Heartland 9200 User Manual 2

1260 E. Van Deinse St. Greenville , MI 48838

Fax (616) 754-9690 Toll Free Phone 1-800-223-3900

www.heartlandapp.com

MODEL 9200/7200 GAS RANGE

Installation and Operating Instructions

WARNING: Improper installation, adjustment, alteration,

service or maintenance can

cause injury or property

damage. Refer to this manual.

For assistance or additional

information, consult a

agency, manufacturer

(dealer). Please read these

instructions thoroughly

before attempting to install

this unit. Failure to follow

installation instructions will

result in costly service calls.

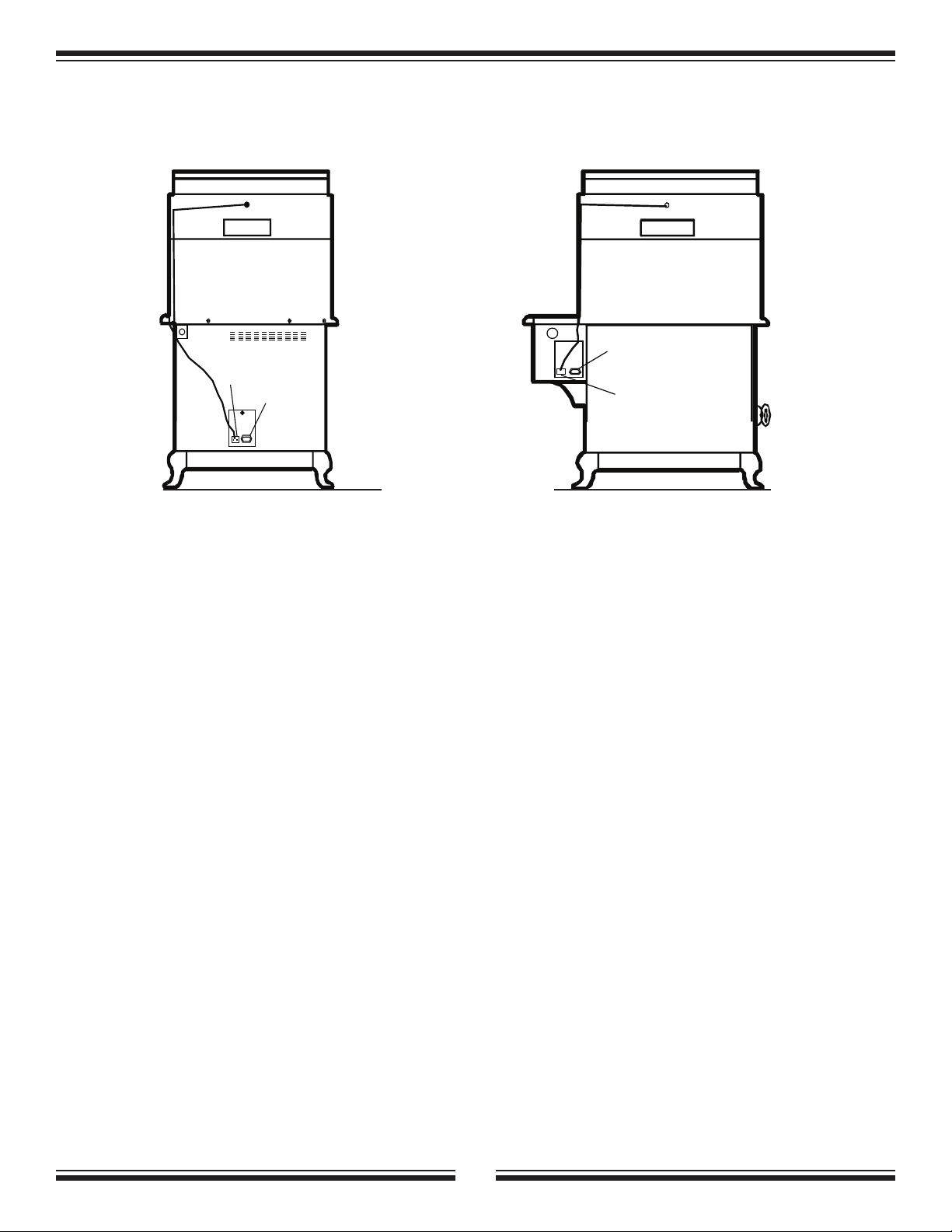

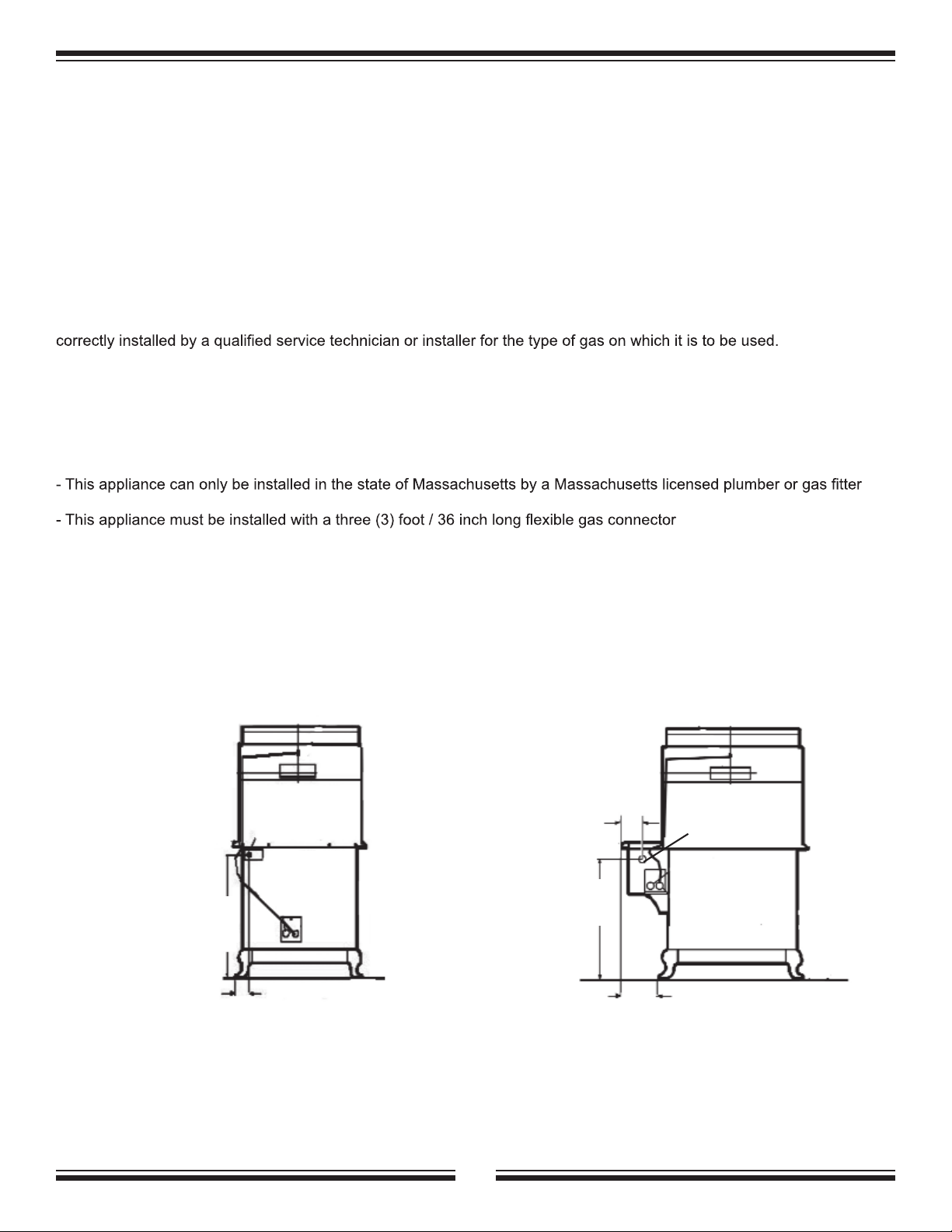

MODEL 9200 MODEL 7200

NOTE: The oven door thermometer does no sense temperature. It is for aesthetics only and is non fuctional.

Note: Please read these instructions thoroughly before attempting to install this unit.

Save these instructions for future use.

ATTENTION INSTALLER: Leave this manual with appliance.

These symbols on the name plate mean the

product has been design certified by CSA

International. It has been tested to conform to

CERTIFIED

C US

Manual #7716.091712

standard ANSI Z21.1 - 2007.

©

2010 AGA MARVEL

WARNING

If the information in this manual is not followed exactly, a or explosion may

result causing property damage, personal injury or death.

For Your Safety

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPOURS OR LIQUIDS IN THE VICINITY OF THIS APPLIANCE

• Do not use the range as a heater.

• Do not heat unopened glass or metal containers in the oven.

•

•

• Avoid the use of aerosol containers near the range.

• Never place pans, cookie sheets or roasters directly on the oven bottom -use the rack in its lowest position.

• Do not cover the entire bottom of the oven with aluminium foil. Allow at least 1” of space all around pots, pans or

.

WARNING

• ALL RANGES CAN TIP

• INJURY TO PERSONS COULD RESULT

• SEE INSTALLATION INSTRUCTIONS

When moving range for service or cleaning.

1 Disconnect electrical power.

4. To reinstall, reverse these instructions.

WARNING

.

1

WARNING

WHAT TO DO IF YOU SMELL GAS!!

•Donottrytolightanyappliance.

•Donottouchanyelectricalswitch;donotuseanyphoneinyourbuilding.

•Immediatelycallyourgassupplierfromaneighbour’sphone.Followthegassupplier’s

instructions.

•Ifyoucannotreachyourgassupplier,calltheredepartment.

Installationandservicemustbeperformedbyaqualiedinstaller,serviceagencyorthegas

supplier.

WARNING

Never use the appliance as a space heater to heat or warm the

room. Doing So may result in carbon monoxide poisoning and

overheating the oven.

WARNING

Never cover any slots, holes or passages in the oven bottom or

cover an entire rack with materials such as aluminum foil. Doing so

blocks airow through the oven and may cause carbon monoxide

poisoning. Aluminum foil linings may also trap heat, causing a re

hazard.

The use of a gas cooking appliance results in the production of heat and moisture in

the room in which it is installed. Ensure that the kitchen is well ventilated: keep natural

ventilation holes open or install a mechanical device. (mechanical extractor hood)

Prolonged intensive use of the appliance may call for additional ventilation, for example

opening of a window, or more effective ventilation, for example increasing the level of

mechanical ventilation where present.

2

Gas Models 9200/7200

CONSUMER WARRANTY

ENTIRE PRODUCT – LIMITED ONE YEAR WARRANTY

AGA MARVELwarrants the replacement or repair of all Parts, including gas components of this stove which prove to

for one year from the date of original purchase. Such parts will be repaired or replaced at the option of Aga-Heartland

without charge, subject to the terms and conditions set out below.

TERMS AND CONDITIONS

1. This warranty applies only for single family domestic use when the stove has been properly installed according

to the instructions supplied by Aga-Heartland and is connected to an adequate and proper utility service. Damage due to

and alteration, or the removal or defacing of the serial plate, cancels all obligations of this warranty. Service during this

warranty must be performed by a factory Authorized Service Person.

2. Warranty applies to product only in the country in which it was purchased.

3. Aga-Heartland is not liable for any claims or damages resulting from any failure of the stove or from service

delays beyond their reasonable control.

4. To obtain warranty service, the original purchaser must present the original Bill of Sale, Model and Serial number.

Components repaired or replaced are warranted through the remainder of the original warranty period only.

5. The warranty does not cover expense involved in making this appliance readily accessible for servicing.

7. Adjustments such as calibrations, levelling, tightening of fasteners, or utility connections normally associated with

original installation are the responsibility of the dealer or installer and not that of the Company

8. If the product is installed outside the normal service area, and cost of transportation expenses (tolls, ferry trip charges,

or mileage expenses, etc.) involved in the repair of the product, or the replacement of a defective part, shall be borne

by the customer (owner).

.

TO ENSURE PROMPT WARRANTY SERVICE, SEND IN YOUR WARRANTY CARD WITHIN 10

DAYS OF PURCHASE.

