Heatmaster 35 TC, 85 TC Installation, Operating And Servicing Instructions

EN • 1

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.B

Installation, Operating and

Servicing Instructions

EN • 2

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.B

WARNINGS 3

Who should read these instructions 3

Symbols 3

Recommendations 3

Applicable standards 3

Warnings 3

INTRODUCTION 4

Totally condensing 4

Operating mode 4

Description of the specifications 6

Production of hot water 6

Frost protection 6

USERS GUIDE 7

Direction for use 7

Settings parameters 7

TECHNICAL CHARACTERISTICS 8

Natural gas categories 9

Propane categories 9

Domestic hot water features 9

ELECTRICAL CONNECTION 10

Wiring diagram 10

INSTALLATION INSTRUCTIONS 11

Dimensions 11

Hydraulic connections 11

Boiler room 11

INSTALLATION 12

Connection to the chimney 12

Connection to the gas 13

Domestic hot water connection 13

Heating connections 14

Installation of a single high temperature circuit with room thermostat ACV 15 control 15

Installation of a weather depending heating circuit high or low temperature 16

Installation of two heating circuit controlled by control unit and ZMC-1 module 18

COMMISSIONING AND MAINTENANCE 20

Commissioning the system 20

Inspection and maitenance 20

Temperature sensor resistance tables 20

Disassembling the burner 21

Disassembling and checking the electrode 21

Cleaning the heat exchanger 21

MCBA PARAMETERS FOR THE SPECIALIST 22

Standby mode 22

Setting the MCBA parameters 23

Request for information on the installation 24

Entering the code 24

MCBA parameters with code restricted access 25

Communication mode 28

Error mode 28

Safety stop [error mode] 29

INDEX

EN • 3

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.B

WHO SHOULD READ THESE INSTRUCTIONS

These instructions should be read by:

- the specifying engineer

- the installer

- the user

- the service engineer

SYMBOLS

The following symbols are used in this manual:

• The parts may only be replaced by genuine factory parts. You

will find a list of the spare parts and their ACV reference

number at the end of this document.

• The burners are preset in our factory for use with natural

gas

[equivalent to G20].

• Specific regulation applicable in Belgium:

The CO2 level, the air and gas flows and the gas / air ratio

are factory set . Any field adjustments of those settings is

not allowed in Belgium.

• It is important to switch the boiler off before carrying out

any work.

• There are no user accessible parts inside the boiler casing.

APPLICABLE STANDARDS

The appliances carry the CE mark in accordance with the

standards in force in the various countries (European Directives

92/42/EC “Efficiency”, 90/396/EC “Gas appliances”). They

also carry the “HR-TOP” label (Gas condensation boilers).

WARNINGS

IF YOU SMELL GAS:

- Immediately isolate the gas supply.

- Open windows and doors to ventilate the area.

- Do not use any electrical appliances and do not operate any

switches.

- Immediately notify your gas supplier and/or your installer.

This documentation is part of the information delivered with the

appliance and must be given to the user and stored in a safe

place!

An approved installer must carry out the assembly, commissioning,

maintenance and repair of the system, in accordance with current

standards in force.

ACV shall not accept any responsibility for damage caused by

non-compliant location of the system or by use of the parts or

connections not approved by ACV for this application.

The manufacturer reserves the right to change the

technical characteristics and specification of its

products without notice.

The availability of some versions and their accessories

is market dependant.

WARNINGS

RECOMMENDATIONS

• Please, carefully read this manual before installing and

commissioning the boiler.

• It is prohibited to carry out any modifications to the inside of

the appliance without the manufacturer’s prior and written

agreement.

• The product must be installed and serviced by trained

engineers, in compliance with current standards.

• Any failure to follow instructions relating to tests and test

procedures may result in personal injury or risks of pollution.

• To guarantee safe and correct operation of the appliance, it

is important to have it serviced and maintained every year by

an approved installer or maintenance company.

• In case of anomaly, please call your service engineer.

• Despite the strict quality standards imposed by ACV during

the manufacture, inspection and transport of its appliances,

you might notice some errors. Please report immediately any

fault to your approved installer. Remember to note the fault

code displayed on the screen.

Risk of scalding

Essential instruction for

the safety of persons

and the environment.

Danger of electrocution.

Essential instruction for

the correct operation of

the installation.

EN • 4

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.B

TOTALLY CONDENSING :

The HeatMaster

®

TC combines the

unique ACV Tank-in-Tank concept with

a dual primary circuit resulting in

exceptional performance from a totally

condensing combination boiler.

Tank-in-Tank technology

ACV’s advanced implementation of thermal storage technology is

tried and tested and is remarkably simple, efficient and reliable.

At the heart of the HeatMaster® TC is a stainless steel tank

through which the flue tubes pass.

This is surrounded by a mild steel shell containing the primary

water, which extends down to the combustion chamber and even

around the flue tubes. The burner fires onto the primary water

which indirectly heats the stainless steel tank containing the hot

water. As with all Tank-in-Tanks, this is corrugated over its full

height and is suspended in the HeatMaster® TC by its hot and

cold water connections.

