Heatmaster G100, G400, G200 Operation And Maintenance Manual

G100, G200, G400

EPA Certified Wood Burning Furnaces

OPERATION AND MAINTENANCE MANUAL

Model: Serial #:

By SteelTech., INC. UL 2523-2009

Version 2 CAN/CSA B366.1-2011

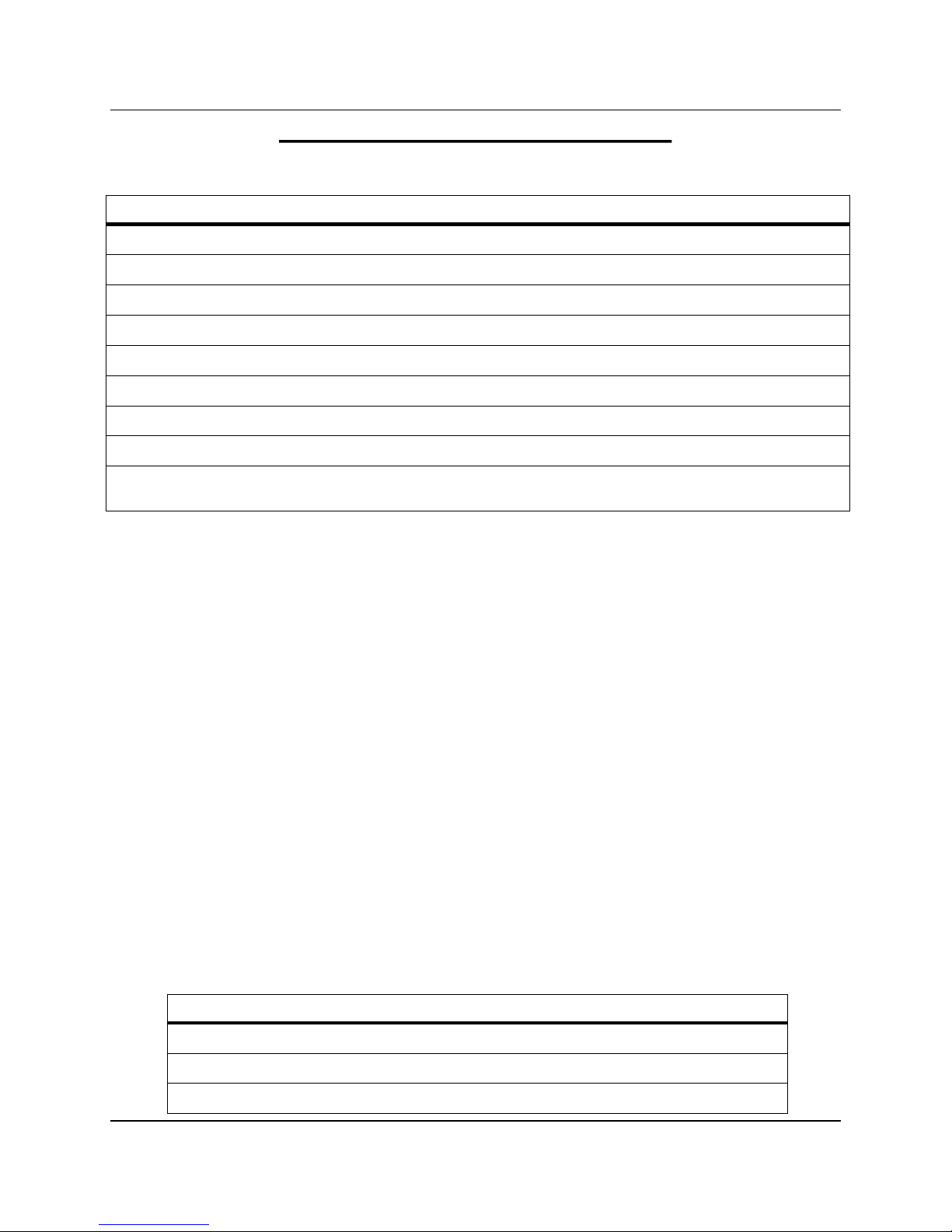

Table of Contents

Warranty & Safety

Warranty Registration & Delivery Form Front Insert

Warranty Details 1

Water Treatment & Testing 2

Safety Precautions 3

Furnace Installation Guide

Furnace Specifications 4

Location 4

Clearances to Combustibles 4

Foundation 5

Trench 5

Indoor Installation 6

Chimney 6, 7

Combustion Air for Indoor Installation 8

Wiring 9

Hydronic Lines 9

Furnace Connections 9

RETAIN THIS MANUAL FOR FUTURE REFERENCE

DO NOT THROW AWAY

CANADA

STEELTECH INC.