If further help is needed concerning this warranty, contact:

Customer Service

AGA MARVEL

1260 E. Van Deinse St.

Greenville, MI 48838

Toll Free Telephone 1-800-223-3900

Fax (616)754-9690

Place of Purchase: ____________________________

Date of Purchase: _____________________________

Serial Number: _______________________________

Model Number: _______________________________

TABLE OF CONTENTS

Page Page

Warning 1

Positioning the Range 8

Electrical Installation 9 Porcelain 26

Exhaust Hood 9 Oven Cleaning 27

Ventless Installation 10 Surface Burners 27

Vented Installation 10 Nickel Trim 28

Installation of Ducting 11 Exhaust Hood Filter 28

Venting Safety Guidelines 12 Oven & Cabinet Light Replacement 28

Gas Line Installation 12 Interior Oven Rack Removal 29

Clearance Diagrams 14, 16 Rack Supports Removal 29

Important Safety Instructions 17 Removal of Oven Door 30

Exhaust Hood Safety 17 Broiling 31

Features 18 Broiling Pan 31

Cooking Controls 18 Setup and Trouble Shooting 32

Oven Features 19 Burner Setup and Adjustment 32

Other Features 19 Air Shutter Adjustment 33

Control Panel Layout 20 Oven Burner Assembly 33

Operation 21 Trouble Shooting Guide 34

Top Burner Operation 21 Conversion Kits and Information 35

Oven Cooking & Lighting 22

Range Thermostat 22

Power Failure Operation 23

Manually Lighting the Top Burner 23

Manually Lighting the Oven Burner 23

Clock/Timer 24

Cooking Guide 25

Care and Cleaning 26

Parts Diagram 37

Parts List 38

Rating Plate

Wiring Diagrams 40

Warranty 3

39

4

Assembly and Installation

To fully enjoy your new range, it is important that you read this booklet thoroughly.

shipping damage, inform your dealer immediately!

Caution when unpacking:

Lift the range by the bottom skirt, do not lift by nickel trim.

Unpacking:

Note: to avoid injury, please wear safety equipment, glasses and gloves, while you are unpacking your new range.

1) Unscrew the 20 screws that hold the crate onto the skid. There are 12 along the bottom and 8 along the top.

2) Next with a pair of snips cut the banding that holds the closet in place. Caution metal banding is under

3) After the screws have been removed, carefully lift the crate over the stove and set it aside.

4) Carefully lift the closet off the stove and set it aside.

5) You are now ready to remove the range from the skid.

tension!

For 30” units have one person at each end stand beside the skid and carefully lift the range by the bottom skirt, and a third

, bending your knees not your

back!

For 48” units have one person at each end and one person stand beside the skid and carefully lift the range by the bottom

, bending

your knees not your back!

6) Finish unpacking the range, removing packing tape around the doors and in the oven.

Both 30” and 48” Ranges consist of two main parts: The Range Body, and the Closet / Exhaust Hood

Tools required for assembly: Phillips/Robertson #2 Screwdriver & 5/16” ( 8 mm) wrench or crescent wrench

when range is equipped with a cord and plug.

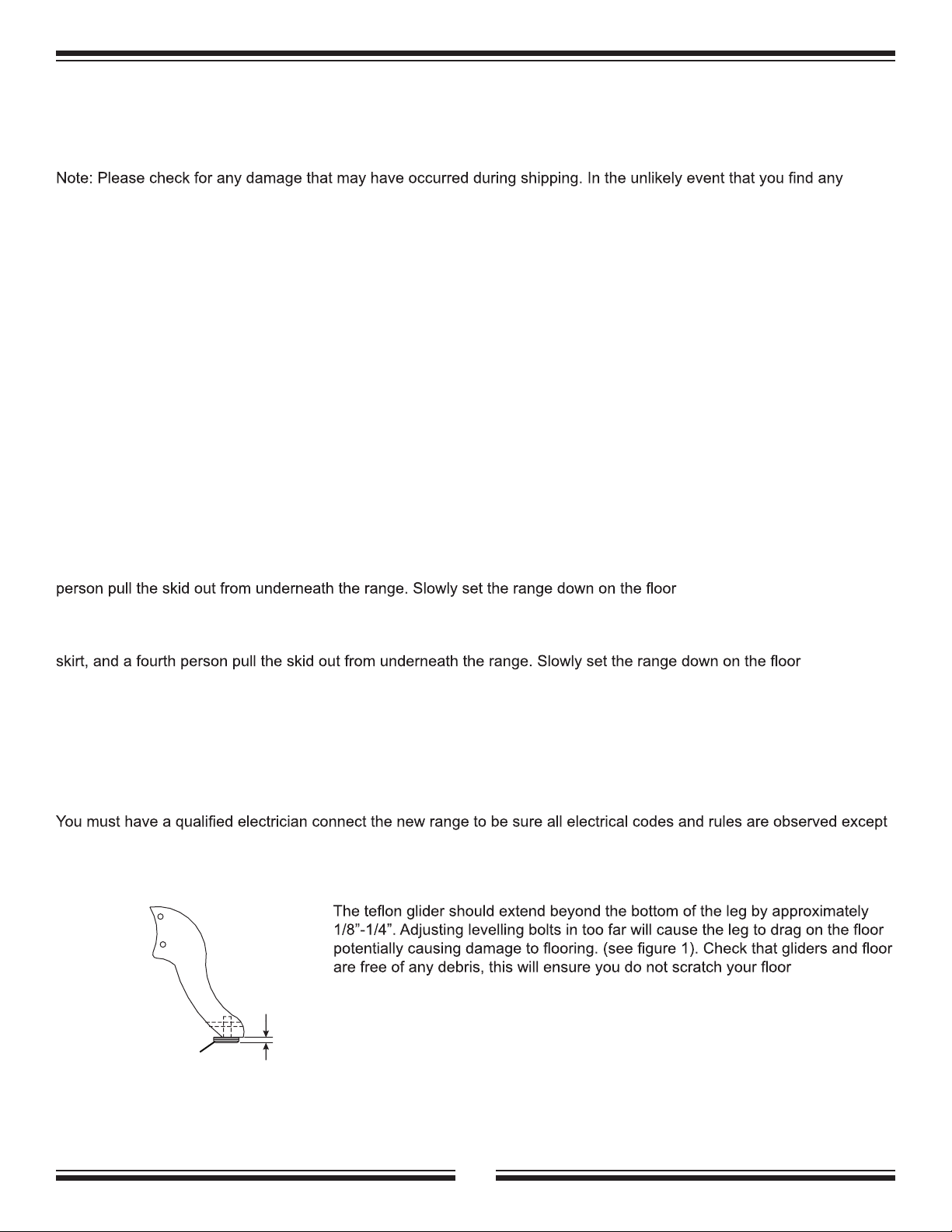

Gliders:

Figure 1

.

1/8” - 1/4”

Teflon Glider

5

BLANK

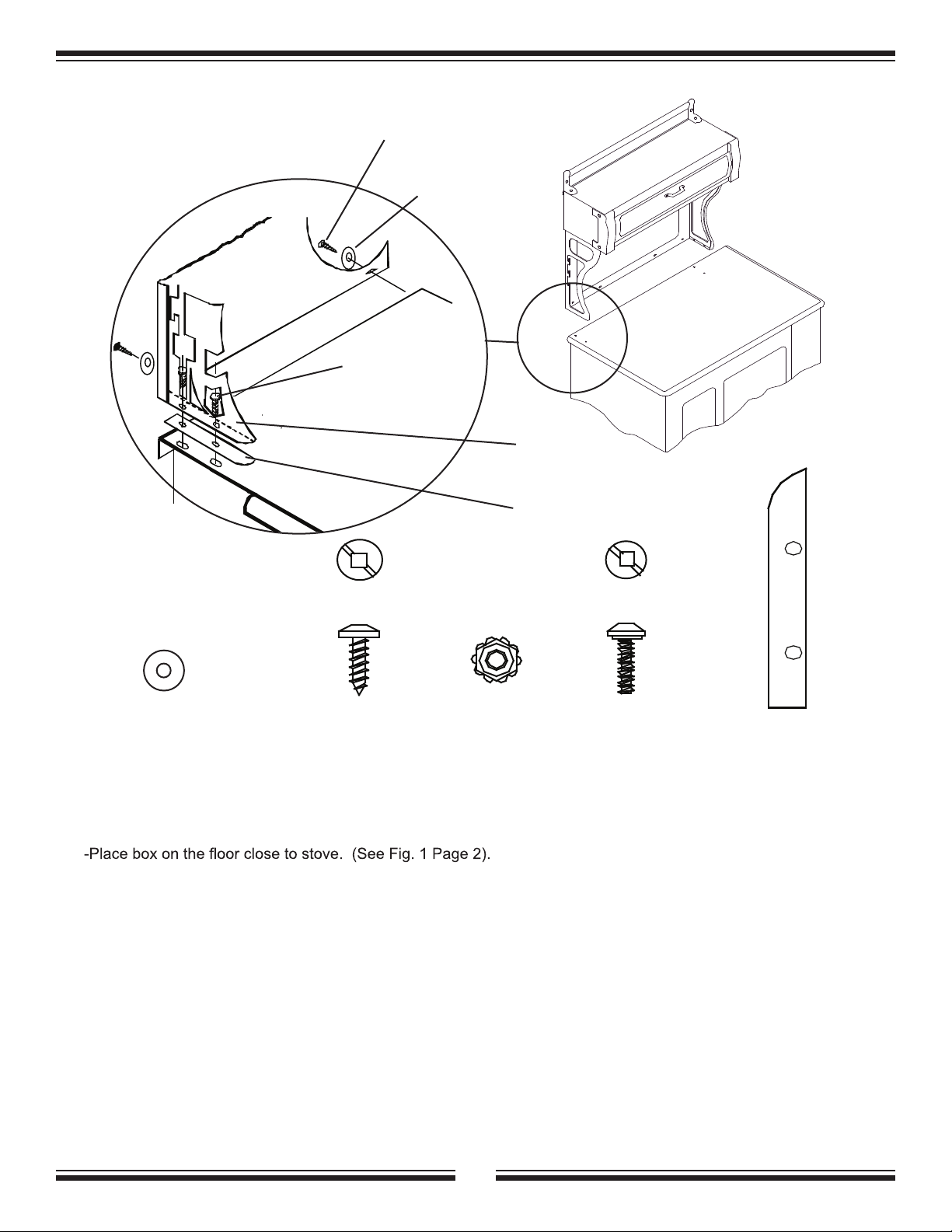

Sheet metal

screw

Steel washer

STOVE

Machine screw

TOP

Bracket

Gasket - Peel off

backing and stick on.

Steel Washer Nut

-Remember when working with the closet, the closet is top heavy . Use your hand to support it during

Sheet metal

screw (black)

Machine screw

(Nickel Plated)

Gasket

installation.

-With a helper,lift closet assembly from box by area that is circled. (See Fig.1 Page 2).

-Rest the closet assembly on the carton,while your helper steadies the closet,peel the closet backing off the

gasket and stick one on each bracket.

-Place closet assembly onto stove body. (See diagram above).

-Line up holes in the bottom (foot) of the bracket with the holes in the stove top,while one person supports the

closet, fasten the closet brackets to the stove top with machine screws.

-To fasten the splashback to the rear of stove, with the Model 7200 use 5 sheet metal screws and washers.

