Page 1

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

InverterFlex® Series

Outdoor Ductless Mini-Split

Heat Pumps

A-VFH18DA-1

A-VFH24TA-1

A-VFH30QA-1

A-VFH36QA-1

A-VFH42PA-1

Heat Controller • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

TABLE OF CONTENTS

Safety Precautions

Warnings and Cautions............................................. 3

Introduction

Model Nomenclature.................................................4

System Application....................................................5

Installation Instructions

Installation Location Selection............................... 6-7

Outdoor unit installation..........................................8-9

Condensate Drain......................................................9

Refrigerant Line Installation

Refrigerant line set installation............................ 10-15

Leak test, evaluation and release of refrigerant....... 16

Electrical Work

Electrical Precautions.............................................16

Unit wiring........................................................... 17-21

Initial Start Up and Checks

Field charging and Final Inspection ................... 21-23

!

Caution

• Contact an authorized service technician for repair or maintenance of

this unit

• Contact an authorized installed for installation of this unit.

• Installation work must be performed in accordance with local and

national electrical codes and standards by authorized personnel only

2

Page 3

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

• Read the follow SAFETY PRECAUTIONS carefully before installation.

• Electrical work must be performed by a licensed electrician. Be sure to use the correct rating of the power

cord and main circuit for the model to be installed.

• Incorrect installation due to ignoring the instruction will cause harm or damage.

n The seriousness is classied by the following indications.

WARNING!

!

CAUTION!

!

The items to be followed are classied by the symbols:

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to property.

This symbol denotes procedure that is PROHIBITED.

WARNING!

!

1) Do not install without an authorized servicer/installer.

2) Install according to this installation instruction. If installation is defective, it can cause water leakage or

electrical shock/re.

3) Use the supplied accessories and specied parts for installation.

4) Install the outdoor unit on a raised concrete pad or blocks to provide a solid, level foundation. In a

location with high winds, anchor the unit and provide an air bafe. In snowy areas (for heat pump

models), install the outdoor unit on a raised platform higher than drifting snow. Provide snow vents, and

awning over the unit.

5) For electrical work, follow local and national electric codes and these installation instructions. An

independent must be used. If defects in the electrical work, will cause electrical shock or re.

6) Use the specied cable and connect tightly. Clamp the cable so that no external force will stress the

connections. Loose wiring may overheat at the connection points and create a possible re hazard.

7) Wiring routing must be properly arranged so that control board cover is xed properly. If control board

cover is not xed perfectly, it will cause overheating at connection point of terminal, re or electrical shock.

8) When charging the unit, take care not to let air/substances other than the specied refrigerant

go into refrigeration circuit. Otherwise, it will cause lower capacity, abnormal high pressure in the

refrigeration circuit, explosion and injury.

9) Do not modify the length of the power supply cord or use an extension cord, and do not share

the single outlet with other electrical appliances. Otherwise, it will cause re or electrical shock.

CAUTION!

!

1) This equipment must be grounded. It may cause electrical shock if grounding doesn’t comply with local/

national electric codes.

2) Do not install the unit in a place where leakage of ammable gas may occur. If gas leaks and

accumulates near the unit, it may cause re.

3) Provide proper condensate drainage per the installation instructions. If not done properly, condensate

can destroy personal property and freeze up in improperly on the unit.

3

Page 4

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

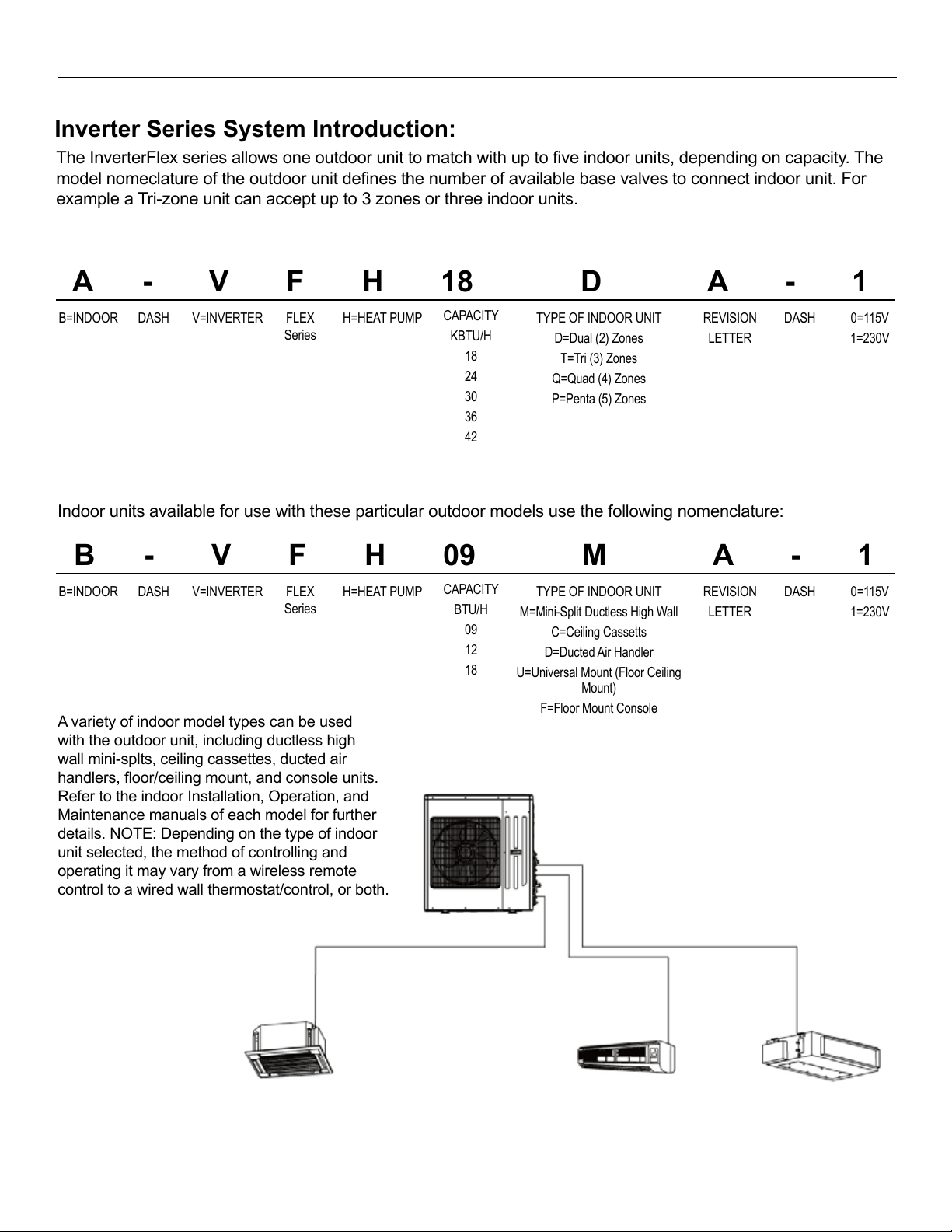

Inverter Series System Introduction:

The InverterFlex series allows one outdoor unit to match with up to ve indoor units, depending on capacity. The

model nomeclature of the outdoor unit denes the number of available base valves to connect indoor unit. For

example a Tri-zone unit can accept up to 3 zones or three indoor units.

Indoor units available for use with these particular outdoor models use the following nomenclature:

A variety of indoor model types can be used

with the outdoor unit, including ductless high

wall mini-splts, ceiling cassettes, ducted air

handlers, oor/ceiling mount, and console units.

