Page 1

HEAT-ZONE-WOOD AIR DUCT KIT

Ceiling Register

Wall Register

Floor Register

Two Duct Kits

Ceiling Register

12" (305mm) minimum clearance

from register to ceiling

Part No: HEAT-ZONE-WOOD

APPROVALS

The Heat-Zone-Wood air duct kit is approved to

use on EPA Fireplaces 7100FP, North Star and

Constitution.

INTRODUCTION

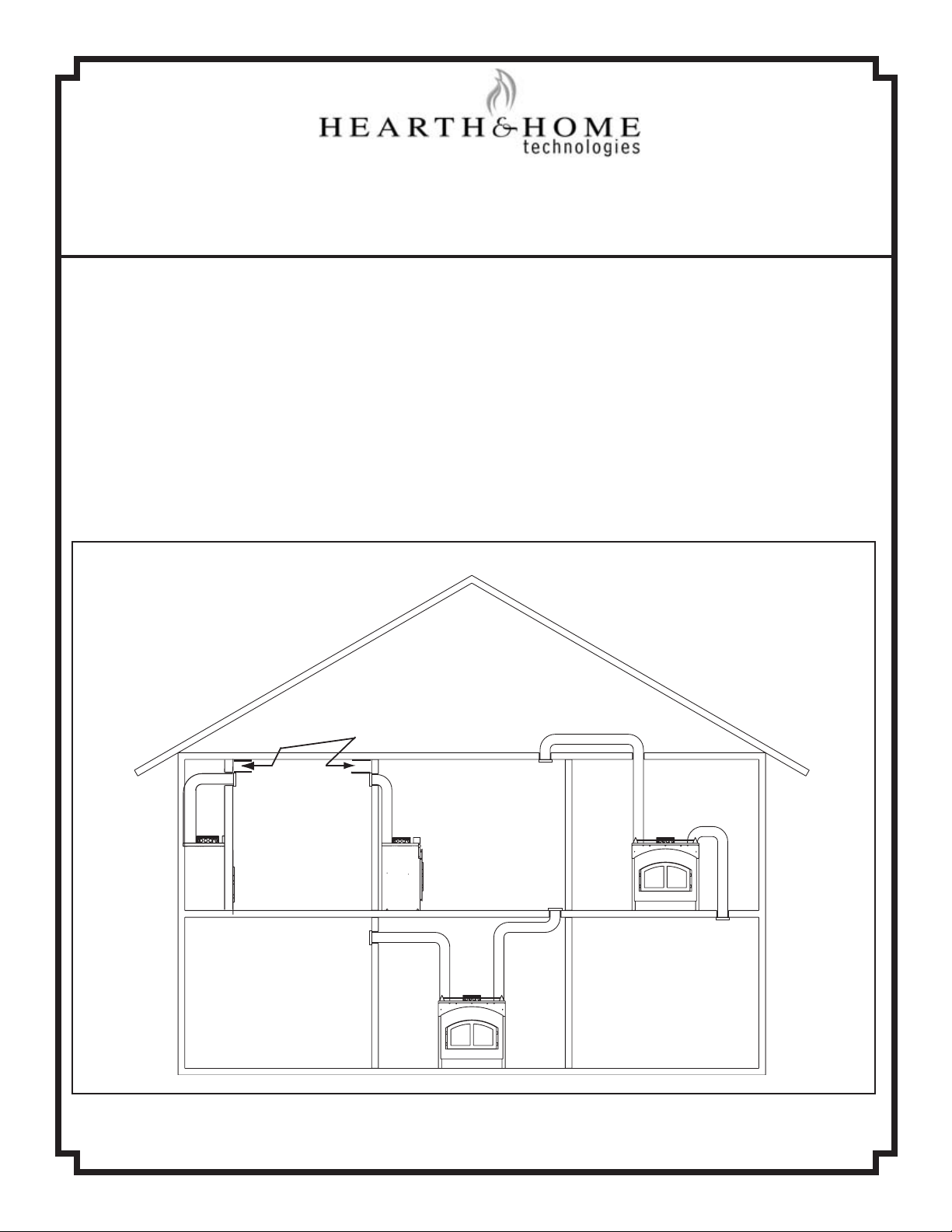

The Heat-Zone-Wood accessory kit conveys warm

air from the replace through air duct(s) to remote

locations in the same room or other rooms of the

building. See Figure 1. One or two Heat-Zone

kits can be installed on the replace.

