Page 1

SERVICE MANUAL

Inverter Flex Multi-Zone

Ductless Mini Split

Outdoor Section

A-VMH18DC-1

A-VMH27TC-1

A-VMH36QC-1

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

Service Manual VMH SerieS Heat Controller, Inc.

CONTENTS

1.General Information of Outdoor Units ........................................................... 3

2. Features........................................................................................................... 4

3. Dimensions ..................................................................................................... 5

4. Wiring Diagram ............................................................................................... 6

5. Refrigeration Cycle Diagram ......................................................................... 8

6. Indoor unit Combinations ............................................................................ 10

7. Installation Details ........................................................................................ 11

8. Electronic Control Function ........................................................................ 20

9. Troubleshooting ........................................................................................... 25

2

Page 3

Heat Controller, Inc. VMH SerieS Service Manual

1. General information of Outdoor Units

Model name Dimension mm(in) Compressor

A-VMH18DC-1 845x320x700(33.3x12.6x27.6) DA130S1C-20FZ

A-VMH27TC-1 845x320x700(33.3x12.6x27.6) DA150S1C-20FZ

A-VMH36QC-1 990x345x965(39x13.6x38) TNB306FPGMC-L

3

Page 4

Service Manual VMH SerieS Heat Controller, Inc.

2.Features

The hydrophilic fin is corrosion resistant and improves heating efficiency in heat mode by absorbing the water on

Operates only in heating mode except during defrosting.

It protects the valves and prevents water from dripping in the cabinet.

Outdoor unit

Power relay control

Low noise air flow system

Hydrophilic aluminum fin

its surface and by spreading the water instead of forming water droplets.

4 way valve control

Anti-rust cabinet

Valve protection cover

Discharge pipe temperature protection

Compressor crankcase heater

4

Page 5

Heat Controller, Inc. VMH SerieS Service Manual

3. Dimensions

Model W D H W1 A B

mm(in)

A-VMH18DC-1

A-VMH24TC-1

A-VMH36QC-1 990(39) 345(13.6) 965(38) 1075(42.3) 624(24.6) 366(14.4)

845((33.3) 320(12.6) 700(27.6) 908(35.7) 560(22) 335(13.2)

5

Page 6

Service Manual VMH SerieS Heat Controller, Inc.

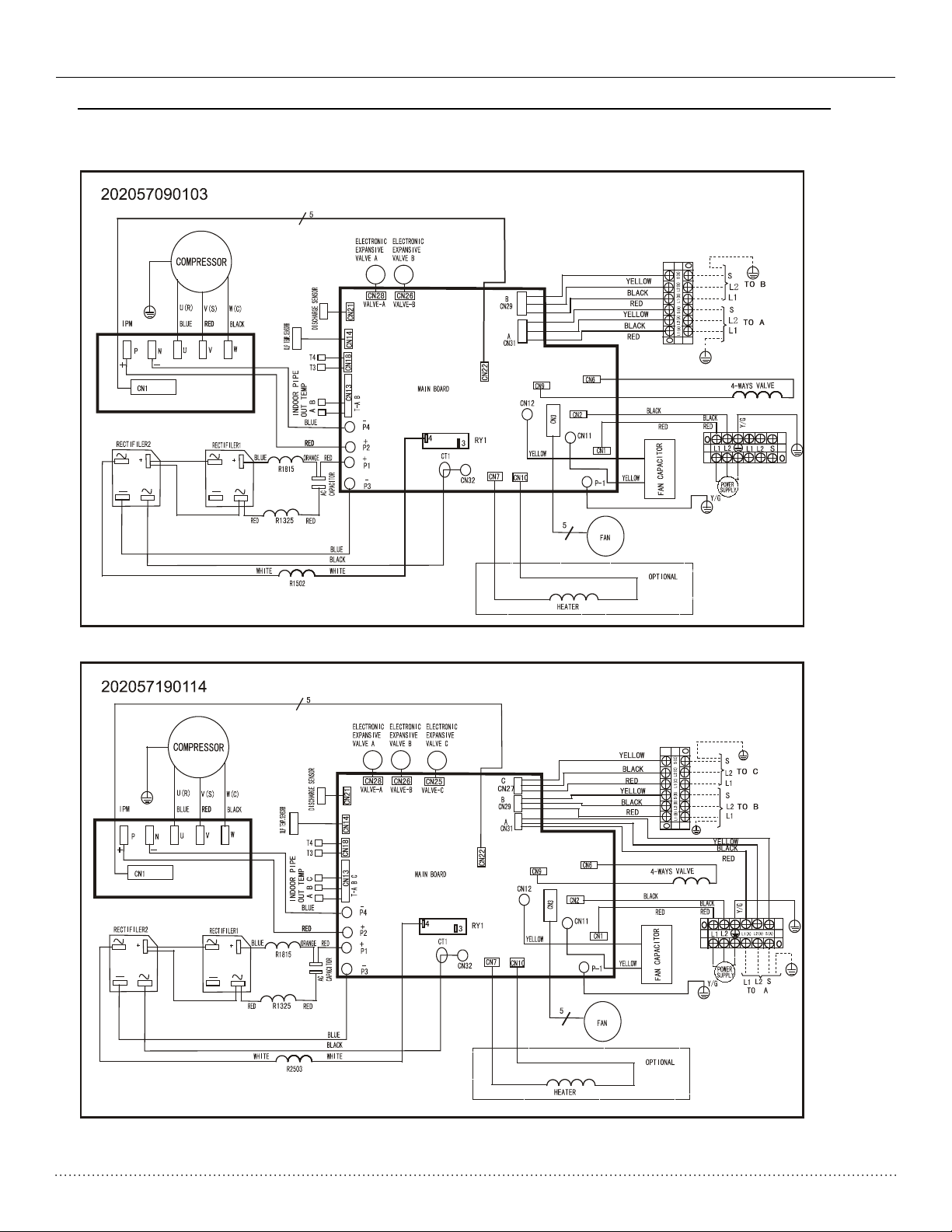

4. Wiring Diagram

4.1 A-VMH18DC-1

4.2 A-VMH27TC-1

6

Page 7

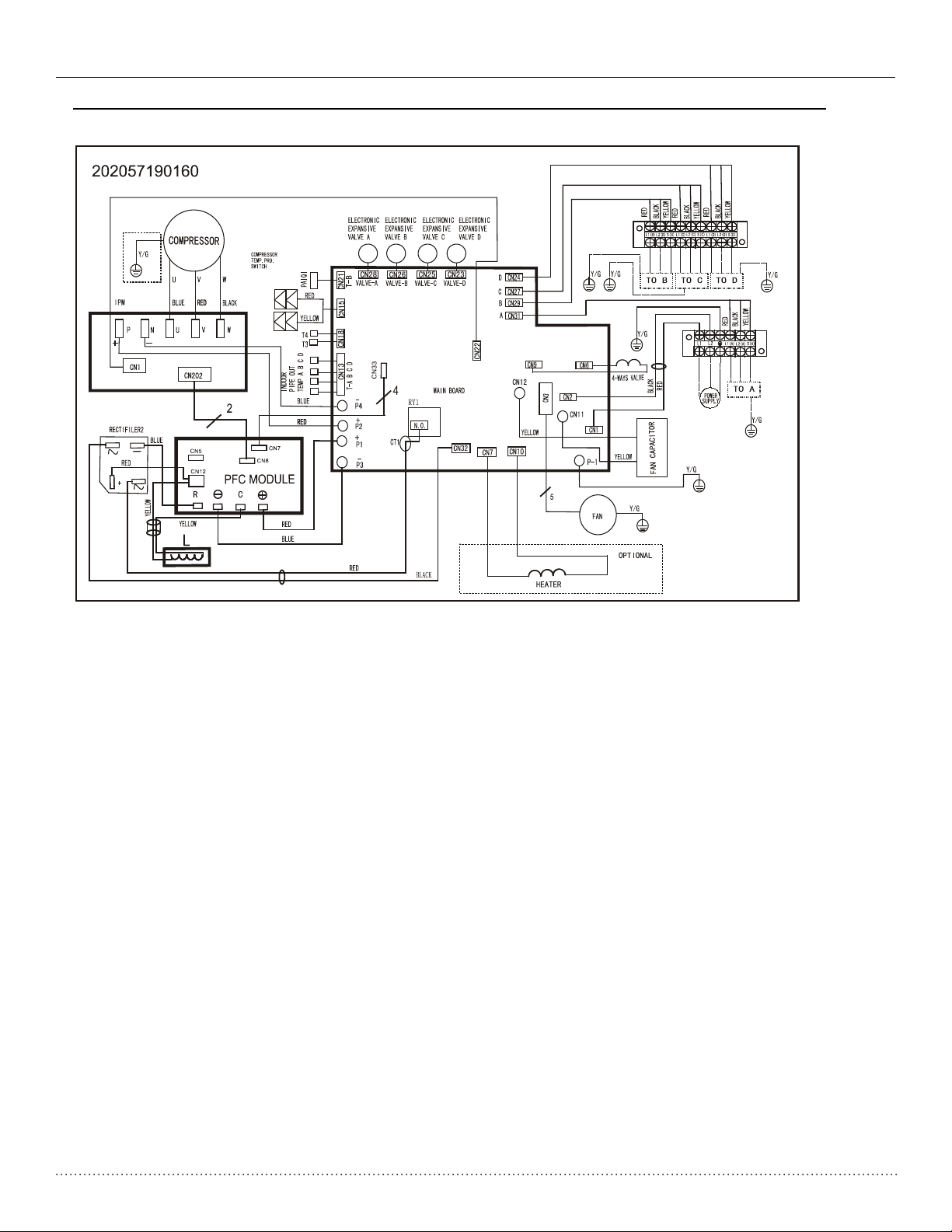

Heat Controller, Inc. VMH SerieS Service Manual

4.3 A-VMH36QC-1

7

Page 8

Service Manual VMH SerieS Heat Controller, Inc.