6

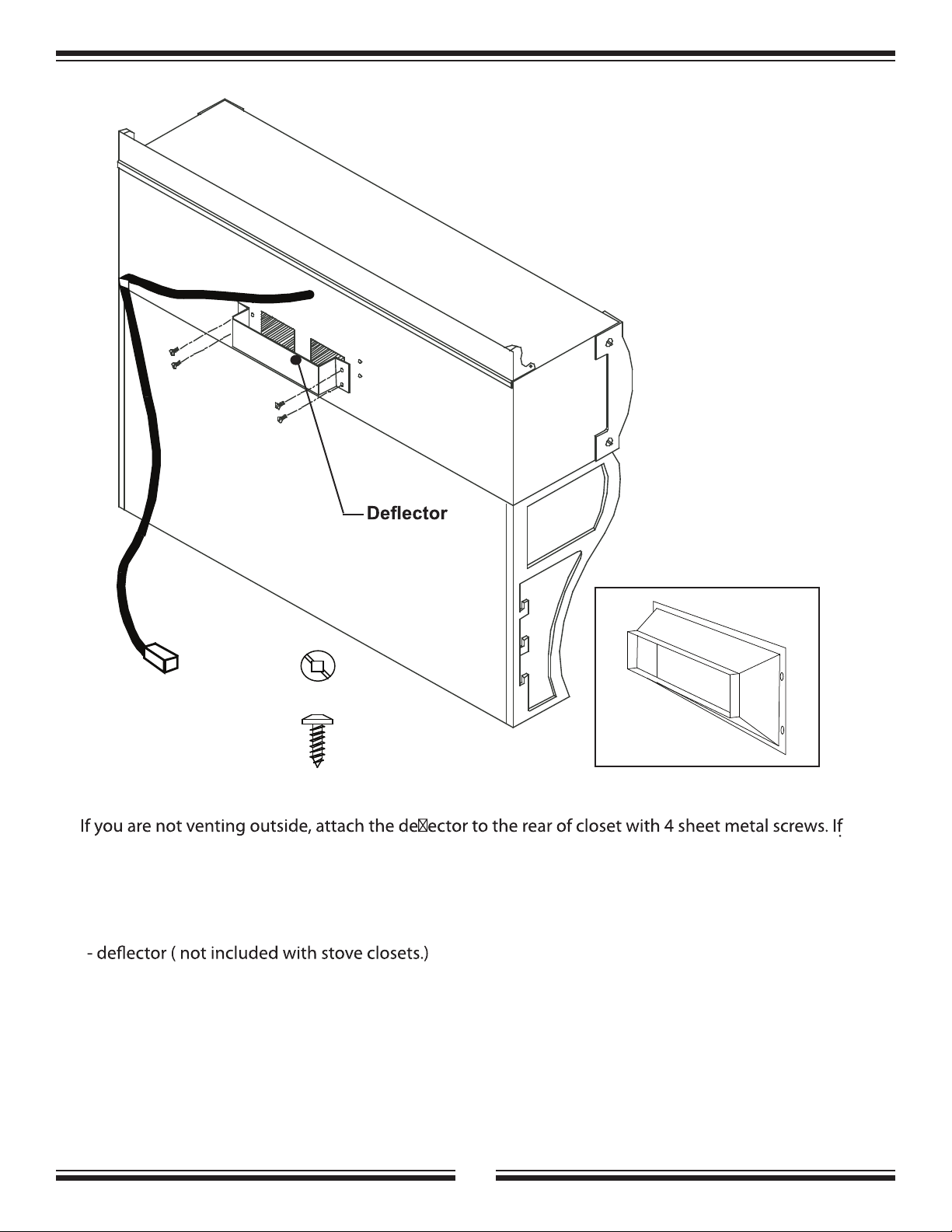

Back of closet

Sheet metal

3 1/2" x 10" Exhaust adaptor

screw

you are venting outside, attach the 3 1/2" x 10" exhaust adaptor with 4 sheet metal screws. Fasten your

exhaust ducting to the adaptor.

Small box contains:

- 3 1/2"x10 exhaust adapter ( not included with woodstove closets.)

Note: maximum run of ducting is 25 linear feet (subtract 5' per 90 deg elbow added to the

exhaust line and 2.5' per 45 deg elbow.)

7

Back of stove

Back of stove

Exhaust Hood In

(female receptacle,

closet

from

)

Power In

(male receptacle)

Model 9200

Power In

(male receptacle)

Exhaust Hood In

(female receptacle,

closet

from )

Model 7200

Positioning the Range

1. When the range is fully assembled, recheck all electrical connections especially between

the exhaust hood and the back of the range. As well, check that all nuts and bolts have been

tightened.

2. Ensure teflon gliders and flooring are clean.

3. Caution: On flooring with very rough surfaces or deep, large grooves the appliance may

have to be lifted and slowly slid into position.

4. Put both hands on the trim and carefully push the range into place. Make sure floor is clear

of all debris. Don’t forget to plug in the main power cord and the exhaust hood power

cable before the range is in its final position. See closet installation instructions.

5. To level the range, simply adjust the levelling screws with teflon pads located at the bottom

of each leg. Using a 5/16” (8 mm) open-end wrench, turn the adjusting screw clockwise to

raise up the corner, and counter-clockwise to lower the corner. (Don’t forget the teflon glider

should extend beyond the bottom of the leg by approximately 1/8”-1/4”.)

6. Note: On soft kitchen flooring, the weight of the stove may cause slight depressions in the

flooring. When the range is in position and levelled, you may want to place coasters under the

teflon gliders of each leg to protect the floor. Remove the coasters when moving the range for

cleaning or servicing.

8

Electrical Installation

THE MODEL 7200/9200 GAS RANGE MUST BE ELECTRICALLY GROUNDED IN COMPLIANCE WITH LOCAL CODES

AND IN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL CODE ANSI/NFPA 70 “LATEST

EDITION” IN THE U.S. OR THE CANADIAN ELECTRICAL CODE, PART I, CSA STANDARD C22.1 IN CANADA or YOUR

NATIONAL ELECTRICAL CODE.

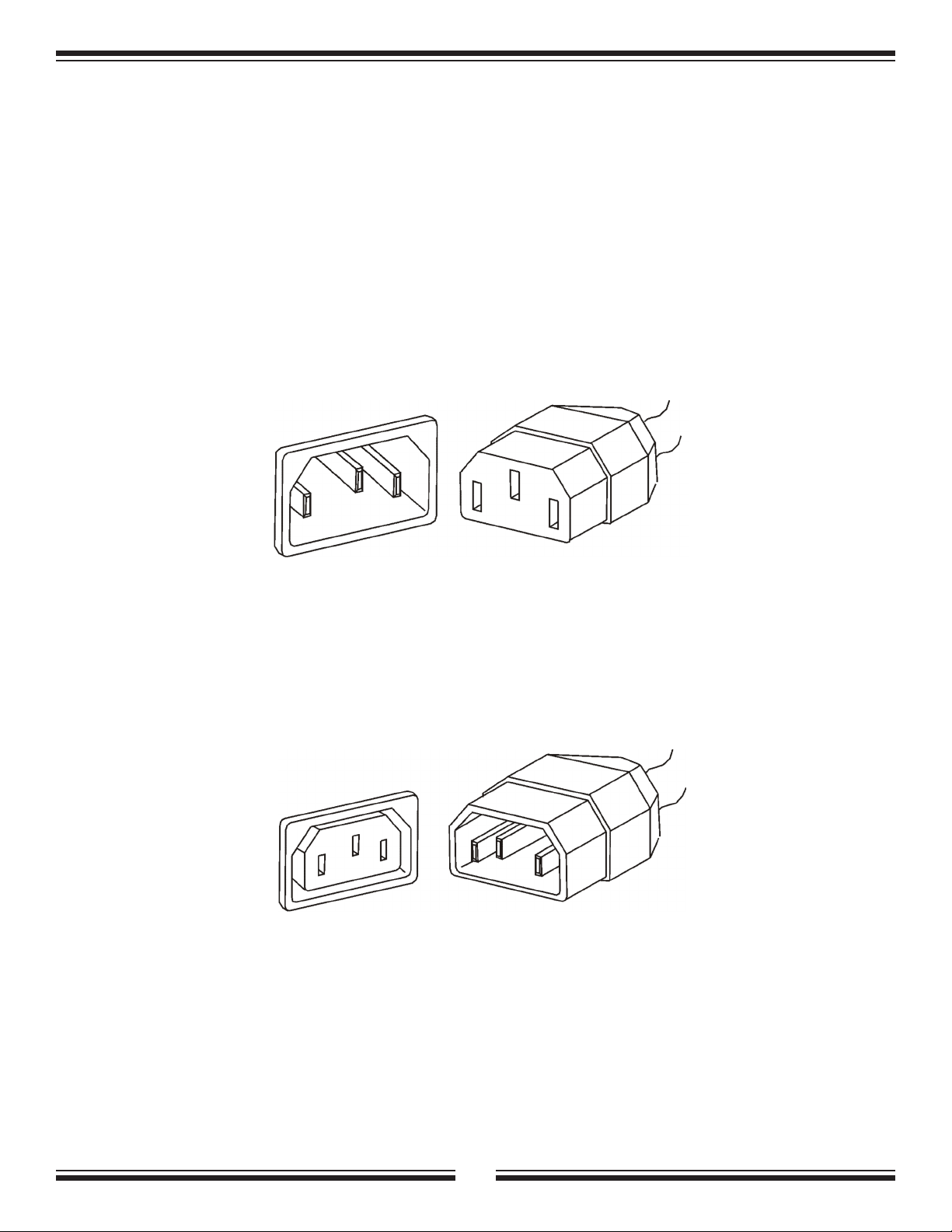

Connect the female end of the power cord to the main power (male) receptacle at the rear of the stove. See Page 8 for

receptacle locations and Figure 2 for receptacle illustration.

This range must be plugged into a properly grounded/earth receptacle. The grounding/earth prong must not be removed

from the plug. DISCONNECT THE ELECTRICAL SUPPLY BEFORE SERVICING THE APPLIANCE.

The receptacle to be used for this appliance must be wired to STANDARD WIRING PRACTICES.

Male Receptacle Female end of cord

Main power hook-up (Figure 2)

Exhaust Hood Electrical Connection

After your exhaust hood has been installed the very last thing to do is to connect the special plug to the

range. The female receptacle for the exhaust hood is located at the rear of the stove by the main power

(male) receptacle (See Page 8 for receptacle locations and Figure 3 for receptacle illustration). Simply

plug the closet power cord into the receptacle, be sure to test all functions of the closet.

Female Receptacle Male end of Closet Power Cord

Closet power hook-up (Figure 3)

Exhaust Hood

Your range is equipped with a two speed range hood that may be either vented directly to the outside,

or may be installed ventless. An exhaust filter is included with your hood. Filters should be cleaned

periodically in soapy water. Extras are available from your dealer or directly from AGA Marvel. Please

order 4 or more filters at one time to save freight and handling charges. Phone your dealer for pricing

and ordering instructions.

9

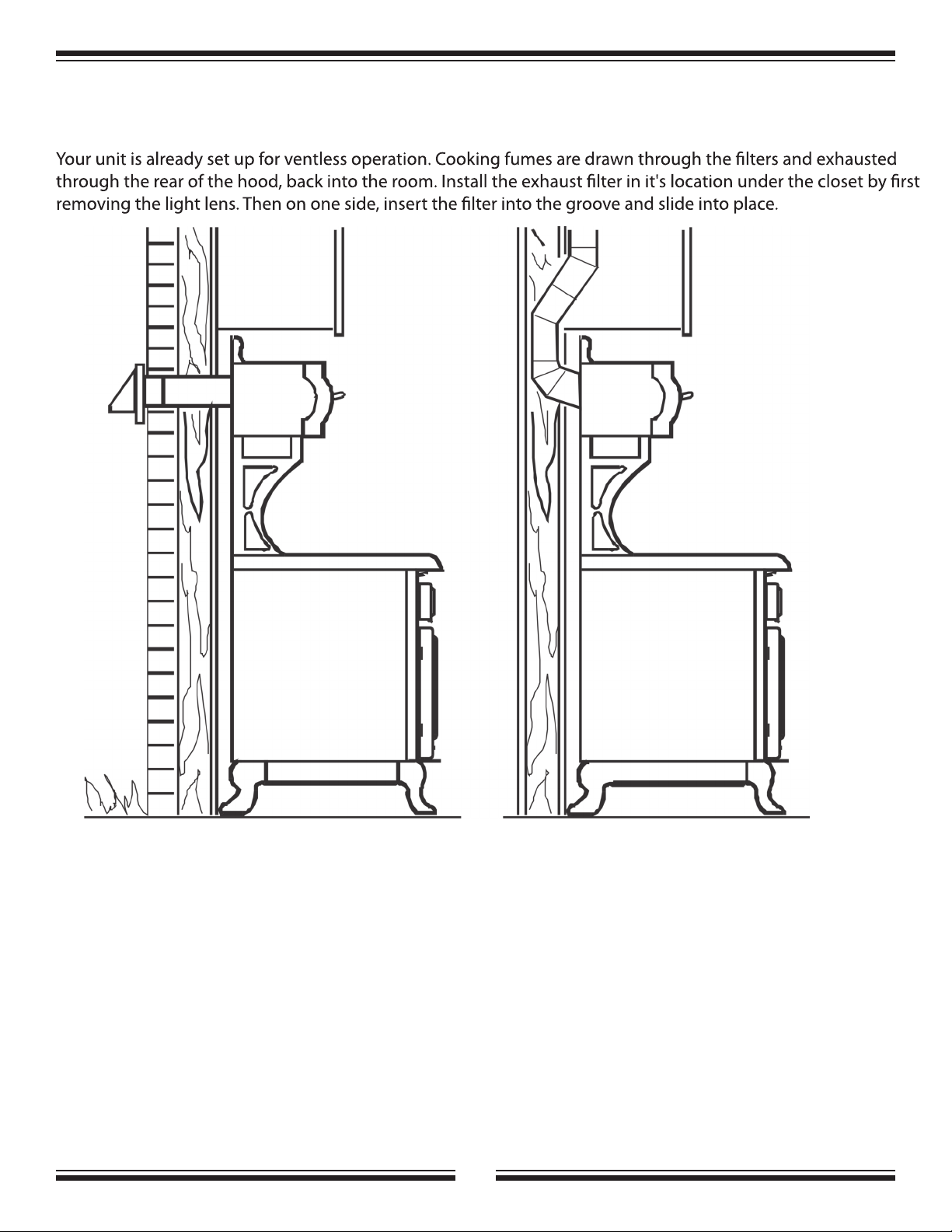

Ventless Installation

Figure 4

Exhaust venting options

Vented Installation, Tools, Material, and Dimensions

Tools required to install vented hood:

Hammer Slot screwdriver

Pliers Electric drill

Measuring tape Drill bits

Sabre saw OR Keyhole saw

Materials Required:

Duct—enough to go through wall or attic to outside. Elbows as required.