Refer to the indoor Installation, Operation, and

Maintenance manuals of each model for further

details. NOTE: Depending on the type of indoor

unit selected, the method of controlling and

operating it may vary from a wireless remote

control to a wired wall thermostat/control, or both.

A - V F H 18 D A - 1

B=INDOOR

H=HEAT PUMP

FLEX

Series

V=INVERTER

DASH

CAPACITY

KBTU/H

18

24

30

36

42

0=115V

1=230V

DASH

REVISION

LETTER

TYPE OF INDOOR UNIT

D=Dual (2) Zones

T=Tri (3) Zones

Q=Quad (4) Zones

P=Penta (5) Zones

B - V F H 09 M A - 1

B=INDOOR

H=HEAT PUMP

FLEX

Series

V=INVERTER

DASH

CAPACITY

BTU/H

09

12

18

0=115V

1=230V

DASH

REVISION

LETTER

TYPE OF INDOOR UNIT

M=Mini-Split Ductless High Wall

C=Ceiling Cassetts

D=Ducted Air Handler

U=Universal Mount (Floor Ceiling

Mount)

F=Floor Mount Console

Outdoor Nomenclature A-VFH18DA-1

Indoor Nomenclature B-VFH09MA-1

EXAMPLE OF TRI-ZONE SYSTEM

Outdoor Unit

Cassette Type

Indoor Unit

Wall Mounted

Indoor Unit

Duct Type Indoor

Unit (Rectangular

air outlet)

4

Page 5

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

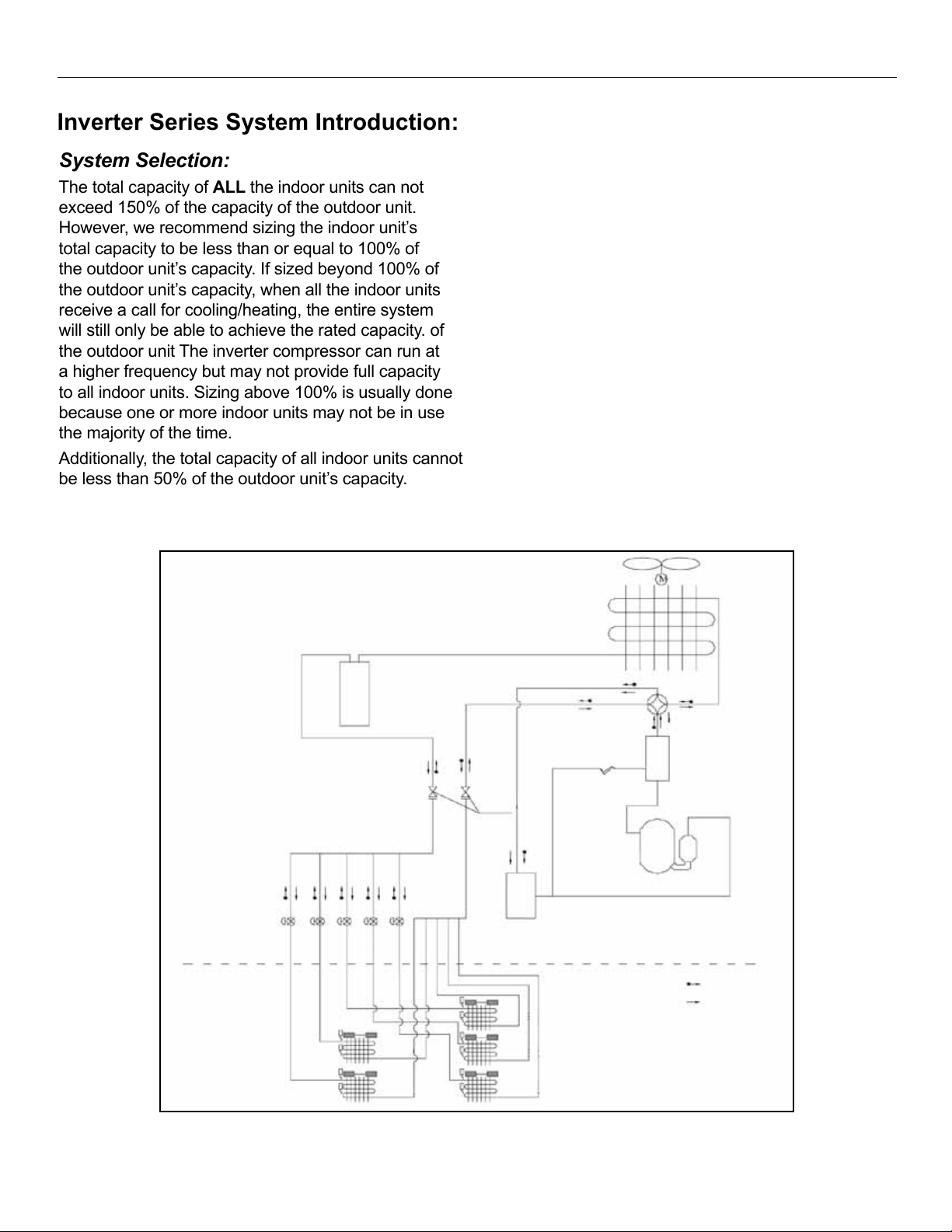

Inverter Series System Introduction:

System Selection:

The total capacity of ALL the indoor units can not

exceed 150% of the capacity of the outdoor unit.

However, we recommend sizing the indoor unit’s

total capacity to be less than or equal to 100% of

the outdoor unit’s capacity. If sized beyond 100% of

the outdoor unit’s capacity, when all the indoor units

receive a call for cooling/heating, the entire system

will still only be able to achieve the rated capacity. of

the outdoor unit The inverter compressor can run at

a higher frequency but may not provide full capacity

to all indoor units. Sizing above 100% is usually done

because one or more indoor units may not be in use

the majority of the time.

Additionally, the total capacity of all indoor units cannot

be less than 50% of the outdoor unit’s capacity.

System Application:

This system is not designed to be a sole source of

heat for a home/building. While the units can operate

in low ambient conditions, they cannot provide the full

rated capacity for heat at low outdoor temperatures. An

additional heat source may be required in areas such

as the northern USA and Canada during the winter.

This system must be run in modes that do not conict.

For example, one indoor unit cannot be run in cool

mode and another indoor unit in heat mode. All indoor

units modes must be harmonized for the system to

properly operate. The fan mode can run in conjunction

with any other mode, while the cooling mode can be

run in conjunction with the dehumidication mode.

However all other modes must match among the

indoor units.

Liquid Receiver

Outdoor Unit

NOTE: The number of indoor units may vary depending on the capacity of the outdoor unit. This is an

example of a ve (5) zone system.