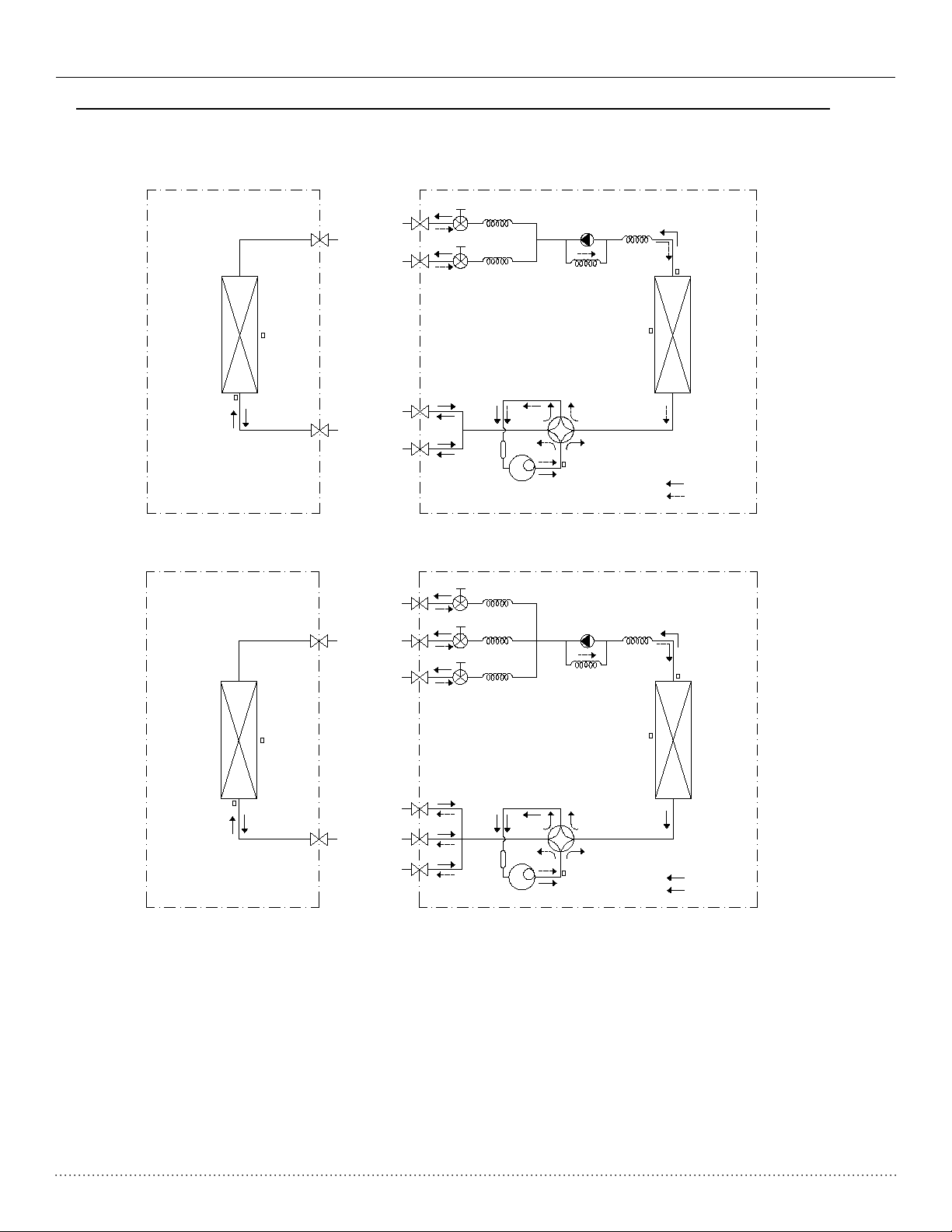

5. Refrigeration Cycle Diagram

8.1 Refrigeration circuit drawing of inverter dual zone: A-VMH18DC-1

INDOOR OUTDOOR

CAPILIARY A

LIQUID VALVE A

LIQUID VALVE B

EXV A

EXV B

CHECK VALVE

CAPILIARY B

CAPILIARY TUBE

T3

Condenser

temp. sensor

HEAT

EXCHANGE

(EVAPORATOR)

T2 Evaporator

temp. sensor

T1 Room

temp. sensor

GAS VALVE A

GAS VALVE B

Accumulator

Compressor

T4 Ambient

temp. sensor

4-WAY VALVE

T5 Discharge

temp. sensor

5.2 Refrigeration circuit drawing of inverter tri-zone: A-VMH27TC-1

INDOOR OUTDOOR

CAPILIARY A

EXV A

EXV B

EXV C

CAPILIARY B

CAPILIARY C

CHECK VALVE

CAPILIARY TUBE

T4 Ambient

temp. sensor

HEAT

EXCHANGE

(EVAPORATOR)

T1 Room

temp. sensor

LIQUID VALVE A

LIQUID VALVE B

LIQUID VALVE C

HEAT

EXCHANGE

(CONDENSER)

COOLING

HEATING

T3

Condenser

temp. sensor

HEAT

EXCHANGE

(CONDENSER)

T2 Evaporator

temp. sensor

GAS VALVE A

GAS VALVE B

GAS VALVE C

Accumulator

Compressor

4-WAY VALVE

T5 Discharge

temp. sensor

COOLING

HEATING

8

Page 9

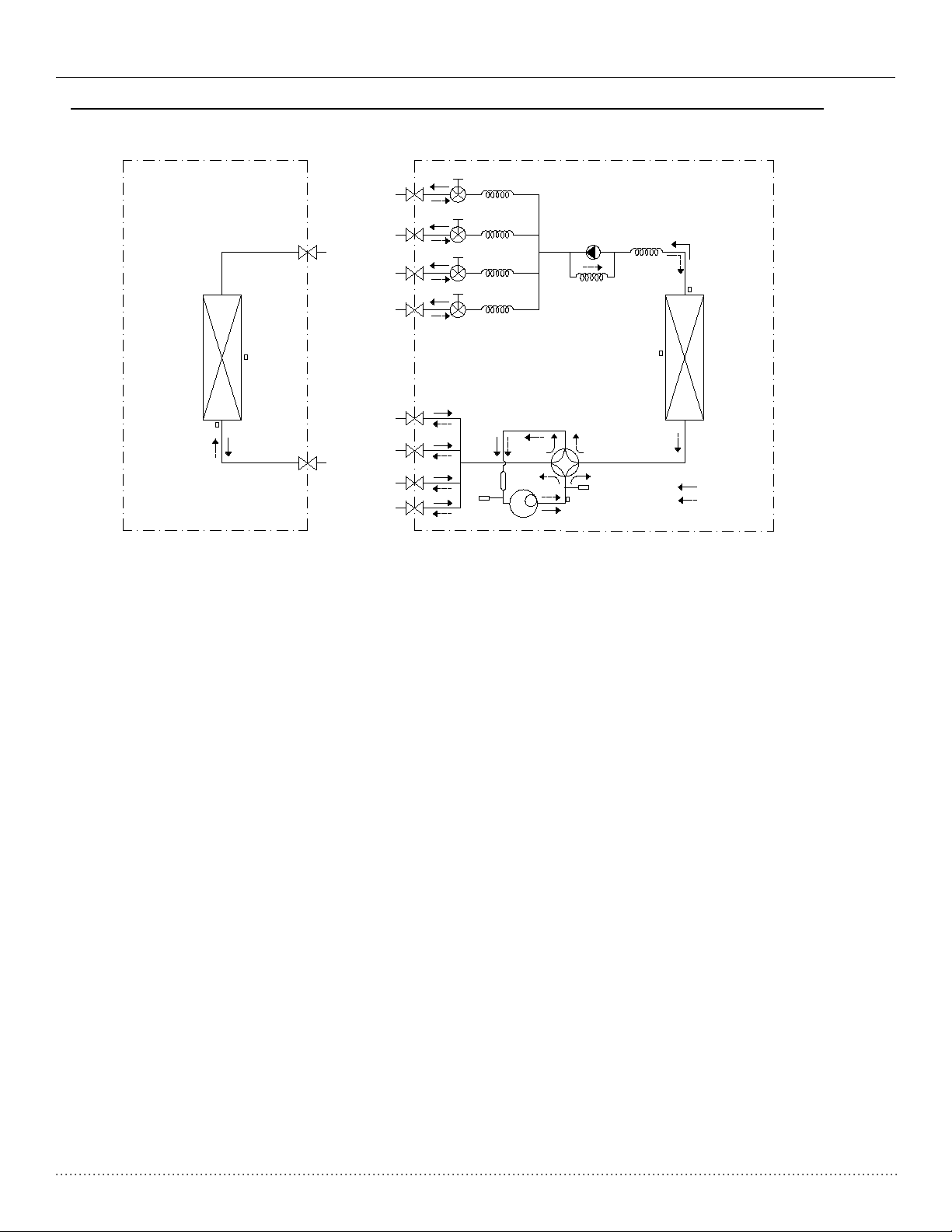

Heat Controller, Inc. VMH SerieS Service Manual

8.3 Refrigeration circuit drawing of inverter Quad-zone: A-VMH36QC-1

INDOOR OUTDOOR

CAPILIARY A

LIQUID VALVE A

LIQUID VALVE B

LIQUID VALVE C

LIQUID VALVE D

EXV A

EXV B

EXV C

EXV D

CAPILIARY B

CAPILIARY C

CAPILIARY D

CHECK VALVE

CAPILIARY TUBE

T3

Condenser

temp. sensor

HEAT

EXCHANGE

(EVAPORATOR)

T2 Evaporator

temp. sensor

T1 Room

temp. sensor

GAS VALVE A

GAS VALVE B

GAS VALVE C

GAS VALVE D

Accumulator

Low pressure

switch

Compressor

T4 Ambient

temp. sensor

4-WAY VALVE

High pressure

switch

T5 Discharge

temp. sensor

HEAT

EXCHANGE

(CONDENSER)

COOLING

HEATING

9

Page 10

Service Manual VMH SerieS Heat Controller, Inc.

Combinations

Unit A

Unit B

9k

—

12k

—

18k

—

9k

9k

9k

12k

Combinations

Unit A

Unit B

Unit C

9k — —

12k — —

18k — —

9k

9k

—

9k

12k

—

9k

18k

—

12k

12k — TRI (1x3)

9k

9k

9k

Combinations

Unit A

Unit B

Unit C

Unit D

9k — —

—

12k — —

—

18k — —

—

9k

9k — —

9k

12k — —

9k

18k — —

12k

12k — —

12k

18k — —

18k

18k — —

9k

9k

9k

—

9k

9k

12k — 9k

9k

18k

—

9k

12k

12k

—

12k

12k

12k

—

QUA(1x4)