Roof cap or wall venthood Caulking to seal around duct

Sheet metal screws

The above are standard parts and are available at any hardware store or heating contractor.

10

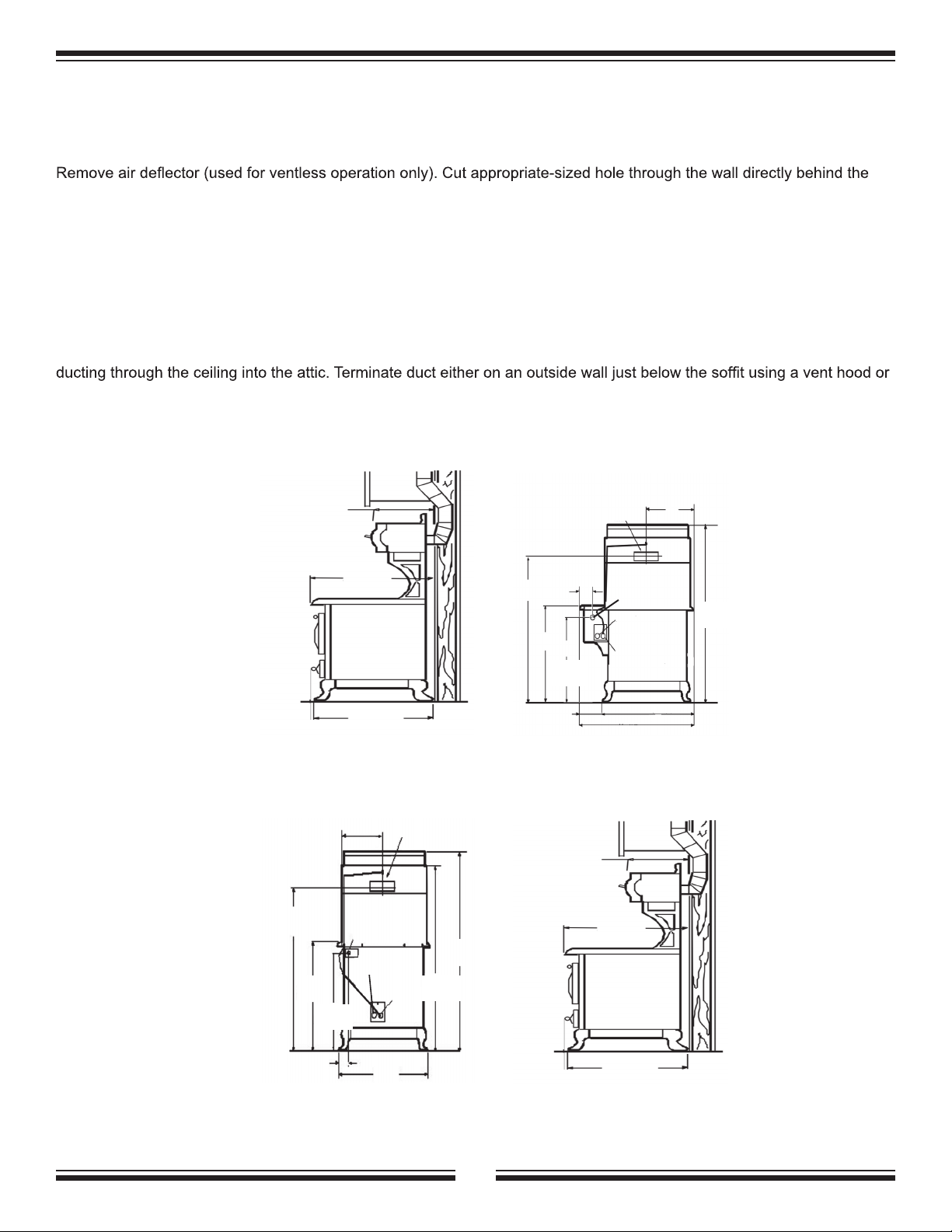

Installation of Ducting

Installation through an outside wall

range hood outlet (see Figure 4, Page 10), making sure no wall studs are cut. Push range into position. From outside of

the house, measure distance from the siding to the range outlet. Cut duct pipe that length, plus 1” (25mm) for overlap into

outlet. Mechanically attach vent hood to pipe. Caulk the back of vent hood and around pipe where it goes through wall

and into range hood outlet so caulking seals against outside siding.

Complete installation by following directions under Ventless Installation.

Installation through an attic to an outside wall

If the vent elbows are embedded in the wall, the range may be positioned as shown in Figure 5, Page 11. Continue the

through the roof with a roof cap. Seal with caulking around and under cap or hood.

Complete your installation by following directions under Ventless Installation.

RangeHoodOutlet

14”

36 cm

3-1/4” x 10”

8 cm x 25 cm

20”

51 cm

56”

142 cm

36-1/8”

92 cm

34”

86 cm

29-1/2”

75 cm

28”

72 cm

13-3/4”

35 cm

Gas Inlet-1/2” NPT

Power

Cord

RangeHoodOutlet

3-1/4” x 10”

8 cm x 25 cm

66-1/4”

168 cm

Exhaust

62-3/8”

Hood

(female)

159 cm

Receptacle

56”

142 cm

Figure 5

Model 7200

36-1/8”

92 cm

76 cm

4-3/4”

12 cm

30”

13”

33 cm.

Receptacle

47-1/2”

122 cm

29-1/2”

75 cm

Gas Inlet-1/2” NPT

Power

Cord

Exhaust

Hood

(female)

39-3/4”

101 cm

66-1/4”

169 cm

3-3/4”

10 cm

29-3/4”

76 cm

Figure 6

Model 9200

11

28”

72 cm

Venting Safety Guidelines

Installation must be done in accordance with all local and national codes. Use only materials which conform to local codes

in effect. Be sure power is disconnected before doing any electrical work. All duct work must be metal and mechanically

fastened. Do not use plastic duct. The range hood should never be exhausted into a wall cavity or an attic where an

accumulation of grease could become a fire hazard. Please ensure closet installation above the appliance conforms to

local code or in the absence of local code the National Fuel Gas Code ANSI Z233.1/NFPA 54.

When the installation is completed, turn on the fan and make sure that there are no obstructions in the line.

Gas Line Installation

The Model 7200 / 9200 are set for natural gas (NG) OR propane (LP) gas at the factory. Be sure your range is

THE RANGE MUST BE INSTALLED IN COMPLIANCE WITH LOCAL CODES, AND IN THE ABSENCE OF LOCAL

REQUIREMENTS, THE INSTALLATION MUST COMPLY WITH REQUIREMENTS OF ANSI Z223.1/NFPA 54 IN UNITED

STATES AND C.S.A. B149.1 IN CANADA.

Note: Appliances installed in the state of Massachusetts:

.

.

- A “T” handle type manual gas valve must be installed in the gas supply line to this appliance.

THE APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING ITS INDIVIDUAL

MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING OF THE GAS SUPPLY PIPING SYSTEM AT TEST

PRESSURES EQUAL TO OR LESS THAN 3.5 KPS (1/2 PSIG).

The maximum propane/natural gas supply inlet must not exceed 14 inches of water column. The minimum gas supply

inlet should be at least 5 inches of water column for natural gas or at least 11 inches of water column for LP gas.

4-3/4”

Gas Inlet to Manifold

12 cm

Gas Inlet to Manifold

30”

34”

76 cm

86 cm

3-3/4” 10 cm

9200 Gas Inlet Locations

10” 25 cm

7200 Gas Inlet Locations

12

Model 9200

Appliances

in the US or in Canada with the Canadian Electrical

Code, Part I, CSA Standard C22, or the Local National

Electrical Code.