Electronic

Expansion Valve

Indoor Unit

Heat Exchanger

Heat Exchanger

System Schematic

Heat Exchanger

Stop

Valve

Heat Exchanger

Heat Exchanger

Heat Exchanger

5

Capillary

Compressor

Gas/Liquid Separator

Four Way Valve

Oil Separator

Heating

Cooling

Page 6

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

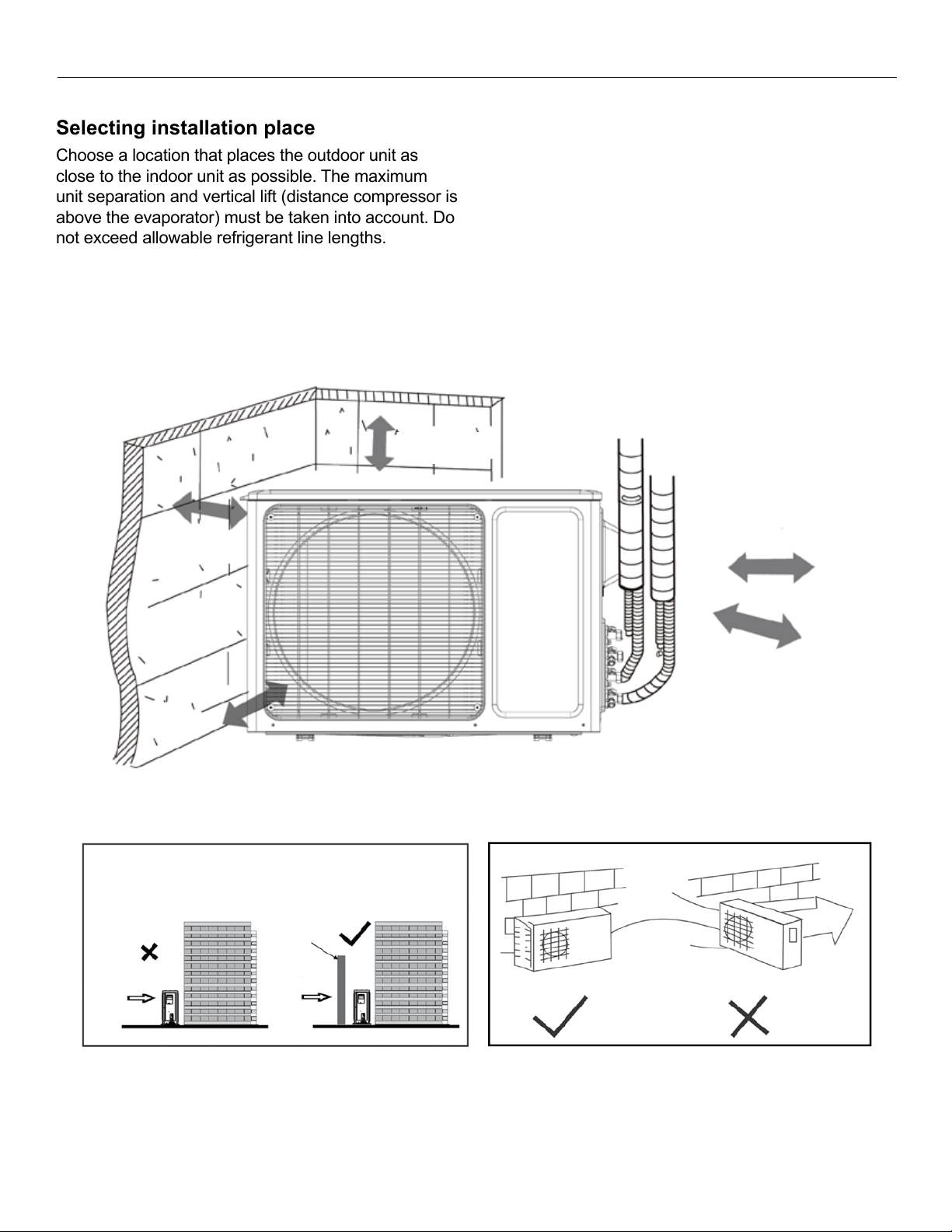

Selecting installation place

Choose a location that places the outdoor unit as

close to the indoor unit as possible. The maximum

unit separation and vertical lift (distance compressor is

above the evaporator) must be taken into account. Do

not exceed allowable refrigerant line lengths.

Outdoor unit

• Unit must be installed in a location that does not

obstruct the airow and ensures clearance are

maintained (Fig. 1)

• If installation location allows the unit to be exposed

to strong winds (such as coastal applications),

ensure that the unit has a wind barrier. This will

assist with preventing strong gusts of wind from

entering the unit’s cabinet and interfering with the

Fig. 1

fan operation. (Fig. 2 and Fig. 3)

Fig. 2

Min. 1.5ft.

(500mm)

Min. 6.5ft. (2000mm)

(Air outlet side)

CorrectIncorrect

Min. 3.5ft.

(1000mm)

Min. 1.5ft.

(500mm)

(Air inlet side)

Min. 1.5ft. (500mm)

Space to the wall

Fig. 3

Correct

Incorrect

6

Page 7

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

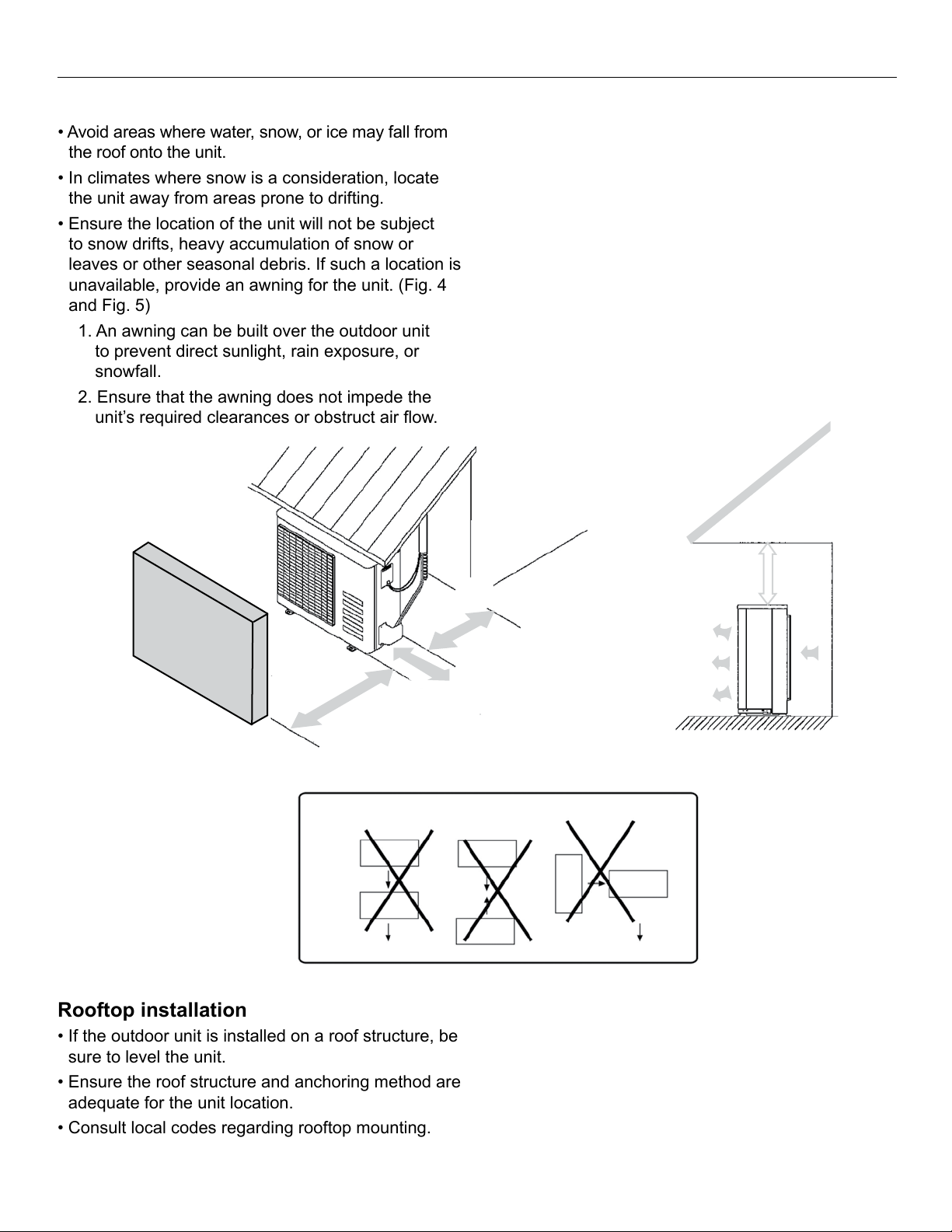

• Avoid areas where water, snow, or ice may fall from

the roof onto the unit.