9k

9k

9k

9k

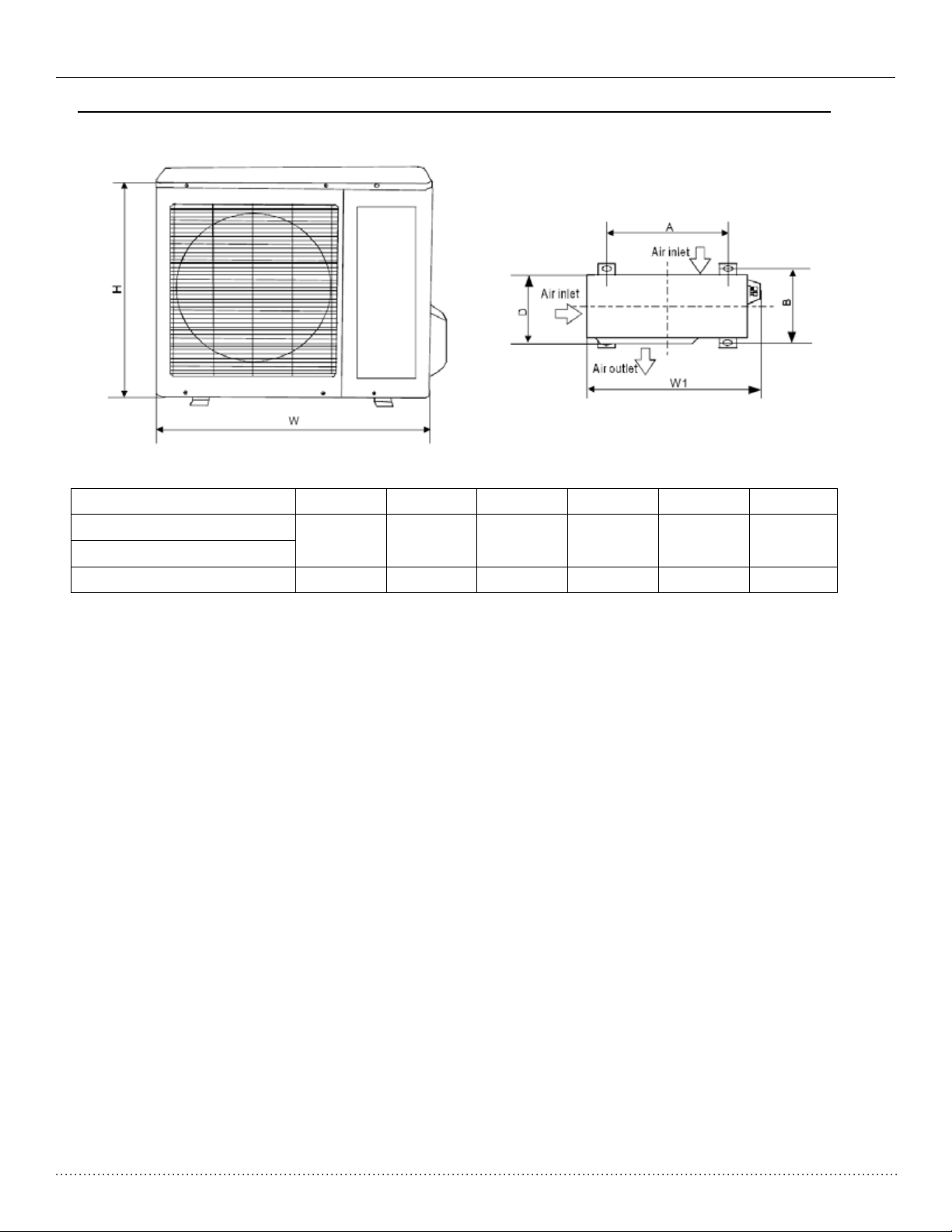

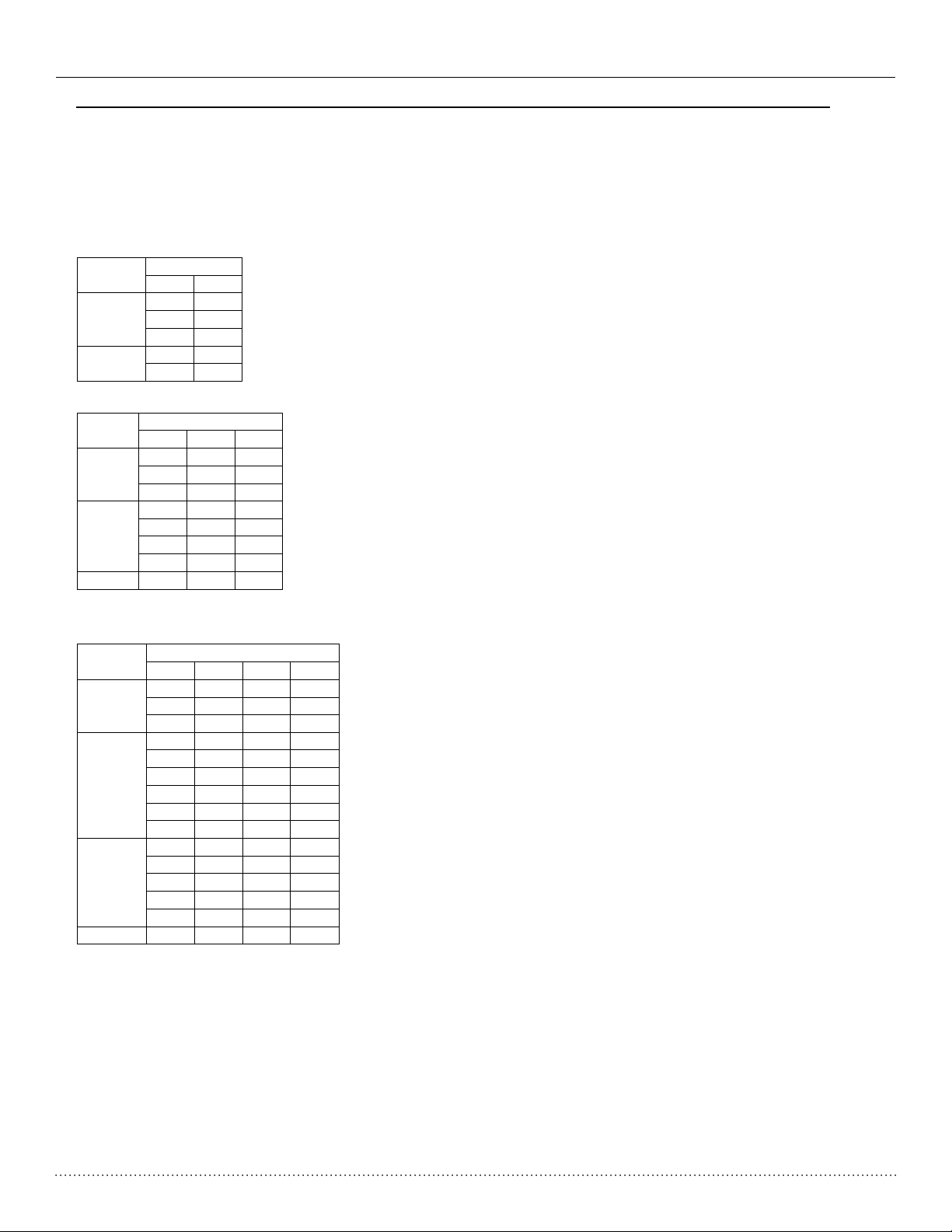

6. Indoor units combination

NOTE: The total capacity of indoor air handlers can not exceed the nominal capacity of the outdoor unit.

The minimum quantity of indoor air handlers is one on any outdoor unit, whether it is a dual, tri, or quad

zone.

6.1 Indoor unit combinations for A-VMH18DC-1

Comb.

Dual(1x1)

Dual (1x2)

6.2 Indoor unit combinations A-VMH27TC-1

Comb.

TRI (1x1)

TRI (1x2)

6.3 Indoor unit combinations A-VMH36QC-1

Comb.

QUA (1x1)

QUA (1x2)

QUA (1x3)

10

Page 11

Heat Controller, Inc. VMH SerieS Service Manual

N.m

N.m

provided with all 12/18k indoor sections.

7. Installation Details

7.1 Wrench torque sheet for installation

Outside diameter Torque Additional tightening torque

mm inch

Ф6.35 1/4 15(153kgf.cm) 16(163kgf.cm)

Ф9.52 3/8 25(255kgf.cm) 26(265kgf.cm)

Ф12.7 1/2 35(357kgf.cm) 36(367kgf.cm)

7.2 Connecting the cables

The power wiring should always follow NEC and local codes, with respect to the unit’s, rating plate. See

installation manual for additional information. Main power connection is 208/230V/1PH~60HZ.

The communicating cable, which connects between the indoor and outdoor units must meet all NEC and

local codes, with respect to the unit’s rating plate. We recommend using 14 AWG/4 conductor Stranded THHN

6

Ф Ф V cable.

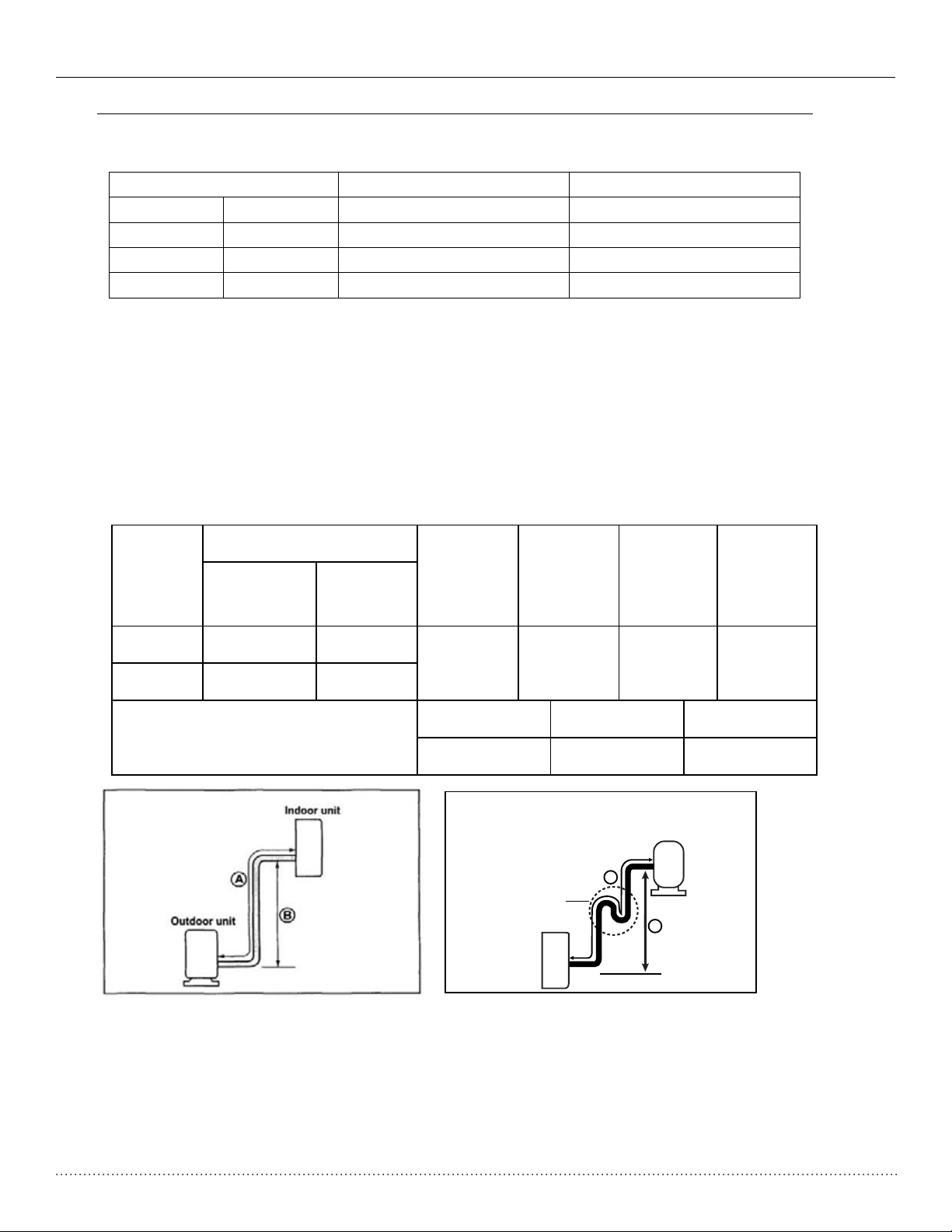

Pipe length and elevation

Pipe size

Unit

Gas inch

(mm)

Liquid inch

(mm)

9K 3/8’’ (Ф9.52) 1/4’’ (Ф6.35)

12K/18K 1/2’’ (Ф12.7) 1/4’’ (Ф6.35)

Max. Total length for all rooms

Standard

length

(m)

(5)

16.5ft

Dual-zone(m) Tri-zone(m) Quad-zone(m)

Max.

Elevation

B (m)

(10)

33ft

Max.

Length

A (m)

(15)

50ft

Additional

refrigerant

(g/m)

(20)

0.2 oz/ft

(30)100ft (45)150ft (60)200ft

2XWGRRUXQLW

$

2LOWUDS

,QGRRUXQLW

%

NOTES:

Capacity test is based on standard length and maximum allowance length is based on reliability.

Oil trap should be installed per (3-5 meters)10-15ft.

Outdoor connections are ¼” (Ф6.35 mm) liquid and 3/8” (Ф9.52 mm) gas, therefore a reducer is

11

Page 12

Service Manual VMH SerieS Heat Controller, Inc.