How to Steps

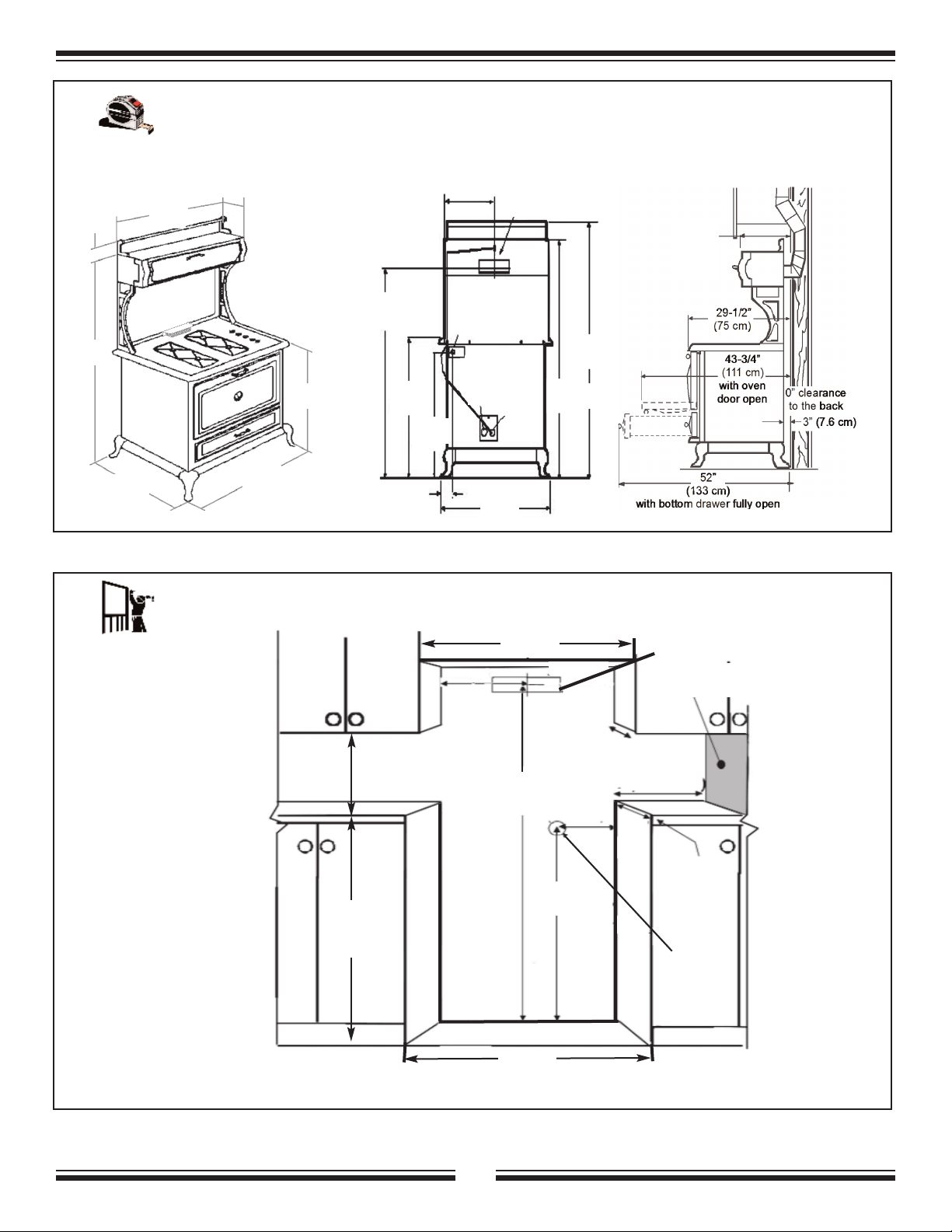

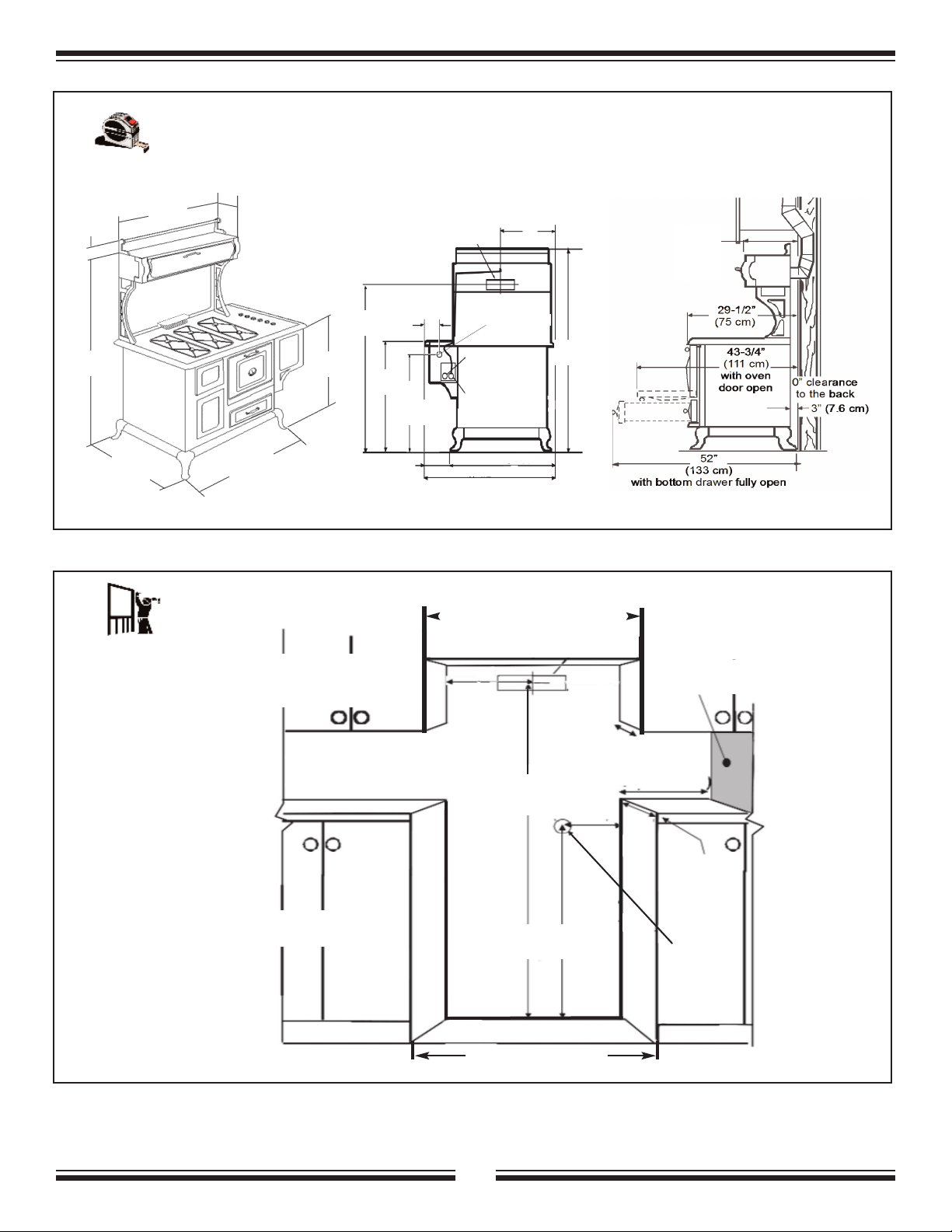

Appliance Clearances (see Page 15 for additional details):

• Sides of stove to adjacent surfaces: 1/2” (1.5 cm) min

• Nickel trim to adjacent surfaces: 0” right and left

• Rear clearance: 0”

• Closet right side to cabinet: 0”

• Top of counter to underside adjacent cabinet: 18” (46

cm)

• Cooktop to underside overhead cabinets: 30-1/4” (77

cm)

• Edge of range to combustible wall on either side: 6”

(15 cm)

• Cut out width for range’s main body: 30” (76 cm)

• Max. countertop depth: 24” (61 cm); height: 36” (91

cm)

• Max. overhead cabinet depth: 13” (33 cm)

Note: If unit is installed beside a refrigerator it is important

that there be at least 5” (13 cm) between the refrigerator

and range for proper air circulation.

Gas

•

• Natural Gas/Propane Conversion kits available from

dealer or factory and must be performed by a licensed

Venting

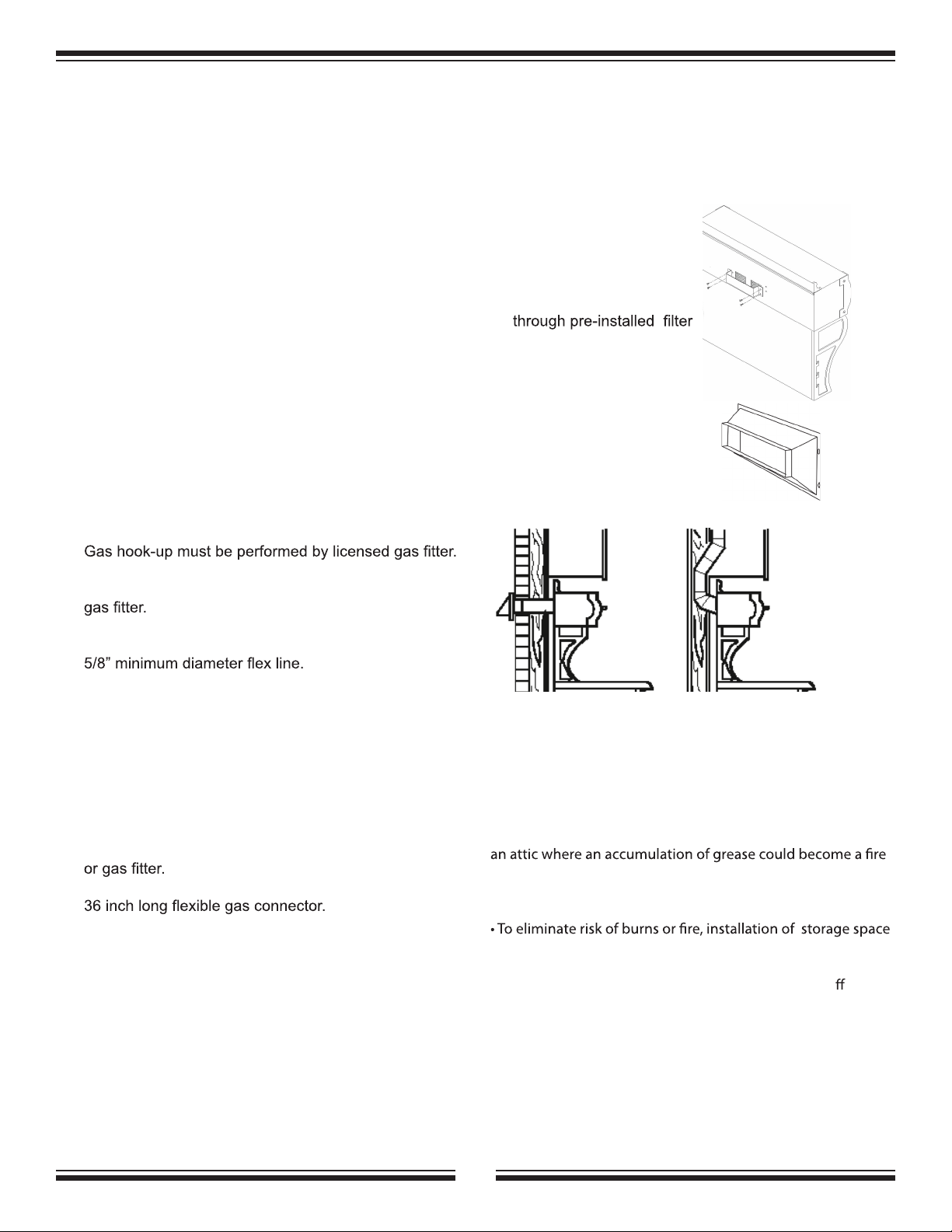

How to Steps

Option 1 - Ventless installation:

• Requires no further set up

(cooking fumes are drawn

and exhausted through

rear of hood, back into the

room.)

Option 2 - Venting directly outside:

• Method 1 - Installation

through outside wall.

• Method 2 - Installation

through attic to outside.

3 1/4” x 10” Exhaust adaptor included with range

.

• Pressure requirements: Nat Gas: 5” W.C. (min);

• LP gas: 11” W.C. (min)

•

• Connection: 1/2” NPT

• An accessible manual shut off valve must be installed

at the appliance.

Stove must be installed in compliance with local codes.

In the absence of local codes, with the National Electrical

code ANSI Z223.1 in the US or in Canada with the CSA

Standard B149.1.

Appliances installed in the state of Massachusetts:

• This appliance can only be installed in the state of

Massachusetts by a Massachusetts licensed plumber

• This appliance must be installed with a three (3) foot /

• A “T” handle type manual gas valve must be installed

in the gas supply line to this appliance in an accessible

location.

Electrical

• Electrical hookup must be performed by a licensed

electrician.

• 120 Volts 60Hz .375 Kw.

• 5 ft (1.5 m) power cord included with 3 prong plug.

• Stove must be electrically grounded in compliance with

local codes. In the absence of local codes, with the

National Electrical code ANSI/NFPA 70 “Latest Edition”

Method 1 Method 2

Safety

• Maximum ducting run: 25 linear feet - subtract 5’ per 90 deg

elbow and 2.5’ per 45 deg elbow. Do not use more than two

elbows. All duct work must be metal. Do not use plastic duct.

The range hood should never be exhausted into a wall cavity or

hazard.

• Installation must be completed in accordance with all local &

national codes.

above range should be avoided. Existing min clearance 30-1/4”

(76 cm).

• Use only materials which conform to local codes in e ect.

• Gas cooking appliances produce heat and moisture - ensure

kitchen is well ventilated. Prolonged intensive use may require

additional ventilation (opening windows or addition of supplementary air exhaust sources).

13

Dimensions

Model 9200

3-7/8”

(10 cm)

cresting

panel

62-3/8”

(159 cm)

(70 cm)

28”

(72 cm)

Rough in

Measurements

27-1/2”

11-3/8”

(29 cm)

29-3/4”

(76 cm)

36-1/8”

(92 cm)

min 18”

(46 cm)

56”

(142 cm)

(10 cm)

36-1/8”

(92 cm)

3-3/4”

13-3/4”

(35 cm)

Gas Inlet-1/2” NPT

34”

(86 cm)

Power

Cord

29-3/4”

(76 cm)

15”

(38 cm)

Range HoodOutlet

3 1/4” x 10”

8 cm x 25 cm

Exhaust

62-3/8”

Hood

(female)

(159 cm)

Receptacle

30”

(76 cm)

13” (33 cm)

cabinet

depth

56”

(142 cm)

13”

33cm.

66-1/4”

(168 cm)

Figure 9

Range Hood Outlet

3-1/2” x 10-1/2”

(8.9 cm x 26.7 cm)

(6” clearance to any com-

bustible side wall)

6” (16 cm)

3-7/8”

(10 cm)

min 36”

(91 cm)

14

(86 cm)

30”

(76 cm)

34”

24”

(61 cm)

Counter

depth

Location

of stove

Gas

Oulet

Figure 10

Model 7200

Appliances

How to Steps

Appliance Clearances (see Page 17 for additional details):

• Sides of stove to adjacent surfaces: 1/2” (1.5 cm) min

• Nickel trim to adjacent surfaces: 0” right and left

• Rear clearance: 0”

• Closet right side to cabinets: 0”

• Top of counter to underside adjacent cabinets: 18” (46

cm)

• Cooktop to underside overhead cabinets: 30-1/4” (77

cm)

• Edge of range to combustible wall on either side: 6”

(15 cm)

• Cut out width for range’s main body: 48/1/2” (123 cm)

• Max. countertop depth: 24” (61 cm); height: 36” (91

cm)

• Max. overhead cabinet depth: 13” (33 cm)

Note: If unit is installed beside a refrigerator it is important

that there be at least 5” (13 cm) between the refrigerator

and range for proper air circulation.

