Heartland HL-CKNG, HL-CKLP Owner's Manual

PLEASE READ THESE INSTRUCTIONS BEFORE INSTALLING OR USING THIS APPLIANCE.

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE.

CUSTOMER: KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Remember, when replacing a part on this appliance, use only spare parts that you can be assured conform to the safety

and performance specification that we require. DO NOT use reconditioned or copy parts that have not been clearly

authorized by HEARTLAND APPLIANCES INC.

Installation, Servicing,

Users Instructions

& Cooking Guide

HEARTLAND COOKMASTER

OWNERS MANUAL

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage,personal injury or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT DO YOU DO IF YOU SMELL GAS

z

Do not try to light any appliance.

z

Do not touch any electrical switch

z

Do not use any phone in your building.

z

Immediately call your gas supplier from a neighbors phone.

Follow the gas suppliers instructions

z

If you can not reach your gas supplier call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

FOR USE IN USA/CANADA

NATIONALLY RECOGNISED

TESTING LABORATORY

05/06 EINS 514594

SECTION CONTENTS PAGE

INSTALLATION SECTION 4

TECHNICAL DATA 5

SITE REQUIREMENTS INTRODUCTION 6

IMPORTANT 6

GAS SUPPLY 6

LOCATION 7 & 8

VENT CONNECTION 9 & 10

ELECTRICAL 10

INSTALLATION CLEARANCES 11

REQUIREMENTS PRELIMINARY INSTALLATION 11

SITE LOCATION 12

SETTING COMBUSTION 12

INSTALLATION BURNER ACCESS 13

INSTRUCTIONS ELECTRICAL CONNECTION 13

TERMINAL STRIP CONNECTIONS 14

BURNER CONTROL 15

ELECTRICAL CHECK 15

COMBUSTION DISCHARGE SAFETY DEVICE 15

ANCILLARY CONTROLS CHECK 16

INSTRUCT THE USER 16

USERS GUIDE 17

INTRODUCTION 18

SAFETY PRECAUTIONS AND HINTS 19

FEATURES AND ACCESSORIES 20 & 21

SETTING THE TIMER FOR USE 22

USING THE TIMER 23 - 24

THE MINUTE TIMER 25

USING THE AUTOMATIC COOKING FACILITY 26

ROASTING/BAKING OVEN OPERATION 27

COOKING WITH YOUR APPLIANCE 28

COOKING CHART - MAIN OVEN 29

CLEANING AND CARING FOR YOUR AGA 30

SERVICING INSTRUCTIONS 31

INTRODUCTION 32

SERVICE SCHEDULE 32

BURNER REMOVAL PREPARATION 33

BURNER ACCESS 33

BURNER REMOVAL 34

BURNER CHAMBER/ BURNER CHAMBER 35

SERVICING

BURNER SERVICING BURNER HEAD CLEANING 36

ELECTRICAL CONTROLS TERMINAL STRIP CONNECTIONS 37

OVERHEAT SAFETY THERMOSTAT 38

FLUE SAFETY THERMOSTAT 38

BURNER COMBUSTION AIR 39

TEST BURNER ON DRY RUN (NO GAS) 40

2

CONTENTS

SECTION CONTENTS PAGE

REPLACEMENT OF PARTS ELECTRODES 41

(BURNER) CONTROL BOX 41

ELECTRICAL COMPONENT ACCESS 42

TRANSFORMER 42

FUSE 42

TO INSTALL NEW FLUE SAFETY DEVICE 43

TO INSTALL NEW COOKER SAFETY OVERHEAT 44

THERMOSTAT

AND OVEN CONTROL THERMOSTAT

TO INSTALL NEW TIMER 44

RE-ASSEMBLE 44

FAULT-FINDING WIRING DIAGRAM - BURNER ONLY 45

WIRING DIAGRAM - APPLIANCE 46

BURNER DOES NOT START 47

TROUBLE-SHOOTING BURNER 48

TROUBLE-SHOOTING CHART 49

SERVICING OR FAULT 50

3

Installation

Section

4

CAUTION:

THIS UNIT IS HEAVY. PROPER EQUIPMENT AND ADEQUATE

MANPOWER MUST BE USED IN MOVING THE RANGE TO

AVOID DAMAGE TO THE UNIT OR THE FLOOR.

Remember, when replacing a part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorized by HEARTLAND

APPLIANCES INC.

THE INSTALLATION OF THIS APPLIANCE MUST CONFORM WITH LOCAL CODES, OR IN

THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL FUEL GAS CODE, ANSI

Z223.1/NFPA 54

DESN 512448

PLEASE NOTE: IT IS ADVISABLE TO

CHECK THE ACTUAL SIZE/WIDTH

OF YOUR APPLIANCE BEFORE

FINALLY FIXING ANY KITCHEN

UNITS, SINCE ENAMELLED CAST

IRON CAN VARY IN SIZE

DIMENSIONS IN MM

5

Gas Inlet 1/2” NPT Unp acked Appliance Weight - 326 Kg (719 lbs)

Electrical Supply 115 V 60 Hz

Natural Gas Propane

Appliance Inlet 10” w.g. 15” w.g.

Pressure (MAX.)

Burner Pressure

- 0.044 w.g. (± 0.012” w.g.) - 0.044 w.g. (± 0.012” w.g.)

(NEGATIVE) (non-adjustable) (non-adjustable)

Max Flue Temp. 445ÞF 450ÞF

CO 0 - 50 ppm 0 - 50 ppm

CO

2

% 8.2% - 9.9% 9.4% - 10.8%

Heat Input 50,000 Btu/hr 50,000 Btu/hr

TECHNICAL DATA

The Aga Cookmaster is a floor standing only cooker, fired by a gas burner. It is suitable for vertical flue outlet only.

