Heatmaster 25 Tc, 85 TC, 35 TC, 120 TC, 45 TC Installation, Operation And Maintenance Instructions

...

664Y6800 • A

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

25 - 35 - 45 - 70 - 85 - 120 TC

HeatMaster

®

EN

FR

NL

ES

IT

DE

PL

RU

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

en

2

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TABLE OF CONTENTS

GENERAL RECOMMENDATIONS ...................................................................4

USER'S GUIDE ...............................................................................................5

Instructions for the end user ............................................................................................................................................. 5

Periodic checks ....................................................................................................................................................................5

Control panel ....................................................................................................................................................................... 6

Parameter setting ...............................................................................................................................................................7

APPLIANCE DESCRIPTION ..........................................................................10

Burner description ............................................................................................................................................................12

TECHNICAL CHARACTERISTICS .................................................................13

Burner characteristics .......................................................................................................................................................13

Single gas categories (All models)..................................................................................................................................14

Double gas categories (HM 70 / 85 / 120 TC only)........................................................................................................16

Combustion characteristics.............................................................................................................................................18

Electrical characteristics (HM TC equipped with a standard charging pump)........................................................20

Electrical characteristics (HM TC < 70 kw equipped with a high eciency pump) ...............................................22

Electrical characteristics (HM TC ≥ 70 kw equipped with a high eciency pump)................................................24

Dimensions ........................................................................................................................................................................26

Chimney connection characteristics .............................................................................................................................28

Calculation of the ue pressure drop, or of the corresponding length in meters of straight pipes ...................30

Hydraulic characteristics ..................................................................................................................................................32

DHW performance ............................................................................................................................................................34

Maximum operating conditions .....................................................................................................................................34

INSTALLATION ........................................................................................... 35

Package contents .............................................................................................................................................................. 35

How to move the boiler ...................................................................................................................................................36

Safety instructions for the installation .......................................................................................................................... 37

Recommendations for the prevention of corrosion and scaling ..............................................................................39

Tools required for the installation ..................................................................................................................................41

Boiler preparation ............................................................................................................................................................. 41

DHW connection ...............................................................................................................................................................43

Heating connection ..........................................................................................................................................................44

Gas connection ..................................................................................................................................................................46

Conversion to propane (HM 85 / 120 TC).......................................................................................................................47

Gas circuit connection......................................................................................................................................................48

en

3

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TABLE OF CONTENTS

STARTING UP .............................................................................................49

Safety instructions for starting up .................................................................................................................................49

Tools required for starting up .........................................................................................................................................49

Checks before starting up ...............................................................................................................................................49

Filling the system .............................................................................................................................................................. 50

Starting up the boiler ....................................................................................................................................................... 51

Checking and adjusting the burner ............................................................................................................................... 52

MAINTENANCE ..........................................................................................53

Safety instructions for the boiler maintenance ...........................................................................................................53

Tools required for maintenance .....................................................................................................................................54

Boiler shut down for maintenance .................................................................................................................................54

Periodic boiler maintenance tasks ................................................................................................................................. 55

Removal, check and reinstallation of the burner electrode.......................................................................................56

Removal and reinstallation of the burner .....................................................................................................................57

Cleaning the exchanger ...................................................................................................................................................58

Removing and cleaning the condensate recovery dish .............................................................................................59

Draining the boiler ............................................................................................................................................................60

Restarting after maintenance .........................................................................................................................................61

In case of problem... ..........................................................................................................................................................62

DECLARATION OF CONFORMITY EC ........................................................63

For specific connection diagrams and the list of associated accessories, the MCBA

parameters and the error codes, refer to the System Control manual provided with

this product.

NOTE

This manual contains important information with respect to the installation, the starting up and the

maintenance of the boiler.

This manual must be provided to the user, who will read it carefully and keep it in a safe place.

We accept no liability should any damage result from the failure to comply with theinstructions

contained in this technical manual.

Essential recommendations for safety

• It is prohibited to carry out any modifications to the appliance without the

manufacturer’s prior and written agreement.

• The product must be installed by a qualified engineer, in accordance with

applicable local standards and regulations.

• The installation must comply with the instructions contained in this manual and

with the standards and regulations applicable to installations.

• Failure to comply with the instructions in this manual could result in personal

injury or a risk of environmental pollution.

• The manufacturer declines all liability for any damage caused as a result of

incorrect installation or in the event of the use of appliances or accessories that are

not specified by the manufacturer.

Essential recommendations for the correct operation of the appliance

• In order to ensure that the appliance operates correctly, it is essential to have it

serviced by a certified installer or maintenance contractor every year.

• In case of anomaly, please call your service engineer.

• Faulty parts may only be replaced by genuine factory parts.

en

4

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

GENERAL RECOMMENDATIONS

If you smell gas:

- Immediately isolate the gas supply.

- Open windows and doors to ventilate the area.

- Do not use any electrical appliances and do not operate any switches.

- Immediately notify your gas supplier and/or your installer.

en

5

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

USER'S GUIDE

INSTRUCTIONS FOR THE END USER

Essential recommendations for safety

• Do not store any flammable or corrosive products, paint, solvents, salts, chloride

products and other detergent products near the appliance.

• This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless supervised or unless they have been given instruction concerning the use

of the appliance by a person responsible for their safety.

PERIODIC CHECKS

Essential recommendations for the correct operation of the appliance

• Make sure that the system water pressure is at least 1 bar when cold.

• If it is required to top up the system to maintain the minimum recommended water

pressure, only add small amounts of water at a time. If a large amount of cold water

is added in a hot boiler, the boiler can be damaged definitively.

• If the system needs to be refilled repeatedly with water, please contact your

installer.

• Regularly check that there is no water on the floor in front of the boiler. If there is,

please call your service engineer.

General remark

• Checking the boiler settings can only be carried out by an ACV-trained installer or

by ACV's maintenance department.