Gas

•

• Natural Gas/Propane Conversion kits available from

dealer or factory and must be performed by a licensed

in the US or in Canada with the Canadian Electrical

Code, Part I, CSA Standard C22, or the Local National

Electrical Code.

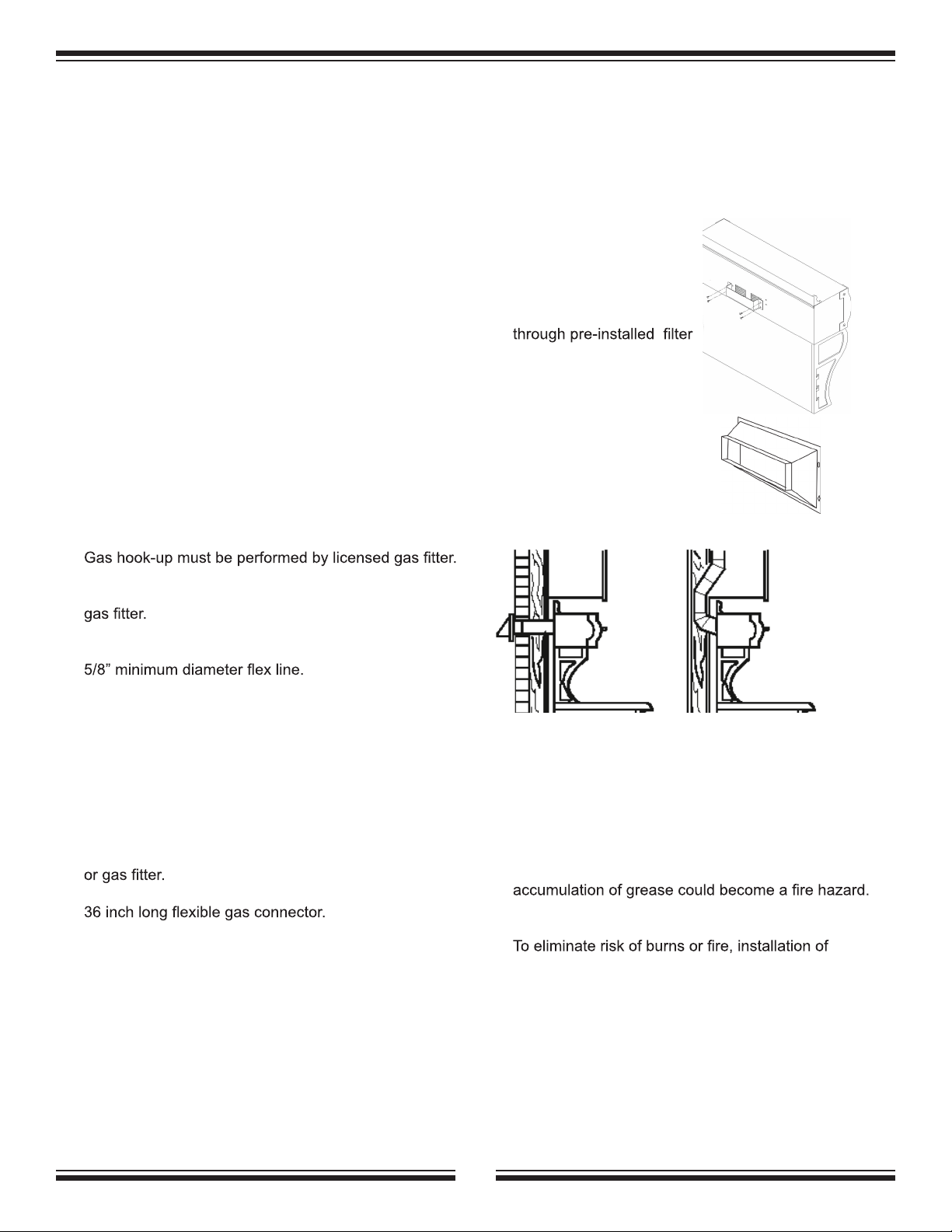

Venting

How to Steps

Option 1 - Ventless installation:

• Requires no further set up

(cooking fumes are drawn

and exhausted through

rear of hood, back into the

room.)

Option 2 - Venting directly outside:

• Method 1 - Installation

through outside wall.

• Method 2 - Installation

through attic to outside

• 3 1/4” x 10” Exhaust adaptor

included with range

• Pressure requirements: Nat Gas: 5” W.C. (min);

• LP gas: 11” W.C. (min)

•

• Connection: 1/2” NPT

• An accessible manual shut off valve must be installed

at the appliance.

Stove must be installed in compliance with local codes.

In the absence of local codes, with the National Electrical

code ANSI Z223.1 in the US or in Canada with the CSA

Standard B149.1.

Appliances installed in the state of Massachusetts:

• This appliance can only be installed in the state of

Massachusetts by a Massachusetts licensed plumber

• This appliance must be installed with a three (3) foot /

• A “T” handle type manual gas valve must be installed

in the gas supply line to this appliance in an accessible

location.

Electrical

• Electrical hookup must be performed by a licensed

electrician.

• 120 Volts 60Hz .375 Kw.

• 5 ft (1.5 m) power cord included with 3 prong plug.

• Stove must be electrically grounded in compliance with

local codes. In the absence of local codes, with the

National Electrical code ANSI/NFPA 70 “Latest Edition”

Method 1 Method 2

Safety

• Maximum ducting run: 25 linear feet - subtract 5’ per

90 deg elbow and 2.5’ per 45 deg elbow. Do not use

more than two elbows. All duct work must be metal.

Do not use plastic duct. The range hood should never

be exhausted into a wall cavity or an attic where an

• Installation must be completed in accordance with all

local & national codes.

•

storage space above range should be avoided. Existing

cabinets min clearance 30-1/4” (76 cm).

• Use only materials which conform to local codes in

effect.

• Gas cooking appliances produce heat and moisture -

ensure kitchen is well ventilated. Prolonged intensive

use may require additional ventilation (opening

windows or addition of supplementary air exhaust

sources).

closet

15

Dimensions

3-7/8”

(10 cm)

Cresting

Panel

62-3/8”

(159 cm)

37-3/4”

(96 cm)

11-3/8”

(29 cm)

36-1/8”

(92 cm)

56”

(142 cm)

36-1/8”

(92 cm)

(12 cm)

30”

(76 cm)

Model 7200

Range Hood

Outlet

3-1/4” x 10”

(8cm x 25cm)

4-3/4”

Gas Inlet 1/2” NPT

Power

Cord

Exhaust Hood

(51 cm)

(female)

Receptacle

20”

66-1/4”

(169 cm)

13”

33cm

.

28”

(72 cm)

Rough in

Measurements

39-3/4”

(101 cm)

Range Hood Outlet

3-1/2” x 10-1/2”

(8.9 cm x 26.7 cm)

min 18”

(46 cm)

min 36”

(91.4 cm)

47-1/2”

(121 cm)

39-3/4”

(101 cm)

481/2” (123 cm)

1” stove clearance must be

measured from the left side

21”

(54cm)

13” (33 cm)

cabinet depth

56”

(142 cm)

5-3/8”

(14 cm)

30”

(76 c )

Figure 11

(6” clearance to any com-

bustible side wall)

6” (16 cm)

24” (61 cm)

Counter

Depth

Location

of Stove

Gas

Outlet

481/2” (123 cm)

16

Figure 12

Important Safety Instructions

1. PROPER INSTALLATION—BE SURE YOUR APPLIANCE IS PROPERLY INSTALLED AND GROUNDED BY A

QUALIFIED TECHNICIAN.

2. NEVER use this appliance as a space heater to heat or warm the room. Doing so may result in Carbon Monoxide

poisoning and in overheating of the oven.

3. Do not leave children alone. Children should not be left alone or unattended in area where appliance is in use.

They should never be allowed to sit or stand on any part of the appliance.

4.

5.

6.

cabinet.

7. .

8. Use only dry potholders—moist or damp potholders on hot surfaces may result in burns from steam. Do not let

potholder touch hot heating elements. Do not use a towel or other bulky cloth.

9. NEVER cover any slots, holes and passages in the oven bottom or cover an entire rack with materials such as

Aluminum

11. There is a potential hazard associated with using a storage cabinet above the appliance - please use caution!

12. It is a good practice to install CO detectors when any gas appliance or furnace is present in the home. Please

follow manufacturer’s recommendations for location and installation of CO detectors.

Exhaust Hood Safety

Caution: Do not store items of interest to children in cabinet above the range or on top of

range cabinet. Children climbing on range to reach items could be seriously injured.

1. .

2.

Oven Safety

Do not touch heating elements or interior surfaces of oven—heating elements may be hot even though they are

dark in colour. Interior surfaces of an oven become hot enough to cause burns. During and after use, do not touch

surfaces are, for example, oven vent openings and surfaces near these openings, oven doors.

1. Use care when opening door—let hot air or steam escape before removing or replacing food.

2. Do not heat unopened food containers—buildup of pressure may cause container to burst and result in injury.

3. Keep oven vent ducts unobstructed.

4. Placement of oven racks—always place oven racks in desired location while oven is cool. If rack must be moved

while oven is hot, do not let potholder contact hot heating element in oven.

17

L

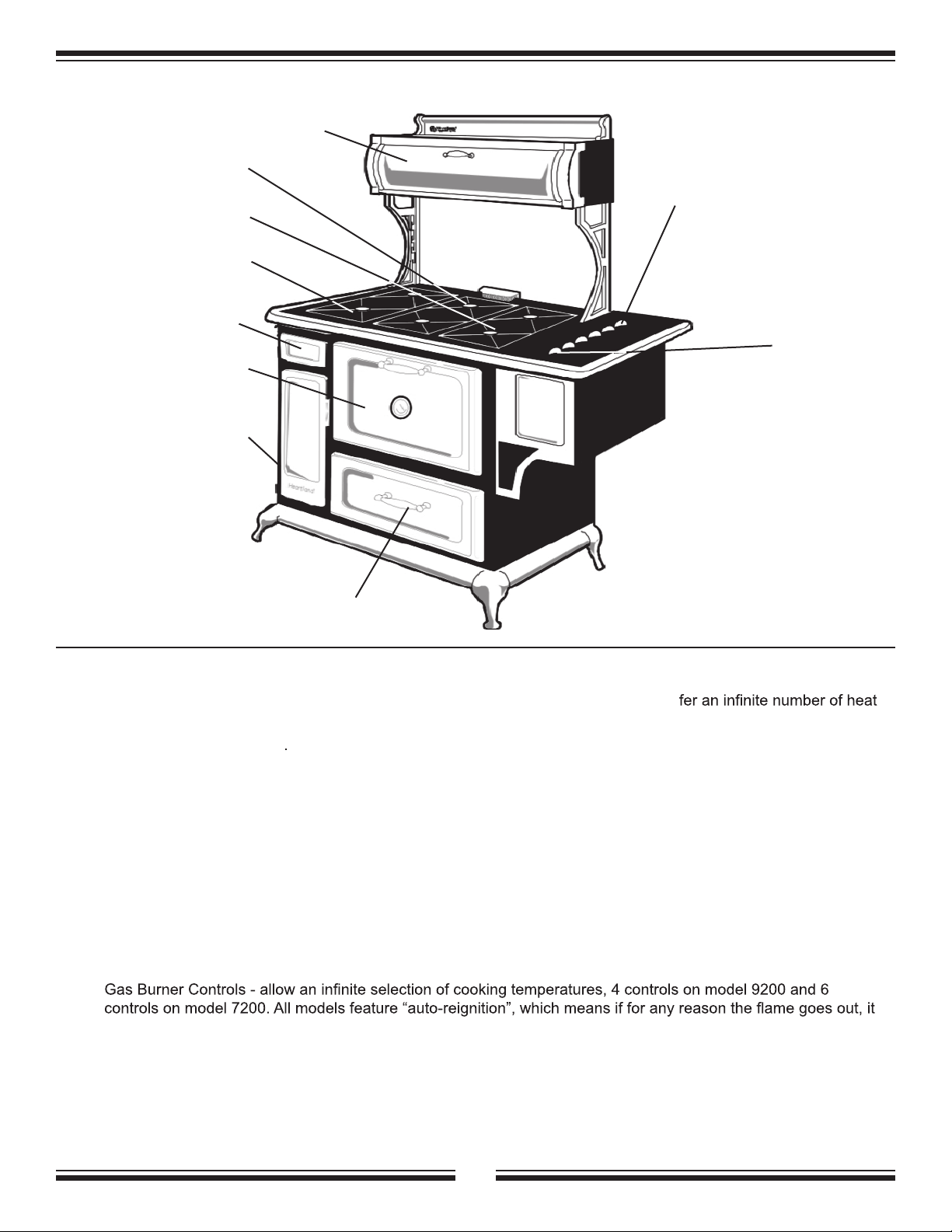

Features

I

A

D

B

C

E

F

H

Figure 13

G

Cooking Controls

The cooking controls are located on the right hand side of the cooktop; these controls of

settings for ease and accuracy in cooking and baking.