The burner fitted to this appliance has been designed and constructed exclusively for use with the Aga

Cookmaster and MUST not be used on any other appliances or any other uses.

Installation Pipes

Pipework from the meter to the appliance must be of adequate size. Do not use pipes of a smaller size than the appliance

gas connection. To avoid undue stress on pipework and burner, adequate support should be used when connecting and

disconnecting union. The complete installation must be tested for soundness and purged in accordance with the

regulations in force.

NOTE: USE SOAPY WATER SOLUTION ON NEW GAS CONNECTIONS TO ENSURE THERE ARE NO GAS LEAKS.

Gas Supply Pipe - U.S. Pipe Threads

NOTE: A GAS CONTROL VALVE MUST BE INSTALLED IN THE GAS PIPELINE EXTERNALLY OF THE RANGE (NOT

SUPPLIED) FOR THE PURPOSE OF TURNING ON OR SHUTTING OFF GAS TO THE APPLIANCE. DO NOT FIT

VALVE BEHIND THE COOKER; IT MUST BE INSTALLED IN AN ACCESSIBLE LOCATION.

The appliance has a 10 mm (1/2”) N.P.T. Male Connection at the front left hand side.

ALL GAS CONTROLS MUST BE U.S. PIPE THREADS.

Maximum Heat Input: 50,000 Btu/h Oven Only

The appliance and its individual shut-off valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressure in excess of 1/2 psig (3.5 kPa). The appliance must be isolated from the

gas supply piping system by closing the individual manual shut-off valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2 psig (3.5 kPa).

Leak testing of the appliance shall be conducted according to the manufacturers instructions.

FLUE SAFETY

DEVICE

For safety purposes, a flue safety device is fitted. This will only operate in adverse flue conditions. If the switch has

operated, it should be pushed in only to reset. If this problem persists, it is necessary to determine and rectify the cause.

If it is found necessary to reset more than once, this may indicate a flue blockage.

INTRODUCTION

IMPORTANT

GAS SUPPLY

Site requirements

6

The appliance is floor mounted and must be installed on a solid floor or base of non-combustible material which is capable

of supporting the total weight.

The location chosen for the appliance must permit the installation and the provision of a satisfactory flue and an adequate

air supply. The location must also provide adequate space for servicing and for air circulation around the appliance. See

“Installation of the Appliance”.

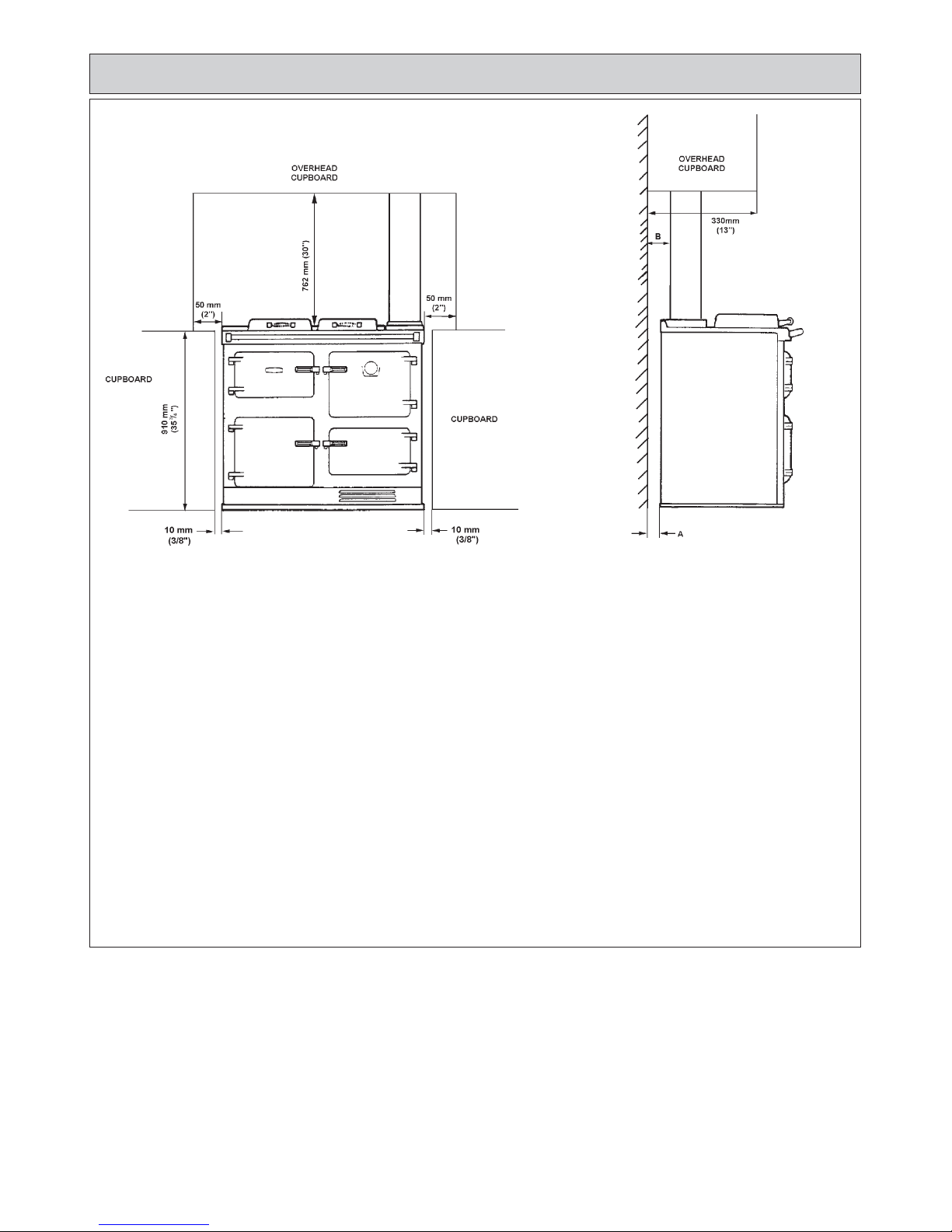

The space in which the appliance is to be fitted must have the following minimum dimensions:

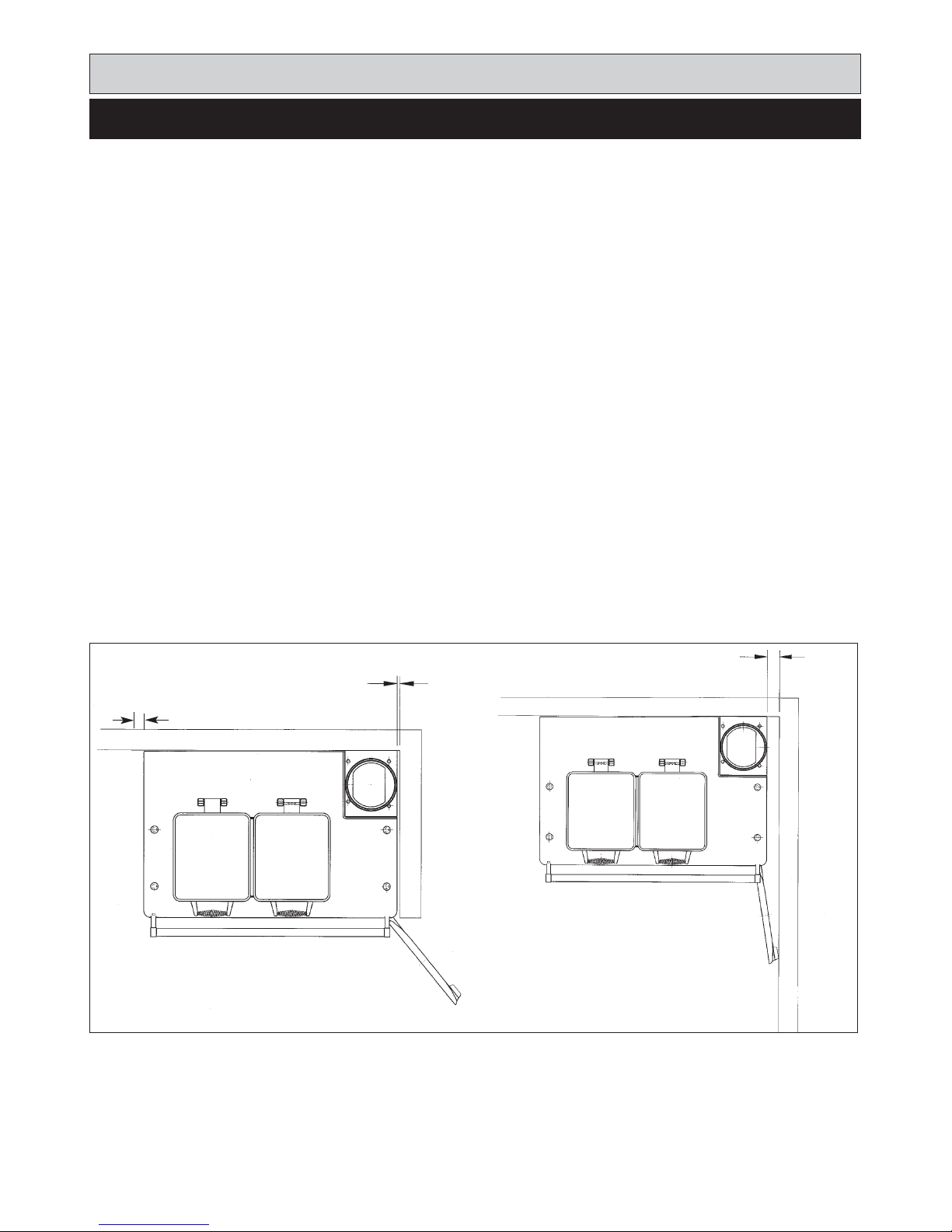

Between wall and LH side of appliance - 10 mm (3/8”)

Between wall and RH side of appliance - 10 mm (3/8”)

SHOULD THE WALL PROJECT BEYOND THE FRONT OF THE APPLIANCE, THEN THE GAP AT THE R.H. SIDE

MUST BE INCREASED TO 50 mm (2”) TO ALLOW REMOVAL OF OVEN SHELVES. (SEE FIG. 1).

Height above the raised hotplate - 762 mm (30”)

Max. depth of cabinets above hotplate - 330 mm (13”)

In addition, adequate clearance must be available at the front of the appliance to enable it to be operated and serviced.

Flue pipes and fittings must not be closer than 57 mm (2

1

/4”) to combustible materials. Any openings in the wall behind

the appliance and in the floor under the appliance shall be sealed.

Spaces around flue pipes passing through walls or floors should be sealed against the passage of smoke and flame.

Where the cooker is to stand in a recess or against a wall which is to be tiled, in no circumstances should the tiles

overlap the cooker top plate.