bar

2

1O3

4

2

5

4

1

3

en

6

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

USER'S GUIDE

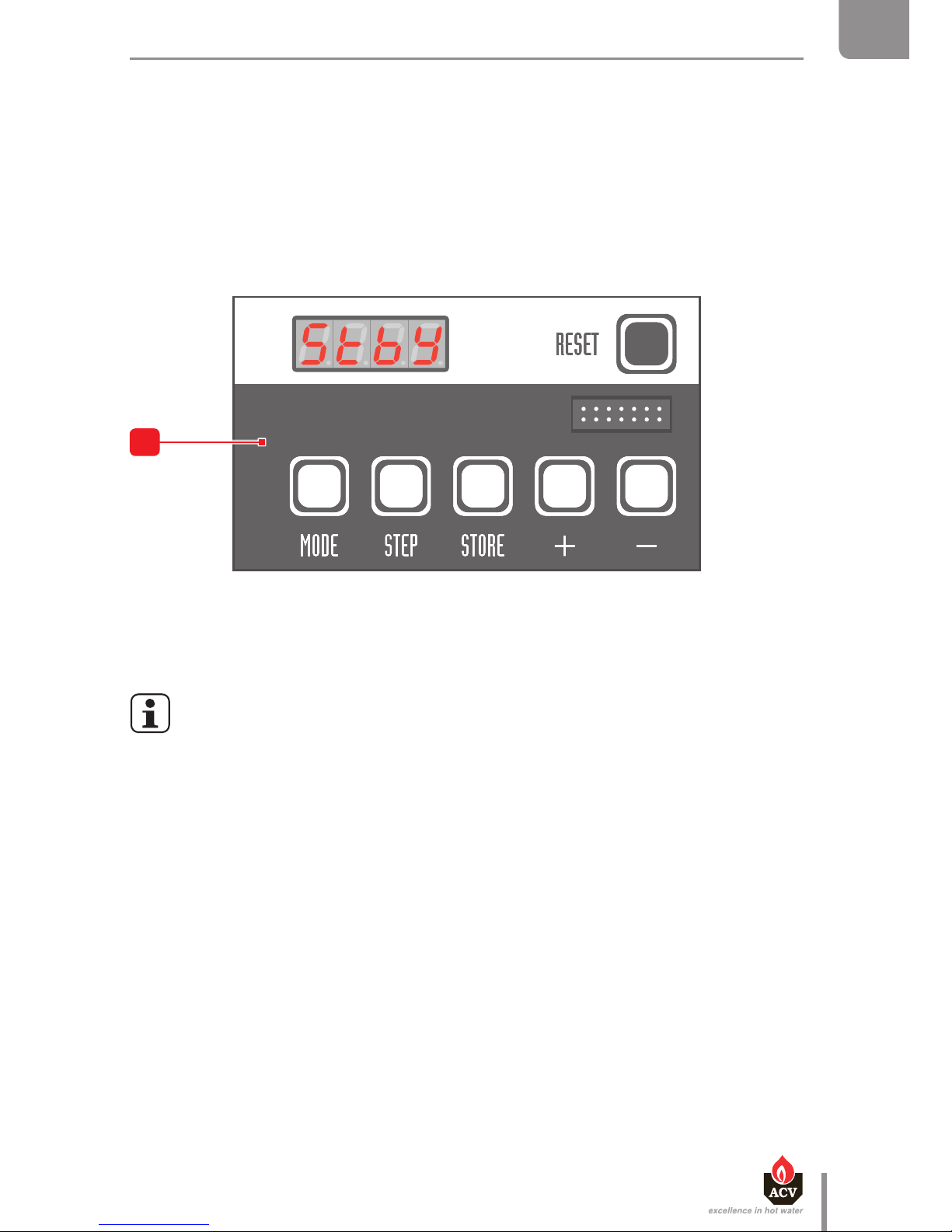

CONTROL PANEL

When the boiler is powered on, it starts in Stand-by mode and displays for 2

seconds before displaying the boiler status.

Description

1. ON/OFF master switch of the boiler - The built-in indicator lights when the appliance is turned on.

2. Summer-winter switch - To activate or deactivate the heating pump. The built-in indicator

lights in winter mode.

3. Pressure gauge - Indicates the primary circuit pressure (min. 1 bar when cold).

4. Pre-cut area - To install an optional Control Unit.

5. User interface of the MCBA controller - Allows to set-up the boiler operation and more

specically, to dene the required temperature of the Domestic Hot Water (DHW) and the Central

Heating (CH) and to activate/deactivate the DHW and heating modes:

• Display : indicates the parameter values, the error codes and the set-up status of

the parameters.

• "Reset" key : to bring the parameters back to the factory-preset values.

• "Mode" key : to toggle the modes and dene various parameters.

• "Step" key : to scroll through the various functions of a mode.

• "Store" key : to save the dened settings.

• "+" key : to increase the displayed value.

• "–" key : to decrease the displayed value.

bar

2

1

O

3

4

5

en

7

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

USER'S GUIDE

To get additional information on how to use the MCBA and the installer-specic settings, refer to the

boiler System Control manual.

General remarks

• The end user is allowed to carry out the set-up mentioned in the following pages.

Any other setup must be carried out by an approved installer.

• If a fault occurs, the MCBA disables the appliance and displays an error code: the

display flashes and the first character is "E" followed by the fault number.

- Reset the appliance by pressing the "RESET" key of the MCBA interface.

- If the error code shows again, contact your installer.