Sealed Burner Features (See Figure 13)

A) Centre Burners - are two maximum 8,000 BTU (2.34 kW)(L/P 7,000 BTU) with simmer of 600 BTU (.2 kW) sealed

gas burners, easy clean, for medium duty cooking tasks.

B) Right Burners (48” models only) - front sealed burner is maximum 10,000 BTU (2.93 kW)(L/P 9,000 BTU) with

simmer of 1000 BTU (.3 kW) and rear is maximum 8,000 BTU (2.34 kW)(L/P 7,000 BTU) with simmer of 600

BTU (.2kW), one for large jobs, one for small, easy clean.

C) Left Burners - front sealed burner is maximum 10,000 BTU (2.93 kW)(L/P 9,000 BTU) with simmer of 1000 BTU

(.3kW) and rear is maximum 8,000 BTU (2.34 kW)(L/P 7,000 BTU) with simmer of 600 BTU (.2 kW) to accurately

maintain temperature.

D)

automatically begins to spark to re-ignite the burner!

18

Figure 14

J

K

T I M E R

A

U

T

O

S T O P

Oven Features

M

f!

F) Gas Oven Features: -4 position racking

-16,500 BTU (4.83Kw) oven burner

G) Broiler - Broiler drawer located under the oven, glides open for easy access for all your broiling needs.

H) More Storage - (model 7200 only) open the rack storage door to gain access to more storage area.

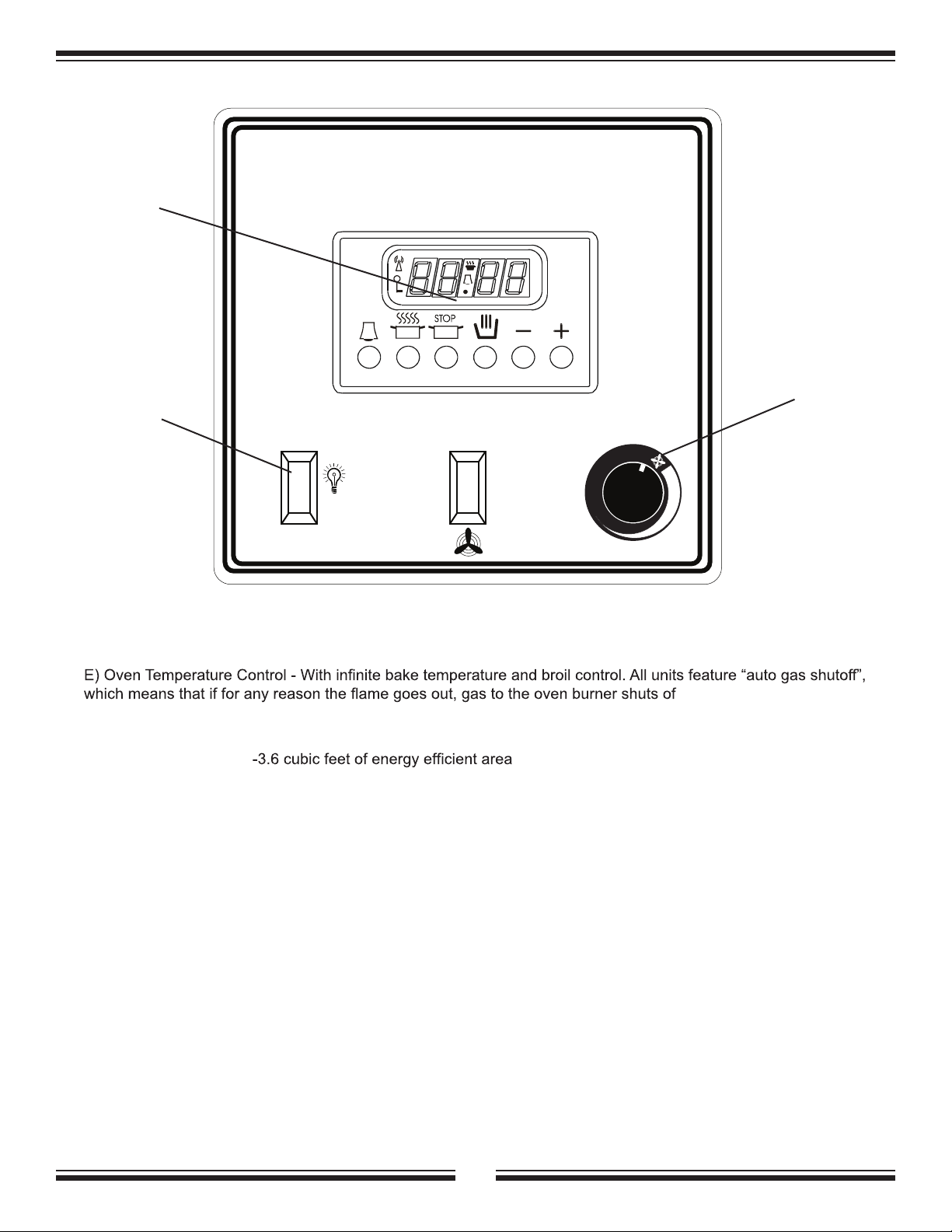

Other Features (See Figure 14)

I) Closet Door - the minute minde r, exhaust fan control and overhead light switch are concealed behind the closet

door.

J) Digital Clock - With minute minder.

K) On -off switch - controls overhead light in exhaust hood.

L) Utensil storage- (model 7200 only) open the drawer to gain access to more storage area.

M) Variable speed control for exhaust fan. Switch starts on high when engaged and adjusts down to low.

19

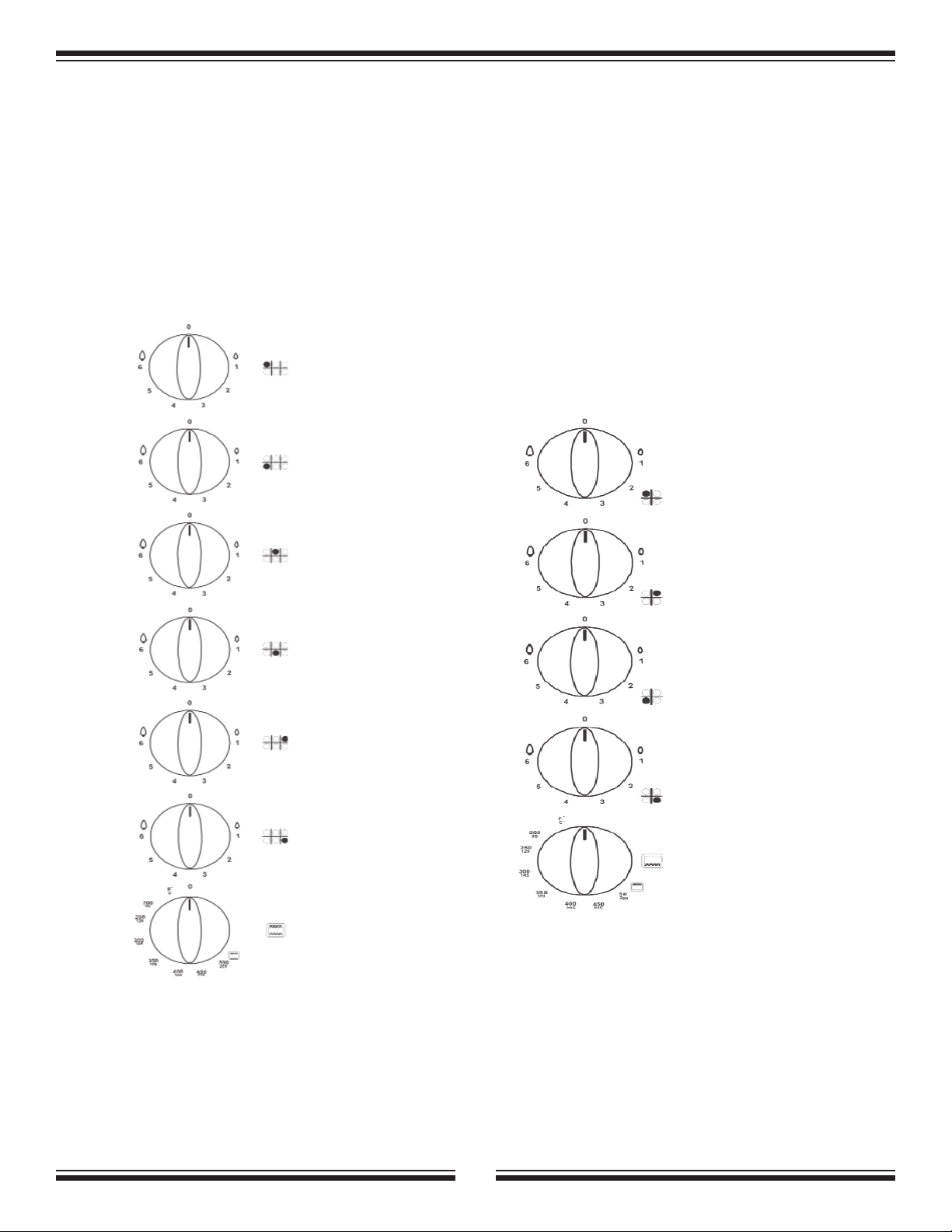

Control Panel Layout

The control panel is laid out in a straight line

and each control is identified by a graphic on

the right side of the knob.

Model 7200

Control Panel

Left Rear Burner

Control (Medium)

Left Front Burner

Control (Large)

Centre Rear Burner

Control (Medium)

Centre Front Burner

Control (Medium)

Model 9200

Control Panel

Left Rear Burner

Control (Medium)

Right Rear Burner

Control (Medium)

t Burner

Left Fr

Control (Large)

on

Right Rear Burner

Control (Medium)

Right Front Burner

Control (Large)

Oven Control

Figure 15

The operation of the controls are described in the following pages.

20

Right Front Burner

Control (Medium)

Oven Control

Operation

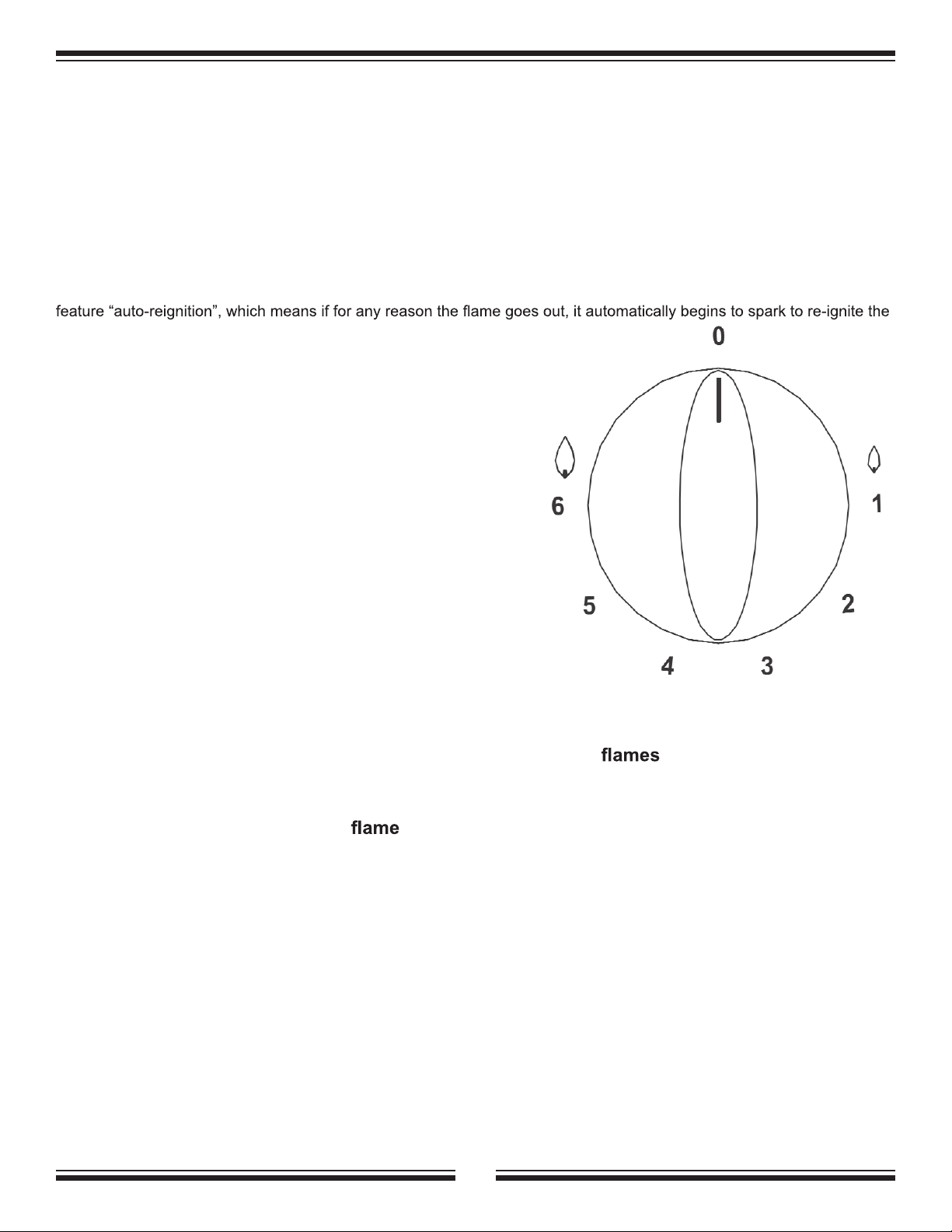

Top Burner Operation

Lighting the Top Burners

Your range is equipped with a spark ignition system that is electrically operated. You need only to push in and turn the

knob to any position and the burner will light. When you turn the knob, you will hear a distinct clicking noise. After the

burner lights, the clicking noise will stop.