• In climates where snow is a consideration, locate

the unit away from areas prone to drifting.

• Ensure the location of the unit will not be subject

to snow drifts, heavy accumulation of snow or

leaves or other seasonal debris. If such a location is

unavailable, provide an awning for the unit. (Fig. 4

and Fig. 5)

1. An awning can be built over the outdoor unit

to prevent direct sunlight, rain exposure, or

snowfall.

2. Ensure that the awning does not impede the

unit’s required clearances or obstruct air ow.

Rooftop installation

• If the outdoor unit is installed on a roof structure, be

sure to level the unit.

• Ensure the roof structure and anchoring method are

adequate for the unit location.

• Consult local codes regarding rooftop mounting.

3. The awning should be at least 2 ft. (0.6m) away

from the top of the unit’s housing.

• Ensure free ow of air into and out of the unit. All air

inlet/outlets should be free of obstructions such as

walls and shrubs. Minimum clearances should be

maintained. (Fig. 1)

• During heating and defrost modes (heat pump

models only), the condensate should be properly

drained away from the unit. • Do not locate two or

more units in any way that will block discharge air

from one unit to another. Be certain that hot air from

one unit will not blow into a nearby unit to prevent

recirculation or discharge air. (Fig. 6)

Fig. 4

Obstacles

Fence or

Min. 6.5ft (2000mm)

Fig. 6

Min. 1.5ft (500mm)

Min. 1.5ft (500mm)

Fig. 5

Min. 3.5ft (1000mm)

(Service space)

• If the outdoor unit is installed on roof structures

or external walls, excessive noise and vibration

may result, and may also be considered a nonserviceable installation.

• Oil traps must be made in the refrigerant line set

(every 10 ft.) when the outdoor unit is located above

the indoor unit.

7

Page 8

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

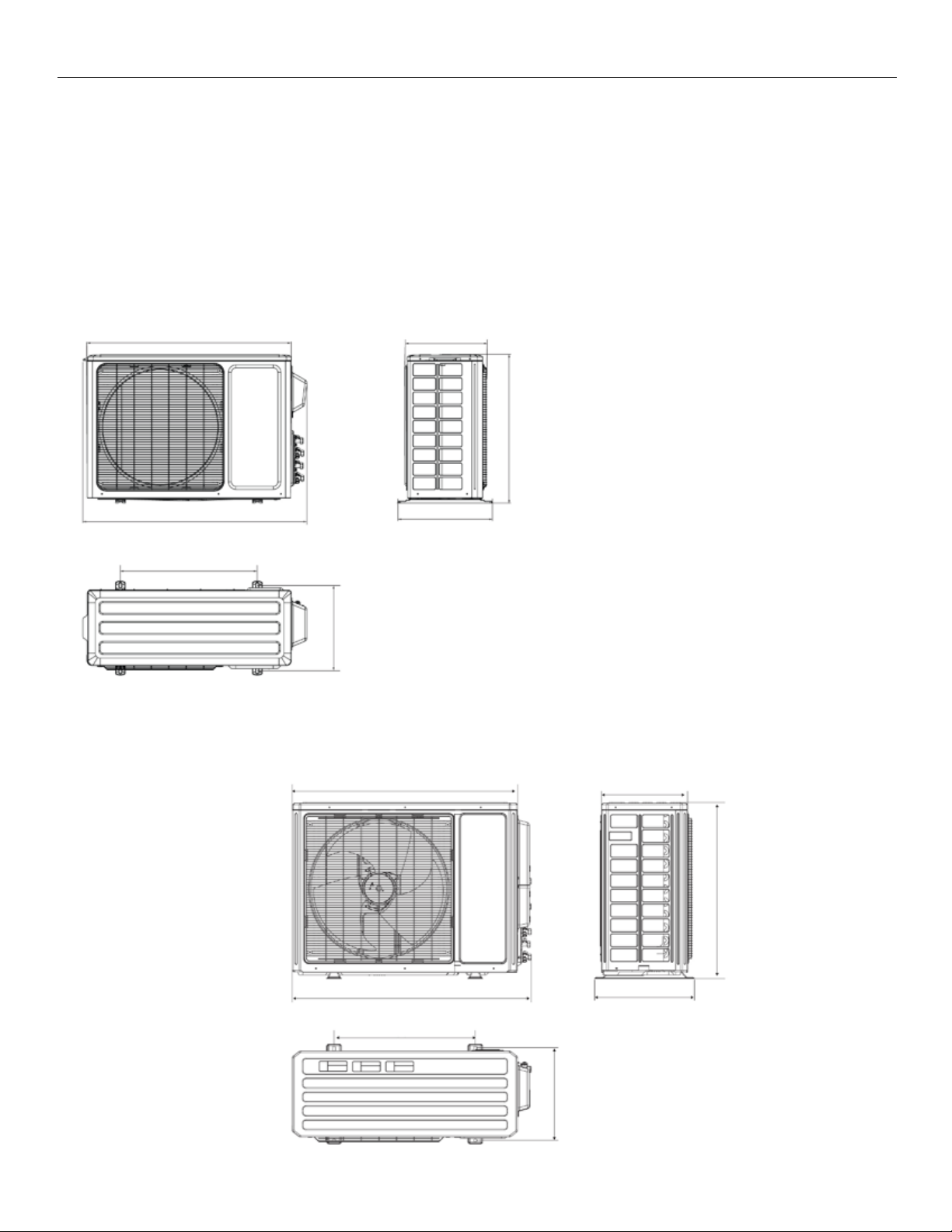

Outdoor Unit Installation

• In a snowy area, slab should be higher than drifting

• Install the outdoor unit on a rigid base (such a

concrete slab) to prevent increasing noise level and

vibration.

• Use a raised concrete pad or concrete blocks to

provide a solid, level surface. Securely anchor the

unit down with bolts.

snow.

• See outdoor installation location information

on pages 6 and 7 for more details and required

clearances.

Anchoring outdoor unit

FIG. 7 18KBTU/H

32.09 in. (815mm)

35.39 in. (899mm)

21.65 in. (550mm)

15.5in. (343mm)

12.44 in. (316mm)

14.88in. (378mm)

Anchor the outdoor unit to the concrete

slab with lag bolts or similar size, may

vary by model.

NOTE: Lag bolts are eld provided and do

not come with the unit.