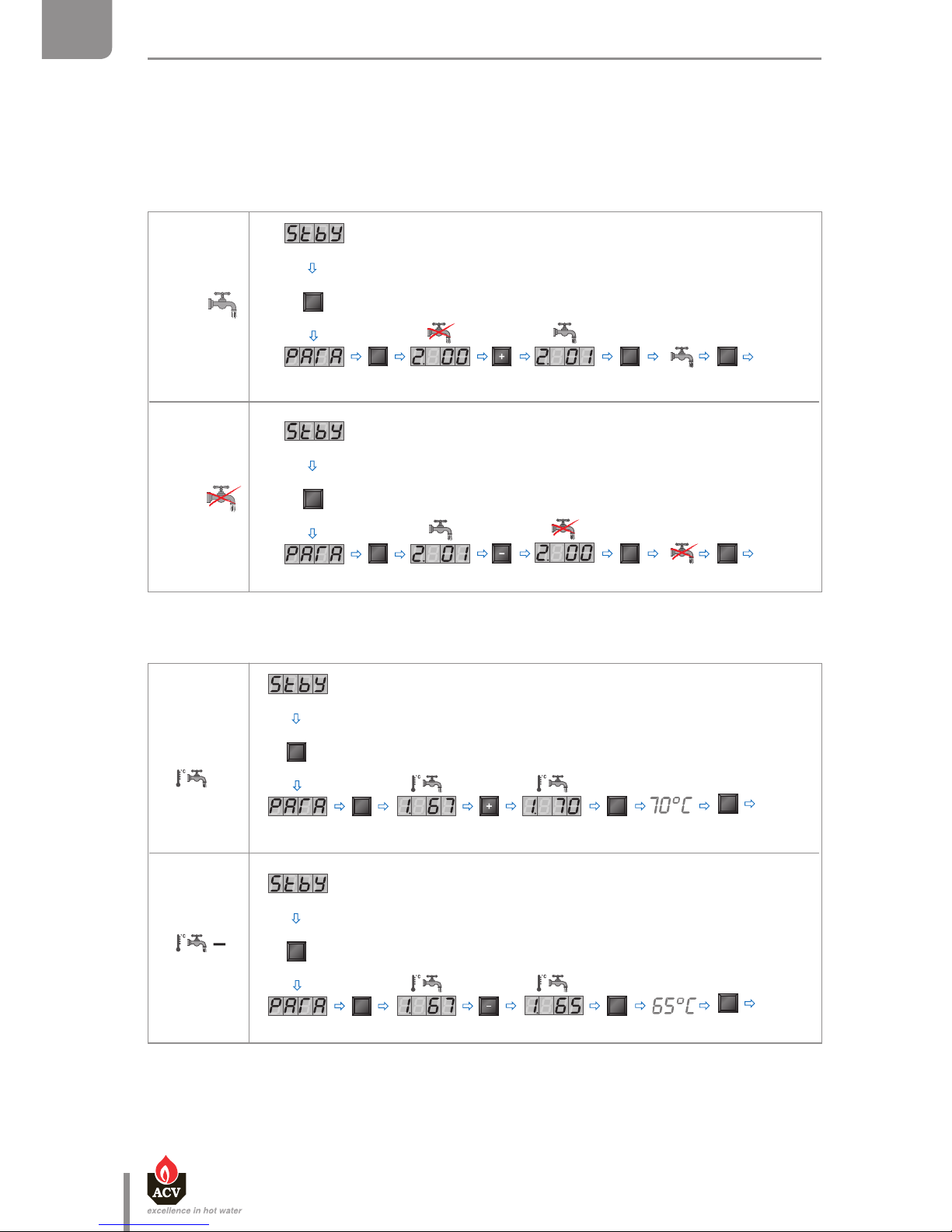

PARAMETER SETTING

The end user is allowed to perform some of the settings: turn on/o the domestic hot water (DHW-)/

heating function and dene the required temperature of the DHW/heating circuits.

Using a special maintenance code to be entered in the MCBA interface, the qualied installers can

access parameters and therefore adjust the boiler settings to specic requirements. The parameters

are normally factory-preset for all normal applications.

en

8

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

USER'S GUIDE

→ Setting the required DHW temperature

DHW mode: When it is enabled through the MCBA, this mode allows to dene the DHW temperature

set-point of the hot water preparation tank. The maximum authorized DHW temperature is 75°C.

→ Enable / disable the DHW mode

2 X

1 X

Mode

Step

X

Mode

Store

1 X

1 X

Stand

by

mode

Stand by mode

ON

2 X

1 X

Mode

Step

2 X

Mode

Store

Stand

by

mode

OFF

2

Stand by mode

1

X

1

X

Mode

Step

2

X

Mode

Store

1

X

Stand

by

mode

1

X

1

X

Mode

Step

2

X

Mode

Store

1

X

Stand

by

mode

+

Stand by mode

Stand by mode

en

9

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

USER'S GUIDE

→ Setting the required heating temperature

Central Heating Mode: When it is enabled through the MCBA, this mode allows to dene the

primary circuit temperature set-point for the heating function. The maximum authorized temperature

for the circuit is 90°C.

→ Enable / disable the central heating mode

3 X

1 X

Mode

Step

2 X

Mode

Store

1 X

Stand

by

mode

3 X

1 X

Mode

Step

2 X

Mode

Store

1 X

Stand

by

mode

ON

OFF

Stand by mode

Stand by mode

4

X

1

X

Mode

Step

2

X

Mode

Store

1

X

Stand

by

mode

4

X

1

X

Mode

Step

2

X

Mode

Store

1

X

Stand

by

mode

+

Stand by mode

Stand by mode

en

10

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

APPLIANCE DESCRIPTION

The HeatMaster® TC series combines ACV's "Tank-in-Tank" concept with a double primary circuit to

reach the high performance of a TOTAL CONDENSATION, double-circuit boiler.

The HeatMaster® models are always delivered with an ACV air/gas premix BG 2000-M burner, with low

NOx emissions. During operation, the burner starts automatically as soon as the boiler temperature

gets lower than the preset temperature and stops as soon as the preset temperature is reached.

The appliance is tted with a built-in low water pressure switch that blocks the appliance when the

pressure is not sucient: the heating circuit must be kept under water pressure (at least 1 bar). If the

pressure reading on the pressure gauge is below 0.5 bar, the pressure switch stops the boiler until the

pressure is higher than 0.8 bar again.

The HeatMaster® TC series is tted with a built-in frost protection: as soon as the boiler temperature

[NTC1 sensor] drops below 7°C, the central heating pump is enabled. As soon as the NTC1 temperature

is lower than 3°C, the burner ignites until the temperature exceeds 10°C. The heating pump continues

to run for 10 minutes.

If an outdoor temperature sensor is connected, the pump is started whenever the outdoor temperature

drops below the preset temperature. To allow the boiler to protect the system against frost, all the

radiator and convector valves should be fully open.

Depending on the model, the HeatMaster® TC are equipped with a high efficiency

charging pump, or with a standard charging pump.