Note: when lighting any one burner, all burners will spark, but only the burner that you have selected will light. All models

burner!

See Page 23 for manual lighting procedure.

6 (HI) - Quick start for cooking, brings water to boil.

5 (MED HI) - Fast fry, pan broil, maintain fast boil on large

amount of food.

4 (MED) - Sauté and brown; maintain slow boil on large amount

of food.

3 (MED LOW) - Cook after starting at HI; cook with little water in

covered pan.

2-1 (LOW) - Steam rice, cereal; maintain serving temperature of

most foods.

Top Burner Control

Figure 16

For safety reasons, always adjust the burner controls so that do not extend beyond the

edges of pots, pans or other cooking utensils.

Large pots or other over-sized cooking utensils may cause random sparking from the burner.

To avoid this condition lower the

size or use smaller-sized cooking utensils.

Do not use a griddle directly on top of grates. To avoid random sparking, please use the AgaHeartland Griddle Pan Kit for Classic Ranges part #7602 (complete with griddle pan support), which

can be purchased from your dealer or directly from AGA Marvel.

21

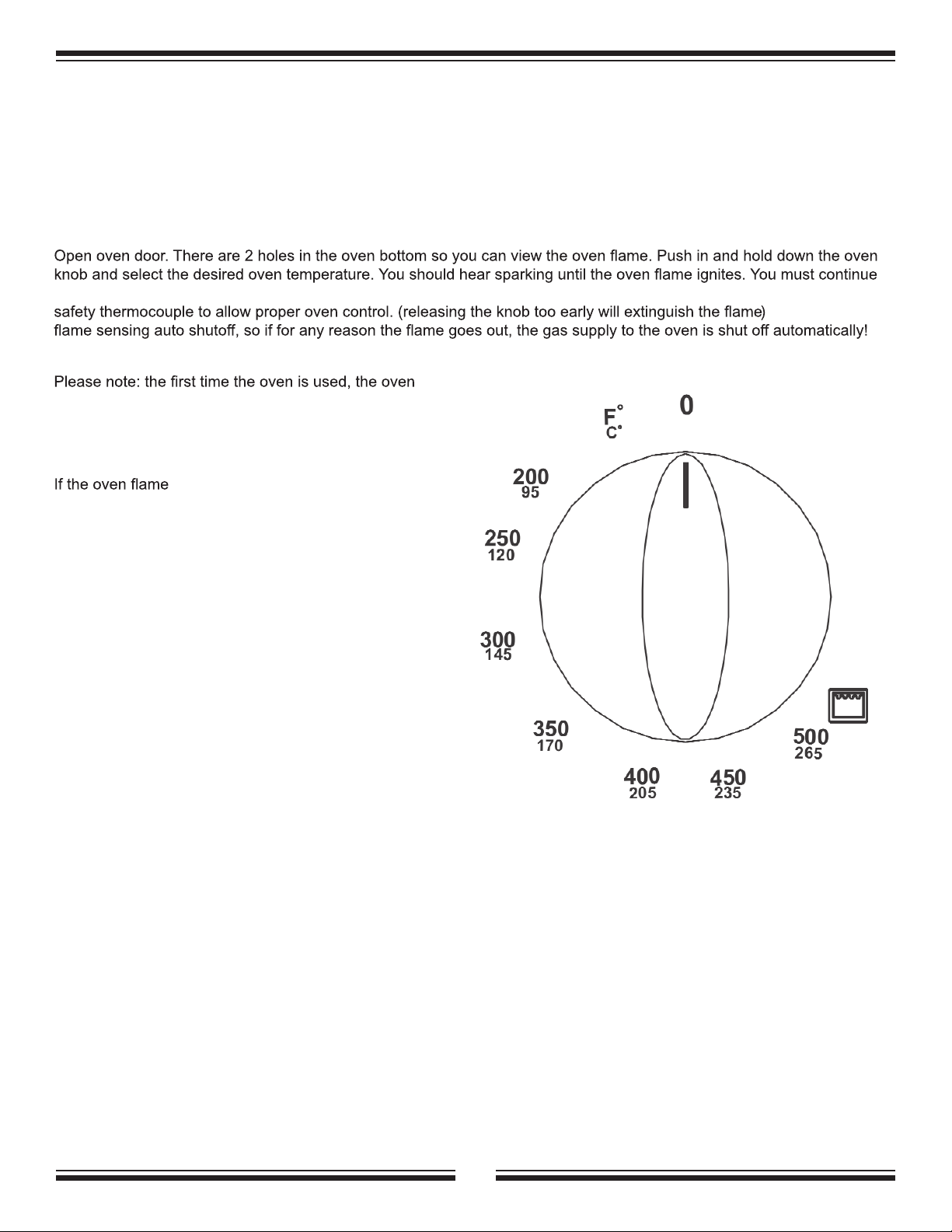

Oven Cooking

Oven Lighting

to keep oven knob depressed for 5-6 seconds after the oven ignition has occurred. The extra 5-6 seconds is toheat up the

All units feature

igniting procedure may have to be repeated 2-4 times to

push out any air in the gas lines.

does not light in 5-6 seconds, STOP.

Release oven knob, this will prevent any further gas

from going into the oven. Wait at least 1 minute before

trying to light oven again. If you are still not successful

see “trouble shooting guide”.

Range Thermostat

The temperature in the oven is transmitted to the

thermostat by the sensor tube located at the rear of the

oven. It must always be in position on its mounting clips

and should not be bent. The sensor causes the burner

to maintain the desired oven temperature.

Oven Control Knob

Figure 17

22

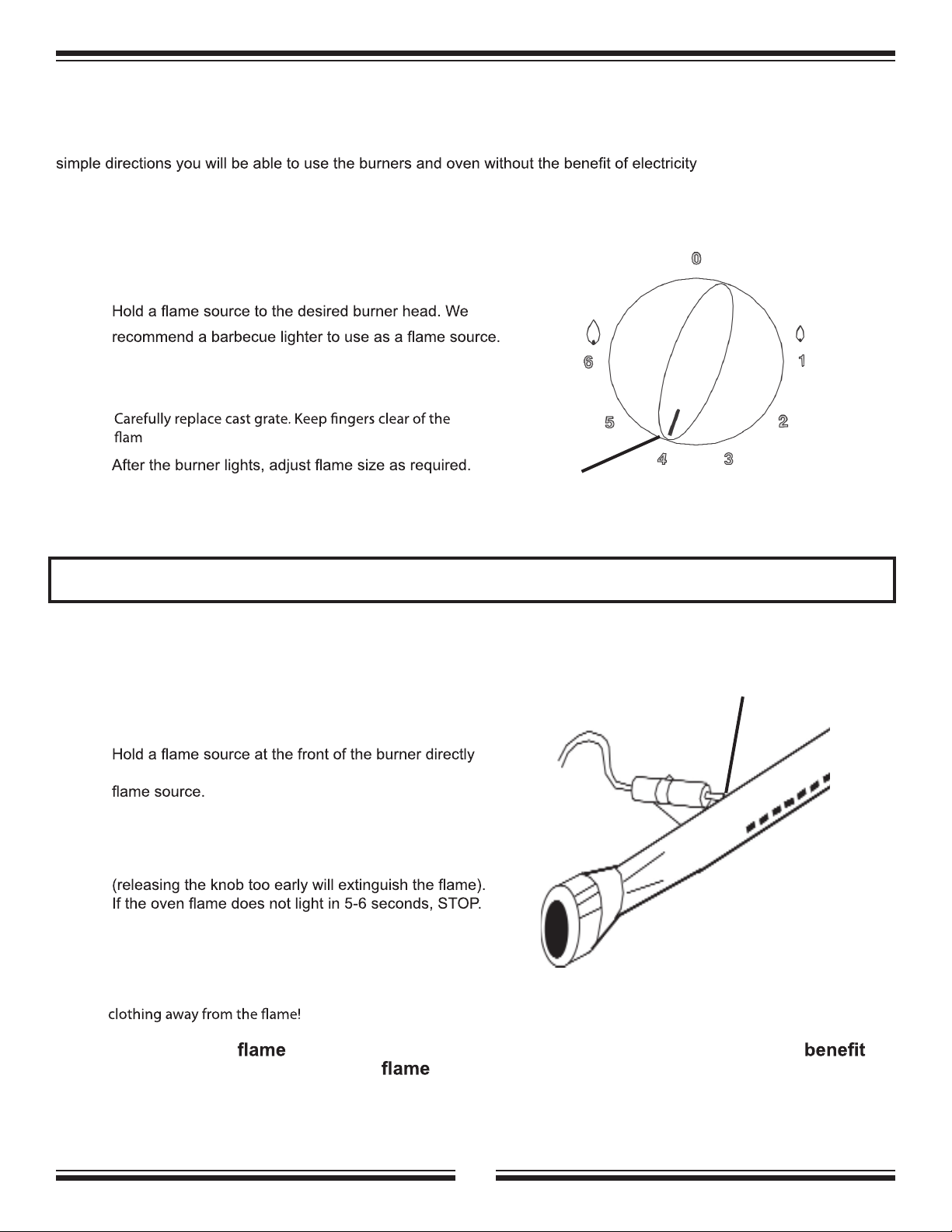

Power Failure Operation

If electrical power is interrupted in your area, you can still cook meals on your Heartland gas range. By following these

.

Caution: make sure your hands and clothing are clear of the burner you are lighting!

Manually Lighting the Top Burners

1) Remove cast grate for unobstructed access to the

burner head.

2)

3) Push in and turn the corresponding control knob to the

medium setting.

4)

5)

e.

Figure 18

When lighting top burners manually, set control to

the medium setting to prevent potential injury from

the flame when replacing the grate.

Top Burner Control

Please note that the “auto reignition” feature will not function without electricity, therefore pay

close attention to any burners in use while electrical power is interrupted!

Manually Lighting the Oven Burner

The oven can be operated safely by lighting the oven burner in

the following manner:

When lighting oven burner manually, light the burner

at the igniter. Keep hands and clothing away from

open flame!

1) Remove the oven bottom.

2)

beside the igniter. We recommend a barbecue lighter as

3) Push in and hold down the knob, continue to hold down

the oven knob and select the desired oven temperature.

4) You must hold oven knob down for at least 5-6 seconds

after ignition to activate the oven safety thermocouple.

5)

Release oven knob. This will prevent any further gas from

going into the oven. Wait at least 1 minute before trying to

light oven again. If you are still not successful see “trouble

shooting guide”.

6) Place oven bottom back into position. Keep fingers and

Oven Burner and Igniter

Figure 19

Please note that the sensing auto shutoff feature is still functional without the

of electricity so if for any reason the goes out, the gas supply to the oven is shut off

automatically!

23

Loading...

Loading...