Possible Air Duct Runs / Locations

PRELIMINARY PREPARATION

1. Contents of kit:

• 16” Snap Lock Starter pipe - cut to

desired length (See Figure 2 on page 2).

• Mounting Plate

• Adapter

• Fan Housing Assembly

• Return Air Grille

• Gasketing

• Variable Speed Wall Rheostat

• Fastener Package

If any parts are missing or damaged, contract your dealer

before starting installation. DO NOT install a damaged kit.

1445 North Highway

Colville, WA 99114

7015-114 September 5, 2003 Page 1 of 4

Figure 1

www.quadrare.com

Page 2

2. This kit is tested and safe when installed in

Adapter

Mounting

Plate

Starter Pipe

Knockout

Cut a

3

"

(

7

6

m

m

)

ho

l

e

in

in

su

l

a

t

io

n

3-13/16"

(97mm)

3-1/8" (79mm)

C

L

accordance with this installation manual. It is your

responsibility to read all instructions before starting installation and to follow these instructions

carefully during installations.

3. Installation of this kit MUST by performed by a

qualied service technician.

4. The Heat-Zone-Wood kit is carefully engineered

and must be installed only as specied. If you

modify it or any of its components you will void

the warranty and you may possibly cause a re

hazard. Installation must be done according to

applicable local, state, provincial and/or national

codes.

5. CAUTION: ALL wiring should be done by a

qualied electrician and shall be in compliance

with local codes and with the National Electric

Code ANSI/NFPA No. 70-current (in the United

States) or with the current CSC22.1 Canadian

Electric Code (in Canada).

6. Plan the location of the replace and warm air

duct run(s).

DUCT RUN REQUIREMENTS

MAXIMUM Duct Run = 40-ft (12m)

MINIMUM Duct Run = 36” (914mm)