The area of the heat transfer surface is therefore much greater

than that of standard direct fired water heaters. A much larger

heat transfer surface means that Tank-in-Tank units recover much

faster than any other kind of hot water storage device - and keeps

boiler cycling to a minimum. The high storage temperature within

the inner tank also results in exceptional hot water outputs.

Dual primary circuit technology

The HeatMaster® TC primary circuit is split into two sections - a

high temperature upper circuit and a low temperature lower circuit,

divided by a separation plate. The hot water storage tank is located

in the upper circuit which always operates at a temperature of

between 60°C and 90°C. This is ideal for hot water production as

it maintains the stored water at constantly high temperatures,

eliminating bacterial formation such as Legionellae, as well as

resulting in high volume hot water production.

The down-firing flue tubes pass through the upper circuit, through

the separation plate and into the lower circuit. The primary water

here operates at a temperature typically between 30°C and 60°C

for heating (dependent on the heating return temperature), perfect

for condensing when working in heating mode.

Dual coil technology

During hot water mode, the bottom circuit operates at a much

lower temperature, typically 5°C to 20°C depending on the

cold water inlet temperature. The incoming cold water enters

the lower primary circuit via an indirect water preheater. As

this preheater is wrapped around the lower flue tubes of the

combustion chamber, it is able to absorb the remaining heat

from the flue gases. The result is that during hot water mode the

HeatMaster® TC totally condenses whether on full or part-load.

INTRODUCTION

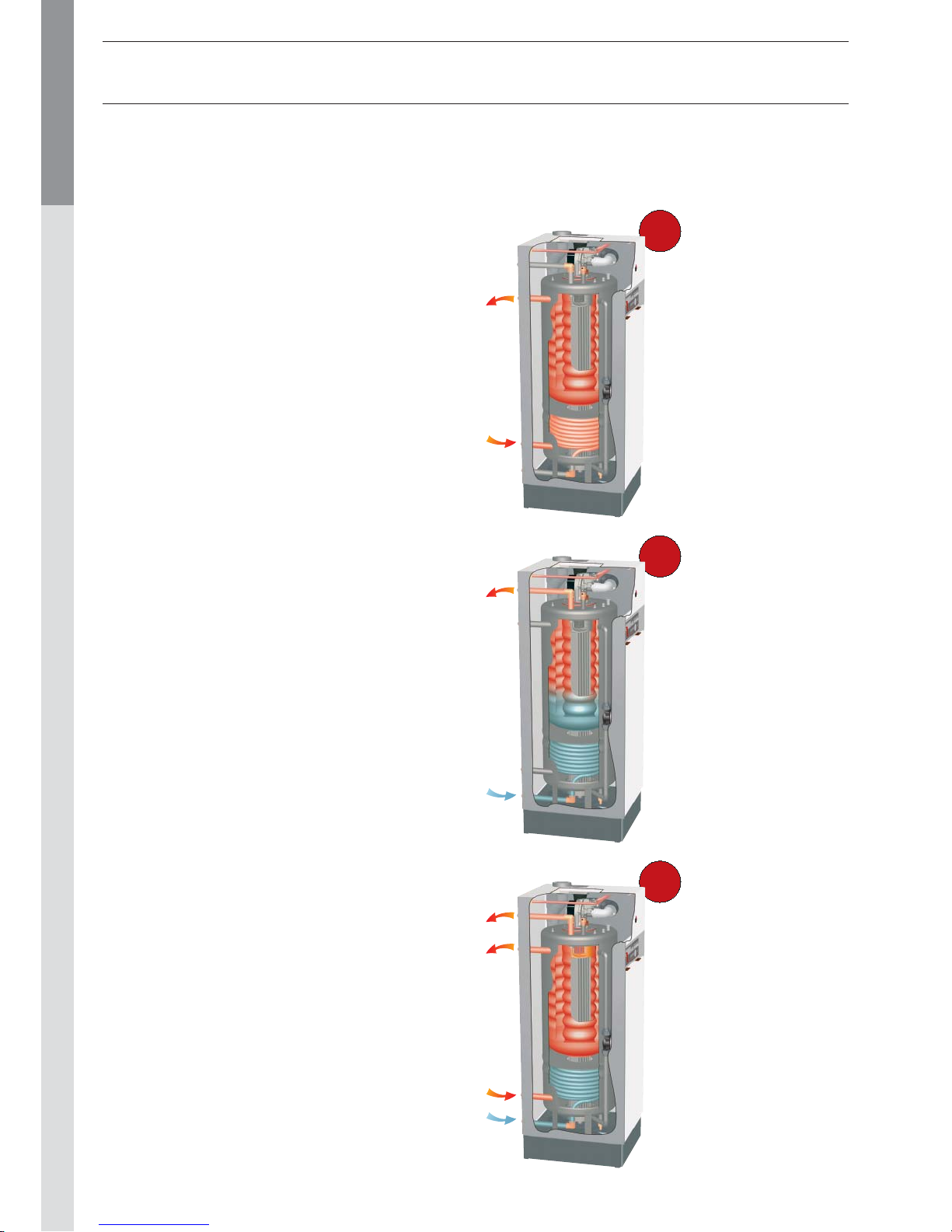

Heating

The heating return

enters the lower circuit

of the boiler, which allows

the boiler to operate

in condensing mode.