BOX 158

WINKLER MB. R6W 4A5

CANADA

PH. (204) 325-9792 FAX (204) 325-9803

STEELTECH INC.

BOX 373

WALHALLA ND 58282

PH. (877) 325-9792 FAX (204) 325-9803

info@heatmasterss.com

www.heatmasterss.com

System Flow Rates 10

Interior Connections 10-13

Operating The Furnace

Filling the Furnace with Water 14

Firing the Furnace 14

Wood Quality, Testing and Storage 15

Loading the Furnace 16

Operating a Gasification Furnace 17

How a Gasification Furnace Works 18

Controls & Safety Devices 19

Care and Maintenance

Troubleshooting

Electrical Troubleshooting

Wiring Diagrams

Cautionary Markings

Furnace Footprints

USA

20, 21

22-24

25-27

28, 29

30

31,32

G Series Outdoor Furnaces

LIMITED WARRANTY

SteelTech Inc. warrants to the original owner of the G Series outdoor furnace that it is free

from defects in workmanship and material, which could cause a leak or malfunction of the

firebox or water jacket, and against corrosion (if the instructions in the owners manual for wa-

ter treatment and maintenance are followed) for the life of the furnace toward the purchase of a

new Heatmasterss furnace, in the following pro-rated schedule.

Warranty schedule: coverage in the initial 5 years is 100%

Year 6-7 is 50%

Year 8-9 is 40%

Year 10-15 is 30%

Year 16-Life is 10%

In addition, all steel components including housing, legs, etc. have a pro-rated warranty for

a period of 10 years with coverage reducing by 10% per year. All firebrick used in the fur-

nace is not warranted. Any parts not manufactured by SteelTech Inc., that are used

on the furnace – such as thermostats, limit switches, pumps, heat exchangers – carry their

own manufacturer’s warranty. SteelTech Inc. will not be liable for the cost of shipping, replacement or repair of these parts.

If warranty requires removing or replacing of the furnace or a part on the furnace, Steel-

Tech Inc. is not responsible for the cost of plumbing, replacement of antifreeze or water

treatment, shipping cost or any other cost other than the replacement component or furnace. SteelTech Inc. always has the right to decide if a part or furnace will be repaired or

replaced and will not be liable for any cost not authorized by a SteelTech Inc representative.

SteelTech Inc. does not warranty any damage caused due to negligence and deterioration

due to lack of proper ongoing maintenance, physical damage caused by abuse or freeze

up, power surges or unauthorized work or modifications to the furnace.

SteelTech Inc. is not liable for any damage or cost which may occur from or during the op-

eration of the furnace or damage incurred due to any heating system failure. The purchaser

assumes all responsibility for the care, maintenance and safe operation the furnace including adding of approved boiler treatment or water. SteelTech Inc does not warrant door

gaskets, exterior paint or finish.

To qualify for warranty all instructions must be followed in operator’s manual, water must

be tested and maintained a minimum of once per year, and warranty registration must be

on file at SteelTech Inc Ind. within 30 days of purchase along with a copy of the original invoice. No warranty can be approved unless the warranty registration and water test verifications are on file at SteelTech Inc.’s office.

The warranty can be violated by operating the furnace in a manner inconsistent with the

owner’s manual

SteelTech Inc Reserves the right to change conditions of warranty at any time.

www.heatmasterss.com

- 1 -

G Series Outdoor Furnaces

WATER TREATMENT AND TESTING

Water Treatment Policy

To qualify for warranty, water must be tested a minimum of once per year and water treatment

added when necessary.

To take a water sample:

1. Locate your water sample bottle, mailing carton and mailing label provided to you by your dealer.

2. Open the boiler drain located at the bottom of the rear of the furnace for 10-15 seconds or until the

water runs clear. CAUTION: Water is hot! Use extreme care or a bucket to run water into and let

cool before collecting sample.