DUCTING MATERIAL

6 inch (152mm) B-Vent Only

DO NOT DUCT into existing furnace plenum

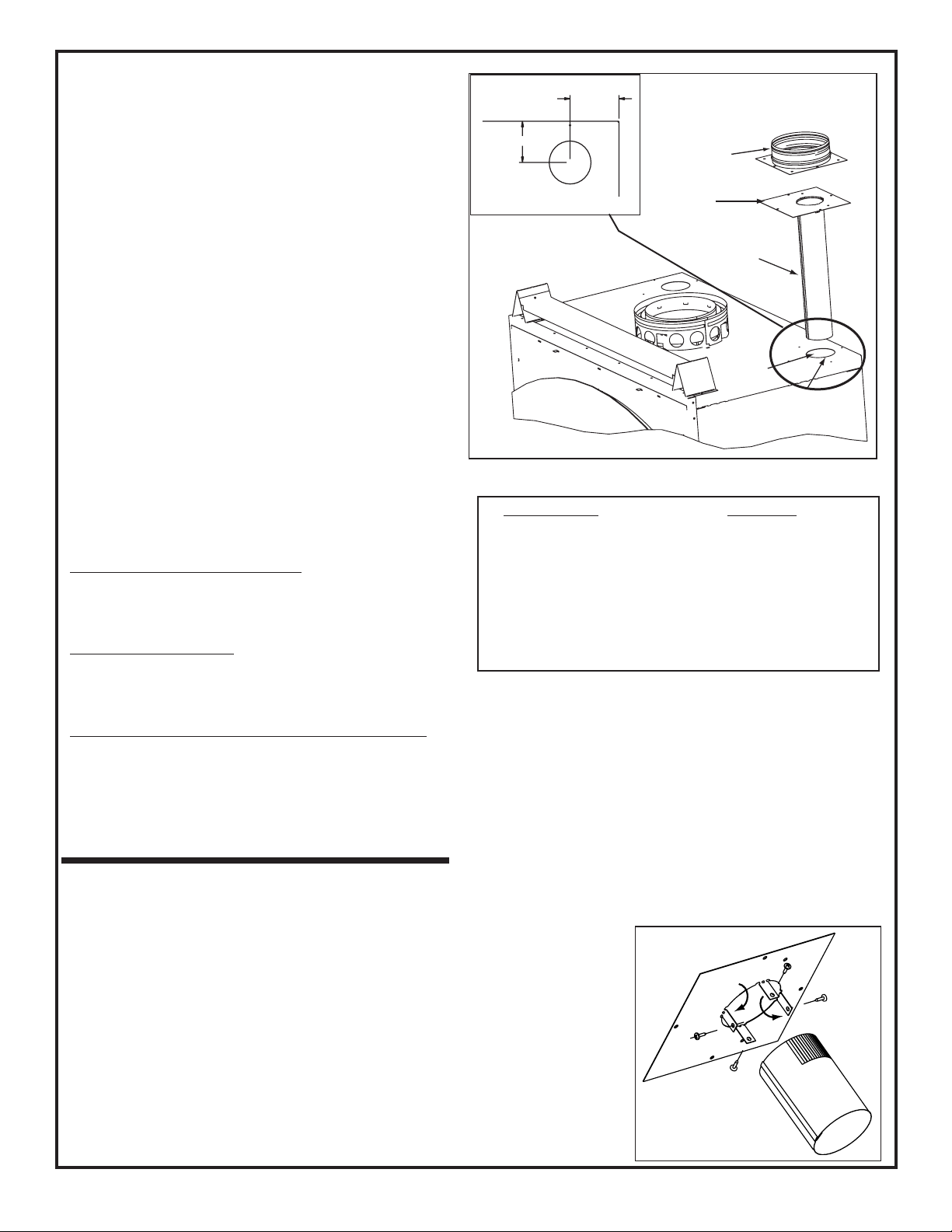

Figure 2

Run Length Cut Pipe

20 - 40 ft (6-12m) 2” (51mm)*

*A minimum of 2” (51mm) pipe must be used to

cover the raw insulation to prevent it tfrom blowing

out through the Return Air Grille.

10 - 20 ft (3 - 6m) 8” (203mm)

3 - 10 ft (1 - 3m) No cut needed**

**Use full 16” (406mm) as supplied

Figure 3

MINIMUM CLEARANCE TO COMBUSTIBLES

1 inch (25mm) from the B-Vent

1

/2 inch (13mm) from top & bottom of outlet box

0 inch (0mm) from the sides of outlet box

12” (305mm) from wall register to ceiling*

*(See Figure 1 on page 1).

INSTALLATION

1. Remove the knockout or cover plate from the top of

the replace and discard it. See Figure 2.

2. Cut a 3” (76mm) hole in the insulation board as per

the dimensions shown in Figure 2.

3. Determine the necessary length of starter pipe from

the following table and cut as required. See Figure 3.

4. The starter pipe is shipped at. After cutting to the

required length, manually roll the pipe together and

snap lock into place. NOTE: It is important the pipe

length be adhered to or it will affect the performance of your replace.

7015-114 September 5, 2003 Page 2 of 4

5. On the Mounting Plate, hand bend the tabs downward. Slide the tabs over the outside of the starter

pipe. Secure with 4 sheet metal screws included in

fasteners package. Figure 4

6. Slide the starter pipe into the replace, matching

the holes in the plate to the holes in the replace.

