mark for the control knob.

2. This log set operates by a thermostatic bulb that is attached to the control valve. The manufacturer

attaches the bulb at a location that should give you fairly accurate operation of the control, however,

the bulb can be relocated to a place farther away from the flame. If this is done, be sure not to crimp

the small tube that attaches the bulb to the valve. This will cause damage resulting in thermostat

malfunction.

3. Follow the safety information on page 15 of the instruction manual.

4. Follow the lighting instructions on page 15 of this instruction manual.

5. NOTE: Your log set main burner will ignite when you complete the next step.

6. Once the pilot is lit, rotate the control knob counterclockwise . As you rotate the control knob

counterclockwise , the main burner will ignite first on the minimum heat setting. Continuing to

rotate the knob counterclockwise will allow the burner to increase to the highest setting.

FIG. 1

IGNITER

CONTROL

KNOB

Page 10

10

7. Allow the unit to operate at the highest setting until the room temperature reaches your comfort

level.

8. Turn the control knob clockwise until the flame goes out. This sets the control valve to operate

in this temperature range.

9. After the log set cycles a few times, you can increase or decrease the temperature setting simply by

rotating the control knob toward “HI” or “LOW”.

10. To turn the main burner off, simply rotate the control knob clockwise to the “PILOT” position.

This will allow the pilot to continue to burn until you are ready to use the log set again.

11. To turn the log set completely off, rotate the control knob clockwise to the “OFF” position. If

this is done, the pilot must be re-ignited the next time you use your log set.

HM2-MIL 18, 24 & 33 LP & Natural Gas (See FIG. 2)

NOTE: This log set is shipped from the factory to operate without the use of any accessory (i.e. wall switch,

thermostat, remote control). If any of these accessories are used, you must follow the appropriate instructions

for these accessories.

+ Notice the marking slots that are located adjacent to the control knobs. These notches are the line-

up points for the control knob positions.

+ The ON/OFF control knob cannot be turned unless it is pushed in slightly.

1. Place the ON/OFF control knob in the “OFF” position.

2. Follow the safety information on page 16 of this instruction manual.

3. Follow the lighting instructions on page 16 of this instruction manual.

4. NOTE: Make sure the ON/OFF switch is in the “OFF” position or your log set main burner will ignite

when you follow the next step.

5. Once the pilot is lit, rotate the ON/OFF control knob counterclockwise to the “ON” position.

6. Flip the ON/OFF switch to the “ON” position.

7. You can now set the log set to HI or LOW by turning the HI/LOW knob to the desired position.

8. Your log set can be operated at any position between HI or LOW, depending on the amount of heat

output you prefer.

9. To turn the main burner off, flip the ON/OFF switch to the “OFF” position. This will allow the pilot

to continue to burn until you are ready to use the log set again.

10. To turn the log set back on, flip the ON/OFF switch to the “ON” position. (You can turn your log set

off and on with the toggle switch.)

11. To turn your log set completely off, flip the ON/OFF switch to the “OFF” position and rotate the

ON/OFF control knob clockwise to the “OFF” position. If this is done, the pilot must be reignited the next time you use the log set.

THTP

TP TH

PILOT

it

PILOT

S

ON

OFF

LO

HI

FIG. 2

PIEZO

ON/OFF

SWITCH

Page 11

INSTALLATION INSTRUCTIONS for HM2 MIL 18,24 & 33 ACCESSORIES

(Wall Switch, Thermostat, Remote Control)

WALL SWITCH

+ It is suggested by the manufacturer that a qualified individual complete this installation.

+ Your HM2 MIL Series log set is shipped from the factory set up to operate without the use of any

of the accessories. To hook up this accessory you must follow these instructions:

+ Notice the electric terminal block on the control valve, located on the left hand side of the valve

when facing the front of the valve and the two wires that are attached to the back of the ON/OFF

switch. (FIG. 3)

1. Remove the wire that is connected to the two terminals marked TH on the terminal block

and remove the other ends of the wires that are attached to the ON/OFF switch and discard

the wire.

2. Run wire (included) from the log set to the location of the wall switch.

3. It is recommended that only the wire furnished with the thermostat

is used.

4. Attach the two wires to the wall switch, one to each of the terminals on the wall switch.

5. Make sure the wall switch is turned off and install the switch in the wall box (not furnished) and

install the cover.