LOCATION

50 mm

(2”)

10mm (3/8”)

FIG. 1A

WALL PROJECTING BEYOND THE

FRONT OF THE APPLIANCE

Site requirements

7

Site requirements

8

FIG. 1B DESN 512558

INSTALLATION CLEARANCES

REAR DIM ‘A’ COMBUSTIBLE WALL 1” (25mm)

NON-COMBUSTIBLE WALL 0” (0mm)

DIM ‘B’ FLUE PIPE CLEARANCE TO 2

1

/4” (57 mm)

COMBUSTIBLE WALL

NON-COMBUSTIBLE WALL 1” (25 mm)

SIDES BELOW HOTPLATE

3

/8” (10 mm)

SIDES ABOVE HOTPLATE 2” (50 mm)

WALL CABINET OVERHEAD 30” (762 mm)

WALL CABINET OVERHEAD 13” (330 mm)

MAXIMUM DEPTH

WALL CABINET ALONGSIDE 30” (762 mm)

A 125 mm (5”) Type B Gas Vent must be used and fastened by screw to the draft hood flue collar.

U.S.

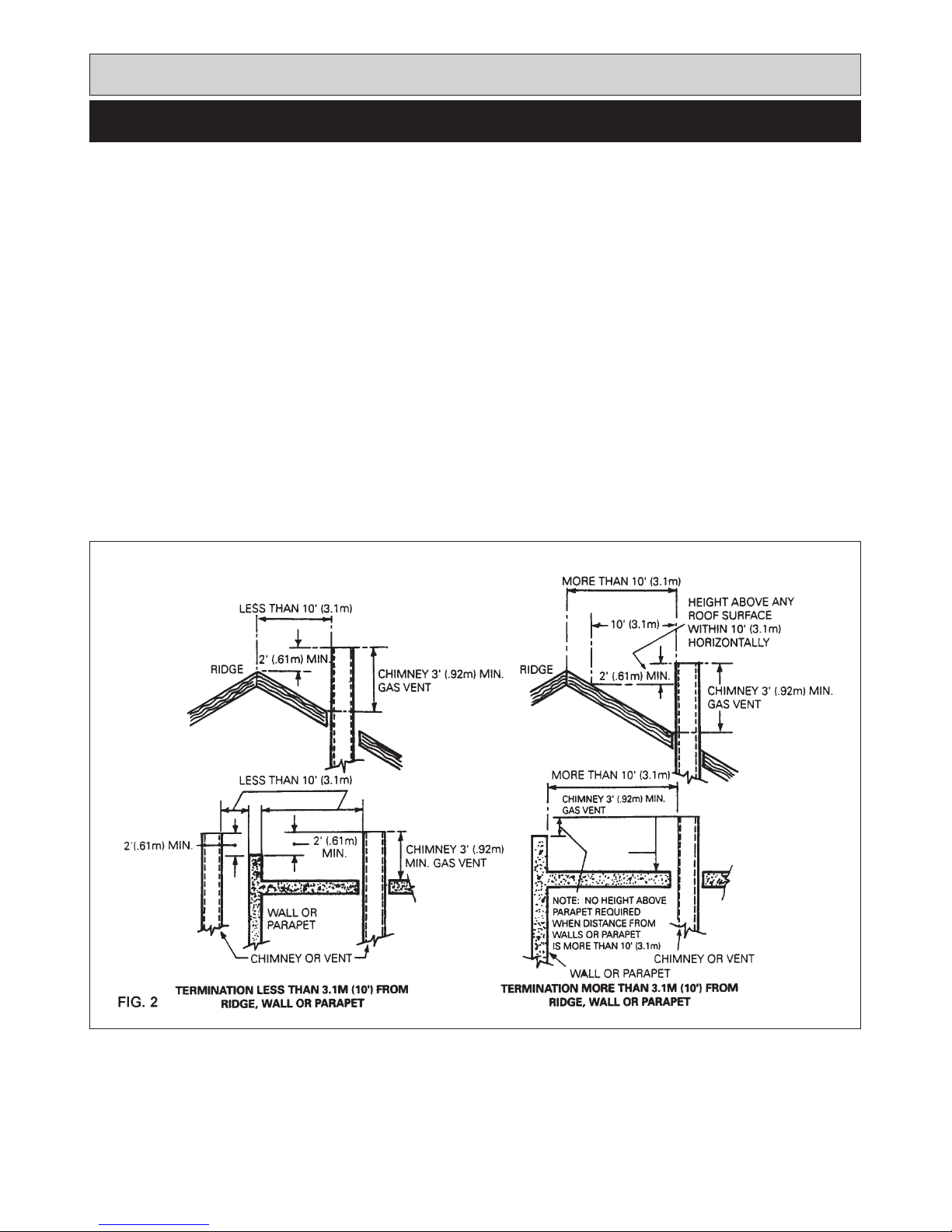

The gas vent must be connected to a chimney or independently and in accordance with Chapter 26, chimney Gas Vent

and Fireplace Systems of the current issue of Equipment and Volume of the ASHRAE Handbook. The gas vent proximity

to combustion materials must be installed as recommended in ANSI/NFPA 211 and according to manufacturers

instructions. Chimneys and vents shall terminate above the roof level and in accordance with the requirements of the

current issue of ANSI/NFPA 211 (see Fig. 2) and be at least 1.53m (5ft) above the flue collar of the draft hood outlet.

Part 7, Venting of Equipment, outlined in the current National Gas Code ANSI Z223, gives detailed guidelines on all these

aspects.

Canada:

The gas vent must be connected to a chimney or independently and in accordance with the CAN/CGA - B149 Installation

Codes.