Hi

Compound meter

Pressure

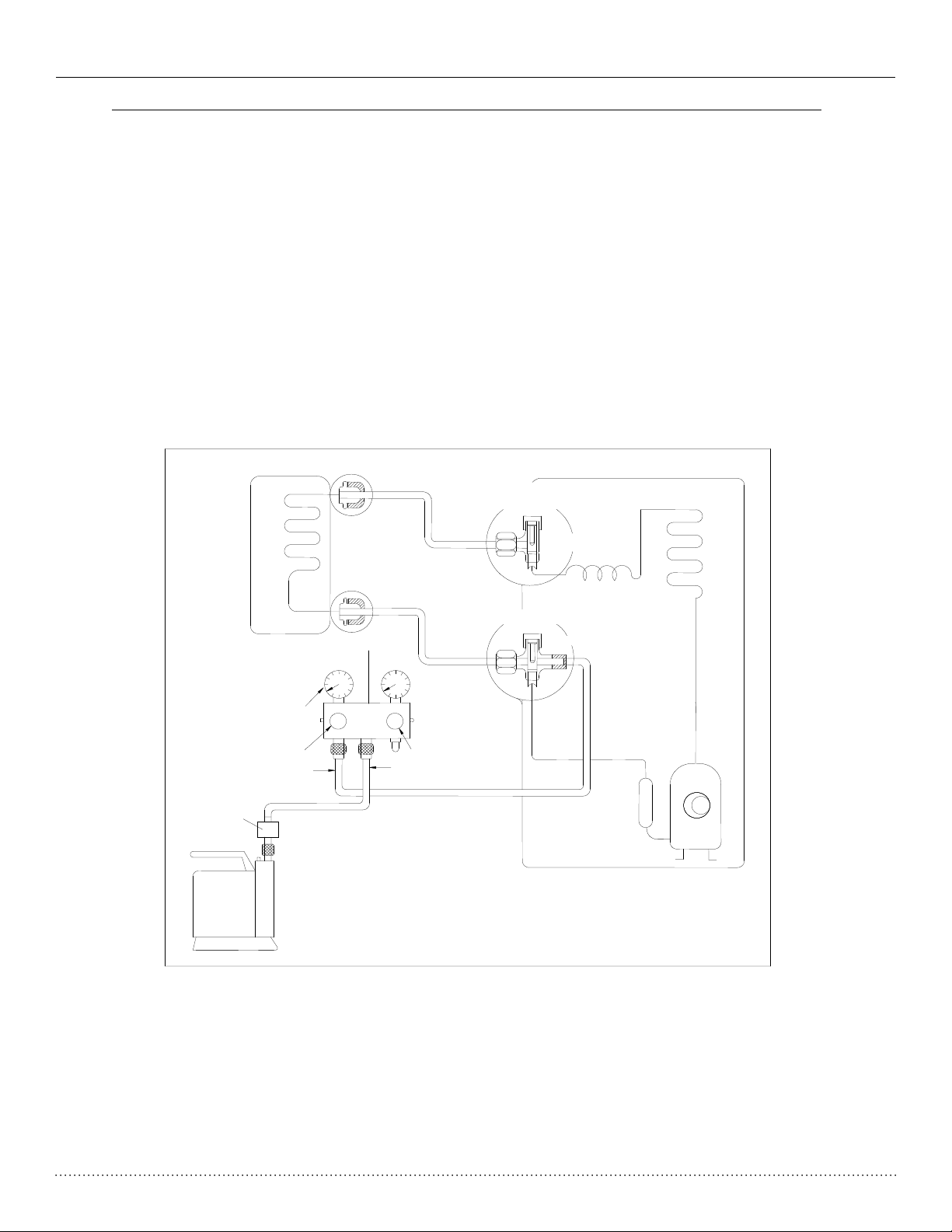

7.4 Installation for the first time

Air and moisture in the refrigerant system have undesirable effects as indicated below:

● Pressure in the system rises.

● Operating current rises.

● Cooling or heating efficiency drops.

● Moisture in the refrigerant circuit may freeze and block capillary tubing.

● Water may lead to corrosion of parts in the refrigerant system.

Therefore, the indoor units and the pipes between indoor and outdoor units must be leak tested and

evacuated to remove gas and moisture from the system.

Gas leak check (Soap water method):

Apply soap water or a liquid neutral detergent on the indoor unit connections and outdoor unit

connections with a soft brush to check for leakage on the connecting points of the piping. If air bubbles

come out, the connections have leaks and those connection points must be tightened. Recheck to

ensure all leakage points are tightened properly and not leaking.

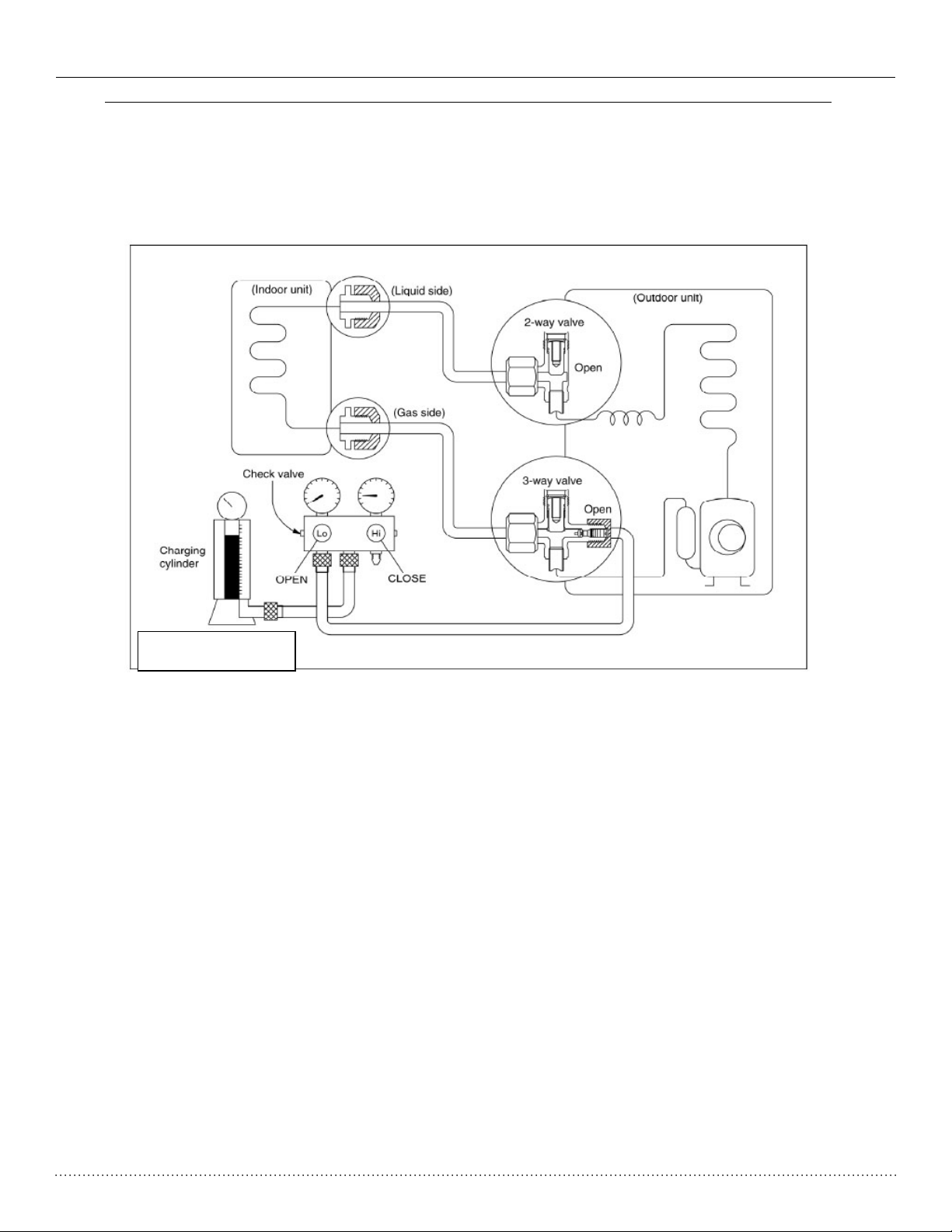

1. Air purging with vacuum pump

Vacuum

pump

Vacuum

pump

(Indoor unit)

-0.1MPa

Handle Lo

Charge hose

(Liquid side)

(Gas side)

Manifold valve

Lo

Charge hose

(Outdoor unit)

Two-way valve

Close

Three-way valve

Close

gauge

Handle Hi

1) Completely tighten the flare nuts of the indoor and outdoor units, confirm that both the 2-way and

3-way valves are set to the closed position.

2) Connect the charge hose with the push pin of handle lo to the 3-way valves gas service port..

3) Connect the charge hose of handle hi connection to the vacuum pump.

4) Fully open the handle Lo of the manifold valve.

5) Operate the vacuum pump to evacuate.

6) Conduct evacuation for 30 minutes and check whether the compound meter indicates -0.1Mpa. If

the meter does not indicate -0.1Mpa after pumping 30 minutes, it should be pumped 20 minutes more. If

12

Page 13

Heat Controller, Inc. VMH SerieS Service Manual

the pressure can’t achieve -0.1Mpa after pumping 50 minutes, please check if there are some leakage

points. Once the meter indicates -0.1mpa, fully close the handle Lo valve of the manifold valve and stop

the operation of the vacuum pump. Confirm that the gauge needle does not move (approximately 5

minutes after turning off the vacuum pump).

7) Turn the flare nut of the 3-way valves about 45° counterclockwise for 6 or 7seconds after the gas

comes out, then tighten the flare nut again. Make sure the pressure display in the pressure indicator is a

little higher than the atmospheric pressure. Then remove the charge hose from the 3 way valve.

8) Fully open the 2 way valve and 3 way valve and securely tighten the cap of the 3 way valve.