6. Attach the two wires at the log set to the two terminals marked TH on the terminal block. (Make

sure the wall switch is turned off.)

7. Notice the notch in the metal plate on the right hand side of the ON/OFF knob. This notch is the

line-up mark for the ON/OFF control knob.

8. Follow the safety information on page 16 of this instruction manual.

9. Follow the lighting instructions on page 16 of this instruction manual.

10. After lighting the pilot and turning on the main ON/OFF control knob, turn the wall switch to the

“ON” position. This should cause the gas log set to come on. You can now adjust the HI/LOW knob

to the desired level.

11. You can turn your log set off and on with the wall switch and not use the ON/OFF control knob.

12. It is recommended that you turn the ON/OFF control knob to the “OFF” position when leaving

home for any period of time.

WALL THERMOSTAT

+ It is suggested by the manufacturer that a qualified individual complete this installation.

+ Your HM2 MIL Series log set is shipped from the factory set up to operate without the use of any

of the accessories. To hook up this accessory you must follow these instructions:

+ Notice the electric terminal block on the control valve, located on the left hand side of the valve

when facing the front of the valve and the two wires that are attached to the back of the ON/OFF

switch. (FIG. 3)

1. Remove the jumper wire that is connected to the two terminals marked TH on the terminal block

and remove the other ends of the wires that are attached to the ON/OFF switch and discard the

wire. (NOTE: The ON/OFF switch will no longer have any function once you have installed one of

the accessories.)

2. Run wire (included) from the log set to the location of the wall thermostat.

3. It is recommended that only the wire furnished with the thermostat is used.

THTP

TP TH

PILOT

it

PILOT

S

ON

OFF

LO

HI

FIG. 3

PIEZO

ON/OFF

SWITCH

TH

11

Page 12

4. Attach the two wires to the wall thermostat, one to each of the terminals on the wall thermostat.

5. Make sure the ON/OFF lever on the wall thermostat is turned off and mount the wall thermostat.

The cover of the thermostat snaps off for access to the mounting screw location.

6. Attach the two wires at the log set to the two terminals marked TH on the terminal block. (Make

sure the wall thermostat is turned off.)

7. Notice the notch in the metal plate on the right hand side of the ON/OFF knob. This notch is the

line-up mark for the ON/OFF control knob.

8. Follow the safety information on page 16 of this instruction manual.

9. Follow the lighting instructions on page 16 of this instruction manual.

10. After lighting the pilot and turning on the main ON/OFF control

knob, turn the wall thermostat ON/OFF lever to the “ON” position.

Adjust the temperature lever to the desired position. The gas log set

will operate on and off depending on the position of the temperature control lever. You can

now adjust the HI/LOW knob to the desired level. If you have the HI/LOW control knob on “HI”

the log set will burn on high flame when the thermostat calls for heat. If you have the HI/LOW

control knob on “LOW” the log set will burn on low flame when the thermostat calls for heat.

11. You can allow your log set to operate by the thermostat setting or, you can keep the log set from

operating by turning the ON/OFF lever to “OFF” on the thermostat.

12. It is recommended that you turn the ON/OFF control knob on the control valve to the “OFF”

position when leaving home for any period of time.

THERMOSTAT REMOTE CONTROL

+ It is suggested by the manufacturer that a qualified individual complete this installation.

+ Your HM2 MIL Series log set is shipped from the factory set up to operate without the use of any

of the accessories. To hook up this accessory you must follow these instructions:

+ Notice the electric terminal block on the control valve, located on the left hand side of the valve

when facing the front of the valve and the two wires that are attached to the back of the ON/OFF

switch. (FIG. 3)

1. Remove the jumper wire that is connected to the two terminals marked TH on the terminal block

and remove the other ends of the wires that are attached to the ON/OFF switch and discard the

wire. (NOTE: The ON/OFF switch will no longer have any function once you have installed one of

the accessories.)

2. Follow the instructions supplied with the Thermostat Remote Control. This is a millivolt gas valve.

It is recommended by Heatmaster, Inc. that all precautions are followed exactly. (In the instructions

supplied with the remote control, there are instructions about a crackling sound system. This is an

optional system and is not available from Heatmaster, Inc.)

3. Notice the notch in the metal plate on the right hand side of the ON/OFF knob. This notch is the

line-up mark for the ON/OFF control knob.