The upper circuit of the

HeatMaster® TC is kept

at a consistently high

temperature due to the

internal shunt pump which

ensures that the primary

water circulates around

the heat exchanger flue

tubes.

Heating and

hot water

Once up to temperature,

the HeatMaster® TC is

capable of producing

heating and hot water

simultaneously.

Hot water

With the upper circuit

maintained at high

temperature, the

HeatMaster® TC is always

ready to supply hot water

on demand.

The cold water enters

through the indirect water

preheater at the base of

the heat exchanger and is

preheated before entering

the hot water tank. The low

temperature of the bottom

circuit results in continuous

condensation of the flue

gases in hot water mode.

Operating modes

In both heating and hot water modes, the premix

gas burner fully modulates the power to match

the system demand.

1

3

2

EN • 5

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.B

INTRODUCTION

4

6

8

1

5

2

3

9

11

16

17

12

14

13

15

18

7

10

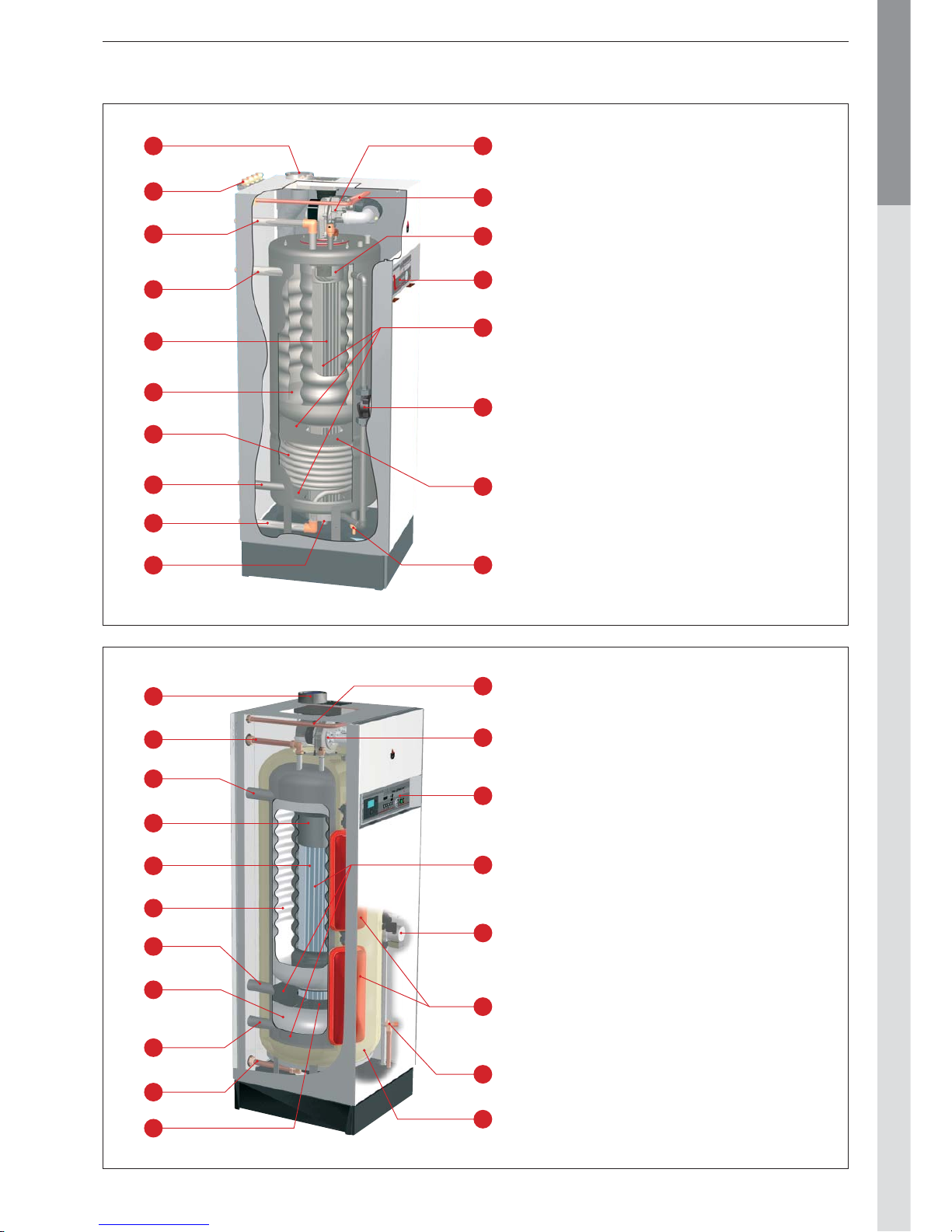

HeatMaster® 35 TC

1. Flue connection concentric Ø 80/125 mm convertible to

parallel connection 80/80 mm

2. Connection frame [optional]

3. Domestic hot water outlet

4. Heating flow

5. Stainless steel heat exchanger

6. Stainless steel Tank-in-Tank hot water store

7. Stainless steel cold water inlet coil

8. Heating return

9. Cold water inlet

10. Condenstrap

11. Modulating premix gas burner

12. Gas connection

13. Combustion chamber

14. Control panel

15. Primary heating circuit

16. Boiler shunt pump

17. Separation plate

18. Drain cock

HeatMaster® 85 TC

1. Flue connection concentric Ø 100/150 mm convertible to

parallel connection Ø 100/100 mm

2. Domestic hot water outlet

3. Heating flow

4. Combustion chamber

5. Stainless steel heat exchanger

6. Stainless steel Tank-in-Tank hot water store

7. Auxiliary tank primary return

8. Indirect water preheater

9. Heating return

10. Cold water inlet

11. Separation plate

12. Gas connection

13. Modulating premix gas burner

14. Control panel

15. Primary heating circuit

16. Boiler shunt pump

17. Primary expansion vessel (2x)

18. Primary safety valve (3 bar)

19. Polyurethane foam insulation

5

7

9

1

6

2

3

10

12

16

13

14

15

19

8

4

17

18

11

EN • 6

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.B

DESCRIPTION OF THE SPECIFICATIONS

The HeatMaster® TC is an hot water producer combined in

a condensing boiler in accordance to the Belgium "HR-Top"

standard. The boiler is certified compliant with "CE" standards as

a connected appliance C13(x) - C33(x) - C43(x) - C53 - C83(x), but

it can also be connected as an open appliance in category B23.

Lining

The boiler is protected by a steel lining that first of all undergoes a

degreasing and phosphation process before being lacquered and

heated at 220°C. The inside of this lining is coated with a layer of

thermal and acoustic insulation, reducing losses to a minimum.

Heat exchanger

The core of the HeatMaster® TC features a new stainless steel

heat exchanger. This piece of technology represents the fruit of

exhaustive research and intensive laboratory testing. It reflects