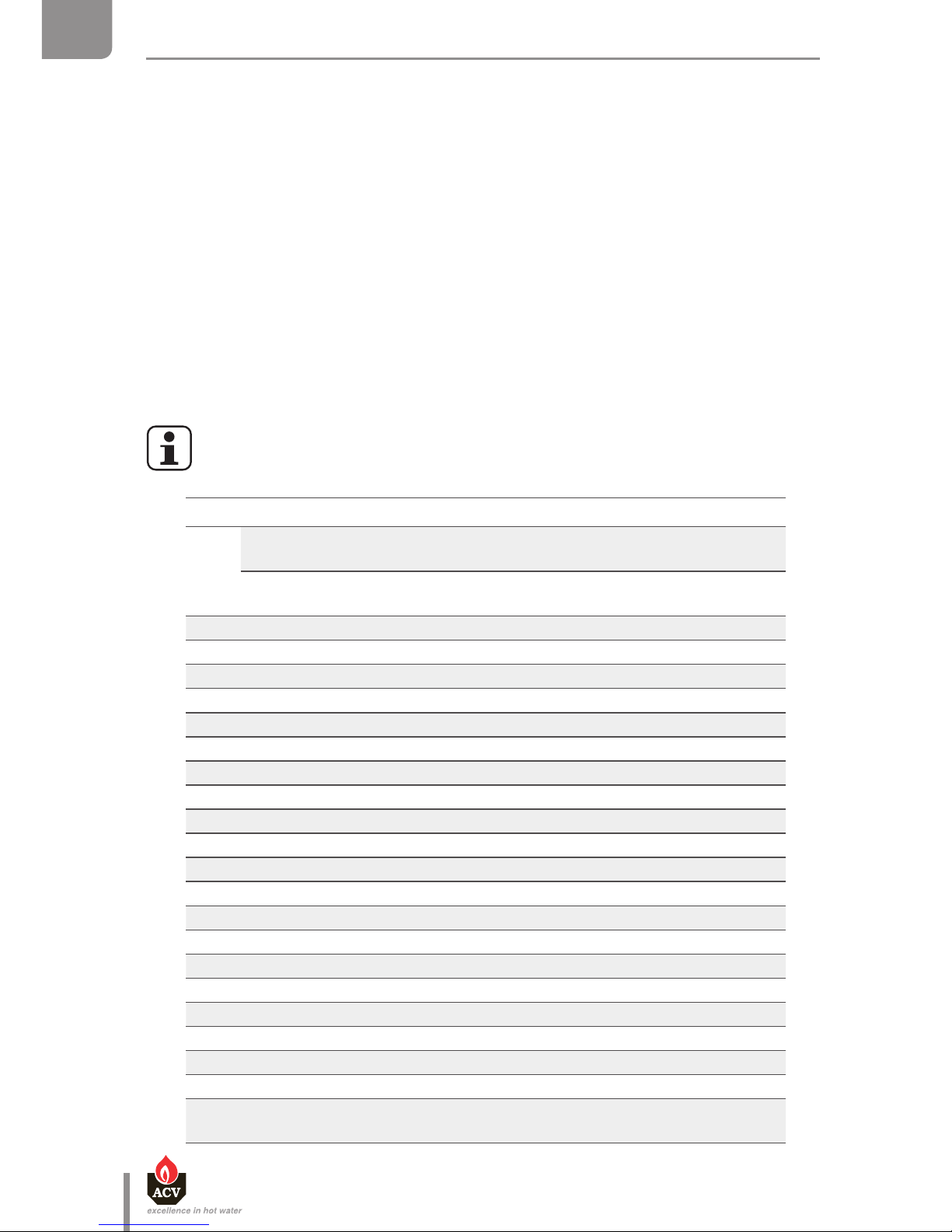

Detail of components

1.

80/125 mm concentric flue pipe connection, that can be transformed into

two 80/80 mm pipes (HM 25 / 35 / 45 TC)

100/150 mm concentric flue pipe connection, that can be transformed into

two 100/100 mm pipes (HM 85/ 120 TC)

2. Domestic hot water outlet

3. Heating circuit outlet

4. Combustion chamber

5. Stainless steel heat exchanger

6. Stainless steel "Tank in Tank" hot water production tank

7. Auxiliary heating circulation loop

8. Indirect water pre-heater

9. Heating circuit inlet

10. Cold water inlet

11. Primary circuit separation disc

12. Gas connection tube

13. Modulating AIR/GAS premix burner

14. Air bleed valve

15. Control panel

16. Heating circuit

17. Electronic board

18. Primary circuit expansion vessel(s) (HM 70 / 85 / 120 TC)

19. Hard expanded polyurethane foam insulation

20. Boiler charging pump (auxiliary circulation loop)

21a. Safety valve (3 bar) (HM TC equipped with a standard pump)

21b Connection + safety valve (3bar) to be installed (HM TC equipped with a

high efficiency pump)

21b

12

13

14

15

16

17

18

19

20

21a

11

10

9

8

7

6

5

4

3

2

1

en

11

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

APPLIANCE DESCRIPTION

en

12

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

APPLIANCE DESCRIPTION

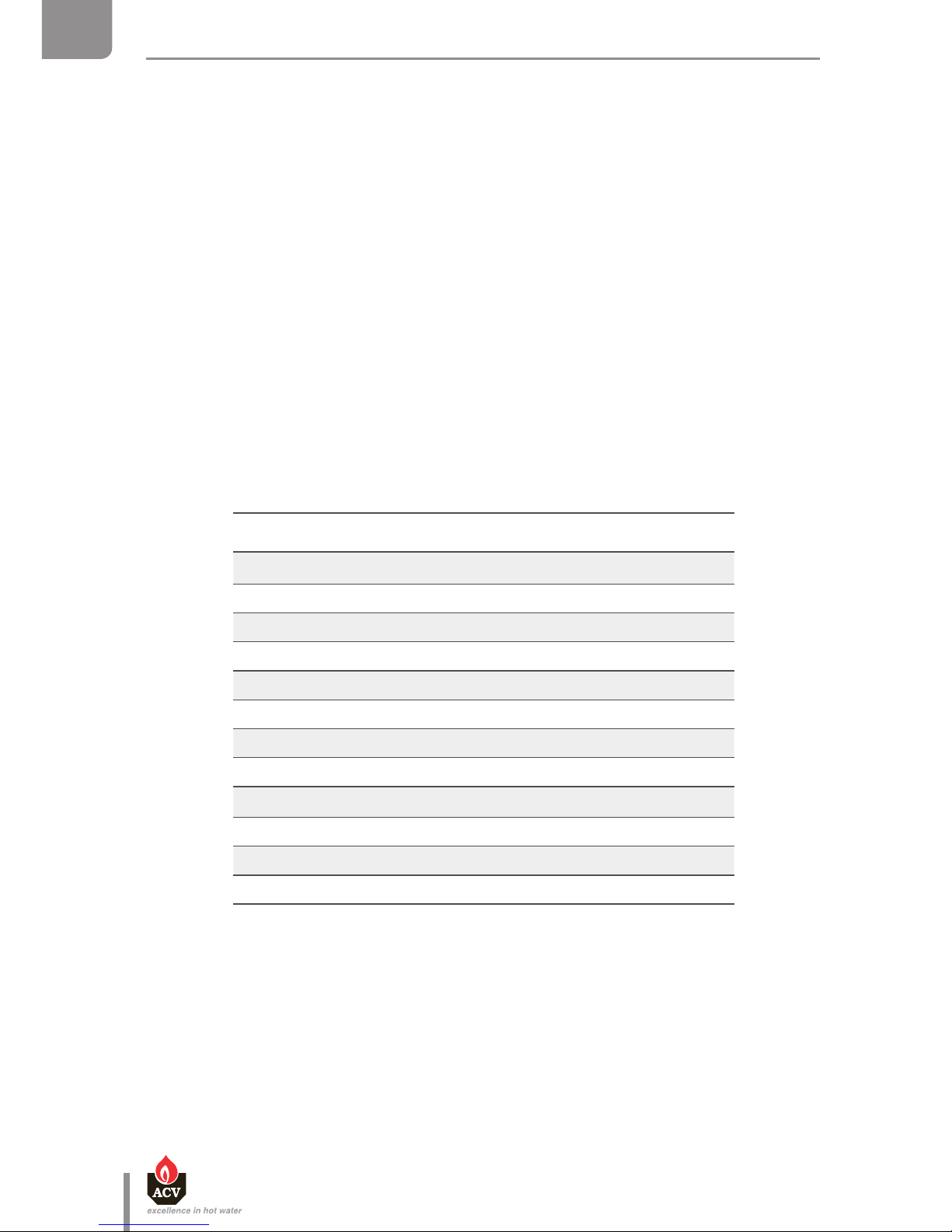

BURNER DESCRIPTION

ACV AIR/GAS premix BG 2000-M burner

Main components of the burner:

- Variable speed fan

- Automatic ignition and ame detection system

- Gas valve/venturi set specially developed for low NOX air/gas premix burners.