4. Follow the safety information on page 16 of this instruction manual.

5. Follow the lighting instructions on page 16 of this instruction manual.

6. After lighting the pilot and turning on the main “ON/OFF” control knob, you can now operate

the log set according to the remote control instructions. You can now adjust the HI/LOW knob

to the desired level. There is a notch in the metal plate at the bottom of the HI/LOW control knob

that is used for a line-up mark. If you have the HI/LOW control knob on “HI” the log set

will burn on high flame when the thermostat calls for heat. If you have the HI/LOW

control knob on “LOW” the log set will burn on low flame when the thermostat calls for heat.

7. It is recommended that you turn the ON/OFF control knob on the control valve to the “OFF” position

when leaving home for any period of time.

12

FIG. 3

PIEZO

ON/OFF

SWITCH

TH

TP TH

HI

S

LO

OFF

THTP

PILOT

it

ON

PILOT

Page 13

LOG PLACEMENT PHOTOS (RO SERIES)

HM2-RO-18 Front View HM2-RO-18 Side View

HM2-RO-24 Front View HM2-RO-24 Side View

HM2-RO-33 Front View HM2-RO-33 Side View

13

WARNING: Failure to position the parts in accordance with these diagrams or failure to use only the

parts specifically approved with the heater may result in property damage or personal

injury.

Page 14

LOG PLACEMENT PHOTOS (SO SERIES)

HM2-SO-18 Front View HM2-SO-18 Side View

HM2-SO-24 Front View HM2-SO-24 Side View

HM2-SO-33 Front View HM2-SO-33 Side View

14

WARNING: Failure to position the parts in accordance with these diagrams or failure to use only the

parts specifically approved with the heater may result in property damage or personal

injury.

Page 15

15

FOR YOUR SAFETY READ BEFORE LIGHTING

A. This appliance has a pilot which must be lighted by hand. When lighting the pilot, follow these instructions exactly.

This appliance is equipped with a push button piezo ignition device which can be used to light the pilot. If the piezo

fails to ignite the pilot, then follow the instructions for lighting pilot with match.

B. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

+ Do not try to light any appliance.

+ Do not touch any electrical switch; do not use any phone in your building.

+ Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

+ If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control handle. Never use tools. If the handle will not push in or turn

by hand, do not try to repair it. Call a qualified service technician. Force or attempted repair may result in fire or

explosion.

D. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and any gas control which has been under water.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information previously listed above.

2. Turn gas control knob clockwise to the “OFF” position. Do not force. (FIG. 5)

3. Wait five (5) minutes to clear out any gas. Then smell for gas, including near the floor. If you smell gas, STOP! Follow

“B” in the safety information above on this label. If you don’t smell gas, go to the next step.

4. Locate pilot - follow metal tube from gas control. The pilot is mounted on a bracket that is fastened to the side of the

right hand cradle. (FIG. 4)

5. Turn knob on gas control (FIG. 5) counterclockwise to the “PILOT” position.

6. Push in control knob all the way and hold in. While still holding the control knob, press in the igniter push button

(FIG. 5) several times. This will cause a spark at the pilot burner which will ignite the pilot flame. Continue to hold

the control knob (FIG. 5) in for about (1) minute after the pilot is lit. Release knob and it will pop back out. Pilot

should remain lit. If it goes out, repeat steps 1 through 6.

+ If the knob does not pop out when released, stop and immediately call your service technician or gas supplier.

+ If the pilot will not stay lit after several tries, turn the gas control knob to “OFF” and call your service technician or

gas supplier.

+ LIGHTING PILOT WITH MATCH: Turn control knob (FIG. 5) to the “PILOT”position. Place a lit match at the

pilot burner (FIG. 4), then push the knob in. Continue to hold the control knob in for about one (1) minute after the

pilot is lit. Release knob and it will pop back out. Pilot should remain lit. If it goes out, repeat the above step.

+ If the pilot will not stay lit after several tries, turn the gas control knob (FIG. 5) to “OFF” and call your service

technician or gas supplier.

7. Turn knob counterclockwise to “HI” or “LOW”.

TO TURN OFF GAS TO APPLIANCE

Turn gas control knob (FIG. 5) clockwise to the “OFF” position. Do not force. If optional power is used, it must be

turned off.