The air gap between vent and combustible materials must be given for the following types of vent:

(i) Type B Vent - 25mm (1in) minimum

(ii) Single wall vent connector - 150mm (6in) minimum

Listed connectors passing through the combustible walls and partitions must be guarded by a ventilated metal thimble not

less than 200mm (8in) diameter.

VENT CONNECTION

Site requirements

9

Chimneys and vents shall terminate above roof level and in accordance with the requirement of the current issue of the

CAN/CGA - B149 Installation Code (Code W) (see Fig. 2) and be at least 1.53m (5ft) above the flue collar of the draft outlet.

1. If suitable, lined brick chimney is used it must be swept before connection and not less than 150mm (6in) internal

diameter.

2. The top of the chimney should be fitted with an approved terminal.

3. The flue route to the chimney should be as direct as possible. Resistance in the form of directional change should be

kept to a minimum. Right angle bends and horizontal runs should be avoided.

4. The chimney terminal should terminate at the highest possible point, preferably in a freely exposed position.

Termination at the roofs eaves is unacceptable.

5. The Aga Distributor or local gas company should be advised if there is any doubt as to the suitability of the flue.

6. Approved factory made chimneys are acceptable with the appliance and should not be less than 10mm (4in) internal

diameter.

7. In the event of an extractor fan being fitted in the vicinity of the range, compensatory ventilation will be required to

satisfy the demands of the fan without influencing combustion efficiency or chimney flue condition.

110/120V 60 Hz 10 AMP FLEXIBLE CORD AND PLUG PARALLEL TYPE. When installed, the appliance must be

electrically grounded in accordance with local codes or, in the absence of codes, with National Electrical Codes

ANSI/NFPA 70.

An electrical socket must be provided within 6 feet of the LH side of the appliance and easily accessible to the user to

disconnect. Do not position socket above the appliance.

Take special care when cutting holes in wall or floor. Electrical wires may be behind the wall or floor covering and could

cause an electrical shock if you touch them.

Locate any electrical circuits that could be affected by the installation of this product and disconnect power circuit

WARNING

Electrical Grounding Instructions

This appliance is equipped with a (three-prong) grounding plug for your protection against a shock hazard and should

be plugged directly into a proper receptacle. Do not cut or remove the grounding prong from this plug.

Do not have a fuse in the neutral or grounding circuit. A fuse in the neutral or grounding circuit could result in electrical

shock.

Do not use an extension lead with this appliance.

Check with a qualified electrician if you are not sure the appliance is properly grounded.

Failure to follow these instructions could result in death or serious injury.

VENT CONNECTION (continued)

ELECTRICAL

Site requirements

10

The appliance is floor mounted. The space in which the

appliance is to be fitted must have the following minimum

dimensions.

Between wall and LH side of appliance - 10mm (1/2”)

Between wall and RH side of appliance - 10mm (1/2”)

SHOULD THE WALL PROJECT BEYOND THE FRONT

OF THE APPLIANCE, THEN THE GAP AT THE R.H.

SIDE MUST BE INCREASED TO 50mm (2”) TO ALLOW

REMOV ALOF OVEN SHEL VES. SEE PAGE 4 - FIG. 1A.

Above the raised insulating cover handle - 60mm (3”)

In addition, adequate clearance must be available at the

front of the appliance to enable it to be operated and

serviced.