The power continually adjusts to demand, which greatly improves the general eciency of the heating

and DHW systems. The burner tube is covered with a metal ber element (NIT) which, besides its

remarkable heat exchange capacity, guarantees longer burner life.

The controller guarantees that the gas pressure at the gas valve outlet is kept equal to the absolute air

pressure at the venturi inlet, corrected by the oset adjustment value. The fan draws the combustion

air through the venturi, whose neck is connected to the gas valve outlet. The pressure dierential

created at the venturi neck by the air ow rate generates a gas intake proportional to its amount (the

higher the air ow rate, the higher the pressure dierential, and therefore the gas intake). The air/gas

mix is then introduced into the burner via the fan.

Detail of components

1.

Fan

2.

Gas valve

3.

Venturi

4.

Burner chamber plate flange

5.

Heat exchanger seal

6.

Insulation

7.

Burner tube

8.

Fan seal

9.

Flame sight glass

10.

Electrode seal

11.

Electrode

12.

Ignition cable (part of the electrode assembly in the HM 45 TC)

12

1

2

3

4

5

6

7

8

10

11

9

en

13

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TECHNICAL CHARACTERISTICS

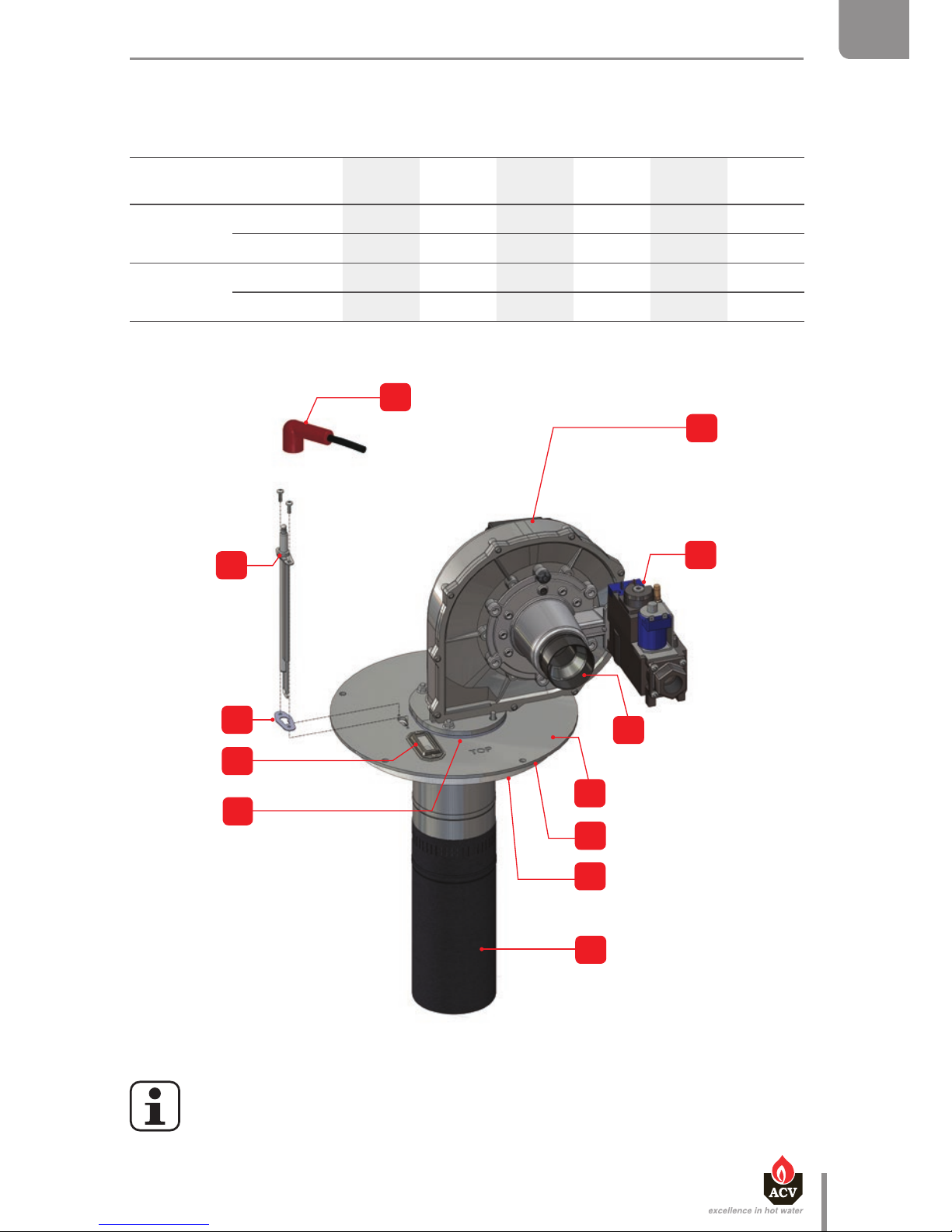

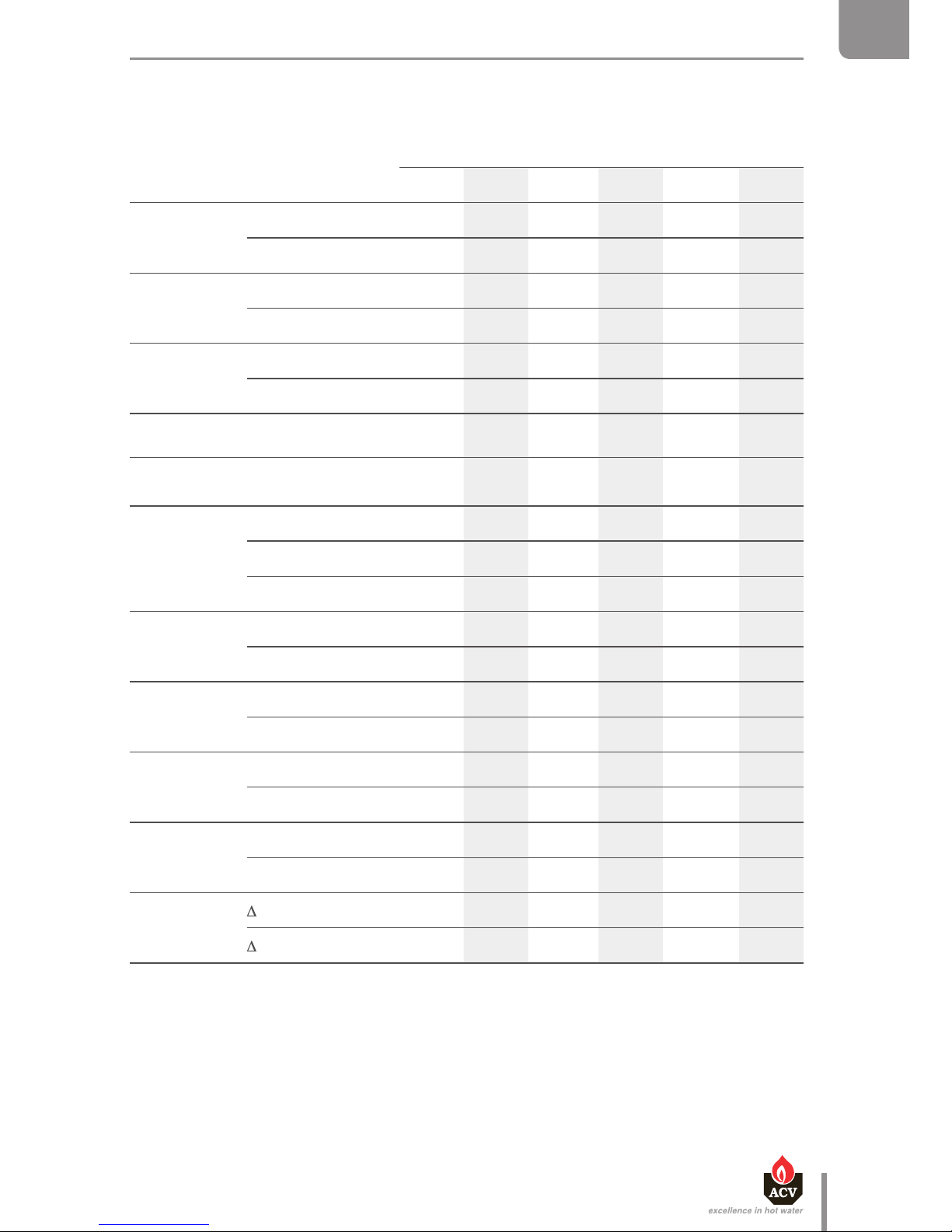

BURNER CHARACTERISTICS

HM 25 TC HM 35 TC HM 45 TC HM 70 TC HM 85 TC HM 120 TC

Gas type

Nat. gas

Propane

Nat. gas

Propane

Nat. gas

Propane

Nat. gas

Propane

Nat. gas

Propane

Nat. gas

Propane

Min fan speed

Nat. gas rpm 1500 2000 1600 1900 1900 1300

Propane rpm 1500 2400 1800 1900 1900 1300

Max. fan speed

Nat. gas rpm 6500 6300 6800 4900 6500 5300

Propane rpm 6100 6500 6900 4500 6000 5300

• The figure shows the HM 120 TC burner. The HM 25 / 35 / 45 / 70 / 85 TC burner

configuration is slightly different.

en

14

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TECHNICAL CHARACTERISTICS

SINGLE GAS CATEGORIES All models

Gas type G20 G25 G20 / G25 G25.1 G31 G30

Pressure (mbar) 20 25 20-25 25 30 37 50 30 50

Country

code

Category

AT

I

2H

I

3P

I

3B/P

BE

I

2E(S)

*

I

2E(R)

**

I

3P

CH

I

2H

I

3P

I

3B/P

CY

I

2H

I

3B/P

CZ

I

2H

I

3P

DE

I

2E

I

2ELL

I

3P

I

3B/P

DK

I

2H

I

3B/P

EE

I

2H

I

3B/P

ES

I

2H

I

3P

FR

I

2Er

I

3P

I

3B/P

GB

I

2H

I

3P

I

3B/P

GR

I

2H

I

3P

HR