FIG. 4

WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing property damage,

personal injury or loss of life.

FIG. 5

IGNITER

CONTROL KNOB

IGNITER

PILOT BURNER

Page 16

16

FOR YOUR SAFETY READ BEFORE LIGHTING

A. This appliance has a pilot which must be lighted by hand. When lighting the pilot, follow these instructions exactly.

This appliance is equipped with a push button piezo ignition device which can be used to light the pilot. If the piezo

fails to ignite the pilot, then follow the instructions for lighting pilot with match.

B. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

+ Do not try to light any appliance.

+ Do not touch any electrical switch; do not use any phone in your building.

+ Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

+ If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob. Never use tools. If the knob will not push in or turn

by hand, do not try to repair it. Call a qualified service technician. Force or attempted repair may result in fire or

explosion.

D. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and any gas control which has been under water.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information previously listed above.

2. Turn main gas control knob (FIG. 7) clockwise to the “OFF” position.

3. Wait five (5) minutes to clear out any gas. Then smell for gas, including near the floor. If you smell gas, STOP! Follow

“B” in the safety information above on this label. If you don’t smell gas, go to the next step.

4. Locate pilot - mounted on the inside of the right hand bracket that holds the burner in place, just behind the front

part of the burner. (FIG. 6)

5. Depress main control knob (FIG. 7) slightly and turn counterclockwise to the “PILOT” position.

With main control knob (FIG. 7) at “PILOT”, depress until it stops and press on the igniter push-button several

times. (FIG. 7) This will cause a spark at the pilot burner which will ignite the pilot flame. Continue to hold the main

control knob (FIG. 7) in for about (1) minute after the pilot is lit. Release knob and it will pop back out. Pilot

should remain lit. If it goes out, repeat steps 1 through 5.

+ If the knob does not pop out when released, stop and immediately call your service technician or gas supplier.

+ LIGHTING PILOT WITH MATCH: Turn main control knob (FIG. 7) to the “PILOT”position. Place a lit match at

the pilot burner, then push the main control knob in. Continue to hold the control knob in for about one (1) minute

after the pilot is lit. Release knob and it will pop back out. Pilot should remain lit. If it goes out, repeat the above

step.

+ If the pilot will not stay lit after several tries, turn the gas control knob (FIG. 7) to “OFF” and call your service

technician or gas supplier.

6. Slightly depress main control knob (FIG. 7) and turn counterclockwise to the “ON” position. Adjust heat output

to the desired level by turning the HI/LOW control knob.

TO TURN OFF GAS TO APPLIANCE

Turn main gas control knob (FIG. 7) clockwise to the “OFF” position. Do not force.

FIG. 6

WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing property damage,

personal injury or loss of life.

FIG. 7

ON/OFF

SWITCH

PIEZO

PILOT BURNER

IGNITOR

TP TH

THTP

HI

LO

PILOT

S

OFF

it

ON

PILOT

Page 17

CLEANING AND MAINTENANCE INSTRUCTIONS

ALWAYS REMEMBER:

1. Do not operate this appliance without the fireplace screen closed.

2. Do not place any combustible material near the appliance.

3. Do not place any paper, trash or other material on the log set or in the heater.

4. Do not touch any part of the appliance when the unit is operation.

Your gas log set is designed to be virtually maintenance free, although periodic visual inspection and

cleaning is required. Follow the instructions below for the correct procedures.

If at any time the flames on your log set look abnormal or an odor is noticed that you feel is coming

from the appliance, contact a qualified service technician or the gas company.

Periodically, visually inspect the main burner flames as well as the pilot flame. The appearance of these

flames should resemble the drawings on page 18. Any measurements are approximate. Flame heights

may vary slightly.

Fireplaces can be very dusty areas, therefore at least monthly during the heating season clean the unit

by following the guidelines below.

CAUTION: Before cleaning the appliance, be sure it is turned completely off. The pilot should also be

turned off. The unit must be completely cooled.

DO NOT USE ANY CLEANING FLUIDS OR TOOLS FOR CLEANING PURPOSES

1. Remove logs from grate assembly and place on the floor close to the fireplace.

2. Lightly vacuum any loose particles or dust from the grate and burner.

3. Lightly vacuum any loose particles or dust from the pilot flame area, being sure not to touch any part

of the pilot with the vacuum.