Refer to unit’s mounting footprint for

mounting hole locations (Fig. 7 - 10)

23.46 in. (596mm)

FIG. 8 24KBTU/H, 30KBTU/H

35.12 in. (892mm)

37.24 in. (946mm)

22.05 in. (560mm)

8

13.43 in. (341mm)

27.56in. (700mm)

15.59in. (396mm)

14.5in. (368mm)

Page 9

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

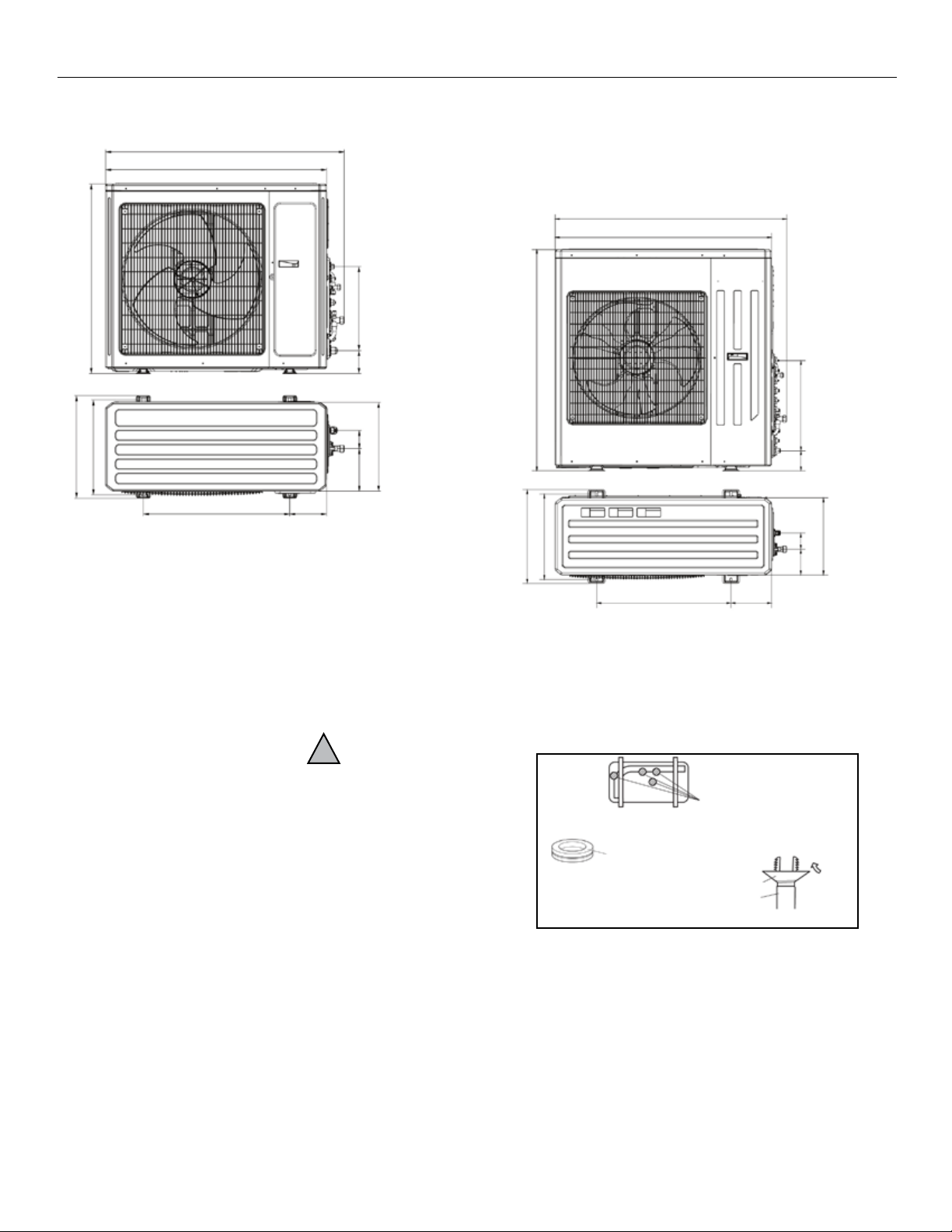

FIG. 9 36KBTU/H

39.13 in. (994mm)

36.22 in. (920mm)

FIG. 10 42KBTU/H

42.8 in. (1087mm)

40 in. (1015mm)

31.06 in. (789mm)

15.55 in. (395mm)

16.81 in. (427mm)

24.62 in. (610mm)

3.78 in. (96mm)

3.78 in.

(96mm)

3.0 in.

(76mm)

6.97 in.

(177mm)

14.57 in. (370mm)

9.02 in. (153mm)

Condensate Drainage

• For heat pump models only.

• Condensate and defrosted water created by the

unit operating in heat mode should be routed

and drained away from the unit.

• Parts needed for condensate drainage are not

factory supplied; they are commercially available.

• Fit the rubber washer onto the drain connector, then

!

43.43 in. (1103mm)

17.32 in. (440mm)

15.79 in. (401mm)

24.84 in. (631mm)

Fig. 11

Bottom frame

Drain plug

Drain connector

Hose (5/8” (16mm) I.D.

17.72 in. (450mm)

3.9 in.

(99mm)

3.0 in.

(76mm)

4.76 in.

(121mm)

14.25 in. (362mm)

7.52 in. (191mm)

Drain-water hole

insert the drain connector into the hole on the base

pan of the outdoor unit. Secure into place. (Fig. 11)

• Connect a locally purchased drain hose. Install

hose to the hose barb end of the drain connector.

• Route the hose to drain location away from

the unit.

• Repeat for each hole on the base of the unit, as

needed.

9

Page 10

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

Refrigerant Line Set Installation

Refrigerant Line Set Installation

1. Purchase line sets through a Heat Controller

distributor with consideration of the minimum

and maximum line lengths. (Page 11)

2. Both liquid and suction lines to be insulated.

3. Connections are made via are nuts.

4. The number of bends and length of refrigerant

lines determine the pressure drop which affects

capacity and efciency of the system, as well

as oil return. Minimize the length and number of

bends when possible during installation.

5. Minimum line set length must be maintained,

even if the installation does not require it. Extra

length that is unnecessary can be coiled up

near the outdoor unit (Do not to block air inlets/

outlets).

6. Choose a location that places the outdoor

unit as close to the indoor unit as possible to

minimize line set lengths.

7. Use only clean, refrigerant grade tubing suitable

for R-410A.

8. Avoid installing refrigerant lines on wet/rainy

days.

9. Always keep tube ends sealed until the nal

connections are to be made.

10. If line sets are being made at the time of

installation, rather than being purchased, be sure

to:

• Remove burrs from cut ends of the tubing

• Use tube benders to prevent kinking.

• Ensure tube cuts are square in relation to the

end of the tube.

• Use the proper diameter tube and are nut

sizes recommended by the manufacturer.

• Insulate both lines with Amraex or equivalent

with a wall thickness of at least 3/8".

• Use copper tubing suitable to withstand

pressures for R-410A refrigerant. We

recommend a minimum wall thickness of

0.027 in. (0.7mm).

11. The tube size should always be the same

diameter as the connections provided at the of

the indoor unit.

Note: On some models, a reducer or an

expander may be shipped with the outdoor

unit in order to adapt the line set connection to

the proper size to mate with the indoor unit’s

connection. Be sure to check for these parts,

should you discover that the outdoor units

service valve sizes differ from the indoor unit’s

connections. If this part is shipped with the

outdoor unit, then it is required to be used.

12.Up sizing/downsizing the refrigerant lines/

connections can result in inadequate oil return to

the compressor or excessive refrigerant return

and will void the warranty.

13.Do not over torque the connections, excessive

force can break the are nut.

14. When routing the line set between the outdoor

and indoor units:

A. Support the tubing adequately to avoid sags

that can trap the oil.

B. Isolate the tubing so it does not transmit

noise from vibration into the structure of the

building.