I

2H

I

3P

I

3B/P

HU

I2

HS

I

3B/P

* HM 25 / 35 / 45 / 70 TC

** HM 85 / 120 TC

en

15

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TECHNICAL CHARACTERISTICS

Gas type G20 G25 G20 / G25 G25.1 G31 G30

Pressure (mbar) 20 25 20-25 25 30 37 50 30 50

Country

code

Category

IE

I

2H

I

3P

IT

I

2H

I

3P

I

3B/P

LT

I

2H

I

3P

I

3B/P

LU

I

2E

I

3B/P

LV

I

2H

NL

I

2L

I

3P

I

3B/P

NO

I

2H

I

3B/P

PL

I

2E

I

3P

I

3B/P

PT

I

2H

I

3P

RO

I

2H

I

2E

I

3P

I

3B/P

SE

I

2H

I

3B/P

SI

I

2H

I

3P

I

3B/P

SK

I

2H

I

3P

I

3B/P

TR

I

2H

I

3B/P

en

16

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TECHNICAL CHARACTERISTICS

DOUBLE GAS CATEGORIES HM 70 / 85 / 120 TC only

Gas type G20 G25

G20

G25

G31 G30

G30 G31

Pressure (mbar) 20 20 25

20

25

30 37 50 30 50

28 - 30

37

50

67

Country code Category

AT

II

2H3P

II

2H3B/P

CH

II

2H3P

II

2H3B/P

II

2H3+

CY

II

2H3B/P

II

2H3+

CZ

II

2H3P

II

2H3+

DE

II

2E3B/P

II

2ELL3B/P

DK

II

2H3B/P

EE

II

2H3B/P

ES

II

2H3P

FI

II

2H3B/P

FR

II

2Er3P

II

2E+3+

GB

II

2H3P

II

2H3+

GR

II

2H3P

II

2H3+

HR

II

2H3P

II

2H3B/P

HU

II

2H3B/P

IE

II

2H3P

II

2H3+

IT

II

2H3P

II

2H3B/P

II

2H3+

en

17

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TECHNICAL CHARACTERISTICS

Gas type G20 G25

G20

G25

G31 G30

G30 G31

Pressure (mbar) 20 20 25

20

25

30 37 50 30 50

28 - 30

37

50

67

Country code Category

LT

II

2H3P

II

2H3B/P

II

2H3+

LU

II

2E3B/P

NL

II

2H3B/P

NO

II

2H3B/P

PL

II

2E3B/P

PT

II

2H3P

II

2H3+

RO

II

2H3P

II

2H3B/P

II

2E3B/P

SE

II

2H3B/P

SI

II

2H3P

II

2H3B/P

II

2H3+

SK

II

2H3P

II

2H3B/P

II

2H3+

TR

II

2H3B/P

en

18

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TECHNICAL CHARACTERISTICS

COMBUSTION CHARACTERISTICS

Main Characteristics

HM 25 TC HM 35 TC HM 45 TC

G20/G25 G31 G20/G25 G31 G20/G25 G31

Input (PCI)

max kW 25.0 25.0 34.9/34.5 31.0 45.6 40.7

min kW 4.7 5 9.8/10.6 10.0 9.0/9.6 8.8

Output at 100%

(80/60°C) kW 24.3 24.3 34.0/33.6 30,2 44.7 39.9

(50/30°C) kW — — — — 47.4 42,3

Eciency at 100%

(80/60°C) % 97.3 97.3 97.3 97.3 98.0 98.0

(50/30°C) % — — — — 103.9 103.9

Eciency at 30% load (EN677) % 108.9 108.9 108.9 108.9 108.9 108.9

Combustion

eciency

at 100% % 98.2 98.2 98.2 98.2 97.9 98.2

NOx (Class 5)