4. Lightly vacuum any dust from the logs.

NOTE: If any of the appliance parts are hit with the vacuum or the grate assembly is moved during

cleaning, gas leaks could occur. If this happens, be sure to check for leaks as described in this

instruction manual.

5. Carefully replace logs on the grate assembly and relight the pilot as instructed in this manual.

17

Page 18

18

MANUAL AND THERMOSTATIC VALVES

MILLIVOLT VALVES

18” Log Set 24” Log Set

33” Log Set

PROPANE GAS NATURAL GAS

NATURAL GAS PROPANE GAS

Page 19

INSTALLATION INSTRUCTIONS

WHEN INSTALLING AS A VENTED DECORATIVE APPLIANCE

When installing as a vented appliance, the following statements and charts must be followed.

+ Thermostat models can not be installed as a vented appliance under ANSI Z21.60-CGA 2.26-

M96T standard (i.e. HM2-Tstat-24 and HM2-Tstat-33).

+ This appliance must be installed only in a solid-fuel burning fireplace with a working flue, and

constructed of noncombustible material.

+ Solid fuels shall not be burned in a fireplace where a decorative appliance is installed.

The minimum permanent free opening (in square inches) that must be provided by either a

fireplace chimney or chimney damper must be provided (See chart on next page.)

+ The chimney damper must be fixed in a manner which will maintain the minimum permanent

vent opening at all times. To accomplish this, install a damper clamp on the edge of the damper

blade to prevent its closing, or drill a hole or holes in the damper.

+ See chart below when installing as a vented decorative appliance for the minimum size

fireplace that can be used.

Height of Front

Opening

Width of Front

Opening

Depth

HM2-18LP

HM2-18 NAT

HM2-MIL-18LP

HM2-MIL-18NAT

15”

20”

14”

HM2-24LP

HM2-24-NAT

HM2-MIL-24LP

HM2-MIL-24NAT

15”

25”

14”

HM2-33-LP

HM2-33-NAT

HM2-MIL-33LP

HM2-MIL-33NAT

15”

34”

14”

19

Page 20

20

TABLE 1A

for

FACTORY BUILT FIREPLACES

Free opening area of chimney damper for venting combustion products from decorative appliances for

installation in solid fuel burning fireplaces.

TABLE 2A

for

MASONRY BUILT FIREPLACES

Free opening area of chimney damper for venting combustion products from decorative appliances for

installation in solid fuel burning fireplaces.

MINIMUM PERMANENT FREE OPENING IN SQUARE INCHES

Chimney

Height (Feet)

10

15

20

25

30

35

40

18” Log Set

LP Gas

16.6

12.6

10.8

9.6

9.1

8

7.5

18” Log Set

Natural Gas

16.6

12.6

10.8

9.6

9.1

8

7.5

24” Log Set

LP Gas

22.1

17.3

14.5

12.6

11.3

10.8

10.2

24” Log Set

Natural Gas

22.1

17.3

14.5

12.6

11.3

10.8

10.2

33” Log Set

LP Gas

22.1

17.3

14.5

12.6

11.3

10.8

10.2

33” Log Set

Natural Gas

22.1

17.3

14.5

12.6

11.3

10.8

10.2

MINIMUM PERMANENT FREE OPENING IN SQUARE INCHES

Chimney

Height (Feet)

6

8

10

15

20

30

18” Log Set

LP Gas

25.7

23.7

21.7

19.9

18.5

16.9

18” Log Set

Natural Gas

25.7

23.7

21.7

19.9

18.5

16.9

24” Log Set

LP Gas

33.8

31.2

28.7

26.1

23.7

21.6

24” Log Set

Natural Gas

33.8

31.2

28.7

26.1

23.7

21.6

33” Log Set

LP Gas

33.8

31.2

28.7

26.1

23.7

21.6

33” Log Set

Natural Gas

33.8

31.2

28.7

26.1

23.7

21.6

Page 21

21

LOG PARTS LIST

KEY

NUMBER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

PART NO.

Log # 429

Log # 430

Log # 431

Log # 432

Log # 444

Log # 409

Log # 439

Log # 440

Log # 441

Log # 416

Log # 438

Log # 415

Log # 426

Log # 427

Log # 428

Log # 410

Log # 409

Log # 424

Log # 408

Log # 435

PART NO.