3. Fill one of the test bottles at least 1/2 to 2/3 full.

4. Fill out the mailing label provided with the test bottle completely, including your email address, the

model number and serial number of your furnace. Make sure to note if the furnace water contains

any antifreeze or additional chemicals.

5. Attach top part of label to sample bottle and bottom part to outside of mailing tube. Place bottle in

tube.

6. Mail to our testing lab. Results can take up to 4 weeks to receive and up to 8 weeks if no email

address is on hand at Heatmaster ss.

You will receive a water test report outlining what must be done (if anything). If any action is

necessary, take another sample and mail it to our test lab again to verify the recommended

changes have been made.

Add the water treatment through the fill pipe located at the top of the furnace when initially filling the furnace with water or after testing, if needed. Ensure that all drains are closed. It is recommended that

water treatment be added at a 1:200 ratio when initially firing the furnace and 1:300 after that. Additional

treatment may have to be added for water with more severe properties or for systems with more chemi-

cally demanding requirements.

Recommended operating levels are as follows:

Conductivity: 100 - 4000 ppm

pH: 8.5 – 10. 5

Nitrates: no less than 730 ppm

Test Parameters and What They Mean

Conductivity

Conductivity is a measurement of minerals in your furnace water. While it is common to have minerals in

water, in excess minerals can cause many problems in hydronic systems including scaling and corrosion.

pH

pH is measurement of alkalinity (hard or soft water). For outdoor furnace water and the water treatment

used in outdoor furnaces it is better to have your water a little harder than softer (recommended pH

range is 9-10.5) as the active ingredients in the water treatment neutralize harder water easier than softer water

Nitrates

Nitrates tested for are a measurement of how much water treatment is in the water. Nitrates measured

are active units of water treatment available to neutralize harmful elements in your furnace water. Nitrates also act to neutralize harmful bacteria that may build up in the furnace water over time.

Glycol

Inhibited glycol provides anti-corrosion elements and freeze protection for outdoor furnaces and is compatible with Outdoor Furnace Water Treatment. Because outdoor furnaces are open to the atmosphere

systems and will have fresh water added occasionally, oxygen is always entering the system and will

break down the glycol over time to create glycolic acid which will harm your furnace system. When this

happens you will be required to drain and flush your furnace system.

It is always suggested to use 100% virgin glycol instead of recycled glycol as it will break down much

sooner and create glycolic acid.

www.heatmasterss.com

- 2 -

G Series Outdoor Furnaces

SAFETY PRECAUTIONS

Read and understand all precautions before operating the furnace.

This wood heater needs periodic inspection and repair for proper operation. It is against

federal regulations to operate this wood heater in a manner inconsistent with operating

instructions in this manual.

ATTENTION: Save these instructions. Retain this manual as long as you own your

G SERIES outdoor furnace. Carefully read and follow these directions.

ATTENTION: BURN WOOD ONLY. LOAD FUEL CAREFULLY OR DAMAGE MAY

RESULT

ATTENTION: The person(s) operating this furnace must comply with all applicable

local and state laws or other requirements,

ATTENTION: The person(s) operating this furnace are responsible to run it in such a

way so that it does not cause a public or private nuisance. Consult with local authorities prior to installation to adhere to local laws and ordinances.

DANGER: Do not start fire with or burn garbage, gasoline, naptha, engine oil or

other inappropriate materials. Only competent persons with a sound understanding of

this heating method should operate this furnace. Improper firing could result in personal injury and/or damage to the unit and void warranty.

ATTENTION: DO NOT OVERFIRE THIS HEATER. Attempts to achieve heat output

rates that exceed the heater design specifications can result in permanent damage to

the heater.

WARNING: All installations and operations of your G SERIES product must follow

state, provincial, and local laws pertaining to operations, wiring, plumbing and building

codes.

WARNING: All models operate at atmospheric pressure. DO NOT obstruct, block or

plug the overflow vent tube in any way, which is located on top of the boiler .

CAUTION: Do not start or operate furnace without checking heating fluid. Furnace

must be filled until heating fluid comes out of vent pipe on the top of the furnace.

CAUTION: Check for buried cables and utility lines before digging the trench to your

furnace.

CAUTION: For safety and proper temperature control keep all doors closed during op-

eration.