C. Avoid sharp edges that could cut the tubes.

D. Trap rises every 10 ft. (5-7m) with a ‘p’

trap, when outdoor unit mounted above the

indoor unit.

10

Page 11

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

VFH InverterFlex System Line Set Requirements

Indoor Model

Maximum Length

B-VFH09

49.2ft (15m)

B-VFH18/24

82ft (25m)

Dual Zone

Tri-Zone

Quad Zone

(L1+L2+L3+L4)

Penta Zone

(L1+L2+L3+L4+L5)

Lx

Refrigerant Line Set Installation

Allowable Length and Height of Line Set

Lx = Length of line set

H1

H2

from farthest indoor unit

For systems with only one indoor unit, the maximum line set length (Lx) is:

Outdoor Model Maximum Length (Lx) Max. Elevation Between Outdoor & Indoor Unit (H1)

A-VFH18/24/30 32.8ft (10m) 24.6ft (7.5m)

A-VFH36/42 82ft (25m) 49.2ft (15m)

For systems with more than one indoor unit, the entire system must pass BOTH requirements below.

Maximum Length Requirement based on Indoor Unit Capacity:

B-VFH12 65.6ft (20m)

Total Allowable Length based on Outdoor Unit Capacity:

Outdoor Model Zoning Based on Actual Number of Indoor Units Installed

(L1+L2)

A-VFH18/24/30 98.4ft

(30m)

A-VFH36/42 104.9ft

(32m)

(L1+L2+L3)

172.25ft (52.5m) 229.6ft (70m) N/A 24.6 ft (7.5m)

157.5ft (48m) 209.9ft (64m) 262.5ft (80m) 49.2 ft(15m)

(See Note 2) Max.

Elevation

Between

Indoor &

Outdoor (H1)

Max. Elevation

Difference

Between each

Indoor Unit

(H2)

24.6 ft (7.5m)

11

Page 12

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

VFH InverterFlex System Line Set Requirements

For systems with only one indoor unit, the maximum line set length (Lx) is:

Outdoor Model Maximum Length (Lx) Max. Elevation Between Outdoor & Indoor Unit (H1)

A-VFH18/24/30 32.8ft (10m) 24.6ft (7.5m)

A-VFH36/42 82ft (25m) 49.2ft (15m)

For systems with more than one indoor unit, the entire system must pass BOTH requirements below.

Maximum Length Requirement based on Indoor Unit Capacity:

Indoor Model

Maximum Length

B-VFH09

49.2ft (15m)

B-VFH12

65.6ft (20m)

B-VFH18/24

82ft (25m)

Total Allowable Length based on Outdoor Unit Capacity:

Outdoor Model Zoning Based on Actual Number of Indoor Units Installed

(See Note 2) Max.

Elevation

Between

Indoor &

Outdoor (H1)

Max. Elevation

Difference

Between each

Indoor Unit

(H2)

Dual Zone

(L1+L2)

Tri-Zone

(L1+L2+L3)

Quad Zone

(L1+L2+L3+L4)

Penta Zone

(L1+L2+L3+L4+L5)

A-VFH18/24/30

98.4ft

(30m)

172.25ft (52.5m)

229.6ft (70m)

N/A

24.6 ft (7.5m)

24.6 ft (7.5m)

A-VFH36/42 104.9ft

(32m)

157.5ft (48m) 209.9ft (64m) 262.5ft (80m) 49.2 ft(15m)

Lx

An outdoor A-VFH36 is installed with (1) B-VFH18 and (2) B-VFH09 indoor units. Based on the Indoor requirement, the

Refrigerant Line Set Installation

Single Zone Example:

An Outdoor A-VFH18 is installed with (1) B-VFH09 indoor unit. The line set must not exceed 32.8ft (10m) and the indoor

unit must not be more that 24.6 ft(7.5m) higher than the outdoor unit.

Multi-Zone Example:

18K indoor unit’s line set can’t exceed 82ft (25m) and each 9K indoor units’ line set can’t exceed 49.2ft (15m). This puts

the total system length (L1+L2+L3) at: 82ft (25m) + 49.2ft (15m) + 49.2ft (15m) = 180ft (54.9m). However using the total

allowable length requirement, we see that an A-VFH36 Tri-Zone system can’t exceed 157.5ft (48m). Therefore, we

must reduce the line set length to some or all of the indoor units. To ensure that the allowable total length requirement

is met, let’s reduce the line set for the B-VFH18 unit to 75ft (22.9m) and the B-VHF09 units to 40ft (12.2m) each. Now

the total length (L1+L2+L3) requirement is met, as the total = 75ft (22.9m) + 40ft (12.2m) + 40ft (12.2m) = 155ft (47.2m),

which is less than the total allowable length of 157.5ft (48m) for an A-VFH36 Tri-Zone system.

Notes:

1. The Max. Allowable Elevation H1 and H2 must also be maintained.

2. The Zoning is based on the actual number of indoor units installed. An outdoor A-VFH42 is capable of having up

to (5) indoor units installed with a max. total line set length of 262.5ft (80m), however if the application is zoned

using only (2) indoor heads, the max. total line set length is reduced to 104.9ft (32m) as the actual application is

a dual zoned system.

12

Page 13

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

Refrigerant Line Set Installation

Due to the mix and match nature of the InverterFlex™ system, reducing and/or

expansion flare connection subassemblies are provided with some models to

accommodate for the different flare connections sizes between indoor and outdoor

units.

The subassemblies provided accommodate for most typical applications, however

the installing contractor may need to purchase additional subassemblies for certain

applications.

A-VFH Outdoor Liquid-Gas Connection Sizes

Liquid Connections 18K 24K 30K 36K 42K

A 1/4” (6.35mm) 1/4” (6.35mm) 1/4” (6.35mm) 1/4” (6.35mm) 1/4” (6.35mm)

B 1/4” (6.35mm) 1/4” (6.35mm) 1/4” (6.35mm) 1/4” (6.35mm) 1/4” (6.35mm)

C n/a 1/4” (6.35mm) 1/4” (6.35mm) 1/4” (6.35mm) 1/4” (6.35mm)

D n/a n/a 1/4” (6.35mm) 3/8” (9.52mm) 1/4” (6.35mm)

E n/a n/a n/a n/a 3/8” (9.52mm)

Gas Connections 18K 24K 30K 36K 42K

A 3/8” (9.52mm) 3/8” (9.52mm) 3/8” (9.52mm) 3/8” (9.52mm) 3/8” (9.52mm)

B 3/8” (9.52mm) 3/8” (9.52mm) 3/8” (9.52mm) 3/8” (9.52mm) 3/8” (9.52mm)

C n/a 3/8” (9.52mm) 3/8” (9.52mm) 1/2” (12.7mm) 1/2” (12.7mm)

D n/a n/a 3/8” (9.52mm) 5/8” (15.9mm) 1/2” (12.7mm)

E n/a n/a n/a n/a 5/8” (15.9mm)

B-VFH Indoor Liquid-Gas Connection Sizes

Subassemblies for A-VFH36QA-1 and AVFH42PA-1 Outdoor Units:

The A-VFH36QA-1 and A-VFH42PA-1 outdoor units come with a set of copper elbow subassemblies with a female flare

nut x male flare fitting.