Log # 436

Log # 437

Log # 416

Log # 438

Log # 415

Log # 405

Log # 406

Log # 407

Log # 410

Log # 409

Log # 408

Log # 274

Log # 411

Log # 412

Log # 413

Log # 414

Log # 416

Log # 433

Log # 415

Log # 274

Log # 434

DESCRIPTION

Front Log

Middle Log

Back Log

Right Log

Left Log

Middle Top Log

Front Log

Middle Log

Back Log

Right Log

Left Log

Middle Top Log

Front Log

Middle Log

Back Log

Right Log

Left Bottom Log

Left Top Log

Middle Top Log

Front Log

KEY

NUMBER

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

DESCRIPTION

Middle Log

Back Log

Right Log

Left Log

Middle Top Log

Front Log

Middle Log

Back Log

Right Log

Left Bottom Log

Left Top Log

Center Right Log

Center Left Log

Front Log

Middle Log

Back Log

Right Log

Left Top Log

Left Bottom Log

Center Bottom Log

Center Right Log

Parts may be ordered directly from:

HEATMASTER, INC.

3625 Benson Road, P.O. Box 1717

Angier, NC 27501

(919) 639-4568

When ordering, please include complete part number, part name and description.

HM2-RO-18 HM2-RO-24 HM2-RO-33

HM2-SO-18 HM2-SO-24 HM2-SO-33

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

28

29

30

31

32

33

34

35

36

37

38

39

40

41

27

Page 22

PARTS DIAGRAM

22

D

F

E

HM2 MANUAL LP & NAT PILOT

A

S

I

D

G

B

FF

C

K

F

C

D

E

HM2 MILLIVOLT LP PILOT

C

C

D

DD

Q

TP TH

B

CC

FF

TO ALL PILOTS

E

PILOT REGULATORS FOR ALL NAT.

D

EE

H

T

TO PILOT HOLE ON VALVE

U

T

HI

THTP

PILOT

HM2 MILLIVOLT VALVE ASSEMBLY

Y

V

E

W

D

N

OUT

IN

S

LO

OFF

it

ON

PILOT

X

D

Y

Z

C

CARLING

AA

BB

ON

AA

OFF

O

D

GG

J

K

L

HM2 MILLIVOLT NAT PILOT

R

M

HM2 MANUAL VALVE ASSEMBLY

Q

N

DD

B

F

E

CC

FF

O

P

Page 23

PARTS LIST

KEY

LETTER

A

A

A

B

B

B

C

D

E

F

F

F

F

G

H

I

I

I

J

K

L

L

M

N

N

PART NO.

11-1181b

11-1182b

11-1183b

11-1350

16-1100

16-1110

01-1080

01-1095

11-1076

11-1075

11-1080

16-1040

16-1045

11-1060

03-1000

11-1265b

11-1270b

11-1275b

11-1295

01-1004

06-1030

06-1031

11-1185

11-1095

11-1100

PART NO.

16-1030

16-1035

11-1164

11-1166

11-1170

11-1036

03-1003

01-1031

11-1036

11-1155

11-1150

16-1050

03-1000

07-1020

16-1014

01-1158

16-1120

11-2265

16-1125

11-1445

02-1075

11-1101

16-1130

11-1441

DESCRIPTION

Burner, HM2-18

Burner, HM2-24

Burner, HM2-33

Pilot Bracket for HM2 Manual

Pilot Bracket for LP HM2 Millivolt

Pilot Bracket for NAT HM2 Millivolt

Screw, 10-32 X 1/2"

Nut, 10-32

Nut & ferrule for 3/16" tubing

#57 Pilot ODS LP (Manual Valve)

#56 Pilot ODS NG(Manual Valve)

ODS Pilot (LP Millivolt Valve)

ODS Pilot (NG Millivolt Valve)

Thermocouple

3/16" Pilot gas line 16"

Grate, HM2-18

Grate, HM2-24

Grate, HM2-33

Valve Cover Plate

Brass 3/8" MPT to 3/8" Flare Male

Half Union

Regulator 10.0 (LP) 3/8"

Regulator 4.0 (Nat) 3/8"