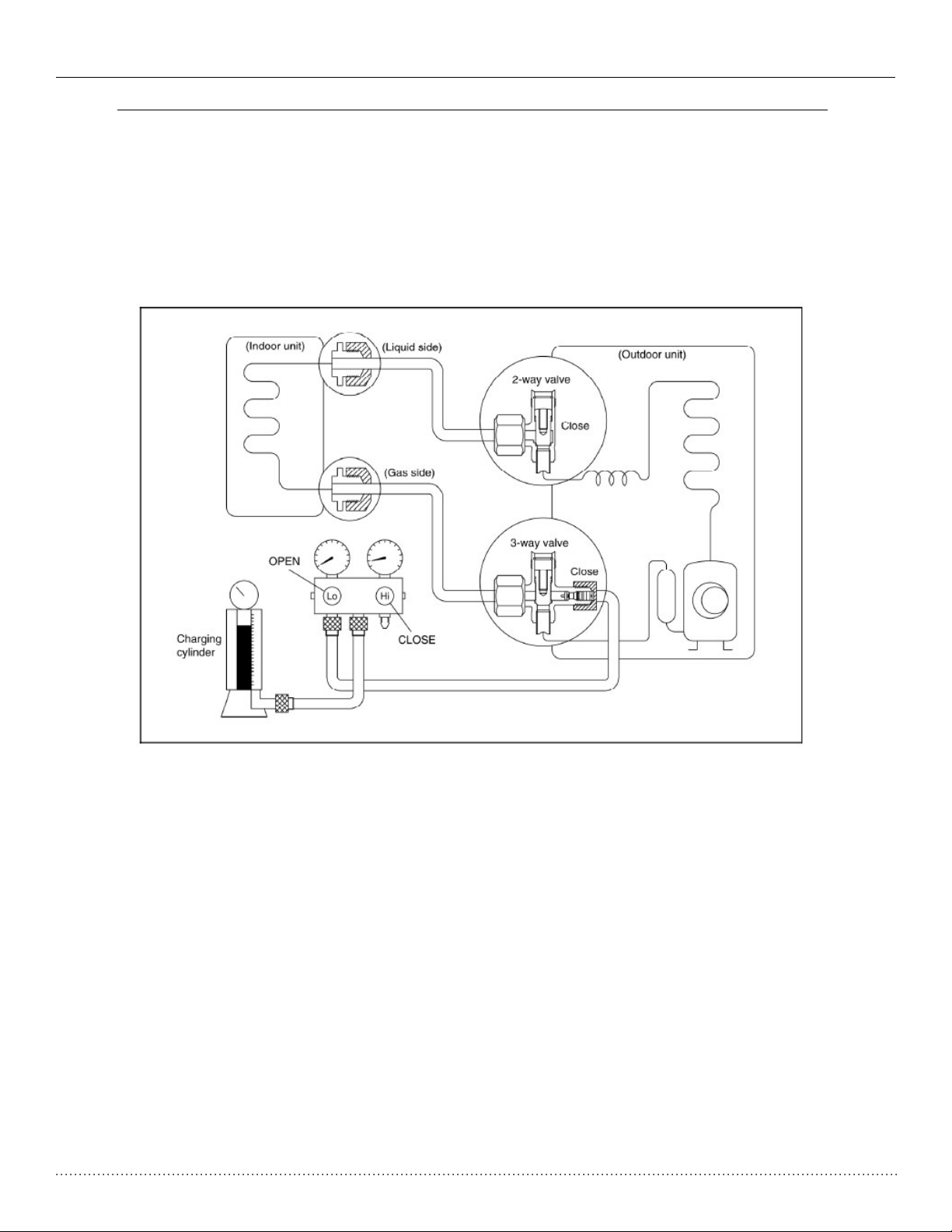

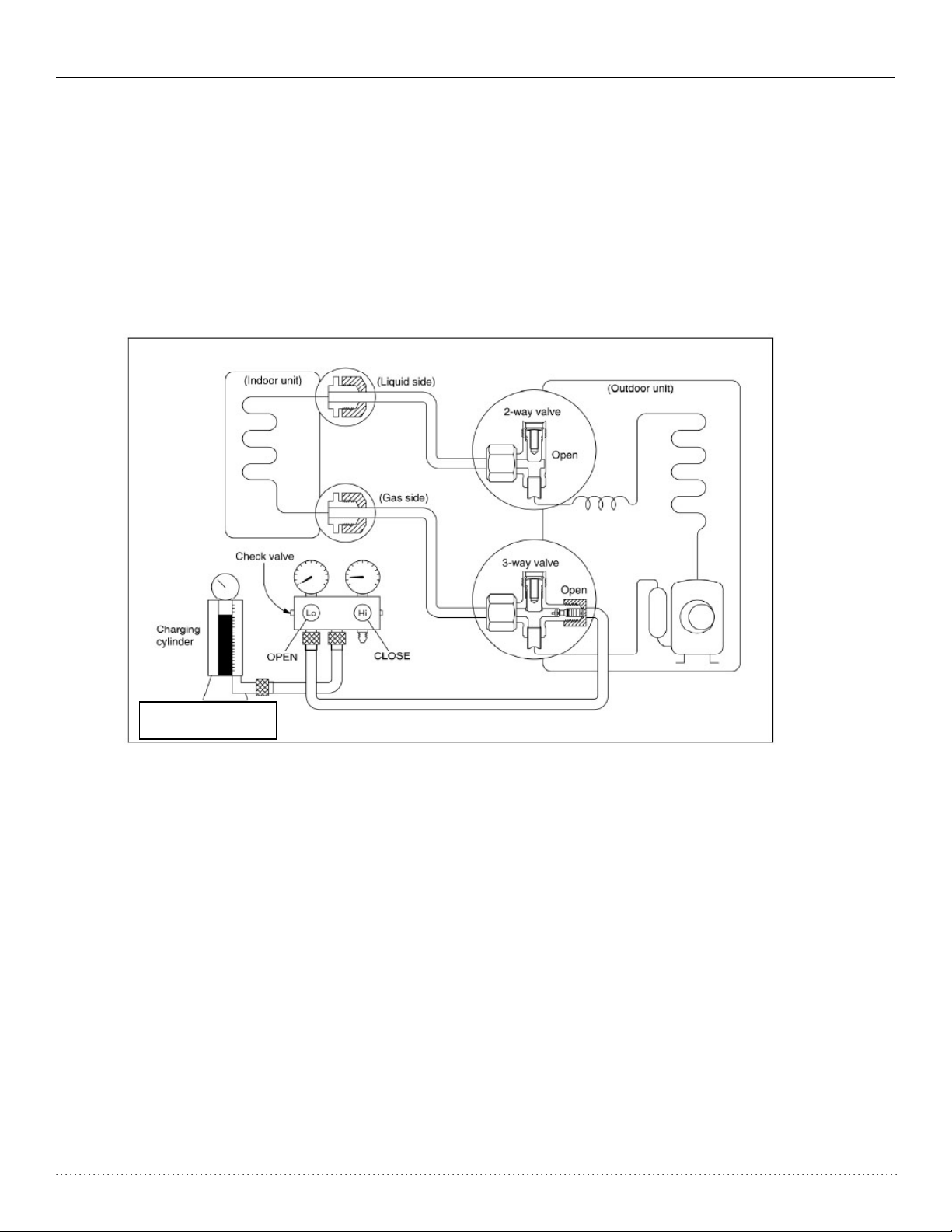

2. Air purging by refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way valves are set to the closed position.

2). Connect the charge set and a charging cylinder to the service port of the 3-way valve.

3). Air purge by open the valves on the charging cylinder and the charge set. Purge the air by loosening

the flare nut on the 2-way valve approximately 45° for 3 seconds then closing it for 1 minute; repeat 3

times. After purging the air, use a torque wrench to tighten the flare nut on the 2-way valve.

4). Check for gas leakage by checking the flare connections using the soap water method.

5). Discharge the refrigerant by closing the valve on the charging cylinder and discharging the refrigerant

by loosening the flare nut on the 2-way valve approximately 45° until the gauge indicates 0.3 to 0.5 Mpa.

6). Disconnect the charge set and the charging cylinder, and set the 2-way and 3-way valves to the open

position.

13

Page 14

Service Manual VMH SerieS Heat Controller, Inc.

7). Replace the valve stems nuts and the service port cap that were previously removed.

Be sure to use a torque wrench to tighten the service port cap to a torque of 18N·m.

Be sure to check for gas leakage using soap water.

3. Adding the refrigerant if the pipe length >(5m)16.5ft

Electronic scale

Procedure:

1). Connect the charge hose to the charging cylinder, open the 2-way valve and the 3-way valve.

Connect the charge hose which you disconnected from the vacuum pump to the valve at the bottom of

the cylinder. Because refrigerant is R410A, turn the cylinder upside down, ensuring the bottom is upward,

to create a liquid charge.

2). Purge the air from the charge hose.

Open the valve at the bottom of the cylinder and press the check valve on the charge set to purge the air

(be careful of the liquid refrigerant).

3) Put the charging cylinder onto the electronic scale and record the weight.

4) Operate the air conditioner in the cooling mode.

5) Open the valves (Low side) on the charge set and charge the system with the proper amount (refer to

table) liquid refrigerant.

14

Page 15

Heat Controller, Inc. VMH SerieS Service Manual

6).When the electronic scale displays the proper weight (refer to the table), disconnect the charge hose

from the 3-way valve’s service port immediately and turn off the air conditioner before disconnecting the

hose.

7). Replace the valve stem caps and the service port that were previously removed.

Use torque wrench to tighten the service port cap to a torque of 18N.m.

Be sure to check for gas leakage using soap water.

7.5 Adding the refrigerant due to loss of charge

Electronic scale

Procedure:

1). Connect the charge hose to the 3-way service port, open the 2-way valve and the 3-way valve.

Connect the charge hose to the valve at the bottom of the cylinder. Because the refrigerant is R-410A,

turn the cylinder upside down, such that the bottom is upward, to ensure a liquid charge.

2). Purge the air from the charge hose.

Open the valve at the bottom of the cylinder and press the check valve on the charge set to purge the air

(Do not vent refrigerant into the atmosphere).

3) Put the charging cylinder onto the electronic scale and record the weight.

4) Operate the air conditioner in the cooling mode.

5) Open the valves (Low side) on the charge set and charge the system with liquid refrigerant, (refer to

the gauge and the pressure of the low side).

6).When the electronic scale displays the proper weight (refer to the gauge and the pressure of the low

15

Page 16

Service Manual VMH SerieS Heat Controller, Inc.

side), disconnect the charge hose from the 3-way valve’s service port immediately and turn off the air

conditioner before disconnecting the hose.

7). Replace the valve stem caps and the service port that were previously removed.

.

Use torque wrench to tighten the service port cap to a torque of 18N

m.

Be sure to check for gas leakage using soap water.

7.6 Replacing the indoor unit

1. Collecting the refrigerant into the outdoor unit

Procedure

1). Confirm that both the 2-way and 3-way valves are set to the open position

Remove the valve stem caps and confirm that the valve stems are in the open position.

Be sure to use a hexagonal wrench to operate the valve stems.

2). Connect the charge hose with the push pin of handle lo to the 3-way valves gas service port.

3). Air purging of the charge hose.

Open the handle Lo valve of the manifold valve slightly to purge air from the charge hose for 5 seconds

and then close it quickly.

4). Set the 2-way valve to the closed position.

5). Operate the air conditioner in the cooling cycle and stop it when the gauge indicates 0.1MPa.

6). Set the 3-way valve to the closed position immediately

16

Page 17

Heat Controller, Inc. VMH SerieS Service Manual

Do this quickly so that the gauge ends up indicating 0.3 to 0.5Mpa.

Disconnect the charge set, and tighten the 2-way and 3-way valve’s stem nuts.

Use a torque wrench to tighten the 3-way valves service port cap to a torque of 1.8 N.m.

Be sure to check for gas leakage using soap water.

7). Remove the defective indoor unit and install the new indoor unit. Follow the next set of procedures to

charge.

2. Air purging by the refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way valves are set to the closed position.

2). Connect the charge set and a charging cylinder to the service port of the 3-way valve

Leave the valve on the charging cylinder closed.

3). Air purging.

Open the valves on the charging cylinder and the charge set. Purge the air by loosening the flare nut on

the 2-way valve approximately 45° for 3 seconds then closing it for 1 minute; repeat 3 times.

After purging the air, use a torque wrench to tighten the flare nut on the 2-way valve.

4). Check the gas leakage

Check the flare connections for gas leakage using soap water.

5). Discharge the refrigerant into charging cylinder.

Close the valve on the charging cylinder and discharge the refrigerant by loosening the flare nut on the

17

Page 18

Service Manual VMH SerieS Heat Controller, Inc.

2-way valve approximately 45° until the gauge indicates 0.3 to 0.5 Mpa.

6). Disconnect the charge set and the charging cylinder, and set the 2-way and 3-way valves to the open

position

Be sure to use a hexagonal wrench to operate the valve stems.

7). Replace the valve stems nuts and the service port cap that were previously removed.

Be sure to use a torque wrench to tighten the service port cap to a torque 18N.m.

Be sure to check the gas leakage using soap water.

7.7 Replacing the outdoor unit

1. Evacuation for the whole system

Procedure:

1). Confirm that both the 2-way and 3-way valves are set to the open position.

2). Connect the vacuum pump to 3-way valve’s service port.

3). Evacuate for approximately one hour. Confirm that the compound meter indicates -0.1Mpa.

4). Close the valve (Low side) on the charge set, turn off the vacuum pump, and confirm that the gauge

needle does not move (approximately 5 minutes after turning off the vacuum pump).

5). Disconnect the charge hose from the vacuum pump.

6). Remove the defective outdoor unit and install the new unit. See the following instructions for

re-charging the new unit.

18

Page 19

Heat Controller, Inc. VMH SerieS Service Manual

2. Refrigerant charging

Procedure:

1). Connect the charge hose to the charging cylinder, open the 2-way valve and the 3-way valve

Connect the charge hose which you disconnected from the vacuum pump to the valve at the bottom of

the cylinder. Because the refrigerant is R-410A, turn the cylinder upside down, such that the bottom is

upward, to ensure a liquid charge.

2). Purge the air from the charge hose

Open the valve at the bottom of the cylinder and press the check valve on the charge set to purge the air

(Do not vent refrigerant into the atmosphere).

3) Put the charging cylinder onto the electronic scale and record the weight.

4). Open the valves (Low side) on the charge set and charge the system with liquid refrigerant

If the system cannot be charge with the specified amount of refrigerant, or can be charged with a little at

a time (approximately (150g),5oz. each time) , operating the air conditioner in the cooling cycle. Wait

approximately 1 minute and then repeat the procedure as needed.

5).When the electronic scale displays the proper weight, disconnect the charge hose from the 3-way

valve’s service port immediately

If the system has been charged with liquid refrigerant while operating the air conditioner, turn off the air

conditioner before disconnecting the hose.

6). Replace the valve stem caps and the service port that were previously removed.

Use torque wrench to tighten the service port cap to a torque of 18N.m.

Be sure to check for gas leakage using soap water.

19

Page 20

Service Manual VMH SerieS Heat Controller, Inc.

No.SW1

Display

Remark

Amendatory capacity demand code

Evaporator outlet temp. for 1# indoor unit

Actual data is measured, however due to display limitations

Condenser pipe temp.

the digital display shows “0.5”, it means the compressor

8. Electronic control function

8.1 Abbreviations

T1: Indoor ambient temperature

T2: Coil temperature of indoor heat exchanger middle.

T2B: Coil temperature of indoor heat exchanger outlet.

T3: Coil temperature of outdoor heat exchanger

T4: Outdoor ambient temperature

T5: Compressor discharge temperature

Ts: Set point temperature.