ACV’s eighty years of experience in using stainless steel for

heating and hot water functions. The particular geometry of the

exchanger pipes is calculated to obtain a very large Reynolds

number throughout its cycles.

The HeatMaster® TC achieves an exceptional output that remains

stable throughout the boiler’s life, given that it causes no oxidation

on the exchanger, which is manufactured entirely from quality

steel.

Burner

ACV uses its BG 2000-M burner for the HeatMaster® TC: this

is an air/gas premix burner providing safe and silent operation

while limiting emissions (NOx and CO) to an incredibly low level.

Although the ACV BG 2000-M boiler is very modern, it uses

proven technology and is manufactured from standard spare

parts that are easily available on the market.

Temperature regulation

The basic version of the HeatMaster® TC is fitted with a

microprocessor controlled regulator (MCBA) which takes over

both the safety functions (ignition, monitoring the flame, limiting

the temperature, etc.) and control of the boiler temperature.

This MCBA also includes a weather-dependent regulator. All you

need to do is connect the outdoor temperature sensor available

as an option to the device. However, this regulator can also

operate with a standard on/off room thermostat In addition,

with the combination of a weather -dependent regulator and a

room thermostat, you can control the temperatures based on

the weather with compensation for the indoor temperature.

There are four user adjustable parameters. By entering a

special maintenance code, qualified ins tallers can access

several other parameters to adapt the boiler to special

requirements. In principle, these parameters are factory set

for all normal applications.

PRODUCTION OF HOT WATER

In addition to its exceptional hot water performances, the ACV

Tank-in-Tank concept provides the follwoing advantages :

- A solution for scale deposits: thanks to the specially designed

corrugations, the hot water tank expands and contracts during

the heating cycle, preventing the formation of scale.

- A guarantee against the risk of Legionnellae Disease and

bacteria: the hot water tank is fully immersed in the primary

circuit and the hot water is constantly kept at a temperature

above 60°C.

- Exceptional resistance against corrosion and aggression:

provided by the stainless steel.

FROST PROTECTION

The boiler is equipped with an integrated frost protection: as soon

as the boiler temperature drops below 7°C, the system activates

the central heating pump. As soon as the NTC1 flow temperature

drops below 3°C, the system automatically ignites the burner until

the temperature rises above 10°C. The pump continues to run

for about 10 minutes.

If an outdoor temperature sensor is connected to the system,

the pump is activated as soon as the outside temperature drops

below the specified threshold.

To provide efficient protection for the whole system against frost,

all the valves on the radiators and the convectors should be

completely open.

INTRODUCTION

EN • 7

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.B

DIRECTIONS FOR USE

Your system must be checked once a year by an approved

installer or maintenance company.