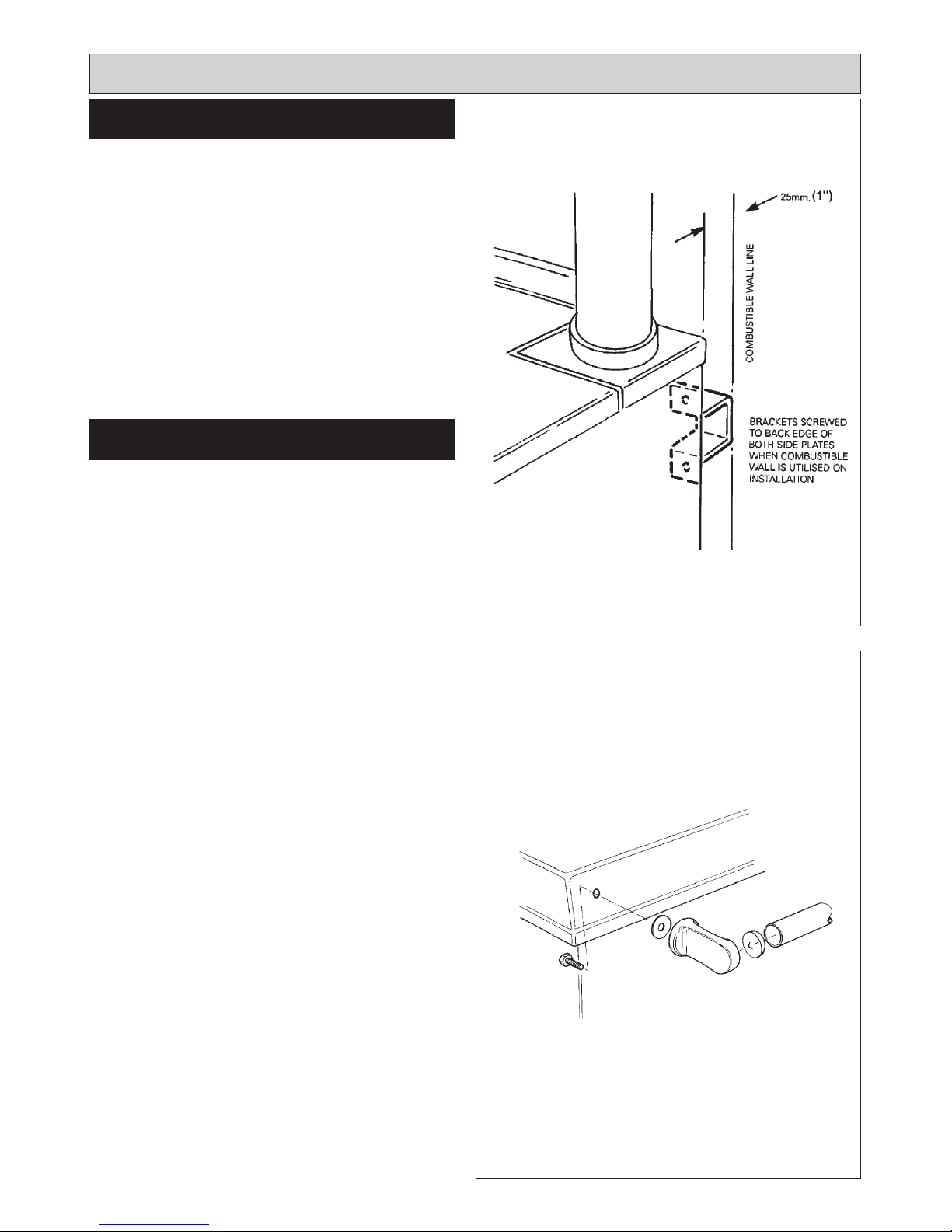

The appliance is delivered in a fully assembled condition

with the exception of the following items which are

supplied separately packed and require assembly:

The appliance rear distance bracket.

The cooker handrail.

Appliance rear distance bracket: if the rear wall is of

combustible material, there must be an air gap of 25mm

(1”) between the wall and the rear of the cooker. Fit the

rear distance brackets as shown in Fig. 3. Whenever

possible it is recommended that the skirting board is

removed for the width of the appliance to enable the rear

edge of the appliance top plate to make contact with the

vertical wall and avoid a rear gap. (Combustible wall

excepted).

Where the cooker is to stand in a recess or against a wall

which is to be tiled, IN NO CIRCUMSTANCES SHOULD

THE TILES OVERLAP THE TOP PLATE.

The handrail brackets are held on the front edges of the

cooker top-plate casting. Remove the travel nuts and

replace with the handrail brackets ensuring the fiber

protecting washers are in position. Insert the handrail with

fitted end caps into the brackets, positioning them

correctly, and tighten the locating bolts (Fig. 4).

Installation requirements

CLEARANCES

PRELIMINARY INSTALLATION

FIG. 3

DESN 510226

FIG. 4

DESN 510454 ‘A’

11

Installation requirements

SITE LOCATION SETTING COMBUSTION

1. Check that the hearth is level, then remove the

appliance from its transit wooden pallet, and position

it with its back against the wall and in its intended

position for flue connection.

2. Locate and fit flue pipe into socket of flue pipe

adaptor, seal joint with rope and fire cement.

3. Connect and terminate the flue system in accordance

with the regulations in force.

Connect the relevant services to the appliance:

1. Gas

2. Electric

3. Flue Pipe

Because this appliance uses a pre-mix burner, no setting

up of combustion is required; the burner automatically

controls the air to gas rate ratio.