8.2 Electric control working environment.

8.2.1 Input voltage: 230V.

8.2.2 Input power frequency:60Hz.

8.2.3 Indoor fan normal working amperage. is less than 1A.

8.2.4 Outdoor fan normal working amperage. is less than 1.5A.

8.2.5 Four-way valve normal working amperage. is less than 1A.

8.2.6 Swing motor: 12V DC.

8.3 Outdoor unit’s digital display

There is a digital display tube in outdoor PCB.

Digital display functions:

• In standby , the LED displays “- -”

• When compressor is operating, the LED displays the running frequency,

• In defrosting mode, The LED displays “dF” or alternatively displays between running frequency and

“dF”(each displays 2s)

• In compressor pre-heating, The LED displays “- -”

• In protection or malfunction modes, the LED displays the associated error code or protection code.

8.4 Outdoor unit point check function

There is a check switch in outdoor PCB.

Push the switch SW1 to check the states of unit when the unit is running. The digital display will display the

following each time the SW1 switch is preserved.

Pressed

10

11

Indoor unit capacity demand code

1

Outdoor unit running mode code Off:0, Cooling:1, Heating:2

2

3

Outdoor unit fan motor state Off:0, Low speed:1, High speed:2

4

5

Evaporator outlet temp. for 2# indoor unit

6

Evaporator outlet temp. for 3# indoor unit

7

Evaporator outlet temp. for 4# indoor unit

8

9

Ambient temp.

Compressor discharge temp. Actual data is measured, however due to display limitations

if the temp. is lower than -9 degrees, the digital display will

show “-9”. If the temp. is higher than 70 degrees, the digital

display will show “70”. If the indoor unit is not connected, the

digital display tube will show: “- -“.

if the temp. is lower than 0 degrees, the digital display will

show “0”. If the temp. is higher than 99 degrees, the digital

display will show single digit and a tens digit. For example if

20

Page 21

Heat Controller, Inc. VMH SerieS Service Manual

connected, the digital display tube will show: “- - “.

12

Inverter current

AD data

EXV open angle for 1# indoor unit

Actual data, divide this number by 8 for actual angle valve is

open.

15

EXV open angle for 3# indoor unit

18

Indoor unit number

The indoor unit can communicate with outdoor unit well.

19

The last error or protection code

00 means no malfunction

21

Ambient temp. of 1# indoor unit

Actual data

22

Condenser pipe temp. of 1# indoor unit

Actual data

――

Check point over

discharge temp. is 105 degree. If the indoor unit is not

13

14

16

17

20

23

24 Condenser pipe temp. of 2# indoor unit Actual data

25 Ambient temp. of 3# indoor unit Actual data

26

27 Ambient temp. of 4# indoor unit Actual data

28 Condenser pipe temp. of 4# indoor unit Actual data

29

EXV open angle for 2# indoor unit Actual data divide 8

Actual data divide 8

Actual data divide 8

EXV open angle for 4# indoor unit

Power supply of outdoor unit AD data (AD data*472/255=actual data)

frequency value Actual data

Ambient temp. of 2# indoor unit Actual data

Condenser pipe temp. of 3# indoor unit Actual data

The following items from 6.4.1 to 6.4.6 are for the explanation of the point check functions.

8.4.1 Frequency of compressor:

Display Frequency of compressor (Hz)

30 30

-- Stand by

60 60

8.4.2 Running mode:

Display Corresponding mode

0 Off

1 Cooling mode

2 Heating mode

8.4.3 Capacity demand:

Cooling mode

Capacity 2000-

2500

Corresponding

Code

1 2 3 4 5 6 7 8 9 >=10

Heating mode

Capacity 2000-25

Corresponding

Code

00

1 2 3 4 5 6 7 8 9-10 >=11

Note:

The capacity is just for reference.

2000-

2500

2000-25

00

3000-

3800

3000-38

00

4500-

5000

4500-50

00

5000-

5500

5500-61

00

5500

-6100

6100-70

00

6100-

7000

6100-70

00

7000-

7500

7000-75

00

7500-

8000

7500-80

00

>7500

>8000

21

Page 22

Service Manual VMH SerieS Heat Controller, Inc.

8.4.4Number of indoor units – displays how many indoor units the outdoor unit is communicating with.

Display Quantity of indoor unit

1 1

2 2

3 3

4 4

8.4.5 Opening degree of electronic expansion valve:

Actual opening degree value equals the display data divided 8

8.5 Protection

8.5.1 Three minutes delay at restart for compressor.

8.5.2 Temperature protection of compressor discharge.

When the compressor discharge temp. is getting higher, the running frequency will be limited as below rules:

----If 216°F<T5< 239°F (102°C<T5<115°C), the frequency or the compressor will decrease to a lower level

every 2 minutes until it reaches F1.

---If T5>239°F(T5>115°C) for 10 seconds, the compressor will stop and restart till T5<194°F (T5<90°C).

8.5.3 Low voltage protection

VOLTAGE

VOLREL1

VOLREL2

VOLREL3

VOLLIMT1

VOLLIMT2

VOLLIMT3

No limit

VOLFRE1

VOLFRE2

Off

Model VOLLIMT1 VOLLIMT2 VOLLIMT3 VOLREL1 VOLREL2 VOLREL3 VOLFRE1 VOLFRE2

A-VMH18DC-1 230 200 120 260 210 135 62 54

A-VMH27TC-1 245 220 120 265 240 135 78 45

A-VMH36QC-1 200 185 120 210 195 135 54 42

Note: if the low voltage protection occurs and does not resume within 3min, it will keep the protection after

the machine is restarted.

22

Page 23

Heat Controller, Inc. VMH SerieS Service Manual

8.5.4 Compressor current limit protection

If the compressor current exceeds the current limit value for 10 seconds, the compressor frequency will be

limited per the table below.

Cooling mode:

Current frequency(Hz) Current limit value(A) Frequency limit

COOL_F10 ICOOLLMT6

COOL_F9 ICOOLLMT5

COOL_F8 ICOOLLMT4

COOL_F7 ICOOLLMT3

COOL_F6 ICOOLLMT2

COOL_F5 ICOOLLMT1

If the current frequency is lower than COOL_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>ICOOL,the AC will display the failure for 30 seconds and stop. The AC will restart 3

minutes later and re-check.

The compressor frequency will decrease to COOL_F4 and

then run at COOL_F4 for 3 minutes.

After that, the frequency will be adjusted according to the

capacity demand, then rise to the next level up every 3

minutes (When the frequency>COOL_F4 via capacity

demand).

Heating mode:

Current frequency(Hz) Current limit value(A) Frequency limit

HEAT_F12 IHEATLMT8 The compressor frequency will decrease HEAT _F4 and

HEAT_F11 IHEATLMT7

HEAT_F10 IHEATLMT6

HEAT_F9 IHEATLMT5

HEAT_F8 IHEATLMT4

HEAT_F7 IHEATLMT3

HEAT_F6 IHEATLMT2

HEAT_F5 IHEATLMT1

If the current frequency is lower than HEAT_F4, the frequency will not be limited.

After 10s of the compressor start, if the current>IHEAT,the AC will display the failure for 30 seconds and stop. The AC will restart 3

minutes later and re-check.

then run at HE AT_F4 for 3 minutes.

After that, the frequency will be adjusted according to the

capacity demand, then rise to the next level up every 3

minutes (When the frequency>Heat_F4 via capacity

demand).

23

Page 24

Service Manual VMH SerieS Heat Controller, Inc.

Model

RECOILINFRE

8.5.5 Indoor / outdoor units communication protection

If any indoor unit can not receive the feedback signal from the outdoor unit for 2 minutes, the AC will stop

and display the failure code.

8.5.6 High condenser coil temp. protection.

When T3>149°F(T3>65°C) for 3 seconds, the compressor will stop while the indoor fan and outdoor fan will

continue.

When T3<126°F(T3<52°C), the protection will release and the compressor will restart after 3 minutes.

8.5.7 Outdoor unit anti-freezing protection

When T2B<32°F(T2B<0°C) for 4 minutes, the indoor unit capacity demand will be zero and resume to

normal when T2B>50°F(T2B>10°C).

8.5.8 Oil return

Running rules:

1. If the compressor frequency remains lower than RECOILINFRE for 2hours,the AC will increase the

frequency to RECOILFRE for 3mins and then resume to the former frequency.

A-VMH18DC-1 45

A-VMH27TC-1 45

A-VMH36QC-1 40

2. During the oil return process, the EXV and indoor units continue with the current running mode, the

frequency will not be limited by the compressor discharge temp. or the current.

8.5.9 Compressor preheating functions

----Preheating permitting condition:

If T4(outdoor ambient temperature) T4<37.4°F(T4<3°C) and newly powered on or if T4<37.4°F(T4<3°C)

and compressor has stopped for over 3 hours, the compressor’s crank case heater will begin to operate.

----Preheating mode:

A weak current flow through the coil of compressor from the wiring terminal of compressor, heats the

compressor without it operating via the crankcase heater.

----Preheating release condition:

If T4>41°(T4>5°C) or the compressor starts running, preheating function will stop.

8.5.10 Compressor crankcase heater

When T4<37.4°(T4<3°C) and the compressor is not running, the crankcase heater will be active.

When T4≧41°(T4≧5°C) or the compressor starts up, the crankcase heater will stop working.

24

Page 25

Heat Controller, Inc. VMH SerieS Service Manual

9. Troubleshooting

9.1 Indoor Mini-Split error code explanations:

Indoor Error

Code

E0

E1 Indoor/ outdoor unit communication error ——

E2 Zero-crossing signal error ——

E3 Indoor fan speed has been out of control ——

E5

E6 Open circuit or short circuit of T1 or T2 temperature sensor ——

P0 IPM module protection or IGBT over-strong current protection P4

P1 Voltage protection E5

P2 Temperature protection of compressor top P0,P1,P2

P3 Outdoor temp. too low protection(Optional for some models) ——

P4 Inverter compressor drive protection E7, P7

P5 Mode conflict ——

LED STATUS

Indoor EEPROM malfunction ——

Open circuit or short circuit of outdoor temperature sensor or outdoor

EEPROM malfunction

Corresponding

Outdoor Error code

E0,E1,E2,

E3,E4,E6

Indoor Ceiling Cassette error codes:

Operation Timer De-frost Alarm LED STATUS

★

X X

X

X X X

★ ★

★

★

★

X X X Open or short circuit of T1 temperature sensor

★

★

X X

X X Indoor / outdoor units communication error

X X Indoor EEPROM malfunction

X X Open or short circuit of T3 or T4 temperature sensor

X

★ ★ ★ ★

★

X

X Open or short circuit of T2 temperature sensor

★

Full-water malfunction

IPM module protection

Voltage protection

Temperature protection of compressor top.

Mode conflict

★

X Inverter compressor drive protection

★ flash at 2.5Hz, light, X extinguished.

25

Page 26

Service Manual VMH SerieS Heat Controller, Inc.

coil outlet temp. sensor or connector of

r or connector of

coil outlet temp. sensor or connector of

board and

Temperature protection of

9.2 Outdoor unit error code explanation:

Outdoor

Error

Code:

E0 Outdoor EEPROM malfunction E5

Indoor unit A’s

E1

sensor is defective

Indoor unit B’s coil outlet temp. sensor or connector of

E2

sensor is defective

Indoor unit C’s coil outlet temp. senso

E3

sensor is defective

Indoor unit D’s

E6

sensor is defective

E4 Open or short circuit of outdoor unit temperature sensor E5

LED STATUS

Corresponding Indoor

Mini-Split error code

E5

E5

E5

E5

E5 Voltage protection P1

E7

P0

P1 High pressure protection (Only for A-VMH-36QC-1) P2

P2 Low pressure protection (Only for A-VMH-36QC-1) P2

P3 Current protection of compressor ——

P4 IPM module protection P0

P6 High temperature protection of condenser ——

P7 Inverter compressor drive protection P4

PF PFC module protection (A-VMH36QC-1) ——

Communication malfunction between IPM

outdoor main board

Temperature protection of compressor discharge or

compressor top.