Max. output mg/kWh 74 81 59 72 42 42

Min. output mg/kWh 33 31 33 31 24 24

Weighted mg/kWh 53 53 41 41 38 38

CO

Max. output mg/kWh 44 55,3 89.1/103.9 119.6 61.3/82.2 184

Min. output mg/kWh 23 9 4.6/17.1 20.9 5.9 4.8

CO

2

Max. output %CO29.3 10.7 9.3 10.5 8.9/9.16 11.2

Min. output %CO

2

8.8 10.7 8.4/9.1 9.8 8.7 9.5

Max gas ow rate

G20/G25

20 mbar m³/h 2.64 3.75 4.8

25 mbar m³/h 2.64 4.25 5.7

Max. gas ow rate

G31

30/37/50 mbar Kg/h 2.0 2.0 2.7

30/37/50 mbar m³/h 1.26 1.26 1.66

Standby loss

T = 45 K

W 187 187 187 187 187 187

T = 30 K

W 113 113 113 113 113 113

en

19

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TECHNICAL CHARACTERISTICS

Main Characteristics

HM 70 TC HM 85 TC HM 120 TC

G20/G25 G31 G20/G25 G31 G20/G25 G31

Input (PCI)

max. kW 69.9 69.9 85.9/85.0 83.6 115/114.6 115

min. kW 24.5 24.5 24.5 24.5 23.2 24.8

Output at 100%

(80/60°C) kW 68.0 68.0 82,.9 83.6 111.6 111.6

(50/30°C) kW — — — — 121.7 121.7

Eciency at 100%

(80/60°C) % 97.3 97.3 97.5 97.5 97.1 97.1

(50/30°C) % — — — — 105.8 105.8

Eciency at 30% load (EN677) % 109.0 109.0 108.4 108.4 108.8 108.8

Combustion

eciency

at 100% % 98.1 98.1 98.0 98.0 97.5 97.5

NOx (Class 5)