12

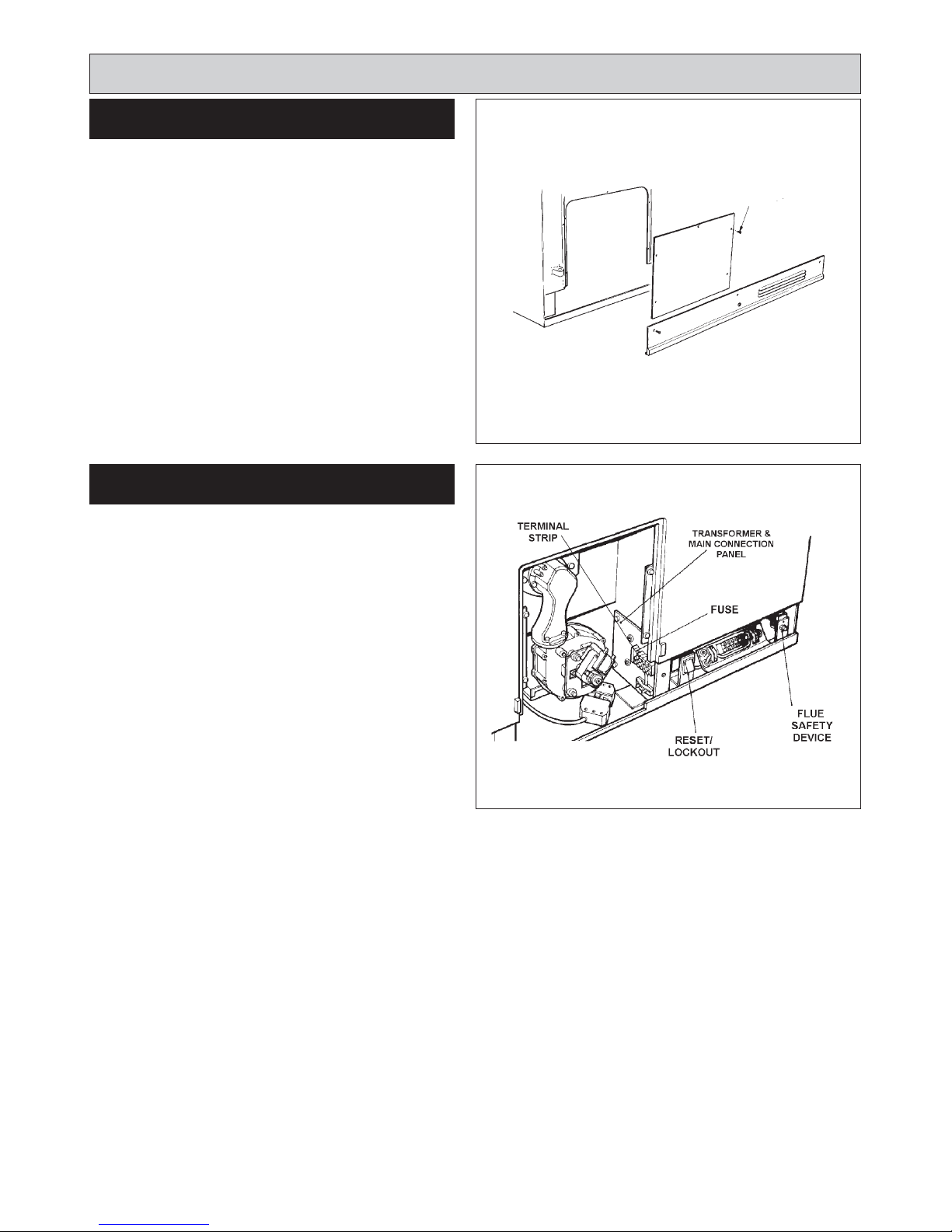

- SEE FIG. 5

1. Open the burner access door.

2. Remove (5) inner panel securing screws and remove

panel.

3 Remove the (3) plinth securing screws and remove

plinth.

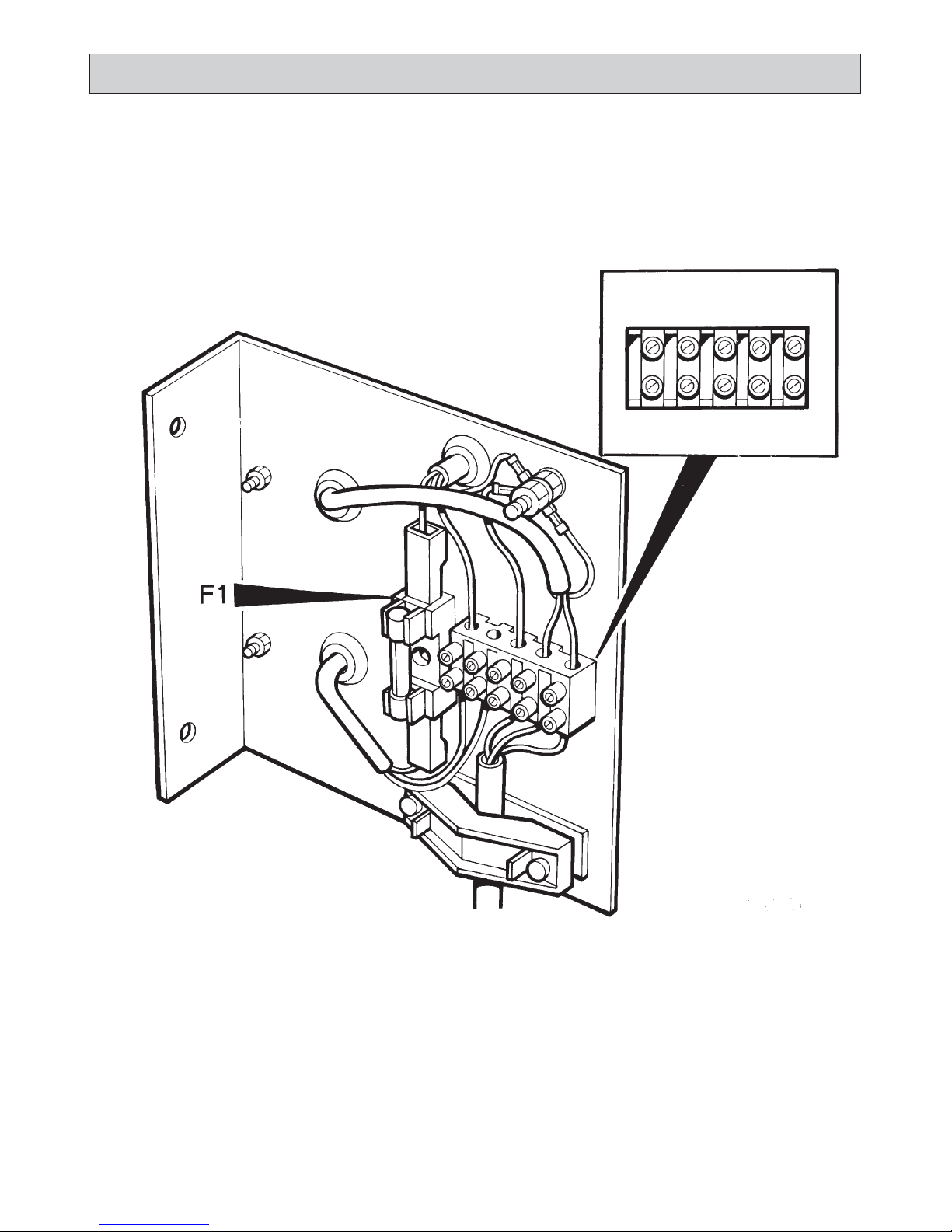

- SEE FIG. 6

This appliance comes with a three-prong plug which

should be connected to a proper receptacle. See page 10

(Electrical). This is fitted internally to the terminal strip

shown in Fig. 6 and Fig. 7.