Starting the burner

During operation, the burner starts automatically as soon as

the boiler temperature drops under the required set point and

it stops as soon as the boiler reaches that temperature.

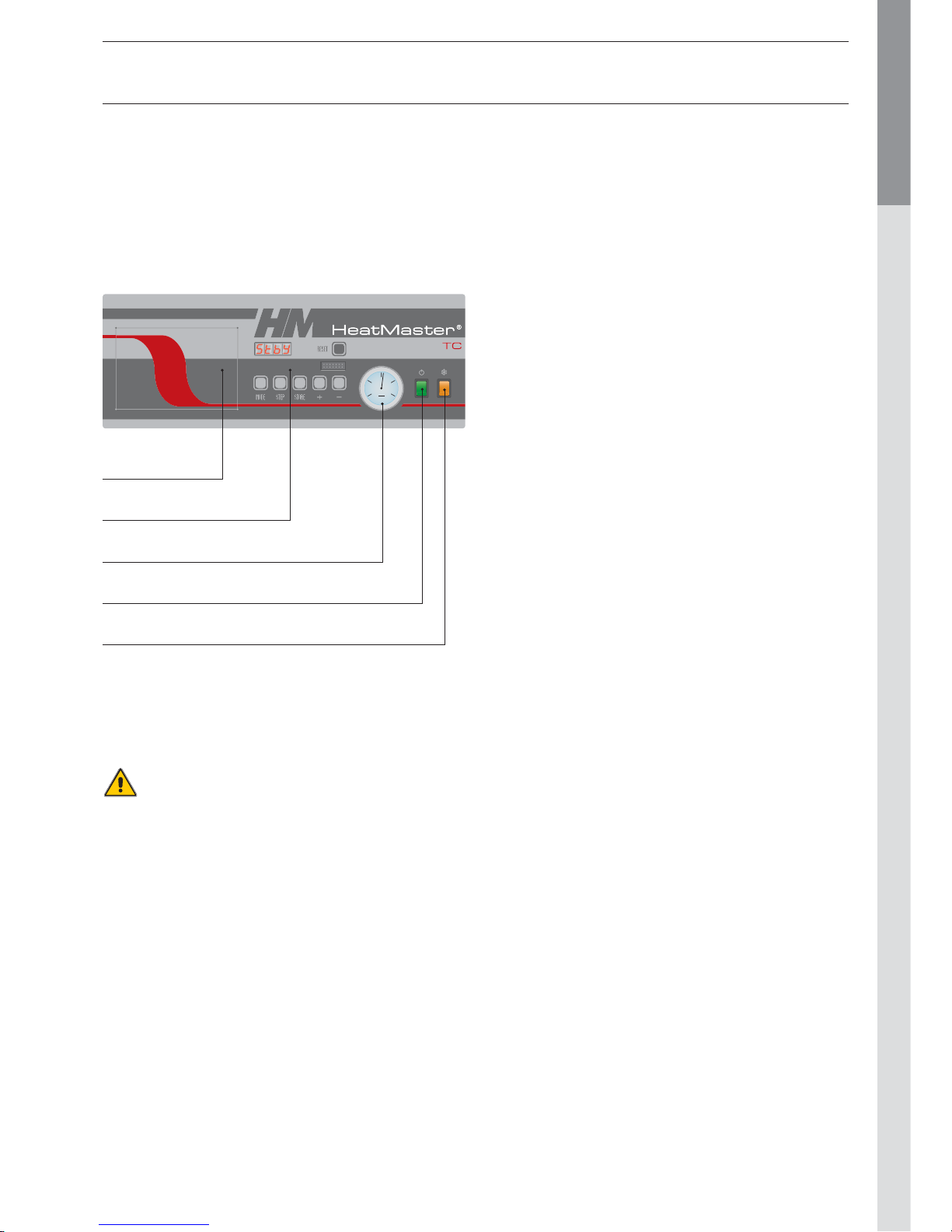

Control panel

SETTINGS PARAMETERS

Setting the domestic hot water temperature:

(Hot water temperature)

- Press Mode: The screen displays PARA.

- Press Step: the first character is 1 and the last t wo characters

give the current hot water temperature setting.

- To change this temperature, press + or - until the last two

digits show the desired temperature value.

- Press Store to save the new temperature setting.

- Press Mode twice to return to Pilot mode (normal operating

mode).

Enabling or disabling the hot water heating mode:

(hot water)

- Press Mode: The screen displays PARA.

- Press Step twice: the first charact er is 2 and the last two

characters give the current setting:

00 = disabled; 01 = enabled.

- To change this parameter, press + or - until the screen displays

the desired value:

00 = disabled; 01 = enabled.

- Press Store to save.

- Press Mode twice to return to Pilot mode (normal operating

mode).

Enabling or disabling Central Heating mode:

(heating)

- Press Mode: The screen displays PARA.

- Press Step three times: the firs t character is 3 and the last

two characters give the current setting:

00 = disabled; 01 = enabled.