3/8" Nipple 3.5" long

Valve, Manual SIT 522

Valve, Thermostatic SIT 504

KEY

LETTER

N

N

O

O

P

Q

R

R

S

T

U

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

GG

DESCRIPTION

Valve, Millivolt LP 10"

Valve, Millivolt NAT 3.5"

Piezo (Manual and Thermostatic)

Piezo (Millivolt Valve Assembly)

Screw, 10-32 X 2 1/2"

Burner Orifice (HMU style)

3/8" Gas Line 12" long

3/8" Flare Nuts

Valve Orifice (HMU style)

Compression connectors, 3/16

Com X 1/8 MPT (Nat Only)

Maxitrol 3.0" Pilot Reg (Man/Therm

Nat Only)

Maxitrol 4.5" Pilot Reg (Millivolt Nat

Only)

3/16" Pilot gas line 2.5" (Nat Only)

3/8" NPT 90° St Elbow

14" long Jumper with 4 Female

Spade Cripons

Screw, 10-32 x 1/4" (Millivolt Valve Only)

HM2 Millivolt Valve Bracket

Carling Single Pole / Single Throw Switch

On/Off Indicator for Switch Y01

Screw, 8-32 x 5/16

Keps Nut, 8-32

Thermostatic bulb holding Plastic Clip

Piezo Wire 12"

3/16" Loxit Nut & Sleeve

23

Parts may be ordered directly from:

HEATMASTER, INC.

3625 Benson Road, P.O. Box 1717

Angier, NC 27501

(919) 639-4568

When ordering, please include complete part number, part name and description.

Page 24

24

HEATMASTER, INC.

LIMITED WARRANTY

All refractory cement logs manufactured by HEATMASTER, Inc. have a lifetime warranty against

breakage due to heat to the original owner in the original installation.

All other logs supplied from HEATMASTER, Inc. have a 2 year warranty against breakage due to heat to

the original owner in the original installation.

+

All metal parts, including burners and grate assemblies are warranted for 5 years.

+

All other mechanical parts are warranted for 1 year.

LIMITATIONS

1.

2.

3.

4.

5.

HEATMASTER, Inc.’s obligations to the purchaser under this warranty is limited to the repair or

replacement of defective part.

Repairs or replacement will be performed by HEATMASTER, Inc. following delivery of the product

by the purchaser to HEATMASTER, Inc.’s facility in Angier, North Carolina. The cost of mailing or

other delivery to HEATMASTER, Inc. shall be borne by the purchaser. The mailing address is:

HEATMASTER, Inc., P.O. Box 1717, 3625 Benson Rd., Angier, NC 27501.

Along with the product, the purchaser shall include a written explanation of the approximate date the

product was purchased, the dealer or person from whom the product was purchased, the date the defect

was first noticed, a description of the nature of the defect, and what the purchaser did, if anything, to

repair or correct the defect.

To the extent allowed by law, any implied warranty of merchantability or fitness applicable to this

product is limited to the duration of this warranty. HEATMASTER, Inc. shall not be liable for loss of

use of this product, loss of time, inconvenience, commercial loss or consequential damages. The remedy

of repair or replacement of a defective part during the warranty period herein specified shall be the

purchaser’s exclusive remedy.

HEATMASTER, Inc. is not responsible for any loss or damages caused by purchaser’s failure to follow

operating and maintenance instructions provided in the owner’s manual.

*******************************

Dear Purchaser:

We are pleased that you have selected our product and take this opportunity to assure you that qualified

service is available if required.

Please review and complete the enclosed Warranty/Registration card.

Who gets the warranty?

What is covered?

What is not covered?

DEFECTIVE PARTS OR BROKEN LOGS FOR REPLACEMENTS MUST BE RETURNED TO

THE FACTORY PREPAID ALONG WITH PROOF OF PURCHASE. FACTORY WILL REPAIR OR

REPLACE AT FACTORY OPTION AND RETURN TO PURCHASER FREIGHT PREPAID.

The warranty is limited to the consumer who originally purchased the product.

This limited warranty covers all imperfections in workmanship and material.

This limited warranty does not cover damage resulting from accident, misuse

or abuse, lack of proper maintenance, affixing of any attachments not

provided with the products, or loss of parts. IN NO EVENT SHALL

HEATMASTER, INC. BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES RESULTING FROM MISUSE OR

MODIFICATION OF THIS PRODUCT.

Loading...

Loading...