For A-VMH-36QC-1 it means

compressor discharge

P4

P2

26

Page 27

Heat Controller, Inc. VMH SerieS Service Manual

9.3 Trouble shooting

9.3.1 Indoor unit trouble shooting

9.3.1.1 Indoor EEPROM malfunction

Shut off the power supply and

turn it on 1 minute later. Is it

still displaying the error code?

Yes

If the EEPROM chip

is welded on PCB,

replace the PCB

directly. Otherwise,

check whether the

EEPROM chip

plugged in PCB well?

Yes

Replace the indoor PCB.

No

EEPROM: a read-only memory chip whose contents can be erased and reprogrammed using a pulsed

Insert the EEPROM well

Re-insert the EEPROM well

voltage.

(EERROM chip may be solid for some models)

27

Page 28

Service Manual VMH SerieS Heat Controller, Inc.

Check wiring on the outdoor

minal follow the

iring diagram. Are all wires

s wit h

Are

no. of outdoor units

Measure Vs, is it moving

(Vs is the voltage between

Turn off the all indoor

Is PFC power LED lamp

Are number of indoor units

heck on the

nt (18). (2

zone, 4

Is Main board

lamp on?

Is all the wiring

between terminal

and Indoor PCB

Change the

wer on by remote

the E1

error code ended

after 3 minutes?

eactor

hange Outdoor Main

outdoor unit PCB

9.3.1.2 Indoor / outdoor units communication error

Power off , then Power on the A/C by the

Breaker. Did E1 error code turn off?

No

and indoor ter

w

connected correctly?

Yes

Turn on all indoor unit

the remote controller.

correct? Refer to PIC 5.

Yes

units. Is IPM power LED

Yes

No

No

change

IPM

Yes

No

Reconnect the wiring

Reconnect the wiring

alternately between positive

value and negative value?

Yes

A:

No

No

Yes

off? Refer PIC 3.

Yes

“ "

Yes

correct? C

outdoor check poi

for dual zone, 3 for tri

for qua zone). Refer PIC 5.

No, fist time

Change

assembly(include wiring) totally

No

change

PFC

Reconnect the wiring

Is the r

connecting well?

C

PCB

No, second time

Yes

Yes

No

No No

E1 error problem solved.

SEE A

Indoor PCB

Po

controller, has

Yes

28

Page 29

Heat Controller, Inc. VMH SerieS Service Manual

check how many indoor units are

Pic 1: Measure the voltage of L2 to S (Vs), is it

moving alternately between positive value and

negative value?

PIC 3: IPM (For dual/tri/quad-zone)

PIC4: Main board LED when power on and unit standby.

PIC 2, Check the wiring.

PFC (quad-zone only)

PIC 5: check point bottom,

press 18 times to

connected.

29

Page 30

Service Manual VMH SerieS Heat Controller, Inc.

Correct the connections

Shut off the power supply, rotate the fan

rubbing/obstructions?

9.3.1.3 Zero-crossing signal error

Check if the connections and

power supply is normal?

Indoor PCB is defective.

Replace indoor PCB.

are normal?

Yes

No

Correct the connections. Turn on the unit

Correct the connections. Turn on the

when the power supply is within 90-110% of

unit when the power supply is good.

rated voltage on unit’s rating plate.

9.3.1.4 Indoor fan speed has been out of control(DC fan motor)

Shut off the power supply and

turn it on 5 seconds later. Is it

still displaying the error code?

Yes

No

The unit operates normally.

Shut off the power supply,

rotate the fan by hand. Does

by hand. Does it rotate freely with any

it rotate properly?

Yes

Check the wires of fan motor.

Are all the connections good?

Yes

Check the voltage between port

1 and 6 of fan motor connector,

is it 310V?

No

Replace indoor main PCB. Is it

still displaying the error code?

No

No

Correct the connections.

No

Replace indoor fan

per wiring diagram.

The unit operates normally.

motor.

Yes

DC motor voltage input and output

5

4

6

1

3

2

NO. Color Signal Voltage

1 Red VDC 310V

2 --- --- ---

3 White Vcc 15V

4 Blue FG 0.3V

5 Yellow Vsp 0-7.5V

6 Black GND 0V

30

Page 31

Heat Controller, Inc. VMH SerieS Service Manual

9.3.1.5 Indoor fan speed has been out of control(AC fan motor)

Shut off the power supply

and turn it on 5 seconds

later.Is it still displaying

the error code?

Yes

No

The unit operates normally.

Shut off the power

supply, rotate the cross

fan by hand. Does it

rotate properly?

freely?

Yes

Check the wires of

fan motor. Are all the

connections good?

Yes

Check the resistance value of

indoor fan motor, is it normal?

Yes

Replace indoor PCB.

No

No

Disassembly the

connection between

fan and motor, check if

the bearing is normal?

Correct the connections

Correct the connections.

per wiring diagram.

No

No

Yes

Replace indoor fan motor.

Replace the bearing.

31

Page 32

Service Manual VMH SerieS Heat Controller, Inc.

Correct the connections per

Is

Is

9.3.1.6 Open or short circuit of temperature sensor.

Check the connections

between temperature

sensor and PCB. Are

the connections good?

No

Correct the connections.

wiring diagram.

Yes

Check the resistance value

of the sensor via Appendix

Yes

Replace indoor or outdoor PCB.

1, is it normal?

No

Replace the sensor and

Replace the sensor

check if the problem

happen again?

9.3.1.7 Full-water malfunction (For Ceiling Cassette)

If the water-level switch

Is

is inserted well?

Yes

If the water-level switch

is broken?

No

If the water pump is

normal?

Yes

No

Yes

No

Insert the water-level switch well

Re-insert the water-level switch well

Replace the water-level switch

Replace the water pump

Check PCB board or replace the indoor main PCB

32

Page 33

Heat Controller, Inc. VMH SerieS Service Manual

If the EEPROM chip is welded on

9.3.1.8 Outdoor temp. too low protection(Optional for some models)

Check if the outdoor ambient

temperature is beyond the normal

operation temperature range.

No

Replace the outdoor ambient

temperature sensor.

Yes

9.3.2 Outdoor unit trouble shooting

9.3.2 1 Outdoor EEPROM malfunction (ODU E0)

Outdoor EEPROM malfunction

PCB, replace the PCB directly.

Otherwise, check whether the

EEPROM chip plugged in PCB

well?

Turn on the unit when outdoor

ambient temperature is in normal

operation temperature range.

No

Re-insert the EEPROM well

Insert the EEPROM well

Yes

Replace the outdoor main board

33

Page 34

Service Manual VMH SerieS Heat Controller, Inc.

9.3.2.2 Voltage protection (ODU E5)

Voltage protection

Check the voltage of

outdoor unit power supply,

whether the voltage

between L(L1) and N (L2) is

about 220~240VAC

Yes

Check whether the voltage

of IPM board P and N is

normal? DC277-356V for

18-27KBtu/h; DC277-410V

for 36KBtu/h

No

Check the power supply

No

Replace bridge rectifiers,

and then check whether the

system can run normally

No

Replace IPM board, and

then check whether the

system can run normally

No

Replace outdoor main board

Yes

Yes

Yes

Trouble is solved

34

Page 35

Heat Controller, Inc. VMH SerieS Service Manual

lit?

9.3.2.3 Communication malfunction between IPM board and outdoor main board(ODU E7)

Communication malfunction between

IPM board and outdoor main board

Is there at least one LED in

the IPM board light?

No

Check the signal wire between

the IPM module and the main

board, is it connected good?

Yes

No

Reconnect and retry. Is

error still display?

displaying?

No

Replace IPM board, and

then check whether the

system can run normally

No

Replace outdoor main

board, and then check

whether the system can run

normally

No

Yes

No

Yes

Yes

Replace the electric control

box

Trouble is solved

35

Page 36

Service Manual VMH SerieS Heat Controller, Inc.

9.3.2.4 Temperature protection of compressor discharge (ODU P0)

Temperature protection of

compressor discharge

Check whether the

compressor discharge temp.

is more than 239°F (115°C)?

No

Check whether the wiring

connection is correct between

compressor discharge temp.

sensor and PCB according to

wiring diagram?

Yes

The discharge temp.

sensor may be

broken.

Check whether the

resistance of compressor

discharge temp. sensor is

right refer to the Appendix 2

No

Check whether there is

a refrigerant leak

No

Correct the wiring connection

Replace the compressor discharge temp. sensor

YesYes

Stop leak and add refrigerant as needed

Yes

Replace outdoor main board

36

Page 37

Heat Controller, Inc. VMH SerieS Service Manual

9.3.2.5 Temperature protection of compressor top (ODU P0)

Temperature protection of

compressor top

Does the compressor

operate?

Yes

Is the unit properly

charged?

No

Properly charge the system

Is there any abnormality of

operation after the system

was charged?

Are all

connections correct?

Yes

Check whether protector is

normal? If protector is normal,

resistance=0

Yes

Replace the outdoor main PCB

NoNo

Reconnect and retest.

No

Replace the protector.

No

Check refrigerant circuit,

such as clogging of

capillary tubes etc.

37

Page 38

Service Manual VMH SerieS Heat Controller, Inc.

9.3.2.6 High pressure protection (ODU P1) (Only for A-VMH36QC-1)

High pressure protection

Is the wiring between

the high pressure switch

and main control board is

connected correctly?

Yes

Is the high pressure

protector broken?

Yes

Short circuit the high

pressure protector socket,

check whether the system

can run normally now?

No

No

Yes

Reconnect it properly

Replace high pressure protector

Check whether

the refrigerant

system is ok

Check whether the

outdoor ambient

temperature is higher than

109.4°F (43°C)?

No

Check whether the outdoor

unit’s airow is obstructed

No

Check whether the heat

exchanger is dirty

No

Check whether the

refrigerant circuit has a

blockage

No

Yes

Yes

Yes

Yes

Stop the unit

Remove all obstructions for proper ventilation

Clean the heat exchanger

Evacuate the refrigerant, then use

high pressure nitrogen or refrigerant

to blow pipe, vacuum and recharge

with refrigerant again

Replace outdoor main board

38

Page 39

Heat Controller, Inc. VMH SerieS Service Manual

9.3.2.7 Low pressure protection (ODU P2) (Only for A-VMH36QC-1)

Low pressure protection

Is the wiring between the

low pressure protector

and main control board

connected correctly?

Yes

Is the low pressure

protector broken?

Yes

Short circuit the low

pressure protector socket,

check whether the system

can run normally now?

No

No

Yes

Reconnect it properly

Replace low pressure protector

Check whether

the refrigerant

system is ok

Check whether the

outdoor ambient

temperature is to low

No

Check if there is

a refrigerant leak

Connect the pressure gauge to

the gauge joint of the system,

check whether the pressure is

lower than 0.14MPa

No

Check whether the

refrigerant circuit is

blocked or not

No

Yes

Yes

Yes

Stop the unit

Find the leak by charging nitrogen or refrigerant

into the system, if the leak is serious there will be

distinct “hissing” sound; if the leakage is small, use a

soap and water mixture or electronic leak detector

to nd the leak and repair.

Evacuate the refrigerant, then use

high pressure nitrogen or refrigerant

to blow out pipe, vacuum and

recharge with refrigerant again

Replace outdoor main board

39

Page 40

Service Manual VMH SerieS Heat Controller, Inc.

9.3.2.8 Current protection of compressor (ODU P3)

Current protection of compressor

Check whether the input

current of the power supply

wire is more than 12.5A

(For 27K, it is 14.5A, For

36K, it is 20A)

Yes

Check whether the

refrigerant system is ok

Check whether the

outdoor ambient

temperature is higher than

122.4°F (50°C)?

No

Yes

Stop the unit

Check whether the outdoor

unit’s airow is obstructed

No

Check whether the heat

exchanger is dirty

No

Is the refrigerant

circuit blocked?