- To change this parameter, press + or - until the screen displays

the desired value:

00 = disabled; 01 = enabled.

- Press Store to save.

- Press Mode twice to return to Pilot mode (normal operating

mode).

Setting the central heating temperature:

(maximum temperature for the heating circuit)

- Press Mode: The screen displays PARA.

- Press Step four times: the first character is 4 and the last

two characters give the current central heating temperature

setting.

- To change this temperature, press + or - until the last two

digits show the desired temperature value.

- Press Store to save the new temperature setting.

- Press Mode twice to return to Pilot mode (normal operating

mode).

Fault:

The temperature setting for the appliance and the safety

functions for its various parts are continuously monit ored by

a regulator controlled by a microprocessor (the MCBA). In the

event of a fault, this MCBA disables the appliance and displays

an error code: the screen flashes displaying E as the first

character, followed by the error code.

To reset the appliance:

- Press "Reset" on the screen.

- Contact your inst aller of the fault happens again.

USERS GUIDE

Heating system

The central heating circuit must be pressurized (see in the

chapter “Installation” how to define the system pressure).

The pressure indicator is located on the right-hand side of the

display.

If your system needs to be refilled more than twice

a year, please contact your installer.

The CH pressure must be a minimum of 1 bar and mus t be

checked by the end user on a regular basis. If the pressure

drops under 0.5 bar, the integrated water pressure switch

blocks the appliance until the pressure in the system returns to

a level above 0.8 bar. The connection for a fill valve is provided

underneath the appliance. The installer can also fit the system

with a separate valve. Make sure that the appliance is powered

off when filling the system. To do this, toggle the Star t/Stop

switch located on the left of the screen to Off. (see the Control

panel).

For more information, please ask your installer when the system

is delivered.

A safety valve is provided at the underneath of the appliance.

If the system pressure exceeds 3 bars, this valve opens and

drains the water from the system. In this case, please contact

your installer.