Max. output mg/kWh 52 85 72/65 85 57/56 49

Min. output mg/kWh 27 27 27 27 10 42

Weighted mg/kWh 28 28 44 44 56 56

CO

Max. output mg/kWh 56.3 90.0 74.4/118.7 98.8 119.2/121.4 103.0

Min. output mg/kWh 2.0 45.0 5.9/55.0 53.8 7.6/61.8 12.8

CO

2

Max. output %CO29.1 10.9 9.3 10.9 9.3 10.2

Min. output %CO

2

8.6 10.0 8.6 8.5/10.0 8.4 10.0

Max gas ow rate

G20/G25

20 mbar m³/h 7.4 9.0 12.2

25 mbar m³/h 8.6 10.5 14.2

Max. gas ow rate

G31

30/37/50 mbar Kg/h 5.43 5.6 7.5

30/37/50 mbar m³/h 2.86 3.4 4.69

Standby loss

T = 45 K

W 342 342 342 342 342 342

T = 30 K

W 206 206 206 206 206 206

en

20

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

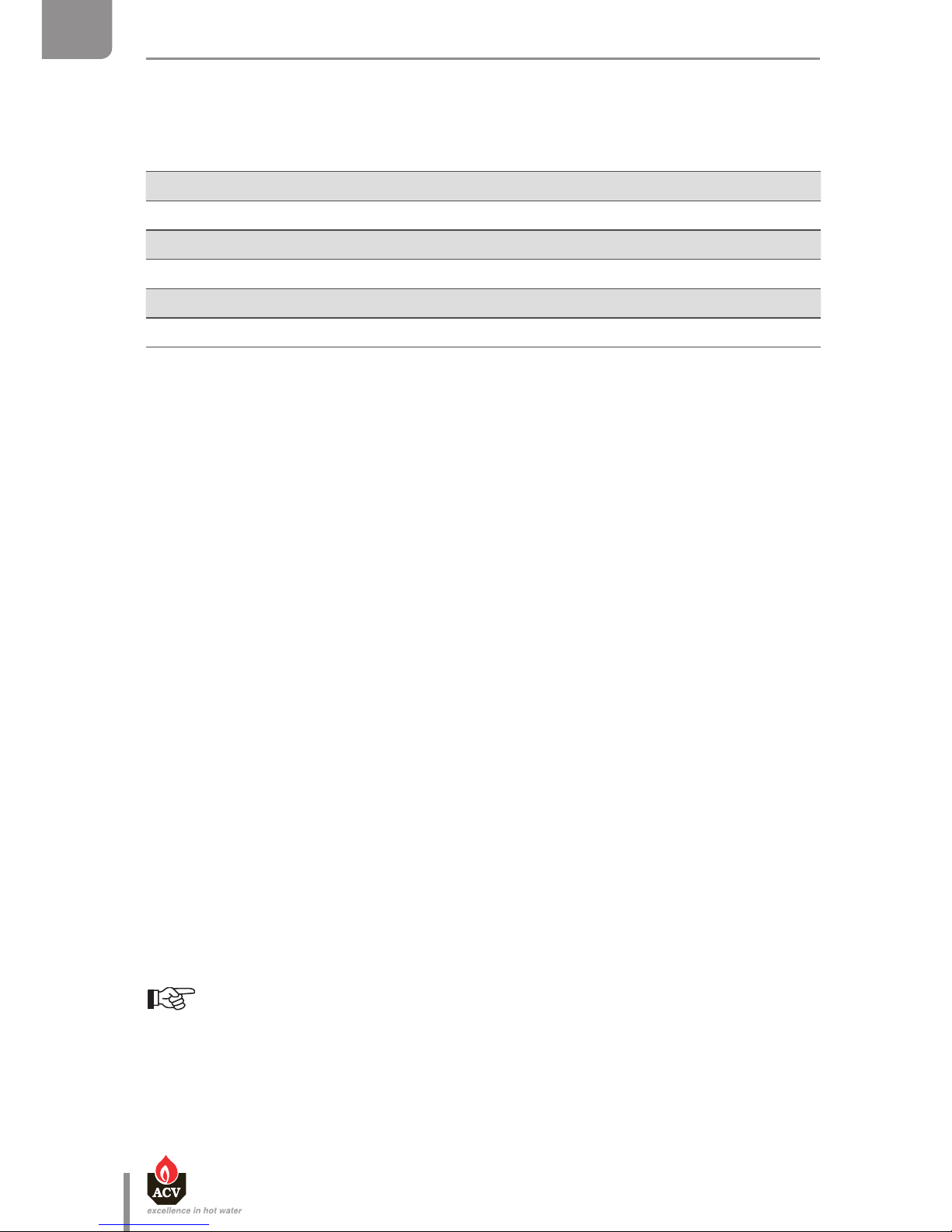

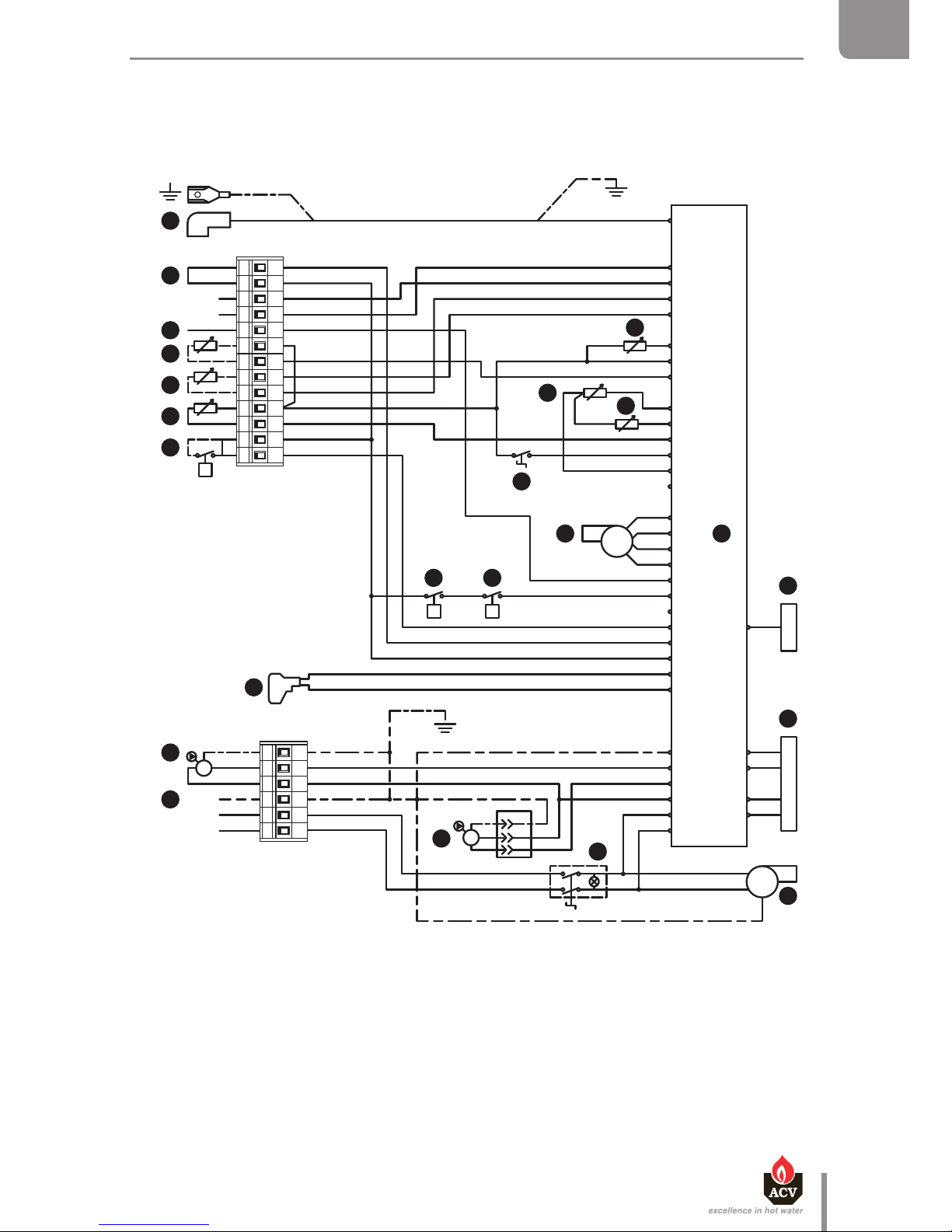

ELECTRICAL CHARACTERISTICS HM TC EQUIPPED WITH A

STANDARD CHARGING PUMP

TECHNICAL CHARACTERISTICS

Description

1. 230 V power supply plug

2. ON/OFF master switch

3. Charging pump

4. Heating pump (option)

5. Gas valve rectifier

6. 230 Volt-24 Volt transformer

7. MCB A

8. Display

9. Low water pressure switch

10. Burner PWM plug

11. Summer/winter switch

12. NTC1 flow sensor

13. NTC2 return sensor

14. NTC5 flue gas temperature sensor

15. Room thermostat (option)

16. NTC3 DHW sensor

17. NTC4 outdoor temperature sensor (option)

18. NTC6 flow sensor for second heating circuit (option)

19. Positive terminal of the ionization current

20. RAM high limit thermostat (option)

21. Ignition and ionization cable

22. 230 Volt burner power supply (HeatMaster® 70 / 85 TC)

23. Gas pressure switch (HeatMaster® 70 / 85 TC)

The ionization current is measured between terminal 19 and ground.

Main Characteristics

HM 25 / 35 TC HM 70 / 85 TC

Rated voltage V~ 230 230

Rated frequency Hz 50 50

Rated current (fuse) A 6 6

Electrical consumption W 176 220 / 230

Input intensity A 0.8 1

IP Class IP 30 IP 30

Br

B

B

V

W

Y/Gr

B

Br

G

R

V

O

R

W

V

R

Bk

B

Bk

O

Br

R

Br

B

R

Br

Bk

Bk

O

Br

B

R

Bk

230V ~ 50Hz

Br

B

Br

B

B

Br

G

R

V

BkB

RB

B

V

G

O

B

BUS B

BUS A

W

Br

Bk

O

Br

R

Bk

Br

G

R

Br

B

Y/Gr Y/Gr

Y/Gr

B

W

L

N

PE

Y/Gr

B

Br

B

B

B

Y/Gr

X12.

P P

X11.

L1

N

PE

M

M

1 2 3 4 5 6 7 8 9 10 11 12 13

1 2 3 4 5 6

X1.6

X1.5

X1.4

X1.3

X1.2

X7

X10.6

X10.7

X10.1

X10.3

X1.1

X2.12

X2.11

X2.10

X2.9

X2.8

X2.7

X2.6

X2.5

X2.4

X2.3

X2.2

X2.1

X3.6

X3.5

X3.4

X3.3

X3.2

X3.1

X4.3

X4.2

X4.1

X5.4

X5.3

X5.2

X5.1

t

V OG

22

23

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

B. Blue

Bk. Black

Br. Brown

G. Grey

O. Orange

R. Red

V. Violet

W. White

Y/Gr. Yellow/Green

en

21

Heat Master TC : 6 64Y6800 • A

EN

FR

NL

ES

IT

DE

PL

RU

TECHNICAL CHARACTERISTICS

Loading...

Loading...