Indoor Unit Liquid Gas

B-VFH09MA-1

B-VFH12MA-1

B-VFH18MA-1 5/8” (15.9mm)

B-VFH12CA-1 3/8” (9.52mm)

B-VFH18CA-1 1/2” (12.7mm)

B-VFH24CA-1 3/8” (9.52mm) 5/8” (15.9mm)

1/4” (6.35mm)

1/2” (12.7mm)

13

Page 14

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

Part #

Flare Nut Size ①

Flare Fitting ②

Length L1

Length L2

06654113

3/8” (9.52mm)

1/4” (6.35mm)

4.37” (111mm)

5.55” (141mm)

06654114

5/8” (15.9mm)

3/8” (9.52mm)

6.92” (176mm)

6.50” (165mm)

Connects to Outdoor Unit

②

Additional Clearance

≈ 9” (220mm)

L1

L2

Top View

06654110 1/4” (6.35mm) 3/8” (9.52mm) 3.11” (79mm) 3.5” (88mm)

06654111 1/2” (12.7mm) 3/8” (9.52mm) 4.45” (113mm) 4.65” (118mm)

06654112 1/2” (12.7mm) 5/8” (15.9mm) 4.45” (113mm) 4.85” (123mm)

06654120 5/8” (15.9mm) 1/2” (12.7mm) 6.92” (176mm) 5.24” (133mm)

06554121* 3/8” (9.52mm) 1/2” (12.7mm) 4.37” (111mm) 3.74” (95mm)

*Note: This subassembly only comes with the A-VFH42PA-1 model.

① Flare Nut

Flare Fitting w/Cap

Connects to Line Set

IMPORTANT: Due to the use of these subassemblies on the connections of the outdoor unit, please be

sure to accommodate for about 9” (220mm) of clearance from the side of the unit where the refrigerant

lines attach.

Unit Length

Required

Subassemblies for A-VFH24TA-1, A-VFH30QA-1 Outdoor Units:

For models A-VFH24TA-1 and A-VFH30QA-1, two (2) subassemblies consisting of a straight piece of copper with a female

flare nut x male flare fitting, are provided to connect any indoor units that have 1/2” (12.7mm) gas connections with the

outdoor unit’s 3/8” (9.52mm) gas connections.

14

Page 15

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

06643008

3/8” (9.52mm)

1/2” (9.52mm)

5.28” (134mm)

Part #

Flare Nut Size ①

Flare Fitting ②

Length L1

Outdoor

①

Flare Fitting

L1

Indoor

Flare Fitting

L1

Part # Flare Nut Size ① Flare Fitting ② Length L1

Indoor

1/2” Gas

Connection

Flare Nut

Connects to Outdoor

Unit Gas Connection

②

(w/Cap-not shown)

Connects to Indoor Unit

3/8” Gas

Connection

Subassemblies for Indoor Units:

Model B-VFH18MA-1 comes with one (1) subassembly consisting of a straight piece of copper with a female flare nut x

male flare fitting, are provided to connect with the outdoor unit’s 3/8” (9.52mm) gas connections.

06643008 3/8” (9.52mm) 1/2” (9.52mm) 5.28” (134mm)

②

① Flare Nut

Connects to Outdoor

Unit Gas Connection

(w/Cap-not shown)

Connects to Indoor Unit

1/2” Gas

Connection

Outdoor

3/8” Gas

Connection

Indoor Units also come with Additional Flare Nuts for ease of installation:

Per the chart below, each indoor model comes with one (1) or two (2) flare nuts in the sizes shown.

Indoor Unit Flare Nut

B-VFH09MA-1

B-VFH12MA-1

B-VFH18MA-1 5/8” (15.9mm)

B-VFH12CA-1 3/8” (9.52mm)

B-VFH18CA-1 1/2” (12.7mm)

B-VFH24CA-1 3/8” (9.52mm) N/A

1/4” (6.35mm) N/A

15

Page 16

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

Leak Test, Evacuation & Release of Refrigerant

The recommended procedure for leak test, evacuation,

WARNING

It is illegal to discharge refrigerant into the

atmosphere. Use proper reclaiming methods

and equipment when working on the refrigerant

containing parts of the unit. Service should be

performed by a QUALIFIED service agency and

certied technicians.

The condensing unit is supplied with a R-410A

factory charge—see rating plate and outdoor

unit for exact amount. Charge must be added for

interconnecting tubing. See Field Charging Section

of this manual.

The unit’s service valves are shipped in the closed

position and should not be opened until nal

connections and evacuation are completed.

and release of refrigerant is outlined below:

1. Complete the nal piping connections to the indoor

and outdoor units using line sets equipped with are

ttings.

2. Connect a charging manifold to the service ports

provided at the service valves.

3. Pressurize the lines and evaporator with nitrogen

and leak check all connections with soap bubbles.

Repair as necessary any faulty joints. If brazing is

required be sure to RELEASE THE NITROGEN

FIRST. Re-test as needed.

4. Connect a vacuum pump to the manifold center

connection, start the pump and open the manifold

valves.

5. Evacuate to 500 microns or less for a minimum of

30 minutes. Close the manifold valves and shut off

the pump. Note the vacuum reading and wait 15

minutes. Take a new vacuum reading. A reading

of 800 microns or higher indicates the presence of

moisture or a leak.

6. Repair as necessary and repeat steps 3, 4 & 5.

7. Conrm that manifold valves are closed and

disconnect the vacuum pump.

8. Remove the caps from the services valves. Open

the valves to the fully ‘back-seat’ position. Replace

service valve caps and tighten.

Electrical Precautions

CAUTION

1. Refer to the unit’s rating plate for power supply voltage. Ensure adequate electrical supply

is available.

2. Ensure the air conditioner is properly grounded.

3. Connect wiring to the unit according to the electrical diagram located on the unit.

4. All wiring must comply with local and national electrical codes and be installed by a qualied electrician.

5. An individual branch circuit must be available.

6. Properly size the HACR breaker/fuse based on nameplate date.

7. Improper connections and inadequate grounding can cause injury or death.

8. Connect all wiring tightly. Loose wiring may cause overheating at connection points and

create a possible re hazard.

9. Match terminal strip numbers/labels and colors between indoor and outdoor wiring. Erroneous wiring may cause re/shock.

10. Always use strain reliefs and outdoor cable cover to protect wiring.

16

Page 17

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

Unit Wiring

The contractor is to provide an individual branch

WARNING

• Before performing any electrical work, ensure

all power is off. Electrical shock may occur.

• All outdoor unit’s capacitor’s to discharge

otherwise electrical shock hazard may occur.

• Ensure the unit is properly grounded.

circuit for over current protection for the unit as

required by code. Some codes may require a

disconnect between the indoor and outdoor unit.

Run power supply wiring through a weatherproof

disconnect box and conduit to the unit connection.

Disconnects are required to be within sight and

easy reach of the unit (usually within 3 feet).

Circuit breakers and disconnect switches should

be properly sized based on the required codes and

the unit’s nameplate requirements. (Fig.12)

ELECTRICAL WIRING

AND SUPPLY VOLTAGE:

All electrical wiring must be done according to

local codes. Additionally installations in the USA,

must conform to the current National Electric Code

(NEC) and Installations in Canada must conform to

current Canadian Electric Code (CEC). Nameplate

data indicates the operating voltage, phase,

ampacity, maximum over current protection, and

minimum voltage.

Model BTUH/H 18 24 30 36 42

POWER

(outdoor)

CIRCUIT BREAKER/FUSE (A) 20 30 45 45 50

NOTE: Subject to change. Always refer to unit’s nameplate.