Installation Instructions

BURNER ACCESS

ELECTRICAL CONNECTION

DESN 511424

DESN 512568

FIG. 6

FIG. 5

13

Installation Instructions

FIG. 7

14

TERMINAL STRIP CONNECTIONS

Installation Instructions

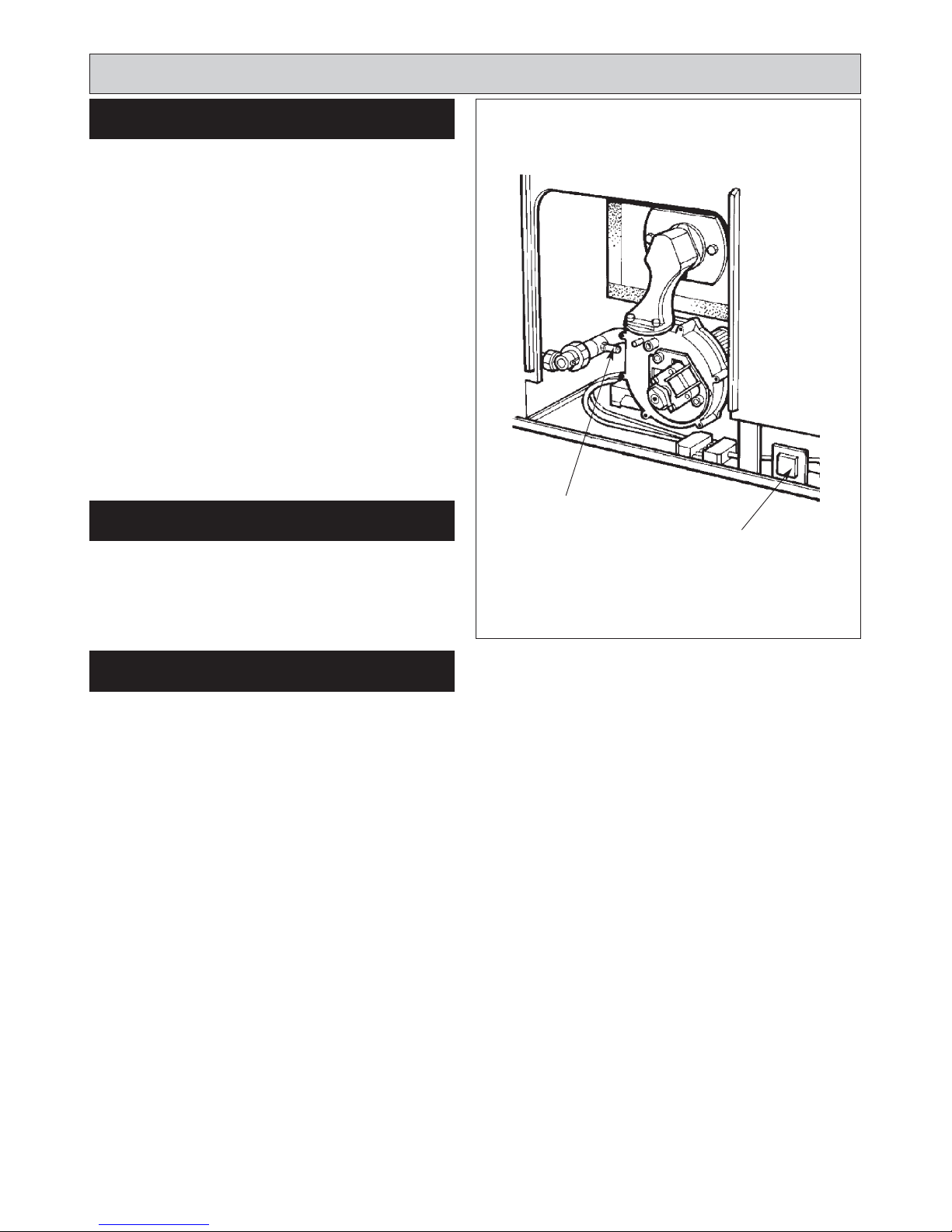

When the thermostat is calling for heat, 230V is supplied

to terminals 10 and 11 on the control box and tab 1 and 2

on the fan, energizing the fan.

There will then be a short delay while the control box

checks that the fan is running and pre-purges. Providing

there is gas to the burner, combustion should be

established after approximately 30 seconds.

On first firing after installation or servicing, the burner may

go to lock out, until all the air has been purged out of the

burner. Wait at least 10 seconds before pressing the reset

button. (See Fig. 8).

Check gas cock is in the on position.

Check inlet gas pressure at test point.

Check to ensure electrical safety is carried out by a

competent person.

For safety purposes, a combustion discharge safety

device is fitted. This will only operate under adverse flue

conditions. If the switch has been operated, it should be

pushed in to reset. If this problem persists, contact your

local engineer to determine and rectify the cause. It is

important not to reset more than once as this may indicate

a flue blockage.

WARNING: The combustion discharge safety device

must not be interfered with or rendered inoperative, as

this could interfere with the safe operation of the

appliance and invalidate the appliance warranty.

BURNER CONTROL

ELECTRICAL CHECK

COMBUSTION DISCHARGE SAFETY

DEVICE

FIG. 8

DESN 512346

RESET BUTTON

GAS SUPPLY

TEST POINT

15

Before leaving the site, check that the operation of cooker

timer and thermostat are capable of controlling the burner

correctly. Check the operation of burner control box.

1. Advise the User that, for continued efficient and safe

operation of the appliance, it is important that adequate

servicing is carried out annually.

2. Hand the Operating Instructions to the User and

demonstrate the correct operation of the appliance and

system controls.

3. Leave the Installation and Servicing Instructions with

the User.

Installation Instructions

ANCILLARY CONTROLS CHECK INSTRUCT THE USER

16

Loading...

Loading...