No

Replace outdoor main

board, and check

whether the system can

run normally

No

Yes

Yes

Yes

Remove all obstructions for proper ventilation

Clean the heat exchanger

Evacuate the refrigerant, then use

high pressure nitrogen or refrigerant

to blow pipe, vacuum and recharge

with refrigerant again

Replace the electrical

control box

40

Page 41

Heat Controller, Inc. VMH SerieS Service Manual

9.3.2.9 IPM module compressor (ODU P4)

IPM module protection

Check whether the voltage range

of P-N on IPM module is normal?

DC277-356V for 18-27KBtu/h;

DC277-410V for 36KBtu/h

Yes

Check whether the

connecting line between main

board and the IPM module is

connected tightly

Yes

Check whether the

connecting line of the

compressor is connected

correctly or tightly

Yes

Replace the IPM module,

check whether the system

can work normally?

No

No

No

No

No

Check whether the

No No

input power supply is

correct? 220-240V,

1PH 60Hz

Yes

Connect it tightly,

check ok or not?

Check whether the

power supply line is

connected correctly

and tightly

Yes

Connect it well

check ok or not?

Check whether

the wires in E-part

box are connected

tightly

Yes No

Check whether the bridge rectiers

are normal? Use the multimeter to

measure the resistance between

each two terminals, check whether

the value of resistance is 0

No

No

No

No

Regulate it to

correct, then check

whether the system

can work normally?

Connect it correctly

and tightly, check ok

or not?

Connect it tightly,

check ok or not?

No

Replace the main board;

check whether the system

can work normally?

No

Replace the compressor.

Check whether the connecting line

of every reactor is normal? If the

line is broken, the resistance of the

two ports is (for all models except

A-VMH36QC-1); Check whether the

PFC module broken A-VMH36QC-1

Yes

Replace the bridge rectiers

8

No

Replace the connecting

line or reactor or replace

Yes

the PFC module for a

A-VMH36QC-1

41

Page 42

Service Manual VMH SerieS Heat Controller, Inc.

9.3.2.10 High temperature protection of condenser (ODU P6)

When outdoor pipe temp. is mroe than 149°F (65°C), the unit will stop, and will run again when outdoor

pipe temp. is less than 126°F (52°C).

High temperature

protection of condenser

Replace the temperature sensor

Check whether the

condenser temperature is

more than 149°F (65°C)

Yes

Check whether the

outdoor ambient temperature is

higher than 122°F (50°C)

No

Check whether the

heat exchanger is dirty

No

No

Yes

Yes

No

No

Check whether the

resistance of condenser

temp. sensor is correct

refer to the Appendix 1

Stop the unit

Clean the heat exchanger

Yes

Replace outdoor main board

No

The refrigerant

circuit is blocked

Yes

high pressure nitrogen or refrigerant to

blow out the pipes, vacuum and recharge

the refrigerant again

42

Evacuate the refrigerant, then use the

Page 43

Heat Controller, Inc. VMH SerieS Service Manual

9.3.2.11 High PFC module protection (ODU P6) (Only for A-VMH36QC-1)

PFC module protecton

Check whether the connecting line

between main board and the PFC

module is connected tightly

Yes

Check whether the voltage range

of P-N on IPM module is normal?

DC277-356V for 18-27KBtu/h;

DC277-410V for 36KBtu/h

No

Check whether the inductance

of PFC module is good? If the

inductance is good, the resistance of

the two ports is 0

Yes

No

No

Yes

No

Connect it tightly,

check normal or not

Replace the outdoor main board

Replace the inductance

Replace the PFC module

9.3.2.12 Inverter compressor drive protection (ODU P7)

The trouble shooting is same process as the IPM module protection, trouble shooting.

Refer to this section.

43

Page 44

Service Manual VMH SerieS Heat Controller, Inc.

K Ohm

K Ohm

K Ohm

K Ohm

-20

115.266

20

12.6431

60

2.35774

100

0.62973

-19

108.146

21

12.0561

61

2.27249

101

0.61148

-18

101.517

22

11.5000

62

2.19073

102

0.59386

-17

96.3423

23

10.9731

63

2.11241

103

0.57683

-16

89.5865

24

10.4736

64

2.03732

104

0.56038

-15

84.2190

25

10.000

65

1.96532

105

0.54448

-14

79.3110

26

9.55074

66

1.89627

106

0.52912

-13

74.5360

27

9.12445

67

1.83003

107

0.51426

-12

70.1698

28

8.71983

68

1.76647

108

0.49989

-11

66.0898

29

8.33566

69

1.70547

109

0.48600

-10

62.2756

30

7.97078

70

1.64691

110

0.47256

-9

58.7079

31

7.62411

71

1.59068

111

0.45957

-8

56.3694

32

7.29464

72

1.53668

112

0.44699

-7

52.2438

33

6.98142

73

1.48481

113

0.43482

-6

49.3161

34

6.68355

74

1.43498

114

0.42304

-5

46.5725

35

6.40021

75

1.38703

115

0.41164

-4

44.0000

36

6.13059

76

1.34105

116

0.40060

-3

41.5878

37

5.87359

77

1.29078

117

0.38991

-2

39.8239

38

5.62961

78

1.25423

118

0.37956

-1

37.1988

39

5.39689

79

1.21330

119

0.36954

0

35.2024

40

5.17519

80

1.17393

120

0.35982

1

33.3269

41

4.96392

81

1.13604

121

0.35042

2

31.5635

42

4.76253

82

1.09958

122

0.3413

3

29.9058

43

4.57050

83

1.06448

123

0.33246

4

28.3459

44

4.38736

84

1.03069

124

0.32390

5

26.8778

45

4.21263

85

0.99815

125

0.31559

6

25.4954

46

4.04589

86

0.96681

126

0.30754

7

24.1932

47

3.88673

87

0.93662

127

0.29974

8

22.5662

48

3.73476

88

0.90753

128

0.29216

9

21.8094

49

3.58962

89

0.87950

129

0.28482

10

20.7184

50

3.45097

90

0.85248

130

0.27770

11

19.6891

51

3.31847

91

0.82643

131

0.27078

12

18.7177

52

3.19183

92

0.80132

132

0.26408

13

17.8005

53

3.07075

93

0.77709

133

0.25757

14

16.9341

54

2.95896

94

0.75373

134

0.25125

15

16.1156

55

2.84421

95

0.73119

135

0.24512

16

15.3418

56

2.73823

96

0.70944

136

0.23916

17

14.6181

57

2.63682

97

0.68844

137

0.23338

18

13.9180

58

2.53973

98

0.66818

138

0.22776

19

13.2631

59

2.44677

99

0.64862

139

0.22231

Appendix 1 Temperature Sensor Resistance Value Table (℃--K) Use appendix 4 to convert °C to °F.

℃

℃

℃

℃

44

Page 45

Heat Controller, Inc. VMH SerieS Service Manual

Appendix 2

Unit: °C ---K Discharge temp. sensor table

-20 542.7 20 68.66 60 13.59 100 3.702

-19 511.9 21 65.62 61 13.11 101 3.595

-18 483 22 62.73 62 12.65 102 3.492

-17 455.9 23 59.98 63 12.21 103 3.392

-16 430.5 24 57.37 64 11.79 104 3.296

-15 406.7 25 54.89 65 11.38 105 3.203

-14 384.3 26 52.53 66 10.99 106 3.113

-13 363.3 27 50.28 67 10.61 107 3.025

-12 343.6 28 48.14 68 10.25 108 2.941

-11 325.1 29 46.11 69 9.902 109 2.86

-10 307.7 30 44.17 70 9.569 110 2.781

-9 291.3 31 42.33 71 9.248 111 2.704

-8 275.9 32 40.57 72 8.94 11 2 2.63

-7 261.4 33 38.89 73 8.643 11 3 2.559

-6 247.8 34 37.3 74 8.358 11 4 2.489

-5 234.9 35 35.78 75 8.084 11 5 2.422

-4 222.8 36 34.32 76 7.82 11 6 2.357

-3 211.4 37 32.94 77 7.566 11 7 2.294

-2 200.7 38 31.62 78 7.321 11 8 2.233

-1 190.5 39 30.36 79 7.086 11 9 2.174

0 180.9 40 29.15 80 6.859 120 2.117

1 171.9 41 28 81 6.641 121 2.061

2 163.3 42 26.9 82 6.43 122 2.007

3 155.2 43 25.86 83 6.228 123 1.955

4 147.6 44 24.85 84 6.033 124 1.905

5 140.4 45 23.89 85 5.844 125 1.856

6 133.5 46 22.89 86 5.663 126 1.808

7 127.1 47 22.1 87 5.488 127 1.762

8 121 48 21.26 88 5.32 128 1.717

9 115.2 49 20.46 89 5.157 129 1.674

10 109.8 50 19.69 90 5 130 1.632

11 104.6 51 18.96 91 4.849

12 99.69 52 18.26 92 4.703

13 95.05 53 17.58 93 4.562

14 90.66 54 16.94 94 4.426

15 86.49 55 16.32 95 4.294 B(25/50)=3950K

16 82.54 56 15.73 96 4.167

17 78.79 57 15.16 97 4.045

18 75.24 58 14.62 98 3.927

19 71.86 59 14.09 99 3.812

R(90℃)=5KΩ±3%

45

Page 46

Service Manual VMH SerieS Heat Controller, Inc.

+

_

~

~

~

~

Appendix 3

1. Reference voltage data:

a) Rectifier : Input :220-230V(AC), output :310V(DC)

b) Inverter module: U,V, W 3ph.

Result

U-V 60-150V(AC)

U-W 60-150V(AC)

V-W 60-150V(AC)

P-N DC 310V

2. Check the Diode Bridge component ( In wiring diagram, rectifier)

Remark: If this part is abnormal, the LED will not light.

~ +

Multi-meter Result

- ~

Forward Resistance Backward Resistance

Infinite Infinite

~1.7M ohm Infinite

+

~1.7M ohm Infinite

46

Page 47

Heat Controller, Inc. VMH SerieS Service Manual

Appendix 4:

47

Page 48

Service Manual VMH SerieS Heat Controller, Inc.

Appendix 5:

Spec.

Outdoor unit

Model 1x2 1x3 1x4

Compressor DA130S1C-20FZ DA150S1C-20FZ TNB306FPGMC-L

Outdoor fan motor YDK70-6FB YDK70-6FB YDK180-8GB

Indoor unit

Model 9k Mini-Split 12k Mini-Split 18k Mini-Split

Indoor fan motor RPG20B RPG20B RPG28H

Model / 12k Cassette 18k Cassette

Indoor fan motor / YDK45-6B YDK45-6B

1. Compressor checking

Measure the resistance value of each winding by using the tester.

Position Resistance Value

DA130S1C-20FZ DA150S1C-20FZ TNB306FPGMC-L

Blue - Red

0.95Ω(20℃) 0.95Ω(20℃) 0.53Ω(20℃)

48

Page 49

Heat Controller, Inc. VMH SerieS Service Manual

2. Fan Motor.

Measure the resistance value of each winding by using the tester.

Position Resistance Value

YDK70-6FB YDK180-8GB YSK27-4G YSK68-4B YDK45-6B YSK25-6L

Black - Red

Red - Yellow

Yellow - Blue

Measure the resistance value of each winding by using the tester

56Ω±8%

(20℃)

76Ω±8%

(20℃)

76Ω±8%

(20℃)

24.5Ω±8%

(20℃)

19Ω±8%

(20℃)

19Ω±8%

(20℃)

Position Resistance Value

RPG20B RPG28H

Black - Red

White - Black

317Ω±8%

(20℃)

252Ω±8%

(20℃)

252Ω±8%

(20℃)

381Ω±8% (20℃) 183.6Ω±8% (20℃)

267Ω±8% (20℃) 206Ω±8% (20℃)

145Ω±8%

(20℃)

88Ω±8%

(20℃)

88Ω±8%

(20℃)

345Ω±8%

(20℃)

150Ω±8%

(20℃)

150Ω±8%

(20℃)

627Ω±8%

(20℃)

374.3Ω±8%

(20℃)

374.3Ω±8%

(20℃)

49

Page 50

10-2012

Loading...

Loading...