bar

2

1O3

4

MCBA display

Pressure gauge

ON/OFF switch

Summer/Winter switch

Pre-cut for an optional

Control Unit controller

EN • 8

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.B

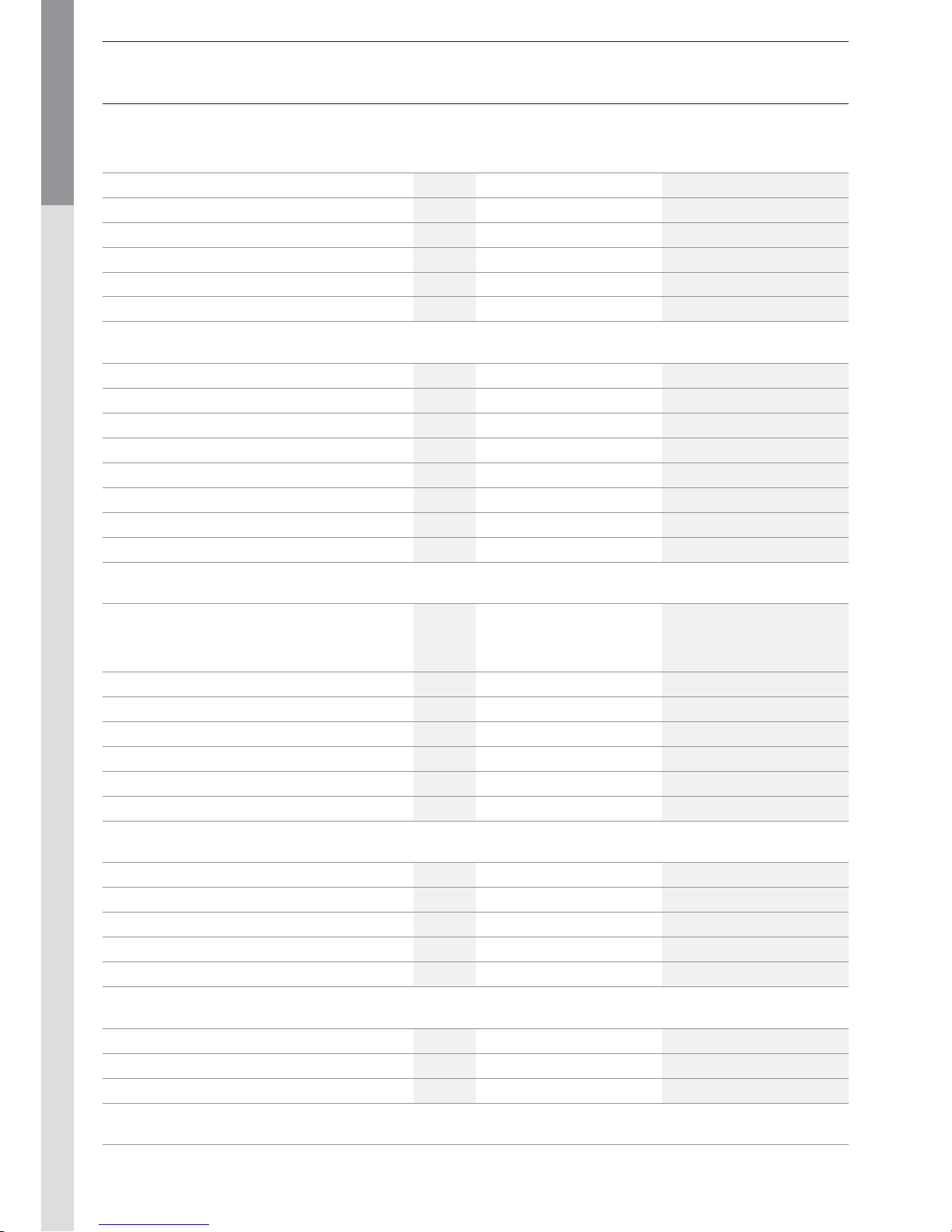

TECHNICAL CHARACTERISTICS

HeatMaster

®

35 TC

HeatMaster

®

85 TC

Central heating Natural gas Propane Natural gas Propane

Max. Input 80/60°C

kW

34,9 30,6 85,0 [92,0] 85,0 [92,0]

Min. Input 80/60°C

kW

10,0 10,0 17,2 17,2

Max. output 80/60°C

kW

34,1 29,9 82,5 82,5

Min. output 80/60°C

kW

9,8 9,8 16,7 16,7

Effi ciency 30% load [EN677]

%

108,5 108,5 107,0 107,0

Effi ciency domestic hot water mode [Δt = 30°C]

%

105,9 105,9 105,0 105,0

Flue gases

CO emissions max. / min. Input

mg/kWh

70 / 6 105 / 17 70 80

NOx emissions max. / min. Input

mg/kWh

59 / 29 72 / 31 70 / 30 85 / 40

NOx classifi cation [EN483] 5 5 5 5

Flue gas temperature — max. Input 80/60°C

°C

60 60 65 65

Flue gas temperature — max. Input 50/30°C

°C

32 32 35 35

Mass fl ow rate of combustion products

kg/h

55 46,5 137 [148] 134 [145]

Flue gas pipe - Max. pressure drop

Pa

130 130 150 150

Concentric fl ue gas channel maximum length Ø 80 / 125 mm

m

20 20 20 20

Gas G20 / G25 G31

Category [varies by country]

I 2E[S]B — I 2Er

I 2L — I 2E

I 2ELL — I 2H

I 2HS

I 3P

I 3+

I 3B

I 2E[R]B — I 2Er

I 2L — I 2E

I 2ELL — I 2H

I 2HS

I 3P

I 3+

I 3B

Gas pressure

mbar

20 / 25 30 / 37 / 50 20 / 25 30 / 37 / 50

G20 gas fl ow rate

m

3

/h

3,7 — 8,99 [9,73] —

G25 gas fl ow rate

m

3

/h

4,3 — 10,46 [11,32] —

G31 gas fl ow rate

m

3

/h

— 1,25 — 3,48 [3,76]

CO

2

max. Input

% CO

2

9,4 10,5 9,3 11,0

CO

2

min. Input

% CO

2

9,0 10,1 8,9 10,6

Hydraulic parameters

Max. operating temperature

°C

90 90 90 90

Total capacity

L

189 189 315 315

Heating circuit capacity

L

108,5 108,5 125 125

Maximum operating pressure central heating

bar

3333

Heat exchanger pressure drop [ΔT = 20°C]