7. Place the Adapter on the Mounting Plate lining up

holes. Using the 4 sheet metal screws included in the

kit, secure the Adapter and Mounting Plate into re-

Figure 4

Page 3

place. After securing to the replace, tape down

Securely Twist

Lock B-Vent to

Adapter

Secure B-Vent to Fan Housing

with sheet metal screws

Return Air Grille

Install with Louvers

pointed down

Bracket

Can rotate

180

o

2 x 4 Wall

Fan Housing

1/2" (13mm)

clearance to

combustibles

must be

maintained.

2 x 4 wall

Sheet Rock

S

e

a

l

g

ri

lle

u

s

in

g

g

a

s

k

e

tin

g

s

u

p

p

li

e

d

w

ith

th

e

k

it

Leave 1/4" (6mm) clearance from

all 4 outer edges

the Adapter edges to the top of the replace with

aluminum tape to prevent leakage.

Also screw the B-Vent to the outlet box on the fan

housing. See Figure 6.

Support duct at intervals of no

greater than 4 ft (1 m) as required by local code.

8. Determine the location for the air register and

fan housing assembly. Cut a 7-5/8” x 13-5/8” (143

x 346mm) hole between framing members (wall

studs or oor joists). The brackets can be rotated

180° and mounted to the back side of the 2 x 4 if

necessary. See Figure 6.

NOTE: The fan and electrical connections

must be accessible for servicing per local code

requirements.

NOTE: If the fan housing is installed in a 2

x 4 wall, the front of the housing will protrude

approximately 1/4” (6mm) from the nished wall.

See Figure 5.

WARNING! 1/2” (13mm) clearance to

combustibles must be maintained.

8. Attach enough 6” (152mm) B-Vent as required

for your installation to the fan housing. A max-

imum of (4) 90° elbows is recommended.

Securely twist lock the B-Vent to the Adapter.

NOTE: Secure the duct so that clearance to the

replace outer wrap is maintained. Tape all seams

with aluminum tape 1-1/4” (32mm) minimum width

or as specied by local codes.)

9. Seal all the way around the inside of the Return

Air Grille to prevent hot air being drawn back into the

venting system using gasketing supplied with the kit.

Leave 1/4”(6mm) clearance from all 4 outer edges.

Trim excess gasketing. See Figure 7.

Figure 6

Figure 5

Figure 7

7015-114 September 5, 2003 Page 3 of 4

Page 4

Junction Box Removed

Wire Clamp

Wire Nuts

Junction Box

Black

White

10. Install the variable speed wall rheostat (with

Remove 2

screws from

Junction Box

access panel

Remove 2 bolts from fan

bracket

setting on “OFF”) in a convenient location. This

switch will control the Heat-Zone fan operation.

11. Remove the Junction Box. Wire 110 VAC

service TO the wall rheostat and FROM the wall

rheostat to the fan Junction Box. Use wire nuts

to secure the 110 VAC service wires to the hot

(black) and neutral (white) fan wires and screw

the 110 VAC ground wire to the Junction Box.

See Figure 8.

12. Secure the Return Air Grille to the fan housing

making sure it is ush. The grille must be installed

with the louvers pointing down.

NOTE: DO NOT USE ADJUSTABLE REGISTERS.

13. Complete the replace installations as per

the instructions found in your Owner’s Manual.

OPERATION

1. Start the replace per the instructions found in

your Owner’s Manual and allow it to warm up.

MAINTENANCE

1. Service and maintain the replace as per the

instructions in your Owner’s Manual.

2. Keep the Return Air Grille clean and free of any

blockage.

FAN REPLACEMENT

1. Remove the 2 screws from the Junction Box

access panel. See Figure 9.

2. Using an 11/32 wrench, remove the 2 nuts

from the fan bracket and remove the fan.

3. Install replacement fan and secure in place.

4. Reattach the Junction Box access panel.

2. Turn the wall rheostat to “ON” and adjust the

variable speed based upon desired air ow.

Figure 9

Figure 8

7015-114 September 5, 2003 Page 4 of 4

Loading...

Loading...