WARNING: When installing the furnace, the chimney should never be connected

to a chimney flue serving another appliance

WARNING: Do not operate furnace in event of power failure

WARNING: Use caution when opening firebox and ash cleaning doors. Push by-

pass rod on front of furnace and slowly crack door open for at least 20 seconds before

opening door.

WARNING: Risk of fire:

- Do not operate with fuel loading or ash removal doors open.

- Do not store fuel or other combustible material within marked installation clear

ances

- Inspect and clean flues and chimney regularly

CAUTION: Hot Surfaces: Keep children away. Do not touch during operation.

www.heatmasterss.com

- 3 -

G Series Outdoor Furnaces

FURNACE INSTALLATION GUIDE

Installation should be performed by a qualified installer and will comply with all

requirements of the agency having jurisdiction.

Furnace Specifications

G100 G200 G400

Max BTU Output 120,000 BTU/hr 232,000 BTU/hr 330,000 BTU/hr

Heat Output (8 Hour Burn) 48,000 BTU/hr 111,500 BTU/hr 180,500 BTU/hr

Furnace Size (W x L x H) 36 x 56 x 74 48 x 72 x 79 51 x 84 x 86

Furnace Weight 1300 lbs 2400 lbs 3000 lbs

Firebox Dimensions (W x L x H) 18 x 18 x 31 28 x 29 x 34 28 x 40 x 39

Chimney Size 6” 6” 8”

Water Capacity 100 gallons 195 gallons 250 gallons

8 Hour Average Efficiency Using

Higher Heating Value of Wood

75.8% 79.0% 74.8%

LOCATION

Where you install the furnace will have an affect on the efficiency of your furnace. Alt-

hough the furnace is very well insulated, installing the furnace outdoors will mean some

heat loss at the furnace. The furnace will have less heat loss when installed indoors

away from the elements that can cause heat loss.

- Maintain adequate clearance of buildings and combustibles.

- Pile and store wood under shelter.

- Do not place or store wood within stove installation clearances or within the space re-

quired for charging and ash removal.

- For indoor installations where fans are used in the fuel storage area they should be

installed so as to not create any negative pressure in the room where your G SERIES

furnace is burning

- Contact all governing authorities in your area prior to installation.

- When choosing the location of your furnace you should consider prevailing wind direc-

tion, distance from home and wood storage for refueling.

- Give consideration for any effect on your neighbors.

CLEARANCES TO COMBUSTIBLES

Whether installing your G SERIES furnace inside a building or outside the following

clearances to combustibles must always be followed or damage and personal injury

may result:

Furnace Roof to Ceiling (Indoor Installations) 6”

Side Walls & Rear 6”

Front (Loading door) 24”

www.heatmasterss.com

- 4 -

Minimum Clearance to Combustibles

G Series Outdoor Furnaces

FURNACE INSTALLATION GUIDE

Installation should be performed by a qualified installer and will comply with all

requirements of the agency having jurisdiction.

FURNACE FOUNDATION

Find the footprint of the furnace in the Appendix of this manual

Inspect the ground conditions that you intend to install your furnace on.

A cement pad of 4-6” in thickness should be used.

Cement pads should be a little bigger than the actual furnace, with about a 4’ extra

length front and back so you have a solid working area.

The furnace can also be placed on 4 cement blocks not less than 6” wide X 10” long

and 3” thick. Place your blocks so the legs will stand on the center of the blocks.

- The furnace may be installed on a combustible floor provided a noncombustible mate-

rial such as metal or masonry liner is used in the following areas:

- Underneath the furnace

- At least 16“ in front of the furnace and 8” on each side of the firebox and lower

combustion chamber doors.

TRENCH

SteelTech Inc recommends the

trench to be 24” to 36” deep and

wide enough to install your water

lines. If possible, have a gradual

slope in your trench to allow drainage away from your lines and out of

the trench bottom.

Most insulated underground pipe

has room for electrical wire in it. If it

does not, place electrical supply in

bottom of trench and cover with 6

inches of dirt.

A minimum of R8 insulation value is

recommended and a water tight vapor barrier such as PVC pipe or

drain tile to encase your insulation

is a must.

NOTE: If you are installing your water lines under an area where vehicles will

cross, you should increase your depth of the trench and use a schedule pipe over your

lines to reduce the pressure generated on the lines.

www.heatmasterss.com

- 5 -

G Series Outdoor Furnaces

FURNACE INSTALLATION GUIDE

Installation should be performed by a qualified installer and will comply with all

requirements of the agency having jurisdiction.