PHASE 1 Phase 1 Phase 1 Phase 1 Phase 1 Phase

VOLT 208/230VAC 208/230VAC 208/230VAC 208/230VAC 208/230VAC

Check the unit wiring diagram for the number of

conductors required. Ensure that the proper AWG

(gauge) and type of wired is used to comply with

code and the unit’s nameplate. Route neatly and

protect from sharp edges and damage.

Inadequate wiring and/or improper electrical

supply will likely result in failure of the compressor

and other electrical components and voids the

warranty.

Fig. 12

Branch circuit breaker

17

Page 18

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

Electrical Work

Outdoor unit power and

communication cable wiring

1. Remove the electrical control cover from the

outdoor unit (Fig. 13).

2. Connect power supply wires to the outdoor unit’s

terminal strip (Fig. 14-19).

3. Connect the communication cable from the

indoor unit to the outdoor unit’s terminal strip on

the left side. Repeat for each indoor unit (Fig.

14-19).

4. Connect the ground wire of the communication

cable to the ground terminal (Fig. 14-19).

5. To prevent water from entering in the unit, form a

loop in the cable (Fig. 13).

6. Insulate any unused conductors with electrical

tape, so that they do not touch any other

exposed electrical or metal parts.

7. Replace the electrical control cover that was

removed in Step 1.

Air inlet (side)

Air outlet

Fig. 13

Air inlet (rear)

Cover

Screw

Loop the

cable

Fig. 14

1. The power cable should be placed in the hole

under connection cable cover.

2. If connecting two indoor units, the connection cable

should be placed in hole A and hole B.

3. If connecting three indoor units, the connection

cable should be placed in hole A, B and C.

4. If connecting four indoor unit, the connection cable

should be placed in hole A, B, C and D.

5. If connecting ve indoor units, the connecting

cables should be places in holes A, B, C, D and E.

18

Page 19

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

Electrical Work

18KBTU/H

Fig. 15

Fig. 16

24KBTU/H

19

Page 20

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

Electrical Work

Fig. 17

30KBTU/H

Fig. 18

20

36KBTU/H

Page 21

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

Electrical Work

Fig. 19

42KBTU/H

Field Charging

Unit performance, efciency, and life depends, to

a large extent, on a proper system charge. Time

spent on getting the charge right at start-up will

payoff in the long run. Operating conditions such

as voltage, air ow, evaporator coil size, and indoor

and outdoor temperature and humidity all have

an effect on the system pressures and superheat

conditions.

Units are factory charged before shipment. See

rating plate on outdoor unit for exact amount.

These units should be critically charged to ensure

proper performance. Some systems may require

additional charging of refrigerant, depending on

line set lengths. If the total line set length is less

than the amount in the table below, no additional

KBTU/H

18 32.8 ft. (10m)

24 98 ft. (30m)

30 / 36 131 ft. (40m)

42 166 ft. (50m)

Total allowable length (for all indoor units)

refrigerant is needed.

If the total length or refrigerant lines for all models is

greater than the amount shown in the chart, additional

refrigerant is needed.

18 - 30 KBTU/H Units

Additional Refrigerant Charge = sum of additional line

length* ft (m) times 0.22 oz/ft (20g/m).

36 - 42 KBTU/H Systems

Additional Refrigerant Charge = sum of additional line

length* ft (m) times 0.24 oz/ft (22g/m).

*Additional line length is the sum of all the line sets

for all indoor units subtracted from the total allowable

length shown in the table.

21

Page 22

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

Field Charging Example

36KBTU/H

Outdoor Unit

OUTDOOR UNIT INDOOR UNIT LINE SET/LENGTH

j 9KBTU/H

k 9KBTU/H

36KBTU/H

l 9KBTU/H

m 9KBTU/H

Four 9KBTU/H

Indoor Units

a / 30 ft (9m)

b / 35 ft (10.6m)

c / 40 ft (12.2m)

c / 50 ft (15.2m)

Total length of refrigerant line set = a + b + c + d

= 30' (9m)+ 35' (10.6m) + 40’ (12.2m) + 49' (15.2m)

= 154 ft (47m) total

The allowable line length for a 36KBTU/H unit is

131 ft (40m) as shown on the table on page 17.

The total line set length for the example installation

is 154 ft (47m) which is greater than the allowable

length, so additional refrigerant is required.

To calculate the additional refrigerant needed ,

multiply the additional line length by .024 oz/ft

(20g/m) for a 36KBTU/H unit. To get the additional

line length, subtract the allowable line length from

the total system line length.

CALCULATION EXAMPLE:

Total system line length 154 ft (47m) minus the

allowable line length 131 ft (40m) = 23 ft (7m)

To determine the additional refrigerant, the additional

line length 23 ft (7m) is multiplied by 0.24 oz/ft

(20g/m) = 5.5 oz (154g)

In this example, 5.5 oz (156g) of additional refrigerant

is needed for a complete charge.

22

Page 23

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

Final Inspection

Do a visual inspection of the entire installation. Complete any nal

steps and clean up the work areas.

Ensure that all units—indoor and outdoor—are working properly.

IMPORTANT!

All panels must be installed, main power turned on and wiring,

refrigerant lines, and condensate drain lines properly connected

before operating the unit.

Operation of the unit will depend on the setting of the thermostat

on the indoor unit. Refer to the indoor unit’s manual for operating

instructions.

Review the system and controls with the homeowner

Ensure that the homeowner is provided with all manuals, warranty

card, receipt and any additional documentation that might be

available or required.

23

Page 24

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

This page is left intentionally blank.

24

Page 25

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

This page is left intentionally blank.

25

Page 26

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

This page is left intentionally blank.

26

Page 27

Heat Controller VFH InverterFlex® - Outdoor Ductless Mini-Split

This page is left intentionally blank.

27

Page 28

VFH InverterFlex® - Outdoor Ductless Mini-Split Heat Controller

'XHWRRQJRLQJSURGXFWLPSURYHPHQWVVSHFLILFDWLRQVDQGGLPHQVLRQVDUH

VXEMHFWWRFKDQJHDQGFRUUHFWLRQZLWKRXWQRWLFHRULQFXUULQJREOLJDWLRQV'HWHUPLQLQJWKH

DSSOLFDWLRQDQGVXLWDELOLW\IRUXVHRIDQ\SURGXFWLVWKHUHVSRQVLELOLW\RIWKHLQVWDOOHU

$GGLWLRQDOO\WKHLQVWDOOHULVUHVSRQVLEOHIRUYHULI\LQJGLPHQVLRQDOGDWDRQWKHDFWXDOSURGXFW

SULRUWREHJLQQLQJDQ\LQVWDOODWLRQSUHSDUDWLRQV

,QFHQWLYHDQGUHEDWHSURJUDPVKDYHSUHFLVHUHTXLUHPHQWVDVWRSURGXFWSHUIRUPDQFH

DQGFHUWLILFDWLRQ$OOSURGXFWVPHHWDSSOLFDEOHUHJXODWLRQVLQHIIHFWRQGDWHRIPDQXIDFWXUH

KRZHYHUFHUWLILFDWLRQVDUHQRWQHFHVVDULO\JUDQWHGIRUWKHOLIHRIDSURGXFW

7KHUHIRUHLWLVWKHUHVSRQVLELOLW\RIWKHDSSOLFDQWWRGHWHUPLQHZKHWKHUDVSHFLILF

PRGHOTXDOLILHVIRUWKHVHLQFHQWLYHUHEDWHSURJUDPV

:HOOZRUWK$YH-DFNVRQ0,3KZZZKHDWFRQWUROOHUFRP

4/2014

28

Loading...

Loading...