mbar

30 30 200 200

Electrical connection

Class

IP

30 30 30 30

Supply voltage

V/Hz

230/50 230/50 230/50 230/50

Maximum absorbed electrical power

A

0,8 0,8 1,0 1,0

Weight empty kg 174 174 284 284

[…] = Domestic hot water mode

EN • 9

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y2800.B

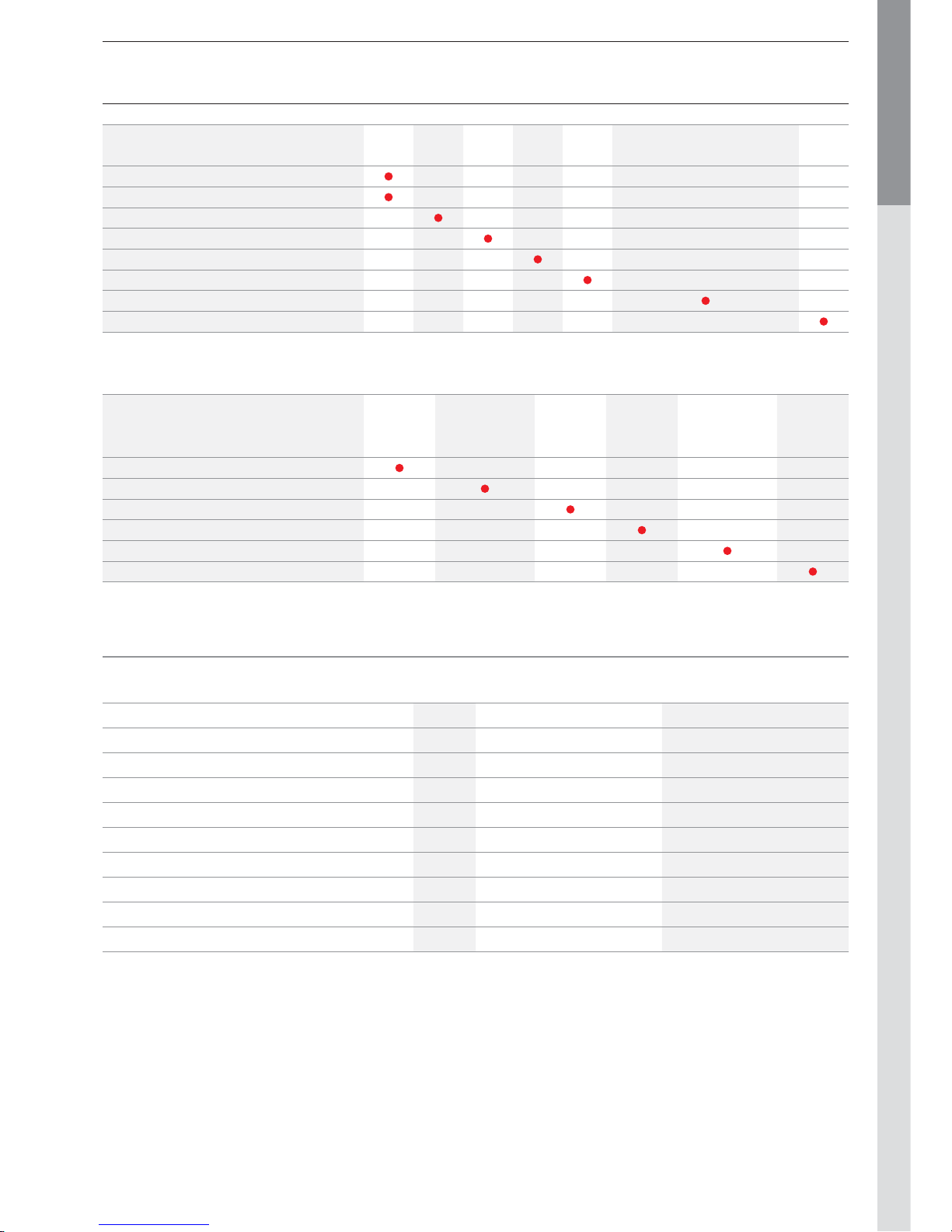

TECHNICAL CHARACTERISTICS

Natural gas categories

BE FR NL LU DE

AT - CH - CZ - DK - ES - IT

FI - UK - IE - PT - SE - GR

HU

I 2E(S)B

[G20] 20 mbar – [G25] 25 mbar

I 2E(R)B *

[G20] 20 mbar – [G25] 25 mbar

I 2Er

[G20] 20 mbar – [G25] 25 mbar

I 2L

[G25] 25 mbar

I 2E

[G20] 20 mbar

I 2ELL

[G20] 20 mbar – [G25] 20 mbar

I 2H

[G20] 20 mbar

I 2HS

[G20] 25 mbar

(*) HeatMaster® 85 TC

Propane categories

DK - NL

NO - IT

BE - CH - ES

FR - UK - IE

PT - FI - SE

IT - GR

AT - CH

CZ - ES

NL - DE

LU - HU

BE - CH

ES - FR

UK - IE

IT - PT

CZ - DK - ES

FI - FR - UK

IE - IT - NL

NO - PT - SE

AT - CH

CZ - DE

FR

I 3P

[G31] 30 mbar

I 3P

[G31] 37 mbar

I 3P

[G31] 50 mbar

I 3+

[G30 + G31] 28 / 30 / 37 mbar

I 3B

[G30] 28 / 30 mbar

I 3B

[G30] 50 mbar

DOMESTIC HOT WATER FEATURES

HeatMaster

®

35 TC

HeatMaster

®

85 TC

Operating conditions at 80°C

Peak fl ow at 40°C [ΔT = 30°C]

L/10’

419 850

Peak fl ow at 40°C [ΔT = 30°C]

L/60’

1312 3177

Constant fl ow at 40°C [ΔT = 30°C]

L/h

1057 2793

Peak fl ow at 45°C [ΔT = 35°C]

L/10’

381 722

Peak fl ow at 45°C [ΔT = 35°C]

L/60’

1080 2717

Constant fl ow at 45°C [ΔT = 35°C]

L/h

898 2394

Peak fl ow at 60°C [ΔT = 50°C]

L/10’

224 459

Peak fl ow at 60°C [ΔT = 50°C]

L/60’

692 1778

Constant fl ow at 60°C [ΔT = 50°C]

L/h

578 1583

Pre-heat time

minutes

37 35

Loading...

Loading...