INDOOR INSTALLATION

ATTENTION: When installing the furnace indoors, always make sure that smoke

and CO detectors are properly installed in the same area as the furnace.

Outside combustion air may be necessary if:

-The furnace does not draw steady, smells, rolls out smoke, is burning poorly or back

drafts or if any of these symptoms are alleviated by opening a window.

- The house is equipped with a well-sealed vapor barrier and tight fitting windows and/

or has any powered devices that exhaust house air.

- There is excessive condensation on windows in the winter.

- A ventilation system is installed in the house

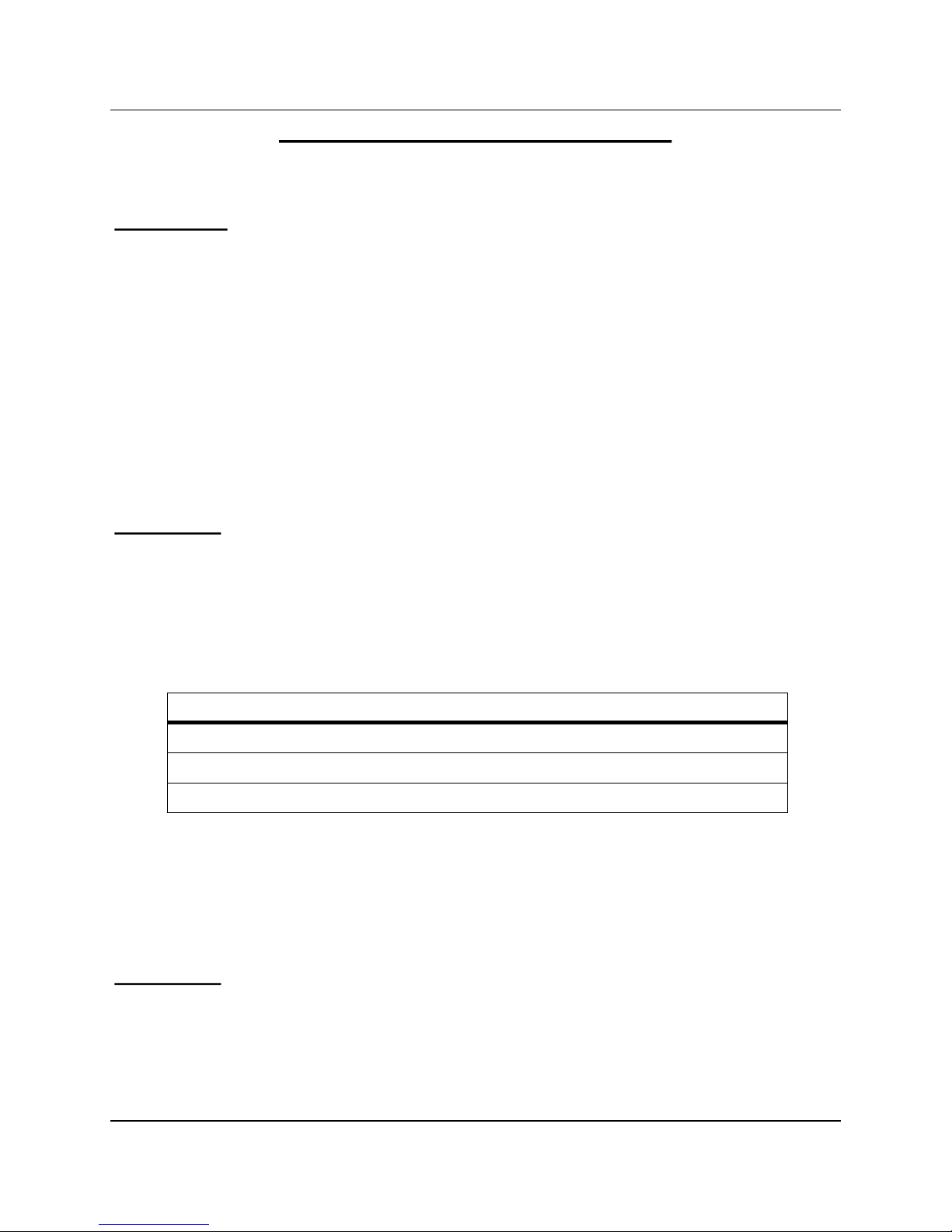

CHIMNEY

The chimney on your G Series outdoor furnace is a stainless steel double wall insulated chimney. When installing the furnace, the chimney should never be connected to a

chimney flue serving another appliance. Make sure chimney, flue pipe and draft inducer fan stay clean and in good condition at all times.

ATTENTION: Before installing, check with local building codes for information regarding chimney height and distances to adjacent buildings, etc. the top of the chimney

must extend at least 3.0 feet above the highest point where it exits the roof and be at

least 2.0 feet taller than any point of the roof within 10.0 feet. For a new chimney, use

an insulated stainless steel system that conforms to type HT (High Temperature) requirements of UL 103 and ULC-S629 and complies with the requirements of Chapter

11 of NFPA 211, Standard for Chimneys, Fireplaces, Vents and Solid Fuel Burning Appliances. The recommended chimney and adapter collar is listed below.

G100 6”

G200 6”

G400 8”

Note: Incorrect chimney installation will void the warranty.

This is a forced air furnace but it is important that the chimney has good draft to further

eliminate any smoke issues.

Note that using a smaller chimney may cause smoke issues and using a larger chimney may negatively affect furnace performance.

ATTENTION: CLEANING OF THE HEAT EXCHANGER, FLUE PIPE, CHIMNEY AND

DRAFT INDUCER IS ESPECIALLY IMPORTANT AT THE END OF THE HEATING

SEASON TO MINIMIZE CORROSION DURING THE SUMMER MONTHS CAUSED

BY ACCUMULATED ASH.

Furnace Chimney Size

www.heatmasterss.com

- 6 -

G Series Outdoor Furnaces

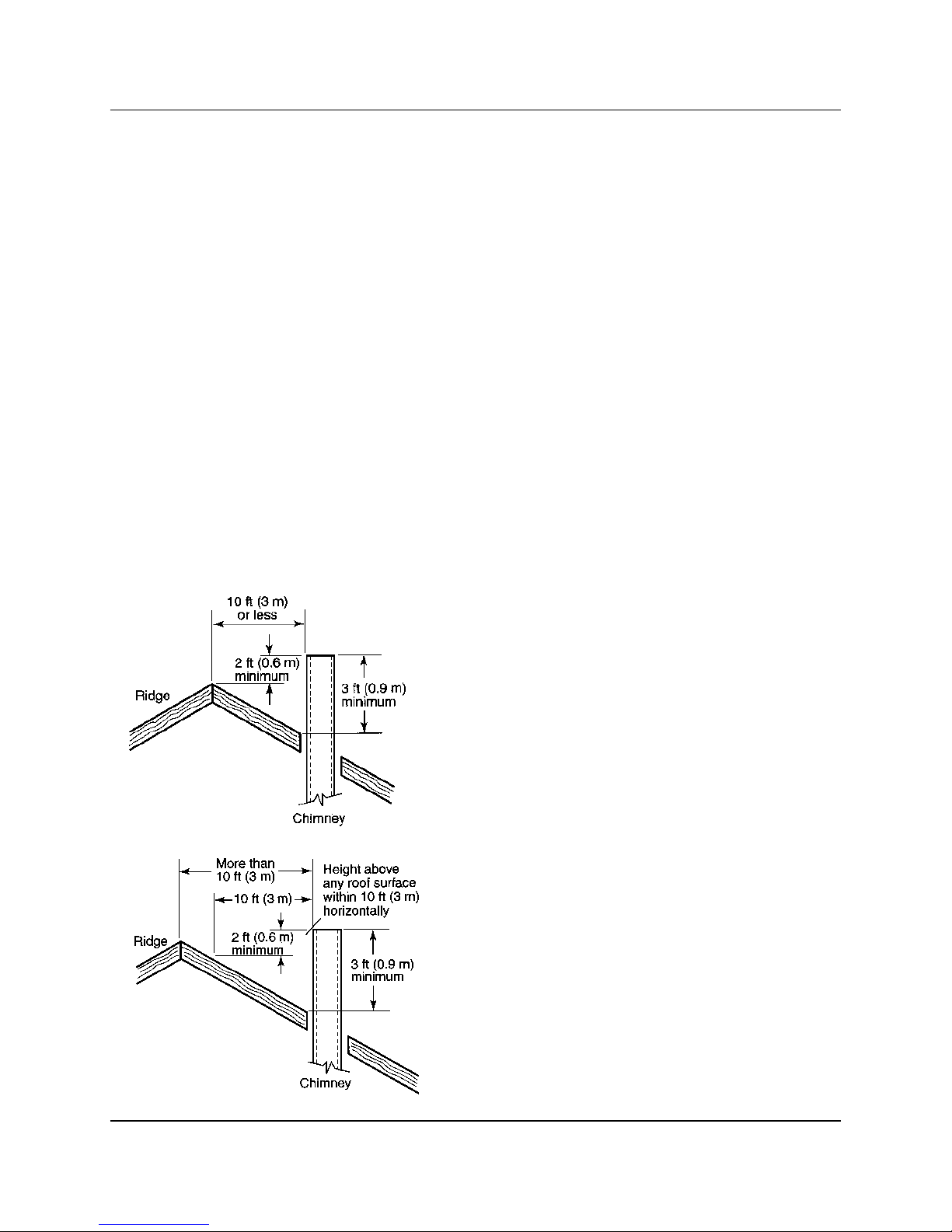

CHIMNEY INSTALLATION

Draft problems may occur because of incorrect chimney installation. Make sure to follow these simple rules to ensure proper performance and safety.

1. The chimney must be connected using a minimum double wall stainless steel

chimney and connecter.

2. Use a direct exit whenever possible. A vertical exit with elbows is always the safest and most trouble free installation.

3. Maximum chimney installation height is 15 ft.

4. Maximum horizontal installation from furnace to exhaust exit is 3 ft

5. Maximum 8 ft run from elbow to elbow but keep as short as possible.

6. Never use an elbow with a greater than 30 degree bend. 45 degree elbows and

tees cannot be used.

7. Elbows should never be installed in floor joists or roof and attic entries.

8. Shields should be used whenever going through floors, attics and roofs to keep

the wood and insulation from getting too hot and possibly catching fire.

9. Make sure to follow local building codes.

Roof Penetrations and Clearances

The basic rule is this: the top of the chimney

must clear the roof penetration point (the upper

edge) by at least 3 feet and must clear anything

within a 10 foot radius by at least 2 feet. This includes: the peak of the house, parapet, dormer,

chimney, or spire. See diagram below.

If the chimney terminates beyond 10 feet from

the ridge of the roof it must clear the upper penetration of the roof by 3 feet. Notice that the flue

still terminates 2 feet above the roof at the 10

foot perimeter:

www.heatmasterss.com

- 7 -

G Series Outdoor Furnaces

COMBUSTION AIR

Fireplaces, other furnaces, clothes dryers, exhaust fans, and other appliances all draw

air from the room in which they are located. Your G Series furnace adds to that draw,

making it important to ensure there is an adequate source of fresh air to offset these

demands. Otherwise, a negative pressure may be created in the room and starve combustion in the furnace.

1. Determine the volume of space (cubic feet) in the room. Include in the calculation

adjacent rooms and areas not closed off by doors.

Volume (CF) = Length (ft) x Width (ft) x Height (ft)

2. Determine the air input requirements of all appliances in the space. Add the BTU

output of all appliances and round the total to the nearest 1000 BTU per hour. Your G

Series Furnace requires 85 CFM (cubic feet/minute).

3. Determine whether the space is ‘confined’ or ‘unconfined’ by dividing the total vol-

ume of the room by the total input requirements for all appliances in the room.

a. If the result is equal to or greater than 50 CF/1000 BTU per hour, then consider the

space ‘unconfined.’

b. If the result is less than 50 CF/1000 BTU per hour, then consider the space

‘confined.’

4. For an ‘unconfined’ space in a conventionally constructed building, the fresh air infil-

tration through cracks around windows and doors NORMALLY provides

adequate air for combustion and ventilation, and therefore no additional make up air is

required.

5. For a ‘confined’ space or an ‘unconfined’ space in a building with unusually tight con-

struction, an additional source of make up air is required. Please consult an HVAC professional to determine the best way to supply make up air for this type of installation.

Important: The furnace room must never be in a negative pressure condition.

Negative pressure could result in smoke in the room.

www.heatmasterss.com

- 8 -

Loading...

Loading...